Introduction: Navigating the Global Market for leather jacket cowhide

Navigating the global market for leather jacket cowhide can pose significant challenges for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. As the demand for high-quality leather products continues to rise, sourcing premium cowhide that meets both aesthetic and durability standards becomes critical. This guide aims to equip international buyers with the insights needed to make informed purchasing decisions by exploring the diverse types of leather jackets available, their various applications, and essential considerations for supplier vetting.

Understanding the nuances of leather quality is vital; this guide delves into the differences between full grain, top grain, and lower-quality leathers, ensuring buyers can discern the best options for their markets. Additionally, it addresses cost factors associated with sourcing leather jackets, providing a comprehensive overview of price points and value assessments. By highlighting best practices in supplier selection and quality assurance, this guide empowers B2B buyers to navigate the complexities of the leather industry effectively.

Whether you are looking to enhance your retail offerings or seeking reliable suppliers for bulk purchases, this resource serves as your go-to reference for successful engagement in the leather jacket cowhide market. With actionable insights tailored to the unique needs of international buyers, you will be well-prepared to capitalize on opportunities in this dynamic sector.

Table Of Contents

- Top 6 Leather Jacket Cowhide Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather jacket cowhide

- Understanding leather jacket cowhide Types and Variations

- Key Industrial Applications of leather jacket cowhide

- 3 Common User Pain Points for ‘leather jacket cowhide’ & Their Solutions

- Strategic Material Selection Guide for leather jacket cowhide

- In-depth Look: Manufacturing Processes and Quality Assurance for leather jacket cowhide

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather jacket cowhide’

- Comprehensive Cost and Pricing Analysis for leather jacket cowhide Sourcing

- Alternatives Analysis: Comparing leather jacket cowhide With Other Solutions

- Essential Technical Properties and Trade Terminology for leather jacket cowhide

- Navigating Market Dynamics and Sourcing Trends in the leather jacket cowhide Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather jacket cowhide

- Strategic Sourcing Conclusion and Outlook for leather jacket cowhide

- Important Disclaimer & Terms of Use

Understanding leather jacket cowhide Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Cowhide | Retains natural grain, strong, develops patina | High-end fashion, luxury brands | Pros: Durable, unique character; Cons: Higher cost, requires care. |

| Top Grain Cowhide | Sanded surface for smooth texture, less durable | Mid-range apparel, fashion retail | Pros: Soft feel, more affordable; Cons: Less durable than full grain. |

| Corrected Grain | Heavily processed, uniform appearance | Budget-friendly products, mass-market retail | Pros: Cost-effective; Cons: Lacks natural character, less breathable. |

| Bonded Leather | Made from leather scraps, glued together | Low-cost fashion items, promotional products | Pros: Very affordable; Cons: Short lifespan, less aesthetic appeal. |

| Vintage Cowhide | Distressed look, often pre-aged | Niche markets, retro-style fashion | Pros: Unique aesthetic; Cons: Inconsistent quality, may require special care. |

What are the Characteristics of Full Grain Cowhide Jackets?

Full grain cowhide is the highest quality leather available, characterized by its natural grain and durability. This type of leather retains the original surface of the hide, showcasing natural imperfections that add to its character. B2B buyers should consider full grain cowhide for high-end fashion brands where product longevity and luxury appeal are paramount. While it commands a higher price, its durability and ability to develop a beautiful patina over time justify the investment.

How Does Top Grain Cowhide Differ from Full Grain?

Top grain cowhide is sanded and treated to create a smoother surface, making it softer and more pliable. This type of leather is suitable for mid-range apparel, appealing to retailers looking for quality without the premium price of full grain. While it offers a luxurious feel, buyers should note that it is less durable than full grain, making it essential to assess target markets and price points when sourcing.

What Should Buyers Know About Corrected Grain Leather?

Corrected grain leather undergoes extensive processing to achieve a uniform appearance, often resulting in a more affordable product. It is ideal for budget-friendly fashion items and mass-market retail applications. However, its heavily processed nature means it lacks the unique character and breathability of higher-quality leathers. Buyers should weigh the cost savings against potential consumer perceptions of quality.

Why Choose Bonded Leather for Promotional Products?

Bonded leather is crafted from leather scraps that are glued together, making it the most economical option. This type is often used in promotional products and low-cost fashion items. While it is very affordable, it has a significantly shorter lifespan and lacks the aesthetic appeal of higher-quality leathers. B2B buyers should consider bonding leather only for short-term use or disposable items.

What are the Unique Features of Vintage Cowhide Jackets?

Vintage cowhide jackets feature a distressed look, often created through pre-aging techniques. This type appeals to niche markets seeking retro-style fashion. While vintage cowhide can offer a unique aesthetic, buyers should be aware of the potential for inconsistent quality and the need for specific care to maintain its appearance. Understanding the target audience’s preferences is crucial when sourcing vintage leather products.

Key Industrial Applications of leather jacket cowhide

| Industry/Sector | Specific Application of leather jacket cowhide | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-end leather jackets for retail collections | Enhances brand image with premium products | Ensure compliance with international leather quality standards; consider sourcing from established tanneries. |

| Automotive | Upholstery for luxury vehicles | Adds luxury appeal and durability to vehicle interiors | Verify leather grades; assess environmental certifications for sustainability. |

| Outdoor and Recreation | Protective gear for motorcyclists | Provides safety and comfort in extreme conditions | Look for abrasion resistance and flexibility; consider local regulations for protective gear standards. |

| Military and Tactical Gear | Combat jackets and uniforms | Ensures durability and reliability in harsh environments | Source from suppliers with experience in military specifications; ensure compliance with defense procurement standards. |

| E-commerce and Retail | Online sales of leather jackets | Expands market reach and caters to diverse customer bases | Evaluate logistics for international shipping; assess the demand for customization and personalization options. |

How is leather jacket cowhide utilized in the fashion and apparel industry?

