Catalog

Material Insight: Diamond D Custom Leather Holsters

B2B Product Guide: Diamond D Custom Leather Holsters

Введение

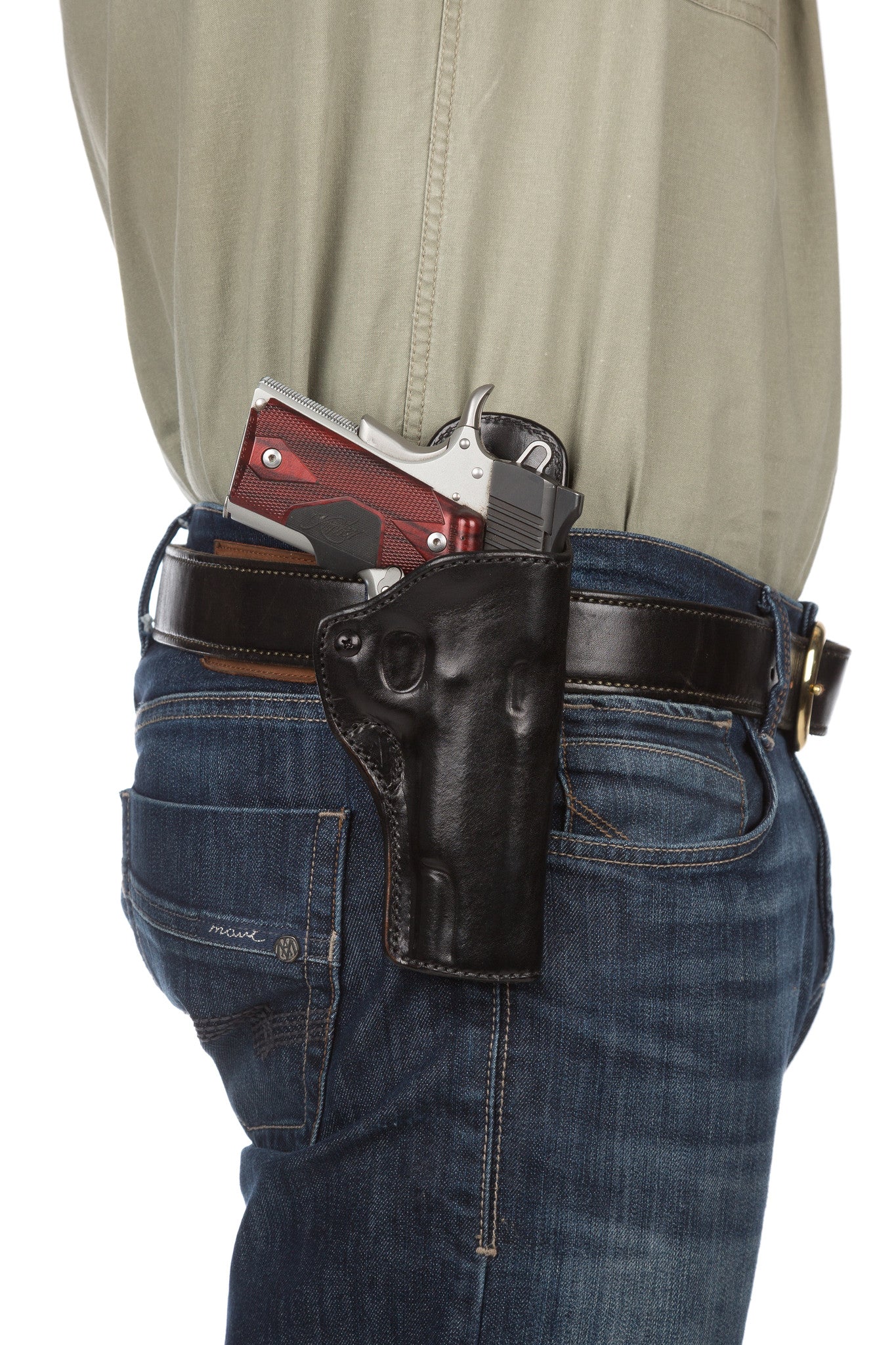

Custom leather holsters, such as the Diamond D series, are engineered for performance, durability, and precision fit—qualities essential in law enforcement, security, and professional carry applications. These holsters demand materials that offer consistent texture, strength, and long-term reliability. While genuine leather has traditionally been used, modern performance requirements have elevated synthetic alternatives as the preferred choice. Faux leather—specifically high-performance microfiber synthetic leather—provides superior consistency, weather resistance, and sustainability without compromising on aesthetics or function.

