Introduction: Navigating the Global Market for custom leather fire helmet shields

In the competitive landscape of firefighting equipment, sourcing custom leather fire helmet shields poses unique challenges for B2B buyers. Ensuring that these essential protective accessories not only meet safety standards but also reflect the identity and pride of firefighting teams can be daunting. This comprehensive guide delves into the multifaceted world of custom leather fire helmet shields, exploring various types, applications, and the nuances of supplier vetting.

B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Germany—will benefit from insights into cost considerations, quality benchmarks, and logistical factors. By addressing these critical elements, this guide empowers international buyers to make informed purchasing decisions, ensuring that the products they acquire meet both functional requirements and aesthetic desires.

Moreover, it highlights the importance of durability and craftsmanship in custom leather shields, which are often handcrafted and tailored to individual specifications. As firefighting continues to evolve, understanding the global market dynamics surrounding these products is essential for establishing long-term supplier relationships and enhancing operational efficiency. Whether you are outfitting a fire department or seeking personalized gear, this guide serves as a crucial resource in navigating the complexities of custom leather fire helmet shields.

Table Of Contents

- Top 4 Custom Leather Fire Helmet Shields Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather fire helmet shields

- Understanding custom leather fire helmet shields Types and Variations

- Key Industrial Applications of custom leather fire helmet shields

- 3 Common User Pain Points for ‘custom leather fire helmet shields’ & Their Solutions

- Strategic Material Selection Guide for custom leather fire helmet shields

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather fire helmet shields

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather fire helmet shields’

- Comprehensive Cost and Pricing Analysis for custom leather fire helmet shields Sourcing

- Alternatives Analysis: Comparing custom leather fire helmet shields With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather fire helmet shields

- Navigating Market Dynamics and Sourcing Trends in the custom leather fire helmet shields Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather fire helmet shields

- Strategic Sourcing Conclusion and Outlook for custom leather fire helmet shields

- Important Disclaimer & Terms of Use

Understanding custom leather fire helmet shields Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Leather Shields | Standard 6″ or 6.5″ size, hand-carved designs | Fire departments, individual firefighters | Pros: Classic look, customizable; Cons: May require longer lead times for customization. |

| Custom Logo Shields | Incorporates department logos, ranks, and names | Branding for fire departments | Pros: Enhances department identity; Cons: Higher cost for intricate designs. |

| Boston Style Shields | Unique shape and style, often with additional ornamentation | Specialty fire units, collectors | Pros: Distinctive appearance; Cons: Less common, may be harder to source. |

| Passport Shields | Compact design, often used for personal identification | Individual firefighters, gifts | Pros: Easy to personalize; Cons: Limited visibility compared to larger shields. |

| Modern Fire Helmet Shields | Streamlined design with contemporary aesthetics | Modern fire departments, trend-conscious users | Pros: Sleek and professional; Cons: May lack traditional charm for some users. |

What Are the Characteristics of Traditional Leather Shields?

Traditional leather fire helmet shields are typically designed to fit standard helmet sizes, measuring either 6″ or 6.5″ in height. These shields are often hand-carved, showcasing intricate designs that reflect the pride of the fire service. Suitable for both individual firefighters and entire departments, they can be customized with names, ranks, and other personal identifiers. B2B buyers should consider lead times for customization, as these can vary significantly depending on the manufacturer’s workload.

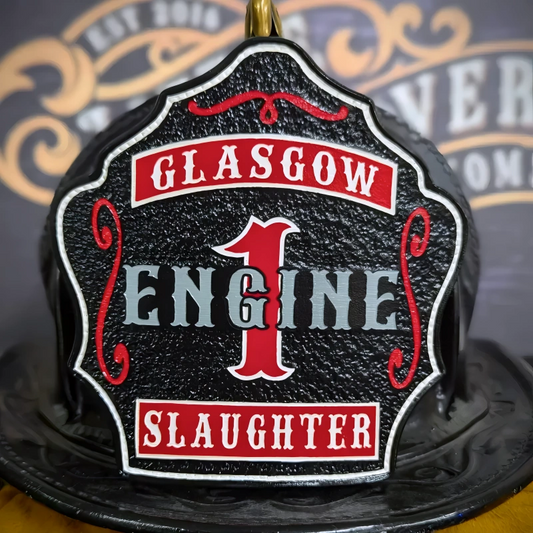

How Do Custom Logo Shields Enhance Department Branding?

Custom logo shields are an excellent choice for fire departments looking to enhance their branding. These shields can incorporate department logos, ranks, and names, promoting a sense of unity and pride among firefighters. They are particularly valuable for marketing purposes, as they visually represent the department’s identity. However, buyers should be aware that the complexity of the design can influence the cost, making it essential to balance aesthetics with budgetary constraints.

What Makes Boston Style Shields Unique?

Boston style shields are characterized by their distinctive shape and additional ornamentation, making them a favorite among collectors and specialty fire units. These shields often feature elaborate designs that can include historical references or unique symbols. While they offer a unique aesthetic, B2B buyers should consider their availability, as these may not be as widely produced as traditional shields.

Illustrative image related to custom leather fire helmet shields

Why Choose Passport Shields for Personal Identification?