In the fashion and apparel sector, leather jacket cowhide is primarily used to create high-end jackets that appeal to consumers seeking luxury and style. These jackets not only enhance a brand’s image but also offer durability and longevity, making them a worthwhile investment for retailers. International B2B buyers should prioritize sourcing from reputable tanneries that adhere to strict quality standards and ethical practices, ensuring that the leather meets both aesthetic and functional requirements.

What role does leather jacket cowhide play in the automotive industry?

In the automotive industry, leather jacket cowhide is utilized for upholstery in luxury vehicles, providing an upscale look and feel to car interiors. The durability of cowhide leather ensures that it withstands daily wear and tear while enhancing the overall aesthetic of the vehicle. Buyers in this sector must consider the grade of leather used, as well as environmental certifications, to align with sustainability goals and consumer expectations for eco-friendly materials.

Illustrative image related to leather jacket cowhide

How is leather jacket cowhide important in outdoor and recreational applications?

Leather jacket cowhide is essential in the outdoor and recreation industry, particularly for protective gear designed for motorcyclists and outdoor enthusiasts. These jackets provide vital protection against abrasions and harsh weather conditions, enhancing safety and comfort for users. B2B buyers should focus on sourcing leather that offers abrasion resistance and flexibility, while also adhering to local regulations that govern protective gear standards.

In what ways is leather jacket cowhide used for military and tactical gear?

In military and tactical applications, leather jacket cowhide is employed to manufacture combat jackets and uniforms that require exceptional durability and reliability in challenging environments. The material’s strength and resilience make it suitable for use in various combat scenarios. Buyers in this sector should ensure that suppliers have a proven track record in meeting military specifications and compliance with defense procurement standards to guarantee product reliability.

How can leather jacket cowhide benefit e-commerce and retail businesses?

For e-commerce and retail businesses, leather jacket cowhide is a popular choice for online sales, allowing companies to expand their market reach and cater to a diverse customer base. The demand for customized and personalized leather products is on the rise, making it essential for businesses to evaluate logistics for international shipping and assess consumer preferences. Establishing strong supplier relationships can enhance product offerings and improve customer satisfaction.

3 Common User Pain Points for ‘leather jacket cowhide’ & Their Solutions

Scenario 1: Sourcing High-Quality Cowhide Leather Jackets

The Problem: B2B buyers often struggle with sourcing high-quality cowhide leather jackets that meet their specific requirements for durability, style, and cost-effectiveness. In regions such as Africa and South America, buyers may face challenges related to inconsistent quality and lack of transparent supply chains. This uncertainty can lead to financial losses and customer dissatisfaction if the products do not meet market expectations.

The Solution: To overcome this challenge, B2B buyers should prioritize sourcing from reputable suppliers who offer certifications for leather quality, such as full grain or top grain leather. Establishing strong relationships with manufacturers who have a proven track record in producing high-quality leather goods is essential. Conduct thorough audits of potential suppliers, examining their production processes and sourcing of materials. Additionally, consider requesting samples and conducting quality tests to evaluate the leather’s texture, durability, and appearance before making bulk orders. This proactive approach can significantly mitigate risks associated with quality inconsistencies.

Illustrative image related to leather jacket cowhide

Scenario 2: Understanding Leather Grades and Quality

The Problem: Many B2B buyers are unaware of the different grades of leather, which can lead to confusion and poor purchasing decisions. For instance, a buyer may mistakenly purchase genuine leather, believing it to be as durable as full grain leather, only to find that it wears out quickly and does not meet customer expectations. This can result in increased return rates and a damaged reputation.

The Solution: To navigate the complexities of leather grading, B2B buyers should invest in educational resources that explain the characteristics of various leather types. Providing training sessions or workshops for purchasing teams can empower them to make informed decisions. Buyers should focus on understanding the key differences between full grain, top grain, and lower-grade leathers. Additionally, creating a checklist for evaluating leather quality—focusing on appearance, texture, and price—can help streamline the purchasing process. This knowledge will not only enhance product selection but also improve overall customer satisfaction.

Scenario 3: Maintaining and Caring for Leather Jackets

The Problem: Leather jackets require specific maintenance to ensure their longevity, yet many buyers overlook this aspect when sourcing products. Poor maintenance can lead to premature wear and tear, resulting in customer complaints and returns. In regions with varying climates, such as the Middle East and Europe, the effects of humidity and temperature on leather can complicate this issue further.

The Solution: B2B buyers should incorporate care instructions into their sales strategies, educating customers about the proper maintenance of cowhide leather jackets. This could include providing care kits alongside purchases, which might contain leather cleaners, conditioners, and instructions for cleaning and storage. Additionally, partnering with suppliers who offer care education materials can enhance the value proposition of the products. By fostering a culture of care and maintenance, buyers can ensure that their customers are equipped to protect their investments, leading to higher customer retention rates and reduced returns.

Illustrative image related to leather jacket cowhide

Strategic Material Selection Guide for leather jacket cowhide

What Are the Key Properties of Full Grain Cowhide for Leather Jackets?

