Introduction: Navigating the Global Market for perforated seat covers

In the ever-evolving automotive industry, sourcing high-quality perforated seat covers can present significant challenges for international B2B buyers. These seat covers not only enhance vehicle aesthetics but also provide essential comfort and protection against wear and tear. As buyers from Africa, South America, the Middle East, and Europe seek to elevate their vehicle offerings, understanding the diverse types, applications, and benefits of perforated seat covers becomes crucial.

This comprehensive guide aims to empower B2B buyers by delving into various seat cover types, including custom-fit options, materials, and design patterns. It will also address critical factors such as supplier vetting processes, pricing strategies, and the importance of quality assurance. By providing actionable insights and industry best practices, this guide ensures that buyers can make informed purchasing decisions that align with their specific market needs and customer preferences.

With an emphasis on durability, style, and functionality, this resource is tailored to help businesses navigate the complexities of the global market for perforated seat covers. Whether you are looking to enhance your product line or seeking reliable suppliers, this guide serves as an essential tool in your procurement strategy, ultimately driving customer satisfaction and business growth.

Table Of Contents

- Top 5 Perforated Seat Covers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for perforated seat covers

- Understanding perforated seat covers Types and Variations

- Key Industrial Applications of perforated seat covers

- 3 Common User Pain Points for ‘perforated seat covers’ & Their Solutions

- Strategic Material Selection Guide for perforated seat covers

- In-depth Look: Manufacturing Processes and Quality Assurance for perforated seat covers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘perforated seat covers’

- Comprehensive Cost and Pricing Analysis for perforated seat covers Sourcing

- Alternatives Analysis: Comparing perforated seat covers With Other Solutions

- Essential Technical Properties and Trade Terminology for perforated seat covers

- Navigating Market Dynamics and Sourcing Trends in the perforated seat covers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of perforated seat covers

- Strategic Sourcing Conclusion and Outlook for perforated seat covers

- Important Disclaimer & Terms of Use

Understanding perforated seat covers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Fit Perforated | Tailored designs for specific vehicle makes and models | Automotive dealerships, fleet management | Pros: Perfect fit, enhances comfort. Cons: Higher cost. |

| Neosupreme Perforated | Water-resistant, durable fabric with a sporty appearance | Rental car companies, outdoor vehicles | Pros: Affordable, easy to clean. Cons: Less luxurious feel. |

| Leatherette Perforated | Elegant look with a soft, leather-like texture | Luxury vehicle markets, executive transport | Pros: Premium appearance, durable. Cons: Can be expensive. |

| Ballistic Fabric Perforated | Heavy-duty fabric resistant to wear and tear | Construction, transport, and utility fleets | Pros: Extremely durable, great for heavy use. Cons: Limited aesthetic options. |

| Spacermesh Perforated | Unique knit fabric for maximum breathability | Hot climate regions, sports vehicles | Pros: Keeps seats cool and comfortable. Cons: May not suit all aesthetics. |

What Are the Characteristics of Custom Fit Perforated Seat Covers?

Custom fit perforated seat covers are designed to align perfectly with specific vehicle models, ensuring full coverage and functionality, including compatibility with airbags. These covers enhance the vehicle’s interior while providing breathability and comfort. They are particularly suitable for automotive dealerships and fleet management companies looking to offer premium upgrades to their vehicles. Buyers should consider the initial investment against the long-term benefits of enhanced vehicle value and customer satisfaction.

Why Choose Neosupreme Perforated Seat Covers for B2B Applications?

Neosupreme perforated seat covers are crafted from a water-resistant and durable fabric that combines a sporty look with affordability. These covers are ideal for rental car companies and outdoor vehicle applications, where durability and ease of cleaning are paramount. While they offer great value for money, buyers should weigh their lower luxurious feel against the need for practicality and cost-effectiveness.

How Do Leatherette Perforated Seat Covers Stand Out?

Leatherette perforated seat covers provide a sophisticated aesthetic with a soft texture that mimics genuine leather. They are commonly used in luxury vehicle markets and executive transport services. These covers not only enhance the vehicle’s appearance but also offer durability and ease of maintenance. Buyers should consider the higher price point and assess whether the premium look aligns with their branding and customer expectations.