Passport shields are a compact option that provides personal identification for individual firefighters. These shields are easy to customize and can serve as meaningful gifts or personal keepsakes. However, their smaller size may limit visibility compared to larger shields, which could be a consideration for departments looking for maximum recognition. B2B buyers should weigh the benefits of personalization against the functional needs of their team.

What Are the Advantages of Modern Fire Helmet Shields?

Modern fire helmet shields present a sleek, contemporary aesthetic that appeals to trend-conscious fire departments. These shields often feature streamlined designs that align with modern firefighting gear. While they provide a professional appearance, buyers should consider whether this modern look meets the traditional values of their department, as some may prefer the classic charm of traditional shields.

Key Industrial Applications of custom leather fire helmet shields

| Industry/Sector | Specific Application of custom leather fire helmet shields | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Firefighting Services | Custom identification shields for firefighters’ helmets | Enhances team identity and morale, promotes professionalism | Quality of leather, customization options, delivery timelines |

| Emergency Response Organizations | Shields for rescue teams during high-stakes operations | Provides a unique identifier in chaotic environments, improves safety | Durability and resistance to harsh conditions, bulk purchasing options |

| Fire Safety Equipment Suppliers | Custom shields as part of fire safety gear packages | Attracts customers with personalized options, increases sales value | Pricing strategies, branding opportunities, lead times |

| Training Facilities | Shields for training exercises and simulations | Instills a sense of realism and professionalism in training | Customization for various ranks and departments, material quality |

| Corporate Gifting | Personalized shields as awards or recognition items for firefighters | Strengthens relationships with clients and enhances brand loyalty | Customization capabilities, order volume discounts, delivery speed |

How Are Custom Leather Fire Helmet Shields Used in Firefighting Services?

In firefighting services, custom leather fire helmet shields serve as essential identification tools for firefighters. These shields often display the firefighter’s name, rank, and department, enhancing team identity and professionalism. For international buyers, particularly in regions like Africa and the Middle East, the ability to customize designs can reflect local culture and values, fostering a sense of pride among personnel. Sourcing high-quality leather that withstands extreme conditions is crucial, as is ensuring timely delivery to meet operational needs.

Illustrative image related to custom leather fire helmet shields

What Role Do Custom Shields Play in Emergency Response Organizations?

Emergency response organizations utilize custom leather fire helmet shields to provide a recognizable identity for their teams during high-pressure situations. These shields can be critical in chaotic environments, allowing team members to identify each other quickly and efficiently. Buyers in South America and Europe may prioritize features such as enhanced durability and resistance to wear, as these factors directly impact safety and operational effectiveness. Bulk purchasing options can also be beneficial for organizations looking to equip large teams.

How Can Fire Safety Equipment Suppliers Benefit from Custom Shields?

Fire safety equipment suppliers can enhance their product offerings by including custom leather fire helmet shields in their inventory. These personalized shields can attract customers looking for unique, high-quality gear that reflects their department’s identity. In competitive markets like Germany, offering customization options can differentiate suppliers from competitors and increase sales value. Key considerations include pricing strategies that accommodate various budgets while maintaining quality and ensuring timely delivery.

Why Are Custom Shields Important for Training Facilities?

Training facilities incorporate custom leather fire helmet shields into their programs to simulate real-life firefighting scenarios. These shields help instill a sense of realism and professionalism among trainees, enhancing the overall training experience. For international buyers, customization for different ranks and departments can be crucial to reflect the hierarchy and structure of their local firefighting services. Ensuring that the materials used are durable and appropriate for repeated use is essential for maximizing the training investment.

How Do Custom Leather Fire Helmet Shields Enhance Corporate Gifting?

In the realm of corporate gifting, personalized custom leather fire helmet shields serve as unique awards or recognition items for firefighters. These gifts can strengthen relationships with clients and foster brand loyalty, especially in industries related to fire safety and emergency services. Buyers should consider customization capabilities that allow for branding and personalization, as well as the potential for order volume discounts to make these gifts more accessible. Timely delivery is also critical to ensure that gifts align with recognition events or ceremonies.

3 Common User Pain Points for ‘custom leather fire helmet shields’ & Their Solutions

Scenario 1: Difficulty in Finding Customization Options for Unique Branding

The Problem: Many B2B buyers, especially those in regions such as Africa or the Middle East, face challenges when seeking custom leather fire helmet shields that reflect their unique branding or departmental identity. Traditional suppliers may offer limited designs or fail to accommodate specific requests, leading to dissatisfaction with the final product. This not only affects the aesthetic appeal of the helmets but can also undermine the sense of pride and camaraderie among team members who wish to display their fire department’s identity.

Illustrative image related to custom leather fire helmet shields

The Solution: To address this issue, buyers should seek out suppliers who specialize in bespoke designs and have a robust portfolio showcasing their previous work. When contacting a supplier, it’s essential to provide detailed specifications, including design elements like logos, colors, and text. Additionally, consider requesting samples or mock-ups to visualize how the customization will look on the actual shield. Engaging in a collaborative design process can ensure the end product meets expectations, enhancing both functionality and team morale.

Scenario 2: Concerns Over Durability and Quality in Harsh Environments

The Problem: Firefighting is a demanding profession, and the equipment used—including custom leather fire helmet shields—must withstand extreme conditions. Buyers often worry about the durability of leather products, particularly in regions with high humidity or extreme temperatures. Concerns about wear and tear, fading, or damage due to environmental factors can lead to hesitation in making a purchase, as the cost of replacement can be substantial.

