Introduction: Navigating the Global Market for italian leather manufacturers

In today’s global marketplace, sourcing high-quality Italian leather manufacturers presents both an opportunity and a challenge for international B2B buyers. As demand for premium leather goods escalates, particularly in regions like Africa, South America, the Middle East, and Europe, navigating the complexities of supplier selection becomes crucial. This guide is designed to empower you with the insights needed to make informed purchasing decisions.

We delve into the diverse landscape of Italian leather manufacturers, exploring various types of products, including bags, garments, and accessories, while highlighting their applications across different industries. Our comprehensive analysis covers essential aspects such as supplier vetting processes, production capabilities, and cost considerations, enabling you to identify the right partners for your business needs.

By understanding the nuances of sourcing from Italy’s rich tradition of leather craftsmanship, you can enhance your product offerings and meet the growing expectations of your clientele. This guide not only clarifies the intricacies involved in the procurement process but also equips you with actionable strategies to ensure a successful collaboration with Italian leather manufacturers, ultimately driving your business forward in a competitive market.

Table Of Contents

- Top 7 Italian Leather Manufacturers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for italian leather manufacturers

- Understanding italian leather manufacturers Types and Variations

- Key Industrial Applications of italian leather manufacturers

- 3 Common User Pain Points for ‘italian leather manufacturers’ & Their Solutions

- Strategic Material Selection Guide for italian leather manufacturers

- In-depth Look: Manufacturing Processes and Quality Assurance for italian leather manufacturers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘italian leather manufacturers’

- Comprehensive Cost and Pricing Analysis for italian leather manufacturers Sourcing

- Alternatives Analysis: Comparing italian leather manufacturers With Other Solutions

- Essential Technical Properties and Trade Terminology for italian leather manufacturers

- Navigating Market Dynamics and Sourcing Trends in the italian leather manufacturers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of italian leather manufacturers

- Strategic Sourcing Conclusion and Outlook for italian leather manufacturers

- Important Disclaimer & Terms of Use

Understanding italian leather manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Artisan Leather Manufacturers | Focus on handcrafted products, often using traditional techniques | High-end fashion, bespoke items | Pros: Unique, high-quality products; Cons: Higher costs, longer lead times. |

| Industrial Leather Producers | Mass production capabilities, often using modern machinery | Bulk orders, commercial goods | Pros: Cost-effective, quick turnaround; Cons: Less customization, potential quality variance. |

| Custom Leather Goods Makers | Tailored solutions based on client specifications | Private label, custom collections | Pros: Full customization; Cons: Minimum order quantities may apply. |

| Vegan Leather Manufacturers | Specialize in synthetic or plant-based alternatives | Eco-friendly products, fashion lines | Pros: Sustainable options; Cons: May not have the same prestige as genuine leather. |

| Luxury Leather Brands | Renowned for prestige, often associated with high fashion | Luxury markets, exclusive collaborations | Pros: Strong brand recognition; Cons: Premium pricing. |

What Are the Characteristics of Artisan Leather Manufacturers?

Artisan leather manufacturers are distinguished by their commitment to traditional craftsmanship. They typically produce smaller quantities of leather goods, focusing on quality over quantity. This type of manufacturer often employs skilled artisans who utilize time-honored techniques to create unique, bespoke products. B2B buyers seeking high-end fashion items or custom goods will find artisan manufacturers particularly suitable, although they should be prepared for longer lead times and higher price points.

How Do Industrial Leather Producers Operate?

Industrial leather producers leverage modern machinery to achieve mass production efficiencies. They are ideal for businesses needing large quantities of leather goods, such as bags or accessories, at competitive prices. These manufacturers often provide a range of materials and styles, enabling B2B buyers to place bulk orders. However, while they offer cost savings and quick turnaround times, the trade-off may include reduced customization options and potential inconsistencies in quality.

What Makes Custom Leather Goods Makers Unique?

Custom leather goods makers specialize in creating tailored products that meet specific client needs. This type of manufacturer is well-suited for private label projects or unique collections, allowing businesses to differentiate their offerings in the market. Buyers can expect full customization options, including design, materials, and branding. However, these manufacturers may require minimum order quantities, which could be a consideration for smaller businesses.

Illustrative image related to italian leather manufacturers

Why Choose Vegan Leather Manufacturers?

Vegan leather manufacturers focus on producing synthetic or plant-based leather alternatives, catering to the growing demand for sustainable fashion. These manufacturers appeal to eco-conscious brands looking to offer environmentally friendly products without compromising on style. While vegan leather can provide a sustainable option, buyers should note that it may not carry the same prestige or tactile qualities as traditional leather, which could influence consumer perception.

What Are the Benefits of Partnering with Luxury Leather Brands?

Luxury leather brands are synonymous with prestige and high fashion, making them attractive partners for businesses targeting affluent consumers. These manufacturers often have a storied history and a reputation for exceptional quality, which can enhance brand image. Collaborations with luxury brands can provide significant marketing leverage. However, buyers should be aware of the premium pricing associated with these products, which may limit their market accessibility.

Key Industrial Applications of italian leather manufacturers

| Industry/Sector | Specific Application of Italian Leather Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-end handbags and accessories | Enhances brand prestige and customer loyalty | Quality of leather, craftsmanship, customization options |

| Автомобили | Interior leather upholstery for luxury vehicles | Elevates vehicle aesthetics and comfort | Durability, compliance with automotive standards, color matching |

| Footwear | Luxury leather shoes | Provides durability and comfort, appealing to premium markets | Material sourcing, design flexibility, production timelines |

| Мебель | Leather upholstery for high-end furniture | Adds luxury and durability to furniture collections | Material quality, design specifications, lead times |

| Sporting Goods | Leather equipment for sports and outdoor activities | Increases performance and longevity of products | Weight, water resistance, and customization capabilities |

