Introduction: Navigating the Global Market for custom leather clothing

In the competitive landscape of custom leather clothing, sourcing high-quality products that resonate with your brand identity can be a daunting challenge for B2B buyers. Whether you are in Nigeria, Brazil, or any part of Europe, the demand for unique, durable, and stylish leather apparel continues to rise. This guide serves as your comprehensive resource, addressing various aspects of the custom leather clothing market, including types of apparel available, their diverse applications, and the crucial process of supplier vetting.

As the global market expands, understanding the intricacies of sourcing becomes essential. This guide will empower you to make informed purchasing decisions by providing insights into cost structures, quality assessments, and market trends. By focusing on the specific needs of international buyers, we aim to bridge the gap between suppliers and businesses, ensuring that you find the perfect custom leather clothing that aligns with your vision and customer expectations.

From medieval and renaissance styles to contemporary cosplay and superhero themes, the range of possibilities in custom leather clothing is vast. Our exploration will highlight key considerations for selecting suppliers who not only meet your specifications but also uphold the highest standards of craftsmanship. By the end of this guide, you will be equipped with the knowledge to navigate the global market confidently, fostering successful partnerships that enhance your product offerings and drive business growth.

Table Of Contents

- A Look at Custom Leather Clothing Manufacturers & Suppliers

- Introduction: Navigating the Global Market for custom leather clothing

- Understanding custom leather clothing Types and Variations

- Key Industrial Applications of custom leather clothing

- 3 Common User Pain Points for ‘custom leather clothing’ & Their Solutions

- Strategic Material Selection Guide for custom leather clothing

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather clothing

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather clothing’

- Comprehensive Cost and Pricing Analysis for custom leather clothing Sourcing

- Alternatives Analysis: Comparing custom leather clothing With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather clothing

- Navigating Market Dynamics and Sourcing Trends in the custom leather clothing Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather clothing

- Strategic Sourcing Conclusion and Outlook for custom leather clothing

- Important Disclaimer & Terms of Use

Understanding custom leather clothing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Medieval Apparel | Authentic designs, durable materials, customizable sizes | Theatrical productions, Renaissance fairs | Pros: Unique appeal, high craftsmanship. Cons: Longer production times. |

| Superhero Apparel | Contemporary designs, vibrant colors, tailored fits | Comic conventions, promotional events | Pros: High market demand, brand visibility. Cons: Niche market, seasonal trends. |

| Renaissance Apparel | Historical accuracy, intricate detailing, varied styles | Costume rentals, themed events | Pros: Strong cultural resonance, premium pricing. Cons: Limited audience reach. |

| Cosplay Apparel | Character-specific designs, various leather finishes | Cosplay events, fan conventions | Pros: Customization options, passionate customer base. Cons: Potential for high competition. |

| Functional Leather Wear | Practical designs, multiple functionalities (e.g., pockets) | Outdoor activities, fashion industries | Pros: Versatile use, practical appeal. Cons: May lack the artistic flair of other types. |

What Are the Characteristics of Medieval Apparel in Custom Leather Clothing?

Medieval apparel features authentic designs that reflect historical accuracy, often crafted from high-quality leather that ensures durability. These garments are typically customizable in size and style, making them ideal for theatrical productions and Renaissance fairs. B2B buyers should consider the craftsmanship and the time required for production, as these garments may take longer to manufacture due to their intricate designs.

How Does Superhero Apparel Stand Out in the Custom Leather Market?

Superhero apparel is characterized by contemporary designs that often include vibrant colors and tailored fits to reflect popular comic book characters. This type of clothing is primarily used in comic conventions and promotional events, making it a lucrative option for businesses looking to capitalize on fandom culture. Buyers should weigh the high market demand and brand visibility against the niche market and potential seasonal trends that can affect sales.

What Makes Renaissance Apparel a Unique Offering in Custom Leather Clothing?

Renaissance apparel is distinguished by its historical accuracy and intricate detailing, appealing to those involved in costume rentals or themed events. The garments often boast a variety of styles, making them suitable for different characters or personas from the Renaissance era. B2B buyers should assess the strong cultural resonance and premium pricing potential, while being mindful of the limited audience reach that may affect sales volume.

Why Is Cosplay Apparel Important for B2B Buyers in the Custom Leather Sector?

Cosplay apparel focuses on character-specific designs that appeal to fans of various genres, utilizing different leather finishes for authenticity. This segment is popular at cosplay events and fan conventions, providing a passionate customer base eager for unique offerings. B2B buyers should consider the extensive customization options available and the potential for high competition in this vibrant market.

What Are the Advantages of Functional Leather Wear for Business Applications?

Functional leather wear combines practical designs with multiple functionalities, such as pockets and weather resistance, catering to outdoor activities and fashion industries. Its versatility makes it an attractive option for B2B buyers looking to meet diverse customer needs. However, while it offers practical appeal, buyers should note that it may lack the artistic flair found in other custom leather clothing types, which could influence consumer preferences.

Key Industrial Applications of custom leather clothing

| Industry/Sector | Specific Application of custom leather clothing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom leather jackets and vests | Enhances brand identity with unique offerings | Quality materials, craftsmanship, and design flexibility |

| Automotive & Motorsports | Leather racing suits and gear | Provides safety and durability for performance | Compliance with safety standards, customization options |

| Entertainment & Events | Costumes for film, theater, and cosplay | Creates memorable experiences and brand storytelling | Fabric quality, detailed craftsmanship, and timely delivery |

| Outdoor & Adventure | Leather gear for outdoor activities | Combines functionality with style for enthusiasts | Weather resistance, durability, and ergonomic design |

| Corporate Branding | Custom leather uniforms and promotional items | Strengthens brand visibility and employee morale | Customization capabilities and bulk order pricing |

How is Custom Leather Clothing Used in the Fashion & Apparel Industry?