The Solution: Buyers should prioritize suppliers who use high-quality leather and offer shields treated with water-resistant finishes or other protective coatings. When sourcing products, inquire about the specific materials used, including the weight and thickness of the leather, as these factors significantly impact durability. It is also beneficial to check for warranty or guarantee options, which can provide peace of mind regarding the longevity of the shields. Additionally, consider regular maintenance routines, such as applying leather conditioner, to prolong the life of the shields and maintain their appearance.

Scenario 3: Long Lead Times and Delays in Order Fulfillment

The Problem: B2B buyers often encounter lengthy lead times when ordering custom leather fire helmet shields, which can delay the outfitting of new personnel or the replacement of worn equipment. This is particularly problematic for organizations that require quick turnarounds due to budget cycles or urgent operational needs. Delays can lead to increased frustration and potential safety risks if firefighters are not adequately equipped.

Illustrative image related to custom leather fire helmet shields

The Solution: To mitigate this issue, buyers should clearly communicate their timelines and urgency when placing orders. Establishing a relationship with a reliable supplier who can accommodate expedited orders or offers a range of stock designs for quick shipment can be invaluable. Additionally, it may be worthwhile to explore suppliers who provide a rush order service, which can significantly reduce lead times. Planning ahead by placing orders well in advance of anticipated needs, especially for bulk purchases, can help ensure that all personnel are equipped on time. Regularly reviewing supplier performance and maintaining open lines of communication can foster a more efficient ordering process.

Strategic Material Selection Guide for custom leather fire helmet shields

What Are the Key Properties of Common Materials Used in Custom Leather Fire Helmet Shields?

When selecting materials for custom leather fire helmet shields, understanding the properties, advantages, and limitations of each option is crucial for B2B buyers. The most common materials include full-grain leather, top-grain leather, synthetic leather, and reinforced leather composites. Each material offers unique benefits that can impact performance, durability, and compliance with international standards.

How Does Full-Grain Leather Perform in Fire Helmet Shields?

Full-grain leather is the highest quality leather available, known for its durability and natural finish. It retains the hide’s original texture and imperfections, which can add character. This type of leather is highly resistant to wear, making it suitable for the demanding conditions firefighters face. It can withstand high temperatures, but it does require proper maintenance to prevent drying and cracking.

Pros: Exceptional durability, excellent temperature resistance, and a classic aesthetic appeal.

Cons: Higher cost compared to other leathers and requires regular maintenance.

Impact on Application: Full-grain leather shields can endure extreme heat and abrasion, making them ideal for frontline firefighting.

Considerations for International Buyers: Compliance with standards such as ASTM F2302 (for heat resistance) is essential, especially in regions with strict safety regulations.

What Are the Advantages of Top-Grain Leather for Custom Shields?

Top-grain leather is a step below full-grain in terms of quality but is still a popular choice for fire helmet shields. It is sanded and treated to remove imperfections, resulting in a more uniform appearance. This material is lighter than full-grain leather and offers good resistance to heat and moisture.

Illustrative image related to custom leather fire helmet shields

Pros: Lighter weight, more uniform appearance, and generally lower cost than full-grain leather.

Cons: Less durable than full-grain leather and may not age as gracefully.

Impact on Application: Suitable for shields that require a balance between aesthetics and functionality, though it may not withstand extreme conditions as effectively.

Considerations for International Buyers: Buyers should ensure that the leather meets local fire safety standards, which may vary by region.

How Does Synthetic Leather Compare for Fire Helmet Shields?

Synthetic leather, often made from polyurethane or PVC, offers a cost-effective alternative to natural leather. It is typically waterproof and resistant to stains, making it easy to clean and maintain. However, synthetic leather may not provide the same level of heat resistance as natural leathers.

Pros: Lower cost, easy maintenance, and water-resistant properties.

Cons: Generally less durable and may not provide adequate heat protection compared to natural leathers.

Impact on Application: Best suited for less demanding environments or as a budget-friendly option for bulk orders.

Considerations for International Buyers: Ensure that synthetic materials comply with relevant safety standards, especially in regions with stringent regulations.

What Role Do Reinforced Leather Composites Play in Custom Shields?

Reinforced leather composites combine layers of leather with synthetic materials to enhance durability and performance. These composites can provide excellent heat resistance and structural integrity, making them suitable for high-stress applications.

Illustrative image related to custom leather fire helmet shields

Pros: Enhanced durability, excellent heat resistance, and a balance of natural and synthetic benefits.

Cons: More complex manufacturing process and potentially higher costs.

Impact on Application: Ideal for high-performance applications where both durability and aesthetics are important.

Considerations for International Buyers: Buyers should verify compliance with international safety standards and consider the specific needs of their local firefighting operations.

Summary Table of Material Selection for Custom Leather Fire Helmet Shields

| Material | Typical Use Case for custom leather fire helmet shields | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Frontline firefighting shields requiring durability | Exceptional durability and heat resistance | Higher cost and requires maintenance | High |

| Top-Grain Leather | Shields needing a balance of aesthetics and functionality | Lighter weight and uniform appearance | Less durable than full-grain | Medium |

| Synthetic Leather | Budget-friendly options for less demanding environments | Lower cost and easy maintenance | Less durable and lower heat protection | Low |

| Reinforced Leather Composites | High-performance applications needing durability | Enhanced durability and heat resistance | Complex manufacturing and higher costs | Medium to High |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions when sourcing custom leather fire helmet shields. Understanding the unique properties and implications of each material will help ensure compliance with safety standards and meet the specific needs of firefighting operations across various regions.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather fire helmet shields

What Are the Main Stages of Manufacturing Custom Leather Fire Helmet Shields?