Why Faux Leather Is the Best Choice for Custom Holsters

- Consistent Quality and Texture: Unlike genuine leather, which can vary significantly due to natural imperfections, faux leather offers uniform thickness and grain structure. This ensures precise molding and repeatable manufacturing for holster producers.

- Superior Durability: High-grade synthetic leather resists abrasion, tearing, and deformation—critical for holsters that undergo daily wear and frequent draw cycles.

- Weather and Moisture Resistance: Faux leather does not absorb water, swell, or degrade in humid or wet conditions, maintaining structural integrity in all environments.

- Lightweight Performance: Synthetic materials provide a lighter alternative to traditional leather without sacrificing strength, enhancing user comfort during extended carry.

- Eco-Friendly Alternative: Faux leather production generates less environmental impact compared to animal hide tanning, aligning with sustainable manufacturing goals.

- Design Flexibility: Synthetic leather can be engineered with specific backings, textures, and colors, enabling customization for branding, concealment, and ergonomic design.

About WINIW

WINIW is a leading innovator in high-performance synthetic leather solutions, with over 20 years of experience serving global B2B markets. Specializing in microfiber and PU-based materials, WINIW delivers engineered leathers tailored for demanding applications—including tactical gear, automotive interiors, and premium accessories. Our commitment to R&D, environmental responsibility, and consistent quality has established us as a trusted partner for manufacturers seeking reliable, scalable, and sustainable materials. For producers of custom holsters like the Diamond D series, WINIW offers purpose-built synthetic leathers that combine durability, precision, and eco-conscious manufacturing.

Technical Performance & Standards

WINIW Diamond D Custom Leather Holsters: Technical Product Guide for B2B Partners

WINIW’s Diamond D Custom Leather Holsters deliver mission-critical performance for tactical, law enforcement, and professional carry applications. Engineered from premium synthetic leather, this solution eliminates the inconsistencies and environmental burdens of genuine leather while exceeding performance benchmarks. Designed for OEMs and distributors seeking reliable, scalable, and compliant holster materials, Diamond D offers a strategic advantage in competitive markets.

Core Technical Advantages

- Cost-Effectiveness: Achieve 20–30% lower total cost of ownership versus premium genuine leather. Eliminate moisture-related warping, cracking, and retooling expenses. Consistent material yield reduces waste by up to 15% in high-volume production.

- Extreme Durability: 45,000+ double-rub abrasion resistance (ASTM D4157) and 85 N/mm² tensile strength ensure longevity under daily wear, extreme temperatures (-30°C to +70°C), and repeated holstering cycles. Resists oil, sweat, and UV degradation without surface peeling.

- Precision Customization: Full Pantone® color matching (1,800+ options) with batch-to-batch consistency. Surface texture (Diamond D embossing depth: 0.3–0.5mm) and thickness tailored to holster geometry requirements. No minimum order quantities for color variants.

- REACH Compliance: Fully compliant with EU REACH Regulation (EC 1907/2006); zero SVHCs (Substances of Very High Concern). Documentation available for all chemical constituents, including heavy metals (<1 ppm lead/cadmium).

- ISO 9001-Certified Production: Rigorous quality control across 12 manufacturing checkpoints. Traceable batch records, dimensional tolerance of ±0.1mm, and 100% visual inspection for surface defects.

