Introduction: Navigating the Global Market for faux leather manufacturer

In today’s global marketplace, sourcing high-quality faux leather manufacturers poses a significant challenge for B2B buyers. With increasing consumer demand for sustainable and ethical alternatives to traditional leather, navigating the diverse landscape of faux leather options—ranging from plant-based materials like Piñatex and Desserto to advanced polyurethane and PVC products—can be daunting. This comprehensive guide aims to demystify the faux leather industry, providing insights into various types of materials, their applications, and essential considerations for supplier vetting.

As international buyers from regions such as Africa, South America, the Middle East, and Europe (including key markets like Germany and Vietnam) seek to make informed purchasing decisions, understanding the nuances of faux leather sourcing becomes crucial. This guide delves into critical factors such as cost analysis, material performance, and sustainability credentials, equipping decision-makers with the knowledge needed to evaluate suppliers effectively.

By emphasizing the importance of quality, durability, and eco-friendliness, this resource empowers businesses to align their sourcing strategies with modern consumer preferences. Whether you’re looking to integrate luxurious faux leather into fashion, upholstery, or automotive applications, this guide will serve as your roadmap to successfully navigating the global market for faux leather manufacturing.

Table Of Contents

- Top 8 Faux Leather Manufacturer Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for faux leather manufacturer

- Understanding faux leather manufacturer Types and Variations

- Key Industrial Applications of faux leather manufacturer

- 3 Common User Pain Points for ‘faux leather manufacturer’ & Their Solutions

- Strategic Material Selection Guide for faux leather manufacturer

- In-depth Look: Manufacturing Processes and Quality Assurance for faux leather manufacturer

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather manufacturer’

- Comprehensive Cost and Pricing Analysis for faux leather manufacturer Sourcing

- Alternatives Analysis: Comparing faux leather manufacturer With Other Solutions

- Essential Technical Properties and Trade Terminology for faux leather manufacturer

- Navigating Market Dynamics and Sourcing Trends in the faux leather manufacturer Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of faux leather manufacturer

- Strategic Sourcing Conclusion and Outlook for faux leather manufacturer

- Important Disclaimer & Terms of Use

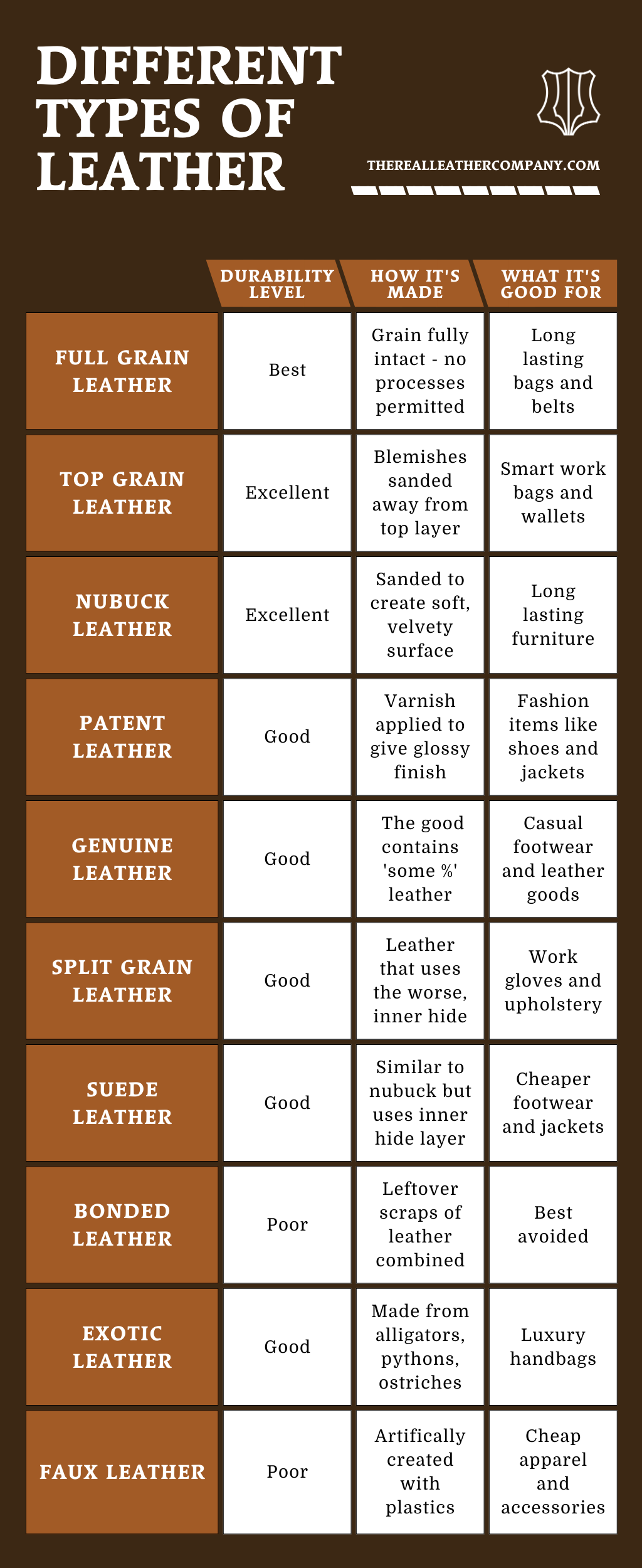

Understanding faux leather manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plant-Based Leather | Made from natural materials like pineapple, cactus, and grapes; eco-friendly. | Fashion, upholstery, accessories | Pros: Sustainable, unique aesthetics. Cons: May have higher costs and limited availability. |

| Polyurethane (PU) Leather | Soft, flexible, and often resembles genuine leather; easy to clean. | Furniture, automotive interiors, fashion | Pros: Durable, versatile, cost-effective. Cons: Less breathable than natural leather. |

| PVC Leather | Made from polyvinyl chloride; often more affordable and widely available. | Upholstery, promotional products | Pros: Low cost, easy to maintain. Cons: Environmental concerns and less durability. |

| Microfiber Leather | Made from synthetic fibers; mimics the texture and look of real leather. | Automotive, upholstery, fashion | Pros: Soft, durable, and stain-resistant. Cons: Can be pricier than other synthetics. |

| Engineered Leather | Combines synthetic and natural fibers; offers a balance of durability and aesthetics. | High-end furniture, fashion, accessories | Pros: Customizable, high performance. Cons: Can require minimum order quantities. |

What Are the Characteristics of Plant-Based Leather Manufacturers?

