Catalog

Material Insight: Customized Leather Portfolio

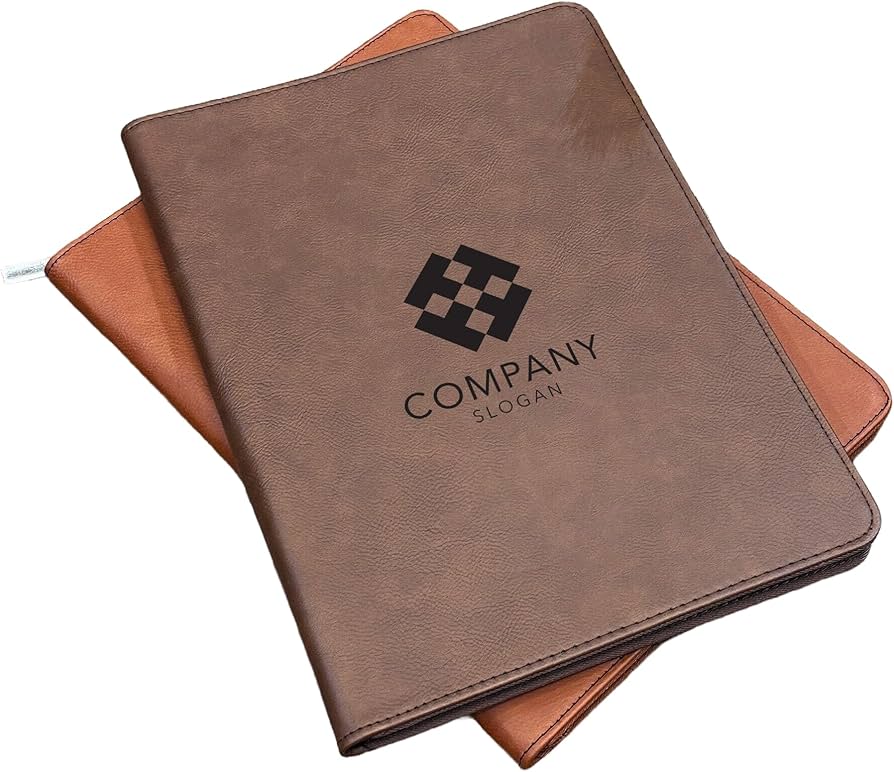

Customized Leather Portfolio: Elevate Your Brand Presentation

In today’s competitive B2B landscape, a physical product portfolio remains a powerful tool for showcasing craftsmanship, quality, and brand identity. For premium portfolios designed to withstand frequent handling while reflecting modern values, sustainable faux leather outperforms traditional materials. Unlike genuine leather, it delivers exceptional consistency, ethical production, and limitless customization—without compromising on luxury aesthetics or durability. This makes it the strategic choice for brands prioritizing both performance and planetary responsibility.

