Catalog

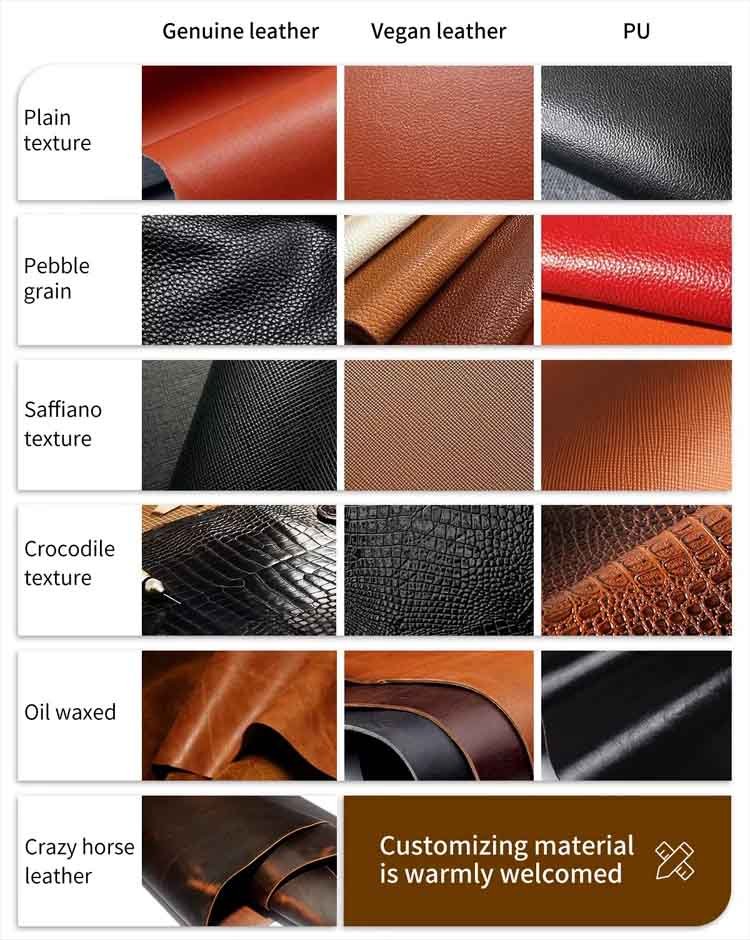

Material Insight: Different Types Of Leather

B2B Product Guide: Understanding Different Types of Leather

Leather has long been a staple material across industries ranging from automotive and furniture to fashion and accessories. Traditionally, leather is categorized into two main types: genuine leather and faux (synthetic) leather. Genuine leather is derived from animal hides and prized for its natural grain, durability, and premium feel. However, it comes with significant environmental, ethical, and cost-related challenges, including high water consumption, chemical processing, and variability in supply and quality.

Faux leather, also known as synthetic or artificial leather, offers a modern alternative engineered to overcome these limitations. Made primarily from polyurethane (PU) or polyvinyl chloride (PVC), faux leather delivers consistent quality, enhanced durability, and improved sustainability when produced responsibly. It is also cruelty-free, fully customizable in texture, color, and performance, and often more cost-effective for large-scale manufacturing.

Why Faux Leather is the Best Choice for Modern Applications

For B2B clients focused on scalability, sustainability, and design flexibility, faux leather stands out as the optimal material choice. Key advantages include:

- Consistent Quality: Unlike genuine leather, which varies due to natural imperfections in hides, faux leather provides uniform texture and thickness across production runs.

- Eco-Friendly Production: Advanced PU-based faux leathers significantly reduce environmental impact by minimizing water use, avoiding hazardous tanning chemicals, and enabling recyclable formulations.

- Design Versatility: Faux leather can be engineered to mimic exotic skins, offer unique textures, or integrate performance features such as UV resistance, breathability, and abrasion resistance.

- Cost Efficiency: With no dependency on livestock or complex tanning infrastructure, faux leather offers stable pricing and reduced lead times.

- Ethical Compliance: As consumer demand for cruelty-free materials grows, faux leather supports brands in meeting ESG (Environmental, Social, and Governance) goals.

