Introduction: Navigating the Global Market for auto leather material

In the fast-evolving landscape of the automotive industry, sourcing high-quality auto leather material presents a significant challenge for international B2B buyers. The quest for durable, aesthetically pleasing, and comfortable leather that meets the stringent demands of modern vehicle interiors can be daunting. This guide aims to demystify the complexities of sourcing automotive leather, providing insights into various types of leather, their applications, and crucial factors for supplier vetting.

We will explore the diverse offerings of raw leather hides, examining the unique qualities that make each type suitable for specific automotive uses—ranging from seat upholstery to dashboard coverings. Additionally, we will address cost considerations and market trends that impact purchasing decisions, particularly for buyers in Africa, South America, the Middle East, and Europe, including regions like Germany and Vietnam.

By equipping B2B buyers with actionable insights and a comprehensive understanding of the auto leather market, this guide empowers them to make informed purchasing decisions. With a focus on quality, compatibility, and supplier reliability, buyers will be better positioned to enhance their automotive offerings, ensuring they meet consumer expectations for luxury, comfort, and durability.

Table Of Contents

- Top 2 Auto Leather Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for auto leather material

- Understanding auto leather material Types and Variations

- Key Industrial Applications of auto leather material

- 3 Common User Pain Points for ‘auto leather material’ & Their Solutions

- Strategic Material Selection Guide for auto leather material

- In-depth Look: Manufacturing Processes and Quality Assurance for auto leather material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto leather material’

- Comprehensive Cost and Pricing Analysis for auto leather material Sourcing

- Alternatives Analysis: Comparing auto leather material With Other Solutions

- Essential Technical Properties and Trade Terminology for auto leather material

- Navigating Market Dynamics and Sourcing Trends in the auto leather material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of auto leather material

- Strategic Sourcing Conclusion and Outlook for auto leather material

- Important Disclaimer & Terms of Use

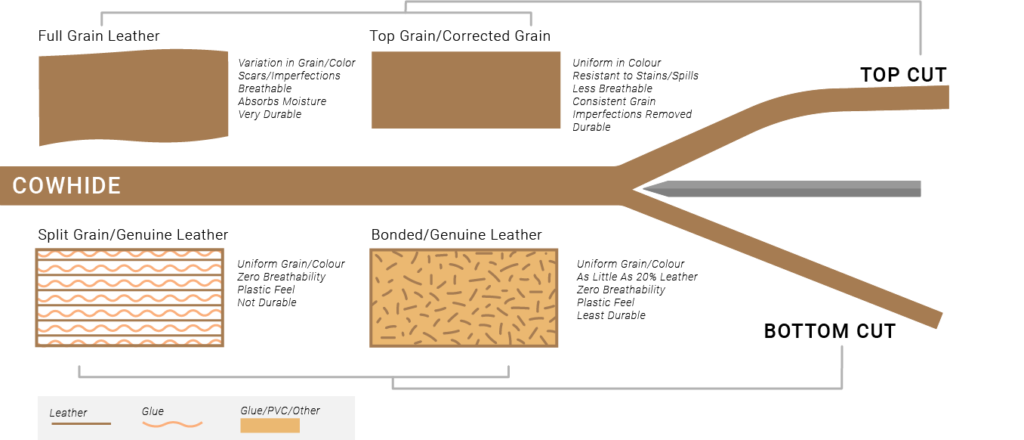

Understanding auto leather material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Grain Leather | Made from the top layer of the hide, retains natural grain; highly durable and breathable. | Luxury car interiors, high-end vehicles. | Pros: Exceptional durability, natural appearance. Cons: Higher cost, can be sensitive to stains. |

| Top-Grain Leather | Sanded and finished to remove imperfections; softer than full-grain but less durable. | Mid-range vehicles, luxury trims. | Pros: Good balance of quality and cost, easier to maintain. Cons: Less durable than full-grain. |

| Split Leather | Derived from the lower layers of the hide; often treated for durability. | Budget-friendly vehicle interiors. | Pros: Cost-effective, decent durability. Cons: Less luxurious feel, prone to wear. |

| Perforated Leather | Features small holes for breathability; often used in sports and performance vehicles. | Sports cars, performance upgrades. | Pros: Enhanced comfort, stylish appearance. Cons: May require more maintenance, potential for wear around perforations. |

| Suede Leather | Soft, napped finish; offers a unique aesthetic but less practical for high-use areas. | Specialty vehicles, custom interiors. | Pros: Luxurious feel, unique look. Cons: Difficult to clean, less durable in high-traffic areas. |

What are the Characteristics of Full-Grain Leather in Automotive Applications?

Full-grain leather is the highest quality leather available for automotive use, crafted from the top layer of the hide. This type retains its natural grain, showcasing unique imperfections that add character. It is known for its exceptional durability and breathability, making it ideal for luxury car interiors. B2B buyers should consider the investment, as full-grain leather is priced higher but offers long-term value due to its resistance to wear and tear. Its natural surface may require special care to prevent staining, which is an important consideration for high-traffic applications.

Why Choose Top-Grain Leather for Mid-Range Vehicles?

