Introduction: Navigating the Global Market for swade material

In today’s competitive marketplace, sourcing high-quality swade material presents a significant challenge for international B2B buyers. Whether you’re in the fashion industry seeking luxurious suede for garments, or in automotive manufacturing looking for durable upholstery, understanding the nuances of swade material is crucial for making informed purchasing decisions. This guide will explore the diverse types of swade, its applications across various industries, and essential factors to consider when vetting suppliers. Additionally, we will address cost considerations and the sourcing strategies most effective for buyers in regions such as Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Vietnam.

The global swade market is characterized by its rich variety and unique properties, making it a sought-after material in both high-end fashion and practical applications. By delving into the intricacies of swade, this guide empowers buyers to navigate the complexities of sourcing, ensuring they can identify quality products that meet their specific needs. From understanding the manufacturing processes to evaluating the reliability of suppliers, you will gain actionable insights that enhance your procurement strategy. Ultimately, this comprehensive resource aims to equip you with the knowledge necessary to confidently invest in swade material, fostering successful partnerships that drive your business forward.

Table Of Contents

- Top 6 Swade Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for swade material

- Understanding swade material Types and Variations

- Key Industrial Applications of swade material

- 3 Common User Pain Points for ‘swade material’ & Their Solutions

- Strategic Material Selection Guide for swade material

- In-depth Look: Manufacturing Processes and Quality Assurance for swade material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘swade material’

- Comprehensive Cost and Pricing Analysis for swade material Sourcing

- Alternatives Analysis: Comparing swade material With Other Solutions

- Essential Technical Properties and Trade Terminology for swade material

- Navigating Market Dynamics and Sourcing Trends in the swade material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of swade material

- Strategic Sourcing Conclusion and Outlook for swade material

- Important Disclaimer & Terms of Use

Understanding swade material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Suede | Soft texture from the underside of animal hides; typically lamb or goat. | Apparel (jackets, shoes), accessories (bags, gloves) | Pros: Luxurious feel, high-end appeal. Cons: Less durable, prone to staining. |

| Synthetic Suede | Made from polyester or other synthetic fibers; mimics the look of genuine suede. | Fashion apparel, upholstery, automotive interiors | Pros: More durable, often machine washable. Cons: May lack the authentic feel and breathability of genuine suede. |

| Замша из микрофибры | Ultra-fine synthetic fibers; soft, lightweight, and highly versatile. | Furniture, clothing, cleaning products | Pros: Stain-resistant, easy to clean. Cons: Can be less breathable than natural suede. |

| Nappa Suede | Luxurious finish, often produced from lambskin; very soft and flexible. | High-end fashion, luxury goods | Pros: Exceptional softness, ideal for upscale products. Cons: Higher cost, requires careful maintenance. |

| Stretch Suede | Contains elastane or spandex for added flexibility; retains suede’s texture. | Activewear, fitted clothing | Pros: Comfortable fit, retains shape. Cons: Limited use in formal applications due to its casual nature. |

What Are the Characteristics of Genuine Suede?

Genuine suede is derived from the inner layer of animal hides, primarily lamb or goat. Its soft, luxurious texture makes it a popular choice for high-end apparel and accessories. While it offers a premium feel, buyers should consider its lower durability and higher maintenance needs, as it is prone to staining and requires professional cleaning. For B2B buyers, sourcing genuine suede often involves assessing the quality of tanning and finishing processes, as these factors significantly influence the final product’s appearance and longevity.

How Does Synthetic Suede Compare to Genuine Suede?

Synthetic suede, made from polyester or similar materials, provides an alternative that mimics the appearance of genuine suede while offering increased durability and ease of care. This type is widely used in fashion apparel and upholstery, making it a practical choice for businesses seeking cost-effective solutions. However, while synthetic suede can be machine-washed and is often more resistant to stains, it may not deliver the same luxurious feel as natural suede. B2B buyers should weigh the benefits of cost and maintenance against the need for authenticity in their product offerings.

What Makes Microfiber Suede a Versatile Option?

Microfiber suede is composed of ultra-fine synthetic fibers, delivering a soft touch and versatility across various applications, including furniture and clothing. Its stain-resistant properties and ease of cleaning make it particularly appealing for businesses in the home furnishings sector. While microfiber suede is less breathable than its natural counterparts, its durability and lower maintenance requirements can justify its use in high-traffic environments. B2B buyers should consider the target market’s preferences for feel and durability when choosing microfiber suede.

Why Is Nappa Suede Considered a Luxury Material?

Nappa suede, known for its exceptional softness and luxurious finish, is typically produced from high-quality lambskin. This type is favored in high-end fashion and luxury goods, making it a sought-after option for brands aiming to convey exclusivity. However, the higher cost and the need for careful maintenance can be drawbacks for some buyers. When sourcing Nappa suede, B2B businesses should focus on the quality of the material and the reputation of the supplier to ensure the best value for their investment.

What Are the Advantages of Stretch Suede?

Stretch suede incorporates elastane or spandex, providing added flexibility and comfort, making it ideal for activewear and fitted clothing. This type retains the classic suede texture while offering a modern twist, appealing to contemporary fashion trends. However, its casual nature may limit its use in more formal applications. B2B buyers should consider the target demographic and application when selecting stretch suede, ensuring it aligns with current market demands for both style and functionality.

