Introduction: Navigating the Global Market for seat cover vinyl material

In the quest for durable and aesthetically pleasing seat cover vinyl material, international B2B buyers face the critical challenge of sourcing high-quality products that meet diverse market demands. Whether you’re outfitting vehicles, marine vessels, or commercial seating, selecting the right vinyl material is essential for ensuring longevity and customer satisfaction. This comprehensive guide delves into various types of seat cover vinyl materials, their applications, and the nuances of the global supply chain.

From understanding the unique properties of marine-grade vinyl to exploring options that withstand extreme weather conditions, this resource equips businesses with the knowledge necessary to make informed purchasing decisions. Additionally, the guide covers essential considerations such as supplier vetting processes, cost analysis, and compliance with regional standards, which are particularly pertinent for buyers from Africa, South America, the Middle East, and Europe, including markets like Germany and Vietnam.

By empowering B2B buyers with actionable insights and expert recommendations, this guide serves as a vital tool for navigating the complexities of the seat cover vinyl material market. With the right information at your fingertips, you can confidently select the best materials that align with your business needs and elevate your product offerings in a competitive landscape.

Table Of Contents

- Top 4 Seat Cover Vinyl Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for seat cover vinyl material

- Understanding seat cover vinyl material Types and Variations

- Key Industrial Applications of seat cover vinyl material

- 3 Common User Pain Points for ‘seat cover vinyl material’ & Their Solutions

- Strategic Material Selection Guide for seat cover vinyl material

- In-depth Look: Manufacturing Processes and Quality Assurance for seat cover vinyl material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘seat cover vinyl material’

- Comprehensive Cost and Pricing Analysis for seat cover vinyl material Sourcing

- Alternatives Analysis: Comparing seat cover vinyl material With Other Solutions

- Essential Technical Properties and Trade Terminology for seat cover vinyl material

- Navigating Market Dynamics and Sourcing Trends in the seat cover vinyl material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of seat cover vinyl material

- Strategic Sourcing Conclusion and Outlook for seat cover vinyl material

- Important Disclaimer & Terms of Use

Understanding seat cover vinyl material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Marine Vinyl | Mold/mildew resistant, UV treated, waterproof | Boat upholstery, outdoor furniture | Pros: Durable, easy to clean; Cons: Can fade if not maintained properly. |

| Automotive Vinyl | High durability, resistant to wear and tear, often padded | Car seats, interiors of vehicles | Pros: Comfortable, customizable; Cons: Higher cost compared to standard vinyl. |

| Искусственная кожа | Soft texture, looks similar to genuine leather | Office furniture, restaurant seating | Pros: Eco-friendly, cost-effective; Cons: Less durable than real leather. |

| Heavy-Duty Vinyl | Thick, robust material, high abrasion resistance | Industrial applications, heavy-use seating | Pros: Extremely durable, long-lasting; Cons: Bulkier, may be less flexible. |

| Stretch Vinyl | Flexible, can conform to various shapes | Custom seat covers, upholstery for unique designs | Pros: Versatile, easy to work with; Cons: May not be as resistant to wear as thicker options. |

What are the Characteristics of Marine Vinyl and Its B2B Suitability?

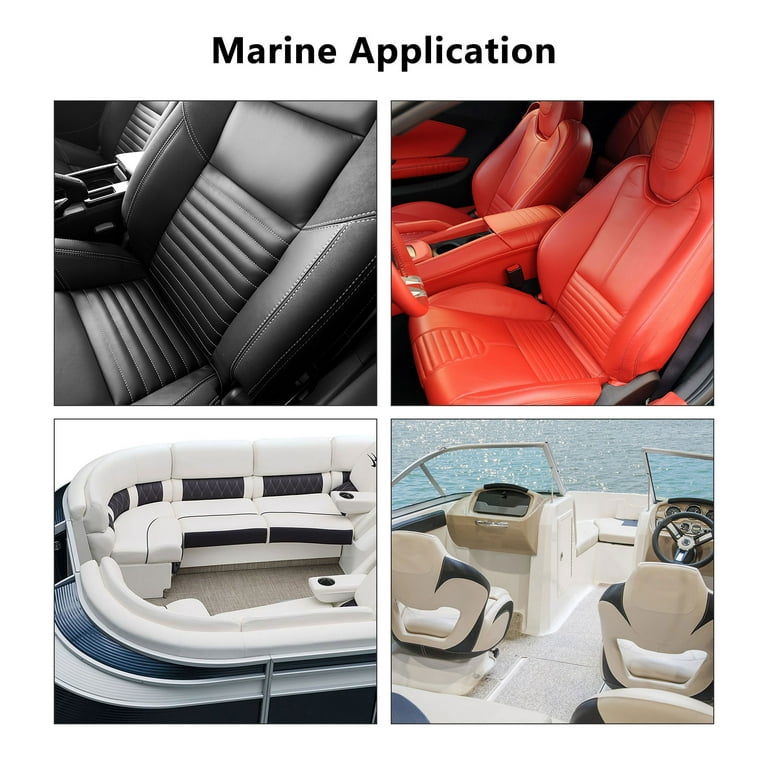

Marine vinyl is engineered to withstand harsh environmental conditions, making it ideal for boat upholstery and outdoor furniture. Its mold and mildew resistance, along with UV treatment, ensure longevity even in direct sunlight. B2B buyers should consider marine vinyl for projects requiring water resistance and durability. However, proper care is essential, as some colors may fade if exposed to prolonged sunlight without protection.

Illustrative image related to seat cover vinyl material

How Does Automotive Vinyl Stand Out in the Market?

Automotive vinyl is specifically designed for vehicle interiors, offering a balance of durability and comfort. It often features padding for added comfort and is resistant to wear and tear, making it suitable for high-traffic areas within cars. B2B buyers in the automotive industry should prioritize automotive vinyl for its customization options and durability, although it may come at a premium price compared to standard materials.

