Introduction: Navigating the Global Market for custom printed faux leather

In the competitive landscape of modern manufacturing, sourcing high-quality custom printed faux leather can pose significant challenges for B2B buyers. With a diverse array of patterns, textures, and applications, navigating this market requires not only understanding the material itself but also the nuances of supplier relationships and pricing strategies. This guide serves as a comprehensive resource, detailing the various types of custom printed faux leather, their applications across industries such as fashion, upholstery, and accessories, and essential tips for vetting suppliers effectively.

For international buyers, particularly those in Africa, South America, the Middle East, and Europe—including key markets like Brazil and Vietnam—making informed purchasing decisions is crucial. This guide empowers you with actionable insights on cost considerations, quality assessments, and the latest trends in faux leather manufacturing. By equipping yourself with this knowledge, you can streamline your sourcing process, reduce risks, and enhance the overall quality of your products. With a clear understanding of the global market dynamics, you’ll be better positioned to leverage custom printed faux leather to meet your business needs while satisfying your customers’ demands for innovation and style.

Table Of Contents

- Top 7 Custom Printed Faux Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom printed faux leather

- Understanding custom printed faux leather Types and Variations

- Key Industrial Applications of custom printed faux leather

- 3 Common User Pain Points for ‘custom printed faux leather’ & Their Solutions

- Strategic Material Selection Guide for custom printed faux leather

- In-depth Look: Manufacturing Processes and Quality Assurance for custom printed faux leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom printed faux leather’

- Comprehensive Cost and Pricing Analysis for custom printed faux leather Sourcing

- Alternatives Analysis: Comparing custom printed faux leather With Other Solutions

- Essential Technical Properties and Trade Terminology for custom printed faux leather

- Navigating Market Dynamics and Sourcing Trends in the custom printed faux leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom printed faux leather

- Strategic Sourcing Conclusion and Outlook for custom printed faux leather

- Important Disclaimer & Terms of Use

Understanding custom printed faux leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Printed Leatherette | Soft, pliable, and vibrant colors; easy to sew and cut. | Fashion accessories, bags, upholstery | Pros: Cost-effective, versatile; Cons: May lack durability compared to real leather. |

| Textured Faux Leather | Varied textures (e.g., pebble, smooth); enhances visual appeal. | Home decor, furniture, automotive | Pros: Aesthetic appeal; Cons: Textures may complicate printing quality. |

| Eco-Friendly Faux Leather | Made from recycled materials; sustainable production methods. | Eco-conscious brands, fashion, upholstery | Pros: Environmentally friendly; Cons: May have limited design options. |

| Customizable Faux Leather | Allows unique designs and patterns; scalable for various uses. | Promotional items, custom gifts | Pros: High customization; Cons: Longer lead times for production. |

| Water-Resistant Faux Leather | Coated for moisture resistance; ideal for outdoor use. | Outdoor gear, bags, and accessories | Pros: Durable in wet conditions; Cons: Higher cost due to specialized materials. |

What Are the Characteristics of Printed Leatherette?

Printed leatherette is a popular choice for many B2B applications due to its soft and pliable nature. It features vibrant colors and designs, making it an ideal material for fashion accessories, bags, and upholstery. This type of faux leather is easy to cut and sew, which is particularly appealing to manufacturers who prioritize efficiency. When purchasing, businesses should consider the balance between cost and quality, as printed leatherette may not offer the same durability as genuine leather but compensates with affordability and a wide range of designs.

How Does Textured Faux Leather Enhance Visual Appeal?

Textured faux leather is distinguished by its varied surface textures, such as pebbled or smooth finishes, which add depth and character to products. This material is widely used in home decor, furniture, and automotive applications, where aesthetics are paramount. B2B buyers should be aware that while textured finishes enhance visual appeal, they can complicate the printing process and may require specialized techniques to ensure high-quality results. Understanding the implications of texture on design and production will aid in making informed purchasing decisions.

Why Choose Eco-Friendly Faux Leather?

Eco-friendly faux leather is crafted from recycled materials and produced through sustainable methods, making it an attractive option for environmentally conscious brands. It is increasingly used in fashion and upholstery, appealing to companies looking to enhance their sustainability credentials. However, buyers should note that the variety of designs and patterns available may be more limited compared to traditional faux leather options. Companies should weigh the benefits of sustainability against design flexibility when considering this type of material.

What Advantages Does Customizable Faux Leather Offer?

Customizable faux leather allows businesses to create unique designs and patterns tailored to their brand identity. This type is particularly advantageous for promotional items and custom gifts, providing a high level of personalization that can enhance customer engagement. Buyers should be mindful that while customization offers significant benefits, it often comes with longer lead times for production. Understanding the trade-offs between customization and delivery timelines will help businesses plan their inventory and marketing strategies effectively.

How Does Water-Resistant Faux Leather Perform in Outdoor Applications?

Water-resistant faux leather is treated to withstand moisture, making it ideal for outdoor gear and accessories. This durability is crucial for products exposed to varying weather conditions, ensuring longevity and reliability. B2B buyers should consider the higher costs associated with water-resistant materials, as they often require specialized manufacturing processes. However, the investment can be justified by the enhanced performance and reduced replacement costs over time, particularly for businesses catering to outdoor enthusiasts or industries requiring durable materials.

