Introduction: Navigating the Global Market for nikwax fabric and leather proof

In an increasingly competitive landscape, sourcing high-quality waterproofing solutions like Nikwax Fabric and Leather Proof is essential for businesses committed to providing durable and breathable footwear. Many international buyers face the challenge of ensuring that their products can withstand diverse environmental conditions, particularly in regions like Africa, South America, the Middle East, and Europe. This comprehensive guide addresses the critical aspects of sourcing Nikwax Fabric and Leather Proof, focusing on its applications, types, and the factors to consider when vetting suppliers.

Navigating the complexities of the global market requires insight into product performance, including how Nikwax enhances the longevity and comfort of footwear by revitalizing its Durable Water Repellency (DWR) without compromising breathability. Buyers will find detailed information on the various formulations available, their specific applications across different types of fabric and leather, and the environmental benefits of choosing PFAS-free options.

Additionally, this guide empowers B2B buyers with actionable insights on pricing, procurement strategies, and supplier evaluation techniques. By leveraging this knowledge, businesses can make informed purchasing decisions that not only meet their quality standards but also align with their sustainability goals. Whether you are a distributor, retailer, or manufacturer, understanding the nuances of Nikwax Fabric and Leather Proof will enhance your product offerings and drive customer satisfaction.

Table Of Contents

- Top 4 Nikwax Fabric And Leather Proof Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for nikwax fabric and leather proof

- Understanding nikwax fabric and leather proof Types and Variations

- Key Industrial Applications of nikwax fabric and leather proof

- 3 Common User Pain Points for ‘nikwax fabric and leather proof’ & Their Solutions

- Strategic Material Selection Guide for nikwax fabric and leather proof

- In-depth Look: Manufacturing Processes and Quality Assurance for nikwax fabric and leather proof

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘nikwax fabric and leather proof’

- Comprehensive Cost and Pricing Analysis for nikwax fabric and leather proof Sourcing

- Alternatives Analysis: Comparing nikwax fabric and leather proof With Other Solutions

- Essential Technical Properties and Trade Terminology for nikwax fabric and leather proof

- Navigating Market Dynamics and Sourcing Trends in the nikwax fabric and leather proof Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of nikwax fabric and leather proof

- Strategic Sourcing Conclusion and Outlook for nikwax fabric and leather proof

- Important Disclaimer & Terms of Use

Understanding nikwax fabric and leather proof Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Nikwax Fabric & Leather Proof | Revitalizes breathability, easy sponge-on application, PFAS-free | Outdoor footwear manufacturers, retailers | Pros: Enhances comfort, environmentally friendly. Cons: Requires cleaning before application. |

| Nikwax Fabric & Leather DUO-Pack | Complete care system for cleaning and waterproofing | Retailers offering comprehensive footwear care | Pros: All-in-one solution, easy to use. Cons: Higher upfront cost compared to single products. |

| Nikwax Footwear Cleaning Gel | Specialized cleaner that revitalizes DWR | Footwear maintenance services, outdoor gear shops | Pros: Cleans effectively, restores DWR. Cons: Needs to be used in conjunction with waterproofing. |

| Nikwax Tent & Gear SolarProof | UV protection and waterproofing for gear | Camping and outdoor equipment retailers | Pros: Protects against UV damage, versatile. Cons: Limited to fabric and gear applications. |

| Nikwax Leather Conditioner | Nourishes and protects leather while maintaining breathability | Leather goods manufacturers, repair services | Pros: Extends leather life, enhances appearance. Cons: Not suitable for synthetic materials. |

What Are the Key Features of Nikwax Fabric & Leather Proof?

Nikwax Fabric & Leather Proof is designed specifically for combination fabric and leather footwear, revitalizing breathability while providing a durable water-repellent (DWR) finish. It is easy to apply with a sponge and is free from harmful chemicals, making it a safe choice for both users and the environment. B2B buyers in outdoor footwear manufacturing can leverage this product to enhance the performance of their offerings, ensuring that end-users enjoy dry and comfortable feet even in damp conditions.

How Does the Nikwax Fabric & Leather DUO-Pack Benefit Businesses?

The Nikwax Fabric & Leather DUO-Pack combines a cleaning gel with a waterproofing agent, providing a complete care solution for outdoor footwear. This package is particularly appealing to retailers looking to offer customers an all-in-one solution for maintaining their footwear. By promoting this DUO-Pack, businesses can increase sales by addressing the complete lifecycle of footwear care, appealing to consumers who prioritize both cleaning and waterproofing.

What Makes Nikwax Footwear Cleaning Gel Essential for Maintenance?

Nikwax Footwear Cleaning Gel is a specialized product aimed at restoring the DWR of waterproof footwear. It effectively removes contaminants that may impair water repellency and breathability, making it a crucial step before applying any waterproofing treatment. B2B buyers in the footwear maintenance sector should consider stocking this product as it not only enhances the effectiveness of waterproofing treatments but also caters to consumers who wish to prolong the life of their footwear.

Why Should Retailers Consider Nikwax Tent & Gear SolarProof?

Nikwax Tent & Gear SolarProof offers a unique solution for outdoor gear, providing both waterproofing and UV protection. This product is ideal for camping and outdoor equipment retailers looking to diversify their offerings. By including SolarProof in their inventory, retailers can appeal to consumers concerned about the longevity of their gear in harsh outdoor conditions, thereby enhancing customer satisfaction and loyalty.

How Does Nikwax Leather Conditioner Support Leather Goods?

Nikwax Leather Conditioner is designed to nourish and protect leather while maintaining its breathability. This product is particularly relevant for B2B buyers in the leather goods manufacturing and repair sectors. By using this conditioner, businesses can ensure that their leather products remain in excellent condition, thus extending their lifespan and enhancing customer satisfaction. However, it is important to note that this product is not suitable for synthetic materials, which may limit its application for some businesses.

