Introduction: Navigating the Global Market for fabric flocking

In an increasingly competitive global marketplace, sourcing high-quality fabric flocking materials poses a significant challenge for B2B buyers. As industries—from automotive to textiles—seek unique and innovative finishes, the demand for flocked products is surging. This guide serves as an essential resource for international buyers, particularly those in Africa, South America, the Middle East, and Europe, including emerging markets like Saudi Arabia and Vietnam. We delve into the intricacies of fabric flocking, covering the various types of flocking materials, their diverse applications, and the latest technologies in flocking processes.

Understanding the nuances of supplier vetting and cost structures is crucial for making informed purchasing decisions. This comprehensive guide not only outlines the benefits and limitations of different flocking methods—such as electrostatic and beater bar applications—but also offers insights into the adhesive types that enhance the durability and aesthetic appeal of flocked surfaces. By equipping buyers with actionable knowledge, we aim to empower them to navigate the complexities of sourcing flocking materials efficiently. With this guide, international B2B buyers will be well-prepared to make strategic decisions that elevate their product offerings and enhance their market share in the fabric flocking sector.

Table Of Contents

- Top 6 Fabric Flocking Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric flocking

- Understanding fabric flocking Types and Variations

- Key Industrial Applications of fabric flocking

- 3 Common User Pain Points for ‘fabric flocking’ & Their Solutions

- Strategic Material Selection Guide for fabric flocking

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric flocking

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric flocking’

- Comprehensive Cost and Pricing Analysis for fabric flocking Sourcing

- Alternatives Analysis: Comparing fabric flocking With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric flocking

- Navigating Market Dynamics and Sourcing Trends in the fabric flocking Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric flocking

- Strategic Sourcing Conclusion and Outlook for fabric flocking

- Important Disclaimer & Terms of Use

Understanding fabric flocking Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electrostatic Flocking | Utilizes electrical charges to align fibers perpendicularly. | Automotive interiors, textiles | Pros: High density, uniform application. Cons: High initial equipment costs. |

| Beater Bar Flocking | Mechanical vibration promotes fiber adherence to adhesive. | Large-scale textile production | Pros: Cost-effective for mass production. Cons: Potential for fiber shedding. |

| Spray Flocking | Uses air pressure to apply flocking material over large areas. | Promotional items, packaging | Pros: Versatile for various substrates. Cons: Messy process with airborne fibers. |

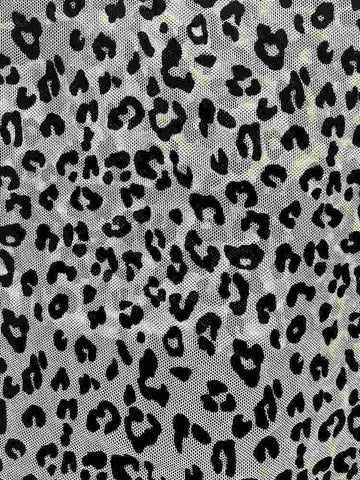

| Flock Transfers | Pre-made flock designs applied with heat and pressure. | Apparel, custom merchandise | Pros: Easy application, detailed designs. Cons: Limited to transfer sizes and designs. |

| Milled vs. Cut Flock | Milled from waste materials; cut for uniformity and quality. | Crafting, specialty applications | Pros: Milled is cost-effective; cut offers durability. Cons: Milled has lower wear resistance. |

What are the Key Characteristics of Electrostatic Flocking?

Electrostatic flocking is characterized by its ability to create a high-density, uniform flock coating through an electrostatic charge. This method is particularly suitable for applications requiring a soft, velvety texture, such as automotive interiors and textiles. B2B buyers should consider the initial investment in specialized equipment, which can be significant, but the durability and aesthetic appeal of the finished product often justify the cost.

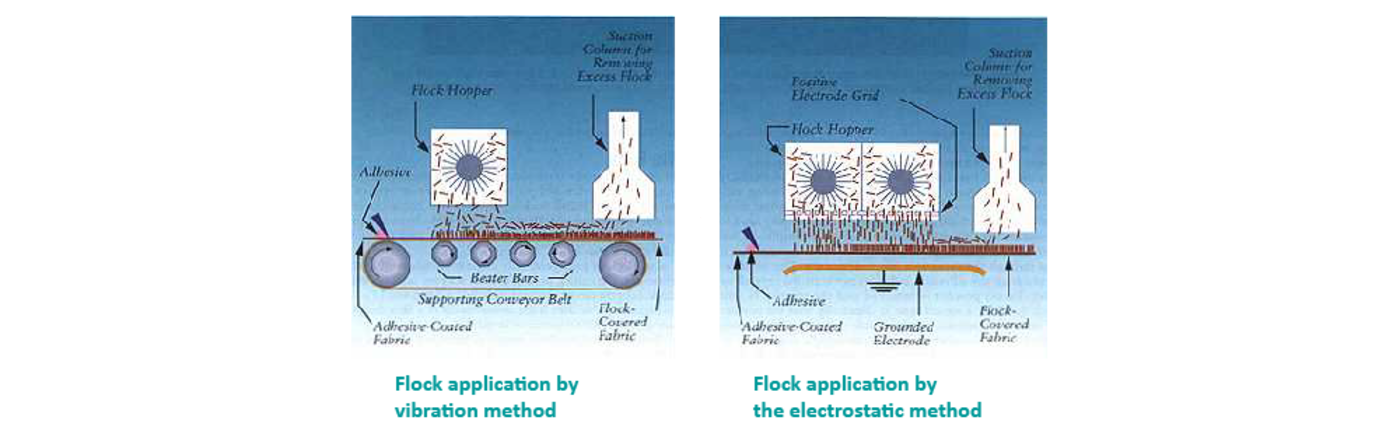

How Does Beater Bar Flocking Work in Industrial Applications?