Key Industrial Applications of swade material

| Industry/Sector | Specific Application of swade material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-end jackets and outerwear | Offers a luxurious feel and aesthetic appeal to consumers | Ensure quality and sourcing transparency; consider local regulations and sustainability practices. |

| Footwear | Dress shoes and boots | Enhances product value through comfort and style | Evaluate durability and maintenance requirements; check for water-resistant finishes. |

| Автомобили | Seat covers and interior linings | Provides a premium touch and comfort in vehicle interiors | Assess compatibility with existing materials; consider the ease of cleaning and maintenance. |

| Accessories | Handbags and belts | Appeals to luxury markets, boosting brand prestige | Focus on color variety and texture quality; ensure ethical sourcing practices are in place. |

| Home Decor | Upholstery and soft furnishings | Adds sophistication and warmth to living spaces | Look for fire-retardant treatments and stain resistance; verify compliance with safety standards. |

How is Suede Material Used in the Fashion and Apparel Industry?

Suede material plays a significant role in the fashion industry, particularly in high-end jackets and outerwear. Its soft texture and luxurious appearance make it a preferred choice for designers aiming to create stylish garments. International buyers need to ensure that the suede sourced meets quality standards and is compliant with local regulations regarding animal welfare. Transparency in sourcing and sustainability practices is also crucial, particularly for markets in Europe and North America, where consumer awareness is high.

What are the Applications of Suede in Footwear?

In the footwear sector, suede is commonly used in the production of dress shoes and boots, enhancing both comfort and style. Its unique texture provides a sophisticated look, appealing to fashion-conscious consumers. Buyers should consider the durability of suede, especially in humid climates found in parts of Africa and South America, where moisture can affect the material’s longevity. Additionally, evaluating maintenance requirements, such as the need for water-resistant treatments, is essential for ensuring product quality.

How is Suede Material Utilized in the Automotive Industry?

The automotive industry utilizes suede for seat covers and interior linings, offering a premium feel that enhances the overall driving experience. Its soft touch and aesthetic appeal can elevate a vehicle’s luxury status, making it attractive to high-end brands. Buyers should assess the compatibility of suede with existing automotive materials and consider ease of cleaning, especially in regions with varied climates. Understanding the durability of suede in automotive applications is crucial for ensuring customer satisfaction.

What Role Does Suede Play in Luxury Accessories?

Suede is widely used in the production of luxury handbags and belts, where its rich texture and appearance can significantly boost brand prestige. These products often target affluent consumers looking for high-quality, stylish accessories. B2B buyers should focus on the variety of colors and textures available, as well as ethical sourcing practices to meet the expectations of socially conscious consumers. Ensuring that the material is durable enough for everyday use while maintaining its luxury appeal is key.

How is Suede Material Applied in Home Decor?

In home decor, suede is utilized for upholstery and soft furnishings, adding warmth and sophistication to living spaces. Its unique texture can transform ordinary furniture into focal points of elegance. Buyers in this sector should look for suede that is treated for fire resistance and stain resistance, particularly in regions with strict safety regulations. Compliance with safety standards and the material’s ability to withstand wear and tear are crucial considerations for ensuring customer satisfaction and product longevity.

3 Common User Pain Points for ‘swade material’ & Their Solutions

Scenario 1: Sourcing Quality Suede Material for High-End Products

The Problem: B2B buyers, especially those in the fashion and luxury goods sectors, often struggle to find high-quality suede materials that meet their brand’s standards. The challenge lies not only in the sourcing process but also in ensuring the material’s consistency in texture, color, and durability. Many suppliers may provide samples that look appealing, but the final products may not align with the luxury experience expected by end consumers. This inconsistency can tarnish a brand’s reputation and lead to costly returns or customer dissatisfaction.

The Solution: To overcome these sourcing challenges, buyers should establish robust relationships with reputable suppliers who specialize in high-quality suede. Conducting factory visits or audits can help assess the production processes and quality controls in place. Additionally, buyers should request detailed specifications for the suede, including its thickness, finishing processes, and dyeing methods. Utilizing a standardized quality checklist during the sampling phase can ensure that the suede meets expectations. Engaging in long-term partnerships with suppliers can also facilitate better pricing and priority access to new materials, ensuring the buyer’s product line remains competitive and high-quality.

Scenario 2: Maintaining Suede Products to Ensure Longevity

The Problem: Another common pain point for B2B buyers is the maintenance and care of suede products. Suede is known for its luxurious feel, but it also requires specific care to prevent staining and damage. Buyers often find themselves fielding complaints about products that have worn poorly or developed unsightly marks, leading to a negative impact on customer satisfaction and brand loyalty. This issue is particularly pertinent for businesses that offer suede items such as shoes, bags, or outerwear, where the customer’s experience directly correlates to the product’s upkeep.

The Solution: To address this maintenance challenge, B2B buyers should invest in providing comprehensive care guidelines to their customers. This could include instructional materials on proper cleaning techniques and recommended protective sprays to repel water and stains. Additionally, offering a line of suede care products, such as brushes and cleaning kits, can not only enhance the customer experience but also create an additional revenue stream. Furthermore, training sales staff to educate customers about the care of suede can reduce future complaints and returns, fostering a more informed consumer base that appreciates the material’s unique qualities.