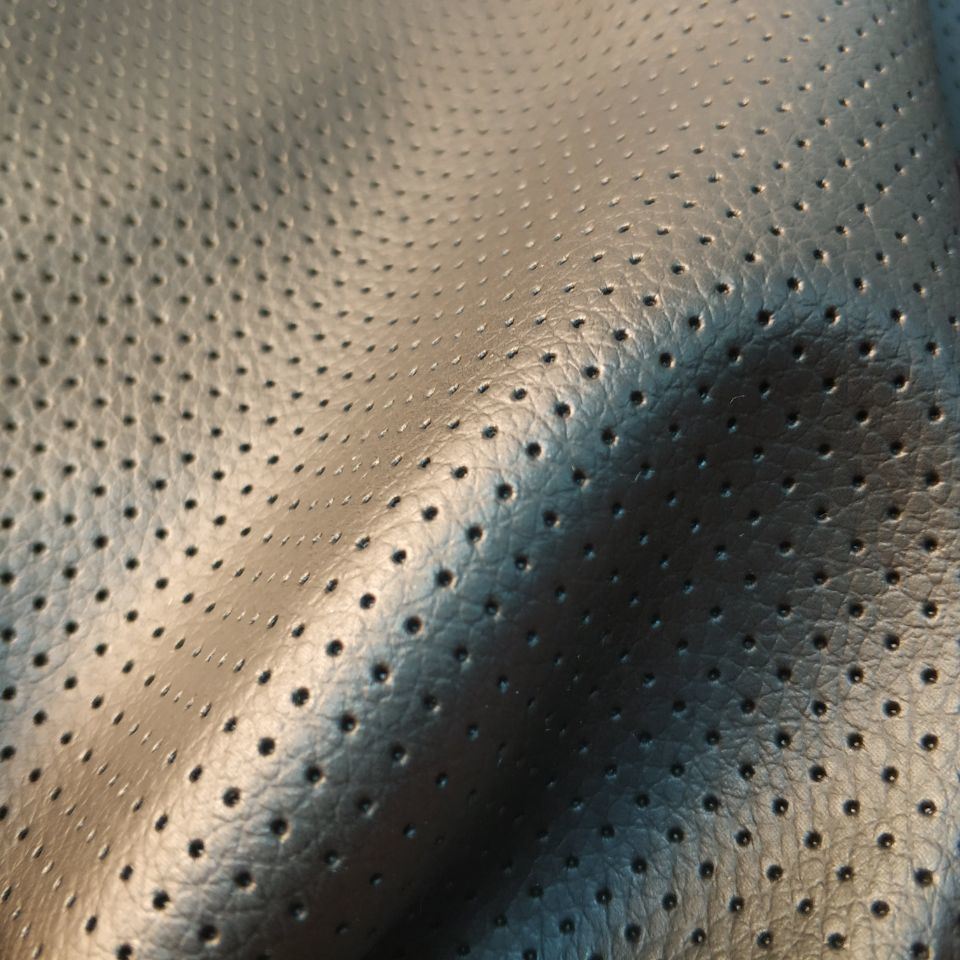

Illustrative image related to perforated seat covers

What Makes Ballistic Fabric Perforated Seat Covers Ideal for Heavy Use?

Ballistic fabric perforated seat covers are constructed from heavy-duty materials that are resistant to wear and tear, making them suitable for construction, transport, and utility fleets. These covers are designed to withstand harsh conditions and heavy usage, ensuring long-term durability. While they provide excellent protection, buyers should consider the trade-off between aesthetics and functionality, as the design may not appeal to all customers.

Why Opt for Spacermesh Perforated Seat Covers in Hot Climates?

Spacermesh perforated seat covers feature a unique knit fabric that maximizes air circulation, making them an excellent choice for vehicles in hot climates or for sports applications. These covers keep seats cool and comfortable, which can enhance the driving experience significantly. However, buyers should evaluate whether the breathable design fits their aesthetic needs, as it may not suit every vehicle’s interior style.

