Introduction: Navigating the Global Market for leather fabric shop

In today’s competitive landscape, sourcing high-quality leather fabric can be a daunting task for international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. The challenge lies not only in finding reliable suppliers but also in navigating the complexities of varying quality standards, pricing structures, and regional preferences. This comprehensive guide to leather fabric shops is designed to demystify the sourcing process, providing valuable insights into the types of leather available, their applications, and effective strategies for supplier vetting.

Throughout this guide, you will discover the nuances of different leather types, from full-grain to suede, and their respective uses in industries such as fashion, upholstery, and automotive. We will delve into critical factors that influence cost, including sourcing options and regional market trends, empowering you to make informed purchasing decisions. Additionally, you will learn how to identify reputable suppliers, ensuring that your investments yield high-quality materials that meet your business needs.

By equipping you with actionable knowledge and industry best practices, this guide aims to streamline your procurement process and enhance your competitive edge in the global leather market. Whether you’re looking to source premium leather for high-end fashion or durable upholstery materials, our insights will help you navigate the complexities and make confident choices that align with your business objectives.

Table Of Contents

- Top 7 Leather Fabric Shop Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather fabric shop

- Understanding leather fabric shop Types and Variations

- Key Industrial Applications of leather fabric shop

- 3 Common User Pain Points for ‘leather fabric shop’ & Their Solutions

- Strategic Material Selection Guide for leather fabric shop

- In-depth Look: Manufacturing Processes and Quality Assurance for leather fabric shop

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather fabric shop’

- Comprehensive Cost and Pricing Analysis for leather fabric shop Sourcing

- Alternatives Analysis: Comparing leather fabric shop With Other Solutions

- Essential Technical Properties and Trade Terminology for leather fabric shop

- Navigating Market Dynamics and Sourcing Trends in the leather fabric shop Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather fabric shop

- Strategic Sourcing Conclusion and Outlook for leather fabric shop

- Important Disclaimer & Terms of Use

Understanding leather fabric shop Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Made from the top layer of hide, retains natural grain and imperfections | High-end furniture, luxury goods | Pros: Durability, breathability, aesthetic appeal. Cons: Higher cost, requires maintenance. |

| Top Grain Leather | Slightly sanded to remove imperfections, maintains a natural look | Upholstery, fashion accessories | Pros: More affordable than full grain, durable. Cons: Less breathable than full grain. |

| Suede | Soft, napped finish created from the underside of the hide | Apparel, handbags, automotive interiors | Pros: Soft texture, versatile. Cons: Less durable, sensitive to moisture. |

| Nubuck | Sanded top grain leather, offers a velvety texture | High-end footwear, upholstery | Pros: Luxurious feel, durable. Cons: Prone to staining, requires special care. |

| Bonded Leather | Made from leather scraps bonded together, often coated for appearance | Budget-friendly products, furniture | Pros: Cost-effective, eco-friendly. Cons: Less durable, quality varies significantly. |

What Are the Characteristics of Full Grain Leather and Its B2B Suitability?

Full grain leather is sourced from the outermost layer of the hide, preserving its natural grain and imperfections. This type of leather is renowned for its durability, breathability, and luxurious appearance, making it ideal for high-end furniture and luxury goods. B2B buyers should consider the long-term investment aspect, as full grain leather tends to age beautifully and develop a unique patina over time. However, it requires regular maintenance and is priced at a premium, which may not suit all budgets.

How Does Top Grain Leather Compare for Commercial Use?

Top grain leather is created by sanding down the surface of the hide to remove imperfections while retaining a natural look. It is widely used in upholstery and fashion accessories due to its balance of quality and affordability. B2B buyers benefit from its durability and ease of care compared to full grain leather, making it suitable for high-traffic environments. However, it is less breathable and may not provide the same luxurious feel as its full grain counterpart.

What Are the Unique Features of Suede for Specific Applications?

Suede is characterized by its soft, napped finish derived from the underside of the hide. This type of leather is primarily used in apparel, handbags, and automotive interiors, offering a unique texture that appeals to consumers. For B2B buyers, suede provides versatility and aesthetic appeal, but it is less durable and sensitive to moisture, which may limit its applications in certain industries. Careful consideration should be given to the intended use and maintenance requirements.

Why Choose Nubuck Leather for High-End Products?

Nubuck is similar to suede but is made from the sanded top grain of the hide, resulting in a velvety texture. It is often used in high-end footwear and upholstery, providing a luxurious feel and durability. B2B buyers should note that while nubuck is attractive and robust, it can be prone to staining and requires special cleaning products. This makes it a suitable choice for premium products where aesthetics are paramount, but buyers should be prepared for the care it demands.

What Are the Cost Benefits of Bonded Leather for Budget-Conscious Buyers?

Bonded leather is manufactured from leather scraps that are bonded together and often coated for a more appealing finish. This type of leather is an economical choice for budget-friendly products and furniture. B2B buyers appreciate its cost-effectiveness and eco-friendly aspects, but they should be aware that the quality can vary significantly. Bonded leather is less durable than other types, making it suitable for lower-end applications where price is a primary concern.