Key Industrial Applications of nikwax fabric and leather proof

| Industry/Sector | Specific Application of Nikwax Fabric and Leather Proof | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Retail | Waterproofing and maintaining breathability of footwear | Enhances product lifespan, leading to increased customer satisfaction and reduced returns | Ensure availability of bulk purchasing options and consider regional shipping logistics |

| Construction | Protective treatment for work boots and gear | Increases safety and comfort for workers in wet environments, potentially reducing workplace accidents | Look for suppliers with reliable delivery schedules and compliance with local regulations |

| Agriculture | Treatment for farming footwear and gear | Protects against moisture damage, ensuring durability and comfort for workers in wet conditions | Source products that are environmentally friendly and compatible with local agricultural practices |

| Military and Defense | Waterproofing of tactical footwear and uniforms | Ensures operational effectiveness in adverse weather, enhancing soldier comfort and performance | Prioritize suppliers who can meet stringent military specifications and timelines |

| Sports and Recreation | Maintenance of sports footwear and gear | Improves performance by keeping athletes dry and comfortable, reducing the risk of blisters and foot fatigue | Consider partnerships with distributors familiar with the sports industry and local market trends |

How is Nikwax Fabric and Leather Proof Used in Outdoor Retail?

In the outdoor retail sector, Nikwax Fabric and Leather Proof is essential for waterproofing and maintaining the breathability of footwear. Retailers can offer this product as part of a comprehensive care system for outdoor gear, enhancing the longevity and performance of footwear sold. By ensuring that customers’ footwear remains effective in wet conditions, businesses can significantly reduce return rates and increase customer satisfaction. International buyers should consider sourcing options that provide bulk purchasing discounts and efficient shipping to ensure timely availability.

What Role Does Nikwax Fabric and Leather Proof Play in Construction?

For the construction industry, Nikwax Fabric and Leather Proof is used to treat work boots and gear, providing essential waterproofing that protects workers in wet environments. This application not only enhances the safety and comfort of workers but also prolongs the life of expensive gear, ultimately saving costs for businesses. Buyers in this sector should prioritize suppliers that can ensure compliance with local safety regulations and offer reliable delivery schedules to avoid project delays.

How Can Agriculture Benefit from Nikwax Fabric and Leather Proof?

In agriculture, Nikwax Fabric and Leather Proof is applied to farming footwear and gear, safeguarding against moisture damage and enhancing durability. This is crucial for agricultural workers who often operate in wet conditions, as it ensures their comfort and performance throughout the workday. B2B buyers in this sector should seek environmentally friendly options that align with local agricultural practices, ensuring that the products do not negatively impact the soil or crops.

Why is Nikwax Fabric and Leather Proof Important for Military and Defense?

Military and defense applications of Nikwax Fabric and Leather Proof focus on waterproofing tactical footwear and uniforms, which is vital for operational effectiveness in adverse weather conditions. This treatment keeps soldiers dry and comfortable, contributing to better performance in the field. Buyers in this sector must ensure that suppliers can meet stringent military specifications and provide timely deliveries, as operational readiness is often time-sensitive.

How Does Nikwax Fabric and Leather Proof Enhance Sports and Recreation?

In the sports and recreation industry, Nikwax Fabric and Leather Proof is utilized to maintain sports footwear and gear, crucial for keeping athletes dry and comfortable during activities. This application reduces the risk of blisters and foot fatigue, enhancing overall performance. B2B buyers should consider forming partnerships with distributors who have a deep understanding of market trends and can provide tailored solutions for the sports sector.

3 Common User Pain Points for ‘nikwax fabric and leather proof’ & Their Solutions

Scenario 1: Maintaining Performance in Challenging Environments

The Problem: B2B buyers often face the challenge of ensuring their footwear remains functional in harsh conditions. For businesses operating in sectors such as construction, outdoor recreation, or agriculture, footwear is essential for employee safety and comfort. However, when footwear absorbs water due to contamination or degradation of the Durable Water Repellency (DWR), it leads to discomfort and potential safety hazards. This not only affects employee morale but can also result in increased costs due to health and safety incidents.