The manufacturing process for custom leather fire helmet shields is a meticulous endeavor that emphasizes craftsmanship, durability, and functionality. This process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Custom Leather Fire Helmet Shields?

The journey begins with selecting high-quality leather, typically 9-10 oz vegetable-tanned leather, known for its durability and ability to withstand harsh conditions. Suppliers often source leather from reputable tanneries that adhere to international standards. After sourcing, the leather is inspected for quality, ensuring it is free from defects such as scars or inconsistencies.

Once the leather is approved, it undergoes cutting. Templates are used to ensure precision, with each piece cut to the desired dimensions for various shield designs. This step is critical as it sets the foundation for the shield’s final appearance and functionality.

What Techniques Are Used in Forming and Assembling Leather Shields?

Forming and assembly are where the artistry of custom leather fire helmet shields truly shines. After cutting, artisans employ various techniques to create intricate designs. Hand carving, tooling, and painting are common methods used to personalize each shield, allowing for custom logos, department names, and other unique identifiers.

Once the decorative elements are complete, the shields are assembled. This involves stitching the components together using heavy-duty, UV-resistant thread to ensure longevity. The stitching not only provides structural integrity but also contributes to the aesthetic appeal of the final product.

Illustrative image related to custom leather fire helmet shields

How Is the Finishing Process Completed for Leather Fire Helmet Shields?

The finishing stage is vital in enhancing the durability and appearance of the shields. This often includes applying a water-resistant clear finish that protects against moisture and environmental wear. Additionally, finishing touches may involve burnishing edges and polishing surfaces to provide a professional look.

Each shield is then subjected to a thorough inspection before moving to the quality assurance phase. This ensures that all manufacturing standards have been met and that the final product aligns with customer specifications.

What Quality Assurance Standards Are Relevant for Custom Leather Fire Helmet Shields?

Quality assurance (QA) is integral to the manufacturing of custom leather fire helmet shields, especially for international B2B buyers. Key standards such as ISO 9001 provide a framework for maintaining quality management systems. This certification ensures that manufacturers implement consistent processes, ultimately leading to high-quality products.

Moreover, industry-specific certifications may apply, such as CE marking in Europe, which indicates compliance with health, safety, and environmental protection standards. Buyers should inquire about these certifications during the procurement process to verify that suppliers meet the necessary regulatory requirements.

Illustrative image related to custom leather fire helmet shields

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch potential issues early. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, periodic inspections are conducted to verify that the process adheres to established quality standards. This includes checking dimensions, stitching quality, and the application of finishes.

-

Final Quality Control (FQC): Before shipping, a comprehensive inspection is performed to ensure that each shield meets the design specifications and quality standards. This includes visual inspections and functional tests to ensure durability and performance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, verifying a supplier’s quality control processes is essential to ensure that they receive a reliable product. Here are several actionable steps:

-

Audits: Request to conduct or review audits of the supplier’s manufacturing processes. Audits can reveal insights into their operational practices and compliance with quality standards.

-

Reports and Certifications: Ask for documentation that demonstrates adherence to quality standards such as ISO 9001 or any relevant industry-specific certifications. This documentation provides assurance of the supplier’s commitment to quality.

-

Third-Party Inspections: Consider engaging third-party inspection services to evaluate the manufacturing processes and products before shipment. These services can provide an impartial assessment of the supplier’s quality assurance protocols.

What Are the QC/CERT Nuances for International B2B Buyers?

Navigating the complexities of quality control and certification can be particularly nuanced for international buyers from regions such as Africa, South America, the Middle East, and Europe. Buyers must be aware of the following:

-

Regional Standards: Different regions may have varying standards and regulations. Understanding local requirements, such as CE marking in Europe or specific fire safety regulations in the Middle East, is crucial for compliance.

-

Cultural Considerations: Communication styles and business practices can vary significantly across cultures. Building relationships and understanding local customs can facilitate smoother negotiations and ensure that quality expectations are clearly communicated.

-

Logistical Challenges: International shipping can introduce risks to product quality. Buyers should ensure that suppliers have robust packaging and handling processes to minimize damage during transit.

By focusing on these aspects of the manufacturing process and quality assurance, B2B buyers can make informed decisions when procuring custom leather fire helmet shields, ensuring they receive products that meet their high standards of quality and durability.

Illustrative image related to custom leather fire helmet shields

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather fire helmet shields’

In the competitive landscape of procurement for custom leather fire helmet shields, B2B buyers must navigate various factors to ensure they receive high-quality products that meet specific requirements. This guide provides a step-by-step checklist to streamline your sourcing process and make informed decisions.

Step 1: Define Your Technical Specifications

Before approaching suppliers, clearly outline your technical requirements. This includes dimensions, design elements, and materials such as the thickness of leather and finish options. Defining these specifications upfront ensures that you communicate your needs effectively and helps suppliers provide accurate quotes.

- Consider custom features: Think about personalization options like department names, ranks, and logos.