In the fashion sector, custom leather clothing, particularly jackets and vests, allows brands to offer unique, high-quality products that stand out in a competitive market. This customization not only enhances the brand’s identity but also meets specific consumer demands for style and fit. B2B buyers in this industry must prioritize sourcing high-quality materials and craftsmanship to ensure the final products resonate with their target demographics, particularly in regions like Europe and South America where fashion trends can vary significantly.

What Role Does Custom Leather Clothing Play in Automotive & Motorsports?

In the automotive and motorsports industry, custom leather racing suits and gear are essential for safety and performance. These garments are designed to withstand extreme conditions while providing comfort and protection to drivers. B2B buyers should ensure that their suppliers comply with international safety standards and offer a variety of customization options to cater to the specific needs of different racing teams and events, especially in regions like the Middle East where motorsports are gaining popularity.

How is Custom Leather Clothing Utilized in Entertainment & Events?

Custom leather clothing plays a pivotal role in the entertainment sector, particularly for costumes in film, theater, and cosplay events. These garments are crafted to enhance character portrayal and create memorable experiences for audiences. B2B buyers need to focus on sourcing high-quality fabrics and detailed craftsmanship to ensure that costumes not only look authentic but also withstand the rigors of performances. Timely delivery is crucial, especially for events that have strict timelines.

Why is Custom Leather Gear Important for Outdoor & Adventure Activities?

In the outdoor and adventure sector, custom leather gear such as bags, jackets, and protective clothing combines style with functionality. This gear is designed for durability and weather resistance, appealing to outdoor enthusiasts who prioritize both aesthetics and performance. B2B buyers should consider ergonomic designs and the ability to withstand harsh conditions when sourcing these products, especially in regions like Africa where outdoor activities are popular.

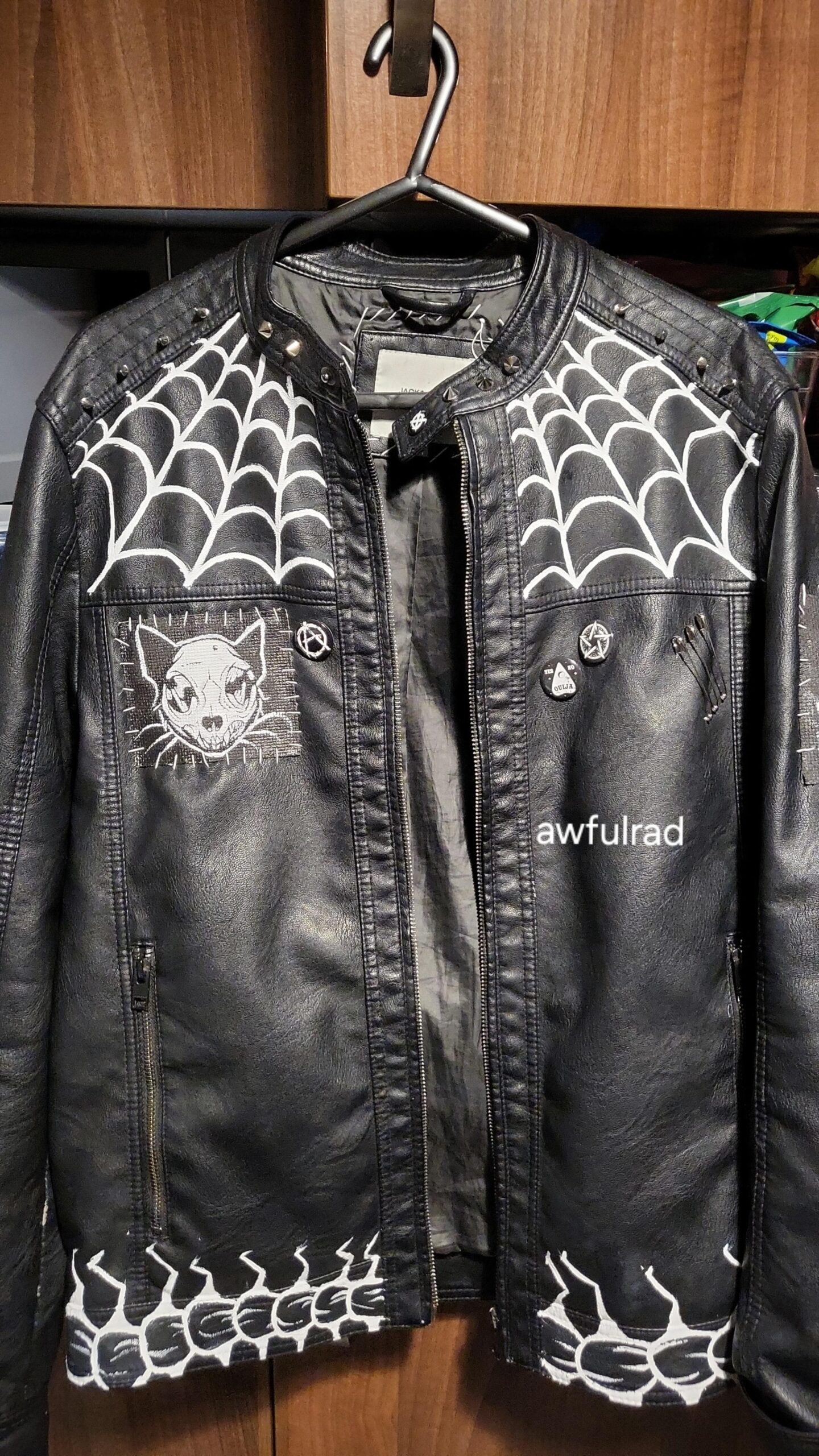

Illustrative image related to custom leather clothing

How Can Custom Leather Clothing Enhance Corporate Branding?