Full grain cowhide is the highest quality leather available, known for its durability and natural appearance. It retains the original grain of the hide, which gives it a unique texture and character. This type of leather is resistant to wear and tear, making it ideal for jackets that need to withstand various environmental conditions. Full grain leather also develops a patina over time, enhancing its aesthetic appeal. From a performance perspective, full grain cowhide can handle temperature fluctuations and is resistant to moisture, though it should be treated with care to maintain its integrity.

What Are the Advantages and Disadvantages of Top Grain Leather in Jacket Manufacturing?

Top grain leather, while slightly less durable than full grain, offers a more uniform appearance due to the sanding process that removes imperfections. This type of leather is more affordable and easier to work with, making it a popular choice among manufacturers. However, it lacks the same level of breathability and aging characteristics as full grain leather. From a B2B perspective, buyers may find that top grain leather is suitable for fashion-oriented markets where aesthetics are prioritized over ruggedness. It is important to note that while top grain leather is generally more cost-effective, it may not meet the durability expectations of high-performance applications.

How Does Genuine Leather Compare to Other Cowhide Options for Jackets?

Genuine leather, often referred to as corrected grain leather, is made from the lower layers of the hide. It is typically less expensive and more widely available, making it an attractive option for budget-conscious buyers. However, it is less durable and may not provide the same level of comfort or longevity as full grain or top grain leather. For international buyers, particularly in developing markets, genuine leather can be an appealing choice for entry-level products. However, it is crucial to manage expectations regarding its performance and lifespan compared to higher-grade leathers.

What Specific Considerations Should International B2B Buyers Keep in Mind When Selecting Leather Materials?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider compliance with local regulations and standards such as ASTM, DIN, or JIS. Preferences for leather quality may vary significantly based on regional market demands. For instance, European markets often favor full grain leather for its durability and aesthetic qualities, while South American buyers might prioritize cost-effectiveness. Additionally, understanding the environmental impact of leather production and sourcing practices can enhance brand reputation and meet consumer expectations for sustainability.

| Material | Typical Use Case for leather jacket cowhide | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Cowhide | High-end leather jackets | Exceptional durability and unique patina | Higher cost and requires careful maintenance | High |

| Top Grain Leather | Fashion-oriented leather jackets | More affordable and easier to manufacture | Less durable and may not age as well | Medium |

| Genuine Leather | Entry-level leather jackets | Cost-effective and widely available | Lower durability and comfort | Low |

| Bonded Leather | Budget-friendly leather products | Very low cost and easy to produce | Lacks durability and can wear out quickly | Low |

This analysis provides B2B buyers with a comprehensive understanding of the various materials used in leather jacket manufacturing, enabling them to make informed decisions that align with their market needs and customer expectations.

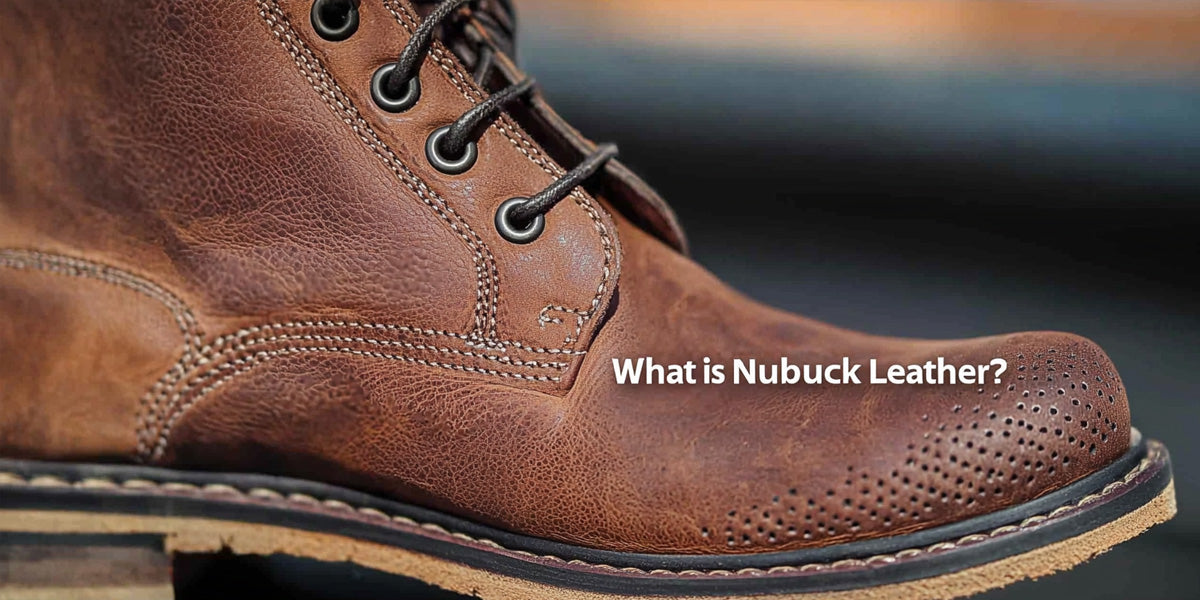

Illustrative image related to leather jacket cowhide

In-depth Look: Manufacturing Processes and Quality Assurance for leather jacket cowhide

What Are the Main Stages of the Manufacturing Process for Cowhide Leather Jackets?

The manufacturing process for cowhide leather jackets involves several critical stages, each requiring specialized techniques to ensure high-quality output. Understanding these stages can help B2B buyers from diverse regions evaluate suppliers effectively.