Why Choose Faux Leather for Office and Restaurant Seating?

Faux leather provides an aesthetically pleasing alternative to genuine leather, offering a soft texture and a wide range of color options. It is an eco-friendly choice that meets the demands of office furniture and restaurant seating. B2B buyers should consider faux leather for its cost-effectiveness and ease of maintenance. However, they should also be aware that it may not match the durability of real leather over time.

What Makes Heavy-Duty Vinyl Ideal for Industrial Applications?

Heavy-duty vinyl is characterized by its thickness and robustness, making it suitable for industrial applications where heavy use is expected. Its high abrasion resistance ensures that it can withstand significant wear and tear, making it a top choice for heavy-use seating. B2B buyers should consider heavy-duty vinyl for its longevity, but they should also note that its bulkiness may limit flexibility in certain designs.

How Does Stretch Vinyl Enhance Custom Upholstery Projects?

Stretch vinyl is designed to be flexible, allowing it to conform to various shapes and sizes, making it perfect for custom seat covers and unique upholstery projects. Its versatility and ease of use make it a favorite among designers and manufacturers looking for creative solutions. B2B buyers should evaluate stretch vinyl for projects requiring adaptability, though they should also keep in mind that it may not offer the same level of wear resistance as thicker vinyl options.

Key Industrial Applications of seat cover vinyl material

| Industry/Sector | Specific Application of seat cover vinyl material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Автомобили | Upholstery for car seats | Enhances durability and aesthetic appeal | UV resistance, ease of cleaning, and color options |

| Marine | Boat seat covers | Water and UV resistance for longevity | Compliance with marine standards, mold resistance |

| Hospitality | Restaurant and café seating | Easy maintenance and stylish presentation | Stain resistance, variety of colors and textures |

| Aviation | Aircraft seating covers | Lightweight and fire-resistant materials | Compliance with aviation safety regulations |

| Recreational Vehicles | RV and camper seating | Comfort and weather resistance | Flexibility in design, ease of installation |

How is Seat Cover Vinyl Material Used in the Automotive Sector?

In the automotive industry, seat cover vinyl material is primarily utilized for car upholstery. The material is designed to withstand wear and tear while providing an aesthetically pleasing appearance. It addresses common issues such as spills and stains, making it easier for car manufacturers and upholstery shops to maintain the vehicle’s interior. Buyers in this sector should prioritize UV resistance and easy cleaning properties, especially in regions with high sun exposure, ensuring that colors remain vibrant over time.

Illustrative image related to seat cover vinyl material

What are the Applications of Seat Cover Vinyl Material in Marine Environments?

Marine applications for seat cover vinyl material include the upholstery of boat seats, where the material must endure harsh marine conditions. This vinyl is specifically engineered to be water-resistant and UV-treated, preventing degradation from sun exposure and moisture. For buyers in the marine sector, compliance with marine safety standards and mold resistance are critical factors to consider when sourcing materials, ensuring both safety and longevity in their products.

How is Seat Cover Vinyl Material Beneficial in the Hospitality Industry?

In the hospitality sector, seat cover vinyl material is commonly used for restaurant and café seating. Its easy maintenance and variety of styles allow businesses to create a welcoming atmosphere while ensuring durability against spills and stains. For international buyers, especially in high-traffic areas, it’s essential to select vinyl that is stain-resistant and available in a range of colors and textures to match their brand identity, enhancing the overall dining experience.

What Role Does Seat Cover Vinyl Material Play in Aviation?

In aviation, seat cover vinyl material is crucial for aircraft seating applications. The material must be lightweight, durable, and fire-resistant to meet stringent aviation safety regulations. Buyers in this sector need to ensure that the vinyl complies with international standards, which can vary by region, particularly in Europe and the Middle East. This compliance not only ensures passenger safety but also enhances the overall aesthetic of the aircraft interior.

Illustrative image related to seat cover vinyl material

How is Seat Cover Vinyl Material Used in Recreational Vehicles?

For recreational vehicles (RVs) and campers, seat cover vinyl material is used to provide comfort and resistance to various weather conditions. This application requires materials that can withstand the rigors of travel while offering easy cleaning solutions. Buyers should consider the flexibility of design and ease of installation when sourcing vinyl for RV seating, as these factors significantly impact user experience and satisfaction during travel.

3 Common User Pain Points for ‘seat cover vinyl material’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Vinyl for Diverse Applications

The Problem: B2B buyers often face challenges in sourcing vinyl materials that meet specific quality standards for various applications, such as automotive, marine, or commercial furniture. These buyers may receive inconsistent product quality from suppliers, leading to issues like premature wear and tear, fading, or even safety concerns related to toxic materials. This inconsistency can result in significant financial losses due to increased replacement costs and customer dissatisfaction.

The Solution: To overcome these sourcing challenges, buyers should prioritize suppliers who offer comprehensive product specifications and third-party testing certifications. When evaluating potential vendors, look for documentation that confirms the vinyl’s durability, UV resistance, and compliance with safety regulations (such as CPSIA or REACH). Request free samples to assess the material’s quality firsthand before placing larger orders. Additionally, establishing long-term relationships with reputable suppliers can lead to better pricing, consistent quality, and improved support for any issues that arise.

Scenario 2: Managing Installation Difficulties with Vinyl Seat Covers

The Problem: Another common pain point for buyers is the complexity involved in the installation of vinyl seat covers. Many vinyl materials are either too stiff or too stretchy, making it difficult to achieve a clean, professional look. This can lead to wasted time and resources during installation and may even require hiring specialized labor, which further inflates project costs.

The Solution: To facilitate a smoother installation process, buyers should select vinyl materials specifically designed for ease of application. Look for products labeled as “easy to sew” or “4-way stretch,” as these features enhance flexibility and adaptability during installation. Additionally, investing in proper tools and equipment, such as heavy-duty sewing machines and upholstery staples, can significantly ease the installation process. Training staff or providing clear instructional materials on best practices can also minimize installation errors, ensuring that the final product meets quality expectations.