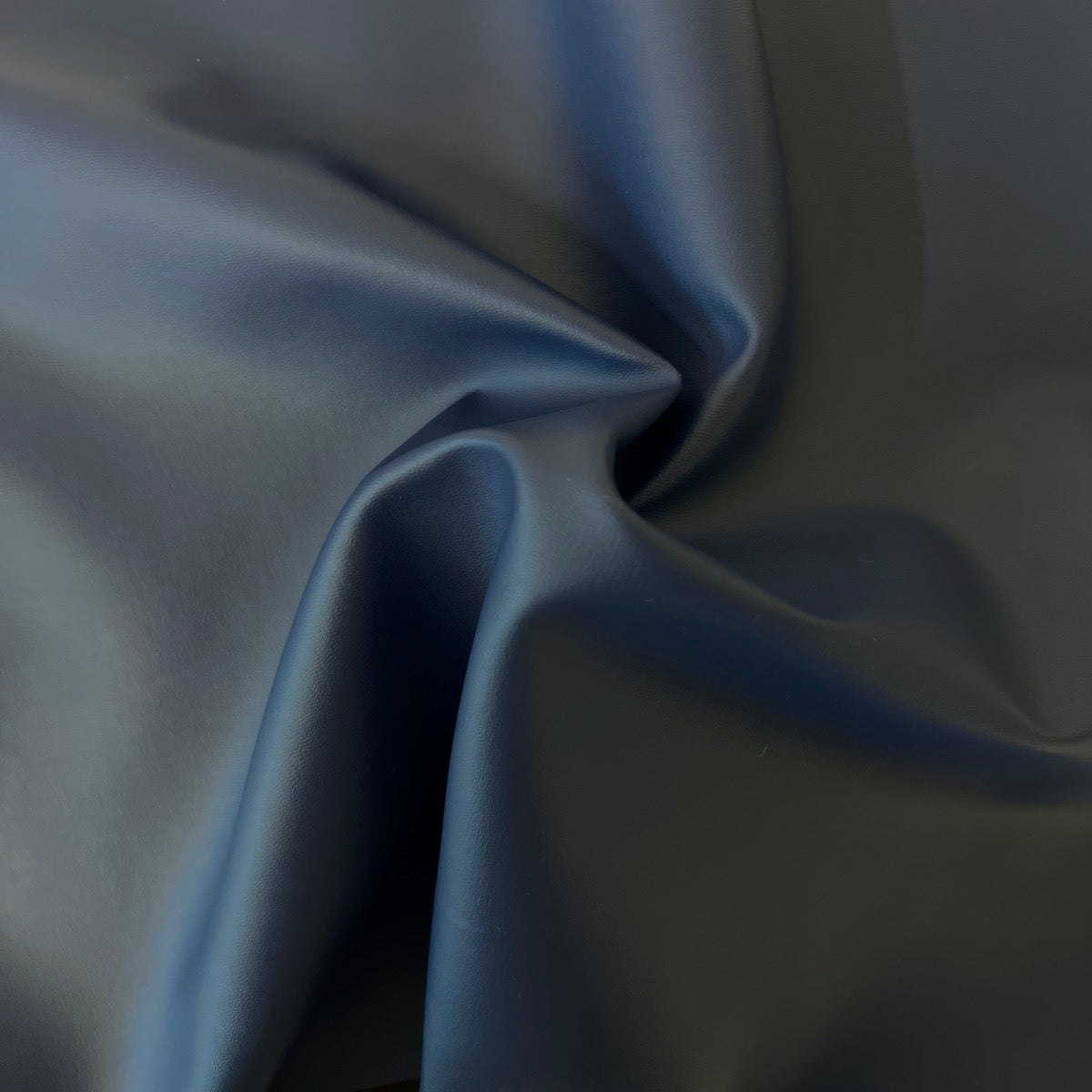

Illustrative image related to leather fabric shop

Key Industrial Applications of leather fabric shop

| Industry/Sector | Specific Application of leather fabric shop | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for car interiors | Enhances vehicle aesthetics and comfort | Material durability, color options, and compliance with safety standards |

| Fashion and Apparel | Production of leather garments and accessories | High-quality, stylish products that appeal to consumers | Availability of various hides, textures, and sustainable sourcing options |

| Furniture and Interior Design | Upholstery for residential and commercial furniture | Adds luxury and durability to furniture pieces | Customization options, weight/thickness of leather, and design compatibility |

| Footwear | Manufacturing of leather shoes | Provides comfort and longevity to footwear | Sizing, leather flexibility, and adherence to fashion trends |

| Sporting Goods | Creation of leather sporting equipment | Enhances performance and durability in products | Specific leather grades, weight, and resistance to wear and tear |

How is Leather Fabric Shop Used in the Automotive Sector?

In the automotive industry, leather fabric shops supply high-quality hides for car upholstery, including seats, dashboards, and door panels. These materials not only enhance the aesthetic appeal of vehicles but also provide comfort and durability. B2B buyers in this sector often prioritize sourcing leather that meets specific durability standards and color options that align with brand identity. International buyers from regions like Europe and the Middle East may also focus on compliance with local safety regulations and environmental standards in sourcing.

What Role Does Leather Fabric Play in Fashion and Apparel?

Leather fabric shops are crucial for fashion designers and apparel manufacturers looking to create high-end garments and accessories. The versatility of leather allows for the production of everything from jackets to bags, appealing to luxury markets. B2B buyers must consider the availability of various leather types, such as lambskin or cowhide, and their respective textures. Sustainable sourcing practices are increasingly important for international buyers, particularly in Europe, where consumers demand environmentally friendly options.

How is Leather Fabric Utilized in Furniture and Interior Design?

In the furniture sector, leather is a preferred material for upholstery due to its durability and luxurious feel. Leather fabric shops provide a range of options for both residential and commercial applications, allowing designers to create bespoke furniture pieces. B2B buyers should focus on customization capabilities, including color and texture options, as well as the weight and thickness of the leather to ensure it meets design specifications. International buyers might also need to consider shipping logistics and tariffs when sourcing from different regions.

Why is Leather Important for Footwear Manufacturing?

The footwear industry relies heavily on leather for its ability to provide comfort and longevity in shoes. Leather fabric shops supply various grades of leather that cater to different styles, from high-end fashion footwear to durable work boots. B2B buyers must consider factors such as sizing, flexibility, and adherence to current fashion trends when sourcing materials. For international buyers, the sourcing process may also involve understanding the local market preferences and ensuring that the leather meets international quality standards.

Illustrative image related to leather fabric shop

How Does Leather Fabric Enhance Sporting Goods?