Material Preparation: How Is Cowhide Processed?

The journey of a cowhide leather jacket begins with the careful selection of raw materials. Cowhides are typically sourced from cattle raised in regions known for quality leather production. Once sourced, the hides undergo a tanning process to transform them from raw skin into durable leather.

Tanning Techniques:

– Vegetable Tanning: Utilizes natural tannins from plant materials, resulting in a softer, more environmentally friendly leather.

– Chrome Tanning: Involves chromium salts, yielding a more water-resistant and quicker tanning process, but may have environmental concerns.

Buyers should inquire about the tanning methods used by suppliers, as these can significantly affect the leather’s quality, durability, and environmental impact.

Illustrative image related to leather jacket cowhide

How Are Cowhide Leather Jackets Formed?

Once the cowhide is tanned, it is cut into patterns that will form the various components of the jacket. This step often utilizes advanced cutting technologies, including laser cutting, which ensures precision and minimizes waste.

Key Techniques:

– Die Cutting: A traditional method that uses molds to cut leather into specified shapes.

– Computer Numerical Control (CNC) Cutting: Offers higher accuracy and efficiency, especially for complex designs.

After cutting, the individual pieces are prepared for assembly. This preparation may include edge finishing and hole punching, which are essential for the assembly phase.

What Does the Assembly Process Entail?

The assembly of cowhide jackets involves stitching the various components together, often employing high-strength threads to enhance durability. This stage is critical for ensuring that the jacket maintains its shape and longevity.

Common Techniques:

– Double Stitching: Provides extra strength, especially in stress areas like seams and armholes.

– Reinforcement: Areas subject to wear, such as pockets and zippers, may receive additional reinforcement to prevent tearing.

The assembly phase also includes attaching zippers, buttons, and any additional hardware, which are crucial for the jacket’s functionality and aesthetic appeal.

What Are the Finishing Touches in Leather Jacket Manufacturing?

Finishing is the final stage in the manufacturing process, where the jacket is treated to enhance its appearance and durability. This may involve dyeing, conditioning, and applying protective coatings.

Finishing Techniques:

– Dyeing: Can be done through immersion or spraying, providing the desired color while maintaining the leather’s natural texture.

– Conditioning: Involves applying oils or waxes to ensure the leather remains supple and resistant to moisture.

Illustrative image related to leather jacket cowhide

At this stage, quality control (QC) checks are also performed to ensure that the final product meets both aesthetic and functional standards.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is crucial in the leather goods industry, particularly for B2B buyers who need to ensure product consistency and reliability.

What Are the International Standards Relevant to Leather Jacket Manufacturing?

International standards such as ISO 9001 provide frameworks for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. Other relevant certifications include:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Particularly relevant for leather used in industrial applications, ensuring that products meet specific performance criteria.

Buyers should verify that their suppliers hold these certifications, as they reflect adherence to international quality standards.

What Are the Key QC Checkpoints During the Manufacturing Process?

Quality control should be integrated into every stage of the manufacturing process. Key checkpoints typically include:

Illustrative image related to leather jacket cowhide

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing monitoring during the manufacturing stages, including checks on stitching quality and material integrity.

- Final Quality Control (FQC): Comprehensive evaluation of the finished product, including visual inspections and functional testing.

These checkpoints help identify defects early and ensure that only high-quality products reach the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must perform due diligence to verify supplier quality control practices. Here are actionable steps:

What Audits and Reports Should Buyers Request?

Buyers should request recent audit reports from suppliers that detail their quality control processes. Third-party audits can provide an unbiased assessment of compliance with international standards.

- Supplier Audits: Regularly scheduled audits of the manufacturing facilities can reveal operational efficiency and adherence to quality standards.

- Documentation: Request documentation of quality control procedures, including testing methods and results.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can provide additional assurance regarding product quality. These services can offer:

- Pre-shipment Inspections: Verification of product quality before shipment to ensure compliance with agreed specifications.

- Laboratory Testing: Analysis of materials to confirm they meet safety and performance standards.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

Illustrative image related to leather jacket cowhide

- Regulatory Compliance: Different regions may have varying regulations regarding leather products. Understanding these requirements is crucial for avoiding import issues.

- Cultural Considerations: Be aware of cultural expectations regarding product quality, which can vary significantly by region.

Conclusion: Ensuring Quality in Cowhide Leather Jacket Manufacturing

B2B buyers of cowhide leather jackets should prioritize understanding the manufacturing processes and quality assurance practices of their suppliers. By focusing on each stage of production, verifying compliance with international standards, and utilizing third-party inspections, buyers can ensure they receive high-quality products that meet their specific needs. This diligence not only enhances supply chain reliability but also fosters long-term business relationships built on trust and quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather jacket cowhide’

Introduction

Navigating the procurement of cowhide leather jackets requires a strategic approach to ensure quality and cost-effectiveness. This checklist serves as a practical guide for B2B buyers, detailing essential steps to source high-quality leather jackets that meet your business needs and standards. By following these steps, you can streamline your sourcing process and make informed decisions.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the leather jackets you intend to purchase. This includes material type, design features, sizes, and any specific craftsmanship details. Having well-defined criteria helps in communicating effectively with suppliers and ensures that you receive products that align with your business requirements.

- Material Quality: Specify whether you want full-grain or top-grain cowhide, as these grades affect durability and appearance.