Scenario 3: Addressing Long-Term Maintenance and Durability Concerns

The Problem: Buyers are often concerned about the long-term maintenance of vinyl seat covers, especially in high-use environments like restaurants or public transport. Common issues include fading, cracking, or mold growth, which not only degrade the appearance of the seats but can also lead to costly replacements and repairs. Buyers may struggle to find materials that can withstand heavy use without requiring excessive upkeep.

The Solution: To tackle these maintenance challenges, selecting high-performance vinyl that is mold and mildew resistant, UV treated, and has a high double rub count is essential. For instance, vinyl that can endure over 250,000 double rubs is ideal for high-traffic areas. Furthermore, establishing a routine cleaning and maintenance schedule can prolong the life of vinyl seat covers. Use mild, non-abrasive cleaners and avoid harsh chemicals that can degrade the material. Educating staff on proper care techniques will also help maintain the aesthetic and functional integrity of the vinyl, ensuring that it remains a cost-effective choice in the long run.

Strategic Material Selection Guide for seat cover vinyl material

What Are the Key Properties of Common Vinyl Materials for Seat Covers?

When selecting vinyl materials for seat covers, understanding the key properties of various options is crucial for ensuring optimal performance and longevity. Below, we analyze four common materials used in the production of seat cover vinyl, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Marine Vinyl

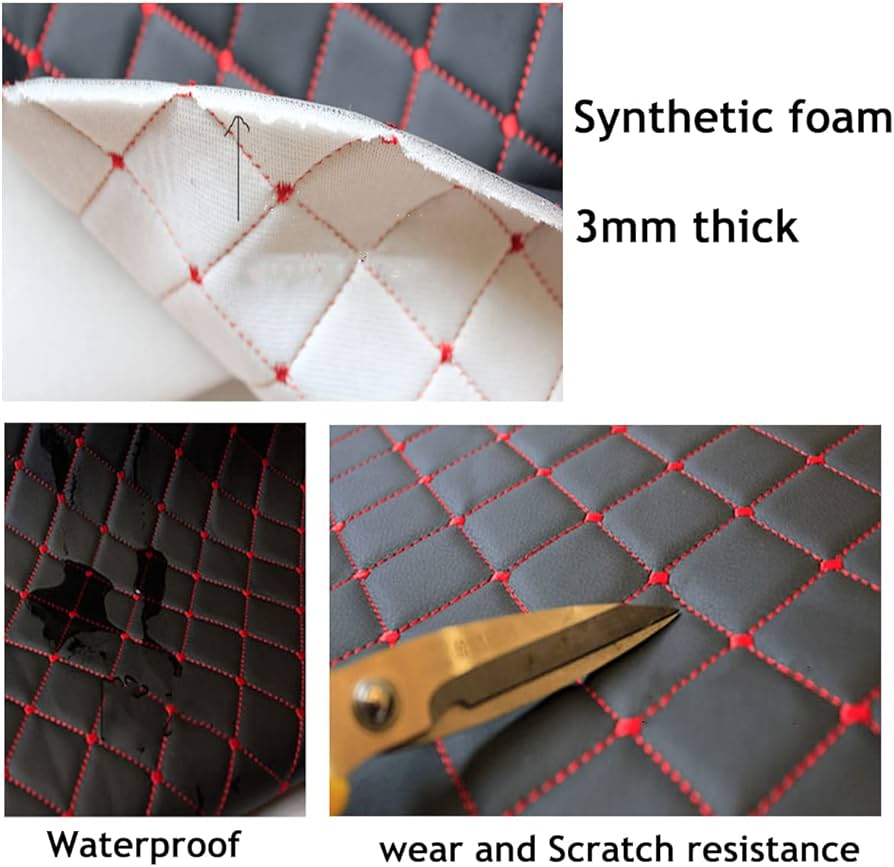

Key Properties: Marine vinyl is engineered to withstand harsh environmental conditions, making it highly resistant to moisture, UV rays, and mildew. It typically has a thickness of around 0.95mm and can endure extreme temperatures, with a cold crack resistance down to -23°F.

Pros & Cons: The durability of marine vinyl is a significant advantage, as it can withstand over 250,000 double rubs, ensuring it holds up well under wear and tear. However, its higher cost compared to standard vinyl can be a drawback for budget-conscious buyers. Additionally, while it is easy to sew and stretch, it may require specialized tools for installation.

Impact on Application: Marine vinyl is ideal for applications in boats, outdoor furniture, and automotive seats, where moisture resistance is critical. Its waterproof nature makes it suitable for environments prone to spills and humidity.

Considerations for International Buyers: Compliance with international standards like ASTM for durability and UV resistance is essential. Buyers from regions with high humidity or UV exposure, such as Africa and South America, should prioritize marine vinyl for its protective qualities.

2. PVC Vinyl

Key Properties: PVC vinyl is a versatile and cost-effective material, often used in various applications due to its excellent chemical resistance and durability. It typically has a lower temperature tolerance compared to marine vinyl but is still suitable for many environments.

Illustrative image related to seat cover vinyl material

Pros & Cons: The affordability of PVC vinyl makes it attractive for mass production, but it may not offer the same level of durability as marine vinyl. It is easy to manufacture and can be produced in various colors and textures, providing flexibility in design. However, its lower resistance to UV exposure can lead to fading over time.

Impact on Application: PVC vinyl is commonly used in automotive seats and indoor furniture, where exposure to harsh environmental conditions is limited.

Considerations for International Buyers: Buyers should ensure that the PVC vinyl meets local regulations regarding phthalate content and other chemical safety standards, especially in regions like Europe where compliance is strict.

3. Polyurethane (PU) Vinyl

Key Properties: PU vinyl offers a softer feel and is more environmentally friendly compared to PVC. It has good abrasion resistance and can withstand a range of temperatures, making it suitable for diverse applications.

