Introduction: Navigating the Global Market for basketball leather

Navigating the complex landscape of the global market for basketball leather presents significant challenges for international B2B buyers. With varying quality standards, material types, and supplier reliability, sourcing high-quality basketball leather can feel like an overwhelming task. This guide aims to demystify the process by providing a comprehensive overview of basketball leather, covering essential aspects such as types, applications, supplier vetting, and cost considerations.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—will find actionable insights tailored to their unique market conditions. Understanding the distinctions between genuine leather, composite leather, and other materials is crucial for making informed purchasing decisions that meet both performance and budgetary needs.

Additionally, this guide will equip buyers with strategies for evaluating suppliers, ensuring product quality, and negotiating prices effectively. By the end of this resource, B2B buyers will be empowered to navigate the global market confidently, making strategic choices that enhance their product offerings and satisfy customer demands. Whether you are a seasoned buyer or new to the basketball leather market, this guide serves as an indispensable tool for success.

Table Of Contents

- Top 7 Basketball Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for basketball leather

- Understanding basketball leather Types and Variations

- Key Industrial Applications of basketball leather

- 3 Common User Pain Points for ‘basketball leather’ & Their Solutions

- Strategic Material Selection Guide for basketball leather

- In-depth Look: Manufacturing Processes and Quality Assurance for basketball leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘basketball leather’

- Comprehensive Cost and Pricing Analysis for basketball leather Sourcing

- Alternatives Analysis: Comparing basketball leather With Other Solutions

- Essential Technical Properties and Trade Terminology for basketball leather

- Navigating Market Dynamics and Sourcing Trends in the basketball leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of basketball leather

- Strategic Sourcing Conclusion and Outlook for basketball leather

- Important Disclaimer & Terms of Use

Understanding basketball leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Leather | Made from animal hide, offers excellent grip and feel. | Professional indoor leagues, high-end retailers. | Pros: Superior performance, durability. Cons: Higher cost, requires maintenance. |

| Композитная кожа | Synthetic material mimicking leather; soft and versatile. | Schools, recreational leagues, and casual play. | Pros: Affordable, low maintenance, immediate playability. Cons: Less durability than genuine leather. |

| Rubber | Durable and weather-resistant; ideal for outdoor use. | Outdoor courts, budget-friendly options. | Pros: Cost-effective, highly durable. Cons: Lacks the feel and grip of leather options. |

| Horween Leather | Premium leather known for its quality and craftsmanship. | High-end basketball manufacturers. | Pros: Exceptional quality, long-lasting. Cons: Premium pricing, limited availability. |

| Suede Leather | Soft texture, often used in high-end or specialty basketballs. | Niche markets, luxury sports retailers. | Pros: Unique feel, aesthetic appeal. Cons: Less practical for regular use, higher maintenance. |

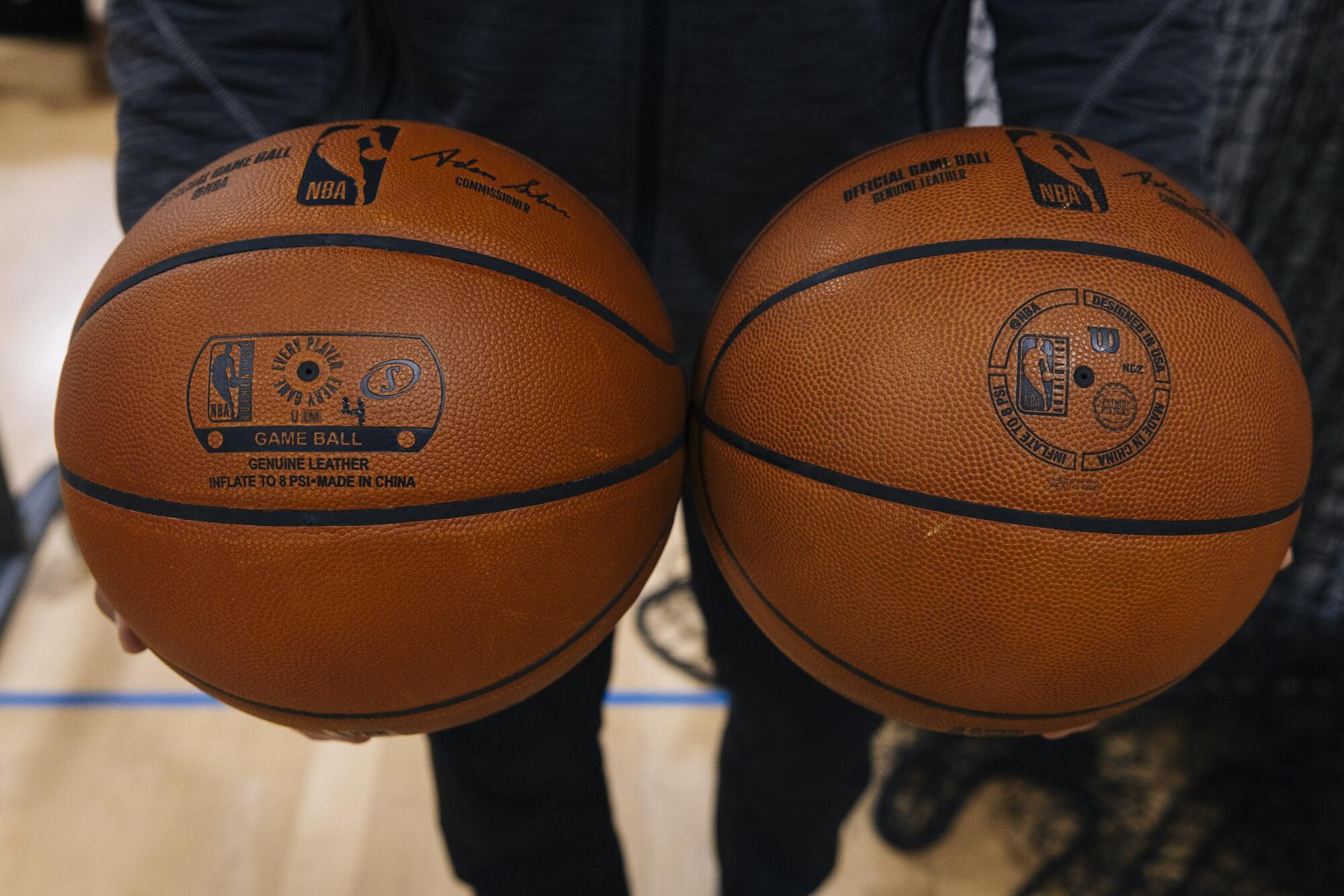

What Are the Characteristics of Genuine Leather Basketballs?