Plant-based leather manufacturers focus on creating sustainable materials derived from agricultural by-products such as pineapples, cacti, and grapes. These manufacturers cater to environmentally conscious brands looking to reduce their carbon footprint. Key B2B purchasing considerations include sourcing practices, material certifications, and the ability to meet specific design requirements. While these materials provide unique aesthetics and sustainability, buyers should be prepared for potentially higher costs and variable supply chains.

How Do Polyurethane (PU) Leather Manufacturers Operate?

Manufacturers of polyurethane leather utilize advanced technology to create a soft and flexible material that closely resembles genuine leather. This type of faux leather is popular for its durability and ease of maintenance, making it suitable for various applications, including furniture and automotive interiors. B2B buyers should assess the manufacturer’s production capabilities, quality assurance processes, and customization options. Although PU leather is cost-effective, its breathability can be a concern for specific applications.

What Distinguishes PVC Leather Manufacturers?

PVC leather manufacturers produce a synthetic alternative made from polyvinyl chloride, known for its affordability and widespread availability. This type of faux leather is often used in upholstery and promotional products. Buyers should consider the environmental implications of PVC production and the long-term durability of the material. While PVC leather is cost-effective and easy to clean, it may not offer the same longevity and aesthetic appeal as higher-end alternatives.

Why Choose Microfiber Leather Manufacturers?

Microfiber leather manufacturers create products from synthetic fibers designed to mimic the texture and appearance of real leather. This material is especially favored in the automotive and upholstery industries due to its soft feel and stain resistance. B2B buyers should evaluate the manufacturer’s ability to provide high-quality materials and their compliance with industry standards. While microfiber leather can be more expensive than other synthetic options, its durability and aesthetic qualities often justify the investment.

What Are the Benefits of Engineered Leather Manufacturers?

Engineered leather manufacturers combine synthetic and natural fibers to produce a material that balances durability and aesthetics. This type of faux leather is customizable and often used in high-end furniture and fashion accessories. Buyers should consider the manufacturer’s ability to meet minimum order quantities and their flexibility in design options. Although engineered leather tends to be pricier, its unique qualities and performance characteristics can provide significant value in competitive markets.

Key Industrial Applications of faux leather manufacturer

| Industry/Sector | Specific Application of faux leather manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Sustainable clothing lines using plant-based faux leather | Enhances brand image by promoting sustainability and ethical sourcing | Verify certifications for vegan materials and sustainability claims |

| Automotive | Upholstery and interior finishes | Provides durable, easy-to-clean surfaces that reduce maintenance costs | Assess material durability and resistance to wear and tear |

| Furniture and Interior Design | Upholstery for residential and commercial furniture | Offers a luxurious look at a lower cost, appealing to budget-conscious clients | Consider custom design options and color availability |

| Footwear | Vegan shoes and accessories | Captures the growing market of eco-conscious consumers | Ensure compliance with international quality and safety standards |

| Home Decor | Decorative items and wall coverings | Adds aesthetic value while being cost-effective and versatile | Evaluate the ease of cleaning and maintenance requirements |

How is Faux Leather Used in Fashion and Apparel?

In the fashion industry, faux leather serves as a sustainable alternative to traditional leather, particularly through the use of innovative plant-based materials like Piñatex and Desserto. This application not only caters to the increasing demand for eco-friendly products but also helps brands differentiate themselves in a competitive market. International buyers should focus on sourcing materials that are certified vegan and sustainable, ensuring they align with their brand values and consumer expectations.

What Role Does Faux Leather Play in Automotive Upholstery?

Faux leather is extensively used in automotive interiors, providing a stylish and durable option for upholstery. Manufacturers favor it for its resistance to wear, ease of cleaning, and ability to maintain a luxurious appearance without the high maintenance of genuine leather. Buyers should prioritize sourcing materials that meet industry standards for durability and can withstand varying climates, especially in regions like Africa and the Middle East where temperature extremes are common.

How is Faux Leather Transforming Furniture and Interior Design?

In the furniture sector, faux leather is a popular choice for upholstery due to its cost-effectiveness and aesthetic appeal. It allows manufacturers to offer a wide range of designs and textures, catering to diverse consumer tastes. For international buyers, it’s crucial to consider the availability of custom design options and color palettes to meet local market preferences, as well as the ease of maintenance and cleaning, which are important for both residential and commercial applications.

Why is Faux Leather Essential in Footwear Manufacturing?

The footwear industry increasingly incorporates faux leather to create stylish and sustainable shoes. This trend aligns with consumer preferences for vegan products and ethical sourcing. Businesses looking to source faux leather for footwear should ensure that the materials comply with international quality standards and are suitable for various designs, thus appealing to eco-conscious consumers across different markets.

What Benefits Does Faux Leather Offer for Home Decor?

Faux leather is gaining traction in home decor, particularly for decorative items and wall coverings. Its versatility allows for creative designs that enhance the aesthetic value of spaces while remaining budget-friendly. Buyers should evaluate the material’s durability and ease of maintenance, ensuring it meets the demands of both residential and commercial environments, particularly in regions where humidity and wear can be concerns.

3 Common User Pain Points for ‘faux leather manufacturer’ & Their Solutions

Scenario 1: Sourcing High-Quality Faux Leather for Diverse Applications

The Problem: B2B buyers often struggle to find high-quality faux leather that meets the specific needs of various applications, such as upholstery, fashion, or accessories. With a plethora of suppliers claiming to offer the best products, discerning buyers may encounter inconsistent quality, leading to dissatisfaction among their end customers. This can be particularly challenging when sourcing for large orders, where the risk of receiving subpar materials increases.