Illustrative image related to seat cover vinyl material

Pros & Cons: The softness and flexibility of PU vinyl make it comfortable for seat covers, enhancing user experience. However, it is generally more expensive than PVC and may not be as durable in high-wear applications.

Impact on Application: PU vinyl is often used in high-end automotive interiors and furniture where comfort and aesthetics are prioritized over extreme durability.

Considerations for International Buyers: Buyers should look for certifications that confirm the material’s environmental safety and compliance with standards like REACH in Europe, as well as ASTM for performance.

4. Synthetic Leather (Biothane)

Key Properties: Synthetic leather, particularly Biothane, combines the look of leather with the durability of vinyl. It is typically waterproof, easy to clean, and resistant to mold and mildew.

Pros & Cons: The aesthetic appeal of synthetic leather is a significant advantage, making it suitable for premium applications. However, it can be more expensive than traditional vinyl options and may require specific care to maintain its appearance.

Impact on Application: Ideal for automotive seats and high-end furniture, synthetic leather provides a luxurious feel while maintaining durability.

Considerations for International Buyers: Buyers should ensure that synthetic leather meets local environmental regulations and standards for durability, especially in markets focused on sustainability.

Summary Table of Vinyl Materials for Seat Covers

| Материал | Typical Use Case for seat cover vinyl material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Marine Vinyl | Boats, outdoor furniture, automotive seats | Excellent moisture and UV resistance | Higher cost compared to standard vinyl | Высокий |

| PVC Vinyl | Automotive seats, indoor furniture | Cost-effective and versatile | Lower UV resistance and durability | Низкий |

| Polyurethane Vinyl | High-end automotive interiors, furniture | Soft feel and environmentally friendly | More expensive, less durable | Med |

| Синтетическая кожа | Premium automotive seats, high-end furniture | Aesthetic appeal and comfort | Higher cost, requires specific care | Высокий |

This analysis provides B2B buyers with a comprehensive understanding of the various vinyl materials available for seat covers, enabling informed decisions based on performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for seat cover vinyl material

What Are the Main Stages of Manufacturing Seat Cover Vinyl Material?

The manufacturing process of seat cover vinyl material involves several critical stages that ensure the final product meets quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Vinyl Production?

Material preparation begins with selecting the right base polymers, typically PVC or PU, which serve as the foundation for the vinyl. These polymers undergo a series of treatments to enhance properties such as flexibility, durability, and resistance to environmental factors. Additives like plasticizers, stabilizers, and pigments are mixed into the base material to achieve desired characteristics, such as color and UV resistance. This mixture is then compounded, ensuring uniform distribution of all components, which is crucial for consistency in the final product.

What Techniques Are Used in Forming Vinyl?

Once the material is prepared, it moves to the forming stage. This typically involves a process called calendering, where the compounded material is passed through a series of rollers to create a flat sheet of vinyl. The thickness of the vinyl can be adjusted by modifying the gap between the rollers, allowing manufacturers to produce various thicknesses suitable for different applications, such as automotive or marine upholstery.

Another technique is extrusion, where the vinyl is forced through a die to create specific shapes or profiles. Extrusion can be particularly useful for creating vinyl with integrated features, such as embossed patterns or textures that enhance aesthetics and grip.

How Is the Assembly of Seat Cover Vinyl Material Conducted?

The assembly stage includes cutting the vinyl sheets to size and sewing or welding them together to create the final seat cover. Advanced sewing machines equipped with specialized needles and threads are used to ensure strong seams that can withstand stretching and wear. In some cases, ultrasonic welding techniques are employed, which use high-frequency sound waves to join materials without the need for stitching, offering a seamless finish.

Quality control measures are integrated throughout the assembly process. Workers inspect seams for consistency and strength, and any defects are corrected before proceeding to the finishing stage.

What Finishing Processes Are Applied to Vinyl Seat Covers?

The finishing stage is crucial for enhancing the appearance and performance of seat cover vinyl. This may include applying coatings to improve scratch resistance, water repellency, and UV protection. Additionally, various treatments can be applied to achieve specific aesthetics, such as a matte or gloss finish.

Finally, the finished products undergo a thorough inspection to ensure they meet the specified requirements before packaging and shipping. This final quality check is vital for maintaining high standards and ensuring customer satisfaction.

What Are the Key Quality Assurance Standards for Vinyl Manufacturing?

Quality assurance in the manufacturing of seat cover vinyl material is governed by various international and industry-specific standards. One of the most recognized standards is ISO 9001, which sets the criteria for a quality management system. Compliance with ISO 9001 indicates that a manufacturer adheres to established processes for consistent product quality and continuous improvement.

In addition to ISO standards, other certifications may apply based on the specific market or application. For instance, CE marking is crucial for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards. Similarly, materials used in specific industries, such as automotive, may need to meet API (American Petroleum Institute) standards for performance and safety.

Illustrative image related to seat cover vinyl material

How Are Quality Control Checkpoints Established During Manufacturing?

To ensure the highest quality of seat cover vinyl material, manufacturers implement several quality control checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials as they arrive at the facility. Manufacturers verify that materials meet predefined specifications before they are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor critical parameters such as thickness, color consistency, and adhesion properties. This allows for immediate adjustments to be made if any deviations from standards are detected.

-

Final Quality Control (FQC): After finishing, the final products undergo a comprehensive inspection. This includes physical tests for durability, flexibility, and resistance to environmental factors. Any products that do not meet quality standards are either reworked or discarded.

What Testing Methods Are Commonly Used in Quality Assurance?

Common testing methods for seat cover vinyl include:

-

Tensile Strength Testing: Measures the maximum amount of tensile (pulling) stress that a material can withstand before failure.

-

UV Resistance Testing: Assesses how well the vinyl can withstand prolonged exposure to sunlight without degrading.

-

Cold Crack Testing: Determines the material’s ability to remain flexible and functional at low temperatures.