- Durability requirements: Specify the conditions the shields must withstand, such as exposure to heat and moisture.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in custom leather fire helmet shields. Look for companies with a strong reputation in the firefighting community and experience in producing high-quality leather goods.

- Check online reviews and testimonials: Look for feedback from other fire departments or organizations that have purchased similar products.

- Evaluate their portfolio: Examine previous work to gauge the quality and variety of designs offered.

Step 3: Request Samples

Before making a bulk order, request samples from shortlisted suppliers. Samples allow you to assess the craftsmanship, material quality, and overall aesthetics of the helmet shields.

- Evaluate the craftsmanship: Look for attention to detail in stitching, tooling, and finishing.

- Test durability: If possible, conduct stress tests to ensure the shields can withstand operational conditions.

Step 4: Inquire About Customization Capabilities

Customization is key for fire helmet shields. Discuss with suppliers their ability to accommodate specific requests and variations in design.

Illustrative image related to custom leather fire helmet shields

- Ask about design proofs: Ensure they provide digital proofs or mock-ups before final production to confirm your vision.

- Understand turnaround times: Inquire about lead times for customization to align with your procurement schedule.

Step 5: Verify Supplier Certifications

Confirm that potential suppliers meet industry standards and hold relevant certifications, particularly in quality management and safety regulations.

- Request documentation: Ask for certifications that demonstrate compliance with safety standards applicable to firefighting gear.

- Assess their manufacturing processes: Understanding their production practices can give you insights into their commitment to quality.

Step 6: Negotiate Terms and Conditions

Once you select a supplier, discuss pricing, payment terms, and delivery schedules. Clear agreements prevent misunderstandings and ensure a smooth procurement process.

- Discuss bulk order discounts: Inquire if there are price breaks for larger orders or repeat purchases.

- Establish clear delivery timelines: Agree on deadlines to avoid delays in receiving your products.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process to monitor the products you receive. This includes inspecting items upon delivery to ensure they meet the agreed-upon specifications.

- Create a checklist for inspection: Develop a list of criteria to evaluate the quality of the shields upon arrival.

- Provide feedback: Share your observations with the supplier to foster a collaborative relationship for future orders.

By following this checklist, B2B buyers can streamline their sourcing process, ensuring they procure high-quality custom leather fire helmet shields that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for custom leather fire helmet shields Sourcing

What Are the Key Cost Components for Custom Leather Fire Helmet Shields?

When considering the sourcing of custom leather fire helmet shields, it’s essential to understand the various cost components involved. The primary costs include:

Illustrative image related to custom leather fire helmet shields

-

Materials: High-quality leather is the cornerstone of any durable helmet shield. Prices can vary significantly based on the type of leather used (e.g., full-grain, top-grain) and whether additional materials (like stitching and finishes) are required. Expect to pay more for premium, water-resistant, or treated leathers.

-

Labor: Skilled craftsmanship is crucial in the production of these shields. Labor costs can vary depending on the region, with artisans in North America typically commanding higher wages than those in regions like South America or parts of Africa. Customization adds to labor time, impacting overall costs.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Manufacturers often factor these into the pricing structure, influencing the final cost of the shields.

-

Tooling: Custom designs may require special tools or molds, which can incur additional upfront costs. These costs are usually amortized over the production run, affecting the price per unit.

-

Quality Control (QC): Ensuring that every shield meets quality standards involves inspection processes that can add to the overall cost. For international buyers, understanding the QC measures in place can be crucial for ensuring product reliability.

-

Logistics: Shipping costs can be significant, especially for international orders. Factors like distance, shipping method, and customs duties can heavily influence the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business sustainability. This margin can vary based on competition and market demand.

How Do Price Influencers Impact Custom Leather Fire Helmet Shield Costs?

Several factors can influence the pricing of custom leather fire helmet shields:

-

Volume/MOQ: Ordering in bulk often results in lower per-unit pricing due to economies of scale. Suppliers may offer discounts for larger orders, making it advantageous for fire departments or organizations to consolidate purchases.

-

Specifications and Customization: The complexity of the design, including custom logos, colors, and additional features, will directly impact costs. Simpler designs will generally be less expensive.

-

Quality and Certifications: Products that come with certifications (like fire resistance or durability tests) may have higher price points due to the assurance of quality. Buyers should consider whether these certifications are necessary for their intended use.

-

Supplier Factors: The reputation and reliability of the supplier play a role in pricing. Established manufacturers may charge more due to their brand value and proven track record.

-

Incoterms: Understanding Incoterms is critical for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the product.

What Negotiation Tips Can Help Buyers Secure Better Pricing?

International buyers, particularly from regions like Africa, South America, and the Middle East, can benefit from the following negotiation strategies:

-

Establish Relationships: Building a rapport with suppliers can often lead to better pricing and terms. Long-term partnerships may yield loyalty discounts.

-

Highlight Volume Potential: If your organization plans to make recurring purchases, emphasize this during negotiations. Suppliers may offer more favorable terms for guaranteed future business.

-

Request Transparent Pricing: Ask for a breakdown of costs to understand where savings might be possible. This transparency can facilitate negotiations.

-

Consider Total Cost of Ownership (TCO): When evaluating offers, consider not only the upfront costs but also the long-term costs associated with maintenance, durability, and replacement.

