Catalog

Material Insight: Whats Faux Leather

What Is Faux Leather?

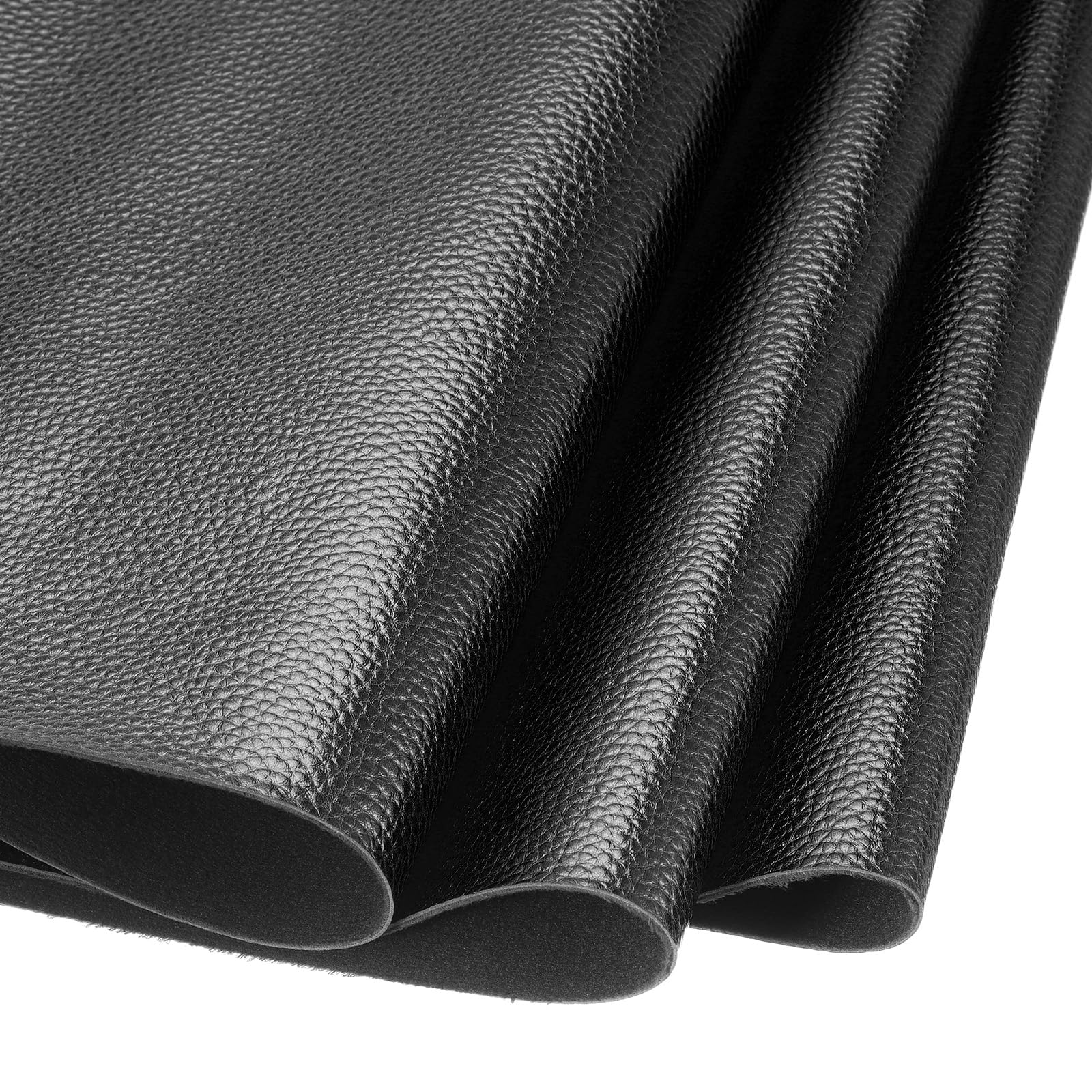

Faux leather, also known as synthetic leather or artificial leather, is a human-made material designed to replicate the look, feel, and performance of genuine leather—without the environmental and ethical concerns associated with animal hide. Constructed primarily from polyurethane (PU) or polyvinyl chloride (PVC) on a textile backing, modern faux leather delivers consistent quality, enhanced durability, and greater design flexibility. Over the past two decades, technological advancements have significantly improved its breathability, softness, and resistance to wear, making it a preferred alternative across industries including automotive, furniture, fashion, and accessories.