-

Waterproof Testing: Evaluates the material’s ability to repel water, ensuring that it performs well in wet conditions.

-

Durability Testing (Double Rub Test): Measures how many times the surface can withstand abrasion before showing signs of wear.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to verify the quality control processes of suppliers should consider the following steps:

-

Request Documentation: Ask for quality management system certifications (such as ISO 9001) and other relevant compliance documents. Suppliers should provide proof of adherence to international standards.

-

Conduct Audits: Periodic audits of the supplier’s manufacturing facility can provide insight into their processes and quality control measures. Buyers can assess the effectiveness of the supplier’s quality management practices firsthand.

-

Review Testing Reports: Suppliers should provide access to testing reports from third-party laboratories that confirm the performance of the vinyl materials against industry standards.

-

Seek References: Engage with other businesses that have sourced from the supplier. Their experiences can offer valuable insights into the supplier’s reliability and quality assurance practices.

-

Check for Transparency: A reputable supplier will be open about their quality control processes and willing to address any concerns buyers may have.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control. Variances in regional standards and regulations can affect the sourcing and use of seat cover vinyl materials. Buyers should be well-informed about local compliance requirements and ensure their suppliers meet these standards.

Illustrative image related to seat cover vinyl material

Additionally, logistics and shipping can introduce risks that may impact product quality. Buyers should establish clear agreements with suppliers regarding packaging, handling, and shipping methods to minimize the risk of damage during transit.

By understanding the complexities of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing seat cover vinyl material, ensuring they receive high-quality products that meet their specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘seat cover vinyl material’

Введение

Sourcing seat cover vinyl material is a critical process for businesses in the automotive, marine, and furniture industries. This guide provides a step-by-step checklist to help B2B buyers navigate the complexities of procurement, ensuring they select high-quality materials that meet their specific needs and standards.

1. Define Your Technical Specifications

Understanding your project requirements is the foundation of successful sourcing. Outline the desired characteristics of the vinyl material, including durability, thickness, UV resistance, and color options. This clarity will guide your discussions with suppliers and ensure that the materials meet industry standards.

Illustrative image related to seat cover vinyl material

- Consider usage: Will the vinyl be used for outdoor applications? If so, prioritize materials that are UV resistant and waterproof.

- Assess durability: Look for specifications such as double rub counts to gauge wear resistance.

2. Research Potential Suppliers

Identifying reliable suppliers is essential. Conduct thorough research to find manufacturers and distributors with a strong reputation in the market. Utilize online directories, trade shows, and industry publications to compile a list of potential vendors.

- Look for reviews: Explore customer feedback and case studies to assess supplier reliability and product quality.

- Check industry experience: Suppliers with a long-standing presence in the market often have proven processes and quality controls.

3. Request Samples

Before making a bulk order, request samples of the vinyl material. This allows you to evaluate the texture, color accuracy, and overall quality firsthand. Ensure that the samples reflect the specifications you require.

- Test for performance: Check how the vinyl holds up under conditions similar to its intended use, such as exposure to sunlight or moisture.

- Assess ease of handling: Determine if the material is easy to sew, staple, or otherwise manipulate during production.

4. Evaluate Supplier Certifications

Certifications can provide assurance regarding the quality and safety of the materials. Verify that potential suppliers hold relevant industry certifications, such as CPSIA compliance, which indicates that the material is safe for consumer use.

Illustrative image related to seat cover vinyl material

- Look for sustainability: Certifications related to environmental practices can also be a significant factor, especially for buyers in regions with strict regulations.

- Confirm testing standards: Ensure that the materials have been tested for factors like UV resistance and mold/mildew resistance.

5. Negotiate Pricing and Terms

Once you have identified a supplier, engage in negotiations to secure the best pricing and terms. Discuss bulk order discounts, payment terms, and shipping options to ensure that your procurement remains within budget.

- Consider total cost of ownership: Evaluate not just the initial purchase price but also factors such as shipping costs, potential tariffs, and the expected lifespan of the material.

- Establish clear terms: Define return policies and warranties to protect your investment and ensure recourse in case of defects.

6. Plan for Logistics and Delivery

Ensure that the logistics of delivery are aligned with your production schedules. Discuss lead times with suppliers and confirm that they can meet your timelines without compromising quality.

- Set expectations: Clearly communicate your timelines and any flexibility you may have.

- Monitor shipments: Stay in touch with suppliers during the shipping process to address any potential delays proactively.

7. Conduct Quality Assurance Checks

After receiving your order, conduct thorough quality checks to ensure that the materials meet your specifications. This step is crucial to avoid complications during production.

- Inspect samples: Compare received materials against samples and specifications to confirm quality.

- Document findings: Keep records of any discrepancies or issues to address with the supplier if necessary.

By following this structured checklist, B2B buyers can streamline the sourcing process for seat cover vinyl material and ensure they make informed decisions that align with their business needs.

Illustrative image related to seat cover vinyl material

Comprehensive Cost and Pricing Analysis for seat cover vinyl material Sourcing

What Are the Key Cost Components in Sourcing Seat Cover Vinyl Material?

When sourcing seat cover vinyl material, understanding the cost structure is critical for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of vinyl used significantly affects the price. Marine-grade vinyl, for instance, is typically priced around $10.44 per yard, depending on the quality and specifications. Prices can vary based on the durability, UV resistance, and other attributes.

-

Labor: Labor costs vary by region and can influence the final pricing of the vinyl. In regions with higher labor costs, such as parts of Europe, the total price may reflect these expenses. Conversely, sourcing from regions with lower labor costs may provide cost savings.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and other indirect costs associated with production. Efficient manufacturing processes can help lower overhead, thus reducing the overall price of the vinyl.

-

Tooling: Custom molds and tools required for specific vinyl designs can incur additional costs. If a buyer requires a unique pattern or texture, these tooling costs should be factored into the total pricing.

-

Quality Control (QC): Ensuring that the vinyl meets industry standards can add to the costs. Third-party testing for certifications, such as CPSIA compliance, can increase the overall price but is essential for guaranteeing product safety and longevity.