-

Be Aware of Regional Differences: Understand the market dynamics and pricing norms in your region versus the supplier’s. This knowledge can strengthen your negotiating position.

Conclusion: Understanding Pricing Nuances for Effective Sourcing

When sourcing custom leather fire helmet shields, awareness of the cost components and pricing influencers is crucial. By leveraging negotiation strategies and understanding the total cost of ownership, international buyers can make informed purchasing decisions that align with their budget and quality requirements. Prices may vary significantly based on customization and supplier, so obtaining multiple quotes and understanding the market landscape will benefit buyers in the long run.

Alternatives Analysis: Comparing custom leather fire helmet shields With Other Solutions

Introduction to Alternatives in Fire Helmet Shields

When it comes to fire safety gear, particularly helmet shields, the choice of materials and designs can significantly impact performance, durability, and overall user satisfaction. Custom leather fire helmet shields are popular for their craftsmanship and personalization options. However, B2B buyers should also consider alternative solutions that may offer comparable benefits or unique advantages. This analysis compares custom leather fire helmet shields with two viable alternatives: synthetic helmet shields and printed helmet decals.

Comparison Table

| Comparison Aspect | Custom Leather Fire Helmet Shields | Synthetic Helmet Shields | Printed Helmet Decals |

|---|---|---|---|

| Performance | High durability and aesthetic appeal; withstands harsh conditions | Durable, lightweight, but may not match leather’s ruggedness | Lower durability; susceptible to wear and tear |

| Cost | Generally higher ($75 – $125) due to craftsmanship | Moderate ($30 – $70); cost-effective option | Low ($10 – $30); affordable for bulk orders |

| Ease of Implementation | Custom order process can take weeks | Readily available; easy to install | Simple installation; minimal effort required |

| Maintenance | Requires occasional conditioning to maintain quality | Minimal upkeep; easy to clean | Low maintenance; typically lasts until faded |

| Best Use Case | Ideal for personalized, ceremonial, or high-profile firefighting roles | Suitable for everyday use and training environments | Best for temporary or promotional uses |

Detailed Breakdown of Alternatives

Synthetic Helmet Shields: A Cost-Effective Option

Synthetic helmet shields are made from materials like PVC or other plastics that mimic the appearance of leather while offering a lighter weight. One of the primary advantages of synthetic shields is their affordability, making them an appealing option for departments with limited budgets. They are also readily available and easy to install, which reduces the time needed for procurement. However, while synthetic shields provide adequate protection and functionality, they may not match the aesthetic appeal and durability of custom leather options, especially under extreme conditions.

Printed Helmet Decals: Affordable and Customizable

Printed helmet decals are an economical alternative that allows for high levels of customization. These decals can be designed to reflect department logos, ranks, and other identifiers, making them visually appealing. Their low cost makes them an attractive option for departments looking to outfit a large number of helmets quickly. However, the downside is that printed decals tend to wear out faster than leather or synthetic shields, especially in harsh firefighting environments. They are best suited for temporary uses, promotional events, or training scenarios where long-term durability is not a primary concern.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate helmet shield depends on various factors, including budget, intended use, and desired durability. Custom leather fire helmet shields excel in performance and personalization, making them ideal for professional firefighters who prioritize aesthetics and longevity. Conversely, synthetic shields offer a balance of cost and functionality for everyday use, while printed decals provide an affordable, quick solution for temporary needs. B2B buyers should assess their specific requirements, considering factors like operational conditions and budget constraints, to make an informed decision that best supports their firefighting personnel.

Essential Technical Properties and Trade Terminology for custom leather fire helmet shields

What Are the Key Technical Properties of Custom Leather Fire Helmet Shields?

When sourcing custom leather fire helmet shields, understanding the technical specifications is crucial for ensuring quality and durability. Here are some essential properties to consider:

Illustrative image related to custom leather fire helmet shields

-

Material Grade

The primary material used in crafting leather fire helmet shields is typically high-grade leather, often 9 to 10 ounces thick. This grade ensures durability and resistance to wear and tear in extreme conditions. Buyers should prioritize suppliers who use premium leather to guarantee long-lasting performance, as inferior materials can lead to rapid degradation. -

Dimensions and Fit

Standard sizes for fire helmet shields are generally around 6 to 6.5 inches in height. Ensuring that the shield fits properly on various helmet types, including composite and traditional leather helmets, is vital. A good fit not only enhances aesthetics but also ensures that the shield does not obstruct visibility or functionality during firefighting operations. -

Water Resistance

Many manufacturers apply a water-resistant finish to their shields, which protects the leather from moisture and enhances longevity. This feature is particularly important for firefighters who often work in wet conditions. Buyers should inquire about the specific treatments used to ensure that the shield can withstand exposure to water without compromising its integrity. -

Customization Options

Customization is a significant aspect of these shields, allowing buyers to incorporate department logos, names, or rank. The ability to personalize not only enhances the shield’s aesthetic appeal but also fosters a sense of pride among firefighters. Understanding the customization process, including the techniques used (e.g., carving, painting, and stitching), can help buyers make informed decisions. -

Durability Standards

Custom leather fire helmet shields should meet specific durability standards, including resistance to heat and impact. This ensures that the shield can protect the firefighter’s identity and personal information during intense situations. Buyers should look for certifications or guarantees that confirm the shields meet these rigorous standards.