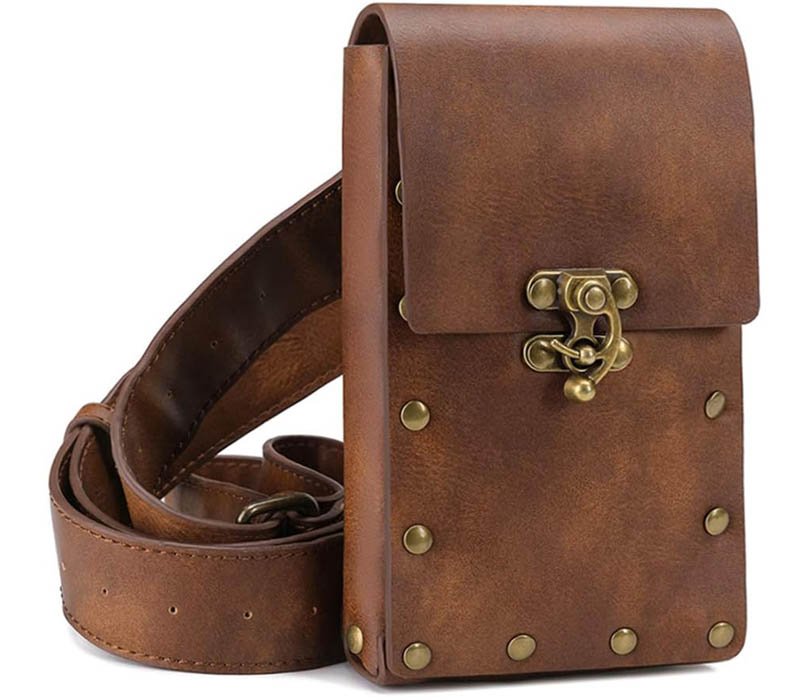

How Are Italian Leather Manufacturers Applied in the Fashion and Apparel Industry?

Italian leather manufacturers are pivotal in the fashion and apparel sector, particularly for high-end handbags and accessories. These artisans create products that not only embody luxury but also enhance brand prestige and customer loyalty. Buyers from international markets, including Africa and South America, should prioritize sourcing leather that meets their quality standards while offering customization options to cater to diverse consumer preferences. The craftsmanship associated with Italian leather ensures that products stand out in a competitive market.

Illustrative image related to italian leather manufacturers

What Role Do Italian Leather Manufacturers Play in the Automotive Sector?

In the automotive industry, Italian leather manufacturers provide premium leather upholstery for luxury vehicles, significantly elevating the vehicle’s aesthetics and comfort. International buyers, especially from Europe and the Middle East, must consider the durability and compliance with automotive standards when sourcing leather. Customization options, such as color matching and texture variations, are also crucial to meet specific design requirements, ensuring that the final product aligns with the brand’s identity.

Why Are Italian Leather Manufacturers Important for Footwear Production?

The footwear industry greatly benefits from the expertise of Italian leather manufacturers, particularly in producing luxury leather shoes. These manufacturers deliver materials that provide both durability and comfort, appealing to premium markets globally. Buyers should focus on the sourcing of high-quality leather that can withstand wear and tear while maintaining aesthetic appeal. Design flexibility is another critical consideration, allowing brands to innovate and keep up with fashion trends.

How Do Italian Leather Manufacturers Enhance Furniture Design?

In the furniture sector, Italian leather manufacturers are essential for creating leather upholstery for high-end furniture pieces. This application adds a layer of luxury and durability that enhances the overall value of furniture collections. Buyers should evaluate the material quality and ensure that the leather meets their design specifications. Lead times are also a critical factor, as timely delivery can affect production schedules and market launch strategies.

Illustrative image related to italian leather manufacturers

What Benefits Do Italian Leather Manufacturers Offer in Sporting Goods?

Italian leather manufacturers are increasingly involved in producing leather equipment for sports and outdoor activities. This application enhances the performance and longevity of products, making them more appealing to consumers who value quality. Buyers need to consider the weight and water resistance of the leather, as well as the potential for customization to meet specific market demands. This ensures that the products not only perform well but also resonate with the target audience.

3 Common User Pain Points for ‘italian leather manufacturers’ & Their Solutions

Scenario 1: Difficulty in Ensuring Quality Consistency Across Orders

The Problem: B2B buyers often face challenges in maintaining quality consistency when placing large orders with Italian leather manufacturers. Variability in craftsmanship, material quality, or even color matching can lead to dissatisfaction, especially when products are intended for retail. This inconsistency can result in increased return rates, damaged brand reputation, and ultimately, lost revenue.

The Solution: To mitigate this issue, buyers should establish a clear and detailed specification document that outlines expectations for quality, materials, and craftsmanship. Engage in a preliminary sampling phase where manufacturers provide samples that meet your specifications. Conduct thorough quality control inspections during production, ideally with on-site visits or third-party inspections, to ensure that the products align with your standards. Building a strong relationship with the manufacturer can also facilitate better communication about quality expectations, helping to ensure that every batch meets the required standards.

Illustrative image related to italian leather manufacturers

Scenario 2: Navigating the Complexities of Customization and Design

The Problem: Customization is a key selling point for many brands, but it can become a pain point when dealing with Italian leather manufacturers. Buyers may struggle to effectively communicate their design ideas or specifications, leading to misaligned expectations and increased lead times. The challenge is compounded when manufacturers have different levels of flexibility in accommodating design changes.

The Solution: To streamline the customization process, B2B buyers should invest time in creating detailed design briefs that include sketches, material swatches, and examples of desired outcomes. Utilize technology by sharing digital prototypes or 3D models to facilitate better understanding. Establish a collaborative approach by scheduling regular check-ins with the manufacturer’s design team to discuss any modifications and ensure alignment. Additionally, consider manufacturers that specialize in custom projects and have a proven track record of flexibility and responsiveness to design changes, which can significantly enhance the outcome.

Scenario 3: Overcoming Logistics and Shipping Challenges

The Problem: Logistics can be a significant hurdle for B2B buyers sourcing from Italian leather manufacturers. Delays in shipping, unexpected tariffs, and difficulties in managing supply chain logistics can lead to stock shortages and disrupted sales channels. These logistical challenges can be particularly acute for international buyers who must navigate complex customs regulations.

The Solution: To address these logistical challenges, buyers should conduct thorough research on shipping options and customs regulations relevant to their location. Establish a reliable logistics partner who specializes in international shipping and understands the intricacies of transporting leather goods. When negotiating with manufacturers, inquire about their shipping practices and timelines to set realistic delivery expectations. It’s also advisable to build in buffer times for production and shipping to mitigate the impact of unforeseen delays. Developing a comprehensive supply chain plan that includes alternative sourcing options can provide additional flexibility in the event of logistical disruptions.