Beater bar flocking relies on mechanical vibration to ensure that fibers adhere effectively to the adhesive-coated substrate. This method is ideal for large-scale textile production, as it is cost-effective and efficient. However, buyers should be aware of the potential for fiber shedding during the flocking process, which could lead to quality control issues if not managed properly.

In What Situations is Spray Flocking Preferred?

Spray flocking is advantageous for covering large areas quickly and is versatile across various substrates, including paper and textiles. This method is commonly used for promotional items and packaging. While it allows for creative applications, the process can be messy, with airborne fibers necessitating careful handling and workspace management to maintain a clean production environment.

What are the Benefits of Using Flock Transfers?

Flock transfers offer a straightforward application method by using pre-made designs that are applied with heat and pressure. This technique is perfect for apparel and custom merchandise, providing detailed and colorful designs without the complexity of traditional flocking methods. However, buyers should consider the limitations in size and design options when choosing this method.

How Do Milled and Cut Flock Differ in Quality and Application?

Milled flock, made from waste materials, is less uniform in length and is the most cost-effective option, making it suitable for crafting and specialty applications. In contrast, cut flock is produced from high-quality synthetic materials, providing better durability and wear resistance, which is essential for high-performance applications. Buyers should assess their specific needs regarding cost, quality, and application type when choosing between these two variations.

Key Industrial Applications of fabric flocking

| Industry/Sector | Specific Application of fabric flocking | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Flocking for interior components like glove compartments and door panels | Enhances aesthetic appeal and provides sound dampening | Ensure compatibility with adhesives and durability standards. Consider local suppliers for reduced shipping costs. |

| Consumer Electronics | Flocking in packaging for electronics | Provides a premium feel and protects sensitive items | Source materials that are antistatic and moisture-resistant. Evaluate flocking methods for consistency. |

| Fashion and Apparel | Flocking on garments for decorative effects | Adds unique texture and differentiation in a competitive market | Look for suppliers with expertise in color matching and design intricacy. Verify the durability of flocked surfaces. |

| Home Decor | Flocking on textiles like curtains and upholstery | Improves tactile quality and aesthetic appeal | Consider sourcing from manufacturers with eco-friendly processes. Assess the range of colors and textures available. |

| Toys and Promotional Items | Flocking on toys and marketing materials | Enhances visual appeal and tactile engagement | Ensure compliance with safety standards for children’s products. Look for flexibility in design and production volume. |

How is Fabric Flocking Used in the Automotive Industry?

In the automotive sector, fabric flocking is extensively used in the production of interior components such as glove compartments, door panels, and headliners. This technique not only enhances the visual appeal of these components but also provides sound dampening and thermal insulation, improving overall passenger comfort. For B2B buyers in regions like the Middle East and Europe, sourcing flocking materials that are durable and compatible with automotive adhesives is crucial, as these components must withstand varying climatic conditions and wear over time.

What Role Does Fabric Flocking Play in Consumer Electronics Packaging?

Fabric flocking is increasingly utilized in the packaging of consumer electronics, providing a luxurious feel while protecting sensitive items from scratches and damage. The flocked surfaces can also have antistatic properties, which are essential for electronic components. Buyers from Africa and South America should focus on sourcing high-quality, moisture-resistant flocking materials to ensure product integrity during shipping and storage. Additionally, the flocking method should be chosen for its ability to maintain consistency in appearance and texture across large production runs.

How is Fabric Flocking Enhancing Fashion and Apparel?

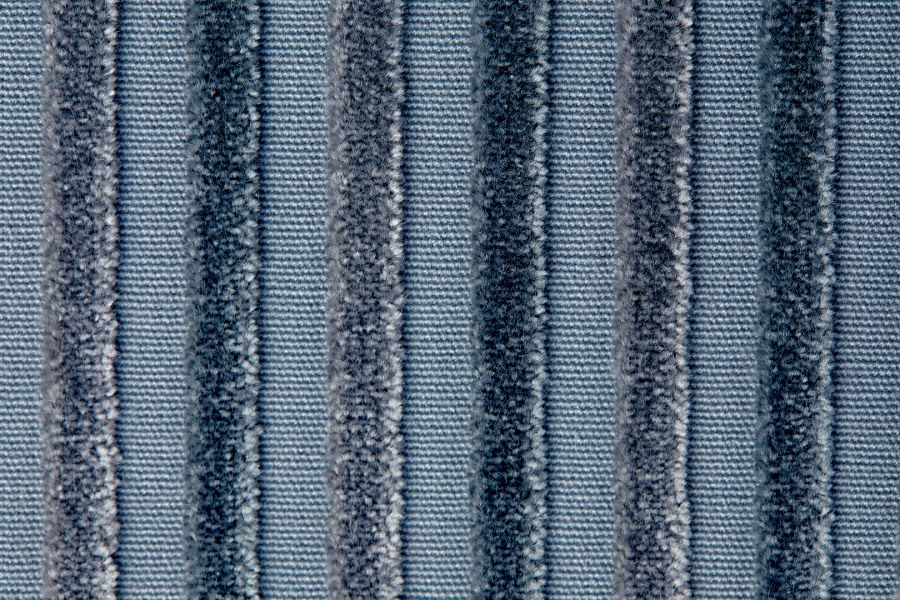

In the fashion industry, flocking is used to create unique textures on garments, adding a luxurious and distinctive look that sets products apart in a crowded market. This decorative technique allows designers to experiment with various colors and patterns, appealing to consumers seeking individuality. B2B buyers should consider suppliers with expertise in advanced flocking techniques to ensure high-quality finishes and durability. It’s also important to verify that the flocking process aligns with sustainable practices, as eco-conscious consumers increasingly demand responsible sourcing.

What Benefits Does Fabric Flocking Offer in Home Decor?