-

Logistics: Shipping costs can vary widely based on the origin and destination. International buyers should consider freight charges, insurance, and potential customs duties when evaluating the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can fluctuate based on market conditions, competition, and supplier relationships.

How Do Price Influencers Impact Seat Cover Vinyl Material Costs?

Several factors influence the pricing of seat cover vinyl material, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Pricing often decreases with larger orders. Suppliers may offer discounts for bulk purchases, which can significantly reduce costs per unit.

-

Specifications and Customization: Custom specifications such as color, texture, and thickness can impact pricing. More complex requests typically lead to higher costs due to increased production complexity.

-

Materials Quality and Certifications: Higher-quality materials with certifications like UV resistance or mold/mildew resistance usually come at a premium. Buyers should weigh the benefits of investing in higher-quality materials against their budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and service levels can also influence pricing. Established suppliers may charge more due to their proven track record and quality assurance practices.

-

Incoterms: Understanding Incoterms is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, impacting the total cost of ownership.

What Buyer Tips Should Be Considered for Effective Negotiation?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Illustrative image related to seat cover vinyl material

-

Negotiation: Always negotiate pricing, especially for larger orders. Suppliers may have flexibility in their pricing structure, especially for long-term contracts or repeat business.

-

Total Cost of Ownership: Beyond the initial price, consider the total cost of ownership, including shipping, handling, and potential maintenance costs. A lower upfront cost might lead to higher long-term expenses if the material is of inferior quality.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and international tariffs that could affect pricing. Establishing relationships with local suppliers may mitigate some of these risks and lead to better pricing.

-

Request Samples: Before committing to a large order, request samples to assess the quality and ensure it meets your specifications. This can save costs associated with returns or reorders.

In summary, a comprehensive understanding of the cost structure, pricing influencers, and negotiation strategies can empower B2B buyers to make informed decisions when sourcing seat cover vinyl material. Always consider the total cost of ownership and the nuances of international procurement to maximize value.

Alternatives Analysis: Comparing seat cover vinyl material With Other Solutions

Understanding Alternatives to Seat Cover Vinyl Material

In the competitive landscape of seating solutions, particularly in industries like automotive, marine, and hospitality, it’s essential to evaluate various materials and technologies. While seat cover vinyl material is a popular choice due to its durability and water resistance, other alternatives may also serve similar functions. This analysis will compare seat cover vinyl with two viable alternatives: fabric upholstery and leather, providing insights that can aid B2B buyers in making informed decisions.

| Comparison Aspect | Seat Cover Vinyl Material | Fabric Upholstery | Leather |

|---|---|---|---|

| Performance | High durability, waterproof, UV resistant | Moderate durability, less resistant to spills and stains | High durability, luxurious feel, natural breathability |

| Cost | $10.44 per yard | $5 – $20 per yard | $20 – $50 per square foot |

| Ease of Implementation | Easy to sew and install | Requires careful handling, may need professional installation | Requires specialized tools and skills for installation |

| Maintenance | Low maintenance, easy to clean | Higher maintenance, requires regular cleaning | Moderate maintenance, needs conditioning |

| Best Use Case | Marine, automotive, outdoor furniture | Indoor furniture, residential use | Luxury vehicles, high-end furniture, and fashion |

What Are the Advantages and Disadvantages of Fabric Upholstery?

Fabric upholstery is a versatile option that can cater to various aesthetic preferences and comfort needs. It typically costs less than vinyl and offers a wider range of textures and patterns, making it appealing for interior design. However, it lacks the waterproof and UV-resistant properties of vinyl, making it less suitable for outdoor or high-moisture environments. Additionally, fabric can stain easily and requires regular cleaning to maintain its appearance.

How Does Leather Compare to Seat Cover Vinyl Material?

Leather is often regarded as a premium material, providing a luxurious look and feel. It is highly durable and can withstand wear and tear, making it an excellent choice for high-end applications such as luxury vehicles and upscale furniture. However, leather is significantly more expensive than both vinyl and fabric, with higher initial costs and ongoing maintenance needs, such as conditioning to prevent cracking. Additionally, the installation process can be complicated, requiring specialized tools and skills.

Making the Right Choice for Your Business Needs

When selecting the appropriate seat cover material, B2B buyers must consider various factors, including performance requirements, budget constraints, and the specific application environment. Seat cover vinyl material excels in durability and low maintenance, making it ideal for outdoor and high-traffic areas. Fabric upholstery may be more suitable for indoor settings where aesthetics are a priority, while leather is best for luxury markets where quality and comfort are paramount.

Ultimately, the right choice will depend on balancing these factors to align with business objectives and customer expectations. By carefully assessing each alternative’s strengths and weaknesses, companies can make informed decisions that enhance their product offerings and meet market demands effectively.

Essential Technical Properties and Trade Terminology for seat cover vinyl material

What Are the Key Technical Properties of Seat Cover Vinyl Material?

When assessing vinyl materials for seat covers, several technical properties are critical to ensuring durability, functionality, and overall performance. Understanding these specifications can greatly influence purchasing decisions.

1. Material Grade

Material grade refers to the quality and classification of the vinyl. Common grades include marine-grade, automotive-grade, and upholstery-grade vinyl. Marine-grade vinyl, for instance, is designed to withstand extreme weather conditions and is often treated for UV resistance, making it ideal for outdoor applications. Selecting the appropriate grade ensures the longevity and suitability of the material for specific uses.

2. Weight and Thickness

The weight of vinyl is typically measured in ounces per square yard (oz/yd²). A heavier weight often indicates a more durable product, which is essential for high-wear applications like car seats. Thickness, measured in millimeters or mils, also contributes to durability and flexibility. For example, a 30 oz. vinyl is generally more robust and can withstand greater stress compared to lighter options, making it suitable for demanding environments.