Illustrative image related to italian leather manufacturers

Strategic Material Selection Guide for italian leather manufacturers

What Are the Key Materials Used by Italian Leather Manufacturers?

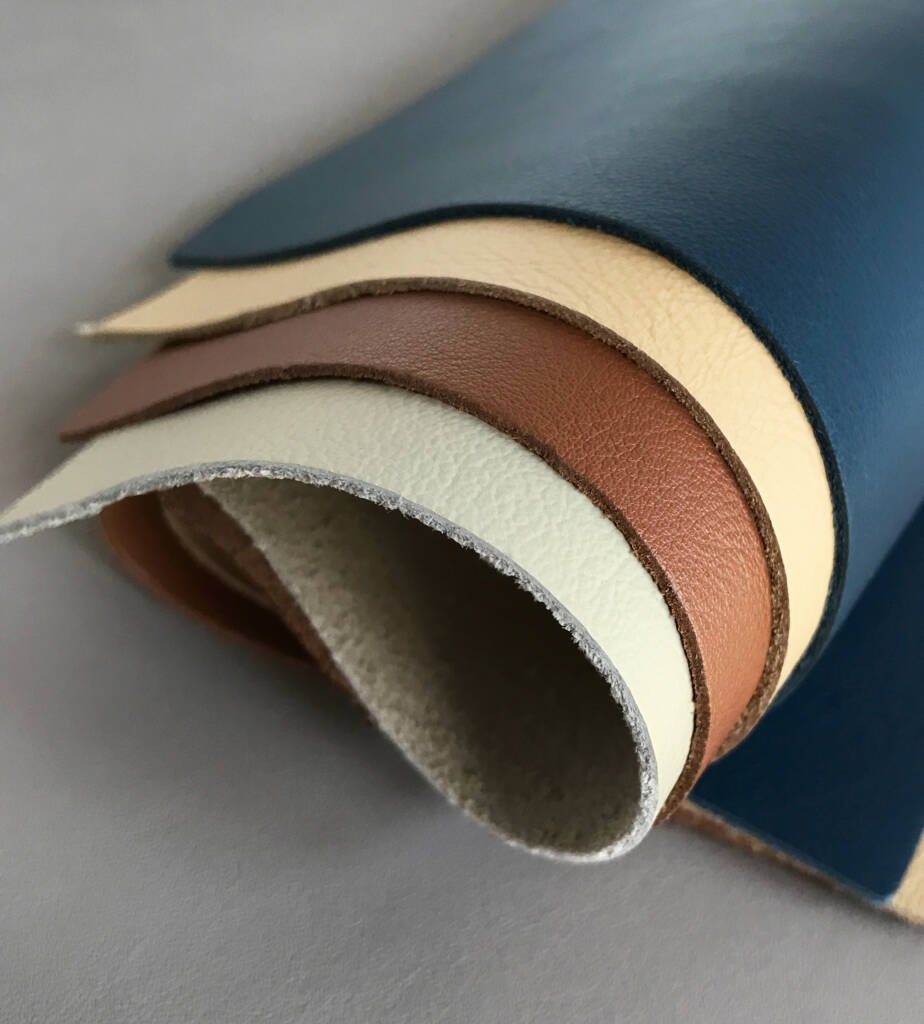

Italian leather manufacturers are renowned for their craftsmanship and the quality of materials they use. Understanding the properties, advantages, and limitations of these materials is crucial for international B2B buyers seeking to make informed purchasing decisions. Below, we analyze four common materials used in the production of Italian leather goods.

How Does Full-Grain Leather Perform in Italian Leather Manufacturing?

Full-grain leather is considered the highest quality leather available. It retains the natural grain and imperfections of the hide, which enhances its durability and aesthetic appeal. Full-grain leather can withstand high temperatures and pressure, making it suitable for a variety of applications, from handbags to furniture.

Pros: Its durability and ability to develop a rich patina over time make it an excellent investment for luxury goods. Additionally, it is resistant to wear and tear.

Cons: The cost of full-grain leather is relatively high, which may impact the pricing of the final product. Manufacturing complexity is also increased due to the need for skilled artisans to work with this material.

Illustrative image related to italian leather manufacturers

Impact on Application: Full-grain leather is compatible with various media, including dyes and finishes, allowing for customization in luxury goods.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should be aware of compliance with international standards for leather goods, such as ASTM and DIN. Full-grain leather is often preferred in markets that value quality and authenticity.

What Are the Benefits of Vegetable-Tanned Leather in Italian Craftsmanship?

Vegetable-tanned leather is made using natural tannins derived from plant materials. This eco-friendly option is popular among manufacturers who prioritize sustainability.

Pros: It is biodegradable and develops a unique character over time. The tanning process also makes it less susceptible to environmental damage.

Illustrative image related to italian leather manufacturers

Cons: The production time is longer, and the leather may be less water-resistant compared to chrome-tanned alternatives.

Impact on Application: This type of leather is ideal for products that require a natural finish, such as wallets and belts.

Considerations for International Buyers: Buyers in Europe, particularly Germany, may favor vegetable-tanned leather due to its eco-friendly properties, aligning with the region’s sustainability goals.

Illustrative image related to italian leather manufacturers

How Does Suede Compare in Terms of Durability and Aesthetics?

Suede is a type of leather with a napped finish, offering a soft texture and luxurious appearance. It is typically made from the underside of the hide, making it less durable than full-grain leather.

Pros: Suede provides a unique aesthetic appeal and is lightweight, making it suitable for fashion accessories.

Cons: It is more susceptible to stains and damage from moisture, which can limit its applications. Maintenance can also be more demanding.

Illustrative image related to italian leather manufacturers

Impact on Application: Suede is often used in high-fashion items, but its sensitivity to elements can restrict its use in more rugged applications.

Considerations for International Buyers: Buyers from South America should consider the climate when selecting suede products, as humidity can affect durability. Compliance with local standards for textile products is also essential.

What Role Does Synthetic Leather Play in Italian Leather Manufacturing?

Synthetic leather, or vegan leather, is made from various materials such as polyurethane (PU) or polyvinyl chloride (PVC). This alternative is gaining traction among consumers seeking cruelty-free options.