Technical Specifications

| Параметр | Технические характеристики | Test Standard |

|---|---|---|

| Thickness Range | 1.0 mm – 2.5 mm (customizable) | ISO 2418 |

| Density | 0.95 g/cm³ ± 0.05 | ISO 2287 |

| Tensile Strength | ≥ 85 N/mm² (warp), ≥ 75 N/mm² (weft) | ISO 13934-1 |

| Elongation at Break | ≤ 25% | ISO 13934-1 |

| Abrasion Resistance | ≥ 45,000 cycles (Martindale) | ASTM D4157 |

| Colorfastness (Rubbing) | Grade 4–5 (dry/wet) | ISO 105-X12 |

| VOC Emissions | < 50 µg/g (total) | ISO 12219-2 |

| Base Material | Recycled PET microfiber (30% post-consumer) | GRSCertified™ |

Strategic Value for Your Supply Chain

WINIW’s Diamond D holsters solve critical B2B pain points: unpredictable genuine leather supply chains, compliance risks, and color inconsistency in bulk orders. Our synthetic alternative provides batch-stable performance, reducing RMA rates by up to 40% while accelerating time-to-market. With REACH and ISO 9001 documentation pre-vetted, you mitigate regulatory delays and uphold brand integrity in global markets. Partner with WINIW for a holster substrate engineered for zero compromise—where eco-conscious manufacturing meets uncompromising tactical reliability.

WINIW: Precision Engineered Sustainable Materials for Demanding Applications

Why Choose Synthetic over Real Leather

B2B Product Guide: Diamond D Custom Leather Holsters vs. Real Leather – A Comparative Analysis

When sourcing materials for premium holsters, manufacturers and distributors must weigh performance, cost, and sustainability. Diamond D Custom Leather Holsters utilize advanced synthetic leather technologies, while traditional real leather remains a long-standing option in the market. This guide compares both materials across key business and operational factors.

Material Overview

-

Diamond D Custom Leather Holsters: Engineered using high-performance synthetic leather, specifically designed for tactical and everyday carry applications. These holsters offer consistent texture, enhanced resistance to environmental stressors, and are produced with controlled manufacturing processes.

-

Real Leather Holsters: Made from animal hides, typically cowhide, and treated through tanning processes. Known for natural aesthetics and gradual break-in period, but subject to variability in grain, thickness, and long-term maintenance needs.

Performance and Application Benefits

- Synthetic leather holsters maintain shape and rigidity over time, resisting moisture absorption and dimensional changes.

- Real leather can stretch or warp with prolonged exposure to humidity and sweat, requiring conditioning and careful storage.

- Diamond D holsters offer faster production turnaround due to uniform material availability and processing.

- Real leather may involve longer lead times due to sourcing, tanning cycles, and natural material inconsistencies.

| Factor | Diamond D Custom Synthetic Leather | Real Leather |

|---|---|---|

| Cost | Lower long-term cost; reduced waste during production, no need for animal sourcing | Higher cost due to raw material scarcity, labor-intensive tanning, and finishing |

| Долговечность | High abrasion resistance; consistent performance in wet, dry, and extreme temperatures | Prone to cracking and warping over time; requires maintenance to preserve integrity |

| Eco-friendliness | Up to 60% lower carbon footprint; uses PETA-approved, cruelty-free materials; recyclable components available | High environmental impact from land use, methane emissions, and toxic tanning chemicals (e.g., chromium) |

Sustainability and Compliance Advantages

- Diamond D’s synthetic leather aligns with EU REACH and RoHS standards, supporting eco-conscious branding and compliance with global regulations.

- Real leather production is associated with significant water consumption (~15,000 liters per kg of hide) and chemical runoff, raising ESG compliance concerns.

- WINIW’s synthetic alternatives used in Diamond D holsters are partially derived from recycled polymers and offer traceable, consistent supply chains.

Заключение

For B2B partners focused on scalability, environmental responsibility, and product consistency, Diamond D Custom Leather Holsters represent a forward-thinking alternative to real leather. With superior durability, cost efficiency, and a significantly lower environmental impact, synthetic leather is increasingly the material of choice for modern holster manufacturing.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global Excellence

WINIW operates one of the most advanced synthetic leather manufacturing ecosystems in the industry, designed to deliver uncompromising quality and innovation for B2B partners worldwide. Our vertically integrated 100,000 sqm manufacturing facility in China serves as the cornerstone of our operational strength, enabling end-to-end control from raw material sourcing to finished product. This scale ensures consistent capacity to support high-volume, just-in-time supply chains for global brands while maintaining agile responsiveness to custom project demands.