Custom leather uniforms and promotional items are effective tools for corporate branding. They not only enhance brand visibility but also boost employee morale through quality and stylish workwear. B2B buyers should seek suppliers who offer customization capabilities and favorable bulk order pricing to ensure that the investment aligns with their branding strategies and corporate image, particularly in markets across Europe and South America where corporate identity plays a significant role.

3 Common User Pain Points for ‘custom leather clothing’ & Their Solutions

Scenario 1: Navigating Quality Concerns in Custom Leather Clothing

The Problem: For B2B buyers, particularly those sourcing custom leather clothing for retail or production, the variability in quality can be a significant concern. Many manufacturers offer leather products that look appealing online but fail to meet the expected standards upon delivery. This discrepancy can lead to customer dissatisfaction, increased returns, and ultimately harm the brand’s reputation. Buyers may struggle to differentiate between premium and substandard leather, which can impact their purchasing decisions and overall business success.

The Solution: To mitigate quality concerns, buyers should prioritize establishing clear communication with suppliers about material specifications and production processes. Request detailed samples of leather, including swatches of different grades, to evaluate texture, durability, and overall craftsmanship. Additionally, consider implementing a quality assurance checklist that includes criteria such as leather type, stitching quality, and finishing techniques. Partnering with manufacturers who provide transparent information about their sourcing and production practices can also help ensure that the products meet quality expectations before bulk purchasing.

Scenario 2: Managing Sizing and Customization Challenges

The Problem: Sizing issues can be a major pain point for businesses dealing with custom leather clothing. Unlike off-the-shelf options, custom apparel requires precise measurements, and any miscommunication or oversight can lead to significant discrepancies. This not only results in wasted materials and production time but also affects customer satisfaction and loyalty when clients receive items that do not fit as intended.

The Solution: To effectively manage sizing and customization, buyers should implement a robust measurement protocol. This includes providing detailed sizing charts and guidelines to their customers, along with a clear method for submitting measurements. Utilizing 3D fitting technology or virtual fitting tools can help visualize how garments will fit on different body types. Moreover, establishing a feedback loop with customers post-delivery can help refine sizing standards and improve future orders. Collaborating with manufacturers who offer flexible customization options can also streamline the process and ensure that the end product aligns with client expectations.

Illustrative image related to custom leather clothing

Scenario 3: Overcoming Supply Chain and Lead Time Issues

The Problem: The custom leather clothing industry often faces supply chain challenges that can lead to extended lead times, impacting buyers’ ability to meet market demands. Delays in sourcing materials, production bottlenecks, or logistical setbacks can create a ripple effect, causing stock shortages and missed sales opportunities. For businesses that rely on timely deliveries to satisfy customer expectations, these issues can be detrimental.

The Solution: To combat supply chain and lead time issues, buyers should consider diversifying their supplier base to include multiple manufacturers. This not only provides alternative sourcing options in case of delays but also fosters competitive pricing. Establishing long-term relationships with suppliers can lead to improved prioritization of orders and enhanced communication regarding lead times. Additionally, implementing an inventory management system that allows for real-time tracking of orders and stock levels can help businesses proactively manage their supply chain. Regularly reviewing and adjusting order quantities based on sales forecasts can also minimize the impact of unexpected delays and ensure consistent product availability.

Strategic Material Selection Guide for custom leather clothing

What Are the Key Properties of Common Materials Used in Custom Leather Clothing?

When selecting materials for custom leather clothing, it is essential to consider the specific properties that influence product performance. Common materials include full-grain leather, top-grain leather, suede, and synthetic leather. Each material has unique characteristics that can significantly impact the final product’s quality and suitability for various applications.

How Does Full-Grain Leather Perform in Custom Leather Clothing Applications?

Full-grain leather is the highest quality leather available, retaining the natural grain and imperfections of the hide. This material is known for its exceptional durability and breathability, making it ideal for high-performance applications. It can withstand significant wear and tear, and its natural oils provide some level of water resistance. However, full-grain leather can be expensive and may require specialized care to maintain its appearance.

For international B2B buyers, particularly in regions like Africa and South America, understanding the sourcing and treatment processes is crucial. Compliance with local regulations regarding animal welfare and environmental standards is essential. Additionally, buyers should be aware of the varying preferences for leather finishes in different markets, as some may favor a more rustic look while others prefer a polished finish.

What Are the Advantages and Disadvantages of Top-Grain Leather?

Top-grain leather is a step down from full-grain leather but still offers a good balance of durability and aesthetics. It is sanded and treated to remove imperfections, resulting in a more uniform appearance. This material is less expensive than full-grain leather and is easier to maintain, making it suitable for a variety of custom leather clothing applications.