Pros: Synthetic leather is often more affordable and easier to maintain than natural leather. It can also be produced in a variety of colors and textures.

Illustrative image related to italian leather manufacturers

Cons: While it may mimic the look of real leather, it often lacks the durability and breathability of natural options. Environmental concerns regarding the production and disposal of synthetic materials are also significant.

Impact on Application: Synthetic leather is widely used in fashion and accessories, appealing to a younger demographic that values sustainability and ethical production.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East may find synthetic leather appealing due to its lower cost and versatility. However, they should ensure that suppliers comply with international environmental standards.

Summary of Material Properties and Considerations

| Материал | Typical Use Case for italian leather manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Luxury handbags, furniture | Exceptional durability and patina | High cost and manufacturing complexity | Высокий |

| Vegetable-Tanned Leather | Wallets, belts | Eco-friendly and unique character | Longer production time, less water-resistant | Medium |

| Замша | Fashion accessories | Soft texture and aesthetic appeal | Susceptible to stains and moisture | Medium |

| Синтетическая кожа | Fashion items, accessories | Affordable and easy to maintain | Lacks durability and environmental concerns | Низкий |

This table provides a concise overview of the materials discussed, aiding B2B buyers in making informed choices based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for italian leather manufacturers

What Are the Main Stages of Manufacturing Processes for Italian Leather Goods?

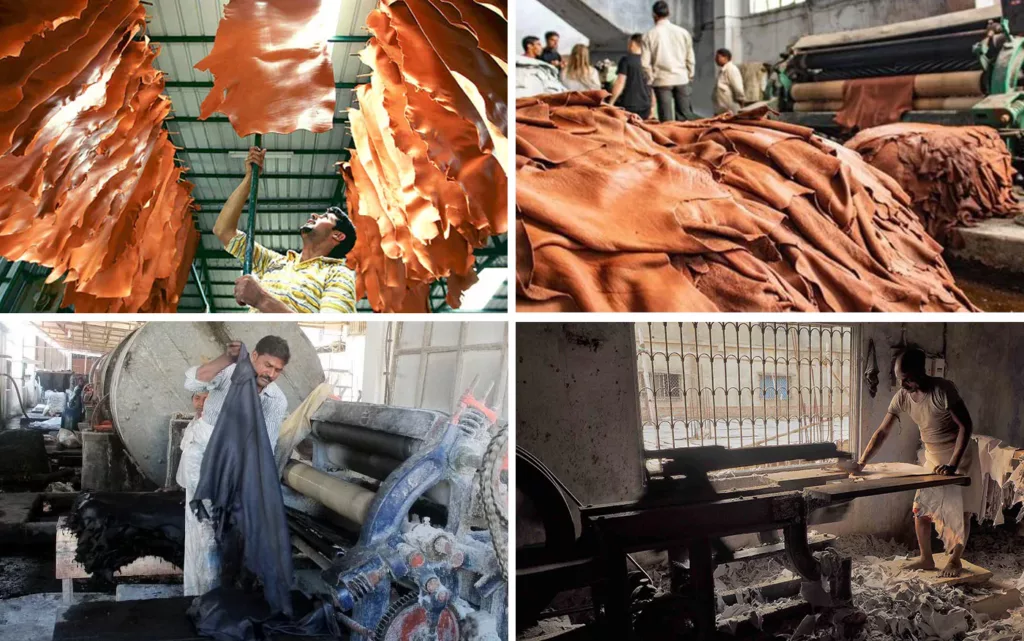

The manufacturing process for Italian leather goods is a meticulous journey that emphasizes craftsmanship and quality at every stage. The main stages of production typically include material preparation, forming, assembly, and finishing.

Illustrative image related to italian leather manufacturers

How Is Material Prepared for Leather Goods Manufacturing?

Material preparation begins with the careful selection of high-quality raw leather, often sourced from reputable tanneries in regions like Tuscany. The leather is treated through processes such as vegetable tanning, which enhances its durability and character while being environmentally friendly. Once selected, the leather is inspected for imperfections, and the necessary cuts are made using paper patterns or CAD technology. This stage is crucial as it sets the foundation for the final product’s quality.

What Techniques Are Used in the Forming Stage of Leather Production?

During the forming stage, artisans utilize a variety of techniques to shape the leather into the desired form. This may involve hand-cutting or machine-cutting techniques, depending on the complexity of the design. Techniques such as molding and stitching are also employed to ensure that the leather maintains its shape and integrity. Artisans may use traditional methods, like saddle stitching, which not only adds strength but also enhances the aesthetic appeal of the product.

How Is the Assembly Process Conducted for Quality Leather Goods?

The assembly process is where individual components come together to form the final product. This stage may involve additional stitching, hardware attachment, and the incorporation of linings. Quality control checkpoints are established throughout this phase to ensure that each item meets the manufacturer’s standards. Workers often collaborate closely, allowing for a seamless integration of various materials, ensuring that every piece is not only functional but also embodies the luxury and style associated with Italian craftsmanship.

What Finishing Techniques Are Commonly Used in Italian Leather Manufacturing?

Finishing is the final touch that elevates leather products to luxury status. Techniques such as polishing, dyeing, and applying protective coatings are commonplace. These processes enhance the leather’s appearance and extend its lifespan. Many manufacturers also offer customization options, allowing for unique finishes that cater to specific market demands. Attention to detail during this stage is paramount, as it can significantly impact the product’s overall impression and customer satisfaction.

Illustrative image related to italian leather manufacturers

What Quality Assurance Practices Are Implemented by Italian Leather Manufacturers?

Quality assurance is a critical component of the manufacturing process, especially in the luxury market. Italian leather manufacturers typically adhere to international standards such as ISO 9001, which ensures consistent quality management systems. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may also be relevant, depending on the product line.

How Are Quality Control Checkpoints Established Throughout the Manufacturing Process?

Quality control checkpoints are strategically implemented at various stages of production. Incoming Quality Control (IQC) is conducted upon receiving raw materials, ensuring that only the best leather enters the production process. In-Process Quality Control (IPQC) occurs during manufacturing, allowing for real-time quality checks to identify issues early. Finally, Final Quality Control (FQC) is performed before shipping, ensuring that each product meets the established quality standards.

What Common Testing Methods Are Utilized to Ensure Leather Quality?