Key Industrial Applications of custom printed faux leather

| Industry/Sector | Specific Application of custom printed faux leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom handbags and accessories | Unique branding opportunities and differentiation | Quality of print, durability, and compliance with fashion trends |

| Furniture and Interior Design | Upholstery for furniture | Aesthetic appeal and customization for client needs | Material quality, print resolution, and colorfastness |

| Автомобили | Custom seat covers and interior accents | Enhanced vehicle aesthetics and personalized branding | Compliance with safety standards and durability under various conditions |

| Home Décor | Custom cushions and decorative items | Unique product offerings that appeal to niche markets | Fabric weight, print clarity, and environmental regulations |

| Promotional Products | Branded giveaways like wallets and key fobs | Effective marketing tool with high visibility | Minimum order quantities and customization options |

How is Custom Printed Faux Leather Used in Fashion and Apparel?

Custom printed faux leather is increasingly utilized in the fashion industry for creating unique handbags, wallets, and accessories. Designers leverage this material to differentiate their products, allowing for intricate patterns and vibrant colors that resonate with target demographics. Buyers in this sector should prioritize sourcing high-quality prints that maintain their integrity over time, ensuring compliance with current fashion trends and consumer preferences.

What Role Does Custom Printed Faux Leather Play in Furniture and Interior Design?

In the realm of furniture and interior design, custom printed faux leather is employed for upholstery, offering both aesthetic appeal and functional benefits. This material allows designers to create customized seating options that reflect individual client tastes while ensuring durability. International buyers should consider factors such as the weight of the fabric, the clarity of the print, and adherence to local environmental regulations when sourcing faux leather for furniture applications.

How is Custom Printed Faux Leather Beneficial for Automotive Applications?

The automotive industry increasingly adopts custom printed faux leather for seat covers and interior accents, enhancing vehicle aesthetics and enabling brand personalization. This application not only elevates the look of the vehicle but also caters to consumer demand for unique, stylish interiors. Buyers should ensure that the materials sourced comply with safety standards and can withstand various environmental conditions, such as heat and moisture.

In What Ways is Custom Printed Faux Leather Used in Home Décor?

Custom printed faux leather finds a place in home décor through the creation of cushions, wall hangings, and decorative items. This versatility allows businesses to offer unique products that cater to niche markets, enhancing their overall product range. Buyers must evaluate the fabric weight and environmental compliance, as well as the print quality, to ensure that the final products meet customer expectations.

How Can Custom Printed Faux Leather Enhance Promotional Products?

In the promotional products sector, custom printed faux leather is frequently used for branded items like wallets and key fobs, serving as effective marketing tools. These products not only provide high visibility for brands but also resonate well with consumers due to their stylish and functional nature. When sourcing, businesses should be mindful of minimum order quantities and the customization options available, ensuring alignment with their marketing strategies.

3 Common User Pain Points for ‘custom printed faux leather’ & Their Solutions

Scenario 1: Navigating Sizing and Pattern Consistency Challenges

The Problem: B2B buyers often face difficulties when it comes to ensuring that their custom printed faux leather products maintain consistent sizing and pattern scaling. This can lead to a mismatch between the expected design and the final product, resulting in wasted materials and increased costs. For instance, a manufacturer creating handbags may find that the printed patterns on their faux leather sheets do not align properly, which can compromise the aesthetic appeal and marketability of the finished products.

The Solution: To address sizing and pattern consistency, buyers should engage in a thorough pre-production process. First, they should upload high-resolution designs (minimum of 300 dpi) and clearly specify the largest element in the pattern along with the desired size for that element. It’s also advisable to request a mock-up of the design before finalizing the order. This allows buyers to visualize the outcome and make necessary adjustments. By investing time in this upfront planning, manufacturers can significantly reduce the likelihood of costly errors, ensuring that their products are both visually appealing and market-ready.

Scenario 2: Managing International Shipping and Customs Complications

The Problem: International B2B buyers frequently encounter challenges related to shipping and customs when ordering custom printed faux leather. Long transit times, unpredictable delays, and unexpected customs fees can hinder timely production schedules and affect overall profitability. For example, a company in South America ordering faux leather from Europe may face weeks of uncertainty regarding delivery, impacting their ability to meet customer demands.

The Solution: To mitigate these shipping challenges, buyers should conduct thorough research on international shipping providers and their respective rates. It’s crucial to account for potential customs duties and taxes by consulting with a customs broker or the local import regulations of their country. Establishing a relationship with a reliable supplier who offers transparent shipping options and tracking capabilities can also help. Furthermore, buyers should consider placing larger orders to meet minimum shipping thresholds, which can sometimes lead to reduced shipping costs and improved delivery timelines. By strategically planning their orders and understanding the logistics involved, businesses can minimize disruptions and maintain a steady supply chain.

Scenario 3: Ensuring Compliance with Safety Standards

The Problem: When sourcing custom printed faux leather, B2B buyers often grapple with ensuring that their materials comply with various safety standards, especially when the end products are intended for children’s use. Non-compliance can result in legal repercussions, damaged brand reputation, and financial losses. A manufacturer producing children’s bags may inadvertently use faux leather that does not meet CPSIA compliance, leading to severe consequences.