- Design Elements: Include information on styles (e.g., bomber, biker, vintage) and functional features (e.g., pockets, lining).

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify potential suppliers who specialize in cowhide leather jackets. A good supplier should have a solid reputation and experience in the industry.

Illustrative image related to leather jacket cowhide

- Online Reviews: Look for testimonials and case studies that showcase their reliability and product quality.

- Industry Connections: Engage with industry networks or trade shows to gather recommendations on reputable suppliers.

Step 3: Evaluate Supplier Certifications

Verify the certifications and standards that suppliers adhere to in their production processes. This step is crucial in ensuring that you are sourcing from companies that prioritize quality and sustainability.

- Quality Assurance: Look for ISO certifications or similar quality management standards that indicate adherence to international quality benchmarks.

- Sustainability Practices: Inquire about sourcing practices and the environmental impact of their leather production.

Step 4: Request Samples

Before making a large order, always request samples of the leather jackets. This allows you to assess the quality, craftsmanship, and overall feel of the product firsthand.

- Sample Evaluation: Examine the sample for texture, flexibility, and any imperfections. High-quality leather should feel soft yet durable.

- Production Consistency: Ensure that the samples reflect the quality you can expect in bulk orders.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to secure favorable pricing and terms. This step is vital for maintaining profit margins and ensuring a sustainable supply chain.

- Bulk Discounts: Discuss potential discounts for larger orders, as many suppliers are willing to negotiate.

- Payment Terms: Clarify payment options and terms, ensuring they align with your cash flow management practices.

Step 6: Confirm Production Lead Times

Establish clear timelines for production and delivery. Understanding lead times helps in planning your inventory and meeting customer demand effectively.

- Production Capacity: Inquire about the supplier’s capacity to handle your order volume within your desired timeframe.

- Contingency Plans: Discuss what measures the supplier has in place for potential delays to avoid disruptions in your supply chain.

Step 7: Establish a Communication Plan

Develop a communication strategy for ongoing interactions with your supplier. Effective communication is essential for addressing any issues that may arise during production or delivery.

Illustrative image related to leather jacket cowhide

- Regular Updates: Schedule periodic check-ins to monitor progress and resolve any concerns promptly.

- Feedback Loop: Create a mechanism for providing feedback on the products received to ensure continuous improvement in quality.

By following this step-by-step checklist, B2B buyers can confidently navigate the sourcing process for cowhide leather jackets, ensuring they procure high-quality products that meet market demands.

Comprehensive Cost and Pricing Analysis for leather jacket cowhide Sourcing

What Are the Key Cost Components in Leather Jacket Cowhide Sourcing?

When sourcing leather jackets made from cowhide, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality of cowhide is a significant cost driver. Full grain leather, known for its durability and aesthetic appeal, commands a higher price than lower grades like corrected grain or bonded leather. The sourcing of high-quality hides directly impacts the final product’s pricing.

-

Labor: Skilled craftsmanship is essential for producing high-quality leather jackets. Labor costs can vary significantly based on the region. For instance, countries with lower labor costs may offer competitive pricing, but this can sometimes compromise quality.

-

Manufacturing Overhead: This includes the costs associated with running a manufacturing facility, such as utilities, rent, and equipment maintenance. Efficient operations can help keep these costs in check, but they still contribute to the overall pricing.

-

Tooling: The initial investment in tooling for production, such as cutting dies and sewing machines, is amortized over the production run. Custom designs may require additional tooling costs, which should be factored into the pricing strategy.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the final product meets specified standards. While this adds to the cost, it is essential for maintaining brand reputation and customer satisfaction.

-

Logistics: Transportation costs, including shipping and handling, are critical, especially for international buyers. The choice of shipping method and destination can greatly affect overall costs.

-

Margin: Manufacturers and suppliers typically add a profit margin on top of the production costs. This margin can vary based on market demand, competition, and brand positioning.

What Influences Pricing in Leather Jacket Cowhide Sourcing?

Several factors can significantly influence the pricing of cowhide leather jackets:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often qualify for discounts, reducing the per-unit price. However, smaller orders may not benefit from the same economies of scale.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Material Quality and Certifications: The presence of certifications for sustainable sourcing or compliance with international quality standards can impact pricing. High-quality materials with certifications are often more expensive but can enhance product value.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can affect pricing. Established suppliers with a track record of quality may charge more, but they often provide better assurance against defects and delays.

-

Incoterms: The terms of trade (e.g., FOB, CIF) dictate who bears the cost and risk during shipping, which can affect the total price. Understanding these terms is vital for budgeting.

What Are Effective Buyer Tips for Negotiating Leather Jacket Cowhide Prices?

For international buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation outcomes:

Illustrative image related to leather jacket cowhide

-

Negotiate from a Position of Knowledge: Familiarize yourself with the market prices for cowhide leather jackets. Understanding the cost structure allows for informed negotiations.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with quality, maintenance, and potential resale value. High-quality jackets may have a higher upfront cost but lower TCO due to durability.

-

Leverage Relationships: Building a strong relationship with suppliers can lead to better pricing and terms. Long-term partnerships often yield favorable conditions.

-

Be Open to Flexibility: If a supplier cannot meet your price, explore alternative options such as adjusting order volumes, specifications, or payment terms to reach a mutually beneficial agreement.

-

Stay Informed About Market Trends: Price fluctuations can occur due to changes in material costs, labor rates, or global supply chain issues. Keeping abreast of these trends can provide leverage during negotiations.