However, top-grain leather is less durable than full-grain leather and may not age as gracefully. It is essential for B2B buyers to consider the end-use of the clothing when selecting this material. For instance, garments intended for heavy-duty use may benefit from the robustness of full-grain leather, while those aimed at fashion-conscious consumers may find top-grain leather more appealing.

Illustrative image related to custom leather clothing

How Does Suede Compare in Terms of Performance and Suitability?

Suede, made from the underside of the hide, is known for its soft texture and luxurious feel. It is lightweight and offers a unique aesthetic that appeals to fashion-forward consumers. However, suede is less durable than both full-grain and top-grain leather and is more susceptible to staining and damage from moisture.

For international buyers, especially in humid climates like parts of Africa and Brazil, the care and maintenance of suede must be considered. Buyers should ensure that the end products are treated with appropriate protective coatings to enhance durability. Understanding local market preferences for suede versus other leather types can also guide material selection.

What Role Does Synthetic Leather Play in Custom Leather Clothing?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to natural leather. It is highly versatile, available in various colors and textures, and is often easier to clean and maintain. Synthetic leather is also animal-friendly, appealing to markets with strong ethical consumerism trends.

However, synthetic leather typically lacks the breathability and durability of natural leather. For B2B buyers, especially in regions with stringent environmental regulations, it is crucial to ensure that the synthetic materials comply with local standards. Additionally, understanding consumer perceptions of synthetic versus natural leather can impact sales strategies.

Illustrative image related to custom leather clothing

Summary of Material Selection Insights for Custom Leather Clothing

| Материал | Typical Use Case for custom leather clothing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end jackets, durable outdoor gear | Exceptional durability and breathability | Expensive and requires care | Высокий |

| Top-Grain Leather | Fashion apparel, everyday wear | Good balance of durability and aesthetics | Less durable than full-grain | Medium |

| Замша | Fashion-forward garments, luxury items | Soft texture and luxurious feel | Less durable and moisture-sensitive | Medium |

| Синтетическая кожа | Budget-friendly options, casual wear | Cost-effective and animal-friendly | Lacks breathability and durability | Низкий |

This guide provides valuable insights for B2B buyers in selecting the right materials for custom leather clothing, ensuring that they meet both performance standards and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather clothing

What Are the Key Stages in the Manufacturing Process of Custom Leather Clothing?

The manufacturing of custom leather clothing involves several critical stages that ensure the final product meets the specific requirements of B2B buyers. These stages include material preparation, forming, assembly, and finishing, each contributing to the overall quality and durability of the clothing.

How is Material Prepared for Custom Leather Clothing?

Material preparation is foundational in the manufacturing process. High-quality leather is sourced from reputable suppliers, ensuring it meets the necessary standards for strength and texture. The leather is then inspected for defects, and only the best hides are selected for use. This stage may also involve tanning, dyeing, and conditioning processes that enhance the leather’s appearance and longevity.

During preparation, it is crucial to maintain consistency in thickness and texture. This is particularly important for custom orders, where variations can lead to discrepancies in the final product. Suppliers often utilize advanced technology to measure and cut the leather precisely, minimizing waste and ensuring uniformity.

What Techniques Are Employed in the Forming Stage?

Once the leather is prepared, the forming stage begins. This involves cutting the leather into specific shapes according to the design specifications provided by the buyer. Techniques such as die-cutting and laser cutting are commonly employed to achieve intricate designs and patterns.

Illustrative image related to custom leather clothing

After cutting, the leather pieces are often pre-formed using molds to give them the desired shape. This is especially important for items like jackets or fitted apparel where the garment’s silhouette is critical. Heat and pressure may be applied during this stage to enhance the leather’s shape retention.

How is the Assembly Process Structured for Custom Leather Clothing?

The assembly process is where the individual leather pieces come together to create the final product. Skilled artisans often hand-stitch the leather using high-quality threads, ensuring durability and a refined finish. The stitching process is a key quality indicator; double stitching is commonly used for high-stress areas to enhance strength.

In addition to stitching, hardware components such as zippers, buttons, and buckles are added during this stage. Quality assurance checks are performed to ensure that all components meet the required standards and that the assembly is performed with precision. This stage may also involve the application of additional treatments, such as waterproofing or protective coatings.

Illustrative image related to custom leather clothing

What Finishing Techniques Enhance the Quality of Custom Leather Clothing?

The finishing stage is crucial for enhancing the aesthetic appeal and functionality of custom leather clothing. This includes processes such as polishing, buffing, and applying protective finishes. The objective is to achieve a high-quality surface that is both visually appealing and resistant to wear and tear.

Moreover, branding elements like labels and tags are added during this stage, often customized to reflect the buyer’s brand identity. A thorough inspection is conducted to check for any defects in the finish, ensuring that the product meets the buyer’s expectations.

How is Quality Assurance Implemented in Custom Leather Clothing Manufacturing?

Quality assurance (QA) is integral to the production of custom leather clothing. It ensures that the final products not only meet the design specifications but also adhere to international standards.

What International Standards Are Relevant for Quality Assurance?

International standards such as ISO 9001 play a significant role in the quality assurance processes of custom leather clothing manufacturers. ISO 9001 focuses on meeting customer expectations and delivering customer satisfaction through effective quality management systems.

Additionally, industry-specific standards like CE marking for safety and compliance in the European market, and API specifications for durability and quality, are crucial for B2B buyers. Understanding these standards helps buyers ensure that their suppliers maintain high-quality production practices.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are essential to maintain product integrity throughout the manufacturing process. Typically, these checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet predefined quality criteria before production begins.