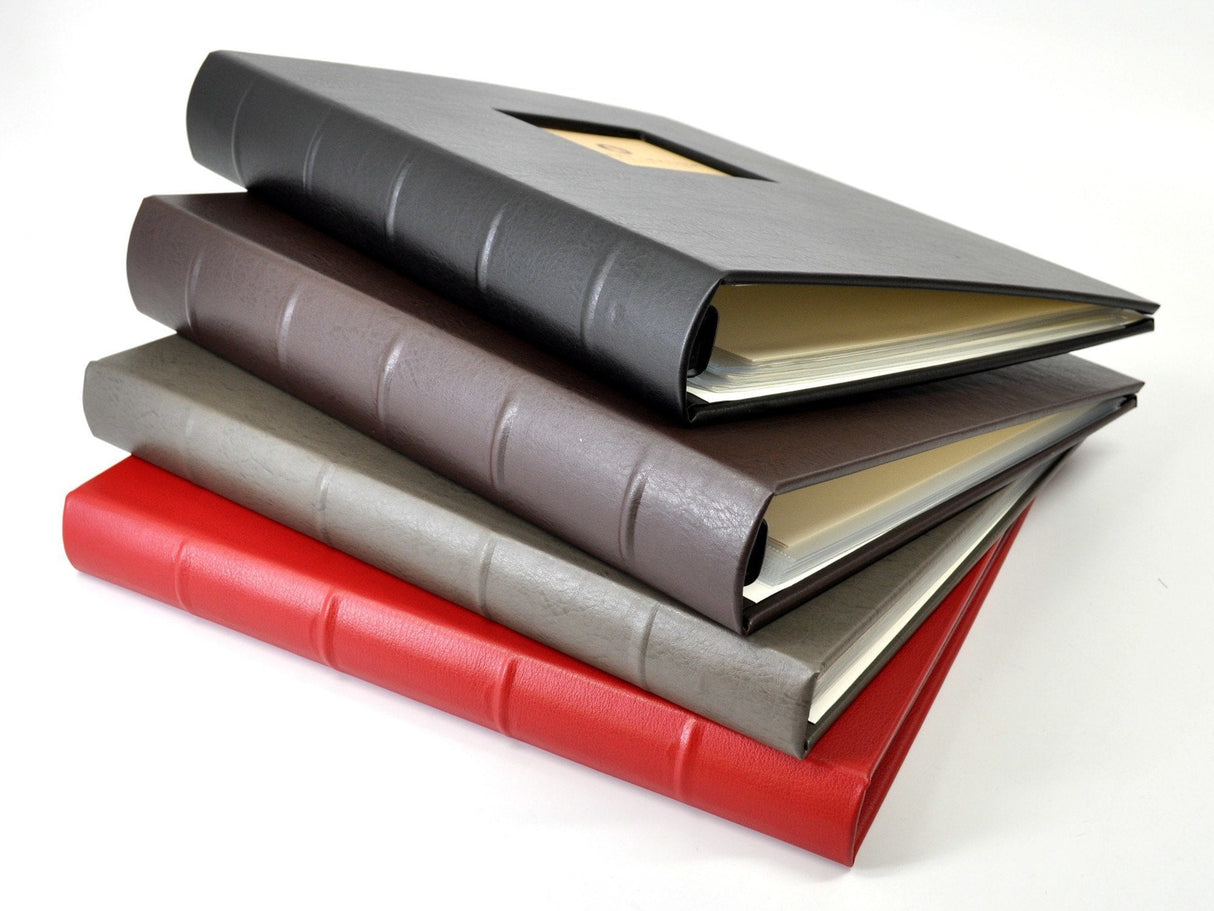

Illustrative image related to nikwax fabric and leather proof

The Solution: To combat this issue, it is crucial for businesses to regularly maintain their footwear with Nikwax Fabric & Leather Proof. The first step is to educate staff on the importance of cleaning footwear with Nikwax Footwear Cleaning Gel before applying the waterproofing treatment. This ensures that any dirt or contaminants that could hinder DWR are removed. Once clean, applying Nikwax Fabric & Leather Proof is straightforward: spray or sponge it onto wet footwear, focusing on seams and areas prone to water entry. This revitalizes the DWR, ensuring that footwear remains breathable and water-repellent, ultimately enhancing employee safety and comfort in challenging work environments.

Scenario 2: Adapting to Diverse Regional Climate Conditions

The Problem: Companies that operate in different regions, especially across Africa, South America, the Middle East, and Europe, encounter varying climate conditions that can affect the performance of their footwear. For instance, humid climates can lead to quick degradation of waterproofing treatments, while dry environments may cause materials to crack. B2B buyers must ensure that the products they select can withstand these diverse conditions without compromising performance, which often leads to uncertainty and potential losses.

The Solution: B2B buyers should leverage the versatility of Nikwax Fabric & Leather Proof by tailoring their usage based on regional climates. For humid areas, regular application is recommended to maintain DWR and breathability. In contrast, for drier climates, it’s beneficial to periodically condition the leather to prevent cracking while still applying the waterproofing treatment. Buyers should consider creating a maintenance schedule that accounts for local weather conditions, ensuring that staff are trained to clean and reproof footwear regularly. This proactive approach not only extends the life of the footwear but also enhances overall performance across diverse climates.

Scenario 3: Environmental Concerns and Sustainable Practices

The Problem: With growing awareness of environmental sustainability, B2B buyers are increasingly concerned about the ecological impact of the products they use. Many conventional waterproofing agents contain harmful PFCs and solvents that can pose risks to both user health and the environment. This creates a dilemma for businesses wanting to provide high-quality, durable footwear while also aligning with sustainable practices and regulations.

The Solution: Nikwax Fabric & Leather Proof offers a sustainable alternative, being PFAS-free and environmentally friendly. B2B buyers should prioritize sourcing products that align with their sustainability goals, ensuring that all footwear maintenance practices adhere to eco-friendly standards. Incorporating Nikwax into regular maintenance not only supports a commitment to sustainability but also helps in marketing the brand as environmentally conscious. Buyers should communicate these benefits to employees and stakeholders, reinforcing the company’s dedication to sustainable practices while maintaining high-performance footwear. This not only meets regulatory requirements but also enhances the brand’s reputation in a competitive market.

Strategic Material Selection Guide for nikwax fabric and leather proof

What Are the Key Materials Used in Nikwax Fabric and Leather Proof?

Nikwax Fabric and Leather Proof is designed to enhance the performance of various footwear materials, ensuring they remain waterproof while maintaining breathability. Understanding the materials involved is crucial for B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. Below, we analyze several common materials relevant to this product.

Which Materials Are Commonly Used in Nikwax Fabric and Leather Proof?

1. Polyester

Key Properties: Polyester is known for its high tensile strength and resistance to stretching and shrinking. It can withstand temperatures up to 150°C and is resistant to UV light and mildew.

Pros & Cons: Polyester is durable and cost-effective, making it suitable for mass production. However, it may not provide the same level of breathability as natural fibers. Manufacturing complexity is relatively low, allowing for efficient production processes.

Impact on Application: Polyester’s compatibility with Nikwax Fabric and Leather Proof is excellent, as the product enhances its water repellency without compromising breathability.

Illustrative image related to nikwax fabric and leather proof

Considerations for International Buyers: Buyers should ensure compliance with local standards, such as ASTM for textiles. In regions like Nigeria, where humidity is high, the breathability of polyester-treated footwear is essential.

2. Gore-Tex®

Key Properties: Gore-Tex® is a membrane material known for its waterproof and breathable properties. It can handle high-pressure water exposure and maintains breathability even in extreme conditions.