Leather is a popular choice for sporting goods, including gloves, balls, and protective gear, due to its strength and performance attributes. Leather fabric shops provide specialized hides that enhance the durability and functionality of these products. B2B buyers should prioritize sourcing leather that meets specific performance criteria, such as weight and resistance to wear. Additionally, international buyers may need to navigate varying regulations related to sporting goods standards in their respective markets.

3 Common User Pain Points for ‘leather fabric shop’ & Their Solutions

Scenario 1: Difficulty in Identifying Quality Leather for Specific Applications

The Problem: Many B2B buyers, especially those sourcing leather for specialized applications like upholstery, fashion, or accessories, struggle to assess the quality of leather materials. With various grades and types available, it can be overwhelming to determine which leather is suitable for a particular project. This issue is compounded by varying international standards and the risk of receiving inferior products that do not meet specifications. Buyers may worry about the durability, finish, and overall performance of the leather, which can affect their end products and reputation.

The Solution: To effectively source high-quality leather, buyers should prioritize establishing strong relationships with reputable leather fabric suppliers. Engage in direct communication to discuss specific needs and applications, and request samples before making bulk purchases. When evaluating leather, look for certifications that indicate quality, such as those pertaining to environmental sustainability or adherence to specific industry standards. Additionally, leverage online resources, such as product descriptions and reviews, to gauge the reputation of the suppliers. By conducting thorough research and due diligence, buyers can ensure they acquire leather that meets their quality expectations.

Scenario 2: Navigating Pricing and Bulk Purchase Discounts

The Problem: B2B buyers often face challenges when trying to understand the pricing structure of leather products, particularly when ordering in bulk. Many suppliers have different pricing tiers based on quantity, but these structures can be confusing. Additionally, buyers may be concerned about the potential for hidden costs associated with shipping, tariffs, or other fees that could impact their budget. This lack of transparency can lead to unexpected expenses and frustration when trying to finalize orders.

The Solution: To navigate pricing effectively, buyers should communicate openly with suppliers about their purchasing intentions and ask for a clear breakdown of costs. Request information on bulk purchase discounts and understand the minimum order quantities that may apply. It is advisable to inquire about any potential additional costs, such as shipping and customs fees, especially when sourcing from international suppliers. Buyers can also benefit from comparing quotes from multiple suppliers to ensure they are receiving competitive pricing. Establishing a long-term partnership with a supplier can also lead to better pricing options and improved negotiation leverage over time.

Illustrative image related to leather fabric shop

Scenario 3: Inconsistent Supply and Lead Times

The Problem: One significant concern for B2B buyers in the leather industry is the inconsistency of supply and lead times, which can disrupt production schedules and affect project timelines. Buyers may find that suppliers have variable inventory levels, especially for specific types of leather, which can lead to delays in fulfilling customer orders. Such unpredictability poses a risk to businesses that rely on timely delivery to maintain their operational flow and meet client demands.

The Solution: To mitigate supply chain issues, buyers should consider diversifying their supplier base. By establishing relationships with multiple leather fabric shops, they can create a more resilient supply chain that can adapt to fluctuations in inventory. Implementing a just-in-time inventory strategy can also help manage lead times, ensuring that stock levels align closely with production needs. Additionally, regular communication with suppliers regarding inventory levels and lead times can foster transparency and allow buyers to adjust their orders proactively. Utilizing order tracking and inventory management software can further enhance supply chain efficiency, enabling buyers to anticipate and manage potential delays.

Strategic Material Selection Guide for leather fabric shop

What Are the Key Properties of Common Leather Materials for B2B Buyers?

When selecting materials for a leather fabric shop, understanding the characteristics of various leather types is crucial for optimizing product performance and meeting client needs. Here, we analyze four common leather materials: Cowhide, Lambskin, Nubuck, and Suede, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

Illustrative image related to leather fabric shop

How Does Cowhide Perform in Leather Applications?

Cowhide is one of the most widely used leathers in various applications due to its durability and strength. It typically has a thickness ranging from 2 to 6 oz. (0.8 to 2.4 mm) and is known for its resistance to wear and tear, making it ideal for upholstery and heavy-duty products.

Pros: Cowhide is highly durable, offers good abrasion resistance, and can withstand temperature fluctuations. Its versatility allows it to be used in various applications, from furniture to automotive interiors.

Cons: The cost can be relatively high, especially for premium grades, and it may require more complex manufacturing processes for specific finishes. Additionally, the weight of cowhide can be a limitation for lightweight applications.

Impact on Application: Cowhide is suitable for products that require long-lasting performance, such as sofas and jackets, but may not be ideal for delicate items.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is essential, especially in markets like Germany and Saudi Arabia, where quality standards are stringent. Buyers should also consider sourcing from sustainable suppliers to meet growing environmental concerns.

Illustrative image related to leather fabric shop

What Are the Unique Features of Lambskin Leather?

Lambskin is another popular leather choice known for its softness and luxurious feel. Typically thinner than cowhide, it ranges from 1 to 3 oz. (0.4 to 1.2 mm) in thickness, making it ideal for high-end fashion and accessories.

Pros: The primary advantage of lambskin is its softness and supple texture, which provides comfort and elegance. It is lightweight, making it suitable for garments that require a delicate touch.

Cons: While lambskin is aesthetically pleasing, it is less durable than cowhide and more susceptible to scratches and stains. This limits its use in high-wear applications.

Impact on Application: Lambskin is best suited for luxury apparel and accessories, such as gloves and handbags, where aesthetics are prioritized over durability.

Illustrative image related to leather fabric shop

Considerations for International Buyers: Buyers from regions like Europe may prefer lambskin for its high fashion appeal. However, they should be aware of specific care instructions and the need for protective treatments to maintain its appearance.

How Does Nubuck Compare to Other Leather Types?