The Solution: To ensure compliance, buyers should prioritize working with suppliers who provide detailed information about their materials’ safety certifications. It’s advisable to specifically ask for documentation regarding CPSIA compliance and any other relevant safety standards in their region. Additionally, buyers should consider conducting independent testing on samples to verify compliance before placing bulk orders. By establishing clear communication with suppliers about safety requirements and conducting due diligence, businesses can safeguard their products and maintain consumer trust. Engaging with legal or compliance experts can further enhance their understanding of the regulations that apply to their specific market, ensuring that all products meet the necessary safety standards.

Strategic Material Selection Guide for custom printed faux leather

What Are the Key Properties of Common Materials Used in Custom Printed Faux Leather?

When selecting materials for custom printed faux leather, it is essential to understand the properties and performance characteristics of each option. The most common materials include polyurethane (PU), polyvinyl chloride (PVC), and silicone. Each material has unique attributes that can significantly impact the end product’s quality, durability, and suitability for various applications.

How Does Polyurethane (PU) Perform in Custom Printed Faux Leather?

Polyurethane (PU) is widely regarded for its flexibility and durability. It exhibits excellent abrasion resistance and can withstand a variety of environmental conditions, making it suitable for products that require a high degree of wear and tear, such as bags and upholstery. PU also has a temperature rating that allows it to perform well in both high and low temperatures, which is crucial for products used in diverse climates.

Pros: PU is lightweight, easy to clean, and offers a more natural look and feel compared to other materials. It is also more environmentally friendly than PVC, as it does not release harmful chemicals during production.

Cons: However, PU can be more expensive than PVC and may have limitations in terms of chemical resistance. This can be a concern for buyers in industries where exposure to solvents or harsh chemicals is common.

What Are the Advantages of Polyvinyl Chloride (PVC) for Custom Faux Leather?

Polyvinyl chloride (PVC) is another popular choice for faux leather applications. It is known for its rigidity and durability, making it suitable for a wide range of products, including automotive interiors and outdoor furniture. PVC can be produced in various thicknesses and finishes, allowing for customization based on specific needs.

Pros: One of the key advantages of PVC is its cost-effectiveness. It is generally less expensive than PU, making it an attractive option for budget-conscious buyers. Additionally, PVC is highly resistant to moisture, making it ideal for outdoor applications.

Cons: On the downside, PVC may not offer the same level of breathability as PU, which can lead to discomfort in certain applications. Furthermore, the production of PVC can involve harmful chemicals, raising environmental concerns.

How Does Silicone Compare to Other Materials in Custom Printed Faux Leather?

Silicone is an emerging material in the faux leather market, known for its exceptional flexibility and durability. It is highly resistant to temperature extremes, UV light, and moisture, making it suitable for outdoor and high-performance applications. Silicone’s unique properties allow it to maintain its integrity over time, even in harsh conditions.

Pros: The primary advantage of silicone is its high resistance to degradation, making it a long-lasting option for products exposed to the elements. It is also hypoallergenic and free from harmful chemicals, appealing to eco-conscious consumers.

Cons: However, silicone can be more expensive than both PU and PVC, which may deter some buyers. Additionally, its manufacturing process can be complex, leading to longer lead times for production.

What Should International B2B Buyers Consider When Selecting Faux Leather Materials?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider compliance with local regulations and standards. For instance, adherence to ASTM, DIN, or JIS standards is crucial for ensuring product safety and quality. Additionally, buyers should be aware of the environmental impact of materials and seek options that align with sustainability goals. Understanding the preferences and market trends in their respective regions can also guide material selection, ensuring that products meet consumer expectations.

Summary Table of Material Selection for Custom Printed Faux Leather

| Материал | Typical Use Case for custom printed faux leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Bags, upholstery, fashion accessories | Lightweight and environmentally friendly | Higher cost and limited chemical resistance | Medium |

| Polyvinyl Chloride (PVC) | Automotive interiors, outdoor furniture | Cost-effective and moisture-resistant | Less breathable and environmental concerns | Низкий |

| Silicone | Outdoor gear, high-performance applications | Exceptional durability and UV resistance | Higher cost and complex manufacturing | Высокий |

In-depth Look: Manufacturing Processes and Quality Assurance for custom printed faux leather

What Are the Main Stages in the Manufacturing Process of Custom Printed Faux Leather?

The manufacturing of custom printed faux leather involves several key stages, each critical to ensuring a high-quality final product. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is material preparation. High-quality synthetic materials, such as polyurethane (PU) or polyvinyl chloride (PVC), are selected based on the desired characteristics of the faux leather, such as texture, durability, and flexibility. These materials undergo thorough inspections to ensure they meet specified standards before processing begins.

During this stage, the chosen base fabric is also prepared. This may involve pre-treating the fabric to enhance its ability to accept inks for printing. Pre-treatment ensures that the colors remain vibrant and adhere properly, reducing the risk of fading or peeling over time.

Forming: How Is Faux Leather Created?

Forming is the next crucial stage, where the prepared materials are processed to create the faux leather. This often involves a lamination process, where the synthetic layer is bonded to the backing fabric, providing the desired look and feel. Techniques such as heat pressing or chemical bonding are commonly employed, depending on the material properties and the intended use of the faux leather.