Top-grain leather is sanded and finished to remove imperfections, resulting in a softer feel compared to full-grain leather. This type is widely used in mid-range vehicles and luxury trims, balancing quality and affordability. B2B buyers appreciate its aesthetic appeal and ease of maintenance, as it is less prone to staining and easier to clean than full-grain. However, it is essential to note that top-grain leather may not offer the same level of durability as full-grain, making it a suitable choice for buyers looking for a quality product without the premium price tag.

What are the Benefits and Drawbacks of Split Leather?

Split leather, derived from the lower layers of the hide, is a more economical option for automotive interiors. It is often treated for added durability and is commonly used in budget-friendly vehicle applications. B2B buyers seeking cost-effective solutions will find split leather appealing; however, it typically lacks the luxurious feel and longevity associated with higher-grade leathers. While it can withstand moderate use, its susceptibility to wear and less refined appearance may deter buyers looking for premium options.

How Does Perforated Leather Enhance Comfort in Performance Vehicles?

Perforated leather is characterized by small holes that enhance breathability, making it a popular choice for sports and performance vehicles. This type not only improves comfort during extended driving but also adds a stylish touch to the interior. B2B buyers should consider the maintenance requirements, as perforated leather may require more attention to prevent wear around the perforations. Its unique aesthetic and comfort features make it a desirable choice for high-performance applications, but buyers must weigh these benefits against potential upkeep challenges.

What Makes Suede Leather Unique for Specialty Vehicles?

Suede leather offers a soft, napped finish that provides a distinctive aesthetic, making it a favored choice for specialty vehicles and custom interiors. While it adds a luxurious feel, suede is less practical for high-use areas due to its susceptibility to stains and difficulty in cleaning. B2B buyers looking to create a unique interior experience may opt for suede, but they should be prepared for the additional care it requires. Its unique look can elevate vehicle interiors, but buyers must consider the trade-offs in durability and maintenance.

Illustrative image related to auto leather material

Key Industrial Applications of auto leather material

| Industry/Sector | Specific Application of auto leather material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Car Seat Upholstery | Enhances comfort and luxury, increasing vehicle resale value | Ensure durability and compatibility with vehicle models |

| Luxury Vehicle Customization | Dashboard and Interior Trim | Provides a high-end aesthetic, attracting premium buyers | Focus on color and texture options to match branding |

| Fleet Management | Replacement Upholstery for Commercial Vehicles | Reduces maintenance costs due to durability and ease of cleaning | Consider bulk purchasing options for cost efficiency |

| Aftermarket Accessories | Steering Wheel Covers | Improves grip and comfort, enhancing driver experience | Assess compatibility with various steering wheel designs |

| Automotive Restoration | Classic Car Upholstery | Preserves vintage aesthetics while ensuring modern comfort | Source materials that match original specifications |

How is Auto Leather Material Utilized in Automotive Manufacturing?

In automotive manufacturing, auto leather material is primarily used for car seat upholstery. This application enhances the overall comfort and luxury of vehicles, making them more appealing to consumers. For B2B buyers, particularly those in regions like Europe or the Middle East, sourcing high-quality leather that meets durability standards is crucial. The leather must withstand wear and tear while maintaining an elegant appearance, which can significantly increase a vehicle’s resale value.

What Role Does Auto Leather Play in Luxury Vehicle Customization?

In the luxury vehicle customization sector, auto leather is extensively used for dashboards and interior trims. This application not only adds a touch of sophistication but also elevates the perceived value of the vehicle. Buyers should consider the color and texture of the leather to ensure it aligns with their brand identity and customer expectations. Sourcing unique and premium leather options can help differentiate luxury vehicles in competitive markets like Germany and South America.

How Can Fleet Management Benefit from Auto Leather Upholstery?

Fleet management companies often utilize auto leather material for replacement upholstery in commercial vehicles. This application is beneficial as it reduces long-term maintenance costs due to the leather’s durability and ease of cleaning. For international buyers, especially in Africa and South America, negotiating bulk purchasing agreements can lead to significant cost savings. Ensuring that the sourced leather meets the specific requirements of various vehicle models is essential for maintaining a professional fleet appearance.

Why is Auto Leather Important for Aftermarket Accessories?

In the aftermarket accessories sector, auto leather is commonly used for steering wheel covers. This application enhances the driver’s grip and comfort, improving the overall driving experience. B2B buyers need to assess the compatibility of leather covers with different steering wheel designs to ensure a proper fit. Sourcing high-quality leather that can endure heavy use while providing a luxurious feel is vital for attracting discerning consumers.

How Does Auto Leather Contribute to Automotive Restoration Projects?

In automotive restoration, especially for classic cars, auto leather material is used to replicate original upholstery while ensuring modern comfort. This application is critical for preserving the vehicle’s vintage aesthetic while upgrading its functionality. Buyers should focus on sourcing materials that match original specifications in terms of color, texture, and quality. This attention to detail not only satisfies restoration enthusiasts but also enhances the overall value of restored vehicles in the marketplace.