Nubuck is a type of leather that has been sanded or buffed to create a soft, velvety surface. It is typically made from cowhide and has a thickness of 2 to 4 oz. (0.8 to 1.6 mm).

Pros: Nubuck offers a unique texture that is both appealing and comfortable. It is also relatively durable, providing good resistance to wear.

Cons: Nubuck is more susceptible to staining and requires special care to maintain its appearance. Additionally, it can be more expensive due to the finishing process.

Illustrative image related to leather fabric shop

Impact on Application: Nubuck is often used in footwear and upholstery, where a soft touch is desired, but it may not be suitable for environments exposed to moisture.

Considerations for International Buyers: Buyers in humid climates, such as parts of Africa and South America, should consider the maintenance requirements of nubuck to ensure longevity.

What Advantages Does Suede Offer for Leather Products?

Suede is another soft leather option, made from the underside of animal hides, typically cow or lamb. It has a thickness similar to nubuck, generally around 1 to 3 oz. (0.4 to 1.2 mm).

Pros: Suede is renowned for its softness and flexibility, making it comfortable for wear. It also has a unique aesthetic appeal, often used in fashion and luxury items.

Cons: Like nubuck, suede is prone to staining and requires careful maintenance. Its durability is lower than that of full-grain leather, limiting its use in high-wear applications.

Impact on Application: Suede is ideal for fashion accessories, upholstery, and garments where softness and appearance are critical.

Considerations for International Buyers: Buyers should be aware of regional preferences for suede, particularly in fashion-forward markets in Europe and the Middle East, where style often takes precedence over durability.

Summary Table of Leather Materials

| Material | Typical Use Case for leather fabric shop | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide | Upholstery, automotive interiors | Highly durable and versatile | Higher cost, complex manufacturing | High |

| Lambskin | Luxury apparel, handbags | Soft and luxurious feel | Less durable, prone to stains | High |

| Nubuck | Footwear, upholstery | Unique texture and comfort | Susceptible to staining, higher cost | Medium |

| Suede | Fashion accessories, garments | Softness and aesthetic appeal | Lower durability, maintenance needed | Medium |

This guide serves as a strategic resource for B2B buyers in the leather industry, helping them navigate material selection based on performance, application suitability, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for leather fabric shop

What Are the Key Stages in the Manufacturing Process of Leather Fabrics?

The manufacturing process of leather fabrics is intricate and involves several critical stages that ensure the final product meets quality and durability standards. Understanding these stages is essential for B2B buyers who seek reliable suppliers.

Material Preparation: How Are Raw Hides Processed?

The first step in the leather manufacturing process involves sourcing and preparing raw hides. Suppliers typically procure hides from various sources, including cattle, sheep, and goats. The hides undergo a curing process to prevent decay, which can involve salting or drying.

Once cured, the hides are soaked in water to remove impurities and restore flexibility. This step is crucial, as it prepares the hides for further processing. Depending on the desired leather type, the hides may also undergo additional treatments, such as dehairing and fleshing, to remove hair and excess fat.

Forming: What Techniques Are Used to Shape Leather?

The forming stage involves techniques that shape the leather into usable forms. This can include cutting, stamping, or molding. Advanced technologies, such as CAD (Computer-Aided Design), are often employed to ensure precision in cutting patterns, especially for large orders.

In this phase, the hides are cut into specific shapes and sizes, depending on the intended application, whether for upholstery, fashion, or other uses. Manufacturers may also use laser cutting for intricate designs, which adds value by creating unique patterns that appeal to niche markets.

Assembly: How Is Leather Fabric Constructed?

During the assembly phase, the cut pieces of leather are stitched or bonded together to create a finished product. This can involve handcrafting techniques for high-end products or automated machinery for mass production.

Illustrative image related to leather fabric shop

Quality stitching is paramount; thus, many manufacturers implement double-stitching or reinforced seams to enhance durability. Depending on the product type, assembly may also include attaching other materials, such as padding or backing, to improve comfort and functionality.

Finishing: What Treatments Are Applied to Enhance Leather?

Finishing is the final stage of the manufacturing process, where leather is treated to achieve desired aesthetics and performance characteristics. This can include dyeing, polishing, or applying protective coatings to enhance durability and resistance to stains.

Innovative finishing techniques, such as aniline dyeing, are popular for their ability to showcase the natural grain of the leather while providing a soft touch. B2B buyers should inquire about the finishing processes used by suppliers, as this can significantly impact the final product’s quality and longevity.

What Quality Assurance Measures Are Essential for Leather Fabric Suppliers?

Quality assurance (QA) is critical in the leather manufacturing process, ensuring that the products meet international standards and customer expectations. B2B buyers should be aware of the various QA measures that suppliers employ.

Which International Standards Should Leather Fabric Suppliers Adhere To?

For B2B buyers, it is essential to ensure that suppliers comply with international quality standards such as ISO 9001. This standard outlines requirements for a quality management system, focusing on continuous improvement and customer satisfaction.

Additionally, industry-specific certifications, such as CE marking for safety compliance in the European market, can provide further assurance of product quality. Buyers should request documentation proving compliance with these standards during the procurement process.

What Are the Key Quality Control Checkpoints in Leather Manufacturing?

Quality control (QC) checkpoints are vital in the leather manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications. Suppliers should conduct visual inspections and physical testing of hides for defects.

-

In-Process Quality Control (IPQC): During manufacturing, random inspections are conducted to monitor the production process and identify any deviations from quality standards. This can include checking stitching quality and adherence to design specifications.

-

Final Quality Control (FQC): Before shipment, finished products undergo a comprehensive inspection to verify they meet quality standards. This includes checking for color consistency, stitching integrity, and overall appearance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should adopt proactive measures to verify the quality control practices of potential suppliers. Here are several strategies:

What Documentation Should Buyers Request?