Genuine leather basketballs are crafted from high-quality animal hides, providing an unmatched grip and feel that enhances player performance. They are primarily used in professional leagues and high-end retail markets, making them a popular choice for serious athletes and teams. When purchasing genuine leather, B2B buyers should consider factors such as sourcing, pricing, and the need for maintenance, as these balls require care to maintain their quality and performance over time.

How Does Composite Leather Differ from Other Basketball Leathers?

Composite leather basketballs are made from synthetic materials designed to replicate the feel of genuine leather while offering a more affordable and low-maintenance alternative. They are suitable for schools, recreational leagues, and casual players who desire a ball that performs well across various surfaces. B2B buyers should focus on the durability and performance characteristics of composite leather, particularly its suitability for indoor and outdoor play, to meet diverse customer needs.

Illustrative image related to basketball leather

What Are the Advantages of Rubber Basketballs?

Rubber basketballs are renowned for their durability and resistance to weather conditions, making them ideal for outdoor play. They are a cost-effective option for budget-conscious buyers, including schools and community centers. However, they lack the premium feel and grip that leather options provide. When sourcing rubber basketballs, B2B buyers should evaluate their target market’s preferences and the intended usage to ensure the right product selection.

Why Is Horween Leather Considered Premium?

Horween leather basketballs are synonymous with quality and craftsmanship. Known for their exceptional durability and performance, these balls are favored by high-end basketball manufacturers. B2B buyers looking to invest in premium products should consider Horween leather for its reputation and long-lasting capabilities, keeping in mind the associated higher costs and potential supply limitations.

What Makes Suede Leather Basketballs Unique?

Suede leather basketballs offer a distinctive soft texture and aesthetic appeal, often targeted towards niche markets and luxury sports retailers. While they provide a unique playing experience, their practicality for regular use may be limited due to maintenance requirements. B2B buyers interested in suede options should assess their market’s demand for specialty products and the potential for higher profit margins.

Key Industrial Applications of basketball leather

| Industry/Sector | Specific Application of basketball leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sporting Goods Manufacturing | Production of high-performance basketballs | Enhances product quality, appealing to professional athletes | Ensure compliance with international quality standards and durability requirements. |

| Custom Sports Equipment | Creation of bespoke basketballs for promotional use | Differentiates brand offerings and enhances customer engagement | Consider customization options, including color, logo placement, and material specifications. |

| Educational Institutions | Supply of basketballs for schools and universities | Promotes athletic programs and student engagement | Focus on bulk purchasing agreements and pricing structures suitable for educational budgets. |

| Retail and E-commerce | Selling premium basketballs in online and brick-and-mortar stores | Attracts high-end consumers looking for quality sports gear | Evaluate supply chain logistics and inventory management for efficient distribution. |

| Leather Goods Production | Development of leather accessories for basketball enthusiasts | Expands product lines and caters to niche markets | Assess leather sourcing for ethical and sustainable practices, as well as consistency in quality. |

How Is Basketball Leather Used in Sporting Goods Manufacturing?

Basketball leather is crucial in the production of high-performance basketballs, where the quality of the leather directly influences the ball’s grip, durability, and overall performance. Manufacturers often collaborate with tanneries to ensure that the leather meets specific standards required by professional leagues. For international buyers, particularly from regions like Africa and South America, sourcing leather that complies with both local and international quality standards is essential. This ensures that the final product can withstand various playing conditions while meeting the expectations of skilled athletes.

Illustrative image related to basketball leather

What Role Does Basketball Leather Play in Custom Sports Equipment?

Custom sports equipment manufacturers utilize basketball leather to create bespoke basketballs tailored for promotional events or specific teams. This application not only enhances brand visibility but also fosters customer loyalty through personalized products. Buyers in this sector should consider factors such as customization options, turnaround times, and minimum order quantities. For businesses in Europe, for instance, understanding regional preferences for design and quality can significantly impact the success of promotional campaigns.

How Can Educational Institutions Benefit from Basketball Leather?

Educational institutions often require basketballs for their athletic programs, making basketball leather an important material for schools and universities. The use of high-quality leather in these products promotes better performance and engagement among students. When sourcing basketballs, institutions should focus on bulk purchasing agreements to secure favorable pricing and ensure that the products meet specific durability requirements suited for frequent use. Buyers from the Middle East and Africa may also benefit from local partnerships to facilitate easier distribution and support.

Why Is Basketball Leather Important for Retail and E-commerce?

In the retail and e-commerce sectors, premium basketballs made from high-quality leather attract consumers looking for top-tier sports equipment. These products often stand out in a crowded market, appealing to serious athletes and collectors alike. Retailers must evaluate their supply chain logistics to ensure timely delivery and manage inventory effectively. For B2B buyers in regions like Germany, understanding consumer trends and preferences can help in selecting the right product mix for their stores.

How Is Basketball Leather Used in Leather Goods Production?

Basketball leather is also utilized in the production of leather accessories tailored for basketball enthusiasts, such as bags, wallets, and keychains. This niche market allows businesses to expand their product lines and cater to passionate fans who appreciate high-quality materials. Buyers should assess the sourcing of leather for ethical and sustainable practices, as well as consistency in quality, to maintain brand integrity. In regions like South America, where craftsmanship is valued, offering unique leather goods can create a competitive advantage.