What Are Common Trade Terms in the Custom Leather Fire Helmet Shield Industry?

Familiarity with industry jargon can streamline the procurement process and facilitate clearer communication with suppliers. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand name. In the context of custom leather fire helmet shields, understanding whether a supplier is an OEM can help buyers gauge the quality and authenticity of the products offered. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell in a single order. Knowing the MOQ is essential for budget planning and can affect inventory management for fire departments looking to outfit multiple helmets. -

RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to solicit price quotes from suppliers. This process helps in comparing costs and understanding the pricing structures of different manufacturers, making it easier to find competitive options for custom helmet shields. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for international buyers to clarify shipping responsibilities, insurance, and liability, ensuring smooth delivery of custom orders. -

Lead Time

This term refers to the time it takes from placing an order to receiving the finished product. Knowing the lead time is vital for planning purposes, especially in emergency services where timely access to gear can be critical. -

Custom Design Fees

These are additional costs associated with creating a unique shield design. Understanding these fees upfront can help buyers budget effectively and ensure they get the desired customization without unexpected expenses.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing custom leather fire helmet shields, ultimately enhancing the safety and identity of their firefighting teams.

Navigating Market Dynamics and Sourcing Trends in the custom leather fire helmet shields Sector

What Are the Key Trends in the Custom Leather Fire Helmet Shields Market?

The global market for custom leather fire helmet shields is being shaped by several pivotal trends. First, the increasing recognition of the importance of personalization in firefighting equipment is driving demand for customized shields that reflect individual firefighters’ identities and departments. This trend is particularly relevant for international B2B buyers in regions such as Africa and South America, where local pride and cultural identity play significant roles in product selection.

Illustrative image related to custom leather fire helmet shields

Additionally, technological advancements in manufacturing processes, such as laser engraving and automated stitching, are enhancing production efficiency and product quality. These innovations allow for more intricate designs and faster turnaround times, which are crucial for B2B buyers needing bulk orders. Furthermore, the rise of e-commerce platforms has simplified sourcing, enabling buyers from Europe and the Middle East to access a broader range of suppliers and products.

Another emerging trend is the focus on durability and functionality. Buyers are increasingly prioritizing shields that not only provide aesthetic appeal but also withstand harsh conditions, thus ensuring longevity and value for money. This demand aligns with the broader trend of investing in high-quality gear to enhance firefighter safety and operational readiness.

How Is Sustainability Influencing B2B Sourcing of Custom Leather Fire Helmet Shields?

Sustainability and ethical sourcing are becoming essential considerations for B2B buyers in the custom leather fire helmet shields sector. The environmental impact of leather production is a growing concern, prompting buyers to seek suppliers that adhere to sustainable practices. This includes sourcing leather from tanneries that utilize eco-friendly tanning processes and prioritize animal welfare.

Moreover, the adoption of ‘green’ certifications, such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification, is gaining traction. These certifications provide assurance that the leather used in helmet shields meets specific environmental and social criteria, thus appealing to buyers who are committed to ethical sourcing.

Illustrative image related to custom leather fire helmet shields

In addition to environmental considerations, there is a rising demand for products that incorporate recycled or upcycled materials. Buyers are increasingly interested in suppliers who offer innovative solutions, such as shields made from repurposed leather or synthetic alternatives that reduce waste. This trend not only addresses environmental concerns but also aligns with the growing consumer preference for sustainable products across industries.

What Is the Historical Context of Custom Leather Fire Helmet Shields?

The history of custom leather fire helmet shields is rooted in the rich traditions of firefighting. Initially, helmet shields served a practical purpose, identifying the wearer’s department and rank. Over time, as firefighting evolved into a respected profession, these shields became symbols of pride and honor, often showcasing intricate designs that reflect local culture and history.

In the early days, shields were often handcrafted by local artisans, leading to a diverse array of styles and materials. As the demand for customization grew, so did the techniques employed in their production. Today, advancements in technology and craftsmanship have allowed for a remarkable range of personalization options, enabling firefighters worldwide to express their unique identities while honoring the legacy of their profession. This evolution underscores the importance of maintaining a balance between tradition and innovation in the sourcing of custom leather fire helmet shields, particularly for B2B buyers who value both heritage and quality.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather fire helmet shields

-

How do I ensure quality when sourcing custom leather fire helmet shields?

To guarantee quality, start by researching potential suppliers thoroughly. Look for companies with established reputations in the firefighting community and positive customer reviews. Request samples of their products to assess craftsmanship, material quality, and customization options. Establish clear quality assurance standards and communicate these with your supplier. Additionally, inquire about their manufacturing processes and any certifications they may have, such as ISO standards, which can serve as indicators of their commitment to quality. -

What are the customization options available for leather fire helmet shields?

Customization options for leather fire helmet shields typically include size, design, color, and personalization elements such as department names, ranks, and logos. Many suppliers offer hand-carving and hand-painting services to create unique designs tailored to your specifications. When discussing customization, be sure to provide detailed requirements and examples of your desired outcomes to ensure the supplier can meet your vision effectively. -

What is the typical minimum order quantity (MOQ) for custom leather fire helmet shields?