Pros & Cons: The primary advantage of Gore-Tex® is its superior performance in wet conditions. However, it comes at a higher cost and requires careful handling during manufacturing to maintain its integrity.

Impact on Application: Nikwax Fabric and Leather Proof is specifically formulated to work with Gore-Tex®, ensuring that the waterproofing does not block the membrane’s breathability.

Considerations for International Buyers: Compliance with international standards such as DIN and JIS is crucial for buyers in Europe and the Middle East. The higher initial investment in Gore-Tex® products may be justified by their longevity and performance.

3. Leather

Key Properties: Leather is a natural material known for its durability and unique aesthetic. It has a high resistance to wear and tear and can withstand various environmental conditions.

Illustrative image related to nikwax fabric and leather proof

Pros & Cons: Leather offers a premium feel and excellent durability, but it requires more maintenance than synthetic materials. The manufacturing process can be complex and environmentally taxing, which may be a concern for eco-conscious buyers.

Impact on Application: Nikwax Fabric and Leather Proof revitalizes leather’s water repellency without compromising its breathability, making it suitable for outdoor footwear.

Considerations for International Buyers: Buyers in regions like South America may be more familiar with leather products. Understanding local preferences for leather care and maintenance can influence purchasing decisions.

4. Nylon

Key Properties: Nylon is a synthetic polymer known for its strength and elasticity. It can withstand temperatures up to 120°C and is resistant to abrasion and chemicals.

Pros & Cons: Nylon is lightweight and durable, making it ideal for outdoor gear. However, it can absorb water if not treated properly, leading to reduced breathability. Manufacturing processes are straightforward, allowing for efficient production.

Illustrative image related to nikwax fabric and leather proof

Impact on Application: Nikwax Fabric and Leather Proof enhances the water repellency of nylon, ensuring that it performs well in wet conditions.

Considerations for International Buyers: Compliance with environmental standards is essential, especially in regions focused on sustainability. Buyers should consider the long-term benefits of investing in treated nylon products.

Summary Table of Material Analysis

| Material | Typical Use Case for Nikwax Fabric and Leather Proof | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Outdoor footwear, casual shoes | Cost-effective and durable | Lower breathability compared to natural fibers | Low |

| Gore-Tex® | High-performance outdoor footwear | Superior waterproofing and breathability | Higher cost and complex manufacturing | High |

| Leather | Premium outdoor footwear, hiking boots | Excellent durability and aesthetic | Requires more maintenance and complex production | Medium |

| Nylon | Lightweight outdoor gear, sports footwear | Lightweight and strong | Can absorb water if untreated | Low |

This analysis provides B2B buyers with critical insights into the materials used in Nikwax Fabric and Leather Proof, enabling informed purchasing decisions that align with regional preferences and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for nikwax fabric and leather proof

What Are the Key Stages in the Manufacturing Process of Nikwax Fabric and Leather Proof?

The manufacturing process for Nikwax Fabric and Leather Proof involves several critical stages designed to ensure high-quality output. The main stages include material preparation, formulation, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality, environmentally friendly raw materials. Nikwax emphasizes the use of water-based formulations that are PFAS-free, ensuring that harmful substances are not included in their products. Suppliers are vetted for compliance with environmental standards, ensuring sustainability throughout the supply chain.

-

Formulation: After materials are prepared, they undergo a precise formulation process. This involves mixing various ingredients to create the waterproofing solution. Nikwax employs advanced techniques to ensure that the Durable Water Repellency (DWR) properties are optimized while maintaining breathability. The formulation process is critical, as the right balance of ingredients determines the efficacy and safety of the final product.

-

Assembly: In this stage, the product is packaged for distribution. Nikwax utilizes automated systems to fill bottles and apply labels, ensuring consistency and efficiency. The assembly process is designed to minimize contamination and maintain product integrity. The use of non-flammable packaging materials aligns with Nikwax’s commitment to safety and environmental protection.

-

Finishing: The final stage includes quality checks and packaging. Products undergo rigorous testing to confirm that they meet established specifications. This stage ensures that the product is ready for the market, with all safety and quality standards adhered to.

How Does Nikwax Ensure Quality Control Throughout the Manufacturing Process?

Quality control (QC) is a vital component of Nikwax’s manufacturing process, adhering to both international standards and industry-specific regulations.

-

International Standards Compliance: Nikwax operates in accordance with ISO 9001, a quality management standard that ensures consistent product quality and continual improvement. This certification indicates that the company follows a systematic approach to managing its processes, leading to reliable products.

-

Industry-Specific Certifications: In addition to ISO 9001, Nikwax products may also comply with CE standards for safety, particularly in markets that demand such certifications. These certifications are crucial for B2B buyers who operate in regions with strict safety regulations.

-

Quality Control Checkpoints: Nikwax implements several quality checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications before being used in production.

– In-Process Quality Control (IPQC): Continuous monitoring occurs during production to identify and rectify any deviations from established processes.

– Final Quality Control (FQC): Finished products undergo thorough testing to verify that they meet performance criteria, including water repellency and breathability. -

Common Testing Methods: Various testing methods are employed to evaluate the performance of the products. These may include:

– Water Resistance Testing: Assessing the level of water repellency.

– Breathability Testing: Measuring moisture vapor transmission rates to ensure comfort.

– Durability Testing: Evaluating the longevity of the waterproofing treatment through rigorous wear simulations.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of their suppliers.

-

Conduct Supplier Audits: Regular audits can provide insights into the manufacturing processes, quality control measures, and compliance with international standards. Buyers should request access to audit reports and certifications to ensure the supplier adheres to established quality protocols.

-

Request Quality Control Documentation: Suppliers should provide documentation outlining their quality control processes, including details about IQC, IPQC, and FQC. This transparency is essential for understanding the measures taken to ensure product quality.