Common testing methods for leather quality include tensile strength tests, colorfastness tests, and water resistance tests. These assessments help verify that the leather meets durability and aesthetic standards. Additionally, tactile tests may be performed to ensure that the leather feels premium and aligns with customer expectations. Manufacturers often keep detailed records of these tests, which can be valuable for B2B buyers seeking assurance of product quality.

Illustrative image related to italian leather manufacturers

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. Buyers can conduct audits of the manufacturing facilities to assess compliance with quality standards. Requesting quality assurance reports and certificates can also provide insight into the supplier’s quality practices. Engaging third-party inspection services can further enhance confidence, ensuring that products meet the required specifications before shipment.

What Are the Nuances of Quality Control Certifications for International Buyers?

Understanding the nuances of quality control certifications is crucial for international buyers. Different regions may have varying standards, and compliance with local regulations is essential. For instance, buyers from the European market may prioritize CE certification, while those from the Middle East might look for specific local compliance standards. It is advisable for buyers to establish clear communication with suppliers regarding these certifications to ensure that products not only meet their quality expectations but also comply with regional regulations.

Conclusion: The Importance of Quality in Italian Leather Manufacturing

In conclusion, the manufacturing processes and quality assurance practices of Italian leather manufacturers are designed to produce high-quality, luxurious leather goods. Understanding these processes allows B2B buyers to make informed decisions when selecting suppliers. By focusing on quality control measures, buyers can ensure that they are investing in products that reflect the rich heritage and craftsmanship of Italian leather, ultimately enhancing their own brand reputation in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘italian leather manufacturers’

Введение

This guide serves as a practical checklist for international B2B buyers seeking to procure from Italian leather manufacturers. The Italian leather industry is renowned for its quality, craftsmanship, and heritage. By following these steps, buyers can streamline their sourcing process and ensure they partner with reliable suppliers who meet their specific needs.

Step 1: Identify Your Product Requirements

Clearly define the types of leather goods you wish to source, whether bags, wallets, or custom items. Understanding your product specifications, including size, design, and materials, is crucial as it guides your supplier selection. Look for manufacturers that specialize in your required product category to ensure they have the expertise and resources to meet your needs.

Illustrative image related to italian leather manufacturers

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential Italian leather manufacturers. Utilize online directories, trade shows, and industry publications to compile a list. Pay attention to each supplier’s reputation, history, and specialties. Reviews and testimonials from other international buyers can provide insights into their reliability and quality.

Step 3: Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications that demonstrate their commitment to quality and sustainability. Certifications such as ISO 9001 for quality management systems or environmental certifications like ISO 14001 can indicate a manufacturer’s adherence to industry standards. This step is vital for ensuring that your supply chain aligns with ethical and quality expectations.

Step 4: Request Samples and Prototypes

Before making a large order, request samples or prototypes of the products you intend to purchase. This allows you to assess the quality of materials, craftsmanship, and overall design. Pay attention to details such as stitching, finishing, and the feel of the leather, as these elements contribute significantly to the final product’s appeal.

Illustrative image related to italian leather manufacturers

Step 5: Evaluate Production Capabilities

Assess the production capacity and capabilities of potential suppliers to ensure they can meet your order volume and deadlines. Inquire about their manufacturing processes, lead times, and flexibility in accommodating changes to your order. A reliable manufacturer should be transparent about their production workflow and able to handle both large and small orders efficiently.

Step 6: Establish Clear Communication Channels

Effective communication is essential for a successful partnership. Ensure that your chosen supplier is responsive and open to discussions regarding your requirements, timelines, and any potential challenges. Establishing clear communication channels early on helps to prevent misunderstandings and aligns expectations.

Step 7: Negotiate Terms and Contracts

Once you’ve selected a supplier, negotiate terms of payment, delivery schedules, and other contractual obligations. Ensure that all agreements are documented clearly to avoid disputes later. Pay attention to terms regarding returns, warranties, and after-sales support, as these factors can significantly impact your business relationship.

Illustrative image related to italian leather manufacturers

By following this checklist, B2B buyers can navigate the complexities of sourcing from Italian leather manufacturers with confidence, ensuring they find the right partners to deliver exceptional products.

Comprehensive Cost and Pricing Analysis for italian leather manufacturers Sourcing

What Are the Key Cost Components in Sourcing from Italian Leather Manufacturers?

When sourcing from Italian leather manufacturers, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The choice of leather significantly affects the cost. High-quality Italian leather, such as vegetable-tanned or full-grain leather, commands premium prices due to its durability and aesthetic appeal. Additionally, sourcing unique materials (e.g., exotic leathers) will also increase costs.

-

Labor: Italian craftsmanship is renowned for its quality, which often results in higher labor costs. Skilled artisans are paid a premium for their expertise, particularly in bespoke or limited-edition products.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Italian manufacturers often invest in state-of-the-art equipment and facilities to ensure high-quality production, which can contribute to overhead costs.

-

Tooling: Initial setup costs for tooling, especially for custom designs, can be significant. This includes the creation of molds and patterns necessary for production, which varies based on the complexity of the product.

-

Quality Control (QC): Ensuring that products meet high standards incurs additional costs. Rigorous QC processes are vital in maintaining the reputation of Italian leather goods, resulting in added expenses.

-

Logistics: Shipping costs can fluctuate based on the destination and the chosen Incoterms. International shipping requires careful consideration of customs duties, taxes, and freight charges.

-

Margin: Manufacturers typically add a margin to cover risks and ensure profitability. This margin varies depending on the brand positioning and market demand.

How Do Price Influencers Affect Sourcing Costs?

Several factors influence pricing when sourcing from Italian leather manufacturers:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Manufacturers may have a minimum order quantity that can impact your initial investment.

-

Specifications and Customization: Custom designs or specific requests can increase costs due to additional labor and material requirements. Be clear about your needs to avoid unexpected expenses.

-

Material Quality and Certifications: Products made from premium materials or those that meet specific certifications (like eco-friendly or cruelty-free) may have higher price tags. Understanding the value of these certifications can aid in decision-making.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers may command higher prices due to their history of quality and service.

-

Incoterms: The chosen Incoterms can significantly impact total costs. Understanding the responsibilities for shipping, insurance, and customs can help avoid unexpected charges.

What Are the Best Tips for Negotiating with Italian Leather Manufacturers?