Illustrative image related to auto leather material

3 Common User Pain Points for ‘auto leather material’ & Their Solutions

Scenario 1: Sourcing High-Quality Leather for Diverse Markets

The Problem: B2B buyers often struggle to find high-quality auto leather that meets the varying preferences and standards of their international clients. For instance, buyers in Africa may prioritize durability and resistance to heat, while those in Europe may focus on aesthetics and eco-friendliness. This discrepancy creates a challenge in sourcing leather that satisfies diverse market demands, leading to potential dissatisfaction from customers.

The Solution: To effectively source leather that aligns with regional preferences, B2B buyers should engage with multiple suppliers who specialize in different types of leather and have a proven track record in their respective markets. Conducting thorough research on suppliers’ reputations, customer reviews, and product offerings is essential. Additionally, buyers should request samples of various leather types to assess their suitability for specific market conditions. Establishing strong relationships with suppliers that understand local market demands can also facilitate better communication and ensure that the leather provided meets quality and performance expectations.

Scenario 2: Managing Inventory and Order Volumes

The Problem: Another prevalent issue for B2B buyers of auto leather material is managing inventory effectively, particularly when dealing with large orders. Fluctuations in demand can lead to overstocking or stockouts, which can result in lost sales or increased storage costs. Buyers may find it challenging to predict the required quantities of leather for different projects, especially when working with new clients or entering unfamiliar markets.

The Solution: Implementing a robust inventory management system can significantly enhance order fulfillment and inventory tracking. This system should include forecasting tools that analyze historical sales data, seasonality, and market trends to better predict future demand. Additionally, buyers should consider establishing minimum order quantities with suppliers to ensure they can respond quickly to changing needs without incurring excessive inventory costs. Regular communication with clients regarding their upcoming projects can also help in adjusting orders proactively, ensuring a balance between supply and demand.

Scenario 3: Ensuring Compliance with Environmental Standards

The Problem: As global awareness of environmental issues rises, many B2B buyers face pressure to source auto leather that complies with stringent environmental regulations. Buyers are often unsure of how to verify the sustainability practices of their suppliers, which can lead to reputational risks and potential legal issues if sourced materials do not meet local or international standards.

Illustrative image related to auto leather material

The Solution: B2B buyers should prioritize sourcing from suppliers who are transparent about their production processes and environmental certifications. This includes looking for leather that is tanned using environmentally friendly methods, such as vegetable tanning, which minimizes chemical use. Buyers can also request documentation and certifications that confirm compliance with relevant environmental regulations. Additionally, forming partnerships with suppliers who are committed to sustainability can enhance the buyer’s brand reputation and appeal to eco-conscious consumers. Regular audits and assessments of suppliers can further ensure adherence to sustainability practices, providing buyers with peace of mind regarding their sourcing decisions.

Strategic Material Selection Guide for auto leather material

What Are the Key Properties of Common Auto Leather Materials?

When selecting auto leather materials, understanding the properties of various types is crucial for ensuring optimal performance in automotive applications. Here, we analyze four common materials used in the automotive leather industry: Full-Grain Leather, Top-Grain Leather, Split Leather, and Synthetic Leather.

Full-Grain Leather: The Premium Choice

Full-grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain and markings, which adds to its character and luxury appeal.

Key Properties: Full-grain leather is highly durable, resistant to wear and tear, and can withstand temperature fluctuations. It also has excellent breathability, which enhances comfort during long drives.

Pros & Cons: The primary advantage of full-grain leather is its longevity and aesthetic appeal. However, it comes at a higher cost and requires more care to maintain its appearance.

Illustrative image related to auto leather material

Impact on Application: This type of leather is ideal for high-end vehicles where luxury and durability are paramount. It is compatible with various upholstery applications, including seats and dashboards.

Considerations for International Buyers: Buyers in regions like Europe (e.g., Germany) may need to ensure compliance with EU regulations regarding leather sourcing and treatment. Standards such as EN 15987 for leather quality may also apply.

Top-Grain Leather: A Balanced Option

Top-grain leather is slightly less expensive than full-grain but still offers a high level of quality. It is sanded and treated to remove imperfections, resulting in a more uniform appearance.

Key Properties: This leather is durable and resistant to stains, making it suitable for automotive use. It also has a softer feel compared to full-grain leather.

Pros & Cons: The main advantage is its affordability compared to full-grain leather while still maintaining a premium look. However, it may not be as durable over time, especially in high-wear areas.

Impact on Application: Top-grain leather is versatile and can be used for seats, door panels, and steering wheels, providing a good balance between luxury and cost.

Considerations for International Buyers: Buyers from Africa and South America may find top-grain leather more accessible due to lower shipping costs and availability. Compliance with local regulations regarding leather treatment should also be considered.

Split Leather: Economical and Functional

Split leather is made from the lower layers of the hide and is often used in less visible areas of vehicles.

Key Properties: While less durable than full-grain or top-grain leather, split leather is still robust and can handle moderate wear and tear. It is typically treated to enhance its resistance to moisture and stains.

Pros & Cons: The primary advantage is its lower cost, making it suitable for budget-conscious projects. However, it lacks the luxurious feel and durability of higher-grade leathers.

Illustrative image related to auto leather material

Impact on Application: Split leather is commonly used for interior components that do not require the same level of luxury, such as back seats or trunk linings.