-

Utilize Third-Party Inspection Services: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These agencies can conduct on-site inspections and testing, verifying the claims made by the supplier.

-

Evaluate Performance History: Buyers should consider the supplier’s track record regarding product performance and customer satisfaction. Requesting references or case studies can help assess the reliability of the supplier’s products in real-world applications.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate specific quality control nuances that can vary by region. Understanding these differences is crucial for successful procurement.

-

Regulatory Compliance: Different regions have varying regulations regarding product safety and environmental impact. Buyers from the European Union, for example, may need to ensure compliance with REACH regulations, which govern the registration, evaluation, and authorization of chemicals.

-

Cultural Expectations: Quality expectations can differ based on cultural norms. Buyers in regions such as Germany may prioritize stringent quality assurance processes, while buyers in emerging markets may focus more on cost-effectiveness.

-

Supply Chain Transparency: In regions where supply chain transparency is critical, buyers should look for suppliers that provide clear visibility into their sourcing and production processes. This can help mitigate risks related to unethical practices or substandard materials.

-

Adaptability to Market Needs: Suppliers should demonstrate flexibility in adapting their quality control processes to meet the specific needs of international markets. This adaptability can enhance the supplier’s reputation and ensure long-term partnerships.

By understanding the manufacturing processes and quality assurance practices of Nikwax Fabric and Leather Proof, B2B buyers can make informed decisions that align with their operational needs and quality standards.

Illustrative image related to nikwax fabric and leather proof

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nikwax fabric and leather proof’

To ensure a successful procurement process for Nikwax Fabric and Leather Proof, this practical sourcing guide provides a step-by-step checklist tailored for B2B buyers. Following these steps will help you make informed decisions that align with your operational needs and sustainability goals.

Step 1: Define Your Technical Specifications

Establish clear specifications for the Nikwax Fabric and Leather Proof product that meets your business needs. Consider the types of footwear and materials you will be treating, as well as any performance requirements such as water repellency and breathability. This clarity will guide your sourcing decisions and ensure compatibility with your products.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers of Nikwax products. Look for suppliers that specialize in outdoor gear or waterproofing solutions, and evaluate their reputation in the market. Pay attention to customer reviews and feedback to gauge their reliability and service quality.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications to ensure compliance with international standards. Look for certifications related to environmental sustainability, such as PFAS-free claims, which are crucial given the growing demand for eco-friendly products. This step helps mitigate risks associated with non-compliance.

Step 4: Request Product Samples

Always request samples of Nikwax Fabric and Leather Proof before finalizing your order. Testing the product on your specific footwear materials will provide valuable insights into its performance and compatibility. Ensure that the samples are representative of the final product to assess quality accurately.

Step 5: Negotiate Pricing and Terms

Engage in discussions with potential suppliers to negotiate pricing and payment terms. Understanding the total cost of ownership, including shipping and any applicable tariffs, is essential for budget management. Ensure that you are aware of bulk purchase discounts, which can significantly reduce costs.

Step 6: Assess Delivery and Logistics Capabilities

Evaluate the supplier’s logistics capabilities to ensure timely delivery of Nikwax products. Consider their shipping options, lead times, and ability to handle international shipments, especially if you’re operating in regions like Africa or South America. Efficient logistics are crucial for maintaining your inventory levels.

Step 7: Establish a Long-term Partnership

Once you have identified a suitable supplier, focus on building a long-term relationship. Regular communication and feedback will help you stay informed about new products and innovations in the market. A strong partnership can lead to better pricing, priority service, and access to exclusive products in the future.

By following this checklist, you can streamline your procurement process for Nikwax Fabric and Leather Proof and ensure that you make well-informed purchasing decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for nikwax fabric and leather proof Sourcing

What Are the Key Cost Components in Nikwax Fabric and Leather Proof Sourcing?

When evaluating the cost structure of Nikwax Fabric and Leather Proof, several core components come into play. These include raw materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The primary ingredients in Nikwax products are environmentally friendly, water-based formulations that are PFAS-free. The cost of these materials can fluctuate based on availability and sourcing regions, impacting overall pricing.

Labor: Labor costs involve the workforce needed for manufacturing, packaging, and quality assurance. As labor rates vary significantly across regions, this can affect the final price for international buyers.

Manufacturing Overhead: This encompasses costs associated with running production facilities, including utilities and maintenance. Efficient manufacturing processes can help mitigate these costs, but they remain a crucial factor in pricing.

Tooling: Investment in specialized equipment for production can lead to initial high costs but can be amortized over time, depending on the production volume.

Quality Control: Ensuring product consistency and performance involves rigorous quality checks, which add to the overall cost. Nikwax’s commitment to high standards can justify a premium price point.

Logistics: Transportation and warehousing costs are significant, especially for international shipments. Factors such as distance, shipping methods, and customs duties can heavily influence the final pricing structure.

Margin: The manufacturer’s profit margin is another integral component, reflecting the brand’s value proposition and market positioning.

How Do Price Influencers Affect Nikwax Fabric and Leather Proof Pricing?

Several factors can influence the pricing of Nikwax Fabric and Leather Proof products.

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to cost savings. Buyers should inquire about volume discounts, as purchasing larger quantities can significantly reduce per-unit costs.

Specifications and Customization: Customized formulations or packaging may incur additional costs. Buyers should assess whether standard offerings meet their needs before opting for tailored solutions.

Materials and Quality Certifications: The use of high-quality, eco-friendly materials can raise prices, but these attributes appeal to environmentally conscious consumers. Certifications can also add to the cost but enhance marketability.

Supplier Factors: The reliability and reputation of the supplier can impact pricing. Established brands like Nikwax often command higher prices due to their proven quality and brand recognition.

Incoterms: Understanding Incoterms is essential for international transactions. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can influence pricing and risk allocation during shipping.

What Tips Can Help International B2B Buyers Negotiate Better Pricing for Nikwax Products?