When negotiating with Italian leather manufacturers, consider the following strategies:

-

Research and Benchmarking: Familiarize yourself with market prices and standards. This knowledge empowers you to negotiate effectively.

-

Focus on Total Cost of Ownership (TCO): Look beyond the initial price and consider the long-term value of quality leather goods. Durable products may require fewer replacements and maintenance, ultimately saving money.

-

Build Relationships: Cultivating strong relationships with manufacturers can lead to better pricing and terms. Establishing trust can make negotiations smoother and more favorable.

-

Be Flexible: If possible, be open to adjustments in order volume or product specifications. This flexibility may lead to better pricing or terms.

-

Understand Pricing Nuances: Be aware that international pricing can vary based on currency fluctuations, trade tariffs, and regional economic conditions. This understanding can help you navigate negotiations more effectively.

Заключение

Sourcing from Italian leather manufacturers involves navigating a complex cost structure influenced by various factors. By understanding these components and employing effective negotiation strategies, international B2B buyers can secure favorable terms while ensuring quality products that reflect the rich tradition of Italian craftsmanship. Always remember to approach negotiations with a clear understanding of your needs and the market landscape to achieve the best possible outcomes.

Disclaimer: Prices and costs mentioned are indicative and may vary based on specific circumstances and market conditions. Always consult with suppliers for accurate pricing tailored to your project.

Alternatives Analysis: Comparing italian leather manufacturers With Other Solutions

Exploring Alternatives to Italian Leather Manufacturers

In the competitive landscape of leather goods, international buyers often seek alternatives to traditional Italian leather manufacturers. Understanding these options helps businesses make informed decisions that align with their brand identity, budget, and market positioning. Below, we compare Italian leather manufacturers with two alternative solutions: synthetic leather production and local artisanal leather makers.

Illustrative image related to italian leather manufacturers

| Comparison Aspect | Italian Leather Manufacturers | Synthetic Leather Production | Local Artisanal Leather Makers |

|---|---|---|---|

| Performance | High durability and aesthetics; recognized luxury status | Varies; can be durable but often lacks the prestige | Varies; often high quality but may not meet mass production needs |

| Cost | Premium pricing; reflects quality and craftsmanship | Generally lower cost; material and production savings | Competitive pricing; varies based on local economy and craftsmanship |

| Ease of Implementation | Established supply chains; requires lead time for custom orders | Quick production cycles; scalable | Custom orders can be time-consuming; depends on artisan availability |

| Maintenance | Requires care to maintain appearance; high resale value | Generally low maintenance; not as long-lasting | Similar care needs as Italian leather; unique finishes may require special attention |

| Best Use Case | Luxury brands and high-end markets | Fast fashion and budget-conscious brands | Niche markets seeking unique, handcrafted items |

What Are the Advantages and Disadvantages of Synthetic Leather Production?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is an increasingly popular alternative due to its lower cost and ethical appeal. It is easy to clean and maintain, making it a practical choice for everyday items. However, the performance can vary significantly depending on the quality of the material used. While synthetic leather can mimic the look and feel of real leather, it typically lacks the prestige associated with Italian craftsmanship and may not hold its value as well over time.

How Do Local Artisanal Leather Makers Compare?

Local artisanal leather makers provide a unique alternative, particularly appealing to businesses looking for bespoke products. They often emphasize craftsmanship and local materials, which can enhance brand storytelling. However, the scalability of production is a limitation; these artisans may not be able to meet large orders as efficiently as Italian manufacturers. Additionally, the quality can vary widely, making it essential for buyers to vet artisans carefully to ensure they meet desired standards.

How Can B2B Buyers Choose the Right Solution?

Choosing the right leather manufacturing solution depends on various factors, including brand positioning, target market, and budget constraints. If your business aims to establish a luxury identity, investing in Italian leather manufacturers may provide the quality and prestige needed. Conversely, for brands focused on affordability or ethical considerations, synthetic leather or local artisans could be more suitable. Ultimately, conducting thorough research and considering the specific needs of your business will guide you toward the optimal choice for your leather goods.

Essential Technical Properties and Trade Terminology for italian leather manufacturers

What Are the Key Technical Properties of Italian Leather?

When sourcing leather products from Italian manufacturers, understanding the technical specifications is crucial for ensuring quality and suitability for your business needs. Here are some essential properties to consider:

Illustrative image related to italian leather manufacturers

1. Material Grade

Material grade refers to the quality classification of leather, typically ranging from full-grain to corrected grain. Full-grain leather is the highest quality, retaining the natural texture and markings, while corrected grain undergoes processing to mask imperfections. For B2B buyers, selecting the appropriate material grade is vital for product longevity and customer satisfaction.

2. Thickness

Measured in millimeters or ounces, the thickness of leather affects its durability and application. Thicker leather is often used in items requiring strength, such as belts and bags, while thinner leather is suitable for garments. Understanding thickness helps buyers determine the best leather for specific products, ensuring they meet market demands.

3. Tannery Process

The tanning process determines the leather’s characteristics, such as flexibility, water resistance, and color retention. Vegetable tanning, for example, is environmentally friendly and results in leather that ages beautifully. Buyers should be aware of the tanning methods used by manufacturers, as this impacts both the ethical sourcing of materials and the final product quality.

Illustrative image related to italian leather manufacturers

4. Finish Type

Leather finishes can vary from matte to glossy and can influence the product’s aesthetic appeal and performance. Common finishes include aniline, semi-aniline, and pigmented. Buyers must consider the finish type based on the intended use and desired appearance of the leather goods.

5. Tolerance Levels

Tolerance levels indicate the acceptable variation in dimensions during the manufacturing process. This is particularly important for custom projects where precision is critical. Understanding tolerance levels helps buyers ensure that products meet specific design requirements and maintain consistency across batches.

6. Color Fastness

Color fastness refers to the resistance of leather to fading or running when exposed to light, water, or friction. This property is essential for maintaining the product’s appearance over time. B2B buyers should inquire about color fastness testing to ensure that the leather products will retain their visual appeal throughout their lifecycle.

What Are Common Trade Terms Used in Italian Leather Manufacturing?

Familiarity with industry terminology can greatly enhance communication between buyers and manufacturers. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another company’s brand name. In the leather industry, this means that a manufacturer can create customized leather goods for a brand, which is crucial for businesses looking to establish their own identity.