Buyers should request quality assurance documentation, including:

- Quality Management System (QMS) Certifications: Proof of ISO 9001 or other relevant certifications.

- Test Reports: Documentation from third-party laboratories confirming that the leather meets specific performance standards, such as durability and chemical resistance.

How Can Audits and Third-Party Inspections Enhance Quality Assurance?

Conducting audits of supplier facilities can provide invaluable insights into their manufacturing processes and quality control measures. Buyers may consider hiring third-party inspection services to conduct audits and provide unbiased reports on the supplier’s quality practices.

What Are the Unique Quality Control Nuances for International Buyers?

B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe should be aware of unique quality control nuances. For instance, European buyers may prioritize compliance with strict environmental regulations, while Middle Eastern buyers might focus on specific aesthetic qualities that align with cultural preferences.

Additionally, understanding regional trade agreements and tariffs can impact the cost of importing leather products. Buyers should remain informed about these factors to make strategic purchasing decisions.

Conclusion: Ensuring Quality in Leather Fabric Sourcing

In conclusion, the manufacturing processes and quality assurance measures in the leather fabric industry are multifaceted and critical for delivering high-quality products. B2B buyers must engage in thorough due diligence, including understanding manufacturing stages, verifying quality control practices, and ensuring compliance with international standards. By doing so, they can secure reliable suppliers and enhance their product offerings in the competitive leather market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather fabric shop’

Introduction

Sourcing leather fabric for your business requires careful planning and execution. This guide outlines essential steps to streamline your procurement process, helping international B2B buyers navigate the complexities of purchasing leather from suppliers across Africa, South America, the Middle East, and Europe. By following this checklist, you can ensure that you select the right materials and suppliers for your needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your requirements for leather fabric. This includes the type of leather (e.g., cowhide, lamb, nubuck), thickness, finish, and color. Specific specifications help suppliers understand your needs, reducing the risk of receiving unsuitable products.

- Consider the application: Will the leather be used for upholstery, fashion, or accessories? Different applications may require different types of leather.

- Establish quality standards: Define the minimum quality you expect to ensure that the materials meet your production standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in leather fabrics. Look for companies with a proven track record and positive reviews from previous clients.

- Utilize trade directories: Websites like Alibaba or industry-specific directories can provide a list of potential suppliers.

- Check certifications: Ensure suppliers adhere to relevant quality and environmental standards, such as ISO certifications or membership in leather associations.

Step 3: Request Samples

Before making bulk orders, always request samples of the leather you intend to purchase. Samples allow you to assess the quality, texture, and color fidelity of the leather.

- Evaluate the samples: Inspect for consistency in grain, color, and finish. This step is crucial to confirm that the leather meets your expectations.

- Test durability: Conduct tests for abrasion resistance and flexibility to ensure the leather can withstand your intended use.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers have relevant certifications that demonstrate their compliance with industry standards. This step is critical for mitigating risks associated with quality and sourcing practices.

Illustrative image related to leather fabric shop

- Look for environmental compliance: Suppliers should adhere to sustainable practices, especially if you are targeting eco-conscious markets.

- Check ethical sourcing: Certifications related to fair trade or animal welfare can enhance your brand’s reputation.

Step 5: Negotiate Terms and Pricing

Once you’ve selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. This is a key step to ensure that you get the best value for your investment.

- Discuss bulk discounts: Inquire about price reductions for larger orders or long-term contracts.

- Clarify payment methods: Agree on secure payment options to protect your financial interests.

Step 6: Establish a Clear Contract

Finalize your agreement with a detailed contract that outlines all terms, including product specifications, delivery schedules, payment terms, and liability clauses. A well-structured contract protects both parties and minimizes the risk of disputes.

- Include quality assurance clauses: Specify the quality benchmarks that must be met upon delivery.

- Outline dispute resolution procedures: Establish clear steps for addressing any issues that may arise during the procurement process.

Step 7: Plan for Quality Control

Develop a quality control plan to monitor the leather’s quality upon arrival. This ensures that the materials meet your specifications and standards before they are used in production.

- Conduct inspections: Set up a system for inspecting the leather for defects or inconsistencies.

- Document findings: Keep records of all inspections and any issues that arise for future reference and accountability.

By following this checklist, B2B buyers can enhance their sourcing efficiency and ensure that they procure high-quality leather materials that align with their business needs.

Comprehensive Cost and Pricing Analysis for leather fabric shop Sourcing

What Are the Key Cost Components in Leather Fabric Sourcing?

When sourcing leather fabric for B2B purposes, understanding the cost structure is crucial. The primary cost components include:

Illustrative image related to leather fabric shop

-

Materials: The price of raw leather is a significant factor, often influenced by the type of animal hide (e.g., cow, lamb, goat) and the tanning process. For instance, high-quality hides can range dramatically in price based on their finish and characteristics, such as grain quality and color.

-

Labor: Skilled labor is required for cutting, stitching, and finishing leather products. Labor costs can vary significantly depending on the region and the complexity of the manufacturing processes.

-

Manufacturing Overhead: This encompasses utilities, rent, equipment depreciation, and other indirect costs that support production. Efficient manufacturing processes can help minimize overhead, impacting overall pricing.

-

Tooling: Costs associated with dies and molds for custom products can add to the initial expenses. Tooling costs are particularly relevant when producing specialized or unique leather items.

-

Quality Control (QC): Implementing QC measures ensures that the leather meets specified standards, which can incur additional costs. Buyers should consider how stringent QC processes are factored into the pricing.

-

Logistics: Shipping and handling costs can greatly influence the total cost, especially for international buyers. Factors such as distance, shipping method, and customs duties should be considered.

-

Margin: Suppliers typically add a profit margin on top of their costs. Understanding the margins applied can help buyers gauge the competitiveness of pricing.

How Do Price Influencers Affect Leather Fabric Costs?