3 Common User Pain Points for ‘basketball leather’ & Their Solutions

Scenario 1: Quality Assurance in Sourcing Basketball Leather

The Problem: B2B buyers often face challenges ensuring the quality of basketball leather. With numerous suppliers claiming to offer premium products, distinguishing between genuine high-quality leather and inferior alternatives can be overwhelming. This is particularly critical in regions where counterfeit products are prevalent, leading to concerns over durability, performance, and safety. Buyers may also struggle with inconsistent quality across shipments, which can disrupt their production schedules and negatively impact their brand reputation.

Illustrative image related to basketball leather

The Solution: To mitigate these risks, buyers should establish a rigorous vetting process for suppliers. Start by requiring certifications that verify the leather’s origin, such as ISO certifications or compliance with international leather standards. Engaging in direct communication with manufacturers can also yield insights into their production methods and quality control measures. For bulk orders, requesting samples before committing to large purchases is advisable. Consider forming partnerships with established tanneries known for their consistent quality, such as Horween or C.F. Stead, which have a solid reputation in the industry. This proactive approach not only ensures the procurement of high-quality leather but also fosters long-term supplier relationships that can lead to better pricing and availability.

Scenario 2: Understanding Different Types of Basketball Leather

The Problem: Many buyers are confused about the various types of basketball leather available, such as genuine leather, composite leather, and synthetic alternatives. This confusion can lead to purchasing decisions that do not meet the specific needs of their target market, whether for professional players or recreational users. For instance, while genuine leather is preferred for its superior feel and performance, it requires a break-in period and is less durable on outdoor courts. Conversely, composite leather offers versatility but may not satisfy the preferences of high-level athletes.

The Solution: Buyers should conduct thorough market research to understand the specific needs of their customers. Segmenting the target market based on skill level, usage (indoor vs. outdoor), and player preference can guide the selection of the appropriate leather type. Providing educational materials that explain the differences and benefits of each type can also help end-users make informed decisions. Collaborating with sports professionals or influencers for product testing can provide valuable feedback on performance and help in positioning the product effectively. Additionally, consider offering a range of options that cater to different segments, from high-end genuine leather for elite players to durable composite leather for casual users.

Scenario 3: Managing Lead Times and Supply Chain Disruptions

The Problem: B2B buyers frequently encounter issues with lead times and supply chain disruptions, particularly when sourcing basketball leather from international suppliers. Delays can stem from various factors, including transportation issues, customs clearance, and unexpected demand fluctuations. Such disruptions can lead to inventory shortages, affecting the ability to meet customer orders on time and potentially harming business relationships.

The Solution: To manage lead times more effectively, buyers should diversify their supplier base and consider local sourcing options where feasible. Developing relationships with multiple tanneries can provide backup options in case one supplier faces delays. Implementing a just-in-time inventory system can also help maintain optimal stock levels while reducing excess inventory costs. Buyers should communicate regularly with suppliers to gain insights into production schedules and potential delays. Additionally, investing in a robust supply chain management system can enhance visibility and allow for proactive adjustments in sourcing strategies. By adopting these practices, buyers can build resilience against disruptions and ensure a steady supply of basketball leather.

Illustrative image related to basketball leather

Strategic Material Selection Guide for basketball leather

When selecting materials for basketball leather, it is essential to understand the various options available and their implications for product performance, durability, and market suitability. This guide analyzes four common materials used in basketball leather, providing insights tailored for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Genuine Leather for Basketballs?

Genuine leather is a traditional choice for basketballs, prized for its natural feel and performance. It typically has a temperature resistance that allows it to maintain its integrity in various climates, making it suitable for both indoor and outdoor use. Genuine leather offers excellent grip and a soft touch, enhancing player control during games.

Pros: The primary advantages of genuine leather include its durability and superior feel, which can significantly enhance the playing experience. It also tends to age well, developing a unique patina over time.

Cons: On the downside, genuine leather requires a break-in period and needs regular maintenance to prevent damage from moisture and wear. Additionally, it is generally more expensive than synthetic alternatives.

How Does Composite Leather Compare in Performance and Cost?

Composite leather is a synthetic alternative designed to mimic the properties of genuine leather. It offers a consistent performance across various conditions and is typically resistant to moisture, making it suitable for both indoor and outdoor basketballs.

Illustrative image related to basketball leather

Pros: The key advantages of composite leather include its affordability and low maintenance requirements. It provides a soft grip and immediate usability, which can be appealing for casual players and training sessions.

Cons: However, composite leather may not offer the same level of durability as genuine leather, particularly in high-intensity play. Over time, it may wear out faster and lose its grip.

What are the Benefits and Limitations of Synthetic Leather in Basketball Production?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is another popular choice for basketballs. It is engineered to provide a good balance of performance and cost-effectiveness.

Pros: Synthetic leather is highly durable and resistant to environmental factors, making it ideal for outdoor use. It is also easier to clean and maintain compared to genuine leather.

Cons: The primary limitation of synthetic leather is its feel; many players find it lacks the natural touch of genuine leather. Additionally, it may not perform as well in extreme temperatures, which can be a consideration for international markets.

What is the Role of Microfiber Leather in Modern Basketballs?

Microfiber leather is a high-tech synthetic material that combines multiple fibers to create a soft, durable surface. This material is increasingly being used in high-end basketballs due to its performance characteristics.

Pros: Microfiber leather offers excellent grip and a soft feel, making it suitable for professional play. It is also lightweight and resistant to wear, which enhances its longevity.

Cons: The main drawback is its higher production cost compared to traditional synthetic leathers, which may deter budget-conscious manufacturers.

