Catalog

Material Insight: Synthetic Leather Upholstery Fabric

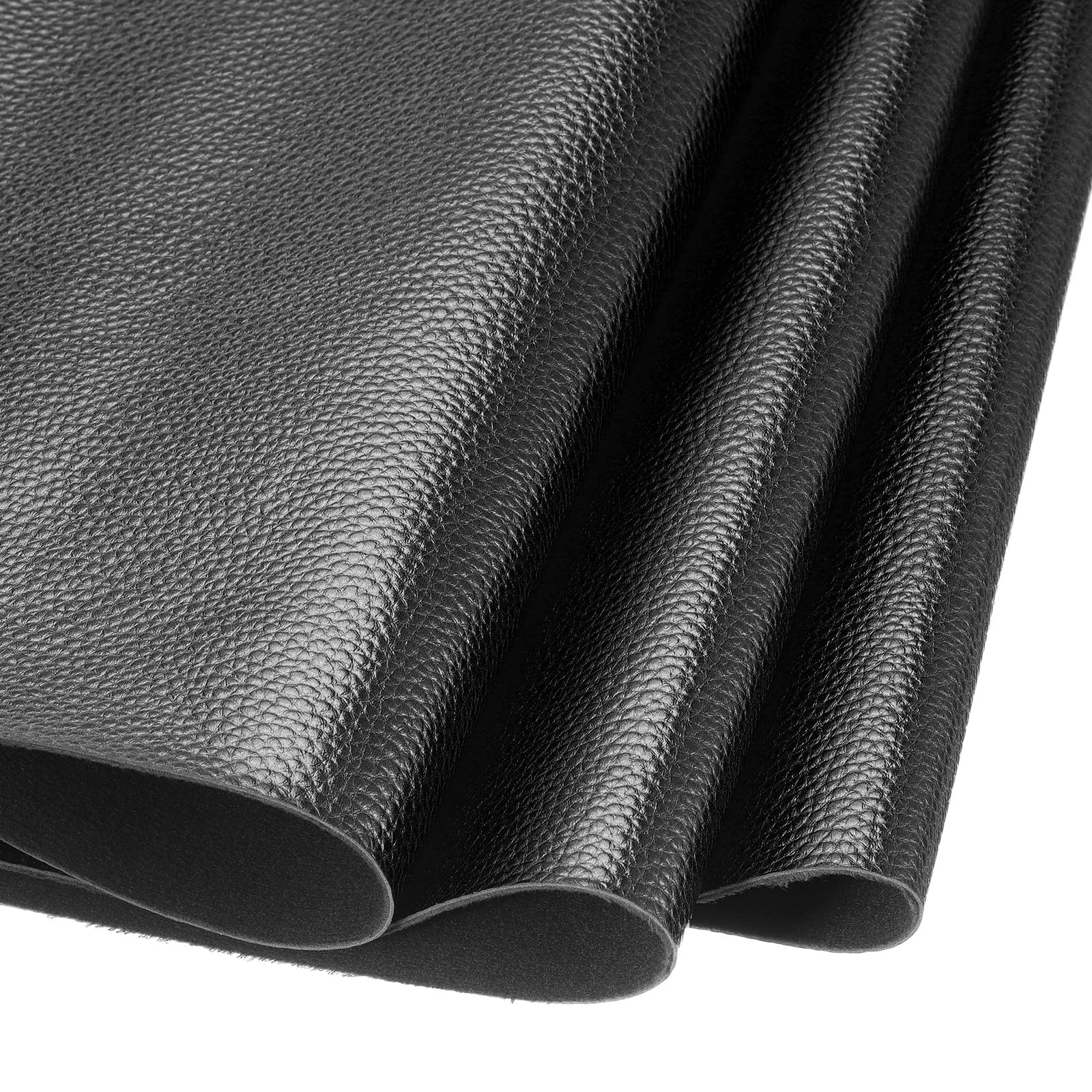

Synthetic Leather Upholstery Fabric: The Modern Standard for Performance Interiors

Synthetic leather upholstery fabric represents a sophisticated fusion of advanced material science and design versatility, engineered specifically for demanding interior applications. Unlike traditional textiles or natural leather, this category delivers consistent performance across furniture, transportation seating, healthcare environments, and hospitality settings. Its engineered structure provides exceptional resistance to abrasion, staining, and microbial growth while maintaining aesthetic refinement—addressing critical commercial requirements where durability, hygiene, and long-term value intersect.