3. Double Rub Count

The double rub count quantifies the durability of vinyl by measuring how many times the material can withstand abrasion before showing wear. This is particularly important for seat covers, which experience frequent use. A double rub count of 250,000 or higher indicates that the vinyl can endure extensive wear and tear, making it a smart choice for industries where longevity is crucial.

4. Cold Crack Resistance

Cold crack resistance is measured by the lowest temperature at which the vinyl remains flexible without cracking. For instance, a vinyl that maintains flexibility down to -23°F is essential for applications in colder climates. This property ensures that the material will not become brittle and fail under extreme conditions, thereby extending its useful life.

5. Water Resistance

Water resistance is a critical property for seat cover vinyl, especially in outdoor or marine applications. This specification indicates how well the material can repel water, preventing mold and mildew growth. Waterproof vinyl is essential for maintaining the integrity and cleanliness of seat covers exposed to moisture.

Illustrative image related to seat cover vinyl material

6. Flame Retardancy

Flame retardancy is an important safety feature for vinyl materials used in public spaces, automotive applications, and marine environments. This property indicates how well the material resists ignition and slows the spread of flames. Compliance with local safety standards is crucial for B2B buyers to ensure that their products meet legal requirements.

What Are Common Trade Terms in the Seat Cover Vinyl Industry?

Understanding industry terminology is vital for effective communication and negotiation in the B2B space.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of seat cover vinyl, an OEM may produce customized seat covers for automotive brands. Understanding OEM relationships can help buyers identify potential suppliers and negotiate better terms.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest order size that a supplier is willing to process. This term is crucial for buyers, as it can affect inventory costs and overall procurement strategies. Knowing the MOQ helps businesses plan their purchases according to their demand forecasts and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a formal document soliciting price bids from suppliers for specific products or services. It is an essential step in the procurement process, allowing buyers to compare offers and negotiate terms. Crafting a comprehensive RFQ can lead to better pricing and terms from suppliers.

Illustrative image related to seat cover vinyl material

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers engaged in international transactions, ensuring that all parties are aware of their obligations.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. This term is vital for supply chain management, as longer lead times can affect inventory levels and customer satisfaction. Buyers should factor lead time into their procurement planning to avoid disruptions.

6. Sustainability Compliance

Sustainability compliance indicates adherence to environmental standards and practices in manufacturing and sourcing materials. For B2B buyers, understanding a supplier’s sustainability practices can be crucial in meeting regulatory requirements and aligning with corporate social responsibility goals.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and ultimately contribute to their business success.

Navigating Market Dynamics and Sourcing Trends in the seat cover vinyl material Sector

What Are the Key Market Trends Influencing the Seat Cover Vinyl Material Sector?

The seat cover vinyl material market is currently experiencing significant growth driven by several global factors. Increasing demand for durable and versatile upholstery options across various industries, including automotive, marine, and furniture, is propelling market expansion. Technological advancements in vinyl production, including improved resistance to wear and tear, UV exposure, and cold cracking, have enhanced product appeal. Additionally, an uptick in outdoor recreational activities is boosting the demand for marine-grade vinyl, particularly in regions like Africa and South America, where outdoor lifestyles are prevalent.

Emerging trends in B2B sourcing include the adoption of digital platforms for procurement, enabling buyers to access a wider range of suppliers and products. E-commerce and online marketplaces are becoming crucial for international buyers, providing real-time pricing and inventory information. Moreover, data analytics is playing a vital role in forecasting demand and optimizing inventory management, allowing businesses to respond swiftly to market fluctuations. Buyers from Europe, particularly Germany and Vietnam, are increasingly focusing on supplier reliability and product quality, which are essential in maintaining competitive advantage in a globalized market.

How Is Sustainability Shaping the Seat Cover Vinyl Material Sector?

Sustainability has become a pivotal consideration in the sourcing of seat cover vinyl materials. The environmental impact of vinyl production, particularly regarding the use of non-renewable resources and chemical emissions, is under scrutiny. As a result, many B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes sourcing materials from manufacturers that utilize eco-friendly processes and offer recyclable or biodegradable options.

Ethical supply chains are increasingly important, with buyers seeking transparency in sourcing practices. Certifications such as OEKO-TEX® and GOTS (Global Organic Textile Standard) are becoming essential for suppliers aiming to appeal to environmentally conscious buyers. These certifications assure buyers that the materials meet stringent environmental and social criteria. By choosing certified products, businesses can enhance their brand reputation while contributing to a more sustainable industry.

Illustrative image related to seat cover vinyl material

What Historical Factors Have Influenced the Seat Cover Vinyl Material Market?

The evolution of the seat cover vinyl material sector can be traced back to the mid-20th century when vinyl became a popular alternative to leather due to its affordability and versatility. Initially used primarily in the automotive industry, advancements in production technology expanded its applications across various sectors, including marine and furniture. The introduction of synthetic fibers and improved manufacturing techniques in the late 20th century led to the development of high-performance vinyl that is resistant to stains, UV rays, and moisture.

Over the years, the market has adapted to changing consumer preferences, with a growing emphasis on aesthetics, durability, and sustainability. The rise of digital technology has also transformed the way vinyl materials are sourced and purchased, making it easier for international buyers to access a diverse range of options. As the industry continues to evolve, it remains essential for B2B buyers to stay informed about these historical trends to navigate the current landscape effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of seat cover vinyl material

1. How do I solve quality issues with seat cover vinyl material?

To address quality issues with seat cover vinyl, begin by establishing stringent quality assurance (QA) protocols with your suppliers. Request samples before placing large orders to assess the material’s durability, texture, and color accuracy. Ensure that the supplier provides certifications that meet international standards, such as CPSIA compliance and UV treatment. If issues arise post-purchase, have a clear return and exchange policy in place, allowing for prompt resolution and minimizing financial loss.