Illustrative image related to basketball leather

Summary Table of Material Selection for Basketball Leather

| Материал | Typical Use Case for basketball leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Professional indoor basketballs | Superior feel and durability | Requires maintenance and break-in | Высокий |

| Композитная кожа | Indoor/outdoor basketballs | Low maintenance and affordable | Less durable than genuine leather | Medium |

| Синтетическая кожа | Outdoor basketballs | Highly durable and easy to maintain | Lacks the natural feel of leather | Низкий |

| Кожа из микрофибры | High-end professional basketballs | Excellent grip and lightweight | Higher production cost | Высокий |

By understanding these materials’ properties, advantages, and limitations, international B2B buyers can make informed decisions that align with their market needs and consumer preferences. This strategic approach ensures that the selected basketball leather not only meets performance standards but also adheres to regional compliance and quality expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for basketball leather

What Are the Key Stages in the Manufacturing Process of Basketball Leather?

The production of basketball leather involves several critical stages that ensure the final product meets the high standards expected by athletes and manufacturers alike. Understanding these stages is vital for B2B buyers, as it allows them to appreciate the craftsmanship and quality assurance behind their products.

1. Material Preparation: How Is Basketball Leather Sourced and Processed?

The initial phase in the manufacturing process begins with sourcing high-quality raw materials, typically animal hides. The selection of hides is crucial, as it directly influences the leather’s durability, texture, and performance. Leading manufacturers, such as Horween, utilize a meticulous selection process, often working closely with suppliers to ensure that only the best materials are chosen.

Once the hides are selected, they undergo tanning, a process that preserves the leather and enhances its qualities. This step can involve various techniques, including vegetable tanning and chrome tanning, each imparting unique characteristics to the leather. For instance, vegetable-tanned leather is known for its durability and natural feel, while chrome-tanned leather offers a more supple texture.

2. Forming: What Techniques Are Used to Shape Basketball Leather?

After tanning, the leather is cut into specific shapes and sizes according to the design requirements of the basketball. This phase involves precision cutting to ensure consistency across batches. Manufacturers often utilize computerized cutting machines that enhance accuracy and minimize waste.

Illustrative image related to basketball leather

The forming stage also includes the application of any necessary treatments to enhance grip and performance. For example, some manufacturers may apply a unique coating to improve moisture resistance, thus ensuring that the leather maintains its integrity during play.

3. Assembly: How Are Basketball Leather Panels Joined Together?

In the assembly stage, the cut leather pieces are stitched together to form the panels of the basketball. This step requires skilled craftsmanship to ensure that the seams are strong and durable. Manufacturers often employ techniques such as double stitching to reinforce these areas, which are subjected to significant stress during play.

Quality manufacturers may also include a bladder inside the leather exterior to maintain the ball’s shape and air retention. The assembly process can vary depending on the type of basketball being produced—whether it’s for professional leagues or recreational use.

Illustrative image related to basketball leather

4. Finishing: What Are the Final Touches Applied to Basketball Leather?

The finishing stage involves several processes that enhance both the aesthetic and functional qualities of the basketball leather. This can include polishing, dyeing, and applying protective coatings. These final touches not only improve the leather’s appearance but also add to its longevity and performance characteristics.

During this phase, manufacturers may also conduct aesthetic inspections to ensure that the finished product meets the visual standards expected by consumers. This attention to detail is essential for establishing a brand’s reputation in the competitive sports market.

What Quality Assurance Practices Are Essential for Basketball Leather Production?

Quality assurance is a critical component of the manufacturing process, ensuring that the basketball leather meets international standards and customer expectations. B2B buyers should be familiar with these practices to make informed purchasing decisions.

1. What International Standards Should Buyers Consider?

Manufacturers of basketball leather often adhere to international quality standards such as ISO 9001, which provides a framework for consistent quality management systems. Compliance with these standards is essential for ensuring that products are manufactured to meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, depending on the intended market and usage of the leather. Buyers should verify that their suppliers hold these certifications to ensure compliance with applicable regulations.

2. How Are Quality Control Checkpoints Structured?

Quality control (QC) is typically structured around several key checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. It ensures that only suitable hides are used in production.

- In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves monitoring each step to identify and rectify any deviations from established standards.

- Final Quality Control (FQC): After assembly and finishing, FQC includes comprehensive testing of the finished product for durability, performance, and visual quality.

Common testing methods may include tensile strength tests, moisture resistance tests, and aesthetic evaluations to ensure that the final product meets or exceeds industry benchmarks.

3. How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should adopt a proactive approach to verify the quality control processes of their suppliers. This can include:

- Conducting Audits: Regular audits of suppliers can help ensure compliance with quality standards and regulations. Buyers should request access to audit reports to assess supplier practices.

- Requesting Quality Reports: Suppliers should provide detailed quality reports that outline testing results and compliance with international standards. These documents can serve as assurance of the supplier’s commitment to quality.

- Engaging Third-Party Inspectors: Independent inspections can provide an unbiased assessment of the manufacturing processes and product quality. Buyers may consider hiring third-party firms to conduct these evaluations.

What Nuances Should International B2B Buyers Be Aware Of?

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should consider specific nuances that may affect their procurement processes.

Illustrative image related to basketball leather

1. Understanding Regional Standards and Compliance

Different regions may have varying regulations and standards concerning leather products. Buyers should familiarize themselves with local laws regarding leather sourcing, environmental impact, and consumer safety to ensure compliance when importing basketball leather.

2. Cultural and Market Preferences

Cultural preferences can influence the type of leather products in demand. For instance, certain regions may favor synthetic or composite leather over genuine leather due to cost and maintenance considerations. Understanding these market dynamics can aid buyers in making more informed purchasing decisions.

3. Logistics and Supply Chain Considerations

Logistics can pose challenges when sourcing basketball leather internationally. Buyers should evaluate suppliers based on their ability to meet delivery timelines, handle customs regulations, and provide reliable shipping options. Establishing a strong relationship with suppliers can facilitate smoother transactions and mitigate potential disruptions.