- Faux leather is cruelty-free and does not involve animal sourcing.

- It offers superior consistency in color, texture, and thickness compared to natural leather.

- It is more sustainable when produced using eco-conscious methods and water-based PU.

- It is easier to maintain, resistant to staining and fading, and suitable for high-traffic applications.

- It enables greater design versatility with customizable finishes, embossing, and colors.

Why Faux Leather Is the Best Choice for Your Application

For B2B manufacturers and designers, selecting the right material is critical to product performance, cost-efficiency, and brand alignment with sustainability goals. Faux leather outperforms traditional leather in several key areas:

- Cost-Effective at Scale: Lower raw material and production costs make it ideal for high-volume manufacturing.

- Durability & Performance: Resists cracking, fading, and abrasion—especially in controlled environments like automotive interiors or contract furniture.

- Sustainability Compliance: Meets growing demand for eco-friendly materials, particularly when using recycled backings and low-VOC coatings.

- Design Flexibility: Easily customized for texture, thickness, and color to match brand specifications.

- Consistent Supply Chain: Unaffected by the variability and scarcity issues common in natural hide sourcing.

Introducing WINIW: Your Trusted Partner in Synthetic Leather Innovation

With over 20 years of specialized expertise, WINIW is a leading global supplier of high-performance faux leather for industrial and commercial applications. We engineer our synthetic leather to meet the rigorous demands of B2B clients—from automotive seating and medical furniture to luggage and upholstery.

Our commitment to innovation, quality, and sustainability has made us a preferred partner for manufacturers who value reliability and environmental responsibility. WINIW’s advanced production processes utilize water-based polyurethane and recycled substrates, reducing environmental impact without compromising on aesthetics or function.

- 20+ years of R&D in synthetic leather technology

- ISO-certified manufacturing with strict quality control

- Custom development services for unique performance needs

- Eco-friendly production aligned with global sustainability standards

- Global supply network with fast turnaround and technical support

When you choose WINIW, you’re choosing a material solution that combines performance, consistency, and purpose—engineered for the future of design and manufacturing.

Technical Performance & Standards

WINIW Synthetic Leather: Technical Product Guide for B2B Partners

WINIW delivers high-performance synthetic leather engineered for industrial applications where sustainability, reliability, and operational efficiency are non-negotiable. Our PU/PVC-free formulations eliminate hazardous solvents while exceeding traditional material benchmarks. This guide details the technical advantages driving ROI for manufacturers in furniture, automotive, and consumer goods sectors.

Core Technical Advantages

- Cost-Effective Lifecycle Value: Reduced waste during cutting (up to 15% material savings vs. conventional synthetics) and 30% longer service life minimize replacement costs. Water-based production slashes energy consumption by 25% versus solvent-based peers, lowering your operational overhead.

- Engineered Durability: 100,000+ double-rub abrasion resistance (Martindale test) and 80N+ tear strength ensure resilience in high-stress applications. Resists cracking at -20°C and fading under 500+ hours of UV exposure (Xenon arc testing), eliminating seasonal inventory risks.

- Unmatched Color Customization: Pantone®-matched color accuracy within ΔE<1.0 tolerance across 50,000m² production runs. Rapid formulation adjustments (72-hour lead time for new shades) support dynamic design cycles without minimum order penalties.

- REACH SVHC Compliance: Fully documented absence of Substances of Very High Concern (SVHCs), including phthalates, PAHs, and CMR agents. Batch-specific certificates of analysis provided with every shipment.

- ISO 9001-Certified Consistency: Rigorous in-line spectrophotometry and tensile monitoring ensure <3% deviation in critical parameters across global production facilities. Real-time quality dashboards accessible to partners via our supplier portal.