The Solution: To ensure a reliable supply of high-quality faux leather, buyers should prioritize establishing partnerships with reputable manufacturers known for their stringent quality control processes. Conducting thorough research on potential suppliers is essential—look for certifications that demonstrate adherence to industry standards, such as ISO or Oeko-Tex. Additionally, request samples before placing bulk orders to evaluate the texture, durability, and overall aesthetic of the material. Engaging in open communication with suppliers can also facilitate better understanding of the manufacturing processes, allowing buyers to make informed decisions about their purchases.

Scenario 2: Navigating the Environmental Impact of Faux Leather

The Problem: As sustainability becomes a priority for many businesses, B2B buyers face the challenge of ensuring that the faux leather they source is environmentally friendly. Many synthetic materials can have a significant ecological footprint, which may conflict with a company’s sustainability goals. Buyers need to navigate the complex landscape of materials to select options that are both appealing and responsible.

The Solution: Buyers should actively seek out manufacturers that specialize in eco-friendly faux leather alternatives, such as those made from plant-based materials or recycled plastics. It’s beneficial to inquire about the production methods and raw materials used, ensuring they align with sustainability certifications like Global Recycled Standard or Cradle to Cradle. Additionally, establishing a clear sustainability policy within your organization can guide procurement decisions, encouraging the selection of materials that not only meet aesthetic and functional requirements but also contribute positively to environmental goals.

Scenario 3: Dealing with Performance and Durability Issues

The Problem: Buyers often find that the faux leather products they purchase may not withstand the rigors of their intended use, leading to rapid wear and tear. This issue is particularly pronounced in sectors such as hospitality or automotive, where durability and ease of maintenance are crucial. Inadequate performance can result in increased costs and customer complaints, undermining the reputation of the buyer’s business.

The Solution: To address performance concerns, buyers should specify their needs clearly during the procurement process. This includes communicating the expected use cases and required durability standards, such as abrasion resistance or water repellency. Collaborating closely with manufacturers to select appropriate materials tailored for specific applications can also enhance longevity. For instance, opting for faux leathers treated with protective finishes or engineered for high-performance can significantly improve durability. Regularly reviewing and testing materials in real-world applications can help identify issues early on, allowing for timely adjustments in sourcing strategies.

Strategic Material Selection Guide for faux leather manufacturer

What Are the Key Materials Used in Faux Leather Manufacturing?

Faux leather, also known as synthetic leather, is crafted from various materials that offer distinct properties and advantages. Understanding these materials is crucial for B2B buyers looking to optimize their supply chains and product offerings. Below, we analyze four common materials used in faux leather production: Polyurethane (PU), Polyvinyl Chloride (PVC), Plant-Based Leathers, and Microsuede.

How Does Polyurethane (PU) Perform in Faux Leather Applications?

Polyurethane is a popular choice for faux leather due to its flexibility and durability. It offers excellent abrasion resistance, making it suitable for high-wear applications like upholstery and fashion accessories. PU faux leather can withstand temperature variations and has good moisture resistance, which enhances its longevity.

Illustrative image related to faux leather manufacturer

Pros: PU is soft and pliable, mimicking the feel of genuine leather closely. It can be produced in various textures and colors, providing design versatility.

Cons: However, PU can be more expensive than PVC and may require more complex manufacturing processes, potentially increasing lead times.

For international buyers, compliance with standards such as ASTM and DIN is essential, especially in markets like Europe and the Middle East, where quality regulations are stringent.

What Are the Benefits of Using Polyvinyl Chloride (PVC) in Faux Leather?

Polyvinyl Chloride (PVC) is another widely used material in faux leather manufacturing. It is known for its high durability and resistance to moisture, chemicals, and UV light. PVC can withstand harsh environmental conditions, making it suitable for outdoor furniture and automotive applications.

Pros: PVC is generally more cost-effective than PU, making it an attractive option for budget-conscious buyers. It also has a longer shelf life due to its resistance to wear and tear.

Illustrative image related to faux leather manufacturer

Cons: On the downside, PVC can be less breathable than PU, which may limit its comfort in certain applications. Additionally, it may not be as environmentally friendly, raising concerns among eco-conscious consumers.

For B2B buyers from regions like Africa and South America, understanding local regulations regarding PVC use is crucial, as some countries may impose restrictions due to environmental concerns.

How Do Plant-Based Leathers Compare in Faux Leather Manufacturing?

Plant-based leathers, such as Piñatex (pineapple leather) and Desserto (cactus leather), are emerging as sustainable alternatives in the faux leather market. These materials are made from agricultural waste, offering an eco-friendly option without compromising on aesthetics or durability.

Pros: Plant-based leathers are biodegradable and often have a unique texture that appeals to environmentally conscious consumers. They are gaining traction among high-end brands, enhancing their marketability.

Illustrative image related to faux leather manufacturer

Cons: The primary challenge is their higher cost and limited availability compared to traditional synthetic options. They may also require specialized handling during manufacturing.

For international buyers, particularly in Europe, compliance with sustainability certifications can enhance brand reputation and market acceptance, making plant-based leathers a strategic choice.

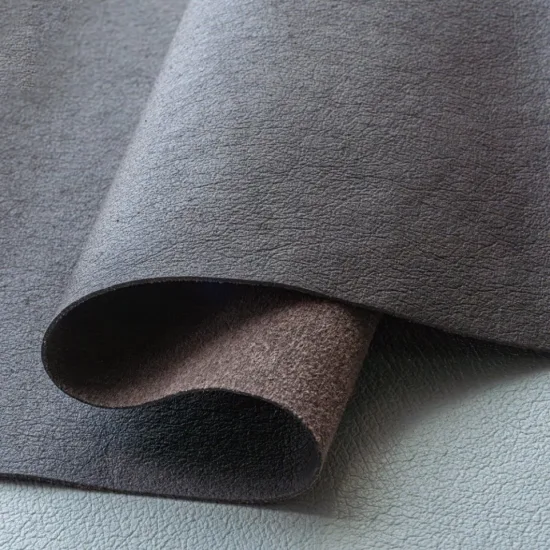

What Role Does Microsuede Play in Faux Leather Manufacturing?