Disclaimer on Indicative Prices

Prices for leather jackets made from cowhide can vary widely based on the aforementioned factors. It is crucial for buyers to obtain detailed quotations from multiple suppliers and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing leather jacket cowhide With Other Solutions

Introduction to Alternatives for Leather Jacket Cowhide

When sourcing leather jackets, particularly cowhide options, B2B buyers often explore various alternatives that may suit their business needs better. Understanding these alternatives helps in making informed decisions regarding product offerings, customer preferences, and market competitiveness. This analysis will compare leather jacket cowhide against synthetic leather and lambskin leather, providing insights into their respective attributes and suitability for different markets.

Comparison Table

| Comparison Aspect | Leather Jacket Cowhide | Synthetic Leather | Lambskin Leather |

|---|---|---|---|

| Performance | Durable, ages well, high breathability | Water-resistant, less durable | Soft, luxurious feel, less durable |

| Cost | Higher initial investment | Generally lower price | Higher than synthetic, lower than cowhide |

| Ease of Implementation | Requires skilled craftsmanship | Easier to mass-produce | Requires skilled craftsmanship |

| Maintenance | Needs regular care, prone to stains | Easy to clean, less upkeep | Requires careful handling, sensitive to wear |

| Best Use Case | High-end fashion, outdoor wear | Budget-friendly options, casual wear | Luxury fashion, high-end garments |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Synthetic Leather?

Synthetic leather, often made from polyurethane or PVC, offers several benefits for B2B buyers, particularly in cost-effectiveness. Its lower price point makes it an attractive option for businesses targeting budget-conscious consumers. Additionally, synthetic leather is generally easier to maintain, as it can be wiped clean and is resistant to water damage. However, it tends to lack the durability and breathability of cowhide leather, which may affect its performance in harsher conditions. For brands focused on sustainability, synthetic leather can also be marketed as a cruelty-free alternative, though the environmental impact of its production may raise concerns.

Illustrative image related to leather jacket cowhide

Why Consider Lambskin Leather as an Alternative?

Lambskin leather is renowned for its softness and luxurious appeal, making it a popular choice in high-end fashion markets. Its lightweight nature allows for comfortable wear, which is especially advantageous for tailored garments. However, lambskin is not as durable as cowhide and is more susceptible to scratches and damage. This fragility may deter buyers looking for long-lasting products, especially in sectors where wear and tear are common. Nevertheless, its unique texture and luxurious feel can justify the higher price point, attracting a clientele willing to invest in premium offerings.

Conclusion: How Can B2B Buyers Choose the Right Leather Jacket Solution?

In choosing the right leather jacket solution, B2B buyers must consider their target market and the specific needs of their customers. Cowhide leather jackets offer durability and a timeless aesthetic, making them ideal for outdoor and rugged use, but they come with a higher cost. Synthetic leather provides a budget-friendly option with easy maintenance, suitable for casual wear, while lambskin leather appeals to luxury markets with its softness but requires careful handling. By weighing these factors against their business goals, buyers can select the most appropriate leather solution to meet their strategic objectives and customer expectations.

Essential Technical Properties and Trade Terminology for leather jacket cowhide

What Are the Key Technical Properties of Leather Jacket Cowhide?

When sourcing cowhide leather for jackets, understanding its technical properties is vital for ensuring quality and longevity. Here are some essential specifications:

-

Material Grade

Leather is graded based on its quality. The highest quality is Full Grain, followed by Top Grain. Full Grain leather retains the natural surface and imperfections, leading to a unique look over time. In contrast, lower grades like Genuine Leather and Bonded Leather are processed and can lack durability. For B2B buyers, selecting the right grade is crucial for product positioning and customer satisfaction. -

Thickness

The thickness of cowhide leather is often measured in ounces (oz) or millimeters (mm). A typical leather jacket might range from 1.1 mm to 1.5 mm thick. Thicker leather offers better durability and protection, making it ideal for motorcycle jackets or outdoor wear. Understanding thickness helps buyers assess the jacket’s intended use and market appeal. -

Tannage Process

The method used to tan leather, such as vegetable tanning or chrome tanning, significantly affects its properties. Vegetable-tanned leather is eco-friendly and develops a rich patina, while chrome-tanned leather is softer and more water-resistant. This distinction impacts the leather’s feel, longevity, and suitability for specific products, guiding buyers in their sourcing decisions. -

Finish and Treatment

The finish applied to leather can vary, including aniline, semi-aniline, or pigmented finishes. Aniline leather shows natural grain and is soft, while pigmented leather is more durable and resistant to stains. Buyers should consider the finish based on the target market and desired aesthetic, as it influences both price and consumer preferences. -

Weight

Leather weight is an important factor, typically measured in grams per square meter (gsm). Heavier weights are generally more durable, suitable for outerwear, while lighter weights may be used for fashion pieces. Understanding weight helps buyers align their product offerings with consumer expectations for durability and style.

What Are Common Trade Terms in the Leather Jacket Cowhide Industry?