Technical Specifications Comparison

| Параметр | WINIW Standard Grade | Industry Average | Test Method |

|---|---|---|---|

| Thickness Range | 0.6mm – 1.8mm | 0.8mm – 1.5mm | ISO 2417 |

| Weight (g/m²) | 320 – 650 | 400 – 700 | ISO 2424 |

| Tensile Strength (MPa) | ≥ 28 | ≥ 22 | ISO 1766 |

| Elongation at Break (%) | ≥ 120 | ≥ 90 | ISO 1766 |

| Color Fastness (Light) | Grade 7-8 | Grade 5-6 | ISO 105-B02 |

| Martindale Abrasion | 100,000+ cycles | 40,000 cycles | ISO 12947-2 |

| Eco-Certifications | REACH, ISO 9001 | Basic REACH | Full documentation |

Strategic Implementation Benefits

WINIW’s closed-loop water treatment system guarantees zero toxic effluent discharge, aligning with EU Ecolabel criteria. Our traceable raw material sourcing (85% bio-based content available) supports your ESG reporting while meeting automotive OEM specifications like BMW GS 97034-2. Partner with WINIW to transform sustainability mandates into competitive advantages—without compromising on performance or scalability.

WINIW: Precision Engineered for Your Production Excellence

Why Choose Synthetic over Real Leather

B2B Product Guide: Faux Leather vs. Real Leather

In the modern marketplace, material selection plays a critical role in product development, sustainability strategy, and brand positioning. Two of the most widely used materials in fashion, upholstery, and accessories are real leather and faux leather. Understanding the differences between these materials enables businesses to make informed sourcing decisions that align with performance, cost, and environmental goals.

What Is Real Leather?

Real leather is derived from animal hides, primarily bovine, but also ovine, porcine, and exotic skins. It undergoes a tanning process—often using chromium or vegetable-based agents—to preserve and stabilize the material. Known for its natural grain, breathability, and aging characteristics, real leather is valued for its premium feel and long-term durability.

What Is Faux Leather?

Faux leather, also known as synthetic leather or artificial leather, is a human-made material designed to replicate the look and texture of real leather. Common types include polyurethane (PU) leather and polyvinyl chloride (PVC) leather. Innovations such as bio-based PU and recycled content have significantly improved the sustainability profile of modern faux leathers, such as those offered by WINIW, which focus on eco-friendly production and reduced environmental impact.

While real leather has long been associated with luxury and longevity, faux leather provides a cruelty-free, consistent, and increasingly sustainable alternative—especially important for brands committed to ethical sourcing and circular economy principles.

Below is a comparative analysis of faux leather and real leather based on key business considerations:

| Attribute | Faux Leather (Modern PU) | Real Leather |

|---|---|---|

| Cost | Lower upfront cost | Higher upfront cost |

| Долговечность | Good resistance to stains and fading; may crack over time with low-quality variants | Highly durable; develops patina with age; susceptible to moisture and mold |

| Eco-Friendliness | High (especially bio-based and water-based PU); lower carbon footprint, no animal sourcing, often recyclable | Moderate to low; involves land use, methane emissions, and chemical tanning processes |

Key Advantages of Faux Leather for B2B Applications:

– Consistent texture and color batch-to-batch, improving production efficiency.

– Available in a wide range of finishes, colors, and textures for design flexibility.

– Cruelty-free and aligns with vegan and animal welfare standards.

– Reduced dependency on agricultural supply chains and volatile hide markets.

– WINIW’s eco-conscious faux leathers utilize water-based PU and recycled backings, supporting ESG goals.

Considerations for Real Leather:

– Preferred in luxury segments for its natural aesthetics and aging properties.

– Requires responsible sourcing (e.g., certified tanneries, traceable hides) to mitigate environmental and ethical concerns.

– Longer lifespan in certain high-use applications when properly maintained.

In conclusion, the choice between faux and real leather depends on the application, brand values, and sustainability targets. For forward-thinking B2B partners, modern eco-friendly faux leathers offer a high-performance, ethical, and cost-effective alternative without compromising on quality or design.

WINIW Factory Capabilities

WINIW Synthetic Leather: Advanced Manufacturing Capabilities for Global Partners

WINIW operates one of the industry’s most advanced synthetic leather manufacturing ecosystems, engineered to deliver consistent quality, innovation, and scalable supply for demanding B2B markets. Our vertically integrated infrastructure ensures end-to-end control from raw material sourcing to finished product, meeting the rigorous expectations of international brands and manufacturers.