In summary, the manufacturing processes and quality assurance practices for basketball leather are intricate and essential for delivering high-quality products. B2B buyers must engage in thorough due diligence when selecting suppliers to ensure that their procurement aligns with industry standards and market demands.

Illustrative image related to basketball leather

Practical Sourcing Guide: A Step-by-Step Checklist for ‘basketball leather’

Введение

This sourcing guide is designed to assist B2B buyers in procuring basketball leather effectively. As the demand for high-quality basketballs rises globally, understanding how to source the right leather is crucial for ensuring product excellence and meeting market expectations. This checklist will help you navigate the complexities of selecting suppliers, materials, and specifications to ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Clearly outline the characteristics you need in basketball leather. This includes weight, thickness, and finish, which can significantly affect the ball’s performance and durability. For example, basketball leather typically ranges from 4.5 oz to 6 oz; knowing your requirements helps in matching the right product to your intended use.

- Consider the type of leather: Genuine leather offers premium quality, while composite leather provides versatility and low maintenance.

- Identify specific applications: Determine if the leather will be used for professional-grade basketballs or recreational use, as this impacts material choice.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Focus on those with a strong reputation in the industry, especially those known for producing high-quality basketball leather. This step is critical as it sets the foundation for the quality of your final product.

- Check industry reviews and testimonials: Look for suppliers with positive feedback from other B2B buyers.

- Explore supplier portfolios: Examine their previous work and whether they align with your quality standards.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This ensures that you are partnering with a reliable supplier who can meet your quality and delivery expectations.

Illustrative image related to basketball leather

- Assess certifications and quality standards: Verify if suppliers comply with international standards, such as ISO certifications, which indicate reliability in production processes.

- Request samples: Obtain leather samples to evaluate the texture, durability, and performance firsthand.

Step 4: Negotiate Terms and Pricing

Engage in negotiations to secure favorable terms and pricing. Understanding the market rates for basketball leather can empower you during negotiations and help establish a mutually beneficial agreement.

- Inquire about bulk pricing: If you plan to order large quantities, ask suppliers for volume discounts.

- Clarify payment terms: Ensure that payment schedules align with your cash flow requirements to maintain operational efficiency.

Step 5: Confirm Shipping and Delivery Arrangements

Ensure that shipping and delivery logistics are clearly defined. This includes lead times, shipping methods, and costs, which can affect your inventory management and production schedules.

- Discuss international shipping options: If you’re sourcing from overseas suppliers, confirm that they can accommodate international shipping, especially to your specific region.

- Establish a timeline: Set clear deadlines for delivery to align with your production schedule, preventing delays.

Step 6: Monitor Quality Control and Compliance

Implement ongoing quality control measures post-purchase. Regularly assess the leather received against your original specifications to ensure it meets your standards.

- Conduct inspections upon receipt: Check for any defects or discrepancies in quality.

- Maintain communication with suppliers: Establish a feedback loop to address any issues promptly and ensure continuous improvement.

By following these steps, B2B buyers can streamline their sourcing process for basketball leather, ensuring they procure high-quality materials that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for basketball leather Sourcing

What Are the Key Cost Components for Sourcing Basketball Leather?

When sourcing basketball leather, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The cost of raw materials is the most significant factor. Premium options like Horween leather can range from $257 per side (18-22 sq ft) to higher-end custom options. Buyers should consider the type of leather—genuine vs. composite—as this affects both price and performance.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as Vietnam, the overall expense for labor-intensive processes like tanning and stitching may be reduced. In contrast, European manufacturers may command higher wages but often offer superior craftsmanship.

-

Manufacturing Overhead: This includes costs associated with the facilities and equipment used in production. Tannery operations may incur overhead costs related to environmental regulations, which can influence pricing.

-

Tooling: Initial tooling costs for custom designs can be substantial. Buyers should factor in these expenses when considering bespoke products, as they can increase the overall investment significantly.

-

Quality Control (QC): Implementing robust QC processes ensures that the leather meets the required specifications and certifications. This might add to the cost but can prevent future losses due to defects.

-

Logistics: Transportation and handling costs can vary widely depending on the source and destination. International shipments may require careful planning to avoid delays and additional tariffs.

-

Margin: Suppliers will typically include a margin to cover their risks and operational costs. This margin can vary based on competition, demand, and the supplier’s reputation.

How Do Price Influencers Impact Basketball Leather Costs?

Several factors can influence the pricing of basketball leather, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to better pricing due to economies of scale. Buyers should negotiate MOQs that align with their needs to optimize costs.

-

Specifications and Customization: Customized leather products can incur additional charges. Buyers should clearly define their specifications to avoid unexpected costs.

-

Material Quality and Certifications: Higher quality leathers with industry certifications (like ISO) may come at a premium but can enhance product value and performance.

-

Supplier Factors: The supplier’s location, reputation, and reliability play a crucial role. Established suppliers may charge higher prices but offer guarantees and better service.

-

Incoterms: Understanding Incoterms is critical for international transactions. These terms dictate who is responsible for shipping costs and insurance, which can significantly affect the total landed cost.

What Tips Can Help Buyers Negotiate Better Prices?

To achieve cost-efficiency in sourcing basketball leather, buyers should consider the following strategies:

-

Negotiation: Engage in discussions with suppliers to explore flexible pricing options based on order size, payment terms, and potential long-term partnerships.

-

Total Cost of Ownership (TCO): Evaluate the total cost beyond the initial purchase price, including logistics, maintenance, and potential returns or defects. This holistic view can lead to better purchasing decisions.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and regional market conditions, as these can impact pricing. Building relationships with local distributors can also provide valuable insights into market trends and pricing strategies.

-

Supplier Relationships: Developing strong relationships with suppliers can lead to better pricing, priority service, and insights into new materials or technologies that may lower costs in the long run.