Navigating the leather industry requires familiarity with specific jargon. Here are key terms that B2B buyers should understand:

Illustrative image related to leather jacket cowhide

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce goods that are marketed under another brand’s name. In the leather industry, this often applies to manufacturers that create leather jackets for various brands. Understanding OEM relationships is crucial for buyers looking to establish partnerships and maintain quality control. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In leather sourcing, MOQs can vary based on the supplier and the specifics of the leather. Knowing the MOQ helps buyers plan their inventory and manage costs effectively. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing information for specific products or materials. In the leather industry, using an RFQ can streamline the procurement process, ensuring buyers receive competitive pricing and terms from multiple sources. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, such as shipping costs, insurance, and risk transfer. Familiarity with these terms is essential for B2B buyers to negotiate contracts and understand their obligations in cross-border transactions. -

Lead Time

Lead time is the period between placing an order and receiving the product. In the leather industry, this can be affected by factors such as production capacity and shipping logistics. Understanding lead times is critical for inventory management and meeting customer demand. -

Finish Quality

This term refers to the final surface treatment applied to the leather, affecting its appearance and durability. High finish quality indicates a well-made product, essential for maintaining brand reputation in competitive markets. Buyers should evaluate finish quality to ensure alignment with customer expectations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing leather jacket cowhide, ensuring they meet market demands and maintain product quality.

Navigating Market Dynamics and Sourcing Trends in the leather jacket cowhide Sector

What Are the Current Market Dynamics and Key Trends in the Leather Jacket Cowhide Sector?

The leather jacket cowhide market is experiencing significant growth driven by a resurgence in demand for high-quality, durable outerwear. Key trends shaping this market include the increasing popularity of vintage and retro styles, which appeal to both younger and older demographics. In addition, the rise of online retail platforms has facilitated easier access to international markets, allowing suppliers to connect with buyers in Africa, South America, the Middle East, and Europe.

Emerging technologies, such as digital design tools and supply chain management software, are transforming how manufacturers produce and distribute leather jackets. For international B2B buyers, this means greater customization options and faster turnaround times. Furthermore, advancements in e-commerce logistics are making it more feasible for businesses to source leather jackets from global suppliers, enhancing competitiveness in local markets.

As sustainability becomes a priority for consumers, buyers are increasingly seeking products that not only meet quality standards but also align with ethical practices. This dynamic is particularly pronounced in European markets, where environmentally-friendly leather production methods are gaining traction, influencing sourcing decisions across continents.

How Is Sustainability and Ethical Sourcing Impacting the Leather Jacket Cowhide Industry?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the leather jacket cowhide sector. The environmental impact of leather production, including water usage and chemical waste, necessitates a shift toward more sustainable practices. Buyers are urged to prioritize suppliers who implement eco-friendly tanning processes and use organic materials, as these practices not only reduce environmental harm but also appeal to a growing consumer base that values sustainability.

The importance of ethical supply chains cannot be overstated. International buyers are increasingly held accountable for the sourcing practices of their suppliers, making it essential to verify that all aspects of production adhere to fair labor standards. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are vital indicators of ethical sourcing and can enhance a company’s reputation in the market.

Incorporating sustainability into sourcing strategies is not merely a trend; it is becoming a fundamental expectation. Buyers who align their procurement practices with sustainability goals stand to gain a competitive edge in an evolving marketplace.

What Is the Historical Context of Leather Jacket Cowhide Production?

The history of leather jacket cowhide production dates back centuries, with leather being a staple material in clothing due to its durability and protective qualities. Traditionally, cowhide was favored for its strength and versatility, making it a preferred choice for outerwear, particularly in regions with harsh climates.

The evolution of leather production techniques, from primitive tanning methods to modern practices, has significantly impacted the quality and variety of leather jackets available today. In recent decades, the sector has seen a shift towards innovative design and manufacturing processes, reflecting changing consumer preferences and technological advancements.

As the market continues to evolve, understanding this historical context provides valuable insights for international B2B buyers looking to navigate sourcing trends and make informed purchasing decisions.

Illustrative image related to leather jacket cowhide

Frequently Asked Questions (FAQs) for B2B Buyers of leather jacket cowhide

-

How do I determine the quality of cowhide leather jackets?

To assess the quality of cowhide leather jackets, look for full grain or top grain leather, as these are the highest quality grades. Inspect the texture and appearance; high-quality leather should exhibit natural imperfections and feel soft yet resilient. Additionally, consider the craftsmanship—check for even stitching and well-finished edges. Lastly, a higher price point often indicates better quality materials and construction, so be wary of deals that seem too good to be true. -

What are the customization options available for leather jackets?

Customization options for leather jackets typically include choice of leather type, color, lining materials, and design features such as pockets and zippers. Many suppliers offer the ability to add logos or embroidery, making it possible to create jackets that align with your brand identity. When discussing customization, ensure you communicate your specific requirements clearly and confirm any associated costs or minimum order quantities (MOQs) with your supplier. -

What is the minimum order quantity (MOQ) for cowhide leather jackets?

MOQs for cowhide leather jackets can vary significantly among suppliers, often ranging from 50 to 200 units. Factors influencing MOQ include the supplier’s production capacity, the complexity of the customization, and the type of leather used. It’s essential to clarify the MOQ with potential suppliers early in negotiations to ensure it aligns with your business needs and budget. -

What payment terms should I expect when sourcing leather jackets internationally?

Payment terms for international sourcing of leather jackets can vary. Common practices include a deposit (typically 30-50%) upfront, with the balance due upon shipment or delivery. Some suppliers may also offer letter of credit options for larger orders. Always negotiate terms that are favorable and ensure they are clearly documented in your purchase agreement to avoid misunderstandings. -

How do I vet suppliers for cowhide leather jackets?

To vet suppliers, start by checking their credentials, such as business licenses and industry certifications. Request samples to assess product quality and consistency. Additionally, seek customer references or reviews to gauge reliability and customer service. It’s also wise to visit their facilities if possible or conduct a virtual audit to inspect their manufacturing processes and working conditions. -

What logistics should I consider when importing leather jackets?