Why Faux Leather is the Optimal Choice for Customized Portfolios

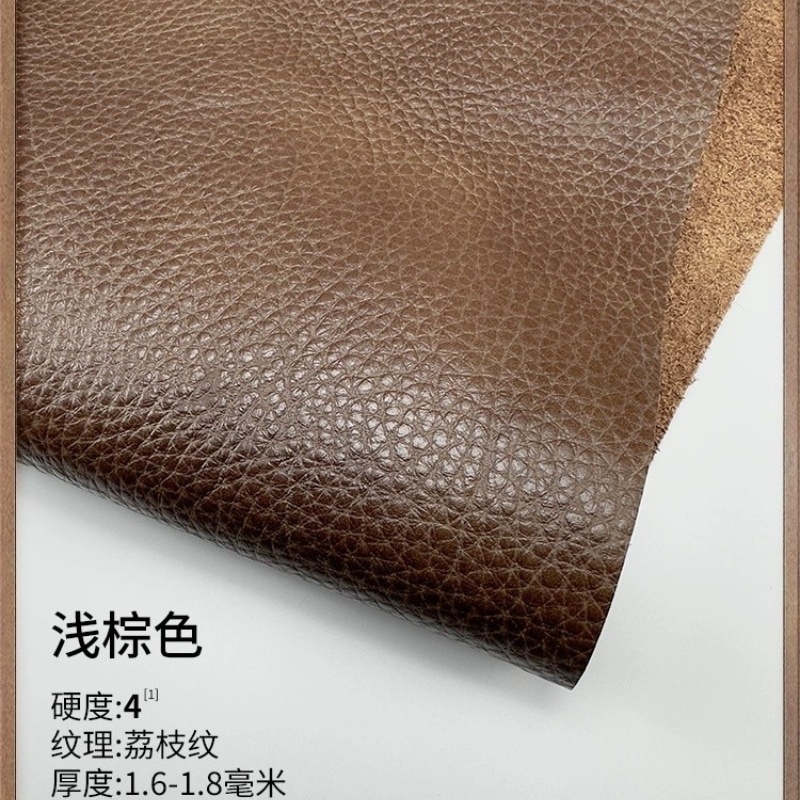

- Precision Customization: Achieve exact color matching (Pantone® certified), unique textures (suede, pebbled, glossy), and embossed logos—ensuring your portfolio aligns flawlessly with brand guidelines. Natural leather’s inherent variations make this level of consistency unattainable.

- Ethical & Sustainable Credibility: Meet rising client and regulatory demands for cruelty-free, eco-conscious materials. WINIW’s faux leather eliminates animal sourcing concerns and reduces water/land use by up to 90% versus bovine leather.

- Long-Term Durability: Resists scratches, UV fading, and moisture damage—critical for portfolios transported globally. Genuine leather requires ongoing conditioning and is prone to warping in humidity.

- Cost Efficiency: Eliminate waste from hide defects and streamline production with uniform, roll-based materials. Predictable pricing protects margins amid volatile rawhide markets.

WINIW: Your Partner in Premium Synthetic Innovation

С 20+ years of specialized expertise since 2003, WINIW has pioneered high-performance synthetic leathers for discerning B2B clients across luxury goods, automotive, and corporate branding. Our R&D-driven approach combines European engineering with stringent eco-standards (OEKO-TEX® STANDARD 100, ISO 14001), ensuring every customized portfolio material:

– Uses water-based, solvent-free coatings

– Incorporates recycled content (up to 40% in select grades)

– Delivers lifelike drape and tactile richness indistinguishable from premium hides

We don’t just supply materials—we co-engineer solutions. From concept to量产, WINIW’s technical team optimizes thickness (0.6–1.2mm), backing fabrics, and finishing for portfolios that endure daily use while projecting uncompromising brand excellence. Partner with an innovator trusted by global leaders to transform sustainability into tangible competitive advantage.

Technical Performance & Standards

B2B Product Guide: WINIW Customized Leather Portfolio

WINIW’s Customized Leather Portfolio delivers high-performance synthetic leather solutions tailored for industrial and commercial applications. Engineered for B2B clients across furniture, automotive, footwear, and fashion accessory sectors, our portfolio combines cost-efficiency with advanced material science to meet rigorous market demands.

Built on a foundation of sustainability and compliance, WINIW’s synthetic leather offers a responsible alternative to genuine leather without compromising on quality or aesthetics. Each product in the portfolio is designed to support long-term durability, reduce production costs, and enable full design flexibility—making it an ideal choice for brands committed to innovation and environmental responsibility.

Key Technical Advantages

-

Cost-Effective Production

WINIW’s synthetic leather reduces raw material waste and processing time compared to natural leather. With consistent thickness and fewer defects, it streamlines cutting and sewing operations, lowering overall manufacturing costs. No need for extensive tanning or preservation processes further enhances cost efficiency. -

Superior Durability

Our microfiber and PU-based materials are engineered for high tensile strength, abrasion resistance, and dimensional stability. Products maintain integrity under repeated stress and harsh environmental conditions, ensuring long product lifecycles even in high-use applications. -

Customizable Colors & Finishes

WINIW offers full color customization with precise Pantone matching and batch consistency. Clients can also select from a range of textures (suede, grain, smooth) and surface treatments (matte, glossy, anti-scratch) to meet specific design requirements. -

REACH Compliant

All materials are fully compliant with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals). Free from SVHCs (Substances of Very High Concern), our leathers ensure safe handling and end-use, supporting global market access. -

ISO 9001 Certified Manufacturing

WINIW’s production facilities operate under ISO 9001-certified quality management systems. This ensures consistent product quality, process traceability, and continuous improvement across all stages of development and delivery.