Microsuede is a synthetic fabric that mimics the softness and texture of suede leather. It is made from polyester fibers and is known for its durability and ease of cleaning, making it suitable for a variety of applications, including upholstery and fashion.

Pros: Microsuede is lightweight and offers excellent stain resistance, making it ideal for products requiring frequent cleaning. It is also available in a wide range of colors and patterns.

Cons: However, microsuede can be less resistant to abrasion compared to PU and PVC, which may limit its use in high-wear applications.

International buyers should consider the varying standards for microsuede in different markets, as well as the growing consumer preference for sustainable materials.

Summary Table of Faux Leather Materials

| Material | Typical Use Case for faux leather manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Upholstery, fashion accessories | Soft, flexible, high abrasion resistance | Higher cost, complex manufacturing | High |

| Polyvinyl Chloride (PVC) | Outdoor furniture, automotive interiors | Cost-effective, durable, moisture resistant | Less breathable, environmental concerns | Medium |

| Plant-Based Leathers | High-end fashion, eco-friendly products | Sustainable, unique textures | Higher cost, limited availability | High |

| Microsuede | Upholstery, fashion, accessories | Soft, stain-resistant, easy to clean | Less abrasion resistance | Medium |

This strategic material selection guide aims to empower B2B buyers with the necessary insights to make informed decisions when sourcing faux leather materials, ensuring they meet both market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for faux leather manufacturer

What Are the Main Stages in the Manufacturing Process of Faux Leather?

Faux leather manufacturing involves several critical stages that ensure the final product meets quality and performance standards. The key stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Faux Leather Production?

The first step in faux leather manufacturing is material preparation, where raw materials are selected based on the desired properties of the final product. Common materials used include polyurethane (PU) and polyvinyl chloride (PVC), which serve as the primary synthetic substrates. In some innovative cases, plant-based materials like pineapple leaves or cactus fibers are also used, appealing to the growing market for sustainable alternatives.

Once the materials are selected, they undergo various treatments to enhance their properties. For instance, coatings may be applied to improve flexibility, durability, and resistance to wear and tear. This stage is crucial for ensuring that the faux leather can mimic the look and feel of genuine leather effectively.

Illustrative image related to faux leather manufacturer

What Techniques Are Used in Forming Faux Leather?

The forming stage involves applying the prepared materials onto a substrate, which is typically a flexible textile or synthetic base. There are several techniques used in this process:

-

Coating: The primary method involves coating the substrate with a polymer layer, which provides the leather-like appearance. This can be done through various methods such as roll coating, spray coating, or dipping.

-

Lamination: In some cases, multiple layers may be laminated together to enhance properties like thickness and texture. This is particularly useful for products requiring additional durability or specific tactile qualities.

-

Embossing: To achieve the desired surface texture, embossing techniques are employed. This process creates patterns that replicate the look of real leather, such as grains associated with crocodile or ostrich leather.

How Is Faux Leather Assembled and Finished?

After the forming process, the faux leather undergoes assembly, which may involve cutting, sewing, or bonding to create finished products such as upholstery, garments, or accessories. The precision of this stage is vital, as it impacts both the aesthetic appeal and functional performance of the end product.

Finishing treatments are applied to enhance the faux leather’s appearance and performance characteristics. These treatments can include:

Illustrative image related to faux leather manufacturer

- Coloring: Dyes and pigments are added to achieve specific color requirements, ensuring consistency across batches.

- Protective Coatings: These coatings enhance durability, making the material resistant to stains, scratches, and fading.

- Softening Agents: To improve the tactile quality, softening agents may be introduced to create a more luxurious feel.

What Are the Key Quality Assurance Practices in Faux Leather Manufacturing?

Quality assurance (QA) is crucial in faux leather manufacturing, ensuring that products meet international standards and client specifications. The process involves several critical checkpoints and adherence to recognized standards.

Which International Standards Are Relevant for Faux Leather Manufacturers?

For B2B buyers, understanding the quality standards applicable to faux leather is essential. Key international standards include:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers maintain consistent quality across all production stages.

- CE Marking: Particularly relevant in Europe, CE marking indicates that the product meets health, safety, and environmental protection standards.

- API Standards: For applications in specialized industries (like automotive), adherence to API standards may be required.

What Are the Common Quality Control Checkpoints?

Quality control (QC) is typically structured around several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, ongoing checks are performed to monitor quality. This includes evaluating the consistency of coatings, the precision of embossing, and the integrity of the assembly.

-

Final Quality Control (FQC): Once the products are completed, a thorough inspection is conducted to assess the final quality. This includes visual inspections, tactile evaluations, and performance tests.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure product reliability.

What Methods Can Be Used for Quality Verification?

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and compliance with international standards firsthand.

-

Quality Reports: Requesting detailed quality reports from suppliers provides insights into their QC processes, including testing results and compliance with standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturing processes and product quality. This is especially beneficial for buyers who are unable to visit suppliers personally.

What Are the Nuances of QC and Certification for International Buyers?

International buyers should be aware of potential nuances in quality certification and standards. Different regions may have varying requirements, and some certifications may not be universally recognized. It’s crucial for buyers to understand these differences and ensure that suppliers are compliant with the standards applicable to their target markets.

Additionally, suppliers should provide documentation that verifies their compliance with relevant standards, ensuring transparency in their manufacturing and quality assurance processes.

Conclusion

Understanding the manufacturing processes and quality assurance practices of faux leather manufacturers is essential for B2B buyers looking for reliable suppliers. By familiarizing themselves with the main stages of production, relevant international standards, and effective methods for verifying quality, buyers can make informed decisions that align with their business needs and market demands. This knowledge not only helps in selecting the right supplier but also in fostering long-term partnerships that prioritize quality and sustainability in the faux leather industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather manufacturer’

This guide aims to provide B2B buyers with a structured approach to sourcing faux leather manufacturers. By following this checklist, you can ensure that you select a reliable supplier who meets your specific needs, whether for fashion, upholstery, or other applications.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, clarify your product requirements. Consider the type of faux leather you need—be it polyurethane (PU), polyvinyl chloride (PVC), or innovative plant-based alternatives. Understanding the specifications helps in communicating effectively with suppliers and ensures they can meet your quality and performance expectations.