Negotiation is key in achieving cost-efficient purchasing. Here are actionable tips for international B2B buyers:

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like durability, performance, and potential replacement costs. A higher upfront investment may lead to lower long-term costs due to fewer replacements.

Understand Pricing Nuances: Different markets may experience varying pricing structures based on local economic conditions, import tariffs, and supply chain costs. Researching these factors can provide leverage during negotiations.

Leverage Long-term Relationships: Building a strong partnership with suppliers can lead to better pricing over time. Suppliers are often willing to provide discounts to loyal customers who commit to ongoing purchases.

Illustrative image related to nikwax fabric and leather proof

Market Research: Conduct thorough market research to compare prices across different suppliers and regions. This knowledge can empower buyers to negotiate more effectively.

Be Prepared for Currency Fluctuations: International buyers should consider the impact of currency exchange rates on pricing. Locking in prices or negotiating in stable currencies can mitigate risks associated with fluctuations.

By understanding the cost structure and pricing influencers, along with employing strategic negotiation techniques, international B2B buyers can make informed purchasing decisions when sourcing Nikwax Fabric and Leather Proof products.

Alternatives Analysis: Comparing nikwax fabric and leather proof With Other Solutions

Exploring Alternatives to Nikwax Fabric and Leather Proof for Waterproofing Solutions

In the competitive landscape of waterproofing products, Nikwax Fabric and Leather Proof stands out due to its unique features and environmental considerations. However, businesses often seek alternatives that may offer different benefits based on their specific needs, such as cost-effectiveness or specialized applications. This analysis aims to compare Nikwax with two alternative waterproofing solutions: a solvent-based aerosol product and a wax-based treatment, examining their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Nikwax Fabric And Leather Proof | Alternative 1: Solvent-Based Aerosol | Alternative 2: Wax-Based Treatment |

|---|---|---|---|

| Performance | High durability and breathability; PFAS-free | Good initial water repellency, but may degrade quickly | Excellent water resistance but can reduce breathability |

| Cost | $12.55 per 300ml | $10-$15 per 400ml | $8-$20 per application |

| Ease of Implementation | Easy sponge-on application; best on wet surfaces | Quick spray application; requires ventilation | Requires heating and careful application |

| Maintenance | Requires reapplication after cleaning | Frequent reapplication needed; may leave residue | Longer-lasting but may need periodic reapplication |

| Best Use Case | Ideal for outdoor enthusiasts needing breathable footwear | Suitable for quick fixes in less demanding environments | Best for gear that undergoes heavy water exposure but may compromise breathability |

Detailed Breakdown of Alternatives

Solvent-Based Aerosol

Solvent-based aerosols are a popular choice for quick waterproofing solutions. They typically provide good initial water repellency and are easy to apply. However, they often contain harmful chemicals, including PFCs, which can pose environmental and health risks. Their effectiveness may diminish quickly, requiring frequent reapplications, especially in demanding conditions. Businesses looking for a quick and convenient solution may find these aerosols appealing, but they must consider the potential drawbacks regarding safety and environmental impact.

Wax-Based Treatment

Wax-based treatments offer robust water resistance and are particularly effective for heavy-duty applications, such as outdoor work gear or hiking boots exposed to extreme conditions. They create a thick barrier against water but can significantly reduce breathability, potentially leading to discomfort during prolonged wear. Application can be more labor-intensive, as it may require heating the wax before use and careful distribution. While these treatments can provide long-lasting protection, businesses must weigh the trade-off between durability and comfort.

Conclusion: How to Choose the Right Waterproofing Solution

When selecting a waterproofing solution, B2B buyers should consider their specific use cases, the environmental impact of the products, and the performance characteristics that best meet their needs. Nikwax Fabric and Leather Proof is an excellent choice for those prioritizing breathability and eco-friendliness, particularly for outdoor enthusiasts and active users. In contrast, solvent-based aerosols may appeal to those seeking a quick and easy application, while wax-based treatments cater to businesses needing robust protection in extreme conditions, albeit with some trade-offs in comfort. Understanding these factors will enable buyers to make informed decisions that align with their operational requirements and sustainability goals.

Essential Technical Properties and Trade Terminology for nikwax fabric and leather proof

What Are the Key Technical Properties of Nikwax Fabric and Leather Proof?

Nikwax Fabric and Leather Proof is a premium waterproofing solution designed specifically for footwear made from fabric and leather. Understanding its technical properties can help B2B buyers make informed purchasing decisions.

1. Durable Water Repellency (DWR)

DWR is a critical property that enhances the water resistance of footwear. It allows water to bead on the surface instead of soaking in, which is essential for maintaining breathability. In B2B transactions, products with high DWR ratings are preferable, as they ensure customer satisfaction by keeping feet dry in wet conditions. This property is vital for outdoor retailers and distributors who cater to active consumers.

2. Breathability

Breathability is the ability of the material to allow moisture vapor to escape while preventing water ingress. Nikwax Fabric and Leather Proof maintains breathability even after treatment, which is essential for comfort during prolonged wear. For businesses, promoting breathable products can enhance brand reputation and customer loyalty, especially in markets where outdoor activities are prevalent.

3. PFAS-Free Composition

Nikwax Fabric and Leather Proof is formulated without per- and polyfluoroalkyl substances (PFAS), making it environmentally friendly. This is increasingly important for B2B buyers focused on sustainability and compliance with international regulations. Offering PFAS-free products can attract environmentally conscious consumers and differentiate businesses in a competitive marketplace.

4. Non-Flammable

The non-flammable nature of Nikwax products reduces safety risks during storage and transportation. This property is particularly important for distributors and retailers in regions with stringent safety regulations. Ensuring that products are safe to handle can minimize liability and enhance operational efficiency.