Introducing WINIW: Trusted Innovation in Synthetic Leather

WINIW is a leading global provider of high-performance synthetic leather solutions, serving B2B clients for over 20 years. Specializing in PU and microfiber leather technologies, WINIW combines advanced R&D with sustainable manufacturing practices to deliver materials that meet the highest industry standards.

Our expertise spans multiple sectors, including automotive interiors, furniture, luggage, footwear, and apparel. With state-of-the-art facilities and a commitment to innovation, WINIW consistently delivers products that balance aesthetics, functionality, and environmental responsibility.

Partnering with WINIW means access to:

– Customized material solutions tailored to specific application needs

– Eco-conscious production aligned with global sustainability standards

– Reliable supply chains and scalable manufacturing capacity

– Technical support and collaborative development services

As industries evolve toward more responsible and efficient material choices, WINIW continues to lead the way in redefining what synthetic leather can achieve.

Technical Performance & Standards

WINIW Synthetic Leather: Technical Advantages for B2B Manufacturing Excellence

WINIW delivers high-performance synthetic leather solutions engineered for demanding industrial applications. Our materials combine advanced polymer science with rigorous environmental stewardship, providing manufacturers with a sustainable, reliable, and technically superior alternative to traditional leather. We prioritize cost efficiency without compromising on durability, safety, or design flexibility – ensuring your end products meet global market requirements while optimizing production value.

Core Technical Advantages

- Cost-Effective Performance: WINIW’s engineered substrates reduce total cost of ownership through consistent thickness control (minimizing material waste), high yield rates in cutting/sewing, and elimination of volatile raw material sourcing risks associated with genuine leather. Lower defect rates directly translate to reduced scrap and rework costs in high-volume production.

- Engineered Durability: Our proprietary coating and lamination processes deliver exceptional resistance to abrasion (tested to ISO 5470), tearing (ASTM D5733), and flexing (Martindale >50,000 cycles for premium lines). UV-stabilized formulations ensure long-term colorfastness and structural integrity, even in challenging environments, extending product lifecycle.

- Precision Color Customization: Leverage WINIW’s advanced dyeing and surface finishing capabilities for exact color matching (Pantone®/RAL). We offer rapid prototyping and batch consistency across large production runs, enabling brand differentiation without minimum order quantity penalties. Digital printing compatibility further expands design possibilities.

- Guaranteed REACH Compliance: All WINIW formulations are rigorously screened against SVHCs (Substances of Very High Concern) per EU REACH Regulation (EC) No 1907/2006. Full material disclosure (including CAS numbers) and annual third-party testing reports are provided, mitigating regulatory risk and ensuring market access across Europe and globally.

- ISO 9001 Certified Quality Management: Our integrated production system, certified to ISO 9001:2015, enforces strict process controls from raw material intake to finished roll. This guarantees batch-to-batch consistency, traceability, and adherence to agreed technical specifications, reducing production line disruptions for our partners.

WINIW Synthetic Leather Product Specifications

| Product Line | Key Applications | Thickness Range (mm) | Abrasion Resistance (Martindale Cycles) | Tensile Strength (N/mm²) | Flex Resistance (DIN 53359) | REACH Compliant | ISO 9001 Certified |

|---|---|---|---|---|---|---|---|

| WINIW PU Leather | Footwear, Bags, Automotive Interiors | 0.6 – 1.2 | 30,000 – 50,000 | 25 – 40 | > 100,000 cycles | Yes | Yes |

| WINIW Microfiber | Premium Upholstery, Luxury Goods, Performance Apparel | 0.8 – 1.5 | 80,000 – 120,000+ | 45 – 65 | > 200,000 cycles | Yes | Yes |

| WINIW Eco-Leather | Sustainable Fashion, Eco-Consumer Products | 0.5 – 1.0 | 25,000 – 40,000 | 20 – 35 | > 80,000 cycles | Yes | Yes |

Note: All products utilize water-based, low-VOC coatings and are free from DMF, AZO dyes, and heavy metals (Cd, Pb, Hg, Cr⁶⁺) as per REACH Annex XVII.