- In-Process Quality Control (IPQC): During the assembly and forming stages, ongoing inspections are conducted to identify any defects or deviations from standards.

- Final Quality Control (FQC): Before products are shipped, a final inspection is performed to ensure that each item meets quality standards and specifications.

These checkpoints help to identify issues early in the production process, reducing waste and ensuring that the final products are of high quality.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must be proactive in verifying the quality control processes of their suppliers. This can be achieved through several methods:

-

Supplier Audits: Regular audits of suppliers’ manufacturing facilities can provide insights into their quality management practices. Buyers should look for compliance with international standards and assess the effectiveness of their quality control processes.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the QC measures in place. These reports should outline inspection results, defect rates, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can be particularly valuable for buyers in regions with varying standards, such as Africa or South America.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, must navigate various quality control nuances. Differences in regulatory requirements, cultural expectations, and market standards can affect how quality is perceived and measured.

Illustrative image related to custom leather clothing

Buyers should familiarize themselves with the specific requirements of their target markets. For example, compliance with European CE standards may differ significantly from the expectations in the Middle East. Understanding these nuances will enable buyers to set clear expectations with their suppliers and ensure that the final products align with their market’s quality standards.

Заключение

In summary, the manufacturing processes and quality assurance protocols for custom leather clothing are intricate and vital for ensuring high-quality products. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ensuring that their custom leather clothing meets both their specifications and international quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather clothing’

Введение

In the competitive landscape of custom leather clothing, sourcing high-quality products that meet your specific requirements is essential for success. This guide provides a practical, step-by-step checklist for B2B buyers looking to procure custom leather apparel. By following these steps, you can ensure that your sourcing process is efficient, reliable, and aligned with your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s crucial to outline your specific requirements. This includes determining the type of leather, design details, and any additional features such as waterproofing or breathability. Having clear specifications helps avoid misunderstandings and ensures that the final product aligns with your vision.

- Material Type: Decide on the leather type (e.g., cowhide, lambskin) based on your target market’s preferences.

- Design Elements: Specify any unique design features, such as stitching patterns or closures.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in custom leather clothing. Focus on those with a proven track record in delivering quality products. Use online directories, trade shows, and industry forums to gather a list of potential partners.

- Supplier Reviews: Look for testimonials and case studies from previous clients to gauge reliability.

- Market Presence: Assess their experience in your target regions, such as Africa or South America, to ensure they understand local preferences.

Step 3: Evaluate Supplier Capabilities

Once you have shortlisted potential suppliers, assess their production capabilities. This involves examining their manufacturing processes, quality control measures, and ability to meet your volume requirements.

- Производственная мощность: Ensure they can handle your order size without compromising quality.

- Quality Assurance: Ask about their quality control protocols to ensure consistency in products.

Step 4: Request Samples

Before making a large order, request samples of their products. This step is vital in evaluating the quality of materials and craftsmanship. Analyze the samples for durability, comfort, and overall aesthetic appeal.

- Material Samples: Ensure that the leather matches your specifications in texture and finish.

- Craftsmanship Check: Inspect stitching and detailing to confirm it meets your standards.

Step 5: Verify Certifications and Compliance

It’s essential to verify that your selected suppliers adhere to relevant industry standards and certifications. This not only ensures product quality but also aligns with ethical sourcing practices.

- Certifications: Look for certifications related to leather quality (e.g., ISO) and sustainable practices.

- Compliance: Ensure that the supplier meets local regulations regarding labor and environmental standards.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate clear terms and conditions. This includes pricing, payment terms, lead times, and warranty policies. Clarity at this stage can prevent disputes later on.

- Pricing Structure: Discuss bulk discounts or payment terms that suit your cash flow.

- Lead Times: Agree on production timelines to align with your inventory needs.

Step 7: Establish a Communication Plan

Finally, establish an ongoing communication plan with your supplier. Regular updates on production status, delivery schedules, and any potential issues can foster a strong working relationship and ensure smooth operations.

- Regular Check-Ins: Schedule periodic meetings to discuss progress and address any concerns.

- Feedback Loop: Create a system for providing feedback on product quality and service to facilitate continuous improvement.

By following this checklist, you can streamline your sourcing process for custom leather clothing and ensure that your business receives high-quality products that meet market demands.

Comprehensive Cost and Pricing Analysis for custom leather clothing Sourcing

What Are the Key Cost Components in Custom Leather Clothing Sourcing?

In the realm of custom leather clothing, understanding the cost structure is crucial for international B2B buyers. The primary components that contribute to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials represent a significant portion of the total cost. The type of leather—be it full-grain, top-grain, or suede—greatly influences pricing. High-quality leathers sourced from reputable suppliers will invariably come at a premium. Additionally, any specialized materials for customization, such as unique dyes or hardware, will add to the cost.

Labor costs can vary widely based on geographic location and the skill level required for craftsmanship. Regions with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality. The intricacies of the design and the level of custom tailoring also affect labor expenses, as more complex designs demand skilled artisans.

Manufacturing overhead encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. These costs are typically spread across the total output, meaning larger orders may benefit from reduced overhead per unit.

Illustrative image related to custom leather clothing

Tooling refers to the costs associated with creating molds, dies, or other equipment necessary for production. For custom orders, these expenses can be substantial, especially if the designs are unique.

Quality Control is another critical cost component. Implementing stringent QC processes ensures that products meet specific standards, which is essential for maintaining brand reputation. However, these processes can add to the overall cost of production.