Flocking is a popular choice in home decor, particularly for textiles such as curtains and upholstery. This process enhances the tactile quality of fabrics, making them more appealing to consumers. For international buyers, particularly from Europe and the Middle East, it’s essential to source flocking materials that are not only aesthetically pleasing but also durable and easy to clean. Additionally, manufacturers should be evaluated for their ability to offer a wide range of colors and textures, allowing for customization in home decor projects.

How is Fabric Flocking Used in Toys and Promotional Items?

In the toy industry, flocking is applied to create soft, textured surfaces that are visually appealing and engaging for children. This technique is also popular in promotional items, where it enhances the tactile experience and visual attractiveness of products. Buyers in regions like South America should ensure that flocking materials comply with safety standards for children’s products. Furthermore, sourcing from suppliers who can provide flexibility in design and production volume is essential for meeting varying market demands.

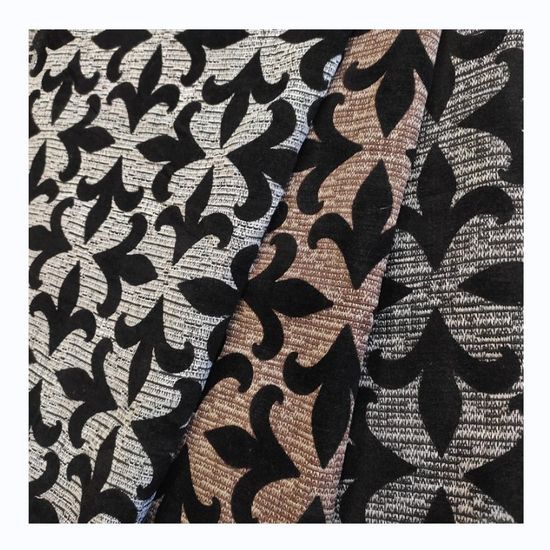

Illustrative image related to fabric flocking

3 Common User Pain Points for ‘fabric flocking’ & Their Solutions

Scenario 1: Difficulty Achieving Consistent Quality in Flocked Products

The Problem: B2B buyers often face challenges in maintaining consistent quality in flocked products, especially when scaling up production. Variability in the application process, such as inconsistent adhesive coatings or flock density, can lead to uneven surfaces, shedding fibers, and ultimately, customer dissatisfaction. This inconsistency can jeopardize relationships with clients and damage brand reputation, particularly in industries like automotive or textiles where quality is paramount.

The Solution: To ensure uniform quality, implement a robust quality control process throughout the flocking operation. Begin by standardizing the adhesive application technique, using automated systems when feasible to minimize human error. Invest in electrostatic flocking equipment that provides consistent particle distribution and density. Regularly calibrate this equipment to maintain optimal performance. Additionally, conduct routine inspections of flocked products to identify and rectify any inconsistencies before they reach clients. Collaborating with suppliers to source high-quality flock fibers and adhesives tailored to your specific needs can also enhance product quality.

Scenario 2: High Production Costs Associated with Flocking

The Problem: Many B2B buyers are concerned about the escalating costs associated with flocking processes, particularly in regions where labor and material costs are rising. The expense of specialized equipment, coupled with the need for skilled labor to operate flocking machines, can strain budgets. This situation becomes even more pressing when buyers need to keep prices competitive in their markets while maintaining profitability.

The Solution: To manage production costs effectively, consider adopting a mixed-method approach to flocking. Evaluate the feasibility of incorporating flock transfers for smaller runs, which can reduce the need for extensive equipment investment and skilled labor. For larger production volumes, investing in automated flocking systems may prove cost-effective in the long run. Additionally, optimizing material usage by conducting a thorough analysis of flocking waste can help identify areas for improvement. Collaborating with suppliers for bulk purchasing of flocking materials can also yield significant cost savings, allowing you to pass these benefits on to your customers.

Illustrative image related to fabric flocking

Scenario 3: Challenges in Sourcing High-Quality Flocking Materials

The Problem: Sourcing high-quality flocking materials can be a daunting task for B2B buyers, particularly those operating in international markets. Variability in material quality can lead to performance issues in the final products, affecting durability and aesthetic appeal. Buyers may also struggle to find suppliers who can meet their specific requirements for fiber type, color, and adhesive compatibility, particularly in regions with limited access to specialty materials.

The Solution: Establish a strategic sourcing plan that focuses on building relationships with reputable suppliers who specialize in flocking materials. Conduct thorough research to identify suppliers with a proven track record in quality and reliability. Request samples of flocking materials to assess their compatibility with your production processes before making large purchases. Additionally, consider attending industry trade shows or conferences to connect with potential suppliers and gain insights into the latest innovations in flocking materials. This proactive approach will not only enhance your supply chain resilience but also ensure you have access to the best materials for your flocking needs.

Strategic Material Selection Guide for fabric flocking

What Are the Key Properties of Common Materials Used in Fabric Flocking?

When selecting materials for fabric flocking, it is crucial to understand the properties and applications of each option. The most common materials used in this process include nylon, rayon, polyester, and cotton. Each material has distinct characteristics that influence its performance, durability, and suitability for various applications.

How Does Nylon Perform in Fabric Flocking Applications?

Nylon is a synthetic material known for its excellent durability and abrasion resistance. It can withstand high temperatures, making it suitable for applications that require thermal stability. Additionally, nylon has a good resistance to chemicals and moisture, which enhances its longevity in various environments.

Pros: Nylon’s key advantages include high wear resistance, a soft feel, and vibrant dye retention, making it ideal for decorative applications. It is particularly effective in automotive interiors and consumer goods where aesthetic appeal is paramount.

Cons: However, nylon can be more expensive than other materials, which may impact cost-sensitive projects. Its production process is also more complex, requiring specialized equipment for optimal results.