WINIW partners with forward-thinking manufacturers to deliver synthetic leather that excels in performance, sustainability, and operational efficiency. Our technical team collaborates closely with your R&D and production departments to tailor solutions meeting exact mechanical, aesthetic, and compliance requirements – driving value across your supply chain while supporting your ESG commitments. Request our full technical datasheets and compliance certificates for detailed validation.

Why Choose Synthetic over Real Leather

B2B Product Guide: Comparing Real Leather and Synthetic Leather Alternatives

In the modern manufacturing and design landscape, material selection plays a critical role in balancing performance, sustainability, and cost. Real leather has long been a benchmark for quality and durability, but advancements in synthetic materials—particularly high-performance synthetic leathers like those developed by WINIW—offer compelling alternatives. This guide compares real leather with various types of synthetic leather across key business and sustainability metrics.

Overview of Material Types

-

Real Leather: Derived from animal hides (typically bovine), real leather is a natural material prized for its breathability, strength, and aging characteristics. It remains a staple in luxury goods, automotive interiors, and premium furniture.

-

PU Leather (Polyurethane Leather): A synthetic alternative that uses a polyurethane coating applied to a fabric backing. Offers a leather-like appearance with improved consistency and lower environmental impact than real leather.

-

PVC Leather (Polyvinyl Chloride Leather): An older synthetic technology using PVC resins. Less breathable and less eco-friendly than PU, but historically lower in cost.

-

Кожа из микрофибры: A high-end synthetic leather made from ultra-fine fibers and polyurethane resins. Mimics the physical structure of real leather and often exceeds it in tensile strength and abrasion resistance.

-

Plant-Based & Bio-Friendly Synthetics: Emerging materials incorporating natural oils or bio-based polymers to reduce reliance on fossil fuels. Performance varies by formulation.

Comparative Analysis

The table below evaluates each material type based on cost, durability, and eco-friendliness—key considerations for B2B procurement and product development.

| Material Type | Cost (Relative) | Durability (Lifespan & Wear Resistance) | Eco-Friendliness (Sustainability & End-of-Life) |

|---|---|---|---|

| Real Leather | Высокий | High – develops patina over time; susceptible to moisture and UV damage | Moderate – uses animal byproducts but involves energy-intensive tanning; biodegradable but often treated with chrome |

| Кожа PU | Medium | Medium – good abrasion resistance; less prone to cracking than PVC | High – lower carbon footprint; recyclable in some cases; no animal sourcing |

| Кожа ПВХ | Низкий | Low – prone to cracking and peeling over time; poor UV resistance | Low – releases harmful dioxins during production and disposal; not biodegradable |

| Кожа из микрофибры | Medium-High | Very High – superior tear strength, abrasion resistance, and dimensional stability | High – often free from heavy metals; recyclable; water-based production available |

| Plant-Based Synthetics | Medium to High | Medium to High – depends on formulation; improving rapidly | Very High – reduced fossil fuel use; biodegradable or compostable options emerging |

Key Business Advantages of Synthetic Leather

- Consistency in Supply: Unlike real leather, synthetic alternatives are not subject to seasonal or agricultural variability.

- Customization Flexibility: Available in a wide range of colors, textures, and performance specs (e.g., UV resistance, water repellency).

- Traceability & Compliance: Easier to certify for environmental and ethical standards (e.g., REACH, RoHS, OEKO-TEX®).

- Animal-Free Certification: Supports cruelty-free and vegan product lines—increasingly important for global branding.

Sustainability Outlook

As industries move toward circular economy models, synthetic leathers—especially water-based PU and microfiber—are gaining favor. WINIW’s advanced synthetic leathers, for example, are engineered for low environmental impact without compromising on performance. These materials support LEED certification, reduce VOC emissions, and align with ESG goals for responsible sourcing.

Choosing the right material depends on your application, market segment, and sustainability targets. While real leather retains prestige in certain markets, high-performance synthetics now offer a viable, often superior alternative for forward-thinking B2B partners.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands at the forefront of sustainable synthetic leather manufacturing, delivering premium, eco-conscious materials engineered specifically for discerning B2B partners worldwide. Our vertically integrated production ecosystem combines scale, innovation, and uncompromising quality control to meet the rigorous demands of international markets, particularly Europe and the USA.