5. Application Method

Nikwax Fabric and Leather Proof is designed for easy application, either through spraying or sponging. Its user-friendly design allows retailers to provide clear instructions to consumers, enhancing the customer experience. For B2B buyers, ease of application can lead to higher sales volumes as customers are more likely to repurchase and recommend the product.

6. Compatibility with Other Products

The product is designed to work seamlessly with Nikwax Footwear Cleaning Gel, creating a complete care system for footwear. Understanding product compatibility is crucial for B2B buyers as it enables them to offer comprehensive solutions to their customers, thereby increasing sales opportunities.

What Are Common Trade Terms Related to Nikwax Fabric and Leather Proof?

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are some common terms relevant to Nikwax Fabric and Leather Proof.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are marketed under another company’s brand. For B2B buyers, understanding OEM relationships can help in sourcing products that align with their brand’s quality standards without incurring the costs of manufacturing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps businesses manage inventory effectively and can influence purchasing decisions. Buyers should negotiate MOQs that align with their sales forecasts to maintain optimal stock levels.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. It is an essential tool for B2B buyers to compare prices and terms from different suppliers, ensuring they make cost-effective purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help B2B buyers understand shipping costs, risks, and delivery responsibilities, facilitating smoother international trade operations.

5. Sustainability Compliance

This term refers to adherence to environmental regulations and practices. For B2B buyers focused on sustainability, understanding compliance requirements can enhance brand credibility and align with consumer preferences for eco-friendly products.

6. Lead Time

Lead time is the amount of time it takes from placing an order to receiving it. For businesses, managing lead times effectively can optimize inventory and improve customer satisfaction by ensuring timely delivery of products.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge to make strategic purchasing decisions, enhancing their competitiveness in the market.

Navigating Market Dynamics and Sourcing Trends in the nikwax fabric and leather proof Sector

What Are the Current Market Dynamics and Key Trends Influencing Nikwax Fabric and Leather Proof?

The global market for waterproofing solutions, including Nikwax Fabric and Leather Proof, is being significantly shaped by the increasing demand for durable and breathable outdoor gear. This demand is driven by a growing outdoor recreation culture, particularly in regions like Africa, South America, and Europe, where activities such as hiking, cycling, and adventure sports are gaining popularity. In addition, urbanization and climate variability are leading consumers to seek footwear that can withstand diverse weather conditions, thus enhancing the appeal of high-performance waterproofing products.

Emerging technologies in the sourcing process are also influencing B2B dynamics. Companies are increasingly leveraging digital platforms for sourcing and supply chain management, enabling real-time inventory tracking and order fulfillment. This shift is particularly relevant for international buyers who require efficient logistics and reliable supply chains to meet market demand. Moreover, the rise of e-commerce in regions such as the Middle East is opening new avenues for the distribution of Nikwax products, allowing for better accessibility and reach among B2B buyers.

Furthermore, the competitive landscape is evolving as brands differentiate themselves through product innovation. For instance, the emphasis on PFAS-free formulations and environmentally friendly practices is becoming a key selling point. Buyers are increasingly looking for suppliers who can offer products that not only perform well but are also sustainable, aligning with global trends towards environmental consciousness.

How Is Sustainability and Ethical Sourcing Impacting the Nikwax Fabric and Leather Proof Sector?

Sustainability is at the forefront of consumer and B2B purchasing decisions in the fabric and leather proof sector. Nikwax’s commitment to creating PFAS-free, water-based products is a significant driver in this context, appealing to environmentally conscious buyers. The environmental impact of traditional waterproofing solutions, often reliant on harmful chemicals and aerosol sprays, has prompted a shift towards safer alternatives. B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainable practices, as this not only enhances brand reputation but also meets regulatory requirements in various markets.

Ethical sourcing is equally vital. Buyers are increasingly aware of the importance of transparency in the supply chain, seeking suppliers who can provide assurances of ethical labor practices and environmentally friendly materials. Certifications such as OEKO-TEX® and Bluesign® are becoming essential in the procurement process, assuring buyers that products meet stringent environmental and safety standards. This trend is particularly pronounced in Europe, where regulatory frameworks are more stringent.

In regions like Africa and South America, ethical sourcing can also be a competitive differentiator. Suppliers who can demonstrate their commitment to local communities and sustainable practices are likely to appeal more to buyers who value corporate social responsibility. As the market evolves, B2B buyers must consider both the performance and sustainability of products like Nikwax Fabric and Leather Proof to align with the values of their end consumers.

What Is the Historical Context of Nikwax in the B2B Market?

Nikwax was founded in 1977 with a mission to develop effective waterproofing solutions that are also environmentally friendly. Initially focusing on waterproofing for outdoor gear, the brand has evolved significantly over the decades. The introduction of water-based, PFAS-free products in the 2000s marked a significant turning point in Nikwax’s commitment to sustainability. This evolution has positioned Nikwax as a leader in the fabric and leather proof market, appealing to a growing segment of environmentally conscious consumers and businesses.

Illustrative image related to nikwax fabric and leather proof

Over the years, Nikwax has expanded its product line to meet the diverse needs of outdoor enthusiasts and professionals, particularly in regions with harsh weather conditions. As the market for outdoor gear continues to grow, Nikwax’s focus on innovation, sustainability, and ethical sourcing remains a crucial element of its business strategy, ensuring that it meets the needs of B2B buyers across the globe.

Frequently Asked Questions (FAQs) for B2B Buyers of nikwax fabric and leather proof

-

How do I solve the problem of my fabric and leather footwear absorbing water?

To address the issue of water absorption in your footwear, start by cleaning them with Nikwax Footwear Cleaning Gel. This product removes contaminants that can attract moisture and mask the Durable Water Repellency (DWR) of the material. After cleaning, apply Nikwax Fabric & Leather Proof to rejuvenate the DWR and maintain breathability. This two-step process ensures that your footwear remains water-resistant and comfortable, particularly in wet or damp conditions. -

What is the best method for applying Nikwax Fabric & Leather Proof?