Scenario 3: Balancing Cost and Quality When Choosing Suede Alternatives

The Problem: With the rise of synthetic materials and alternatives to traditional suede, B2B buyers face the dilemma of balancing cost and quality. While synthetic options may offer better durability and easier maintenance, they often lack the luxurious appeal of genuine suede. Buyers may find themselves caught between the desire to provide high-quality products and the necessity of maintaining profitability. This conflict can lead to indecision about product lines and missed market opportunities.

The Solution: To navigate this dilemma, buyers should conduct a thorough market analysis to understand consumer preferences and trends in material usage. Engaging in focus groups or surveys can provide insights into what customers value most—be it sustainability, luxury, or affordability. Buyers can also consider a hybrid approach by offering a range of products that includes both genuine suede and high-quality synthetic alternatives. This strategy allows businesses to cater to different customer segments while maintaining brand integrity. Additionally, educating consumers about the benefits of each material can help them make informed choices, fostering a connection between the brand and its customers.

Strategic Material Selection Guide for swade material

What Are the Key Properties of Suede Material?

Suede is primarily derived from the underside of animal hides, most commonly lamb, goat, or calf. This unique sourcing gives suede its characteristic softness and napped texture, which is appealing for various high-end applications. However, suede’s properties also include low breathability and moisture-wicking abilities, making it less suitable for environments with high humidity or exposure to water.

What Are the Pros and Cons of Different Types of Suede?

-

Natural Suede

– Key Properties: Natural suede is known for its luxurious feel and aesthetic appeal. It typically offers moderate heat retention, making it suitable for cooler climates.

– Pros: High-quality appearance, softness, and suitability for fashion items such as jackets, shoes, and handbags.

– Cons: Prone to staining and water damage, requiring professional cleaning. It also has a higher cost due to the sourcing and tanning processes involved.

– Impact on Application: Best suited for indoor and luxury applications where exposure to the elements is minimal.

– Considerations for Buyers: Compliance with international standards such as ASTM for leather goods is essential. Buyers should also consider local preferences for color and texture, which can vary by region. -

Synthetic Suede (e.g., Ultrasuede)

– Key Properties: Made from polyester or nylon, synthetic suede mimics the look and feel of natural suede while offering enhanced durability and water resistance.

– Pros: More affordable than natural suede, easier to clean, and resistant to stains and moisture.

– Cons: Lacks the luxurious feel of genuine suede, and the environmental impact of synthetic materials can be a concern.

– Impact on Application: Suitable for a wider range of applications, including automotive interiors and fashion items, where durability is a priority.

– Considerations for Buyers: Buyers in regions with strict environmental regulations may prefer synthetic options due to their lower ecological footprint. -

Recycled Suede

– Key Properties: This material is made from repurposed suede scraps, offering a sustainable alternative to new suede.

– Pros: Environmentally friendly, often available at a lower cost, and retains the softness and aesthetic qualities of natural suede.

– Cons: Variability in quality and color consistency, which can affect product uniformity.

– Impact on Application: Ideal for eco-conscious brands looking to reduce waste while maintaining quality.

– Considerations for Buyers: International buyers should ensure that recycled suede meets their quality standards and compliance with regulations in their respective markets.

Summary Table of Suede Material Options

| Материал | Typical Use Case for swade material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Suede | High-end fashion items | Luxurious feel and appearance | Prone to staining and water damage | Высокий |

| Synthetic Suede | Automotive interiors, fashion items | Durable and water-resistant | Lacks the luxurious feel of genuine suede | Medium |

| Recycled Suede | Eco-friendly fashion accessories | Environmentally sustainable | Variability in quality and consistency | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to navigate the complexities of suede material. Understanding the properties, advantages, and limitations of each type will enable informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for swade material

What Are the Main Stages in the Manufacturing Process of Swade Material?

The manufacturing of swade material, a luxurious and versatile fabric, involves several critical stages that ensure its quality and functionality. Understanding these stages is essential for B2B buyers looking to source high-quality swade for various applications.

Material Preparation: How Are Raw Materials Processed for Swade?

The first step in the manufacturing process is the preparation of raw materials. Swade is typically made from the underside of animal hides, with lambskin being the most common source. The process begins with the procurement of high-quality hides, which are then cleaned and treated to remove any impurities.

Once cleaned, the hides undergo a tanning process using natural or synthetic tannins. This step is crucial as it transforms raw hides into leather, rendering them durable and less prone to decomposition. After tanning, hides are dried and may be split to achieve the desired thickness for swade.

Forming: What Techniques Are Used to Shape Swade?

Following material preparation, the forming stage involves creating the distinctive texture and appearance of swade. This is achieved through a specialized texturing process that involves buffing the inner side of the leather, resulting in the soft, napped surface characteristic of swade.

Manufacturers may also apply various finishing techniques, such as sanding and dyeing, to enhance the aesthetic appeal of the material. The dyeing process is particularly important as it allows manufacturers to offer swade in a wide array of colors, appealing to diverse market preferences.

Assembly: How Are Swade Products Constructed?