What Are the Benefits of Using Rayon in Flocking?

Rayon, a semi-synthetic fiber derived from cellulose, offers a luxurious appearance and soft texture. It is less expensive than nylon and can be dyed in a wide range of colors, making it appealing for decorative flocking applications.

Pros: The primary advantage of rayon is its affordability and aesthetic appeal, which allows manufacturers to produce visually striking products without incurring high material costs. Rayon is suitable for fashion items and home textiles.

Cons: On the downside, rayon has lower durability compared to nylon and is more susceptible to wear and tear. It also has limited moisture resistance, which can be a concern in humid environments.

How Does Polyester Compare in Terms of Flocking Applications?

Polyester is another synthetic option that is widely used in fabric flocking. It is known for its strength and resistance to shrinking and stretching. Polyester can also handle a range of temperatures, making it versatile for various applications.

Pros: The key advantage of polyester is its durability and resistance to environmental factors, making it suitable for outdoor applications and industrial uses. It is also relatively low-cost compared to nylon, providing a good balance between performance and price.

Cons: However, polyester may not achieve the same level of softness and luxurious feel as nylon or rayon, which could limit its appeal in high-end decorative applications.

Illustrative image related to fabric flocking

What Role Does Cotton Play in Flocking Processes?

Cotton, a natural fiber, is often used in milled flocking. It is known for its softness and comfort, making it a popular choice for consumer textiles.

Pros: The primary advantage of cotton is its cost-effectiveness and pleasant texture. It is biodegradable, which appeals to environmentally conscious consumers and manufacturers.

Cons: However, cotton has lower abrasion resistance and durability compared to synthetic fibers. It is also more susceptible to moisture damage, making it less suitable for applications exposed to harsh conditions.

Summary Table of Material Selection for Fabric Flocking

| Material | Typical Use Case for fabric flocking | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Automotive interiors, consumer goods | High durability and abrasion resistance | Higher cost and complex production | High |

| Rayon | Fashion items, home textiles | Affordable and visually appealing | Lower durability and moisture resistance | Medium |

| Polyester | Industrial applications, outdoor use | Strong and resistant to environmental factors | Less softness compared to nylon/rayon | Medium |

| Cotton | Consumer textiles, eco-friendly products | Soft texture and cost-effective | Low durability and moisture susceptibility | Low |

In conclusion, the choice of material for fabric flocking significantly impacts the performance and suitability of the final product. International B2B buyers should consider these factors, along with regional compliance standards and preferences, to make informed decisions that align with their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for fabric flocking

What are the Key Stages in the Manufacturing Process of Fabric Flocking?

Fabric flocking involves a series of well-defined manufacturing stages that ensure the final product meets the desired quality and aesthetic standards. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to fabric flocking

Material Preparation: How are Flocking Materials Sourced and Processed?

The first stage in the flocking manufacturing process involves sourcing high-quality raw materials, which typically include synthetic fibers such as nylon, polyester, and rayon. These fibers are either milled or cut, with cut flock being preferred for its uniformity and better performance in applications requiring durability. After sourcing, the fibers undergo cleaning to remove any residual oils from the manufacturing process. They are then dyed to achieve the desired color and treated to ensure they can accept an electrostatic charge, which is crucial for the flocking process.

How is the Flocking Process Formed?

The flocking process itself employs several application techniques, with electrostatic flocking being the most common. This method utilizes high-voltage electrostatic systems to propel the fibers onto a substrate coated with adhesive. The electrical charge causes the fibers to stand upright, creating a dense and uniform flock coating. Other methods include beater bar flocking, which involves mechanically vibrating the substrate to promote fiber adhesion, and spray flocking, which is useful for covering larger areas.

What Assembly Techniques are Employed in Fabric Flocking?

After applying the flock to the substrate, assembly processes may vary depending on the end product. For instance, in the automotive industry, flocked materials are often integrated into components such as glove compartments and interior trims. The assembly stage also includes quality checks to ensure that the flock is securely adhered and that there are no defects in the flocked surface.

What Finishing Techniques are Used in Fabric Flocking?

The finishing stage involves several processes aimed at enhancing the flocked surface’s appearance and performance. This may include additional treatments to improve durability, softness, and water resistance. Post-application curing is essential, as it solidifies the adhesive bond and ensures the fibers remain in place. Finally, products are packaged in moisture-proof materials to maintain quality during storage and transport.

Illustrative image related to fabric flocking

How is Quality Assurance Implemented in Fabric Flocking?

Quality assurance (QA) is critical in the flocking industry, ensuring that products meet international standards and customer expectations. The QA process typically involves several checkpoints and testing methods.

What International Standards Should B2B Buyers Be Aware of?

International standards such as ISO 9001 play a significant role in the quality assurance of flocked products. This standard focuses on quality management systems and helps ensure that suppliers maintain consistent product quality. Additionally, industry-specific certifications like CE marking in Europe and API standards for specific applications provide further assurance of compliance with safety and performance criteria.

What Are the Key Quality Control Checkpoints in Fabric Flocking?

Quality control (QC) is implemented at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before they are used in production.

-

In-Process Quality Control (IPQC): This stage includes ongoing inspections during the flocking process to monitor adhesive application, fiber density, and adherence quality. Regular checks help identify issues early, minimizing defects in the final product.

-

Final Quality Control (FQC): The final product undergoes rigorous testing to ensure it meets established quality benchmarks. This may include visual inspections, tactile evaluations, and performance testing for durability and wear resistance.

What Common Testing Methods Are Utilized in Quality Control?

Several testing methods are employed to assess flocked products’ quality:

-

Adhesion Tests: These tests evaluate the bond strength between the flock and the substrate, ensuring durability in various applications.

-

Abrasion Resistance Tests: This measures the flock’s ability to withstand wear and tear, particularly important for automotive and consumer goods.