The optimal application method for Nikwax Fabric & Leather Proof is to apply it on clean, wet footwear. Use a sponge or spray bottle to ensure even coverage, focusing on seams and areas that typically absorb water. Maintain a distance of about 6 inches from the surface while applying. After two minutes, wipe off any excess product with a cloth and let the footwear dry naturally. This technique ensures effective penetration and revitalizes the DWR without softening the leather. -

What are the environmental benefits of using Nikwax products?

Nikwax products, including Fabric & Leather Proof, are environmentally friendly as they are water-based, PFAS-free, and non-flammable. Unlike traditional aerosol waterproofing products, which can pose health and environmental risks, Nikwax emphasizes sustainability. By opting for Nikwax, buyers contribute to reducing harmful chemicals in the environment, making it a responsible choice for businesses committed to eco-friendly practices. -

What is the minimum order quantity (MOQ) for Nikwax products?

The minimum order quantity for Nikwax products can vary based on the supplier and region. Typically, distributors may set a MOQ to ensure efficient shipping and handling. It’s advisable to check directly with your chosen supplier or distributor for specific MOQ details. This will help you plan your inventory effectively and ensure that you can meet your customers’ demands without overcommitting. -

How can I vet suppliers for Nikwax products?

To vet suppliers for Nikwax products, conduct thorough research on their reputation and experience in the market. Check for certifications, customer reviews, and references from other businesses. It’s also beneficial to inquire about their supply chain practices, warranty policies, and after-sales support. Establishing a relationship with a reliable supplier ensures consistent product quality and dependable delivery schedules. -

What payment terms are typically offered for B2B purchases of Nikwax products?

Payment terms for B2B purchases of Nikwax products can differ based on the supplier’s policies and the buyer’s creditworthiness. Common terms include net 30, net 60, or advance payment options. Discussing payment options upfront with your supplier can help in negotiating favorable terms that suit your business cash flow. Always ensure that you have a clear understanding of the terms before finalizing any orders. -

What quality assurance measures are in place for Nikwax products?

Nikwax maintains rigorous quality assurance measures to ensure that their products meet high performance standards. These may include regular testing for effectiveness, compliance with environmental regulations, and adherence to industry benchmarks. As a B2B buyer, you can request documentation of quality testing and certification to ensure that the products you are sourcing will perform as expected in your applications. -

What are the logistics considerations when sourcing Nikwax products internationally?

When sourcing Nikwax products internationally, consider logistics factors such as shipping costs, lead times, and customs regulations. Understanding the import duties and taxes applicable in your region is crucial to avoid unexpected expenses. Collaborating with suppliers who have experience in international shipping can streamline the process, ensuring timely delivery and compliance with local regulations. Establishing clear communication with your supplier regarding shipping methods and tracking can further enhance the logistics process.

Top 4 Nikwax Fabric And Leather Proof Manufacturers & Suppliers List

1. Nikwax – Fabric & Leather Proof

Domain: nikwax.com

Registered: 1999 (26 years)

Introduction: Fabric & Leather Proof is a high-performance waterproofer designed to revitalize the breathability of all combination fabric and leather footwear. It is easy to apply by hand, non-flammable, and PFAS-free. The product enhances water repellency and maintains breathability without softening leather, keeping feet warmer and drier. It is recommended for use with Gore-Tex®, eVent®, BDRY®, and all other…

2. Nikwax – Fabric & Leather Proof

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Nikwax Fabric & Leather Proof is a waterproofer designed for use on clean, wet footwear. It is intended to renew the Durable Water Repellent (DWR) treatment on shoes that are already waterproof. The product can also be applied to backpacks, although it is primarily marketed for footwear.

3. Hoffman Boots – Nikwax Fabric & Leather Proof™

Domain: hoffmanboots.com

Registered: 1998 (27 years)

Introduction: Nikwax Fabric & Leather Proof™ is easy and quick to apply; either spray or sponge on to wet shoes. It provides highly Durable Water Repellency (DWR) which develops on air drying. The product leaves a flexible water repellent treatment on individual fibres of fabric and leather, allowing moisture vapour to pass through, maintaining breathability and keeping your feet dry. It has been specifically d…

4. Nikwax – Fabric & Leather Proof

Domain: old.nikwax.com

Registered: 1999 (26 years)

Introduction: Fabric & Leather Proof is a high-performance waterproofer designed to revitalize breathability of all combination fabric and leather footwear. It is easy to apply by hand, non-flammable, and PFC-free. The product enhances water repellency and maintains breathability without softening leather, keeping feet warmer and drier. It is recommended for use with Gore-Tex®, eVent®, BDRY®, and all other wate…

Strategic Sourcing Conclusion and Outlook for nikwax fabric and leather proof

As international B2B buyers consider sourcing Nikwax Fabric and Leather Proof, understanding its strategic advantages becomes crucial. This product not only revitalizes the breathability and water repellency of footwear but also aligns with increasing consumer demand for environmentally friendly solutions. By opting for Nikwax’s PFAS-free and non-flammable formulations, businesses can enhance their product offerings while addressing sustainability concerns prevalent in markets across Africa, South America, the Middle East, and Europe.

The ease of application and effectiveness of Nikwax products ensure that they meet the needs of diverse end-users, from outdoor enthusiasts to professionals requiring reliable footwear in challenging conditions. Regular cleaning and maintenance using complementary products like Nikwax Footwear Cleaning Gel can further enhance customer satisfaction and product longevity.

In a competitive global marketplace, strategic sourcing of Nikwax Fabric and Leather Proof can position businesses as leaders in quality and sustainability. We encourage B2B buyers to explore partnerships with Nikwax to not only meet market demand but to drive growth and innovation in their offerings. By investing in quality and sustainability, your business can thrive in the evolving landscape of consumer preferences.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.