The assembly of swade products typically occurs after the material has been finished and cut into specific shapes. This stage involves sewing or bonding the swade pieces together to create the final product, whether it be apparel, accessories, or upholstery. High-quality stitching techniques are critical here to ensure durability and maintain the soft texture of the swade.

In some cases, manufacturers may incorporate additional materials, such as linings or reinforcements, to enhance the product’s functionality. For example, in the production of swade shoes, a sturdy sole is often attached to provide support and durability.

Finishing: What Final Touches Are Added to Swade Products?

The finishing stage is the last step in the production process, where swade products undergo final inspections and treatments. This may include applying a protective coating to enhance water resistance, although it’s important to note that swade is generally not waterproof.

Quality finishing techniques, such as edge painting and polishing, are also applied to ensure that the products meet the aesthetic standards expected in the market. Finally, products are packaged appropriately for shipping to maintain their quality during transit.

What Quality Assurance Standards Are Relevant for Swade Material?

For B2B buyers, understanding the quality assurance processes in place for swade materials is paramount. Various international standards and industry-specific certifications guide manufacturers in maintaining high-quality production practices.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is one of the most recognized quality management standards globally. It outlines the requirements for a quality management system (QMS) that organizations must adhere to in order to ensure consistent quality in their products and services. Manufacturers of swade material can achieve ISO 9001 certification by demonstrating their commitment to quality processes, which can provide B2B buyers with assurance regarding the reliability of their suppliers.

In addition to ISO 9001, other certifications such as CE marking (for products sold in the European Economic Area) and industry-specific standards (like the American Petroleum Institute (API) standards for oil and gas applications) may also be relevant depending on the end-use of the swade material.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are essential throughout the manufacturing process to ensure that swade meets established standards. The typical QC process includes:

-

Incoming Quality Control (IQC): This initial inspection occurs when raw materials, such as hides, arrive at the manufacturing facility. Inspectors check for defects, consistency, and compliance with specifications.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to monitor the production process. This includes verifying that tanning, texturing, and dyeing processes meet quality standards.

-

Final Quality Control (FQC): Once products are completed, a final inspection is carried out to assess the overall quality, appearance, and functionality of the swade items before they are packaged and shipped.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must be proactive in verifying the quality assurance processes of their suppliers to mitigate risks associated with sourcing swade material. Here are several strategies to ensure supplier credibility:

-

Conduct Audits: Regular audits of suppliers can provide firsthand insights into their manufacturing processes and quality control systems. This can include both announced and unannounced visits to assess compliance with quality standards.

-

Request Quality Reports: Buyers should ask for detailed quality reports from suppliers, including testing results and compliance with international standards. This documentation can provide transparency regarding the quality of materials used and the efficacy of the QC processes.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased evaluation of the manufacturing processes and final products. These inspectors can perform checks at various stages of production, ensuring that the materials meet specified quality standards.

What Nuances Should International B2B Buyers Consider Regarding QC?

International B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality control practices. Cultural differences, varying standards, and logistical challenges can affect the sourcing process.

-

Cultural Sensitivity: Understanding the local business culture and practices is essential when dealing with suppliers from different regions. Building strong relationships and clear communication can significantly enhance the quality of the sourcing experience.

-

Regulatory Compliance: Different countries may have unique regulatory requirements that affect the importation of swade materials. Buyers should familiarize themselves with these regulations to avoid potential legal issues.

-

Logistics and Shipping: The transportation of swade products requires careful handling to prevent damage. Buyers should work closely with suppliers to establish robust logistics solutions that ensure timely and safe delivery of products.

By understanding these aspects of manufacturing processes and quality assurance for swade material, B2B buyers can make informed decisions that align with their quality expectations and market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘swade material’

This guide aims to assist B2B buyers in effectively sourcing suede material for their businesses. Whether you’re in the fashion, automotive, or upholstery industries, following this checklist will ensure you make informed decisions that align with your quality standards and business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical specifications for the suede material. This includes details such as the type of animal skin (e.g., lamb, goat), thickness, finish, and color preferences. Having precise requirements helps streamline the sourcing process and ensures that potential suppliers can meet your needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of suede material. Focus on manufacturers with a strong track record in your target markets—Africa, South America, the Middle East, and Europe. Utilize industry directories, trade shows, and online platforms to gather a list of potential partners.

- Check Reviews and Ratings: Look for feedback from previous customers to gauge reliability and product quality.

- Explore Supplier Websites: Investigate their product offerings, company background, and certifications.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that your selected suppliers have the necessary certifications. This includes quality management (ISO 9001) and environmental compliance certifications. Certified suppliers are more likely to adhere to industry standards, ensuring that you receive a high-quality product.

- Request Documentation: Ask suppliers to provide copies of their certifications for your records.

- Assess Sustainability Practices: Consider suppliers that implement sustainable sourcing and tanning processes, which can add value to your brand.

Step 4: Request Sample Materials

Once you’ve narrowed down your supplier options, request samples of the suede material. This step allows you to assess the texture, color, and overall quality firsthand. Evaluate how well the samples meet your specifications and whether they align with your brand’s standards.

- Conduct Stress Tests: If applicable, perform tests to evaluate durability and performance, particularly if the suede will be used in high-wear applications.