- Material Type: Decide if you prefer traditional synthetic materials or eco-friendly options like cactus or pineapple leather.

- Application Needs: Specify whether the faux leather will be used for upholstery, accessories, or garments, as this influences durability and texture.

Step 2: Research Potential Suppliers

Conduct thorough research to identify manufacturers that specialize in faux leather. Look for companies with a strong reputation in the industry and a diverse product range.

- Online Reviews and Ratings: Check platforms like Trustpilot or industry-specific forums to gauge customer satisfaction.

- Industry Certifications: Look for certifications such as ISO or OEKO-TEX, which indicate compliance with environmental and safety standards.

Step 3: Evaluate Supplier Capabilities

Assess the manufacturing capabilities of potential suppliers to ensure they can meet your volume and quality requirements.

- Production Capacity: Inquire about their ability to handle large orders without compromising quality.

- Technology and Innovation: Evaluate whether they use advanced technologies for production, which can enhance the material’s quality and reduce lead times.

Step 4: Request Samples

Always request samples before making a bulk order. This step is crucial for assessing the material’s look, feel, and durability.

- Material Testing: Test the samples for abrasion resistance, flexibility, and color fastness to ensure they meet your standards.

- Comparison: Compare samples from multiple suppliers to make an informed decision based on quality.

Step 5: Verify Supplier Certifications

Ensure that your chosen supplier holds necessary certifications that reflect their commitment to quality and sustainability.

- Environmental Compliance: Check for certifications that demonstrate adherence to eco-friendly practices, such as the use of non-toxic materials.

- Quality Standards: Ensure they have certifications that speak to the quality of their products, which can reduce the risk of defects.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, discuss pricing, payment terms, and delivery schedules.

- Pricing Transparency: Ensure that you understand all costs involved, including shipping and any potential tariffs.

- Lead Times: Confirm the timeline for production and delivery to avoid disruptions in your supply chain.

Step 7: Establish Communication Protocols

Effective communication is vital throughout the sourcing process. Establish clear channels for ongoing discussions and updates.

Illustrative image related to faux leather manufacturer

- Regular Check-Ins: Schedule regular updates to discuss progress and address any issues promptly.

- Contact Points: Identify key contacts on both sides for efficient communication and resolution of queries.

By following this structured checklist, B2B buyers can confidently navigate the process of sourcing faux leather manufacturers, ensuring they select a partner that aligns with their business goals and product requirements.

Comprehensive Cost and Pricing Analysis for faux leather manufacturer Sourcing

What Are the Key Cost Components in Faux Leather Manufacturing?

Understanding the cost structure of faux leather manufacturing is essential for B2B buyers looking to source competitively. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of raw materials significantly influences costs. Faux leathers can be made from various substrates, including polyurethane (PU) and polyvinyl chloride (PVC), as well as innovative plant-based materials like pineapple, cactus, and grape. The sourcing of these materials impacts the overall price, with plant-based alternatives typically positioned at a premium due to their sustainable nature.

-

Labor: Labor costs vary by region and production scale. In countries with lower labor costs, such as Vietnam, manufacturers may offer more competitive pricing. However, higher-skilled labor may be required for specialized faux leather finishes, which can raise costs.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and administrative costs. Overhead can vary based on the manufacturing location and the efficiency of production processes.

-

Tooling: Custom tooling for specific faux leather designs adds to initial costs. If buyers require unique patterns or textures, they should anticipate higher upfront expenses for mold creation and machinery setup.

-

Quality Control (QC): Ensuring the faux leather meets specific quality standards is crucial, especially for industries such as automotive and fashion. Rigorous QC processes can add to costs, but they are necessary to avoid defects and ensure long-term performance.

-

Logistics: Transportation costs depend on the distance from the manufacturer to the buyer, as well as the chosen shipping method. Incoterms also play a significant role in determining who bears the shipping costs, which can affect the overall pricing.

-

Margin: Manufacturers typically apply a profit margin that reflects their operational costs and market conditions. This margin can vary significantly based on brand positioning and market demand.

How Do Price Influencers Affect Faux Leather Sourcing?

Several factors can influence the pricing of faux leather, which buyers should consider when negotiating.

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing. Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should evaluate their needs to optimize order sizes.

-

Specifications and Customization: Custom designs or specific material requirements can lead to increased costs. Buyers should clearly communicate their specifications and assess whether the added expense aligns with their budget.

-

Quality and Certifications: Faux leather products that meet specific quality certifications, such as those for environmental sustainability or durability, may command higher prices. Understanding these certifications can help buyers assess value.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established manufacturers with a track record of quality may charge a premium, but they often provide greater assurance of product performance.

-

Incoterms: Familiarity with Incoterms is essential for understanding shipping responsibilities and costs. Different terms can significantly affect the total landed cost of the faux leather.

What Negotiation Strategies Can B2B Buyers Employ?

To achieve cost-efficiency in sourcing faux leather, buyers should consider the following strategies:

-

Negotiate Based on Volume: Leverage larger order quantities to negotiate better pricing. Suppliers may offer discounts for bulk purchases, allowing buyers to reduce their overall costs.

-

Evaluate Total Cost of Ownership (TCO): Buyers should look beyond the initial price and consider the TCO, which includes shipping, storage, and potential waste. Understanding TCO can lead to better purchasing decisions.

-

Research Market Trends: Staying informed about market trends and competitor pricing can provide leverage in negotiations. Buyers should be prepared to discuss alternatives or present competitive offers from other suppliers.

-

Build Relationships: Establishing a long-term relationship with suppliers can lead to more favorable terms and pricing. Trust and reliability often result in better negotiation outcomes.

Conclusion

Navigating the cost and pricing landscape of faux leather manufacturing requires a comprehensive understanding of various components and influencers. By leveraging effective negotiation strategies and focusing on the total cost of ownership, international B2B buyers can optimize their sourcing decisions, ensuring both quality and cost-effectiveness in their purchases. As pricing can vary widely based on numerous factors, it’s advisable to seek indicative quotes and perform thorough market comparisons.