-

Colorfastness Tests: These tests determine how well the colors hold up under various environmental conditions, such as exposure to sunlight or moisture.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers should take proactive steps to verify their suppliers’ quality control measures to ensure they receive high-quality products. Here are some effective strategies:

What Steps Can Buyers Take for Supplier Audits?

Conducting supplier audits is a critical step in verifying quality control practices. Buyers should establish a checklist that includes:

- Review of the supplier’s quality management system and compliance with international standards.

- Assessment of manufacturing processes and equipment used for flocking.

- Examination of records related to IQC, IPQC, and FQC processes.

How Can Buyers Request Quality Control Reports?

Buyers should request detailed quality control reports from suppliers, which should include test results and certifications for the products being purchased. This documentation can provide insights into the supplier’s quality practices and help identify any potential issues.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can further enhance quality assurance for B2B buyers. These independent inspectors can conduct on-site evaluations and provide unbiased assessments of the supplier’s quality control processes and product quality. This is particularly valuable for international buyers seeking to mitigate risks associated with overseas sourcing.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Cultural and regulatory differences can impact supplier practices and compliance levels. Buyers should:

- Understand regional standards and regulations that may affect product quality and safety.

- Establish clear communication channels with suppliers to ensure alignment on quality expectations.

- Be prepared to adapt quality control measures based on the specific conditions and capabilities of suppliers in different regions.

By comprehensively understanding the manufacturing processes and quality assurance practices in fabric flocking, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who deliver high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric flocking’

To assist B2B buyers in procuring fabric flocking, this step-by-step guide outlines essential actions to ensure a successful sourcing process. Each step is designed to help you navigate the complexities of the flocking industry while making informed decisions.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the flocking materials you need. This includes the type of fiber (e.g., nylon, polyester), length, and diameter of the flock, as well as the required adhesive compatibility. Defining these parameters helps suppliers provide accurate samples and quotes, ensuring that the final product meets your quality standards.

Illustrative image related to fabric flocking

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in fabric flocking. Look for companies with experience in your specific industry and region. Utilize platforms like industry trade shows, online directories, and trade associations to compile a list of potential partners.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that your chosen suppliers possess the necessary certifications and comply with international quality standards. Certifications such as ISO 9001 or environmental compliance certifications can indicate a supplier’s commitment to quality and sustainability. Ask for documentation that proves their adherence to these standards.

Step 4: Request Samples and Conduct Quality Tests

Before placing a large order, request samples of the flocking materials to evaluate their quality. Conduct tests to assess durability, adhesion, and aesthetic appeal. This step is critical as it allows you to determine if the flock meets your expectations and is suitable for your application.

Step 5: Analyze Pricing and Payment Terms

Obtain detailed quotes from potential suppliers and analyze pricing structures. Compare the costs not only of the flocking materials but also of shipping, handling, and any additional services such as customization. Pay attention to payment terms and conditions, as favorable terms can improve your cash flow management.

Step 6: Review Lead Times and Delivery Options

Discuss lead times with suppliers to understand how quickly they can fulfill your orders. Consider your production schedule and the importance of timely delivery. Additionally, inquire about shipping options and logistics to ensure that materials arrive on schedule and in good condition.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear lines of communication with your supplier to facilitate quick resolution of any issues that may arise. Regular check-ins and updates can help build a strong relationship and ensure that both parties are aligned on project goals.

By following these steps, B2B buyers can streamline the procurement process for fabric flocking, ensuring that they select suppliers who meet their technical, quality, and logistical requirements. Each step is designed to mitigate risks and enhance the overall sourcing experience, paving the way for successful partnerships in the fabric flocking market.

Comprehensive Cost and Pricing Analysis for fabric flocking Sourcing

What Are the Key Cost Components in Fabric Flocking?

When sourcing fabric flocking, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The choice of flock fibers (nylon, rayon, polyester) significantly impacts costs. Cut flock, while more expensive due to its uniformity and durability, offers better performance in high-wear applications. Additionally, the adhesive used for bonding the flock to substrates can vary in price based on its formulation (water-based, plastisol, or two-part systems).

-

Labor: Labor costs encompass skilled workers needed for the flocking process, including machine operators and quality control personnel. In regions with higher labor costs, such as Europe, this can constitute a significant portion of the total expenditure.

-

Manufacturing Overhead: This includes indirect costs related to factory operations, such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs, making sourcing from established suppliers beneficial.

-

Tooling: Initial investments in specialized flocking equipment can be substantial. For example, automatic systems can range from tens to hundreds of thousands of dollars, while handheld units are more affordable. Buyers should consider these upfront costs when evaluating suppliers.

-

Quality Control (QC): Ensuring that flocked products meet specifications requires investment in quality assurance processes, which include testing for adhesion, durability, and appearance. Suppliers with robust QC systems may charge a premium but can reduce the risk of defects.

-

Logistics: Transportation costs can vary widely based on distance, shipping methods, and regional tariffs. For international buyers, understanding Incoterms is crucial for determining responsibilities and cost implications.

-

Margin: Supplier margins can vary significantly based on their operational efficiencies, market positioning, and the level of customization required by buyers.

How Do Price Influencers Affect Fabric Flocking Costs?

Several factors can influence the pricing of fabric flocking:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate favorable terms based on anticipated order volumes.

-

Specifications and Customization: Custom designs or unique specifications can increase costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Material Selection: The choice of flocking materials (natural vs. synthetic, cut vs. milled) can significantly impact pricing. Buyers should weigh the benefits of higher-quality materials against their budget constraints.

-

Quality and Certifications: Products that meet specific industry certifications or quality standards may command higher prices. Buyers should consider whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may offer better quality assurance but at a higher cost. New entrants might provide competitive pricing but pose risks related to quality and delivery.