- Check for Color Consistency: Ensure that the color matches your expectations and that there are no significant variations between samples.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your chosen suppliers to establish favorable pricing and terms. Be transparent about your budget and expected order volumes. Effective negotiation can lead to better pricing, payment terms, and shipping arrangements.

- Discuss Minimum Order Quantities (MOQs): Understand the MOQ to ensure it aligns with your purchasing needs.

- Inquire About Bulk Discounts: Ask if there are price reductions for larger orders, which can significantly impact your bottom line.

Step 6: Finalize Logistics and Delivery

Once terms are agreed upon, confirm the logistics of your order. Clarify shipping methods, delivery timelines, and any additional costs associated with transportation. Efficient logistics are crucial to ensure timely delivery, especially if your production schedule is tight.

- Determine Shipping Preferences: Decide whether you prefer air freight for faster delivery or sea freight for cost savings.

- Establish Communication Channels: Maintain open lines of communication with your supplier throughout the shipping process to address any issues promptly.

Step 7: Review and Establish Long-Term Partnerships

After your initial order is fulfilled, take the time to review the supplier’s performance. Consider factors such as product quality, responsiveness, and reliability. Establishing a strong relationship with your supplier can lead to more favorable terms and priority service in future orders.

- Schedule Regular Check-ins: Maintain communication to discuss any changes in your needs or product specifications.

- Consider Future Collaborations: Explore opportunities for joint ventures or exclusive agreements to enhance your sourcing strategy.

Comprehensive Cost and Pricing Analysis for swade material Sourcing

What Are the Key Cost Components in Swade Material Sourcing?

When sourcing swade material, a comprehensive understanding of the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The base cost of swade, which can vary significantly based on the type of animal skin used (e.g., lamb, calf, or synthetic alternatives). High-quality, premium-grade swade will naturally incur higher costs.

-

Labor: This encompasses the costs associated with skilled artisans required for tanning, finishing, and quality control. Labor costs can vary by region, with countries like China offering lower labor rates compared to European manufacturers.

-

Manufacturing Overhead: This includes costs related to the facility, utilities, and administrative expenses that are indirectly tied to production. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom molds and machinery specific to swade processing can add to the initial setup costs. Buyers should inquire about these costs if they require specialized designs or unique textures.

-

Quality Control (QC): Ensuring the finished product meets specified standards is essential, especially for high-end applications. QC processes can add to the overall cost but are necessary for maintaining product integrity.

-

Logistics: Transportation costs are influenced by distance, mode of transport, and shipping terms. International buyers need to consider these factors in their overall pricing strategy.

-

Margin: Suppliers will typically include a profit margin that can vary based on market conditions, competition, and the supplier’s pricing strategy.

How Do Price Influencers Impact Swade Material Costs?

Several factors can influence the pricing of swade material:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs. Buyers should assess their needs and negotiate favorable terms based on expected volumes.

-

Specifications and Customization: Customized swade products can lead to increased costs due to additional labor and materials. Clearly defining specifications upfront can help manage costs.

-

Material Quality and Certifications: High-quality swade or those with specific certifications (e.g., eco-friendly tanning processes) may command higher prices. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge more, but they often provide better assurance of product consistency.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. These terms dictate who is responsible for shipping costs, insurance, and tariffs, all of which can affect the total cost.

What Are the Best Buyer Tips for Negotiating Swade Material Prices?

To ensure cost-efficiency in swade material sourcing, consider the following strategies:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, especially for larger orders. Leverage market research to understand typical pricing structures and use this information in discussions.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs associated with maintenance, durability, and potential wastage. This holistic view can guide more informed sourcing decisions.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import tariffs, and other costs that may apply when sourcing from different countries. This is particularly relevant for buyers in Africa, South America, the Middle East, and Europe, where such factors can significantly affect overall expenses.

-

Build Long-term Relationships: Establishing a strong relationship with suppliers can lead to better pricing and priority service over time. Long-term partnerships often yield better negotiation leverage and more favorable terms.

-

Request Samples: Before committing to a large order, request samples to evaluate quality. This can prevent costly mistakes and ensure that the product meets your expectations.

Заключение

Understanding the cost components and pricing influencers of swade material is essential for B2B buyers. By employing strategic negotiation tactics and considering the total cost of ownership, buyers can make informed decisions that optimize their sourcing strategies while ensuring quality and value. Always remember to account for regional nuances and supplier dynamics to achieve the best possible outcomes in your procurement efforts.

Alternatives Analysis: Comparing swade material With Other Solutions

Exploring Alternatives: A Comprehensive Comparison for B2B Buyers

In the competitive landscape of materials used for fashion and upholstery, ‘swade material’ stands out for its luxurious feel and aesthetic appeal. However, understanding viable alternatives is essential for B2B buyers aiming to make informed decisions. This comparison will analyze ‘swade material’ against two popular alternatives: synthetic suede and genuine leather.