By understanding these cost components, price influencers, and negotiation strategies, B2B buyers can make informed decisions when sourcing basketball leather, ensuring both quality and value in their purchases.

Alternatives Analysis: Comparing basketball leather With Other Solutions

Exploring Alternatives to Basketball Leather for B2B Buyers

In the world of sports equipment manufacturing, particularly basketballs, the choice of materials is crucial for performance, durability, and user satisfaction. While basketball leather, especially premium options like Horween leather, is a popular choice, there are viable alternatives worth considering. This section compares basketball leather with composite leather and rubber basketballs, helping B2B buyers make informed decisions based on their specific needs.

Illustrative image related to basketball leather

| Comparison Aspect | Basketball Leather | Композитная кожа | Rubber Basketballs |

|---|---|---|---|

| Performance | Excellent grip and feel; preferred for indoor play. | Good grip; versatile for both indoor and outdoor use. | Durable and robust; ideal for outdoor conditions. |

| Cost | High-end, around $257 per unit. | Mid-range, typically between $30-$100. | Budget-friendly, usually under $30. |

| Ease of Implementation | Requires skilled craftsmanship; long lead times. | Easily mass-produced; readily available. | Simple manufacturing process; widely accessible. |

| Maintenance | Requires regular care and conditioning. | Low maintenance; easy to clean. | Very low maintenance; water-resistant. |

| Best Use Case | Professional indoor games; premium offerings. | Training sessions; casual play; multi-surface use. | Recreational use; outdoor play; schools. |

What Are the Advantages and Disadvantages of Composite Leather?

Composite leather has emerged as a strong competitor to traditional basketball leather. It offers a balance between performance and affordability, making it suitable for both casual and competitive play. The softer grip of composite leather provides immediate usability without the break-in period associated with genuine leather. However, while it performs well on multiple surfaces, it may not deliver the same premium feel and durability as high-quality basketball leather, particularly in professional settings.

How Do Rubber Basketballs Compare to Basketball Leather?

Rubber basketballs are the most economical option, primarily designed for outdoor use. Their robust construction makes them resistant to wear and tear, ideal for rough surfaces. However, they often lack the grip and feel that players seek for indoor performance. This makes them less suitable for professional games but a great choice for schools, parks, and casual play. While they offer significant cost savings, the trade-off is a lesser playing experience compared to leather options.

Conclusion: How Should B2B Buyers Choose the Right Basketball Material?

When selecting the appropriate basketball material, B2B buyers must consider several factors, including target market, budget, and intended use. For high-end products aimed at professional athletes, investing in premium basketball leather may be justified. Conversely, for casual play or educational institutions, composite leather or rubber may be more suitable due to lower costs and versatility. By understanding the strengths and weaknesses of each option, buyers can align their product offerings with customer expectations, ensuring both satisfaction and profitability.

Essential Technical Properties and Trade Terminology for basketball leather

What Are the Key Technical Properties of Basketball Leather?

Understanding the technical properties of basketball leather is crucial for B2B buyers, particularly those sourcing materials for sports equipment manufacturing. Here are several essential specifications:

1. Material Grade

Material grade refers to the quality of the leather used in basketball production. High-grade leather, such as that sourced from reputable tanneries like Horween, ensures durability, performance, and feel. For manufacturers, selecting the right material grade can significantly impact the final product’s marketability and longevity, which is vital for maintaining brand reputation.

Illustrative image related to basketball leather

2. Thickness (Weight)

The thickness of basketball leather is typically measured in ounces per square foot (oz). Standard weights for basketball leather range from 4.5 oz to 6 oz. Thicker leather may provide enhanced durability but can also affect the ball’s weight and handling. Buyers must consider how the thickness aligns with their product specifications and target market preferences, as it directly influences playability and performance.

3. Finish Type

The finish applied to basketball leather can vary from matte to glossy. A matte finish often provides better grip, while a glossy finish may enhance aesthetic appeal. Understanding the finish type is crucial for manufacturers aiming to meet specific consumer preferences, especially in professional and amateur sports markets.

4. Surface Texture

The texture of the leather affects grip and handling during gameplay. A pebbled or embossed texture can enhance traction, which is critical for performance. B2B buyers should evaluate texture options based on the intended use of the basketball, whether for indoor, outdoor, or professional play.

5. Color Fastness

Color fastness measures the resistance of the leather’s dye to fading and wear over time. This property is particularly important for basketballs that will be exposed to varied playing conditions. Ensuring high color fastness can help maintain the product’s visual appeal and longevity, which is essential for customer satisfaction and repeat business.

6. Durability Rating

Durability rating assesses how well the leather withstands wear and tear over time. This rating can be particularly important for outdoor basketballs, which face harsher conditions. Buyers should prioritize durability in their sourcing decisions to minimize returns and ensure customer loyalty.

What Common Trade Terms Should B2B Buyers Know?

Navigating the basketball leather supply chain involves familiarizing oneself with industry-specific terminology. Here are several common terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are then marketed under another company’s brand. In the context of basketball leather, an OEM might supply leather to sports brands for their basketball production. Understanding OEM relationships can help buyers identify reliable suppliers and streamline their procurement processes.

Illustrative image related to basketball leather

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For basketball leather, MOQs can vary significantly based on the supplier and material specifications. Knowing the MOQ is essential for buyers to plan their inventory and production schedules effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. B2B buyers often use RFQs to compare costs and services from multiple suppliers, ensuring they secure the best deal for basketball leather.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is critical for buyers engaged in international sourcing of basketball leather, as they help clarify the costs and risks involved in transportation.

5. Lead Time

Lead time is the duration from placing an order to the delivery of goods. In the basketball leather industry, understanding lead time is crucial for planning production schedules and meeting market demand. Buyers should communicate clearly with suppliers to ensure timely delivery.

Illustrative image related to basketball leather

6. Sustainability Standards

Sustainability standards refer to the environmental and ethical practices adhered to during the sourcing and production of leather. Buyers increasingly prioritize suppliers that comply with sustainable practices, as this can influence brand image and market appeal. Understanding these standards is becoming essential in the global leather market.