-

Incoterms: Understanding the implications of Incoterms can help buyers manage costs effectively. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) define responsibilities for shipping and insurance, impacting the total landed cost.

What Buyer Tips Can Help Optimize Fabric Flocking Sourcing?

B2B buyers can leverage several strategies to optimize their sourcing of fabric flocking:

-

Negotiation Skills: Engage suppliers in discussions about pricing, terms, and potential discounts for bulk orders. Building long-term relationships can lead to more favorable pricing over time.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the initial purchase price. Consider factors such as durability, maintenance, and potential waste reduction when selecting flocked products.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and regional market conditions that can affect pricing. Establishing relationships with local suppliers may mitigate some of these risks.

-

Research and Compare Suppliers: Conduct thorough market research to identify suppliers that align with your quality and pricing expectations. Request samples to assess the quality before committing to larger orders.

Disclaimer on Indicative Prices

Please note that the prices associated with fabric flocking can vary based on numerous factors, including material choice, order volume, and supplier conditions. It is advisable to obtain quotes from multiple suppliers to ensure competitive pricing tailored to your specific requirements.

Alternatives Analysis: Comparing fabric flocking With Other Solutions

Exploring Alternatives to Fabric Flocking: A Comparative Analysis

In the realm of decorative and functional surface applications, fabric flocking stands out due to its unique texture and aesthetic appeal. However, various alternatives may better suit specific operational needs and budget constraints. This section explores viable alternatives to fabric flocking, comparing their performance, cost, ease of implementation, maintenance, and ideal use cases.

Comparison Table

| Comparison Aspect | Fabric Flocking | Digital Printing | Embroidery |

|---|---|---|---|

| Performance | Durable, high-density finish | High-resolution images, versatile | High durability, tactile quality |

| Cost | Moderate | Varies widely; can be low to high | Higher due to labor and materials |

| Ease of Implementation | Requires specialized equipment | Relatively easy with standard printers | Labor-intensive, requires skilled personnel |

| Maintenance | Low (once applied) | Low, but depends on ink quality | Moderate; may require repairs |

| Best Use Case | Textiles, automotive parts | Apparel, promotional items | Apparel, uniforms, accessories |

In-Depth Analysis of Alternatives

1. What are the advantages and disadvantages of Digital Printing?

Digital printing is a modern technique that allows for high-resolution graphics and designs to be printed directly onto various substrates. Its primary advantage is versatility; it can produce complex designs and colors with relative ease. Additionally, it requires less setup time compared to flocking, making it ideal for short runs or custom orders. However, the cost can vary significantly based on the quality of the inks used, and while it excels in visual detail, it may lack the tactile richness and durability of flocked surfaces.

2. How does Embroidery compare to Fabric Flocking?

Embroidery is a traditional method that involves stitching designs directly onto fabric, offering a textured and durable finish. Its key advantages include a high-quality, professional appearance and excellent wear resistance, making it particularly suitable for uniforms and branded apparel. However, the initial setup costs can be higher due to labor and materials, and the process can be time-consuming. Additionally, it may not be as versatile in design as digital printing or flocking, limiting its application in some contexts.

Making the Right Choice: Which Solution Fits Your Needs?

When selecting a surface application method, B2B buyers should consider several factors, including the intended use of the product, budget constraints, and desired aesthetic. Fabric flocking offers a unique combination of texture and durability, ideal for applications where a soft touch and visual appeal are paramount. However, if high-resolution graphics are required or if the project involves frequent design changes, digital printing may be more suitable. For applications where durability and a professional finish are critical, especially in corporate or uniform settings, embroidery could be the best choice. Ultimately, understanding the specific needs of your project will guide you in selecting the most effective solution for your organization.

Essential Technical Properties and Trade Terminology for fabric flocking

What Are the Key Technical Properties of Fabric Flocking?

Understanding the technical properties of fabric flocking is essential for B2B buyers in various industries, including automotive, fashion, and packaging. Here are some critical specifications:

1. Material Grade

Material grade refers to the quality of the fibers used in flocking, which can include natural fibers (like cotton) or synthetic fibers (like nylon and polyester). Higher-grade materials typically offer better durability and aesthetic appeal. Selecting the right material grade is crucial for ensuring product longevity and customer satisfaction.

2. Flock Length

Flock length varies from 0.25 mm to 5 mm, affecting the texture and visual impact of the finished product. Shorter fibers may provide a finer finish, while longer fibers can create a more pronounced texture. This specification is vital for buyers to match their design requirements and functional needs, such as grip or softness.

3. Adhesive Type

The type of adhesive used in the flocking process can significantly affect the durability and performance of the flocked surface. Common adhesive types include water-based, plastisol, and two-part systems. Selecting an appropriate adhesive ensures that the flock remains securely attached to the substrate over time, which is particularly important for high-traffic applications.

4. Application Method

Different flocking methods, such as electrostatic, beater bar, and spray application, yield varied results in terms of fiber density and distribution. B2B buyers must understand the implications of each method for their production processes, as some methods may be more suitable for large-scale operations, while others might be better for detailed designs.

5. Flock Density

Flock density refers to the concentration of fibers applied to a substrate. Higher density typically results in a more luxurious appearance and enhanced performance characteristics, such as sound absorption or thermal insulation. This property can influence the overall cost and marketability of the flocked product.

6. Moisture Content

The moisture content of flock fibers is a critical factor in the electrostatic flocking process. Maintaining a specific moisture level can enhance the conductivity of the fibers, ensuring they adhere properly to the adhesive. Buyers should be aware of this when sourcing materials to ensure optimal flocking results.

What Are Common Trade Terms Used in Fabric Flocking?