Illustrative image related to italian leather manufacturers

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is essential for budgeting and planning inventory. Manufacturers often set MOQs to ensure cost efficiency in production.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This document outlines the specific requirements of the leather goods needed, allowing manufacturers to provide detailed proposals. Utilizing RFQs can streamline procurement and ensure competitive pricing.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade, covering aspects like shipping, insurance, and customs. Familiarity with Incoterms is essential for B2B buyers to navigate logistics effectively and avoid misunderstandings.

5. Lead Time

Lead time refers to the period required to produce and deliver goods after an order is placed. Understanding lead times is critical for inventory management, especially for businesses with specific market deadlines or promotional campaigns.

6. Private Label

Private label products are manufactured by one company for branding and sale by another. In the leather industry, this allows retailers to offer unique products without investing in manufacturing capabilities. Buyers should consider private labeling as a strategy for brand differentiation.

Illustrative image related to italian leather manufacturers

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when partnering with Italian leather manufacturers, ensuring high-quality products that meet market demands.

Navigating Market Dynamics and Sourcing Trends in the italian leather manufacturers Sector

What Are the Current Market Dynamics and Key Trends in the Italian Leather Manufacturers Sector?

The global leather goods market is poised for significant growth, driven by rising consumer demand for high-quality and luxury products. Italian leather manufacturers, known for their craftsmanship and heritage, are strategically positioned to capitalize on this trend. Key drivers include an increasing preference for premium leather products in emerging markets, particularly in Africa and South America, where consumers are becoming more brand-conscious and willing to invest in luxury items. Additionally, European markets such as Germany are experiencing a resurgence in demand for artisanal products, reflecting a shift towards quality over quantity.

Emerging B2B technology trends are also reshaping the sourcing landscape. Digital platforms and supply chain management tools are enabling international buyers to streamline their procurement processes. Manufacturers are leveraging these technologies to improve transparency and efficiency in their operations. Moreover, innovations in design and production, such as 3D modeling and virtual prototyping, are enhancing product development timelines and allowing for greater customization, which is particularly appealing to B2B buyers seeking unique offerings.

How Is Sustainability and Ethical Sourcing Impacting the Italian Leather Industry?

Sustainability is becoming a cornerstone of the Italian leather manufacturing sector, with environmental impact considerations influencing sourcing decisions. As global awareness of ecological issues rises, buyers are increasingly seeking manufacturers that adhere to sustainable practices. This includes the use of vegetable-tanned leather, which is less harmful to the environment than traditional tanning methods that use harmful chemicals.

Illustrative image related to italian leather manufacturers

Ethical sourcing is equally vital, with a focus on supply chain transparency. B2B buyers are encouraged to partner with manufacturers that prioritize fair labor practices and animal welfare. Certifications such as the Leather Working Group (LWG) accreditation serve as indicators of a manufacturer’s commitment to responsible sourcing. These credentials not only enhance brand reputation but also resonate with environmentally conscious consumers, making them a powerful marketing tool.

What Is the Historical Context of Italian Leather Manufacturing?

The roots of Italian leather manufacturing trace back centuries, with a rich tradition of craftsmanship that has evolved over time. The modern era began in the 1950s, when skilled artisans in Italy began to establish brands that emphasized quality and design. This period marked a shift towards the global luxury market, with Italian leather goods gaining recognition for their elegance and durability.

As the industry grew, so did the emphasis on artisanal techniques, with many manufacturers maintaining family-run operations that preserve traditional practices. Today, the combination of historical craftsmanship with contemporary design innovations allows Italian leather manufacturers to offer products that appeal to a diverse, global audience. This legacy not only enhances the brand value but also attracts international buyers looking for authenticity and quality in their sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of italian leather manufacturers

-

How do I select the right Italian leather manufacturer for my business needs?

Choosing the right Italian leather manufacturer involves several key steps. Start by assessing your specific requirements, including product type, quality standards, and budget. Research potential manufacturers by reviewing their portfolios, client testimonials, and industry reputation. It’s essential to communicate directly with manufacturers to understand their production capabilities, lead times, and flexibility regarding customizations. Request samples to evaluate the quality of their leather and craftsmanship. Finally, consider their experience with international trade and logistics, particularly if you are sourcing from regions like Africa, South America, or the Middle East. -

What is the typical minimum order quantity (MOQ) when sourcing Italian leather products?

Minimum order quantities (MOQs) can vary significantly among Italian leather manufacturers, often depending on the complexity of the products and the manufacturer’s policies. Generally, MOQs for custom designs may range from 50 to 500 units. For stock items, some manufacturers might offer lower MOQs. It’s advisable to discuss your needs with the manufacturer upfront to find flexibility in their MOQ policies, especially if you are a startup or entering a new market. This can help you manage inventory costs while still providing a diverse product range. -

What customization options are available when working with Italian leather manufacturers?

Most Italian leather manufacturers offer a range of customization options, including design modifications, material selection, and hardware choices. You can typically customize dimensions, colors, and finishes to align with your brand’s identity. Some manufacturers also provide bespoke services, allowing clients to create unique items based on specific designs or concepts. When discussing customization, ensure that you communicate your vision clearly and inquire about any additional costs or lead times associated with bespoke orders. -

What payment terms should I expect when partnering with Italian leather manufacturers?

Payment terms can vary by manufacturer, but common practices include a deposit (usually 30-50%) upon order confirmation, with the balance due before shipping. Some manufacturers may offer net payment terms based on your relationship and order history. It’s crucial to discuss and agree on payment terms upfront, ensuring clarity on accepted payment methods (such as bank transfers or letters of credit) and any potential penalties for late payments. This will help establish a smooth transaction process and foster a positive supplier relationship. -

How can I ensure quality assurance when sourcing from Italian leather manufacturers?

To ensure quality assurance, start by establishing clear quality standards and expectations in your initial discussions with the manufacturer. Request samples and conduct thorough inspections of the materials and craftsmanship before full-scale production begins. Many manufacturers follow rigorous quality control processes, so inquire about their QA protocols, including testing for durability and compliance with international standards. Regular communication throughout the production process can also help address any potential quality issues promptly. -

What logistics considerations should I keep in mind when importing Italian leather goods?