Why Synthetic Leather Upholstery Fabric Is the Optimal Choice

- Unmatched Durability & Longevity: Withstands high-traffic use without cracking, fading, or peeling, reducing replacement frequency and lifecycle costs.

- Total Design Flexibility: Available in infinite colorways, textures (suede, pebbled, smooth), and thicknesses to align with brand identity and functional needs.

- Eco-Performance Integration: Formulated with recycled content, water-based PU/PVC alternatives, and OEKO-TEX® certified processes to meet stringent sustainability mandates.

- Low Maintenance & Hygiene Compliance: Non-porous surface resists liquid penetration, simplifies cleaning, and inhibits bacterial growth—critical for healthcare and public spaces.

- Cost Predictability: Eliminates natural leather’s supply volatility and grading inconsistencies, ensuring budget stability for large-scale projects.

WINIW: Engineering the Future of Upholstery Solutions

For over 20 years, WINIW has pioneered synthetic leather innovation for global B2B markets. Our R&D-driven approach combines deep material science expertise with a commitment to circular economy principles. We partner with furniture manufacturers, automotive OEMs, and contract specifiers to transform performance challenges into competitive advantages—through rigorously tested, eco-conscious materials that never compromise on aesthetics or ethics. As your trusted technical partner, we deliver not just fabric, but scalable solutions engineered for tomorrow’s sustainability standards.

Technical Performance & Standards

WINIW Synthetic Leather Upholstery Fabric – B2B Product Technical Guide

WINIW’s synthetic leather upholstery fabric is engineered for commercial and industrial applications requiring high performance, durability, and regulatory compliance. Designed with advanced polyurethane (PU) technology, our material delivers a premium aesthetic and tactile experience while meeting stringent global standards for safety, sustainability, and quality management.

Key Technical Advantages

-

Fire Retardant Performance (UK & US Standards Compliant)

WINIW’s synthetic leather meets critical fire safety regulations required in public and commercial spaces. It complies with UK Fire Safety Regulations (BS 5852:2006, Crib 5) for furniture used in contract environments and passes US standards including CAL 117 and NFPA 260 for flame resistance. This ensures suitability for use in hospitality, healthcare, transportation, and office sectors. -

Легко чистить и обслуживать

The tightly bonded surface structure resists stains, moisture, and microbial growth. Routine cleaning requires only mild soap and water, reducing maintenance costs and downtime. The material is also resistant to common disinfectants, making it ideal for high-traffic and hygiene-sensitive environments. -

Soft Touch and Premium Hand Feel

WINIW utilizes micro-foamed PU layers and advanced embossing techniques to replicate the suppleness and tactile comfort of premium genuine leather. The result is a consistently soft, luxurious surface with excellent drape and flexibility—ideal for seating, wall panels, and interior trims. -

REACH Compliant – Safe for People and Environment

Our synthetic leather is fully compliant with the EU REACH regulation (EC 1907/2006), ensuring the absence of SVHCs (Substances of Very High Concern) and restricted hazardous substances. This commitment supports sustainable manufacturing and end-user safety across global markets. -

ISO9001-Certified Manufacturing Process

WINIW operates under an ISO9001-certified quality management system, guaranteeing consistent product performance, traceability, and process control. Every batch undergoes rigorous in-line and final inspection to maintain dimensional accuracy, bond strength, and visual quality.

Technical Specifications

| Property | Технические характеристики |

|---|---|

| Base Material | High-tenacity polyester knit fabric |

| Coating | Micro-foamed polyurethane (PU) |

| Thickness | 0.8 mm – 1.2 mm (customizable) |

| Weight | 380 – 450 g/m² |

| Tensile Strength (warp/weft) | ≥ 90 N/5cm / ≥ 80 N/5cm |

| Tear Strength | ≥ 9 N (Elmendorf) |

| Color Fastness to Rubbing | Dry: ≥ 4, Wet: ≥ 3 (ISO 105-X12) |

| Light Fastness | ≥ 4 (ISO 105-B02, 20-hour exposure) |

| Fire Resistance | BS 5852 Crib 5, CAL 117, NFPA 260 |

| REACH Compliance | Fully compliant (SVHC-free) |

| Antibacterial Treatment | Optional (ISO 22196, >99% inhibition) |

| Cold Crack Resistance | Passes -20°C (ISO 14363) |

| VOC Emissions | Low emission, suitable for indoor environments |

WINIW’s synthetic leather upholstery fabric combines performance-driven engineering with environmental responsibility, making it a trusted choice for B2B clients in furniture, transportation, healthcare, and architectural interiors. With scalable production and global compliance, WINIW supports sustainable innovation without compromising on quality or safety.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather Upholstery Fabric vs. Real Leather

For commercial furniture, automotive interiors, and high-traffic hospitality applications, material selection critically impacts performance, sustainability, and total cost of ownership. WINIW provides premium synthetic leather solutions engineered specifically for demanding B2B environments. Below is an objective comparison to inform strategic procurement decisions.