Once the faux leather is formed, it is then cut into sheets or rolls according to the specifications provided by the customer. Precision cutting is essential to minimize waste and ensure consistency in product dimensions.

Assembly: What Steps Are Involved?

In the assembly phase, the faux leather is prepared for printing. This may include additional treatments, such as coating the surface for increased durability or preparing it for specific printing techniques. The assembly process also includes ensuring that all components are aligned correctly for optimal printing results.

After assembly, the material is passed to the printing stage, where custom designs are applied. Advanced digital printing technologies are often used to achieve high-resolution prints, allowing for intricate patterns and vibrant colors. This step requires careful calibration to ensure that colors match the intended designs accurately.

Finishing: What Quality Enhancements Are Applied?

Finishing is the final stage of the manufacturing process. This may involve additional coatings to enhance the material’s water resistance, UV protection, or scratch resistance. Quality checks are conducted at this stage to ensure that the product meets industry standards.

Additionally, the faux leather undergoes inspection for any defects, such as inconsistencies in the print or material flaws. Final products are then rolled or packaged according to client specifications, ready for shipping.

What Quality Assurance Practices Are Essential for Custom Printed Faux Leather?

Quality assurance (QA) is critical in the manufacturing of custom printed faux leather to maintain product integrity and meet customer expectations. Implementing robust QA practices ensures that the final products are safe, durable, and of high quality.

Which International Standards Are Relevant?

For B2B buyers, understanding international standards is crucial. Many manufacturers adhere to ISO 9001, which sets out the criteria for a quality management system. This standard emphasizes a process approach to enhance customer satisfaction by meeting customer requirements and improving processes.

Other relevant certifications may include CE marking, which indicates compliance with European safety standards, and various industry-specific certifications such as those from the American Petroleum Institute (API) for materials used in specific applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to ensuring that products meet required standards throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to verify they meet specified quality standards before being used in production.

- In-Process Quality Control (IPQC): Continuous checks are made during the manufacturing process to identify and rectify any issues immediately.

- Final Quality Control (FQC): The finished products undergo thorough inspection to confirm they meet the required specifications and standards before packaging and shipping.

Which Testing Methods Are Commonly Used?

Various testing methods are employed to ensure the quality of custom printed faux leather. These may include:

- Adhesion Testing: To assess the durability of the print on the faux leather.

- Abrasion Testing: To evaluate the wear resistance of the material.

- Colorfastness Testing: To determine how well the colors hold up under exposure to light and washing.

These tests help verify that the faux leather can withstand the rigors of its intended application, ensuring customer satisfaction.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to mitigate risks associated with international sourcing.

What Steps Can Buyers Take to Ensure Supplier Compliance?

- Conduct Supplier Audits: Regular audits of suppliers can provide insights into their quality control processes and adherence to international standards. This can include on-site visits to assess their manufacturing capabilities and quality assurance measures.

- Request Quality Reports: Buyers should ask for detailed quality reports that outline the testing methods used, results of quality checks, and compliance with relevant standards.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes and product quality. These inspectors can conduct assessments before shipment to ensure that products meet agreed specifications.

What Are the QC Nuances for International Buyers?

International buyers should be aware of specific nuances when dealing with suppliers in different regions. Variations in manufacturing practices, regulatory requirements, and cultural differences can impact quality assurance efforts. Therefore, it’s essential for buyers to conduct thorough research on potential suppliers and understand local industry standards and practices.

In conclusion, the manufacturing processes and quality assurance measures for custom printed faux leather are multifaceted and critical for ensuring high-quality outcomes. By understanding these processes and verifying supplier quality, B2B buyers can confidently source faux leather products that meet their business needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom printed faux leather’

This guide serves as a practical checklist for international B2B buyers looking to procure custom printed faux leather. Whether you are sourcing for fashion, upholstery, or accessory production, following these steps will ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the custom printed faux leather meets your product requirements. Consider factors such as thickness, texture, and intended use (e.g., upholstery, garments, or accessories). Be specific about the desired print quality, as high-resolution prints (300 dpi) are crucial for vibrant and clear designs.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers specializing in custom printed faux leather. Look for suppliers with a strong reputation in your target market, particularly in regions like Africa, South America, the Middle East, and Europe. Utilize platforms like trade directories and industry-specific forums to gather insights and reviews about their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before proceeding, ensure that your chosen suppliers possess the necessary certifications that demonstrate compliance with safety and quality standards. Certifications such as CPSIA compliance for children’s products or ISO standards can indicate a supplier’s commitment to quality. Verify these certifications to mitigate risks associated with product safety and legality.

Step 4: Request Samples

Always request samples of the faux leather before placing a bulk order. This allows you to assess the material’s quality, texture, and print fidelity firsthand. Pay attention to the color accuracy and pattern scaling in the samples, as these factors can significantly impact the final product.

Step 5: Negotiate Terms and Conditions

Engage in negotiations regarding pricing, minimum order quantities, and payment terms. Be clear about your expectations for lead times, especially if you have a specific timeline for product launches. Discuss shipping terms, including international shipping rates and any customs duties that may apply, to avoid unexpected costs.