Several factors influence the pricing of leather fabric, particularly in the B2B landscape:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate for better pricing based on their order volumes.

-

Specifications and Customization: Customized orders may incur higher costs due to additional labor, tooling, and materials required. Clear communication of specifications can help prevent unexpected price increases.

-

Material Quality and Certifications: Higher quality leather typically demands higher prices. Certifications, such as those for sustainability or specific tanning processes, can also affect pricing.

-

Supplier Factors: The reputation and reliability of the supplier play a critical role in pricing. Established suppliers may charge a premium for their services, but they often provide better quality assurance and reliability.

-

Incoterms: Understanding the terms of shipment (e.g., FOB, CIF) can impact the total cost. Buyers should clarify who bears the shipping costs and risks to accurately assess pricing.

What Are Effective Buyer Tips for Sourcing Leather Fabric?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially when placing bulk orders. This can lead to discounts or favorable terms.

-

Total Cost of Ownership (TCO): Consider all costs associated with the leather, including transportation, customs, and potential waste from defective materials. TCO provides a more comprehensive view than just the purchase price.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and international tariffs that may affect costs. Establishing contracts in stable currencies can mitigate risks.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers allows for comparison and can provide leverage during negotiations.

Disclaimer on Pricing

It is important to note that the prices for leather fabrics can vary significantly based on market conditions, supplier relationships, and fluctuations in raw material costs. The figures provided here are indicative and should be verified through direct supplier communication for the most accurate quotes.

Alternatives Analysis: Comparing leather fabric shop With Other Solutions

When considering sourcing leather materials for various applications, it is essential to evaluate the available options thoroughly. While a leather fabric shop offers a dedicated platform for purchasing leather, alternative solutions may provide different benefits that could better align with a buyer’s specific needs. This analysis will compare the traditional leather fabric shop against two viable alternatives: direct sourcing from manufacturers and synthetic leather options.

Comparison Table

| Comparison Aspect | Leather Fabric Shop | Direct Sourcing from Manufacturers | Synthetic Leather Options |

|---|---|---|---|

| Performance | High-quality natural leather; various types available | Variable quality; depends on the manufacturer | Durable and resistant to wear; varies by type |

| Cost | Generally mid to high price range | Can be lower cost with bulk orders | Typically lower initial cost |

| Ease of Implementation | Easy to navigate online; wide selection | May require negotiation and logistics | Simple procurement through retailers |

| Maintenance | Requires care to maintain quality | Varies by supplier; may have warranties | Low maintenance; easy to clean |

| Best Use Case | Ideal for bespoke projects and high-end applications | Large orders for production needs | Cost-effective alternatives for mass production |

Detailed Breakdown of Alternatives

Direct Sourcing from Manufacturers

Direct sourcing from manufacturers allows businesses to bypass intermediaries, potentially reducing costs. This method can be especially advantageous for companies looking to place large orders, as manufacturers often offer bulk pricing that can significantly lower per-unit costs. However, this approach requires a more complex logistics process, including negotiation and establishing a reliable supply chain. Quality can also be inconsistent, as it heavily depends on the manufacturer’s reputation and capabilities.

Synthetic Leather Options

Synthetic leather, or faux leather, is an increasingly popular alternative to traditional leather due to its affordability and lower environmental impact. It is typically easier to clean and maintain, making it suitable for a wide range of applications, from upholstery to fashion. While synthetic leather offers durability and resistance to wear, it may not provide the same aesthetic appeal or longevity as genuine leather. Additionally, it lacks the unique character and patina that natural leather develops over time, which can be a significant consideration for luxury markets.

Illustrative image related to leather fabric shop

Conclusion: How to Choose the Right Solution for Your Needs

For B2B buyers, the decision between a leather fabric shop, direct sourcing from manufacturers, or synthetic leather options hinges on specific project requirements and budget constraints. If quality and customization are paramount, a leather fabric shop may be the best choice. However, businesses focused on large-scale production may find direct sourcing more cost-effective. Alternatively, those seeking affordable and low-maintenance materials might benefit from synthetic leather. Ultimately, understanding the unique benefits and limitations of each option will empower buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for leather fabric shop

What Are the Key Technical Properties of Leather Fabric?

When dealing with leather fabrics in a B2B context, understanding the following technical properties is crucial for making informed purchasing decisions:

-

Material Grade: Leather is categorized into grades based on quality and processing methods. Full-grain leather is the highest quality, retaining the natural surface and strength, while split leather is a lower grade, made from the fibrous part of the hide. Recognizing material grades helps buyers assess durability and suitability for various applications, from upholstery to fashion.

-

Weight/Thickness: Measured in ounces or millimeters, the weight of leather directly influences its application. For instance, lighter leathers (1-3 oz) are suitable for garments, while heavier options (4-6 oz) are better for upholstery or bags. Understanding weight ensures that buyers select the right leather for their intended use, impacting both performance and cost.

-

Tannage Type: The tanning process affects leather’s appearance, durability, and environmental impact. Chrome-tanned leather is prevalent for its quick processing and vibrant colors, while vegetable-tanned leather is known for its eco-friendliness and aging characteristics. Buyers should consider tannage when sourcing leather to align with their brand values and product requirements.

-

Finish: The surface treatment of leather can vary significantly, impacting aesthetics and functionality. Common finishes include aniline, semi-aniline, and pigmented, each offering different levels of protection and visual appeal. Understanding finishes helps businesses select leather that meets both design and functional criteria, such as stain resistance.

-

Size and Yield: Leather hides are sold by square footage, typically ranging from 3 to 30 square feet or more. Yield refers to the usable area of the hide after accounting for defects and imperfections. Knowledge of size and yield is essential for buyers to estimate costs and ensure they order enough material for their projects.

Which Trade Terminology Should You Understand in the Leather Fabric Industry?