Comparison Table

| Comparison Aspect | Swade Material | Synthetic Suede | Genuine Leather |

|---|---|---|---|

| Performance | Soft, luxurious feel; less durable; prone to staining | Good durability; water-resistant; maintains appearance well | Highly durable; excellent resistance to wear and tear |

| Cost | Moderate to high | Generally lower | Higher due to sourcing and processing costs |

| Ease of Implementation | Requires specific care; professional cleaning recommended | Easy to clean; machine washable | Requires conditioning and care; professional cleaning recommended |

| Maintenance | High; prone to staining; needs regular upkeep | Low; resistant to stains; easy maintenance | Moderate; requires regular conditioning and cleaning |

| Best Use Case | High-end fashion items; indoor applications | Everyday items; versatile applications | Long-lasting products; heavy-duty applications |

What Are the Advantages and Disadvantages of Synthetic Suede?

Synthetic suede, often made from polyester or polyurethane, offers a compelling alternative to traditional swade material. Its primary advantage is durability; it is resistant to water and stains, making it suitable for various applications, including upholstery and fashion. Additionally, synthetic suede is typically more affordable, appealing to budget-conscious buyers. However, it may lack the luxurious feel and breathability of natural swade, making it less desirable for high-end fashion items.

How Does Genuine Leather Compare to Swade Material?

Genuine leather is another alternative that offers significant advantages over swade material. Known for its durability, genuine leather can withstand wear and tear, making it ideal for long-lasting products like bags and shoes. It also develops a unique patina over time, enhancing its aesthetic appeal. However, genuine leather often comes at a higher price point and requires regular maintenance to keep it in good condition. Unlike swade, it is less prone to staining, but it does require professional cleaning and conditioning.

Conclusion: Making the Right Choice for Your Business Needs

When selecting the right material for your business, it’s crucial to assess your specific needs and target market. If luxury and softness are paramount, swade material could be the ideal choice, particularly for high-end fashion items. For versatile, everyday applications, synthetic suede may provide the best balance of cost and durability. Conversely, genuine leather remains a strong option for buyers seeking long-lasting products with a classic appeal. By weighing the pros and cons of each alternative, B2B buyers can make informed decisions that align with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for swade material

What Are the Key Technical Properties of Swade Material?

When sourcing swade material, understanding its technical properties is essential for ensuring quality and suitability for specific applications. Here are the critical specifications to consider:

1. Material Grade

Material grade refers to the quality of the swade, which can vary based on the source animal hide, processing methods, and treatments applied. Higher grades, often derived from lamb or calf skin, offer superior softness and durability, making them ideal for luxury applications like high-end apparel and accessories. For B2B buyers, selecting the right material grade is crucial to meeting customer expectations and maintaining brand reputation.

2. Thickness

Thickness is a vital specification that impacts the texture, weight, and overall usability of swade. Standard thicknesses range from 0.6 mm to 1.2 mm, with thinner swade being more flexible and softer, while thicker swade provides added durability. Buyers must consider the intended application—thinner swade may be preferable for garments, while thicker varieties may be better suited for footwear or upholstery.

3. Tolerance

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing process. For swade, maintaining tight tolerances ensures consistent quality and fit in final products. Buyers should verify manufacturers’ tolerance levels to avoid complications during production and ensure seamless integration into their supply chains.

4. Finish Type

The finish type of swade can significantly influence its appearance and performance. Common finishes include brushed, embossed, or coated options, each offering different aesthetic and functional properties. A well-defined finish can enhance the material’s resistance to stains and wear, making it crucial for buyers to specify their finish requirements to align with end-use demands.

5. Water Resistance

Although swade is known for its luxurious feel, it is inherently more susceptible to moisture compared to other leathers. Some manufacturers offer treated swade with water-resistant properties, which can extend the material’s life and usability in various applications. Buyers should assess the environmental conditions their products will face and consider investing in water-resistant options for enhanced durability.

What Are Common Trade Terms Related to Swade Material?

Familiarity with industry jargon is essential for effective communication and negotiation in the swade market. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of swade, OEMs often supply raw materials to brands that incorporate these materials into their finished products. Understanding OEM relationships can help buyers negotiate better pricing and quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For swade material, MOQs can vary significantly based on the supplier and product specifications. Buyers must be aware of MOQs to effectively manage inventory and ensure that production runs meet demand without excess costs.

3. RFQ (Request for Quotation)

An RFQ is a formal process through which buyers solicit price quotes from suppliers for specific products or services. When purchasing swade, issuing an RFQ allows buyers to compare prices, terms, and quality among different suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which is particularly important for B2B transactions involving swade material across different regions. Understanding Incoterms helps buyers avoid unexpected costs and logistical issues.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. For swade materials, lead times can vary based on production capacity and shipping methods. Buyers should account for lead times in their supply chain planning to ensure timely delivery and avoid disruptions in production.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing swade material, ultimately enhancing their product offerings and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the swade material Sector

What Are the Current Market Dynamics and Key Trends in the Swade Material Sector?

The global swade material market is experiencing notable shifts driven by evolving consumer preferences, technological advancements, and economic factors. A key trend is the increasing demand for luxury and premium materials, particularly from markets in Africa, South America, the Middle East, and Europe. As urbanization and disposable incomes rise, buyers are seeking high-quality swade for fashion items, accessories, and home decor. Additionally, e-commerce platforms are becoming increasingly significant in sourcing swade materials, allowing international buyers to access a broader range of suppliers and products.