Key Differentiators for Commercial Applications:

- Supply Chain Consistency: Synthetic leather offers uniform color, texture, and performance batch-to-batch, eliminating the natural variations inherent in real leather hides. This ensures predictable manufacturing yields and seamless large-scale project execution.

- Design Flexibility & Customization: Achieve precise color matching, extensive texture options (including non-animal仿 patterns), and tailored performance properties (e.g., enhanced stain resistance, specific tensile strength) impossible with natural hides. Accelerate time-to-market for bespoke projects.

- Hygiene & Maintenance: Non-porous synthetic surfaces resist liquid penetration, inhibit microbial growth, and clean effortlessly with standard commercial disinfectants – a critical advantage for healthcare, transportation, and food service sectors. Real leather requires specific pH-balanced cleaners and conditioning to prevent drying/cracking.

- Resource Efficiency: Modern synthetic leather production, particularly water-based PU systems like WINIW’s, utilizes significantly less land and water per square meter compared to livestock farming and tanning. Traceable, consistent input materials streamline sustainable sourcing.

- Total Lifecycle Cost: While initial material cost is a factor, consider long-term expenses: synthetic leather typically requires less frequent replacement in high-use settings and incurs lower maintenance costs compared to real leather, which is susceptible to scratches, stains, and requires ongoing conditioning.

Comparative Analysis: Core Performance Metrics

| Factor | Synthetic Leather Upholstery Fabric (e.g., WINIW Premium PU) | Real Leather (Full-Grain/Top-Grain) |

|---|---|---|

| Cost (Initial) | Generally 20-40% lower material cost per square meter. Higher consistency reduces waste during cutting/sewing. | Higher initial material cost due to hide scarcity, grading, and tanning complexity. Natural flaws increase waste. |

| Durability (Commercial Use) | Engineered for high abrasion resistance (typically 50,000+ double rubs ASTM D4060). Highly resistant to scratches, stains, fading (UV-stabilized), and consistent performance across the entire hide. Non-porous surface prevents fluid ingress. | Varies significantly by grade and tannage. Aniline leathers show wear/stains easily (15,000-25,000 double rubs common). Susceptible to scratches, water rings, and requires conditioning to prevent drying/cracking. Natural grain variations create weak points. |

| Eco-Friendliness | WINIW utilizes water-based PU systems, eliminating DMF and minimizing VOCs. Production avoids deforestation, methane emissions, and toxic tannery effluent (e.g., chromium III/VI). Recyclable content options available. Significantly lower water footprint and land use. Traceable, controlled manufacturing. | Tanning (especially chrome) generates hazardous wastewater. Livestock farming contributes significantly to deforestation, methane emissions, and high water consumption. Biodegradability is slow and often negated by tanning chemicals. Limited traceability in complex hide supply chains. |

WINIW Recommendation for B2B Procurement:

Prioritize synthetic leather upholstery fabric for projects demanding predictable performance, stringent hygiene, design versatility, and demonstrable environmental responsibility. WINIW’s advanced formulations deliver the aesthetic appeal and tactile quality clients expect, while exceeding real leather in critical commercial durability metrics and offering a significantly lower, verifiable environmental impact throughout the product lifecycle. This translates to reduced operational costs, enhanced brand sustainability credentials, and superior long-term value for contract furniture, transportation, and hospitality partners. Request WINIW’s detailed technical datasheets and EPD (Environmental Product Declaration) for specific product validation.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with innovative, sustainable, and durable material solutions. Our manufacturing capabilities and operational excellence are built on a strong foundation of scale, expertise, and quality control.

Our state-of-the-art production facility spans over 100,000 square meters, making it one of the largest synthetic leather manufacturing bases in Asia. This extensive infrastructure enables us to maintain high production capacity while ensuring flexibility for customized orders and large-volume deliveries.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, eco-friendly formulations, and application-specific development.