Core Manufacturing Strengths

- 100,000 sqm State-of-the-Art Facility: Our purpose-built campus integrates production, R&D, and quality assurance under one roof, enabling agile response to large-volume orders while minimizing lead times. This scale supports annual capacities exceeding industry benchmarks for consistent global supply chain integration.

- Dedicated R&D Innovation Hub: A 150+ member technical team pioneers eco-conscious material science, developing proprietary technologies like water-based PU systems and recycled-content substrates. We collaborate directly with partners to customize textures, performance attributes, and sustainability profiles for specific applications.

- Strict Multi-Stage Quality Control: Every batch undergoes 27+ validation checkpoints aligned with EU REACH and U.S. CPSIA standards. Our QC protocol includes:

- Raw material traceability via blockchain-enabled systems

- Real-time in-line testing for colorfastness, abrasion resistance, and VOC emissions

- Final certification by third-party labs (e.g., SGS, Intertek) for global compliance

Global Compliance & Sustainability Commitment

WINIW’s manufacturing framework is built for seamless entry into regulated markets. Our facility holds ISO 14001 and OEKO-TEX® STeP certifications, with 92% of production lines utilizing renewable energy. This ensures partners receive materials that satisfy:

| Market Requirement | WINIW Certification | Environmental Impact Reduction |

|---|---|---|

| EU Chemical Safety | REACH SVHC Compliant | 65% lower CO₂ vs. conventional PU |

| U.S. Consumer Safety | CPSIA & Prop 65 Verified | Zero heavy metals or phthalates |

| Circular Economy | GRS-certified recycled options | 40%+ post-industrial recycled content |

With 12+ years of exporting to Tier-1 automotive, fashion, and furniture brands across Europe and North America, WINIW provides the operational resilience and ethical manufacturing rigor essential for premium B2B partnerships. Our facility’s scale and certification depth eliminate supply chain risks while advancing your sustainability goals.

Contact Us for Samples

B2B Product Guide: WINIW® Synthetic Leather Solutions

WINIW is a leading innovator in high-performance synthetic leather, delivering sustainable, durable, and customizable solutions for global B2B partners across industries such as automotive, furniture, apparel, and accessories. Our advanced microfiber technology replicates the look, feel, and performance of genuine leather—without the environmental impact.

Engineered for excellence, WINIW synthetic leather offers consistent quality, superior abrasion resistance, and enhanced breathability. As part of our commitment to sustainability, our production process reduces water consumption, eliminates animal sourcing, and incorporates recycled materials where applicable.

- Designed for high-wear applications with excellent tear and scratch resistance

- Available in a broad range of textures, colors, and finishes—including matte, glossy, soft-touch, and embossed

- Custom development services for thickness, backing fabric, and performance additives (anti-microbial, UV-resistant, flame-retardant)

- Compliant with global standards: REACH, RoHS, OEKO-TEX®

- Eco-conscious manufacturing with low-VOC emissions and recyclable packaging

Our microfiber base provides a stable structure that ensures long-term durability and dimensional stability, making WINIW ideal for mass production and precision cutting.

Product Specifications Overview

| Property | Typical Value/Range |

|---|---|

| Thickness | 0.6 mm – 2.0 mm |

| Backing Options | Knit, woven, non-woven |

| Weight (g/m²) | 200 – 500 |

| Abrasion Resistance | >50,000 cycles (Martindale) |

| Color Fastness | Grade 4–5 (ISO 105-B02) |

| Cold Crack Resistance | ≤ -30°C |

| Customization Lead Time | 15–25 days (sample to bulk) |

Why Choose WINIW Synthetic Leather?

- Sustainable alternative to PU and PVC leathers

- Reduced carbon footprint compared to animal leather

- High yield in cutting efficiency due to consistent roll goods

- Ideal for brands pursuing ESG and circular economy goals

We support large-volume orders with reliable lead times and global logistics partnerships. Our technical team collaborates closely with clients to match material performance with application requirements.

Want to know what faux leather is made of and how it can benefit your business?

Learn more about the science and sustainability behind modern synthetic leather.

Contact us today:

MKT88@MicrofiberLeather.com

Free samples available upon request.

Elevate your product line with WINIW—where innovation meets responsibility.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.