Logistics involves the transportation of raw materials and finished goods. Factors like distance, shipping methods, and Incoterms significantly impact logistics costs. For international buyers, understanding these elements is vital, as they can fluctuate based on geopolitical factors or global supply chain issues.

Margin is the final component, representing the profit the supplier aims to achieve. This can vary depending on market conditions, competition, and the perceived value of the product.

Illustrative image related to custom leather clothing

How Do Price Influencers Affect Custom Leather Clothing Costs?

Several price influencers can affect the total cost of custom leather clothing. Volume and Minimum Order Quantity (MOQ) play a crucial role; larger orders often lead to discounts, while small orders may incur higher per-unit costs.

Specifications and customization are also significant. The more intricate the design or the higher the demand for unique features, the higher the price is likely to be. Buyers should clearly communicate their requirements to avoid unexpected costs.

Material quality and certifications can also impact pricing. High-quality, certified leathers may come at a premium but can enhance product durability and customer satisfaction, justifying the higher investment.

Supplier factors are critical as well. The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge more, but they also provide assurance regarding product consistency.

Incoterms dictate the responsibilities of buyers and sellers in terms of shipping and customs duties. Understanding these terms can help buyers manage logistics costs effectively.

What Are the Best Negotiation and Cost-Efficiency Strategies for B2B Buyers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings. Start by researching market rates and establishing a clear understanding of the pricing components discussed above. This knowledge can empower buyers during negotiations.

Consider discussing Total Cost of Ownership (TCO) rather than just upfront costs. This approach takes into account not only the purchase price but also factors like durability, maintenance, and potential resale value.

Illustrative image related to custom leather clothing

When dealing with suppliers, being flexible with order volumes can yield better pricing. If possible, consolidate orders to meet MOQs for discounts, or collaborate with other businesses to share costs.

Lastly, be mindful of pricing nuances specific to international transactions. Currency fluctuations, tariffs, and import duties can all affect the final cost. Engaging with local experts or consultants can provide insights into these factors, helping to mitigate unexpected expenses.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on supplier, region, and market conditions. Always conduct thorough research and consult with multiple suppliers to get the most accurate and competitive pricing.

Alternatives Analysis: Comparing custom leather clothing With Other Solutions

Exploring Alternatives to Custom Leather Clothing for B2B Buyers

When considering custom leather clothing, it is essential to evaluate alternative solutions that may meet similar needs while offering distinct advantages or disadvantages. This analysis will help B2B buyers, particularly those in diverse regions such as Africa, South America, the Middle East, and Europe, make informed decisions based on performance, cost, and other critical factors.

Illustrative image related to custom leather clothing

| Comparison Aspect | Custom Leather Clothing | Синтетическая кожа | Tailored Textile Apparel |

|---|---|---|---|

| Performance | High durability and longevity; resistant to wear and tear | Moderate durability; less resistant to extreme conditions | Varies; can be durable but generally less than leather |

| Cost | Generally higher due to quality materials and craftsmanship | Typically lower; cost-effective for bulk orders | Mid-range; varies based on fabric and design complexity |

| Ease of Implementation | Requires skilled artisans for production | Easier to mass-produce; less skill required | Can be tailored by various textile manufacturers |

| Maintenance | Requires special care to maintain appearance | Easy to clean; resistant to stains | Maintenance depends on the fabric; some require special care |

| Best Use Case | High-end fashion, costumes, and specialized apparel | Budget-friendly options for promotional items or everyday wear | Casual and formal wear where leather is not a necessity |

What are the Pros and Cons of Synthetic Leather as an Alternative?

Synthetic leather, often made from polyurethane or PVC, serves as a popular alternative to custom leather clothing. Its main advantage is cost-effectiveness; it is generally less expensive, making it a suitable option for businesses looking to produce promotional items or bulk orders without significant investment. Moreover, synthetic leather is easier to clean and maintain, providing practicality in everyday applications. However, it lacks the durability and luxurious feel of genuine leather, which may deter buyers seeking high-quality or bespoke items. Additionally, synthetic materials may not perform well under extreme conditions, limiting their use in specialized applications.

How Does Tailored Textile Apparel Compare?

Tailored textile apparel offers another alternative for B2B buyers. This option encompasses a range of materials, including cotton, polyester, and blends, which can be customized to meet specific design requirements. The primary advantage of tailored textile apparel is its versatility; it can cater to various market segments and styles, from formal wear to casual outfits. Additionally, the production process can be less labor-intensive compared to leather, allowing for quicker turnaround times. However, the durability of textile materials can vary significantly, often falling short of leather’s resilience, and they may require more frequent replacement. This could lead to higher long-term costs for businesses focusing on quality and longevity.

How Can B2B Buyers Choose the Right Solution for Their Needs?

In conclusion, choosing the right solution depends on the specific needs of the business. For companies prioritizing durability, luxury, and bespoke craftsmanship, custom leather clothing remains an unmatched choice. However, for those on a tighter budget or seeking practicality, synthetic leather or tailored textile apparel may provide adequate alternatives. B2B buyers should carefully assess their target market, the intended use of the clothing, and their budget constraints to select the most suitable option. Conducting thorough market research and considering customer preferences will further enhance decision-making, ensuring that the chosen apparel aligns with brand identity and operational goals.

Essential Technical Properties and Trade Terminology for custom leather clothing

What Are the Key Technical Properties of Custom Leather Clothing?