Step 6: Clarify the Design Process

Ensure you understand the process for submitting your designs for custom printing. Confirm the required file formats, resolutions, and any limitations on design elements. Discuss the possibility of receiving a mock-up before the final print to visualize how your design will appear on the faux leather.

Step 7: Establish a Clear Communication Channel

Effective communication is key to a successful partnership. Set up a designated point of contact within the supplier’s organization for any queries and updates. Regular check-ins can help preemptively address any issues that may arise during the production process, ensuring that your order stays on track.

By following this checklist, B2B buyers can navigate the complexities of sourcing custom printed faux leather with confidence, ultimately leading to successful product outcomes.

Comprehensive Cost and Pricing Analysis for custom printed faux leather Sourcing

When sourcing custom printed faux leather, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers, especially those operating in diverse international markets like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Custom Printed Faux Leather Production?

The cost structure of custom printed faux leather encompasses several critical components:

-

Materials: The primary cost driver, materials used for faux leather can vary widely in price based on quality and sourcing. High-quality synthetic materials may be more expensive but offer better durability and aesthetics.

-

Labor: Labor costs depend on the complexity of production. Skilled labor is required for printing and finishing processes, impacting overall costs. Regions with higher labor costs may influence sourcing decisions.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and administrative costs. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Initial costs for tools and machinery necessary for production can be significant. Custom designs may require specialized tooling, which can add to upfront expenses.

-

Quality Control (QC): Ensuring that the final product meets specifications involves QC costs. This may include testing for durability and compliance with safety standards, especially for products intended for children’s use.

-

Logistics: Shipping and handling costs are vital, especially for international buyers. These costs can vary significantly based on the shipping method, distance, and customs duties.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market competition and supplier reputation.

How Do Pricing Influencers Affect Custom Printed Faux Leather Costs?

Several factors can influence the pricing of custom printed faux leather:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often have different pricing tiers based on order size. Higher volumes usually attract lower unit prices, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Custom designs, print specifications, and material choices can significantly impact pricing. Unique or intricate designs may incur additional costs, while standard offerings could be more cost-effective.

-

Quality and Certifications: Products that meet specific quality certifications (e.g., CPSIA compliance) may come at a premium. Buyers should consider the importance of certifications in their target markets.

-

Supplier Factors: Supplier location, reputation, and production capabilities can influence pricing. Established suppliers with a good track record may charge more but offer reliability and quality assurance.

-

Incoterms: Understanding the terms of shipment is crucial for international buyers. Incoterms define who is responsible for shipping costs, insurance, and customs duties, which can significantly affect the total cost.

What Negotiation Tips Can Help Buyers Secure Better Pricing?

B2B buyers can leverage several strategies to optimize their sourcing costs:

-

Bulk Orders: Consider placing larger orders to benefit from volume discounts. Collaborating with other businesses to increase order size can also be beneficial.

-

Long-Term Contracts: Establishing long-term relationships with suppliers can lead to more favorable pricing and terms.

-

Assess Total Cost of Ownership: Evaluate the long-term costs associated with the product, including maintenance, durability, and potential returns. A higher upfront cost may be justified by lower long-term expenses.

-

Market Research: Stay informed about market trends and competitor pricing. This knowledge can provide leverage in negotiations.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import duties, and shipping costs, as these can impact the final price. Engaging with local experts or consultants can provide valuable insights into specific markets.

Заключение

In summary, a thorough understanding of the cost structure and pricing influencers is essential for B2B buyers seeking custom printed faux leather. By focusing on strategic sourcing, negotiation, and the total cost of ownership, businesses can secure high-quality materials that meet their specific needs while optimizing their expenses. As a reminder, prices can fluctuate based on various factors, and it’s advisable to seek quotations from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing custom printed faux leather With Other Solutions

When evaluating solutions for product design and manufacturing, it’s essential to consider various materials that can meet specific needs. Custom printed faux leather is a popular choice due to its versatility and aesthetic appeal, but there are viable alternatives that may suit different applications and requirements. This analysis will compare custom printed faux leather with two alternatives: genuine leather and printed canvas.

Comparison Table

| Comparison Aspect | Custom Printed Faux Leather | Genuine Leather | Printed Canvas |

|---|---|---|---|

| Performance | Durable, water-resistant, and easy to clean | Highly durable, breathable, but can be sensitive to moisture | Moderate durability, not water-resistant, can fade over time |

| Cost | Generally lower cost than genuine leather | Higher cost due to sourcing and treatment | Typically lower cost, depending on print quality |

| Ease of Implementation | Easy to cut, sew, and print with custom designs | Requires specialized tools and skills for cutting and sewing | Simple to handle and print, often using standard printing methods |

| Maintenance | Low maintenance; wipe clean | Requires regular conditioning and care | Low maintenance, but may require careful handling to avoid fading |

| Best Use Case | Fashion accessories, upholstery, and promotional items | Luxury goods, high-end fashion, and durable products | Banners, bags, and items needing vibrant graphics |

In-Depth Analysis of Alternatives

What are the Advantages and Disadvantages of Genuine Leather?