Considerations for International Buyers: Buyers in the Middle East may prefer split leather for cost-effective vehicle modifications. Understanding local market preferences for leather quality is essential.

Synthetic Leather: The Eco-Friendly Alternative

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), mimics the look and feel of real leather while being more affordable.

Key Properties: It is resistant to moisture, easy to clean, and available in various colors and textures. Synthetic leather can also be engineered to meet specific performance requirements.

Pros & Cons: The main advantage is its cost-effectiveness and ease of maintenance. However, it may not provide the same level of comfort or durability as genuine leather.

Impact on Application: Synthetic leather is increasingly used in budget vehicles and for applications where cost and maintenance are more critical than luxury.

Considerations for International Buyers: Buyers from regions with strict environmental regulations may prefer synthetic options due to their lower environmental impact. Compliance with ASTM standards for synthetic materials may also be necessary.

Summary Table of Auto Leather Materials

| Материал | Typical Use Case for auto leather material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Luxury vehicle interiors | Exceptional durability and aesthetics | Higher cost and maintenance required | Высокий |

| Top-Grain Leather | Premium seats and dashboards | Good balance of quality and price | Less durable than full-grain | Medium |

| Split Leather | Budget interiors and less visible areas | Cost-effective for large projects | Lacks luxury feel and durability | Низкий |

| Синтетическая кожа | Budget vehicles and easy maintenance | Affordable and easy to clean | May not match comfort of real leather | Низкий |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and considerations of various auto leather materials, facilitating informed purchasing decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for auto leather material

What Are the Main Stages in the Manufacturing Process of Auto Leather Material?

The manufacturing of auto leather is a complex process that involves several key stages, each crucial for ensuring the quality and durability of the final product. Understanding these stages can help B2B buyers make informed decisions when sourcing leather materials for automotive applications.

1. Material Preparation: Sourcing and Selection

The first step in the manufacturing process is sourcing raw hides, typically from cattle. The quality of the leather is highly dependent on the animal’s breed, diet, and living conditions. After sourcing, hides undergo a selection process where they are graded based on their quality, texture, and any defects.

Post-selection, the hides are treated to remove hair, fat, and other impurities. This process may include soaking, liming, and fleshing, which prepares the hides for tanning. Tanning is a critical step that converts raw animal hides into leather, making it durable and resistant to decay.

Illustrative image related to auto leather material

2. Tanning Process: Key Techniques

Tanning can be performed using various methods, with chrome tanning and vegetable tanning being the most common. Chrome tanning is preferred for automotive leather due to its speed and ability to produce softer, more supple leather. Conversely, vegetable tanning is more environmentally friendly but takes longer and results in stiffer leather.

In addition to tanning, dyeing techniques are employed to enhance the color and aesthetic appeal of the leather. The choice of dye can influence both the look and the performance of the leather, making it crucial for B2B buyers to understand these options.

3. Forming and Finishing: Shaping the Leather

Once tanned and dyed, the leather is cut into various shapes and sizes according to the specifications of the automotive manufacturer. This includes pieces for seats, dashboards, door panels, and other interior components. Advanced cutting techniques, such as laser cutting, are often employed to ensure precision.

Illustrative image related to auto leather material

The finishing stage involves applying coatings and treatments that enhance the leather’s appearance and durability. This may include processes like embossing for texture, coating for protection against stains and wear, and conditioning to maintain softness.

What Quality Control Measures Are Essential for Automotive Leather?

Quality assurance in the production of auto leather is vital for ensuring that the final product meets industry standards and customer expectations. B2B buyers should be aware of the various quality control measures in place throughout the manufacturing process.

Relevant International Standards for Automotive Leather

International standards such as ISO 9001 play a significant role in defining quality management systems for manufacturers. Compliance with these standards ensures that the manufacturing processes are consistent and that products meet customer and regulatory requirements. Additionally, automotive-specific certifications like the CE mark signify that the leather meets safety and environmental standards.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process to monitor and evaluate the leather’s quality. These checkpoints include:

Illustrative image related to auto leather material

- Incoming Quality Control (IQC): Evaluates the quality of raw hides upon arrival, checking for defects and ensuring they meet specified standards.

- In-Process Quality Control (IPQC): Conducted during various stages of production to detect any issues early. This includes monitoring the tanning process and dye application.

- Final Quality Control (FQC): The final inspection before shipment, focusing on the overall quality, appearance, and compliance with customer specifications.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is crucial for ensuring the reliability of leather products.

Conducting Supplier Audits

One effective method is to conduct supplier audits, which provide insights into the manufacturing processes, quality control measures, and compliance with industry standards. These audits can be performed by the buyer or a third-party inspection agency, offering an objective assessment of the supplier’s capabilities.

Reviewing Quality Control Reports

Buyers should request and review quality control reports that document the results of inspections at various checkpoints. These reports should detail any deviations from standards and the corrective actions taken. Understanding these reports can give buyers confidence in the supplier’s commitment to quality.

Illustrative image related to auto leather material

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can also be beneficial. These independent organizations can verify the quality and compliance of the leather products before shipment, providing an additional layer of assurance for buyers.