When engaging in the custom leather clothing market, understanding the technical properties is crucial for ensuring quality and longevity. Here are some essential specifications:

1. Material Grade

Material grade refers to the quality of leather used in production, which can range from full-grain to corrected grain. Full-grain leather, made from the top layer of animal hide, retains its natural imperfections and is known for its durability and breathability. On the other hand, corrected grain leather has been sanded and treated to remove imperfections, making it more uniform but less breathable. For B2B buyers, selecting the right material grade is vital for meeting customer expectations regarding quality and price.

2. Tolerance

Tolerance in leather manufacturing refers to the allowable variation in dimensions and characteristics of the finished product. For example, a tolerance of ±1mm in stitching can significantly affect the fit and finish of a custom garment. Understanding these tolerances helps buyers ensure that their specifications are met accurately, reducing the chances of returns and dissatisfaction.

3. Weight

The weight of leather is often measured in ounces per square foot, impacting the garment’s feel, durability, and intended use. Lighter weights (typically 1-2 oz) are suitable for soft garments like shirts, while heavier weights (4-6 oz) are better for jackets and heavy-duty apparel. Buyers must consider the end use of the clothing to select the appropriate weight that aligns with their brand and customer expectations.

4. Finish Type

The finish type refers to the surface treatment applied to the leather, which can affect its look and feel. Common finishes include aniline (natural finish) and pigmented (dyed and coated). Aniline finishes allow the natural beauty of the leather to shine through, while pigmented finishes provide a more uniform appearance and added protection against wear. Understanding the finish type is essential for buyers to communicate their design vision effectively.

5. Stitching Quality

The quality of stitching is a critical property that affects both aesthetics and durability. Factors such as stitch count, thread type, and stitching technique play a vital role in the garment’s longevity. High-quality stitching can prevent unraveling and improve the overall robustness of the clothing. For B2B buyers, specifying stitching quality is essential to ensure that the final product meets their durability standards.

What Are Common Trade Terms Related to Custom Leather Clothing?

Navigating the landscape of custom leather clothing requires familiarity with industry-specific terminology. Here are some common trade terms:

Illustrative image related to custom leather clothing

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the custom leather industry, this could mean that a buyer sources leather products made by a specific manufacturer under their brand name. Understanding OEM relationships can help buyers leverage existing expertise and resources.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For custom leather clothing, MOQs can vary significantly based on the supplier and the complexity of the garment. Knowing the MOQ is essential for buyers to plan their inventory and understand the financial implications of their orders.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for a specific quantity of goods or services. In the custom leather sector, submitting an RFQ allows buyers to compare prices, lead times, and terms from multiple suppliers, facilitating informed purchasing decisions.

Illustrative image related to custom leather clothing

4. Incoterms

Incoterms, or International Commercial Terms, are a series of pre-defined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers manage logistics and reduce risks associated with international shipping.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the finished product. In custom leather clothing, lead times can vary based on the complexity of the design and the supplier’s capacity. Understanding lead times is crucial for buyers to manage customer expectations and optimize their inventory planning.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that their custom leather clothing meets both quality standards and market demands.

Navigating Market Dynamics and Sourcing Trends in the custom leather clothing Sector

What Are the Current Market Dynamics and Key Trends in Custom Leather Clothing?

The custom leather clothing sector is experiencing a transformative period fueled by several global drivers. Increasing consumer demand for personalized and unique apparel is at the forefront, with buyers seeking distinctive designs that reflect their individuality. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where cultural diversity drives the need for tailored solutions. Additionally, the rise of e-commerce platforms has enabled international B2B buyers to access a broader range of suppliers, enhancing competition and driving innovation within the market.

Emerging technologies are reshaping the sourcing landscape, with advancements such as 3D printing and computer-aided design (CAD) allowing manufacturers to streamline production processes and reduce lead times. These technologies not only improve efficiency but also enhance the customization capabilities that buyers seek. Furthermore, the integration of AI-driven analytics in supply chain management is becoming more prevalent, enabling suppliers to better forecast trends and manage inventory effectively. As a result, B2B buyers can expect more agile responses to market demands.

International buyers must also be aware of regional market dynamics, such as fluctuating raw material prices and varying regulatory environments. For instance, in regions like Nigeria and Brazil, local sourcing challenges may arise due to infrastructural issues or political instability. Understanding these dynamics will empower B2B buyers to make informed decisions and establish resilient supply chains that can adapt to changing market conditions.

How Important Is Sustainability and Ethical Sourcing in the Custom Leather Clothing Sector?

The environmental impact of leather production has raised significant concerns, making sustainability and ethical sourcing critical considerations for B2B buyers in the custom leather clothing sector. As consumers increasingly prioritize eco-friendly products, businesses are compelled to adopt sustainable practices that minimize their carbon footprint. This includes sourcing leather from tanneries that employ environmentally friendly processes and use vegetable-based dyes instead of harmful chemicals.

Moreover, ethical supply chains are gaining traction as consumers become more aware of the social implications of their purchases. B2B buyers should look for suppliers that uphold fair labor practices and provide transparency throughout their supply chains. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) can serve as indicators of a supplier’s commitment to sustainability and ethical practices. By prioritizing these certifications, buyers not only align with global sustainability goals but also enhance their brand reputation, appealing to a broader customer base.

Investing in sustainable and ethically sourced custom leather clothing can yield long-term benefits, including improved customer loyalty and potentially higher margins. As buyers navigate the complexities of sourcing, understanding the importance of these principles will be essential in building a responsible and profitable business model.