Genuine leather is renowned for its durability and luxurious feel, making it a preferred choice for high-end products. Its breathable nature allows for better comfort in fashion items like shoes and bags. However, the cost of genuine leather is significantly higher, which may not be feasible for every business, especially startups or those targeting cost-sensitive markets. Additionally, genuine leather requires regular maintenance to preserve its quality, which can be a drawback for businesses looking for low-maintenance solutions.

How Does Printed Canvas Compare as an Alternative?

Printed canvas is another alternative that offers a different set of advantages. It is typically less expensive than both custom printed faux leather and genuine leather, making it accessible for businesses on a budget. Canvas is easy to print on, allowing for vibrant designs and patterns. However, its performance in terms of durability and water resistance is inferior to faux leather, which may limit its use in certain applications. Printed canvas is best suited for items like banners or promotional bags where aesthetic appeal is crucial but where exposure to moisture is minimal.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right material depends largely on the specific needs of the project and the target market. Custom printed faux leather presents a balanced option, providing durability, aesthetic flexibility, and cost-effectiveness, making it suitable for a wide range of applications, from fashion to upholstery. On the other hand, if a luxury or high-durability product is required, genuine leather may be worth the investment despite its higher cost. For businesses focused on cost-efficiency and vibrant visuals, printed canvas can be an effective alternative, especially for marketing materials. Ultimately, assessing the product requirements, budget constraints, and maintenance capabilities will guide B2B buyers to the most suitable choice for their needs.

Essential Technical Properties and Trade Terminology for custom printed faux leather

What Are the Key Technical Properties of Custom Printed Faux Leather?

When considering custom printed faux leather, understanding its technical properties is vital for B2B buyers. These specifications not only influence product quality but also affect usability and cost-efficiency.

1. Material Grade

Material grade refers to the quality of the faux leather used in production. It is typically categorized into grades based on durability, texture, and finish. Higher-grade materials offer better performance in terms of wear resistance and aesthetic appeal. For B2B buyers, selecting the appropriate material grade is crucial to ensure the final product meets market demands and customer expectations.

2. Tolerance

Tolerance in faux leather production signifies the allowable deviation in dimensions and print quality. This is especially important in custom printing, where precise alignment and sizing of patterns can affect the overall look of the product. For B2B transactions, understanding tolerance levels ensures that the final product adheres to specifications, reducing the risk of costly reprints or product failures.

3. Print Resolution

Print resolution is a measure of the detail in the printed design, typically expressed in DPI (dots per inch). Higher DPI values indicate sharper and more detailed prints, which are essential for intricate designs. For B2B buyers, specifying print resolution can significantly impact the perceived value of products and the satisfaction of end-users.

4. Compliance Standards

Compliance standards refer to regulations that faux leather products must meet, especially when intended for children’s products or other sensitive applications. For example, CPSIA (Consumer Product Safety Improvement Act) compliance ensures that materials are free from harmful chemicals. Buyers must prioritize suppliers who adhere to these standards to mitigate legal risks and enhance marketability.

5. Weight and Thickness

The weight and thickness of faux leather can vary significantly, impacting its application. Lighter materials may be ideal for apparel, while heavier grades are more suitable for upholstery. Understanding these properties allows B2B buyers to choose the right type of faux leather for their specific needs, ensuring functionality without compromising on aesthetics.

What Are Common Trade Terms in the Custom Printed Faux Leather Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are then marketed by another company. In the context of custom printed faux leather, OEM partnerships can streamline production and reduce costs. B2B buyers often seek OEMs to leverage their expertise and capabilities in manufacturing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers as it affects inventory management and cost structure. Buyers must negotiate MOQs that align with their production needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. It is a vital tool for B2B buyers to gauge market pricing and negotiate favorable terms. Crafting a clear RFQ can streamline procurement processes and lead to better supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping, insurance, and customs duties. For B2B buyers, understanding Incoterms is essential to avoid misunderstandings and ensure smooth logistics in cross-border transactions.

5. Lead Time

Lead time is the duration between placing an order and receiving the final product. For custom printed faux leather, lead time can vary based on complexity and supplier capabilities. Buyers must account for lead times in their project timelines to ensure timely product launches and customer satisfaction.

Incorporating these technical specifications and trade terms into your decision-making process will empower B2B buyers to make informed choices in the custom printed faux leather market, enhancing both product quality and business efficiency.

Navigating Market Dynamics and Sourcing Trends in the custom printed faux leather Sector

What Are the Key Trends Influencing the Custom Printed Faux Leather Market?

The custom printed faux leather market is witnessing significant growth driven by various global factors. A surge in demand for sustainable and cruelty-free materials is reshaping consumer preferences, especially in regions like Europe and North America. This trend is echoed in emerging markets across Africa and South America, where local manufacturers are increasingly focusing on eco-friendly production methods. Furthermore, technological advancements in printing techniques, such as digital printing, are making it easier for manufacturers to offer customizable designs with shorter lead times. This flexibility appeals to B2B buyers looking for unique products that cater to specific customer needs.

Moreover, the rise of e-commerce platforms is facilitating direct sourcing for international buyers, enabling them to access a broader range of suppliers and products. The ability to order small quantities without compromising on quality allows businesses in diverse sectors—such as fashion, automotive, and furniture—to experiment with new designs and materials. As buyers seek to differentiate their offerings, collaborations with designers and artists are becoming more common, leading to innovative patterns and styles that resonate with end consumers.