When importing leather jackets, consider factors such as shipping methods, customs duties, and lead times. Determine whether you will use air or sea freight based on urgency and cost. Familiarize yourself with import regulations in your country, including any tariffs applicable to leather goods. Partnering with a logistics provider experienced in international shipping can streamline this process and ensure compliance. -

How can I ensure quality assurance (QA) for my leather jacket orders?

Implementing a robust QA process involves setting clear quality standards and conducting inspections at various stages of production. Consider hiring a third-party inspection service to evaluate the products before shipment. Additionally, establish a return policy and warranty terms with your supplier to address any quality issues that may arise post-delivery. -

What are the trends in leather jacket designs that I should be aware of?

Current trends in leather jacket designs include a focus on sustainable materials and production methods, vintage styles, and multifunctional features. Popular styles include bomber jackets, moto jackets, and oversized fits. Keeping abreast of fashion trends can help you align your offerings with market demands, attracting a wider customer base and enhancing your competitive edge in the B2B market.

Top 6 Leather Jacket Cowhide Manufacturers & Suppliers List

1. Buffalo Jackson – Legacy Men’s Leather Jacket

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Buffalo Jackson offers a range of cow leather jackets for men, crafted from full grain leather, which is the highest grade of leather quality available. The jackets are designed to develop a unique patina over time, enhancing their character. Key products include the Legacy men’s leather jacket, featuring a vintage flight design with brown full grain leather, zippered sleeve cuffs, chest pockets, …

2. The Jacket Maker – Full-grain Cowhide Leather Jackets

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Full-grain Cowhide Leather Jackets for Men | The Jacket Maker. Price range: $220.00 – $395.00 USD. Available sizes: XS, S, M, L, XL, 2XL, 3XL, 4XL. Material: Cowhide Leather. Types of jackets include: Biker Jackets, Bomber Jackets, Hooded Leather Jackets, Trench Coats, Leather Blazers, and more. Customization options available.

3. Aero Leather – Horsehide and Cowhide Jackets

Domain: aeroleatherclothing.com

Registered: 1997 (28 years)

Introduction: Horsehide and cowhide are two popular types of leather used for jackets. Cowhide is more widely available, flexible, lighter in weight, and has more natural blemishes. It comes from female cows used for breeding or milk production. Horsehide, on the other hand, is less common, known for its strength, durability, and abrasion resistance. It has a coarser grain, significant variations in thickness, …

4. Taylor’s Leatherwear – Pittsburgh Cowhide Leather Motorcycle Jacket

Domain: taylorsleatherwear.com

Registered: 1997 (28 years)

Introduction: Product Name: Pittsburgh Cowhide Leather Motorcycle Jacket

Brand: Taylor’s Leatherwear, Inc.

Price: $489.00

Best Seller: Yes

Original Use: Worn by the Pittsburgh PA Police Department

Material: Soft and Durable Top Grain Leather (Drum Dyed Black Cowhide)

Lining: 3M™ Thinsulate™ Zip-out Quilted Liner

Style Name: Pittsburgh

Style Number: 4473Z

Length of Size Large Regular: Approx 25″

Features:

– All…

5. LeatherCult – Cowhide & Sheepskin Jackets

Domain: leathercult.com

Registered: 2010 (15 years)

Introduction: Cowhide leather jackets are known for their durability, strength, and resistance to wear and tear, making them ideal for rugged use. They offer a classic look and are often heavier than sheepskin jackets. On the other hand, sheepskin leather jackets are lighter, softer, and more comfortable, providing a luxurious feel. They are less durable than cowhide but offer excellent insulation and warmth. T…

6. MARA Leather – Cowhide Jackets

Domain: maraleatherstore.com

Registered: 2022 (3 years)

Introduction: Cow Skin Jacket – MARA Leather

– Product Types: Men’s Genuine Cowhide Skin Leather Motorcycle Jacket, Men’s Cowhide Leather Jacket Genuine Pony Skin, Men’s Cowhide Western Fringe Jacket, Men’s Cow Skin Hair On Brown Leather Vest, Men’s Hair On Cowhide Vest, Men’s White Hair On Cowhide Jacket, Men’s Hair On Pony Skin Leather Jacket, Men’s Hair On Cowhide Leather Jacket

– Price Range: $184.95 – $339…

Strategic Sourcing Conclusion and Outlook for leather jacket cowhide

In conclusion, the strategic sourcing of cowhide leather jackets represents a significant opportunity for international B2B buyers. By understanding the diverse grades of leather, particularly the superiority of full grain cowhide, buyers can ensure they are investing in high-quality products that not only meet customer expectations but also deliver long-term value. The importance of proper care and maintenance of these jackets cannot be overstated, as it prolongs the life of the product and enhances customer satisfaction.

Moreover, as global markets continue to evolve, suppliers who prioritize quality craftsmanship and sustainable practices will stand out. Buyers from Africa, South America, the Middle East, and Europe should seek partnerships with manufacturers who share these values, ensuring their offerings resonate with environmentally conscious consumers.

Looking ahead, the demand for premium leather goods is expected to grow, making now the ideal time to refine sourcing strategies. By prioritizing quality and sustainability in procurement decisions, B2B buyers can position themselves advantageously in the competitive leather market. Embrace this opportunity to enhance your product line and meet the rising expectations of discerning customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.