Minimum order quantities can vary significantly among suppliers, ranging from a single unit for personalized shields to larger quantities for wholesale orders. It’s essential to communicate your needs upfront and ask about bulk pricing options if you require multiple shields. Some suppliers may offer discounts for larger orders, making it economically advantageous for departments or organizations looking to equip many firefighters. -

What payment terms should I expect when ordering custom leather fire helmet shields?

Payment terms can vary by supplier, but it is common to encounter options such as a deposit upfront with the balance due upon delivery. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) for established clients. Always clarify payment methods accepted, such as bank transfers, credit cards, or PayPal, and ensure to review any international transaction fees that may apply, especially if you’re sourcing from abroad. -

How long does it typically take to receive a custom leather fire helmet shield order?

Lead times for custom orders can range from a few weeks to several months, depending on the complexity of the design, the supplier’s workload, and the quantity ordered. It’s advisable to inquire about estimated production and shipping times upfront, especially if you have a deadline for an event or training. Some suppliers may offer expedited production options for an additional fee, which can be beneficial for urgent orders. -

What logistics considerations should I be aware of when importing fire helmet shields internationally?

When importing custom leather fire helmet shields, consider shipping costs, customs duties, and import regulations specific to your country. Work with suppliers who have experience in international shipping and can provide assistance with paperwork, such as commercial invoices and customs declarations. Ensure you are aware of any restrictions on leather products in your region, as this can affect your ability to import certain items. -

How can I verify the legitimacy and reliability of a custom leather fire helmet shield supplier?

To verify a supplier’s legitimacy, check for business registration details, customer reviews, and industry certifications. Engaging with other buyers in forums or social media groups dedicated to firefighting gear can provide insights into their experiences. Additionally, request references from previous clients and consider conducting a site visit if feasible. A reliable supplier should be transparent about their production processes and willing to answer any questions you have. -

What are the common quality assurance practices for custom leather fire helmet shields?

Quality assurance practices for custom leather fire helmet shields often include thorough inspections of raw materials, adherence to manufacturing standards, and final product evaluations before shipping. Suppliers may employ skilled artisans to ensure each shield meets design specifications and durability requirements. Ask potential suppliers about their quality control processes, such as random sampling and testing, to ensure you are receiving a product that meets your expectations for performance and longevity.

Top 4 Custom Leather Fire Helmet Shields Manufacturers & Suppliers List

1. Fully Involved Leatherworks – Custom Fire Helmet Shields

Domain: fullyinvolvedleatherworks.com

Registered: 2014 (11 years)

Introduction: Leather Fire Helmet Shields are customizable, hand carved designs that fit traditional style helmets, including composite and leather types, as well as the Phoenix TL-2. They measure 6 1/2″ tall and feature carved, tooled, hand-painted designs with real stitching, sealed with a water-resistant clear finish for durability. Products include various custom options such as American Flag, Boston Style,…

2. Five Alarm Fronts – Custom Leather Gear

Domain: fivealarmfronts.com

Registered: 2012 (13 years)

Introduction: Five Alarm Fronts and Leatherworks specializes in custom leather work for fire departments, including Fire Helmet Fronts, Leather Suspenders, Radio Straps/Holsters, and Duty Belts. All products are handmade to order by firefighters in the U.S.A. using 9/10oz leather. The company emphasizes a one-off approach to provide quality shields tailored to customer specifications. Current turnaround times f…

3. Engine Company – Custom Leather Fire Helmet Shields

Domain: enginecompanyleather.com

Registered: 2013 (12 years)

Introduction: Custom Leather Fire Helmet Shields, handcrafted with a focus on quality. Current lead time for shields is 8 weeks. Available categories include Traditional 6″ Shields, Traditional 6.5″ TL2 Shields, Traditional 6″ Patent Shields, Traditional 6.5″ TL2 Patent Shields, 6″ LA Shields, Boston Devices, and Passports.

4. Fire Helmet Shields – Custom Leather Fronts

Domain: firehelmetshields.com

Registered: 2013 (12 years)

Introduction: Custom leather fire helmet shields for firefighters, fully personalized and durable. Crafted with precision, designed to withstand tough conditions. Customization options include department name, rank, and number. Products include: 1. Titan-Leather Fire Helmet Front – $79.95 2. Legacy Passport Fire Helmet Shield – $124.95 3. Custom Engraved Leather Firefighter Shield – The Galt – $104.95 4. Thin R…

Strategic Sourcing Conclusion and Outlook for custom leather fire helmet shields

In conclusion, the strategic sourcing of custom leather fire helmet shields presents a unique opportunity for international B2B buyers to enhance their firefighting gear with high-quality, personalized products. Key takeaways from this guide emphasize the importance of selecting suppliers who prioritize craftsmanship, durability, and customization. By collaborating with manufacturers that understand the specific needs of firefighters, businesses can ensure that their purchases reflect not only the identity of their departments but also the resilience required in the field.

Illustrative image related to custom leather fire helmet shields

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for specialized firefighting equipment is expected to grow. Buyers are encouraged to explore partnerships with reputable suppliers who can deliver tailored solutions that meet local regulations and preferences. This proactive approach not only fosters strong supplier relationships but also contributes to the overall safety and pride of firefighting teams.

Looking ahead, the landscape for custom leather fire helmet shields is bright. Now is the time for B2B buyers to invest in quality gear that symbolizes commitment and excellence in firefighting. Engage with trusted manufacturers today to secure the best products for your team’s future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to custom leather fire helmet shields

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.