Navigating the leather fabric industry requires familiarity with specific jargon. Here are some key terms that every B2B buyer should know:

Illustrative image related to leather fabric shop

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the leather industry, an OEM may supply leather components for a brand’s products. Understanding OEM relationships can help buyers negotiate better pricing and ensure quality standards.

-

MOQ (Minimum Order Quantity): This is the smallest amount of a product that a supplier is willing to sell. MOQs are critical in the leather industry due to the high costs associated with raw materials. Buyers need to know MOQs to plan their inventory effectively and avoid overcommitting financially.

-

RFQ (Request for Quotation): An RFQ is a document issued by a buyer to solicit price quotes from suppliers. In the leather market, RFQs can help buyers compare prices, terms, and delivery times, ensuring they make informed purchasing decisions. It’s an essential step in the sourcing process.

-

Incoterms (International Commercial Terms): These are a set of predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is vital for understanding shipping costs and logistics.

-

Lead Time: This term indicates the time taken from placing an order to the delivery of goods. In the leather industry, lead times can vary based on the complexity of the order and the supplier’s capabilities. Buyers should consider lead times to ensure timely production schedules.

By grasping these technical properties and trade terms, B2B buyers can navigate the leather fabric market more effectively, making strategic decisions that align with their business goals.

Navigating Market Dynamics and Sourcing Trends in the leather fabric shop Sector

What Are the Current Market Dynamics and Sourcing Trends in the Leather Fabric Sector?

The global leather fabric market is currently experiencing a surge, driven by a combination of consumer demand for high-quality materials and the growing interest in bespoke craftsmanship. This trend is particularly pronounced among B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Germany. Buyers are increasingly seeking diverse leather products, ranging from upholstery materials to high-end fashion applications. The rise of e-commerce platforms has also transformed sourcing strategies, enabling businesses to access a wider range of suppliers and products from around the world.

Emerging technologies are reshaping the leather fabric sector, with innovations such as digital printing and laser cutting enhancing customization options. Furthermore, the integration of artificial intelligence in inventory management and demand forecasting is allowing businesses to streamline operations, reduce waste, and improve responsiveness to market trends. As international trade continues to evolve, buyers are prioritizing suppliers who can offer flexibility in order quantities and rapid delivery times, aligning with the just-in-time inventory practices that are becoming more prevalent in the industry.

How is Sustainability Influencing B2B Sourcing Decisions in the Leather Fabric Sector?

Sustainability has become a pivotal consideration for B2B buyers in the leather fabric market. The environmental impact of traditional leather production methods has prompted a significant shift towards more sustainable practices. Buyers are increasingly looking for suppliers who adhere to ethical sourcing standards, utilizing environmentally friendly tanning processes and sourcing materials from certified suppliers. This shift not only enhances brand reputation but also aligns with the growing consumer demand for sustainable products.

Illustrative image related to leather fabric shop

Certifications such as the Leather Working Group (LWG) and the Global Organic Textile Standard (GOTS) are gaining traction, providing buyers with assurance regarding the sustainability and ethical practices of their suppliers. Additionally, the introduction of alternative materials, such as plant-based leathers and recycled leather, is further driving the trend towards sustainable sourcing. B2B buyers who prioritize sustainability can differentiate their offerings in a competitive market, appealing to a growing segment of environmentally-conscious consumers.

What is the Historical Context of the Leather Fabric Market That Shapes Today’s B2B Landscape?

The leather fabric market has a rich history that dates back thousands of years, with its roots in ancient civilizations that used animal hides for clothing and shelter. Over time, the industry has evolved significantly, transitioning from traditional tanning methods to modern processes that utilize advanced technology. The industrial revolution marked a turning point, introducing mass production and making leather goods more accessible to the general public.

In recent decades, the leather industry has faced challenges related to environmental concerns and ethical sourcing, prompting a shift towards more sustainable practices. This evolution has shaped the current B2B landscape, where buyers are now more informed and discerning, seeking suppliers who can provide not only high-quality materials but also transparency and ethical assurance in their supply chains. As the market continues to adapt, understanding this historical context is crucial for B2B buyers aiming to navigate today’s complex sourcing dynamics effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of leather fabric shop

-

How do I choose the right leather fabric supplier for my business needs?

Selecting the right leather fabric supplier involves evaluating several factors, including product quality, reliability, and communication. Start by researching suppliers with strong reputations in the industry and check their certifications. Request samples to assess the quality of leather, and inquire about their production processes and ethical sourcing practices. Additionally, consider their ability to provide customized solutions and their responsiveness to inquiries. Establishing a good relationship and clear communication channels can facilitate smoother transactions. -

What are the most common types of leather used in upholstery and fashion?

The most common types of leather used in upholstery and fashion include full-grain, top-grain, and bonded leather. Full-grain leather is the highest quality, retaining the natural grain and durability, making it ideal for high-end furniture. Top-grain leather is slightly processed to remove imperfections but still maintains quality and elegance. Bonded leather is a more affordable option made from leather scraps, suitable for budget-conscious projects. Understanding these types can help you choose the right material for your specific application. -

What are typical minimum order quantities (MOQs) for leather fabric?

Minimum order quantities for leather fabric can vary significantly depending on the supplier and the type of leather. Generally, MOQs range from 5 to 50 yards for upholstery leather, while some specialty leathers may have higher MOQs. It’s essential to discuss your specific needs with the supplier, as many are willing to accommodate smaller orders for new clients or for bulk purchases. Negotiating MOQs can also be beneficial, especially if you plan to establish a long-term relationship. -

How can I ensure the quality of leather before making a bulk purchase?