What Testing Methods Are Commonly Used for Auto Leather Quality?

To ensure the durability and performance of automotive leather, various testing methods are employed. These tests assess factors such as strength, flexibility, and resistance to wear and tear.

Common Testing Methods Include:

- Tensile Strength Tests: Measure the leather’s resistance to pulling forces, ensuring it can withstand everyday use without tearing.

- Abrasion Resistance Tests: Evaluate how well the leather can endure friction and wear, particularly important for high-traffic areas like seats.

- Colorfastness Tests: Assess the leather’s ability to retain its color when exposed to light and moisture, which is critical for maintaining aesthetic appeal over time.

Conclusion: The Importance of Quality Assurance in Auto Leather Supply Chains

In the competitive automotive industry, the quality of leather materials can significantly impact the overall perception of vehicle interiors. B2B buyers must prioritize suppliers that demonstrate robust manufacturing processes and stringent quality assurance measures. By understanding the manufacturing stages, quality control checkpoints, and testing methods, buyers can make informed decisions that ensure they receive high-quality auto leather that meets their specifications and enhances their products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto leather material’

The following practical guide provides a clear and actionable checklist for B2B buyers seeking to procure auto leather material. This guide is designed to streamline your sourcing process and ensure you make informed decisions.

Step 1: Define Your Technical Specifications

Before diving into the sourcing process, establish clear technical specifications for the leather you need. This includes determining the type (e.g., full-grain, top-grain), thickness, color, and texture. Defining these parameters helps narrow down options and ensures that the leather meets the specific requirements of your automotive applications.

Illustrative image related to auto leather material

Step 2: Research and Identify Potential Suppliers

Conduct thorough market research to identify reputable suppliers who specialize in automotive leather. Look for companies that have a strong track record in the industry and positive reviews from other buyers. Consider leveraging trade shows, industry forums, and online marketplaces to gather a list of potential candidates.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities and ensure they have experience in supplying leather for automotive applications. Pay attention to their ability to meet your volume requirements and delivery timelines.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers adhere to international quality standards and environmental regulations. Certifications such as ISO 9001 for quality management and OEKO-TEX for sustainable production practices can provide reassurance regarding the material’s quality and safety. This step is vital for maintaining compliance and ensuring that the leather is safe for use in vehicles.

Step 5: Request Samples for Quality Assessment

Before making a bulk order, request samples of the leather you are considering. This allows you to assess the material’s quality, texture, and durability firsthand. Evaluate how the leather responds to common automotive conditions, such as exposure to sunlight and spills, to ensure it meets your performance expectations.

Step 6: Compare Pricing and Terms

Once you have selected a few potential suppliers, compare their pricing structures and payment terms. Look beyond the initial cost; consider factors such as shipping fees, minimum order quantities, and lead times. Negotiating favorable terms can lead to significant cost savings and a better overall partnership.

Illustrative image related to auto leather material

Step 7: Establish a Clear Communication Channel

Effective communication is essential for a successful sourcing process. Establish a direct line of communication with your supplier for any queries or issues that may arise. Ensure that both parties have a clear understanding of expectations regarding quality, delivery schedules, and after-sales support.

By following these steps, B2B buyers can streamline their sourcing process for auto leather materials, ensuring they select high-quality products that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for auto leather material Sourcing

What Are the Key Cost Components for Sourcing Auto Leather Material?

When sourcing auto leather material, understanding the cost structure is essential for effective budgeting and procurement strategies. The primary cost components include:

-

Materials: The quality of leather significantly impacts costs. Full-grain and top-grain leathers are generally more expensive due to their durability and aesthetic appeal. Prices can range from $17 to over $300 per square meter, depending on the type and quality of the leather.

-

Labor: Labor costs vary based on the manufacturing location and the expertise required for leather processing. Regions with lower labor costs may offer competitive pricing, but it’s vital to ensure that quality is not compromised.

-

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Custom tooling for specific leather cuts or designs adds to the initial investment. This cost is often amortized over larger production runs, making it essential to consider the minimum order quantity (MOQ).

-

Quality Control (QC): Ensuring the leather meets quality standards incurs additional costs. Robust QC processes are crucial, especially when sourcing from international suppliers, to avoid defects that could lead to costly returns.

-

Logistics: Transportation costs can fluctuate based on distance, shipping method, and Incoterms. International shipping may require additional customs duties and insurance, impacting overall costs.

-

Margin: Suppliers typically add a margin to cover their risks and profits. Understanding the supplier’s margin expectations can help in negotiating better prices.

How Do Price Influencers Affect Auto Leather Material Costs?

Several factors influence the pricing of auto leather materials, and understanding these can aid in better negotiations:

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally attract lower per-unit prices. Buyers should assess their needs carefully to optimize order sizes.

-

Specifications and Customization: Custom specifications, such as specific colors or finishes, can increase costs. Standardized options may be more cost-effective.

-

Material Quality and Certifications: High-quality leather often comes with certifications (e.g., environmental compliance, durability tests) that may add to the cost but can enhance the product’s value.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more, but they often provide better quality assurance and service.