Illustrative image related to faux leather manufacturer

Alternatives Analysis: Comparing faux leather manufacturer With Other Solutions

Understanding Alternatives to Faux Leather Manufacturing

In today’s marketplace, international B2B buyers are increasingly seeking sustainable and high-quality materials for their products. Faux leather manufacturers offer a synthetic alternative to traditional leather, but several other innovative solutions are emerging that cater to the same needs. This analysis will compare faux leather with two viable alternatives: plant-based leathers and engineered polyurethane (PU) products.

Comparison Table

| Comparison Aspect | Faux Leather Manufacturer | Plant-Based Leathers | Engineered Polyurethane (PU) |

|---|---|---|---|

| Performance | Good durability and aesthetic appeal | Varies, generally durable but may have limitations | High durability and performance, resistant to wear |

| Cost | Moderate price point | Generally higher due to sourcing and production | Competitive pricing, often lower than faux leather |

| Ease of Implementation | Simple to work with, widely available | May require specialized knowledge for handling | Standard manufacturing practices, easy to integrate |

| Maintenance | Easy to clean and maintain | Maintenance depends on the specific material used | Low maintenance, typically resistant to stains |

| Best Use Case | Fashion and upholstery | Eco-friendly fashion, accessories, and upholstery | High-performance applications such as automotive interiors |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Plant-Based Leathers?

Plant-based leathers, derived from materials such as pineapple, cactus, and grapes, offer a sustainable alternative to both traditional leather and faux leather. The primary advantage is their eco-friendliness; they utilize agricultural waste and reduce the carbon footprint associated with synthetic materials. However, plant-based leathers may not always match the durability and performance of faux leather, making them less suitable for high-stress applications. They can also be more expensive due to the sourcing of raw materials, which may impact budget-conscious buyers.

How Does Engineered Polyurethane Compare to Faux Leather?

Engineered polyurethane (PU) is a synthetic alternative that excels in both performance and aesthetic qualities. PU products are designed to mimic the look and feel of genuine leather while providing enhanced durability and resistance to wear and tear. One of the key advantages of PU is its cost-effectiveness, often being less expensive than traditional faux leather. However, the production of PU can involve chemical processes that may raise sustainability concerns, making it less attractive for eco-conscious businesses.

How Should B2B Buyers Choose the Right Solution?

When selecting the right material for your business needs, it’s essential to consider several factors. Evaluate the specific application of the material—whether it’s for fashion, upholstery, or automotive interiors—alongside performance requirements, budget constraints, and sustainability goals. Faux leather manufacturers may provide a balanced solution for many applications, but exploring alternatives like plant-based leathers and engineered PU can offer unique advantages depending on your brand’s values and target market.

Illustrative image related to faux leather manufacturer

Ultimately, aligning your choice with your business objectives and consumer expectations will guide you in selecting the most suitable material for your products.

Essential Technical Properties and Trade Terminology for faux leather manufacturer

What Are the Key Technical Properties of Faux Leather for Manufacturers?

When sourcing faux leather, understanding the technical properties is crucial for ensuring product quality and meeting application requirements. Here are essential specifications to consider:

1. Material Composition

Faux leather can be made from various materials, primarily polyurethane (PU) and polyvinyl chloride (PVC). PU is known for its softness and breathability, making it ideal for fashion and upholstery. PVC, on the other hand, is more durable and water-resistant, suitable for outdoor applications. Understanding material composition helps manufacturers select the right product for their specific needs, impacting durability and customer satisfaction.

2. Abrasion Resistance

Abrasion resistance measures how well a material can withstand wear and tear from friction. This property is typically assessed using tests like the Wyzenbeek or Martindale test. High abrasion resistance is vital for applications such as upholstery or automotive interiors, where surfaces are frequently subjected to contact. Specifying the right level of abrasion resistance ensures that the faux leather will maintain its appearance and functionality over time.

Illustrative image related to faux leather manufacturer

3. Thickness and Weight

The thickness and weight of faux leather can influence its application and feel. Thicker materials tend to be more durable and suitable for heavy-duty applications, while lighter materials are often used in fashion and accessories. Manufacturers should specify the desired thickness to ensure the faux leather meets design and performance expectations.

4. Tolerance

Tolerance refers to the allowable variation in dimensions and properties of the faux leather. This can include width, thickness, and color consistency. Tight tolerances are critical for applications requiring precision, such as automotive interiors, where mismatched components can lead to costly reworks. Understanding tolerance specifications helps ensure that all parts fit seamlessly in the final product.

5. Fire Retardancy

Fire retardancy is a critical property for faux leather used in public spaces or furniture. Materials can be treated to meet specific fire safety standards, which vary by region. Ensuring compliance with these regulations not only enhances safety but also expands market opportunities in sectors with stringent fire codes.

What Are Common Trade Terms Used in the Faux Leather Industry?

Navigating the faux leather manufacturing landscape requires familiarity with industry jargon. Here are some key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are used in another company’s end product. In the faux leather industry, OEMs may supply materials to furniture manufacturers or fashion brands. Understanding OEM relationships can help buyers identify reliable sources for their supply chain.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum amount of product that a supplier is willing to sell. This term is critical for buyers to understand, as it can impact inventory management and cash flow. When sourcing faux leather, knowing the MOQ helps buyers plan their orders effectively and avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. Including detailed specifications in an RFQ for faux leather ensures that suppliers provide accurate pricing and availability, facilitating better negotiation and decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is essential for B2B transactions involving faux leather, as they dictate costs, risks, and the point at which ownership transfers. Familiarity with Incoterms can prevent misunderstandings and disputes in international trade.

5. Lead Time

Lead time is the period from order placement to delivery. In the faux leather industry, lead times can vary based on production schedules and shipping logistics. Recognizing lead times helps buyers manage project timelines and customer expectations effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing faux leather, ensuring quality products that meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the faux leather manufacturer Sector

What Are the Key Market Dynamics and Trends in the Faux Leather Manufacturing Sector?