By being informed about these technical properties and trade terms, B2B buyers can make better purchasing decisions, ensuring that they source high-quality basketball leather that meets their specific needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the basketball leather Sector

What Are the Key Market Dynamics and Trends in the Basketball Leather Sector?

The basketball leather market is experiencing robust growth driven by several global factors. First, the increasing popularity of basketball across regions such as Africa, South America, and the Middle East is creating a surge in demand for high-quality basketball products. The rise of professional leagues and grassroots initiatives in these areas is fostering a greater appreciation for premium materials, particularly leather. Moreover, technological advancements in leather tanning and processing are leading to the development of innovative products that enhance performance, such as moisture-resistant and durable leather options.

Emerging B2B tech trends are also shaping the sourcing landscape. Digital platforms that facilitate direct connections between manufacturers and buyers are gaining traction, reducing the reliance on traditional intermediaries. This shift allows international buyers to access a broader range of suppliers and negotiate better pricing and terms. Additionally, the integration of data analytics is enabling companies to optimize their supply chains, track market trends, and forecast demand more accurately.

Illustrative image related to basketball leather

Sourcing dynamics are further influenced by regional preferences and economic conditions. For instance, buyers in Europe may prioritize premium, traditional leather sourced from reputable tanneries, while those in emerging markets might focus on cost-effective, composite leather alternatives. Understanding these regional nuances is crucial for international buyers looking to navigate the complex landscape of the basketball leather sector effectively.

How Is Sustainability and Ethical Sourcing Transforming the Basketball Leather Industry?

Sustainability is becoming increasingly important in the basketball leather market, driven by growing consumer awareness and regulatory pressures. The environmental impact of leather production, including water usage and chemical runoff, has prompted buyers to seek more sustainable options. Ethical sourcing practices, such as ensuring fair labor conditions and minimizing environmental harm, are now essential criteria for B2B partnerships.

Buyers are encouraged to look for suppliers that utilize environmentally friendly tanning processes, such as vegetable tanning, which reduces harmful chemical use. Certifications like the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) can serve as indicators of a supplier’s commitment to sustainable practices. By prioritizing these ‘green’ certifications, businesses can not only enhance their brand reputation but also align with the increasing consumer demand for responsible sourcing.

Illustrative image related to basketball leather

Additionally, the trend toward using composite leather, which often incorporates recycled materials, is gaining momentum. This alternative provides a balance between performance and sustainability, appealing to a wider range of buyers who prioritize both quality and environmental responsibility.

How Has the Basketball Leather Sector Evolved Over Time?

The evolution of basketball leather can be traced back to its roots in traditional leather craftsmanship, where artisans meticulously crafted basketballs from animal hides. Over the decades, advancements in tanning technology have allowed for the production of specialized leathers that enhance performance, durability, and aesthetics.

The introduction of composite leather in the 1990s marked a significant turning point, catering to a market that demanded versatility and low maintenance. These synthetic alternatives provided immediate playability and a softer grip, making them a popular choice for both indoor and outdoor play. As the market continues to evolve, the focus on sustainability and ethical sourcing is poised to shape the future of basketball leather, blending tradition with modern values.

Frequently Asked Questions (FAQs) for B2B Buyers of basketball leather

-

How do I choose the right basketball leather supplier for my business?

Selecting the right supplier involves evaluating several key factors. Start by researching the supplier’s reputation in the industry, checking for certifications and quality assurance processes. Request samples to assess the leather’s quality and performance in real-world conditions. Additionally, verify their experience in international trade, especially in your region, to ensure they understand local regulations and logistics challenges. Finally, consider their ability to customize orders to fit your specific needs, including weight, color, and texture. -

What types of basketball leather are available for purchase?

Basketball leather typically comes in two main types: genuine leather and composite leather. Genuine leather is preferred for its premium feel and durability, making it suitable for professional-grade basketballs. Composite leather, on the other hand, offers a softer grip and requires less maintenance, making it ideal for recreational use. When sourcing, consider your target market’s preferences and the intended use to determine which type aligns best with your product offerings. -

What is the minimum order quantity (MOQ) for basketball leather?

MOQs can vary significantly between suppliers. Many manufacturers require a minimum order of 100 square feet for basketball leather, while others may have different thresholds based on their production capabilities. It’s advisable to inquire directly with potential suppliers about their MOQ to determine if it aligns with your business needs. Keep in mind that larger orders may also provide opportunities for bulk discounts. -

How can I ensure quality assurance in my basketball leather orders?

To ensure quality assurance, request detailed specifications and samples before placing a large order. Establish clear communication regarding your quality standards, and inquire about the supplier’s quality control processes. Many reputable suppliers will have certifications that demonstrate their commitment to quality. Additionally, consider arranging third-party inspections to validate the quality of the leather prior to shipment. -

What payment terms are typically offered by basketball leather suppliers?

Payment terms can vary widely among suppliers, but common practices include advance payments, letters of credit, or payment upon delivery. It’s essential to negotiate terms that suit your cash flow and risk tolerance. Be wary of suppliers demanding excessive upfront payments, as this could indicate potential financial instability. Establishing a clear contract outlining payment schedules, amounts, and penalties for late payments is crucial for protecting your interests. -

What logistics considerations should I keep in mind when importing basketball leather?

Logistics play a vital role in the timely delivery of your basketball leather. Consider factors such as shipping methods (air or sea), customs regulations in your country, and potential tariffs or duties. Working with a freight forwarder can streamline the shipping process and help navigate international trade complexities. Additionally, ensure that you have a reliable supply chain in place to handle any delays or issues that may arise during transit. -

Can I customize my basketball leather orders in terms of color and texture?