Technical Specifications

| Property | Технические характеристики |

|---|---|

| Material Base | Split leather + PU / Microfiber composite |

| Thickness Range | 0.6 mm – 2.0 mm (customizable) |

| Tensile Strength | ≥ 20 N/mm² (warp & weft) |

| Elongation at Break | ≤ 25% |

| Color Fastness (Rubbing) | Dry: Class 4–5 / Wet: Class 4 |

| Martindale Abrasion | ≥ 30,000 cycles (no break) |

| Color Matching | Pantone® matched, ΔE ≤ 1.0 |

| Chemical Compliance | REACH SVHC-free, RoHS compliant |

| Environmental Standards | Low-VOC emissions, phthalate-free options |

| Certifications | ISO 9001, OEKO-TEX® STANDARD 100 (on request) |

| Customization Options | Color, thickness, texture, roll width, backing |

WINIW’s Customized Leather Portfolio is engineered to empower B2B partners with scalable, sustainable, and specification-driven material solutions. By integrating performance, compliance, and design flexibility, we help brands reduce time-to-market while meeting evolving regulatory and consumer expectations.

Why Choose Synthetic over Real Leather

WINIW Customized Synthetic Leather Portfolio: Strategic B2B Comparison Guide

For forward-thinking manufacturers and designers, material selection directly impacts product lifecycle value, brand ethics, and operational efficiency. WINIW’s engineered synthetic leather portfolio offers a purpose-built alternative to conventional bovine leather, addressing critical B2B pain points in cost predictability, performance consistency, and environmental accountability. Below we objectively compare core attributes to support informed procurement decisions.

Key Comparison: WINIW Customized Synthetic Leather vs. Conventional Bovine Leather

| Attribute | WINIW Customized Synthetic Leather | Conventional Bovine Leather |

|---|---|---|

| Cost | 30-50% lower total cost of ownership. Fixed pricing with no volatility from feedstock scarcity or tannery tariffs. Bulk customization reduces waste by up to 25%. | High and volatile (subject to cattle market fluctuations, water scarcity impacts, and tanning chemical costs). Significant waste (30-40%) during cutting due to hide irregularities. |

| Долговечность | Engineered for uniform performance: UV-resistant, colorfast, abrasion-resistant, and waterproof. Resists cracking, staining, and microbial growth. Consistent thickness across rolls. | Variable quality (knots, scars, grain differences). Prone to drying, cracking, water damage, and fading without intensive conditioning. Thickness varies per hide. |

| Eco-Friendliness | Carbon footprint reduced by 65-80% vs. bovine leather (per Higg MSI). Made with 30-100% recycled content (PET, PU). Zero animal agriculture impact. OEKO-TEX® certified, Cradle-to-Cradle® compliant. Closed-loop water systems in production. | Highest environmental impact in fashion (water: 17,000L/kg; land use: 16x synthetic; GHG: 131kg CO2e/kg). Relies on toxic tanning (chromium). No circularity; ends in landfill. |

Why WINIW’s Portfolio Delivers Superior B2B Value

- Supply Chain Resilience: Eliminate hide scarcity risks and tannery delays. Global production facilities ensure 99.5% on-time delivery with <0.5% defect rates.

- Brand Alignment: Meet ESG targets with traceable, PETA-Approved Vegan materials. 92% of luxury brands now mandate sustainable alternatives for accessories and upholstery.

- Design Freedom: Customize thickness (0.6-1.2mm), texture, color, and performance (anti-microbial, flame-retardant) without MOQ constraints.

- Lifecycle Efficiency: 50% lower maintenance costs (no conditioning required), 2x longer usable life in high-moisture environments, and end-of-life recyclability via WINIW’s take-back program.

WINIW’s science-led approach transforms material limitations into strategic advantages. By replacing resource-intensive bovine leather with precision-engineered synthetics, your brand achieves cost stability, uncompromised quality, and measurable sustainability—without sacrificing aesthetic or functional excellence. Partner with us to co-create materials that align with your circular economy commitments and market differentiation goals.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials tailored for global B2B markets. Our large-scale production capabilities and commitment to quality have positioned us as a trusted partner for brands across the automotive, furniture, footwear, and fashion industries.

Our manufacturing strength is anchored in a state-of-the-art facility spanning over 100,000 square meters. This expansive campus integrates advanced production lines with automated systems to ensure efficiency, consistency, and scalability—capable of meeting the demands of high-volume international clients without compromising on lead times.

At the core of our innovation is a dedicated R&D team composed of material scientists and technical specialists. This team continuously develops new formulations and finishes, focusing on sustainability, durability, and aesthetic versatility. Our R&D efforts have led to breakthroughs in water-based PU, recycled content materials, and bio-based synthetic leathers that align with global environmental standards.