-

Incoterms: Understanding Incoterms is crucial for determining who bears the costs and risks during shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect total costs.

What Are Essential Tips for Negotiating Auto Leather Material Prices?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, there are several tips to consider for effective negotiation:

Illustrative image related to auto leather material

-

Conduct Market Research: Familiarize yourself with prevailing market prices and trends to ensure that your expectations align with industry standards.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial price. Consider maintenance, durability, and potential resale value of the leather to understand its long-term value.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and terms. Suppliers may be more willing to offer discounts to repeat buyers.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs that unlock volume discounts. This strategy can significantly reduce costs.

-

Negotiate Payment Terms: Flexible payment terms can enhance cash flow, allowing you to manage your finances better while purchasing high-quality materials.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It’s important to note that the prices mentioned are indicative and can fluctuate based on market conditions, currency exchange rates, and supplier pricing strategies. Buyers should seek formal quotes from suppliers and consider obtaining samples to assess quality before committing to large orders. This approach ensures that the selected leather meets both aesthetic and functional requirements, ultimately contributing to the success of automotive projects.

Alternatives Analysis: Comparing auto leather material With Other Solutions

When considering automotive interiors, the choice of materials is crucial. While auto leather material is a popular option due to its luxurious appeal and durability, several alternatives offer distinct advantages depending on specific needs and applications. This analysis will compare auto leather material with two viable alternatives: synthetic leather and high-quality fabric upholstery, enabling B2B buyers to make informed decisions.

| Comparison Aspect | Auto Leather Material | Синтетическая кожа | High-Quality Fabric Upholstery |

|---|---|---|---|

| Performance | High durability, resistant to wear and tear | Good durability, but may wear faster than leather | Varies by fabric; can be less durable but offers comfort |

| Cost | Higher initial investment | Generally more affordable | Cost-effective, with a wide price range |

| Ease of Implementation | Requires specialized skills for installation | Easier to work with, often DIY-friendly | Typically straightforward to install, depending on the fabric |

| Maintenance | Easy to clean, requires occasional conditioning | Easy to clean, less maintenance than leather | Varies; some fabrics may stain easily, requiring more upkeep |

| Best Use Case | Luxury vehicles, high-end applications | Budget-friendly vehicles, eco-conscious brands | Family cars, everyday use vehicles |

What are the Pros and Cons of Synthetic Leather as an Alternative?

Synthetic leather, also known as faux leather or vegan leather, is designed to mimic the look and feel of genuine leather. One of its main advantages is cost-effectiveness, making it accessible for manufacturers focused on budget-friendly options. Additionally, synthetic leather is easier to maintain than natural leather; it can be wiped clean without the need for conditioning. However, its durability can be a concern, as it may not withstand the same level of wear and tear over time, particularly in high-traffic areas of a vehicle.

How Does High-Quality Fabric Upholstery Compare?

High-quality fabric upholstery offers a versatile and often more affordable alternative to leather. Fabrics can provide exceptional comfort and breathability, making them ideal for family vehicles or everyday use. They also come in a wide array of colors and patterns, allowing for greater customization. However, fabric upholstery may require more maintenance, as certain materials can stain easily and may not be as durable as leather or synthetic options. In high-wear environments, fabrics may show signs of wear more quickly than leather counterparts.

Illustrative image related to auto leather material

How Can B2B Buyers Choose the Right Solution?

Selecting the appropriate material for automotive interiors depends on various factors, including budget, vehicle type, and intended use. For luxury applications where aesthetics and durability are paramount, auto leather material remains a top choice. Conversely, for those looking to reduce costs while still maintaining a stylish appearance, synthetic leather can be an excellent option. High-quality fabric upholstery is ideal for family-oriented vehicles where comfort and ease of cleaning are prioritized. Ultimately, B2B buyers should evaluate their specific requirements and balance cost, performance, and maintenance when making their decision.

Essential Technical Properties and Trade Terminology for auto leather material

What Are the Key Technical Properties of Auto Leather Material?

When selecting auto leather for upholstery and interiors, understanding its technical properties is crucial. Here are several critical specifications that B2B buyers should consider:

-

Material Grade

The grade of leather is a key indicator of quality and durability. Full-grain leather, for instance, is the highest quality, retaining the natural grain and character of the hide, making it more durable and resistant to wear. In contrast, split leather is lower in quality and often less durable. Selecting the right grade affects not just the aesthetic appeal but also the longevity of the upholstery. -

Thickness

Leather thickness is typically measured in ounces or millimeters. A thicker leather (around 1.2-1.4 mm) is generally more durable and suitable for high-traffic areas like car seats. Conversely, thinner leather may be used for less demanding applications such as door panels. Understanding thickness helps buyers choose the right type of leather for specific applications in automotive interiors. -

Tensile Strength

This property measures the leather’s resistance to being pulled apart. High tensile strength indicates that the leather can withstand significant stress, making it ideal for areas that experience frequent use, such as seats and steering wheels. Evaluating tensile strength is essential for ensuring that the material will perform well over time. -

Flexural Strength

Flexural strength refers to the leather’s ability to resist bending and flexing without cracking. This is particularly important for automotive applications where the leather will be subjected to constant movement and stress. High flexural strength ensures that the leather maintains its appearance and functionality over time. -

Abrasion Resistance

This property measures how well the leather can withstand wear from friction. Leather with high abrasion resistance is essential for areas that experience a lot of contact, such as seat cushions and armrests. Buyers should prioritize this property to ensure that the upholstery remains visually appealing and functional over the vehicle’s lifespan.