How Has the Custom Leather Clothing Market Evolved Over Time?

The custom leather clothing market has a rich history that reflects broader shifts in consumer behavior and fashion trends. Traditionally, leather garments were crafted for functionality and durability, serving essential roles in protection and utility. Over time, as fashion evolved, so too did the perception of leather clothing, transitioning from purely utilitarian to a symbol of luxury and personal expression.

In recent decades, the rise of niche markets has allowed for a renaissance of custom leather clothing, with artisans and small manufacturers offering bespoke services that cater to individual tastes. This shift has paved the way for a diverse range of styles, from medieval and renaissance designs to contemporary fashion statements, appealing to various consumer segments. The evolution of technology has also played a significant role, enabling manufacturers to create intricate designs and high-quality products that were once labor-intensive and time-consuming.

Today, the custom leather clothing sector stands at the intersection of tradition and innovation, presenting exciting opportunities for international B2B buyers. Understanding this historical context enriches the sourcing process, allowing buyers to appreciate the craftsmanship and cultural significance behind each piece, ultimately enhancing their purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather clothing

-

How do I ensure quality when sourcing custom leather clothing?

To guarantee quality, begin by vetting potential suppliers thoroughly. Request samples to evaluate material, craftsmanship, and durability. Look for certifications that affirm their adherence to international quality standards. Engage in direct communication to discuss your specific requirements and gauge their responsiveness. Additionally, consider visiting their manufacturing facilities if feasible, or rely on third-party inspection services to conduct quality checks before shipment. -

What is the best way to customize leather clothing for my business needs?

The ideal customization process starts with clear communication of your design specifications. Collaborate closely with your supplier to define your desired styles, materials, colors, and any branding elements. Utilize mood boards or sketches to convey your vision. Inquire about the supplier’s capability to accommodate unique designs and whether they provide mock-ups or prototypes. Establish a feedback loop during the production phase to ensure that your requirements are met accurately. -

What should I consider when determining minimum order quantities (MOQ)?

When negotiating MOQs, consider your budget, storage capacity, and projected sales volume. Suppliers often set MOQs based on production efficiency, so understanding their capabilities is crucial. Discuss your needs openly to explore flexibility in order sizes, especially for initial orders. Additionally, evaluate if the supplier can accommodate smaller orders for testing market response before committing to larger quantities. -

What are common payment terms in B2B transactions for custom leather clothing?

Payment terms can vary significantly among suppliers, but common practices include a deposit upfront (typically 30-50%) with the balance due upon completion or before shipment. Some suppliers may offer favorable terms such as net 30 or net 60 days, allowing you to manage cash flow. Always clarify payment methods accepted, and consider using secure platforms for transactions to mitigate risks. -

How do I manage logistics and shipping for international orders of custom leather clothing?

Managing logistics involves coordinating with your supplier to understand their shipping capabilities and preferred carriers. Discuss incoterms (like FOB or CIF) to clarify responsibilities regarding shipping costs and risks. Consider using a freight forwarder who specializes in international shipping to streamline the process. Also, ensure that you account for customs regulations and duties in your target markets to avoid delays. -

What are the best practices for vetting suppliers of custom leather clothing?

Begin by researching potential suppliers through industry directories and trade shows. Check their online presence, reviews, and testimonials from other B2B buyers. Request references and inquire about their experience with similar products. Conduct interviews to assess their responsiveness and willingness to collaborate. If possible, visit their manufacturing facility to inspect their operations firsthand and establish a relationship. -

What should I know about lead times for custom leather clothing production?

Lead times can vary based on the complexity of the design and the supplier’s production capacity. Typically, you can expect a lead time ranging from 4 to 12 weeks. It’s essential to discuss timelines upfront and factor in additional time for revisions and shipping. Establishing a clear timeline with your supplier will help manage your inventory and ensure timely delivery to your customers. -

How can I ensure compliance with international trade regulations when importing leather clothing?

To ensure compliance, familiarize yourself with the import regulations of your country, including any tariffs, quotas, and safety standards applicable to leather goods. Work with a customs broker who can guide you through the necessary documentation and processes. Verify that your supplier adheres to ethical sourcing practices and environmental regulations, as compliance with these standards can affect your brand reputation and market access.

A Look at Custom Leather Clothing Manufacturers & Suppliers

We are currently compiling a detailed list of top custom leather clothing suppliers. Please check back later.

Strategic Sourcing Conclusion and Outlook for custom leather clothing

In navigating the landscape of custom leather clothing, strategic sourcing emerges as a pivotal approach for international B2B buyers. By prioritizing quality craftsmanship and material integrity, businesses can differentiate themselves in a competitive market. Sourcing from reputable suppliers ensures not only the longevity of products but also fosters customer loyalty through unique offerings tailored to specific cultural and regional preferences.

Buyers from diverse regions, including Africa, South America, the Middle East, and Europe, must leverage local insights to tailor their sourcing strategies. Understanding regional tastes and trends, such as the growing demand for sustainable materials or traditional craftsmanship, can enhance product appeal and market penetration.

As the custom leather clothing sector continues to evolve, embracing innovation—whether through design or sustainability—will be essential for long-term success. Now is the time for B2B buyers to capitalize on these trends, forging partnerships that emphasize quality and creativity. By taking a proactive approach to sourcing, you can position your business for future growth in this dynamic industry. Engage with suppliers who share your vision, and together, you can create custom leather pieces that resonate with your target market and stand the test of time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.