Familiarity with industry jargon is essential for effective communication and negotiation in the fabric flocking sector. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the flocking industry, understanding OEM relationships is crucial for ensuring compatibility and quality assurance in products.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory effectively and understand cost implications.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products or services. This term is important for buyers to streamline procurement processes and compare costs across different vendors.

Illustrative image related to fabric flocking

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers navigate shipping, insurance, and liability issues, which are critical for cross-border trade.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving it. Knowledge of lead times is essential for B2B buyers to plan production schedules and meet market demands efficiently.

6. Flocking Density

This term describes the amount of flock material applied per unit area. High flocking density can enhance product aesthetics and functionality, making it a key consideration for buyers when specifying product requirements.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right flocking solutions to meet their specific industry needs.

Navigating Market Dynamics and Sourcing Trends in the fabric flocking Sector

What Are the Key Market Dynamics and Trends in the Fabric Flocking Sector?

The fabric flocking sector is currently experiencing a notable resurgence, driven by evolving consumer preferences for unique and tactile products. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of several key trends shaping the market. Firstly, the demand for customization and differentiated products is increasing, leading to a rise in flocking applications across various industries, including automotive, textiles, and packaging. This is particularly significant in regions like Saudi Arabia and Vietnam, where local manufacturers are looking to enhance product offerings to compete on a global scale.

Moreover, technological advancements in flocking equipment—such as automated electrostatic systems—are making the process more efficient and cost-effective. These innovations are appealing to businesses aiming to reduce production times and improve quality consistency. Additionally, the growing interest in sustainable materials has led to the development of eco-friendly flocking options, which can attract environmentally-conscious consumers and businesses alike.

Emerging markets are also tapping into digital platforms for sourcing flocking materials, allowing for a more streamlined procurement process. This is crucial for B2B buyers looking to access a wider range of suppliers and materials without the traditional barriers of geographic limitations. As global supply chains become more interconnected, buyers should prioritize partnerships with suppliers who demonstrate agility and responsiveness to market changes.

How Are Sustainability and Ethical Sourcing Impacting the Fabric Flocking Industry?

Sustainability is becoming an imperative in the fabric flocking sector, as businesses increasingly recognize the environmental impacts of their sourcing decisions. Traditional flocking materials, often derived from synthetic fibers, can contribute to pollution and waste. Therefore, B2B buyers must consider suppliers that offer sustainable options, such as biodegradable or recycled materials.

Illustrative image related to fabric flocking

The importance of ethical supply chains cannot be overstated. Buyers should seek partners who comply with international labor standards and demonstrate transparency in their sourcing practices. Certifications like OEKO-TEX and Global Recycled Standard (GRS) are indicators of a supplier’s commitment to sustainability and ethical practices, which can enhance a buyer’s brand reputation and appeal to conscious consumers.

Furthermore, adopting ‘green’ materials in flocking not only aligns with sustainability goals but can also lead to cost savings in the long run. By investing in eco-friendly flocking options, businesses can reduce waste, lower energy consumption, and even qualify for government incentives aimed at promoting sustainable manufacturing practices. This strategic shift is essential for B2B buyers who want to stay competitive in a market increasingly driven by consumer demand for sustainability.

What Is the Evolution of the Fabric Flocking Process and Its Implications for B2B Buyers?

The history of fabric flocking dates back to medieval times when rudimentary methods were used to apply fiber dust to surfaces. However, it wasn’t until the 1970s that technological advancements enabled a more refined flocking process, making it a popular decoration method. By the 1980s and early 1990s, interest waned, but recent years have seen a resurgence in flocking applications due to enhanced technologies and a growing appreciation for tactile aesthetics.

For B2B buyers, understanding this evolution is crucial as it highlights the technological advancements that have improved quality and efficiency in flocking. Modern flocking techniques, such as electrostatic application, offer greater precision and consistency, making them attractive options for businesses looking to enhance their product lines. Additionally, the shift towards digital sourcing and automation reflects broader trends in manufacturing that B2B buyers should embrace to remain competitive in the global marketplace.

Illustrative image related to fabric flocking

In summary, the fabric flocking sector presents numerous opportunities for B2B buyers willing to adapt to market dynamics, prioritize sustainability, and leverage technological advancements to optimize their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of fabric flocking

-

How do I choose the right flocking method for my business?

Choosing the right flocking method depends on your production volume and application requirements. Electrostatic flocking is ideal for large-scale operations due to its efficiency and uniformity. For smaller projects, a hand-held unit might suffice. Consider the substrate material, desired finish, and whether you need multicolor options. Assess your budget, as equipment costs can vary significantly. Consulting with suppliers about their capabilities and past projects can help you make an informed decision tailored to your business needs. -

What types of flock materials should I consider for my products?

When selecting flock materials, consider the intended use and desired properties. Nylon and polyester are durable and suitable for high-wear applications, while rayon offers a softer finish for decorative items. Milled flock is cost-effective but less uniform, whereas cut flock provides consistency in length and feel. Evaluate factors such as abrasion resistance, softness, and colorfastness based on your target market’s preferences. Discuss these factors with suppliers to ensure you select the best material for your applications. -

What are the minimum order quantities (MOQs) for flocking materials?

Minimum order quantities for flocking materials can vary widely among suppliers. Some may require small MOQs for trial orders, while others might have higher thresholds to justify production costs. Typically, MOQs range from 50 to 500 kilograms, depending on the material and customization options. It’s advisable to communicate your needs clearly to potential suppliers and negotiate terms that accommodate your business model, especially if you are a smaller enterprise or testing a new product line. -

What payment terms should I expect when sourcing flocking materials internationally?

Payment terms in international trade can vary based on the supplier’s policies and your buyer-seller relationship. Common terms include payment in advance, letters of credit, or net payment terms (e.g., 30, 60, or 90 days post-delivery). Be prepared to discuss and negotiate terms that align with your cash flow needs. Ensure to clarify any potential fees associated with currency exchange or international transfers, and verify the supplier’s credibility to mitigate risks. -

How can I ensure quality assurance when sourcing flocking materials?