In addition, geopolitical factors and supply chain disruptions caused by events like the COVID-19 pandemic have prompted businesses to reconsider their sourcing strategies. Many are shifting towards local suppliers to mitigate risks associated with international shipping and tariffs, which further influences market dynamics.

How Is Sustainability Impacting the Sourcing of Custom Printed Faux Leather?

Sustainability is no longer just a buzzword; it is a critical consideration for B2B buyers in the custom printed faux leather sector. The environmental impact of traditional leather production is prompting businesses to seek alternatives that align with their corporate social responsibility (CSR) goals. Custom printed faux leather is often seen as a viable option due to its lower ecological footprint, particularly when made from recycled materials or bio-based polymers.

The importance of ethical supply chains is also gaining traction. Buyers are increasingly interested in understanding the sourcing practices of their suppliers, looking for certifications such as Global Recycle Standard (GRS) and OEKO-TEX® Standard 100. These certifications ensure that products meet environmental and safety standards, providing reassurance to businesses that their materials are sourced responsibly.

Moreover, as consumers become more environmentally conscious, they expect brands to reflect these values in their product offerings. For B2B buyers, partnering with suppliers who prioritize sustainability can enhance brand reputation and customer loyalty. This trend is particularly relevant in regions like Europe, where regulatory frameworks are becoming stricter regarding environmental standards. Consequently, investing in sustainable faux leather not only meets market demands but also positions businesses favorably in a competitive landscape.

What Is the Historical Context of Custom Printed Faux Leather Development?

The evolution of custom printed faux leather can be traced back to the late 20th century when synthetic materials began to gain popularity as alternatives to animal leather. Initially, these materials were primarily used for cost-effective applications in fashion and upholstery. However, as consumer awareness of animal welfare and environmental issues increased, the demand for faux leather surged.

In the early 2000s, advancements in technology allowed for more sophisticated production methods, enabling the development of high-quality faux leather that closely mimicked the look and feel of real leather. This innovation opened new avenues for customization, allowing businesses to print unique designs and patterns on faux leather materials. Today, custom printed faux leather is widely used across various industries, from fashion accessories to automotive interiors, reflecting a growing trend toward personalization and unique consumer experiences.

In summary, the custom printed faux leather market is evolving rapidly, driven by sustainability, technological advancements, and changing consumer preferences. B2B buyers across the globe must stay informed about these trends to make strategic sourcing decisions that align with market demands and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of custom printed faux leather

-

How do I ensure the quality of custom printed faux leather before placing a large order?

To ensure the quality of custom printed faux leather, request samples from potential suppliers before committing to a bulk order. Evaluate the texture, flexibility, and color accuracy of the samples. Additionally, inquire about their quality assurance processes, including any certifications like CPSIA compliance, which ensures safety standards, particularly if the product is intended for children’s items. Establishing a clear communication line with the supplier regarding your quality expectations will also help mitigate issues down the line. -

What are the best practices for customizing designs on faux leather?

When customizing designs on faux leather, ensure your artwork is high resolution (at least 300 dpi) and ideally a seamless pattern for the best print results. Provide specific scaling instructions for the largest design elements to achieve the desired visual impact. Many suppliers offer mock-up services, which can be invaluable for visualizing how your design will look on the final product. Also, verify that you own the rights to any images used to avoid copyright infringement. -

What is the minimum order quantity (MOQ) for custom printed faux leather?

The minimum order quantity (MOQ) for custom printed faux leather typically varies by supplier. Many suppliers require at least two sheets per design, while others may have higher MOQs based on production capabilities. Always confirm the MOQ with your supplier before placing an order, as it can significantly impact your purchasing strategy, especially for smaller businesses or startups looking to test the market. -

How can I vet suppliers for custom printed faux leather effectively?

To vet suppliers for custom printed faux leather, start by reviewing their online presence, including customer testimonials and case studies. Request references from previous clients, particularly those in your industry or region. Additionally, consider conducting a factory visit if feasible, or ask for a virtual tour to understand their production processes. Assess their responsiveness and willingness to accommodate your customization needs, as these factors often reflect their commitment to customer service. -

What payment terms should I expect when sourcing custom printed faux leather?

Payment terms for custom printed faux leather can vary widely among suppliers. Common practices include upfront payments, partial deposits, or payment upon delivery. When negotiating, aim for terms that protect your cash flow while also ensuring the supplier feels secure in the transaction. Be cautious of suppliers requiring full payment upfront, especially if they are new to you. Establishing clear terms in a formal agreement will help prevent misunderstandings. -

What logistics considerations should I keep in mind for international shipping of faux leather?

When arranging international shipping for custom printed faux leather, consider the supplier’s shipping options and delivery times. Understand the potential customs duties, VAT, and other fees that may apply upon importation, as these can significantly affect your overall costs. It’s advisable to work with a logistics partner experienced in international trade who can guide you through the customs process and ensure compliance with local regulations in your target market. -

How do I handle potential delays in the production and shipping of my faux leather order?