Which Trade Terms Should B2B Buyers Understand When Purchasing Auto Leather?

Familiarity with industry jargon can streamline the purchasing process and enhance communication between buyers and suppliers. Here are some common trade terms relevant to auto leather:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products to be sold under another company’s brand. In the context of auto leather, it often pertains to manufacturers supplying leather for new vehicles. Understanding OEM relationships is vital for buyers looking to source materials that meet specific automotive standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it affects procurement strategies and inventory management. Knowing the MOQ helps businesses plan their purchases effectively and avoid excess stock. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to invite suppliers to submit price proposals for specific products. In the auto leather industry, issuing an RFQ can help buyers compare costs and terms from multiple suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with these terms is essential for understanding shipping responsibilities, risk transfer, and cost allocation, especially in international transactions. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. In the automotive leather industry, understanding lead times is critical for project planning and ensuring that production schedules are met. Buyers should always inquire about lead times to avoid delays in their operations. -

Full Hide vs. Half Hide

These terms refer to the size of leather pieces available for purchase. A full hide is a complete animal skin, while a half hide is half of that. Understanding these distinctions helps buyers determine how much material they need for their specific applications, optimizing costs and minimizing waste.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring they select the right auto leather materials for their needs.

Navigating Market Dynamics and Sourcing Trends in the auto leather material Sector

Market Overview & Key Trends in the Auto Leather Material Sector

The global auto leather material market is witnessing significant growth, driven by several key factors. The increasing demand for luxury vehicles, particularly in emerging markets such as Africa and South America, is propelling the adoption of high-quality leather upholstery. Additionally, the automotive sector is increasingly integrating advanced technologies, such as 3D printing and automated cutting, into leather production and application processes. These innovations not only enhance efficiency but also allow for greater customization, appealing to B2B buyers looking to differentiate their offerings in competitive markets.

Moreover, sustainability is becoming a pivotal consideration. As consumers worldwide become more environmentally conscious, international B2B buyers are increasingly prioritizing suppliers who can demonstrate sustainable practices. This includes sourcing leather from tanneries that utilize eco-friendly processes and materials. In Europe, especially Germany, stringent regulations are influencing sourcing decisions, pushing manufacturers toward compliant and ethical suppliers. Emerging markets are also beginning to adopt similar standards, motivated by both consumer demand and international trade requirements.

Another notable trend is the growing prevalence of synthetic leather alternatives. While genuine leather maintains its appeal for luxury applications, synthetic options are gaining traction due to their lower cost and versatility. This shift presents both challenges and opportunities for B2B buyers. Sourcing decisions may need to balance the authenticity and prestige of genuine leather against the practicality and cost-effectiveness of synthetic alternatives, depending on the target market.

How is Sustainability & Ethical Sourcing Influencing Auto Leather Material Procurement?

Sustainability and ethical sourcing are critical themes reshaping the auto leather material sector. The environmental impact of traditional leather production, which often involves harmful chemicals and extensive water use, has prompted a shift toward more responsible practices. B2B buyers are increasingly seeking suppliers that prioritize sustainable sourcing, including the use of vegetable-tanned leather and low-impact dyeing processes. These practices not only mitigate environmental harm but also enhance brand reputation in an increasingly eco-conscious marketplace.

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers are now more vigilant about the origins of their materials, demanding transparency from suppliers regarding labor practices and sourcing methods. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming essential criteria for supplier selection. These certifications provide assurance that materials are sourced responsibly, aligning with the ethical values of end consumers.

Investing in sustainably sourced auto leather materials is not just a regulatory compliance issue; it is also a competitive advantage. Brands that adopt ethical sourcing practices can leverage this commitment in their marketing strategies, appealing to a growing segment of consumers who prioritize sustainability in their purchasing decisions.

Brief Evolution of the Auto Leather Material Sector

The auto leather material sector has evolved significantly over the past few decades. Initially, leather was primarily sourced from livestock, with an emphasis on durability and comfort for consumers. As automotive design advanced, so did the demand for varied textures, colors, and finishes, leading to innovations in tanning and processing techniques.

Illustrative image related to auto leather material

The late 20th century saw the introduction of synthetic leathers, which provided cost-effective alternatives and greater design flexibility. In recent years, the focus has shifted toward sustainability, prompting manufacturers to adopt eco-friendly practices and certifications. This evolution reflects broader consumer trends towards quality, customization, and environmental responsibility, shaping the landscape of auto leather materials today.

In conclusion, B2B buyers in the auto leather material sector must navigate a complex interplay of market dynamics, sustainability considerations, and evolving consumer preferences to make informed sourcing decisions. Understanding these trends will be essential for establishing competitive advantages in a rapidly changing marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of auto leather material

-

How do I select the right type of auto leather material for my needs?