To ensure quality assurance, begin by vetting suppliers through references and reviews. Request samples to assess the material’s texture, durability, and color quality before placing larger orders. Establish clear quality standards and specifications in your purchase agreements. Discuss inspection processes, including pre-shipment inspections or third-party audits, to ensure compliance with your quality requirements. Maintaining open communication with suppliers throughout the production process can also help address any issues early. -

What are the logistics considerations for importing flocking materials?

Logistics considerations for importing flocking materials include shipping methods, customs regulations, and lead times. Decide whether to use air freight for quicker delivery or sea freight for cost-effective shipping, depending on your urgency and budget. Familiarize yourself with customs documentation and import duties specific to your country to avoid delays. Collaborating with a reliable logistics partner can streamline the process, ensuring timely delivery and compliance with regulations. -

How can I customize flocked products to meet market demands?

Customization of flocked products can be achieved through various means, including color selection, flock length, and adhesive types. Discuss your design requirements with suppliers, as many offer tailored solutions to meet specific market needs. Consider incorporating unique patterns or textures to differentiate your products in a competitive landscape. Additionally, leveraging customer feedback on desired features can guide your customization strategy, ensuring alignment with market trends. -

What are the environmental considerations when sourcing flocking materials?

When sourcing flocking materials, consider the environmental impact of production processes and materials used. Opt for suppliers who utilize sustainable practices, such as recycling textile waste for milled flock or using eco-friendly adhesives. Inquire about the supplier’s compliance with international environmental standards and certifications. Additionally, evaluate the lifecycle of the flocked products to ensure they meet sustainability expectations, as consumers increasingly prioritize environmentally responsible options in their purchasing decisions.

Top 6 Fabric Flocking Manufacturers & Suppliers List

1. Swicofil – Flocking Solutions

Domain: swicofil.com

Registered: 1996 (29 years)

Introduction: Flocking is a process that applies short monofilament fibers, typically made of nylon, rayon, or polyester, onto a substrate to create a velvety or brush-like surface. Flocked products are prevalent in various applications including T-shirts, perfume packaging, automotive interiors (like glove compartments and door moldings), floor coverings, and more. The process has seen a resurgence in interest…

2. Search For Fabric – Flocked Fabrics

Domain: searchforfabric.com

Registered: 2020 (5 years)

Introduction: Flocked fabrics are a unique textile innovation characterized by a velvet-like texture and intricate patterns. The flocking process involves applying minuscule fiber dust particles to fabric surfaces using adhesive and high voltage, creating a tactile and visually appealing texture. Flocked fabrics are versatile and used across various industries, including automotive (for interior components), to…

3. Flockit – Flocking Solutions

Domain: flockit.com

Registered: 2007 (18 years)

Introduction: Flocking is the application of millions of tiny fibers onto an adhesive-coated surface to create a velvet-like texture. It is commonly used in jewelry boxes, glove compartments, waterfowl decoys, and various decorative and functional applications. Flocking has a historical background dating back to ancient China and has evolved to be used in products such as wallpaper, women’s clothing, carpets, a…

4. Fashion Fabric LA – Flocking Fabrics

Domain: fashionfabricla.com

Registered: 2014 (11 years)

Introduction: Flocking Fabrics – Sold By The Yard

5. AccTrims – Flocking Fabric

Domain: acctrims.com

Registered: 2021 (4 years)

Introduction: Flocking fabric is made by planting nylon or viscose fluff on various fabrics, resulting in a soft, suede-like texture that is bright in color and unique in style. It is warm, fashionable, and favored by consumers.

Pros:

– Antifouling: Flocking fabric has excellent antifouling properties due to its nylon composition, allowing for easy cleaning of dirt and stains.

– Waterproof: The plush nylon pr…

6. Big Z Fabric – Upholstery Grade Solid Flocking Velvet Fabric

Domain: bigzfabric.com

Registered: 2010 (15 years)

Introduction: {‘product_name’: ‘Upholstery Grade Solid Flocking Velvet Fabric’, ‘color’: ‘Black’, ‘length’: ’40 Yards Roll’, ‘price’: ‘$278.46’, ‘original_price’: ‘$335.60’, ‘material’: ‘100% Polyester’, ‘width’: ’56″/57″‘, ‘backing’: ‘100% Cotton’, ‘stretch’: ‘No Stretch’, ‘uses’: [‘Couches’, ‘Furniture’, ‘Head Boards’, ‘Shoes’, ‘Dress’, ‘Clothing’, ‘Automotive’, ‘more’], ‘shipping_info’: ‘Ships via FREIGHT SH…

Strategic Sourcing Conclusion and Outlook for fabric flocking

In navigating the fabric flocking landscape, strategic sourcing emerges as a critical component for international B2B buyers. As flocking techniques continue to evolve, the demand for unique and high-quality flocked products is on the rise. Buyers should prioritize sourcing from suppliers who offer innovative flocking materials and techniques, as these can significantly enhance product differentiation in competitive markets.

Understanding the various flocking processes—from electrostatic to beater bar methods—allows buyers to select the most suitable options for their applications, ensuring quality while optimizing costs. Additionally, investing in reliable adhesive systems and understanding the characteristics of different flock materials can further improve product performance and customer satisfaction.

As you look to the future, consider how the integration of advanced flocking technologies can elevate your offerings. Embrace the opportunity to connect with suppliers who not only meet your immediate needs but also share your vision for innovation. By fostering these strategic partnerships, you can secure a competitive edge in diverse markets across Africa, South America, the Middle East, and Europe. Start exploring these opportunities today and position your business for success in the dynamic world of fabric flocking.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to fabric flocking

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.