To manage potential delays in production and shipping, maintain regular communication with your supplier about your order status. Discuss their average production times and any potential bottlenecks they foresee. Additionally, consider building buffer time into your project timelines to account for unexpected delays. If possible, negotiate penalties or incentives related to delivery timelines in your contract to encourage timely fulfillment. -

What are the environmental considerations when sourcing faux leather?

When sourcing faux leather, it’s important to consider the environmental impact of the materials and production processes. Inquire about the types of materials used in the faux leather and whether they are sourced sustainably. Check if the supplier has certifications for eco-friendly practices, such as low emissions or recycling programs. By partnering with environmentally responsible suppliers, you can align your business practices with sustainability goals and appeal to eco-conscious customers.

Top 7 Custom Printed Faux Leather Manufacturers & Suppliers List

1. Contrado – Custom Printed Faux Leather Fabric

Domain: contrado.com

Registered: 2004 (21 years)

Введение: Custom Printed Faux Leather Fabric

– Price: From $37.50

– Composition: 85% PVC, 15% Polyester

– Max Width: 1.39yd

– Weight: 20.65oz

– Certification: Greenguard Certified

– Features: Soft polyester back, PVC face, fire rated, suitable for upholstery and bags, vibrant printing on a super bright white base.

– Care Instructions: Surface wipe only, clean gently by hand with mild soapy damp cloth.

– Shi…

2. Pip Supply – Custom Printed Faux Leather Sheets

Domain: pipsupply.com

Registered: 2018 (7 years)

Введение: Custom Printed Faux Leather Sheets – CPSIA compliant faux leather – Free Domestic Shipping for orders $75 and up – Current Processing Time: 4-8 Business Days

3. Bags of Love – Custom Printed Faux Leather Fabric

Domain: bagsoflove.com

Registered: 2003 (22 years)

Введение: Custom Printed Faux Leather Fabric

– Price: from $37.50

– Material: 100% vegan faux leather with a PVC face and soft poly back

– Ideal for: upholstery, bag making, phone cases, and more

– Features: leather effect texture, vibrant colors, sharp and crisp details

– Customer Rating: 4.9/5 based on 883 reviews

– Design Options: single image, collage, text, or pattern repeat

4. Zipper Valley – Printed Faux Leather

Domain: zippervalley.com

Registered: 2020 (5 years)

Введение: Printed Faux Leather is pliable, vibrant, and bursting with personality. It is easy to cut and sews beautifully on domestic machines. Ideal for bags, wallets, key fobs, embroidery, and other creative projects. Available styles include Printed Pebble with various patterns. Regular prices range from $8.99 to $16.49, with discounts on select items. In stock items: 11, out of stock items: 3. Fast proc…

5. Etsy – Printed Faux Leather Sheets

Domain: etsy.com

Registered: 2004 (21 years)

Введение: This company, Etsy – Printed Faux Leather Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Print Ninja – Specialty Book Covers

Domain: printninja.com

Registered: 2003 (22 years)

Введение: Cloth and Faux Leather Covers are specialty options for book printing. They provide a premium look and feel, suitable for various project types including books and card games. These covers can enhance the durability and aesthetic appeal of printed materials. The service includes options for custom designs and finishes, allowing for unique branding and presentation.

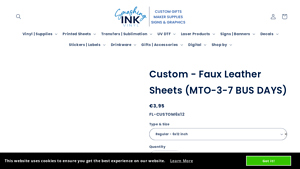

7. Smashing Ink – Custom Faux Leather Sheets

Domain: smashinginkvinyl.com

Registered: 2017 (8 years)

Введение: {“product_name”: “Custom – Faux Leather Sheets”, “sku”: “FL-CUSTOM6x12”, “price”: “$3.99”, “available_sizes”: [{“size”: “6×12 inch”, “price”: “$3.99”}, {“size”: “6×24 inch”, “price”: “$7.75”}, {“size”: “6×36 inch”, “price”: “$10.75”}, {“size”: “6×48 inch”, “price”: “$14.50”}, {“size”: “12×12 inch”, “price”: “$7.75”}, {“size”: “12×24 inch”, “price”: “$14.50”}, {“size”: “12 inch x 1 yard”, “price”: …

Strategic Sourcing Conclusion and Outlook for custom printed faux leather

In the evolving landscape of custom printed faux leather, strategic sourcing emerges as a pivotal factor for B2B buyers aiming to enhance product offerings and maintain competitive advantages. By carefully selecting suppliers who provide high-quality materials and reliable printing capabilities, businesses can ensure the delivery of vibrant, durable products that meet diverse customer needs. The growing demand for sustainable and ethically sourced materials further emphasizes the importance of aligning with manufacturers who prioritize environmental responsibility.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, have a unique opportunity to leverage the versatility of custom printed faux leather across various applications—from fashion to home decor. The ability to customize patterns and designs not only fosters brand differentiation but also caters to local market trends and consumer preferences.

Looking ahead, as global markets continue to expand, the potential for innovation in faux leather applications will only grow. B2B buyers are encouraged to explore partnerships with reputable suppliers, invest in quality materials, and stay attuned to emerging trends. By doing so, they can position themselves as leaders in their respective industries and capitalize on the burgeoning demand for custom printed faux leather.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.