2. What is the best vinyl material for automotive seat covers?

The best vinyl material for automotive seat covers is typically marine-grade vinyl, known for its durability, water resistance, and UV protection. It withstands extreme temperatures and is resistant to mold and mildew, making it suitable for both indoor and outdoor applications. Look for materials with high double rub counts (over 250,000) for durability and ensure they are CPSIA compliant. Additionally, consider the thickness and flexibility of the vinyl to ensure it fits well around contours and maintains a professional appearance.

Illustrative image related to seat cover vinyl material

3. How can I customize my order of seat cover vinyl material?

Most suppliers offer customization options for seat cover vinyl material, including color selection, texture variations, and specific dimensions. When placing an order, specify your requirements clearly, including the desired color from the supplier’s palette and any unique design elements. Some suppliers may also accommodate small custom runs for unique projects. Always confirm the minimum order quantity (MOQ) for customized orders to avoid unexpected costs.

4. What are the typical payment terms for international vinyl suppliers?

Payment terms for international vinyl suppliers can vary widely, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipping. Some suppliers may offer net 30 or net 60 terms for established customers. Always discuss payment methods accepted (such as wire transfers, letters of credit, or PayPal) and consider using escrow services for larger transactions to protect your investment.

5. How do I vet suppliers for seat cover vinyl material?

To vet suppliers effectively, conduct thorough research on their business history, customer reviews, and industry certifications. Request references from previous clients and verify their capacity to meet your order volume and delivery timelines. It’s beneficial to visit their production facilities if possible or request virtual tours. Lastly, evaluate their responsiveness and communication style, as these factors are crucial for a successful long-term partnership.

Illustrative image related to seat cover vinyl material

6. What logistics considerations should I be aware of when importing vinyl materials?

When importing vinyl materials, consider shipping methods, customs regulations, and potential tariffs that may apply. Choose a reliable freight forwarder familiar with your destination country’s import regulations. Ensure that all necessary documentation, such as commercial invoices and packing lists, are accurate and complete to avoid delays. Additionally, factor in lead times for production and shipping, as well as any possible delays at customs.

7. What is the minimum order quantity (MOQ) for seat cover vinyl material?

Minimum order quantities (MOQ) for seat cover vinyl material can vary significantly between suppliers. Some may have a low MOQ of just a few yards, while others may require orders in the hundreds of yards to keep costs manageable. Always inquire about the MOQ before placing an order, and if you require a smaller quantity, ask if the supplier offers sample yards or smaller custom runs to meet your needs.

8. How can I ensure compliance with international regulations when sourcing vinyl materials?

To ensure compliance with international regulations when sourcing vinyl materials, familiarize yourself with the specific regulations in your target market regarding safety, environmental impact, and import standards. Request compliance documentation from suppliers, such as material safety data sheets (MSDS) and certifications like CPSIA or REACH. Collaborate with legal experts or consultants who specialize in international trade to navigate regulatory requirements effectively.

Top 4 Seat Cover Vinyl Material Manufacturers & Suppliers List

1. Fabric Warehouse – Upholstery Vinyl Fabrics

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Введение: Upholstery Vinyl Fabric, various types including Nassimi Classic, Premium, Impulse, Enviro Leather, Glitter Vinyl, Reptile & Bird Vinyl, 3 Ply Vinyl, Picnic Table Vinyl, and Table Top Vinyl. Discounts available: 10% OFF (5), 20% OFF (17), 30% OFF (66), 40% OFF (101), 50% OFF (5), 60% OFF (8), 70% OFF (17). Color options include Beige, Black, Blue, Bronze, Brown, Clear, Gold, Gray, Green, Ivory, Kh…

2. NW Seat Covers – Fabric Seat Cover Materials

Domain: nwseatcovers.com

Registered: 2004 (21 years)

Введение: Product: Seat Cover Materials – Fabric by the Yard

Production Time: 3-5 Business Days

Shipping & Delivery: 3-6 Days

Price: $19.99 USD

Width: Approximately 50-60 inches

Material Options: MoonShine Camo (Muddy Girl, Serenity, Toxic, Wildfire, Undertow, Harvest Moon), MossyOak (Blades, Pink), NextCamo (Bonz), Realtree (AP Grey, Max-4), Vinyl (Black, Grey, Tan)

Shipping: Free over $100

Customer Review…

3. Midwest Fabrics – Vinyl Upholstery Solutions

Domain: midwestfabrics.com

Registered: 1999 (26 years)

Введение: Vinyl Upholstery Fabric: Stylish & Durable Solutions, Various types of upholstery vinyl including automotive, marine, and contract fabrics, Multiple brands such as Morbern, Enduratex, and Spradling, Options for closeout and original OEM fabrics, Wide selection of colors and textures, Suitable for indoor and outdoor furniture, Available by the roll or in full yardage, Includes specialty fabrics lik…

4. Fabric Wholesale Direct – Vinyl Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Введение: This company, Fabric Wholesale Direct – Vinyl Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for seat cover vinyl material

In the dynamic landscape of seat cover vinyl material sourcing, understanding the nuances of quality, pricing, and supplier relationships is paramount. The diverse range of marine vinyl fabrics available today offers not only aesthetic versatility with over 60 color options but also essential performance features such as UV resistance, mold and mildew protection, and durability under extreme conditions. Buyers must prioritize these attributes to ensure long-lasting products that meet end-user expectations while optimizing their procurement costs.

Strategic sourcing plays a crucial role in mitigating risks and enhancing supply chain efficiency. By leveraging bulk purchasing opportunities and establishing strong partnerships with reliable suppliers, businesses can secure competitive pricing and consistent quality. This approach is particularly beneficial for international buyers in regions like Africa, South America, the Middle East, and Europe, where market dynamics and consumer preferences vary significantly.

As we look ahead, the demand for high-quality, durable seat cover vinyl materials is poised to grow. International buyers are encouraged to stay proactive in their sourcing strategies, focusing on collaboration and innovation to meet evolving market needs. Embrace the opportunity to enhance your product offerings and solidify your position in the competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.