Core Manufacturing Strengths Driving Your Success:

- Industry-Leading Production Capacity: Operate a state-of-the-art 100,000 sqm manufacturing facility, enabling scalable production volumes to support large global contracts while maintaining agile responsiveness to client timelines.

- Dedicated R&D Innovation Hub: Leverage the expertise of our in-house R&D team, continuously developing next-generation eco-materials with enhanced performance (durability, texture, colorfastness) and reduced environmental impact (water-based PU, recycled content options, OEKO-TEX® certified processes).

- Rigorous Quality Assurance System: Implement multi-stage, ISO-certified QC protocols at every production phase – from raw material inspection to final roll validation – ensuring 100% compliance with stringent European REACH and U.S. CPSIA safety standards.

- Proven Global Export Infrastructure: Maintain established logistics networks for seamless, reliable delivery to key markets across Europe and North America, with full documentation for customs clearance and adherence to regional regulatory frameworks.

Partner with WINIW to secure a consistent supply of high-performance, responsibly produced synthetic leather that elevates your end products and aligns with the sustainability expectations of global consumers. Our facility and expertise are built to be your strategic manufacturing advantage.

Contact Us for Samples

WINIW Microfiber Leather – B2B Product Guide

WINIW is a global leader in high-performance synthetic leather solutions, delivering premium microfiber leather alternatives for industries seeking sustainable, durable, and cost-effective materials. Our advanced manufacturing processes ensure consistent quality, exceptional texture, and superior physical properties tailored to diverse industrial applications.

Our microfiber leather is engineered to mimic the look and feel of genuine leather while offering enhanced environmental and performance benefits. Ideal for automotive interiors, furniture, footwear, accessories, and technical applications, WINIW products meet stringent international standards for durability, color fastness, and eco-compliance.

Key Advantages of WINIW Microfiber Leather

- High tensile and tear strength for long-lasting performance

- Excellent abrasion resistance, ideal for high-use applications

- Breathable and soft texture, closely resembling natural leather

- Consistent thickness and grain pattern for improved yield and reduced waste

- Eco-friendly production with low-VOC emissions and recyclable materials

- Resistant to UV degradation, water, and common chemicals

- Customizable in color, texture, thickness, and finish to meet client specifications

Industry Applications

- Automotive: Seat covers, dashboards, door panels, steering wheels

- Furniture: Sofas, chairs, office seating, modular units

- Footwear: Athletic, casual, and safety shoes requiring flexibility and durability

- Bags & Luggage: Handbags, backpacks, travel cases

- Electronics: Protective cases, smartwatch bands, tablet covers

- Industrial: Protective gloves, machinery covers, technical upholstery

Environmental Commitment

WINIW prioritizes sustainability through:

- Water-based, solvent-free production processes

- Compliance with REACH, RoHS, and OEKO-TEX® standards

- Reduced carbon footprint compared to traditional leather tanning

- Recyclable base materials and minimal waste generation

Product Specifications Overview

| Property | Standard Range |

|---|---|

| Thickness | 0.6 mm – 2.0 mm |

| Weight | 200 g/m² – 600 g/m² |

| Width | 137 cm, 147 cm, 157 cm |

| Durability (Martindale) | 30,000 – 100,000+ cycles |

| Color Fastness | ≥ Grade 4 (ISO 105-B02) |

| Backing Material | PU-coated polyester microfiber |

Custom engineering available for specific performance requirements such as flame retardancy, anti-microbial treatment, or enhanced softness.

Explore Different Types of Leather Alternatives

Discover how WINIW’s range of microfiber leather types—suede, full-grain, nubuck, and specialty technical variants—can meet your product needs.

Contact our materials team today for technical data sheets, compliance documentation, or application support.

Request Free Samples

Evaluate WINIW microfiber leather firsthand with no cost or obligation.

For product inquiries, customization options, or to request samples:

Электронная почта: MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.