The faux leather manufacturing sector is witnessing significant transformation, driven by an increasing global demand for sustainable and ethical materials. This shift is largely influenced by consumer awareness regarding environmental issues and animal welfare, compelling businesses to seek alternatives to traditional leather. Key markets in Africa, South America, the Middle East, and Europe are particularly responsive to these trends, as buyers prioritize materials that align with both ethical considerations and performance requirements.

Emerging technologies are reshaping sourcing practices within the faux leather industry. Innovations in material science, such as the development of plant-based leathers derived from pineapple, cactus, and grape waste, are gaining traction. These materials not only offer aesthetic and functional benefits but also contribute to a circular economy by utilizing agricultural by-products. Additionally, advancements in manufacturing processes, such as digital printing and 3D modeling, are enhancing customization capabilities, allowing businesses to meet specific market demands swiftly.

International buyers should remain vigilant about fluctuating raw material prices and supply chain disruptions, which can affect the availability of faux leather products. Establishing relationships with reliable suppliers who can provide transparency in sourcing and production practices will be crucial for mitigating risks. Furthermore, understanding regional regulations and certifications regarding sustainability will enable buyers to make informed decisions that resonate with their brand values.

How Is Sustainability Influencing Sourcing Decisions in the Faux Leather Sector?

Sustainability has become a non-negotiable factor in the sourcing strategies of B2B buyers within the faux leather industry. The environmental impact of synthetic materials, particularly those derived from petroleum, has prompted a shift towards more sustainable options. Manufacturers are increasingly adopting eco-friendly practices, such as using water-based adhesives and non-toxic dyes, to reduce their carbon footprint.

Ethical sourcing is equally important, as buyers are expected to ensure that their supply chains are free from exploitative practices. Transparency in sourcing is paramount, with buyers seeking suppliers who can demonstrate compliance with international labor standards and environmental regulations. Certifications such as Global Recycle Standard (GRS) and OEKO-TEX® serve as benchmarks for assessing the sustainability of faux leather materials, providing buyers with the assurance they need to make responsible purchasing decisions.

Moreover, the rise of consumer demand for “green” products is pushing brands to prioritize suppliers who can offer certifications and documentation that validate their sustainable claims. By aligning sourcing strategies with sustainability goals, businesses can enhance their market position and appeal to eco-conscious consumers.

What Is the Evolution of Faux Leather Manufacturing?

The evolution of faux leather manufacturing has been marked by significant technological advancements and changing consumer preferences. Initially developed in the early 20th century, faux leather emerged as a cost-effective alternative to genuine leather, with early iterations primarily made from linen and coated with linseed oil. Over the decades, advancements in polymer technology led to the creation of more durable and versatile synthetic materials, including polyurethane (PU) and polyvinyl chloride (PVC).

The late 20th century saw a shift towards greater realism in faux leather, with manufacturers employing advanced embossing techniques to mimic the texture and appearance of genuine leather. Today, the industry is at the forefront of innovation, with a focus on sustainable production methods and the incorporation of plant-based materials. This evolution reflects the growing importance of ethical considerations in manufacturing, positioning faux leather as a viable choice for consumers and businesses alike in the quest for sustainable fashion and furnishings.

Frequently Asked Questions (FAQs) for B2B Buyers of faux leather manufacturer

-

How do I choose the right faux leather supplier for my business needs?

Selecting the right faux leather supplier involves evaluating several key factors. Start by reviewing their product range to ensure they offer the textures, colors, and materials you require. Check their reputation through customer testimonials and case studies. It’s also essential to assess their production capabilities, including minimum order quantities (MOQs) and lead times. Additionally, inquire about their sustainability practices and certifications, especially if your brand emphasizes eco-friendliness. Finally, ensure they have a reliable logistics system for international shipping to your location. -

What are the benefits of using faux leather over genuine leather?

Faux leather offers numerous advantages compared to genuine leather, particularly for B2B buyers. Firstly, it is typically more cost-effective, allowing businesses to reduce production costs. Faux leather is also vegan, appealing to environmentally conscious consumers. Additionally, it is easier to clean and maintain, which can enhance the longevity of products. The material is versatile, available in various textures and colors, which can be customized to meet specific design needs. Finally, faux leather is often more resistant to staining and fading, ensuring a durable product. -

What customization options are available when ordering faux leather?

Most faux leather manufacturers offer a range of customization options to meet specific business requirements. You can typically request different textures, colors, and finishes to align with your brand’s aesthetic. Some suppliers may also provide the option to create unique patterns or designs, especially for bulk orders. It’s important to discuss your customization needs during the initial conversations with potential suppliers. Ensure you understand any additional costs associated with custom orders and the impact on lead times. -

What are the typical minimum order quantities (MOQs) for faux leather?

Minimum order quantities (MOQs) for faux leather can vary significantly between manufacturers. Some suppliers may have no MOQ, allowing you to order as little as a single yard, which is ideal for small businesses or testing new designs. Others may require MOQs ranging from 50 to several hundred yards, particularly for custom orders. When evaluating suppliers, clarify their MOQ policies and consider how they align with your production needs. Understanding MOQs can help you manage inventory and budget effectively. -

How do I ensure the quality of faux leather products?

To ensure the quality of faux leather products, request samples before placing a bulk order. This allows you to assess the material’s feel, durability, and finish. Inquire about the supplier’s quality assurance processes, such as testing for abrasion resistance and colorfastness. Certifications and compliance with international standards can also indicate a supplier’s commitment to quality. Additionally, consider their return and warranty policies, which can provide recourse if the products do not meet your expectations. -

What payment terms should I expect when sourcing faux leather internationally?

Payment terms can vary widely among faux leather manufacturers, especially in international trade. Common payment methods include bank transfers, letters of credit, and PayPal. Many suppliers may require a deposit upfront, often ranging from 30% to 50%, with the balance due before shipment. It’s crucial to clarify payment terms during negotiations to avoid misunderstandings. Additionally, be aware of currency fluctuations and potential transaction fees when dealing with international suppliers, as these can impact your overall costs. -

What logistics considerations should I keep in mind when importing faux leather?