Yes, many suppliers offer customization options for basketball leather, including variations in color, weight, and texture. Customization can help you differentiate your products in the marketplace. When discussing your needs with suppliers, provide clear specifications and examples to ensure they understand your vision. Be mindful that custom orders may have different MOQs and lead times, so plan accordingly. -

What are the advantages of sourcing basketball leather from international suppliers?

Sourcing basketball leather internationally can provide access to higher-quality materials and competitive pricing that may not be available locally. Countries known for their leather production often have established supply chains and expertise in manufacturing, resulting in better quality products. Additionally, international suppliers may offer innovative materials and technologies that can enhance your product offerings. However, it is crucial to conduct thorough due diligence to mitigate risks related to quality, compliance, and logistics.

Top 7 Basketball Leather Manufacturers & Suppliers List

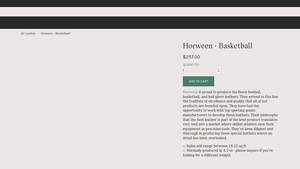

1. Horween – Basketball Leather

Domain: thetanneryrow.com

Registered: 2011 (14 years)

Введение: {“name”: “Horween Basketball Leather”, “brand”: “Horween”, “price”: “$257.00”, “description”: “Horween is proud to produce the finest football, basketball, and ball glove leathers. They extend to this line the tradition of excellence and quality that all of our products are founded upon. They have had the opportunity to work with top sporting goods manufacturers to develop these leathers. Their ph…

2. Leatherhead Sports – Handmade Leather Basketballs

Domain: leatherheadsports.com

Registered: 2010 (15 years)

Введение: Handmade Leather Basketballs made from top quality, American tanned leather. Designed to resemble the original style lace-up basketball. Can be dribbled and shot. Available products include: Bourbon Basketball ($200.00, on sale from $250.00), Naismith Basketball ($250.00), Onyx Basketball ($250.00), Black and Tan Basketball ($250.00), Gold Basketball ($250.00), Blue and White Basketball ($250.00),…

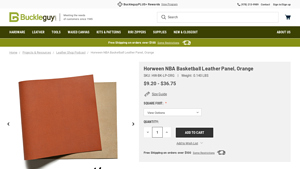

3. Buckleguy – Horween NBA Basketball Leather Panel

Domain: buckleguy.com

Registered: 2002 (23 years)

Введение: {‘name’: ‘Horween NBA Basketball Leather Panel’, ‘color’: ‘Orange’, ‘tannage’: ‘Chrome Tanned’, ‘type’: ‘Sports Leather’, ‘tannery’: ‘Horween’, ‘weight’: ‘4.5-5 oz (1.8-2.0mm)’, ‘cut’: ‘Panel’, ‘firmness’: ‘Semi-Soft’, ‘sizes’: [{‘size’: ‘0.5 Square Foot’, ‘dimensions’: ‘6.5 inch x 11 inch’}, {‘size’: ‘1.0 Square Foot’, ‘dimensions’: ’13 inch x 11 inch’}, {‘size’: ‘1.5 Square Foot’, ‘dimensions’: …

4. Leather WKS – Basketball Leather Panels

Domain: leatherwks.com

Registered: 1998 (27 years)

Введение: {“name”: “Basketball”, “price”: {“regular_price”: “$26.95 USD”, “sale_price”: “$26.95 USD”}, “shipping”: “calculated at checkout”, “colors”: [“Black”, “Brown”, “Cognac”], “sizes”: [{“size”: “12\”x12\” pre cut panel”, “price”: “$26.95”}, {“size”: “20-25 SQFT (Half Hide)”, “price”: “$309.95”}], “description”: “Embossed top grain cowhide in uniform small bumpy texture like a basketball. Aniline drum …

5. Reddit – Genuine Leather Basketball

6. Spalding – Composite Leather Basketballs

Domain: spalding-basketball.com

Введение: Composite leather basketballs are made from synthetic fibers and resins designed to replicate the look and feel of genuine leather. They offer a softer grip and consistent performance, especially on indoor courts, without the break-in time or maintenance required by real leather. Composite leather combines the best features of rubber and genuine leather, providing a soft feel, reliable grip, and i…

7. Molten – FX Basketball (NFHS Approved)

Domain: moltenusa.com

Registered: 1997 (28 years)

Введение: {“products”:[{“name”:”FX Basketball (NFHS Approved)”,”price”:”$53.98″},{“name”:”B7G5000-Q5Z”,”price”:”$159.49″},{“name”:”B7G3800-Q5Z”,”price”:”$54.98″},{“name”:”BG2000″,”price”:”$17.98″,”availability”:”Out of Stock”},{“name”:”BG3800″,”price”:”$49.98″},{“name”:”BG4500″,”price”:”$104.98″},{“name”:”BG5000″,”price”:”$144.98″},{“name”:”BGMX-C Basketball”,”price”:”$49.98″},{“name”:”BGRX Premium Rubber B…

Strategic Sourcing Conclusion and Outlook for basketball leather

As the demand for high-quality basketball leather continues to grow across global markets, strategic sourcing has become essential for B2B buyers looking to enhance their offerings. By partnering with reputable suppliers like Horween and C.F. Stead, businesses can secure premium leather that meets the rigorous standards of professional athletes. This not only elevates product quality but also builds brand credibility in competitive markets such as Africa, South America, the Middle East, and Europe.

Illustrative image related to basketball leather

Understanding the nuances between genuine leather and composite leather is crucial. While genuine leather offers superior feel and performance, composite options provide durability and versatility, catering to a broader range of consumer preferences. This insight allows buyers to tailor their product lines effectively, aligning with market demands and consumer behavior.

Looking ahead, the basketball leather market presents significant opportunities for growth. Buyers are encouraged to leverage these insights to refine their sourcing strategies and explore innovative product development. By staying attuned to market trends and consumer needs, businesses can position themselves as leaders in the sporting goods industry. Engage with trusted suppliers today to secure a competitive edge and drive your business forward in this dynamic market landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.