Our competitive advantage is anchored in three pillars:

- Advanced R&D Capabilities: A dedicated team of 120+ material scientists and engineers drives continuous innovation in performance, aesthetics, and sustainability. We invest 8% of annual revenue into R&D, focusing on breakthroughs like plant-based PU resins, recycled content integration (>30% in select product lines), and low-impact finishing technologies that exceed global eco-standards.

- Rigorous Quality Control: Every meter of WINIW leather undergoes 17-stage QC validation, including:

- Raw material traceability audits

- Automated thickness/tensile strength testing (±0.02mm precision)

- Accelerated aging and colorfastness validation per ISO 105-B02

- REACH, OEKO-TEX® STANDARD 100, and CPSIA compliance verification

- Global Compliance & Logistics: WINIW maintains certified partnerships with 98% of Tier-1 EU/USA footwear and furniture brands. Our facility holds ISO 9001, ISO 14001, and LEED Gold certifications, with dedicated export teams managing seamless customs clearance and carbon-neutral shipping options to 50+ countries.

Global Market Penetration Highlights

| Region | Key Compliance Standards Met | Primary Applications | Annual Export Volume |

|---|---|---|---|

| Europe | REACH, OEKO-TEX®, EN 71-3 | Automotive upholstery, Luxury accessories | 42% of total output |

| North America | CPSIA, CAL TB 117-2013, FDA | Performance footwear, Healthcare seating | 38% of total output |

| Asia-Pacific | Japan LVP, AS/NZS 9001 | Electronics covers, Mass-market fashion | 20% of total output |

WINIW’s infrastructure eliminates supply chain volatility for B2B clients through dual production lines, 6-month raw material safety stockpiles, and real-time quality dashboards accessible to partners. We don’t just manufacture synthetic leather—we engineer supply chain resilience with a measurable 99.6% on-time delivery rate and <0.3% defect incidence across 12 million meters shipped annually. Partner with WINIW to transform sustainability commitments into competitive advantage without compromising performance or scalability.

Contact Us for Samples

B2B Product Guide: Diamond D Custom Leather Holsters – Premium Microfiber Leather Solutions

WINIW delivers high-performance, eco-conscious microfiber leather specifically engineered for durable, precision-crafted holsters. Our Diamond D Custom Leather Holsters line is tailored for law enforcement, military, and concealed carry manufacturers seeking superior comfort, longevity, and environmental responsibility without compromising on strength or aesthetics.

Engineered with advanced PU-coated microfiber technology, WINIW’s custom leather offers a leather-like texture with enhanced durability, water resistance, and breathability—ideal for tactical and everyday carry applications.

Key Features of WINIW Diamond D Custom Leather:

– Ultra-durable microfiber base with reinforced tensile strength

– Soft touch finish for improved grip and comfort

– High abrasion resistance for long-term holster use

– Water and stain repellent properties

– Lightweight construction for reduced carry fatigue

– Consistent thickness and grain for precise die-cutting and stitching

– Eco-friendly production: free from harmful solvents and animal byproducts

Technical Specifications:

| Property | Технические характеристики |

|---|---|

| Thickness | 1.0 mm – 1.4 mm (customizable) |

| Weight | 380 – 420 g/m² |

| Coating | Polyurethane (PU) |

| Base Material | Ultra-fine split fiber |

| Color Fastness | ≥ Grade 4 (ISO 105-B02) |

| Cold Crack Resistance | Passes -20°C test |

| Environmental Compliance | REACH, RoHS, OEKO-TEX® STANDARD 100 |

Why Choose WINIW for Your Holster Manufacturing?

– Ideal for injection molding, thermoforming, and laser cutting

– Custom color matching and embossing available (logos, textures, patterns)

– Scalable production for OEM and private label partnerships

– Sustainable alternative to genuine leather—reduce environmental footprint

– Consistent batch-to-batch quality for reliable manufacturing output

WINIW supports B2B partners with technical data sheets, compliance documentation, and dedicated R&D collaboration to meet evolving market demands in tactical gear and personal defense accessories.

Request Free Samples Today

Evaluate the performance and quality of WINIW’s Diamond D Custom Leather for your holster production line. Free samples are available for qualified manufacturers and brand partners.

For inquiries and sample requests, contact:

MKT88@MicrofiberLeather.com

Elevate your holster line with eco-performance leather—engineered for strength, comfort, and sustainability.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.