To ensure quality before bulk purchasing, request physical samples of the leather types you are considering. Evaluate the samples for texture, smell, and durability. Ask for details regarding the tanning process, which can affect the leather’s longevity and appearance. Additionally, check for certifications related to environmental and ethical standards. Establishing a clear quality assurance process, including inspections upon delivery, can further safeguard your investment. -

What payment terms should I expect when sourcing leather fabric internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payments, letters of credit, or payment upon delivery. Many suppliers may require a deposit (usually 30-50%) before production begins, with the balance due upon completion or delivery. It’s crucial to clarify payment terms upfront to avoid any misunderstandings. Additionally, consider the impact of currency fluctuations and transaction fees when making international payments. -

How do logistics and shipping work for international leather fabric purchases?

Logistics for international leather purchases typically involve coordinating with freight forwarders or shipping companies to handle transportation. Factors to consider include shipping methods (air or sea), estimated delivery times, and costs. Ensure that the supplier provides necessary documentation, such as bills of lading and customs declarations, to facilitate a smooth customs clearance process. Also, discuss who will be responsible for duties and taxes upon arrival in your country. -

What customization options are available when ordering leather fabric?

Many suppliers offer customization options, including color, texture, thickness, and specific finishes. You can often request unique patterns or embossing to meet your design specifications. Discuss your requirements with the supplier to explore available options and any associated costs. Keep in mind that customized orders may have longer lead times, so plan accordingly to meet your production schedules. -

How can I evaluate the ethical practices of a leather fabric supplier?

Evaluating a supplier’s ethical practices involves researching their sourcing and production methods. Look for suppliers who adhere to industry standards and certifications related to environmental sustainability and animal welfare. Request information about their supply chain transparency, labor practices, and any certifications they may hold, such as ISO or Leather Working Group certifications. Engaging in direct communication with the supplier can also provide insight into their commitment to ethical practices.

Top 7 Leather Fabric Shop Manufacturers & Suppliers List

1. Hide & Leather House – Leather Hides & Products

Domain: hidehouse.com

Registered: 1996 (29 years)

Introduction: The Hide & Leather House, Inc. offers a wide range of leather products, including: 1. Leather Hides: Over 3,000 types in stock, including: – Bags & Personal Leather Gear – Belting & Strapping – Chap & Motorcycle Hides – Eco Friendly Tannage – Footwear & Shoe Hides – Garment Hides – Hair on Hides – Upholstery Hides – Nonstock Leather Hides – Saddlery, Veg-Tan & Latigo Hides – Sample Cards – Polyure…

2. Mood Fabrics – Genuine Leather by the Yard

Domain: moodfabrics.com

Registered: 2001 (24 years)

Introduction: Buy Leather Fabric by the Yard | Genuine Leather Material

3. Leather Hide Store – Premium Upholstery Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Upholstery Leather Supplier, Leather Hide Store offers a wide range of premium upholstery hides in various colors and types. Key product details include: 100% genuine cowhide, available in colors such as Black, Blue, Brown & Gold, Dark Brown, Green, Grey, Metallic, Orange, Pink & Purple, Red & Burgundy, Tan & Beige, Taupe, White & Cream, and Yellow. Leather types include Aniline, Auto Distress, Fu…

4. Calico Corners – Faux Leather Fabrics

Domain: calicocorners.com

Registered: 1995 (30 years)

Introduction: Leather, suede, or faux fur fabrics add texture to a room’s décor. Aniline-dyed, high grade leather is sold by half or full hides in a variety of colors and textures. Available products include: Edison – Faux Leather Navy ($49.99, discounted to $37.49), Edison – Faux Leather Shiraz ($49.99, discounted to $37.49), Edison – Faux Leather Slate Grey ($49.99, discounted to $37.49), Edison – Faux Leathe…

5. American Leather – Leather Fabrics & Recliners

Domain: americanleather.com

Registered: 1997 (28 years)

Introduction: Leather Fabrics B2B Portal, Collections include Accent Chairs, Beds and Headboards, Classics Collection, Motion Classics Collection, Stationary Comfort Recliner Collection, Comfort Relax Collection, Comfort Sleeper Collection, Comfort Theatre Collection, Design Your Recline, Comfort Air Collection, L-Series, Elements Collection, Ottomans and Benches Collection, Personalize Collection, Re-invented …

6. Buyleatheronline – Italian Leather Hides

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Introduction: Italian leather supply store offering a wide range of leather hides for sale, including types such as Aniline, Brush Off, Crocodile Embossed, Crust, Distressed, Dry Milled, Embossed, Hair on Hide, Hand Buffered, Latigo, Metallic, Nappa, Nubuck, Patent, Pigmented, Printed, Pull Up, Suede, and more. Leather categorized by animal (e.g., Baby Calfskin, Buffalo, Cowhide, Crocodile, Exotic Leathers), co…

7. Fabric Wholesale Direct – Leather Fabrics

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Leather Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for leather fabric shop

What Are the Key Takeaways for B2B Buyers in the Leather Fabric Market?

In the dynamic landscape of leather sourcing, businesses must prioritize strategic partnerships to enhance their competitive edge. By focusing on quality and sustainability, buyers can secure premium leather products that align with evolving consumer preferences. The diverse range of leather options available—from upholstery to fashion—allows businesses to cater to varied market demands, ensuring a robust portfolio.

Illustrative image related to leather fabric shop

How Does Strategic Sourcing Impact Your Business?

Strategic sourcing not only streamlines procurement processes but also fosters long-term relationships with suppliers, which can lead to better pricing and reliability. In regions like Africa, South America, the Middle East, and Europe, leveraging local suppliers can significantly reduce lead times and shipping costs, enhancing overall operational efficiency.

What’s Next for International Buyers?

As the leather market continues to evolve, international buyers are encouraged to stay ahead of trends and innovations. Engaging with reputable suppliers and exploring new sourcing channels will be critical in capturing growth opportunities. By prioritizing strategic sourcing, businesses can not only meet current demands but also position themselves favorably for future challenges. Embrace the potential of leather sourcing today and elevate your business to new heights in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to leather fabric shop

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.