Emerging technologies, such as artificial intelligence and blockchain, are also influencing sourcing strategies. AI can help buyers analyze market trends and consumer behavior, while blockchain enhances transparency and traceability in the supply chain. Furthermore, the trend towards customization and personalization is prompting suppliers to offer unique colors, textures, and finishes, catering to specific market demands.

In terms of market dynamics, China remains the largest producer of swade materials, followed by countries in Europe and North America. However, as the market expands, buyers should consider diversifying their sourcing locations to mitigate risks associated with geopolitical tensions and supply chain disruptions.

How Is Sustainability and Ethical Sourcing Impacting the Swade Material Sector?

Sustainability is increasingly becoming a focal point for B2B buyers in the swade material sector. The environmental impact of traditional swade production—particularly the use of animal hides and the tanning process—has prompted a shift towards more sustainable practices. Ethical sourcing is crucial, as consumers are becoming more aware of the origins of the materials they purchase. This trend is particularly relevant in regions such as Europe and North America, where regulations and consumer expectations regarding sustainability are stringent.

Buyers are encouraged to prioritize suppliers that utilize eco-friendly tanning processes and sustainable practices in their operations. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) can serve as benchmarks for ethical sourcing. Additionally, the rise of synthetic swade alternatives offers a more sustainable option, as these materials can be produced with a lower environmental footprint while still providing the desired aesthetics and functionality.

Investing in ethically sourced swade materials not only meets consumer demands but also enhances brand reputation and loyalty. By aligning with sustainable practices, B2B buyers can differentiate themselves in a competitive market, ultimately driving long-term growth.

How Has the Swade Material Sector Evolved Over Time?

The evolution of the swade material sector can be traced back to its origins in Sweden, where artisans first recognized the potential of using the softer underside of animal hides for creating luxurious gloves. Over time, the versatility of swade was discovered, leading to its application in a variety of products, including jackets, shoes, and handbags.

As fashion trends evolved, so did the production processes and sources of swade. Today, while traditional methods still hold value, advancements in technology and material science have led to the development of synthetic alternatives that mimic the qualities of natural swade. This evolution reflects a broader trend in the textile industry towards innovation and sustainability, ensuring that the swade material sector continues to thrive in a modern, environmentally conscious marketplace.

Understanding these dynamics is essential for international B2B buyers looking to navigate the complexities of sourcing swade materials effectively. By recognizing the historical context and current trends, businesses can position themselves strategically to capitalize on market opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of swade material

-

How do I ensure the quality of suede material before purchasing?

To ensure the quality of suede material, request samples from suppliers to evaluate texture, color consistency, and finish. Additionally, inquire about the tanning process and materials used, as these factors significantly affect durability and appearance. Collaborate with suppliers who provide certifications or quality assurance documentation. Establish a clear quality control process that includes inspections upon delivery to confirm that the received goods meet your specifications. -

What is the best type of suede for high-end fashion applications?

For high-end fashion applications, Italian suede is often regarded as the best option due to its superior softness and luxurious feel. It is typically tanned with premium aniline dyes that penetrate deeply, offering vibrant colors and a refined finish. When sourcing, consider suede made from lambskin, as it is lighter and softer than cowhide, making it ideal for garments, bags, and shoes designed for upscale markets. -

What are the key considerations when sourcing suede material internationally?

When sourcing suede material internationally, consider factors such as supplier reliability, production capabilities, and compliance with international quality standards. It’s essential to verify the supplier’s reputation through reviews and testimonials. Additionally, understand the logistics involved, including shipping times and costs, customs regulations, and potential tariffs. Establish clear communication channels to address any issues promptly. -

What are typical minimum order quantities (MOQs) for suede material?

Minimum order quantities (MOQs) for suede material can vary significantly based on the supplier and the specific type of suede. Typically, MOQs range from 50 to 100 yards for custom colors or finishes. It’s advisable to discuss your specific needs with potential suppliers and negotiate MOQs, especially if you are a smaller business or just starting. Some suppliers may offer lower MOQs for specific items or promotional orders. -

What payment terms should I expect when sourcing suede material?

Payment terms when sourcing suede material can vary widely among suppliers. Common practices include a 30% deposit upfront with the remaining balance due upon delivery or a net 30 to net 60 days payment after receipt of goods. Always clarify payment methods accepted, such as wire transfers, letters of credit, or payment through platforms like PayPal. It’s beneficial to establish a mutually agreeable payment schedule to ensure a smooth transaction process. -

How can I customize suede material to meet my specific requirements?

Customization options for suede material often include selecting specific colors, finishes, and textures. When working with suppliers, provide detailed specifications and, if possible, samples of desired materials for reference. Discuss dyeing options, embossing, or other treatments that can enhance the suede’s look and feel. Many suppliers also offer bespoke services, so don’t hesitate to ask about their capabilities in producing unique designs tailored to your brand. -

What quality assurance measures should I implement when working with suede suppliers?

Implementing quality assurance measures involves establishing clear specifications, conducting regular inspections, and maintaining open communication with suppliers. Develop a checklist that includes criteria such as color accuracy, texture consistency, and overall finish. Consider conducting pre-shipment inspections or using third-party quality control services to verify that the materials meet your standards before they are dispatched. This proactive approach minimizes risks and ensures product satisfaction. -

What logistics considerations should I keep in mind when importing suede material?