Selecting the right auto leather involves understanding the specific requirements of your application. Consider the type of leather—full-grain and top-grain options are recommended for their durability and aesthetic appeal. Evaluate the color and texture to ensure they complement your vehicle’s design. Additionally, assess the leather’s maintenance requirements and compatibility with your car’s make and model. Consulting with suppliers about their offerings can provide further insights tailored to your needs. -

What are the key benefits of using leather in automotive applications?

Automotive leather offers numerous advantages, including enhanced comfort, durability, and aesthetic appeal. It is resistant to spills and abrasions, making it suitable for high-traffic areas within vehicles. The luxurious look of leather elevates the overall interior design, while its ease of maintenance ensures long-lasting beauty. Investing in quality leather can significantly enhance the driving experience for customers seeking luxury and comfort. -

What is the typical minimum order quantity (MOQ) for auto leather materials?

Minimum order quantities for auto leather can vary by supplier and material type. Generally, many suppliers set a MOQ of half a hide, roughly 25 square feet, or equivalent in square meters. It is crucial to check with individual suppliers to understand their specific MOQs, as this can impact your sourcing strategy. Larger orders may also yield better pricing, so consider your inventory needs when negotiating with suppliers. -

How can I ensure the quality of auto leather before purchasing?

To ensure leather quality, request samples from potential suppliers to evaluate the texture, appearance, and durability. Look for certifications that guarantee the leather meets industry standards, such as ISO certifications. Additionally, inquire about the supplier’s quality assurance processes, including testing for wear resistance and colorfastness. Establishing a relationship with reputable suppliers who are transparent about their sourcing and production methods can also help ensure quality. -

What payment terms should I expect when sourcing auto leather internationally?

Payment terms can vary widely depending on the supplier’s policies and the nature of the transaction. Common terms include a deposit upfront, with the balance due upon delivery or before shipping. Some suppliers may offer letters of credit or payment through escrow services for added security. Always clarify payment methods, timelines, and any potential currency exchange implications to avoid misunderstandings during the transaction. -

What should I consider regarding logistics when importing auto leather?

When importing auto leather, consider shipping methods, lead times, and customs regulations in your destination country. Air freight is faster but more expensive, while sea freight is more economical for larger shipments. Ensure that all necessary documentation, such as invoices, packing lists, and certificates of origin, are prepared to facilitate smooth customs clearance. Partnering with a reliable freight forwarder can help navigate these complexities and ensure timely delivery. -

How do I vet suppliers of auto leather materials effectively?

Vetting suppliers involves several steps: first, check their industry reputation by looking for reviews or testimonials from other B2B buyers. Assess their production capabilities and quality control measures by requesting information on their processes. It’s also beneficial to visit their facilities if possible or conduct virtual tours. Lastly, ensure they comply with relevant regulations, including environmental standards, which can impact your brand’s sustainability goals. -

Can I customize the leather materials I purchase for my automotive applications?

Yes, many suppliers offer customization options for auto leather, including color, texture, and finish. Discuss your specific requirements with suppliers to explore available customization services. Be prepared to provide detailed specifications and possibly pay additional costs for bespoke orders. Customizing leather can enhance the uniqueness of your automotive offerings and cater to specific market demands, making it a worthwhile investment.

Top 2 Auto Leather Material Manufacturers & Suppliers List

1. Leather Hide Store – Auto Upholstery Essentials

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Введение: Auto Upholstery Leather for Cars & Trucks, quality leathers that meet or exceed color fastness standards (UV resistance) for aftermarket auto use. Key product lines include: Essentials Line (durable, soft, and supple), Market Street (smoother leather with a buttery feel and rich color), Urban (heavier weight with lots of grain), Dakota (high performance distressed leathers). Special note: aftermar…

2. Buy Leather Online – Premium Automotive Leather

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Введение: Leather for Car Seats and Automotive: Premium automotive leather designed for car interiors, including seats, dashboards, and door panels. Features include durability, aesthetic appeal, and ease of maintenance. Types of leather available include full-grain and top-grain. Key benefits: enhanced comfort, durability against spills and stains, sophisticated look, and simple maintenance. Available prod…

Strategic Sourcing Conclusion and Outlook for auto leather material

The global automotive leather market presents significant opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As the demand for high-quality materials rises, strategic sourcing becomes paramount. Buyers should prioritize suppliers who offer premium-grade leather, ensuring durability and aesthetic appeal that meets the rigorous standards of automotive applications.

Illustrative image related to auto leather material

Understanding the nuances of leather types—such as full-grain and top-grain—can enhance the decision-making process, allowing buyers to select materials that not only elevate vehicle interiors but also withstand daily wear and tear. Additionally, the ability to customize colors and textures enables businesses to cater to diverse customer preferences, enhancing their competitive edge.

As we look to the future, the automotive industry is poised for innovation, with sustainable sourcing practices gaining traction. Buyers are encouraged to explore partnerships that align with eco-friendly initiatives, ensuring long-term sustainability and market relevance. By embracing these strategies, B2B buyers can position themselves at the forefront of the automotive leather market, driving growth and profitability in a dynamic landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.