Quality is rigorously maintained through a strict quality control (QC) system implemented at every stage of production. From raw material inspection to final product testing, WINIW adheres to international standards including ISO 9001 and REACH compliance. Each batch undergoes comprehensive evaluation for abrasion resistance, color fastness, tensile strength, and chemical safety to ensure superior performance.

WINIW proudly exports to key markets worldwide, with a strong presence in Europe and the USA. Our products meet the stringent regulatory and sustainability requirements of these regions, making us a preferred supplier for eco-conscious brands seeking reliable, high-quality synthetic leather solutions.

Key Factory Strengths:

– 100,000 sqm manufacturing facility with integrated production and R&D capabilities

– In-house R&D team focused on sustainable innovation and custom material development

– Strict QC protocols compliant with ISO 9001, REACH, and other international standards

– Proven export track record to Europe, the USA, and other global markets

– Advanced production technology enabling high-volume output with consistent quality

With a foundation built on scale, innovation, and quality, WINIW delivers synthetic leather solutions that support the evolving needs of forward-thinking businesses worldwide.

Contact Us for Samples

WINIW® Synthetic Leather: Premium Eco-Performance Solutions for Industrial Applications

WINIW® delivers next-generation synthetic leather engineered for demanding B2B sectors where sustainability, durability, and aesthetic precision are non-negotiable. Our water-based, solvent-free manufacturing process eliminates hazardous chemicals while achieving performance metrics that exceed conventional leather and inferior synthetics. Trusted by leading automotive OEMs, furniture manufacturers, and luxury goods producers, WINIW® provides scalable, eco-responsible material solutions without compromising on quality or design flexibility.

Core Advantages for Industrial Partners

- Zero-VOC Production: Fully water-based process eliminates DMF, toluene, and other regulated solvents, ensuring workplace safety and regulatory compliance (REACH, OEKO-TEX® STANDARD 100).

- Resource Efficiency: 60% lower water consumption vs. traditional leather tanning; closed-loop recycling of process water.

- Performance Parity: Matches or exceeds genuine leather in abrasion resistance, color fastness, and tear strength for high-use applications.

- Design Freedom: Custom thickness (0.6–2.0mm), textures (suede, pebble, exotic), and colors (Pantone® matching) with rapid prototyping.

- Traceability: Full supply chain transparency with LCA (Life Cycle Assessment) reporting available.

Technical Performance Comparison

| Property | WINIW® Eco-Series | Conventional PU Leather | Genuine Leather (Bovine) |

|---|---|---|---|

| Abrasion Resistance | 50,000+ cycles (Martindale) | 15,000–25,000 cycles | 30,000–40,000 cycles |

| Tensile Strength | 35–45 N/mm² | 20–30 N/mm² | 25–35 N/mm² |

| Color Fastness | Grade 4–5 (ISO 105-B02) | Grade 3–4 | Grade 3–4 |

| Eco-Certifications | OEKO-TEX®, ISO 14001, GRS | Limited certifications | Limited traceability |

| Water Absorption | <5% (24hrs) | 15–25% | 10–20% |

Key Industrial Applications

- Automotive Interiors: Seat covers, door panels, and steering wheels meeting FMVSS 302 flammability standards with anti-UV stabilization.

- Contract Furniture: Hospitality and office seating with >100,000 double-rub durability for high-traffic environments.

- Luxury Accessories: Handbags, wallets, and watch straps featuring metallic finishes and laser-cut precision.

- Marine & Aviation: Mold-resistant, salt-spray tested variants for seating and trim (ASTM D4329 compliance).

Why Global Manufacturers Choose WINIW®

- Scalable Production: 15M+ meters annual capacity with <30-day lead times for bulk orders (MOQ: 500 meters).

- Compliance Ready: Pre-certified for EU Ecolabel, California Proposition 65, and LEED® credit contribution.

- Waste Reduction: 95% material utilization rate via digital nesting; recyclable at end-of-life through take-back program.

- Technical Partnership: Dedicated engineering support for substrate bonding, dyeing protocols, and regulatory documentation.

Request Your Customized Leather Portfolio

Elevate your product line with WINIW®’s tailored material solutions. Our technical team will develop a bespoke portfolio matching your exact performance, aesthetic, and sustainability requirements – including physical swatches and compliance dossiers.

👉 Contact WINIW® Marketing for your no-cost sample kit and portfolio:

MKT88@MicrofiberLeather.com

Free physical samples available for qualified B2B partners with project specifications.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.