When importing faux leather, logistics plays a critical role in ensuring timely delivery and cost management. Evaluate shipping options based on your delivery timelines and budget—air freight is faster but more expensive than sea freight. Additionally, consider the supplier’s location and the associated shipping times. Be aware of customs duties and import regulations in your country, as these can affect overall costs. Establishing a reliable freight forwarder can also simplify the logistics process, ensuring compliance and smooth transportation of goods. -

How can I assess the environmental impact of faux leather production?

To assess the environmental impact of faux leather production, research the manufacturer’s sustainability practices and materials sourcing. Inquire about the use of eco-friendly materials, such as recycled plastics or plant-based alternatives, which reduce reliance on fossil fuels. Certifications from recognized environmental organizations can also provide assurance of sustainable practices. Additionally, ask about the production processes employed by the manufacturer, as some techniques can be more environmentally friendly than others. Understanding these factors can help align your sourcing decisions with your brand’s sustainability goals.

Top 8 Faux Leather Manufacturer Manufacturers & Suppliers List

1. Alternative Leathers – Plant-Based Materials

Domain: alternativeleathers.com

Registered: 2022 (3 years)

Introduction: This company, Alternative Leathers – Plant-Based Materials, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Sallie Tomato – Faux Leather Collection

Domain: sallietomato.com

Registered: 2015 (10 years)

Introduction: Faux Leather collection by Sallie Tomato includes 66 products, with 65 being faux leather and 1 vinyl. Available colors include Beige (5), Black (10), Blue (6), Brown (10), Green (6), Grey (6), Navy (4), Orange (1), Pink (4), Purple (2), Red (6), Teal (1), White (2), Yellow (2). Textures available are Alligator (4), Basket Weave (6), Crocodile (4), Legacy (15), Limited Edition (6), Lite (4), Ostri…

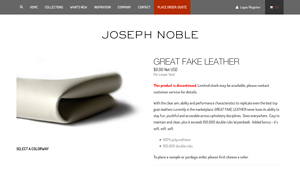

3. Joseph Noble – Great Fake Leather

Domain: josephnoble.com

Registered: 1998 (27 years)

Introduction: Product Name: Great Fake Leather

Product Code: #2400

Content: 100% polyurethane

Back: Polyester/Cotton

Width: 54 Inches

Weight: 14 oz per linear yard

Price: $0.00 Net USD Per Linear Yard

Availability: Discontinued, limited stock may be available

Performance: Exceeds 100,000 double rubs Wyzenbeek

Suggested Use: Upholstery

Cleaning Code: W/S, Bleach (10:1)

Environmental Notes: Solvent/DMF Free, Phth…

4. Skai – Artificial Leather

Domain: skai.com

Registered: 1998 (27 years)

Introduction: skai® artificial leather is a high-quality alternative to genuine leather, made through advanced manufacturing processes that replicate the look and feel of real leather. Key components include a flexible textile substrate, a polymer coating for softness and volume, and a finish for enhanced properties like dirt resistance. The product is vegan, durable, easy to clean, and available in a wide rang…

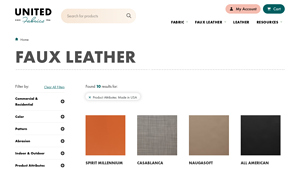

5. United Fabrics – Faux Leather Essentials

Domain: unitedfabrics.com

Registered: 1997 (28 years)

Introduction: Faux Leather | United Fabrics

– Product Attributes:

– Antimicrobial

– Bleach Cleanable

– Ink Resistant

– PVC Free

– Made in USA

– Contains Recycled Content

– Project Type: Commercial, Residential

– Application: Indoor, Outdoor

– Additional Features:

– Stain Resistant

– Moisture Barrier

– Brand Partners: Alta, Crypton Home, Crypton Leather, Nanotex, Sunbrella, Supreen

6. DESSERTO – Cactus-Based Vegan Material

Domain: desserto.com.mx

Registered: 2019 (6 years)

Introduction: DESSERTO is a cactus-based, technically advanced plant-based material designed to replace plastics and leather. It is a sustainable vegan material applicable in various industries, including fashion, automotive, and interior design. The product is developed from organic cactus plantations and utilizes patented technology. DESSERTO aims to drive the transition to sustainability and is certified as …

7. Majilite – Novasuede TM

Domain: majilite.com

Registered: 1997 (28 years)

Introduction: Majilite specializes in faux leather and suede, offering products such as Novasuede TM, which mimics the luxurious look and feel of fine kid suede while providing exceptional strength, comfort, and breathability. Their faux leather is available in various effects, including metallic surfaces and authentic leather looks, allowing for extensive customization. The company operates a custom manufactur…

8. Sewport – Faux Leather

Domain: sewport.com

Registered: 2015 (10 years)

Introduction: Faux leather, also known as synthetic leather, is a petroleum-based alternative to genuine leather. It is soft to the touch, water-resistant, and highly resistant to stains, making it easy to clean. While less durable than real leather, it is resistant to abrasions and cuts, ideal for upholstery in homes with children or pets. Faux leather can be produced in various colors, including unconventiona…

Strategic Sourcing Conclusion and Outlook for faux leather manufacturer

As the faux leather market continues to evolve, international B2B buyers must recognize the transformative potential of strategic sourcing. By leveraging innovative materials such as plant-based leathers and high-performance synthetic options, businesses can meet the growing demand for sustainable and ethically produced alternatives. Sourcing faux leather not only offers cost-effective solutions but also opens doors to a diverse array of textures and finishes that can enhance product offerings across various industries, from fashion to upholstery.

Investing in strong supplier relationships is paramount. Buyers should prioritize partnerships with manufacturers who demonstrate a commitment to quality, sustainability, and technological advancements. This not only ensures consistent supply but also positions your brand as a leader in sustainability, appealing to increasingly eco-conscious consumers.

Looking ahead, the global faux leather industry is poised for significant growth, driven by innovation and changing consumer preferences. By embracing strategic sourcing now, businesses can capitalize on this momentum. Engage with suppliers from regions like Africa, South America, the Middle East, and Europe to explore new opportunities and elevate your product line. The future of faux leather is bright—seize the opportunity to lead in this dynamic market.

Illustrative image related to faux leather manufacturer

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.