When importing suede material, logistics considerations include shipping methods, transit times, and customs clearance processes. Choose a reliable freight forwarder familiar with textile imports to navigate any regulatory requirements. Be aware of potential delays at customs and plan for them in your supply chain timeline. Additionally, consider the implications of shipping costs on your overall budget and negotiate with suppliers to determine the best shipping arrangements that align with your delivery needs.

Top 6 Swade Material Manufacturers & Suppliers List

1. Leather Hide Store – Premium Suede Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Введение: Suede leather offered in a variety of colors and sizes. Tanned with premium aniline dyes that penetrate through the entire leather. Each piece is finished through a fine sanding process for an even surface and velvety touch. Suede is single-sided, with only the top side fully buffed and polished. Ideal for applications like shoes, handbags, luggage, and furniture. Care instructions include using a…

2. The Fabric Outlet – Doro Suede

Domain: thefabricoutlet.com

Registered: 2000 (25 years)

Введение: Suede Fabric by the Yard – Smooth faux leather suede fabric, ideal for rustic or contemporary furniture. Durable and easy to care for. Available in various styles and shades. Sold by the yard. Key products include: Doro Suede – $39.99/yard, Vista – $39.99/yard, GEO – Herringbone Suede – $39.99/yard, Blitz – $29.99/yard. Shipping available to the United States. Store credit exchanges permitted on u…

3. Sewport – Suede Fabric

Domain: sewport.com

Registered: 2015 (10 years)

Введение: {“fabric_name”: “Suede Fabric”, “also_known_as”: [“Fuzzy leather”, “napped leather”, “Ultrasuede”], “fabric_composition”: “The underside of animal skins or a similar synthetic material”, “fabric_breathability”: “Low”, “moisture_wicking_abilities”: “Low”, “heat_retention_abilities”: “High”, “stretchability”: “Low”, “prone_to_pilling_bubbling”: “Low”, “country_of_origin”: “Sweden”, “biggest_exportin…

4. CNC Fabrics – Faux Suede Fabric

Domain: cncfabrics.com

Registered: 2011 (14 years)

Введение: Faux Suede fabric, high quality, smooth and fuzzy finish, heavyweight, suitable for apparel (pants, skirts, jackets, gloves, handbags) and upholstery (chair and couch coverings, pillows). Available in various colors and prints. Free samples upon request. Products include Aqua Suede Print, Black Faux Suede, Charcoal Faux Suede, Cinnabar Red Faux Suede, Dark Teal Suede Print, Godiva Brown Faux Suede…

5. MasterClass – Suede Leather

Domain: masterclass.com

Registered: 1995 (30 years)

Введение: Suede is a high-quality form of leather made from the underside of animal hides, characterized by a soft, smooth surface. Commonly made from lambskin, it can also be derived from goats, pigs, calves, and deer. Suede is softer, thinner, and less durable than full-grain leather. It is used in fashion items such as shoes, accessories, and jackets. Types of suede include sheepskin suede (softest), cow…

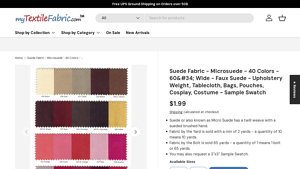

6. My Textile Fabric – Suede Fabric – Microsuede

Domain: mytextilefabric.com

Registered: 2011 (14 years)

Введение: {“Product Name”: “Suede Fabric – Microsuede”, “Colors Available”: 40, “Width”: “60 inches”, “Type”: “Faux Suede”, “Uses”: [“Upholstery”, “Tablecloth”, “Bags”, “Pouches”, “Cosplay”, “Costume”], “Sample Swatch Price”: “$1.99”, “Fabric Composition”: “100% Polyester”, “Fabric Weight”: “Approximately 225 grams per square meter”, “Cleaning Instructions”: “Dry Clean Only”, “Shipping”: “Ships from Los Ang…

Strategic Sourcing Conclusion and Outlook for swade material

Why is Strategic Sourcing Essential for Suede Material?

In conclusion, strategic sourcing of suede material is vital for international B2B buyers aiming to enhance their product offerings while maximizing cost-efficiency. Understanding the unique properties of suede, including its luxurious texture and versatility, allows businesses to cater to specific market demands, particularly in fashion and luxury goods. Buyers should prioritize sourcing from reputable suppliers who adhere to quality standards, ensuring that the suede’s integrity remains intact throughout the supply chain.

How Can Buyers Stay Ahead in the Suede Market?

As the global market for suede continues to evolve, particularly with the rise of synthetic alternatives, it’s crucial for buyers from Africa, South America, the Middle East, and Europe to stay informed about trends and innovations. Investing in high-quality suede not only elevates product appeal but also builds brand loyalty among discerning consumers.

What Steps Should You Take Next?

For businesses looking to capitalize on suede’s luxurious appeal, now is the time to forge strong supplier partnerships and explore sustainable sourcing options. By doing so, companies can ensure they are well-positioned to meet future demands while enhancing their competitive edge. Embrace the opportunities within the suede market, and take proactive steps towards your sourcing strategy today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.