- Continuous investment in research to advance polyurethane (PU) and polyvinyl chloride (PVC) technologies, including water-based and solvent-free systems that meet global environmental standards.

- In-house development of specialty finishes, textures, and functional properties such as abrasion resistance, UV protection, and antimicrobial treatment.

Quality is at the core of our manufacturing process. WINIW enforces strict quality control protocols across every production stage:

- Raw material inspection and traceability systems.

- Real-time monitoring during coating, calendaring, and finishing processes.

- Final product testing for physical properties, color fastness, and compliance with international standards (REACH, RoHS, CA Prop 65, etc.).

Our products are trusted by clients across Europe and the United States, where demand for sustainable and high-performance materials is rapidly growing. WINIW maintains long-term partnerships with automotive, furniture, apparel, and footwear brands by consistently delivering:

- Reliable supply chain performance.

- Environmentally responsible production practices.

- Customization supported by technical expertise.

Through our manufacturing scale, innovation-driven R&D, and uncompromising QC standards, WINIW is positioned as a strategic partner for global businesses seeking premium synthetic leather solutions.

Contact Us for Samples

WINIW Premium Synthetic Leather Upholstery Fabric: B2B Performance & Sustainability Guide

WINIW delivers engineered synthetic leather solutions designed for demanding commercial upholstery applications. Our microfiber-based fabrics combine uncompromising durability with verified eco-credentials, meeting the rigorous performance and sustainability expectations of forward-thinking manufacturers. Partner with us to elevate product longevity, reduce environmental impact, and access scalable innovation.

Core Performance & Sustainability Advantages

- Eco-Conscious Composition: Base materials utilize 30-60% certified recycled PET content; coatings are 100% water-based (zero DMF, heavy metals, or PVC).

- Commercial-Grade Durability: Exceeds 50,000+ double rubs (Martindale), with superior tear strength (>45N) and colorfastness (≥4-5 on Blue Wool Scale).

- Low Environmental Footprint: OEKO-TEX® STANDARD 100 Class I and Global Recycled Standard (GRS) certified; production reduces water usage by 90% vs. traditional leather.

- Design Flexibility: Customizable textures (suede, pebble, smooth), colors (Pantone® matched), and performance additives (anti-microbial, flame retardant).

- End-of-Life Responsibility: Fully recyclable through WINIW’s closed-loop take-back program (TERA Cycle® partnership).

Ideal Applications Across Industries

- Contract Furniture: Office seating, lounge systems, and conference tables requiring 24/7 resilience.

- Hospitality Interiors: Hotel headboards, banquettes, and reception furniture demanding stain resistance and easy cleaning.

- Transportation: Automotive seating (EVs & conventional), aircraft interiors, and marine upholstery.

- Healthcare & Senior Living: Antimicrobial surfaces meeting ISO 22196 standards for high-touch environments.

Technical Specifications Overview

| Product Line | Base Material | Weight (g/m²) | Width (cm) | Abrasion Resistance | Key Eco-Certifications |

|---|---|---|---|---|---|

| EcoLuxe™ Series | 70% Recycled PET | 480-520 | 137 | 65,000+ rubs | GRS, OEKO-TEX®, ISO 14001 |

| PrimeTec® Pro | 45% Recycled PET | 550-600 | 137 | 80,000+ rubs | OEKO-TEX®, UL ECV® |

| AquaShield™ | 100% Virgin Microfiber | 500-540 | 137 | 55,000+ rubs | OEKO-TEX®, GREENGUARD Gold |

Why Global Manufacturers Choose WINIW

- R&D-Driven Innovation: Proprietary microfiber matrix technology developed in ISO 17025-accredited labs for consistent performance.

- Scalable Supply Chain: 12 global production hubs ensure 99.5% on-time delivery for volumes from 5,000 to 500,000+ meters monthly.

- Technical Partnership: Dedicated engineering support for substrate integration, compliance testing (CA 117, BS 5852), and rapid prototyping.

- Total Cost Transparency: Reduced waste (±15% vs. leather), lower maintenance costs, and extended product lifecycle ROI.

Elevate your upholstery solutions with WINIW’s sustainable performance fabrics—engineered for the circular economy without sacrificing luxury or resilience.

Request Technical Dossiers & Free Physical Samples

Contact our B2B Solutions Team: MKT88@MicrofiberLeather.com

Specify target application, volume requirements, and preferred certification standards for priority processing.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.