Logistics play a crucial role in the import process of Italian leather goods. Consider factors such as shipping methods, customs regulations, and potential tariffs that may apply to your specific products. Work with manufacturers who have experience in international shipping to ensure they can handle the logistics efficiently. Additionally, it’s beneficial to partner with a reliable freight forwarder who understands the nuances of shipping leather products, including proper documentation and handling requirements to avoid delays or damage during transit. -

How do I handle disputes or issues with my Italian leather manufacturer?

In the event of disputes or issues with your manufacturer, maintaining open communication is key. Document all correspondences and agreements related to your order, as this will serve as a reference if conflicts arise. Approach the situation professionally, clearly outlining your concerns and seeking a resolution that benefits both parties. Many manufacturers value long-term relationships, so they may be willing to negotiate or provide solutions. If necessary, consult legal advice to understand your rights and obligations under the contract. -

What are the trends in the Italian leather industry that I should be aware of?

Staying informed about industry trends is vital for B2B buyers. Current trends include a growing demand for sustainable and ethically sourced materials, such as vegetable-tanned leather and vegan alternatives. Additionally, customization and personalization are increasingly popular, allowing brands to offer unique products that resonate with consumers. Technological advancements in production processes and design also play a role in shaping the industry. Engaging with industry publications and attending trade fairs can help you stay ahead of these trends, ensuring your offerings remain competitive in the market.

Top 7 Italian Leather Manufacturers Manufacturers & Suppliers List

1. Szoneier Leather – Custom Leather Goods

Domain: szoneierleather.com

Registered: 2025 (0 years)

Введение: Custom Leather Bags, Custom Leather Purses, Custom Leather Wallets, Custom Leather Belts, Custom Leather Straps, Custom Leather Accessories, Custom Leather Boxes, Personalized Leather Goods, Custom Leather Fabrics Solutions, Private Label Manufacturing, Custom Leather Goods, Custom Fabrics, Custom Leather Textures, Product Development, Shipping Solutions, Amazon FBA Service, Dropshipping Service, …

2. Del Giudice Roma – Italian Leather Goods

Domain: delgiudiceroma.com

Registered: 2013 (12 years)

Введение: Del Giudice Roma offers a range of Italian leather goods including women’s and men’s bags, wallets, belts, and bespoke/custom options. Women’s bags include various styles such as backpacks, bucket bags, clutch bags, crossbody bags, handle bags, hobo bags, saddle bags, shoulder bags, tote/shopper bags, small/mini bags, briefcases, messenger bags, travel/weekender bags, and wallets/coin purses. Men’…

3. Pierotucci – Handmade Leather Goods

Domain: pierotucci.com

Registered: 1998 (27 years)

Введение: Pierotucci offers Made in Italy Private Label manufacturing for a variety of leather products including handbags, bags, jackets, wallets, leather cases, key rings, belts, dog harnesses, and watch holders. All products are handmade by artisans in Tuscany, using high-quality Italian leather sourced locally. Customization options are available, allowing clients to modify existing designs or create ne…

4. Tuscany Leather – Handmade Leather Goods

Domain: tuscanyleather.it

Registered: 2004 (21 years)

Введение: Tuscany Leather offers a range of handmade leather goods from Italy, including women’s handbags, shoulder bags, backpacks, wallets, and accessories. For men, they provide bags, wallets, and business accessories such as briefcases and laptop bags. The company emphasizes tradition, sustainability, and authenticity, with products made by local artisans in Tuscany. They feature various collections lik…

5. Italian Shoe Factory – Handmade Leather Goods

Domain: italianshoefactory.com

Registered: 2005 (20 years)

Введение: Handmade leather goods manufacturer for luxury designer or private label items. Offers low minimum quantities and quick re-order times. Vegan leather production available on demand. Expertise in designing and manufacturing handbags and accessories for private labels. Prototyping services for various leather goods including purses, clutches, functional bags, work bags, laptop bags, belts, and more….

6. Cuoieria Fiorentina – Italian Leather Handbags

Domain: cuoieriafiorentina.it

Registered: 2000 (25 years)

Введение: Italian Leather Handbags and Leather Bags Made in Italy, Fast worldwide shipping, Women Bags: mini bags, tote bags, crossbody bags, bucket bags, backpacks, shopping bags, clutch bags, shoulder bags, messenger bags, accessories, charms, leather wallets, women’s belts, necessaire, phone bags, foulards, notebook, women shoes, travel bags, travel accessories, special price, Men’s Bags: crossbody, back…

7. Boldrini – Luxury Leather Handbags & Business Bags

Domain: leelinebags.com

Registered: 2024 (1 years)

Введение: 1. Boldrini: Luxury leather goods, including handbags and business bags; uses vegetable-tanned leathers from local tanneries in Tuscany; known for high-quality craftsmanship and stylish designs; offers free delivery within 3-8 days.

2. Fontanelli: Specializes in classic leather accessories such as belts and bags; uses vegetable-tanned leather; located in Florence, Tuscany.

3. Nicoli: Focuses on fa…

Strategic Sourcing Conclusion and Outlook for italian leather manufacturers

As the demand for high-quality Italian leather goods continues to rise globally, strategic sourcing emerges as a crucial factor for international B2B buyers. By partnering with reputable Italian manufacturers, businesses can access unparalleled craftsmanship, innovative designs, and sustainable production practices. The integration of modern technology with traditional techniques not only enhances product quality but also streamlines the supply chain, allowing for flexibility in meeting diverse market needs.

Moreover, Italian leather manufacturers are increasingly embracing eco-friendly practices, such as the use of vegetable-tanned leather and sustainable sourcing of materials, making them attractive partners for buyers focused on sustainability. This commitment to quality and ethics resonates with consumers, particularly in regions like Africa, South America, the Middle East, and Europe, where market preferences are evolving towards responsible luxury.

Illustrative image related to italian leather manufacturers

Looking ahead, international buyers are encouraged to engage with Italian leather manufacturers to explore unique customization options and innovative designs that can set their brands apart. The richness of Italy’s leather heritage, combined with modern production capabilities, presents an exciting opportunity for businesses to thrive in competitive markets. Take the next step in your sourcing strategy—connect with Italian artisans and elevate your product offerings today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to italian leather manufacturers

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.