Key Industrial Applications of perforated seat covers

| Industry/Sector | Specific Application of Perforated Seat Covers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom vehicle interiors for luxury models | Enhances vehicle aesthetics and comfort, increasing market appeal | Need for high-quality materials and precise fit for various models |

| Transportation Services | Fleet vehicle interiors for taxis and buses | Provides durability and ease of cleaning, reducing maintenance costs | Consideration for bulk orders and quick delivery times |

| Hospitality | Vehicle interiors for hotel shuttles | Improves guest experience with comfort and style | Customization options to match hotel branding |

| Agriculture | Utility vehicle interiors for farming equipment | Protects against dirt and wear, ensuring longevity | Requirement for weather-resistant materials suitable for outdoor use |

| Military | Tactical vehicle interiors | Provides durability and ease of maintenance in harsh conditions | Need for compliance with military standards and specifications |

How Are Perforated Seat Covers Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, perforated seat covers are essential for custom vehicle interiors, especially for luxury models. These covers not only enhance the aesthetics of vehicles but also improve passenger comfort through better breathability. Manufacturers face the challenge of ensuring that the seat covers fit various models precisely, which requires sourcing high-quality materials that can withstand daily wear and tear. International buyers must prioritize suppliers who can deliver tailored solutions that meet their specific design and functionality requirements.

What Role Do Perforated Seat Covers Play in Transportation Services?

For transportation services, such as taxis and buses, perforated seat covers are vital for maintaining fleet vehicles. These covers offer durability and ease of cleaning, which helps reduce maintenance costs over time. Given the high usage rates of these vehicles, businesses need reliable suppliers who can provide bulk orders and ensure quick delivery to minimize downtime. Additionally, the covers must comply with safety standards while providing comfort to passengers.

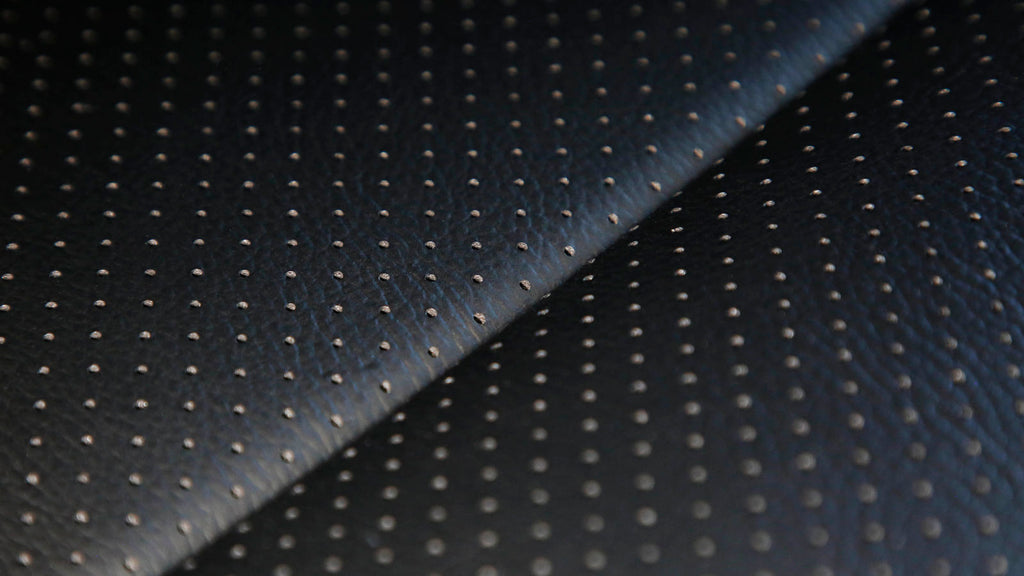

Illustrative image related to perforated seat covers

How Do Hospitality Businesses Benefit from Perforated Seat Covers?

In the hospitality industry, vehicle interiors for hotel shuttles often utilize perforated seat covers to enhance the guest experience. These covers not only provide comfort during travel but also contribute to the overall style and branding of the hotel. Customization options are crucial for hotels looking to match their vehicles with their branding. Suppliers must be able to offer a range of colors and patterns while ensuring high-quality materials that stand up to frequent use.

Why Are Perforated Seat Covers Important for Agriculture?

In agriculture, utility vehicles often face harsh conditions, making perforated seat covers an ideal choice for protecting interiors from dirt and wear. These covers help extend the life of the vehicle’s seats, ensuring that they remain comfortable and functional for the long term. Buyers in this sector should focus on sourcing weather-resistant materials that can withstand outdoor elements while providing easy maintenance and cleaning solutions.

How Do Military Applications Utilize Perforated Seat Covers?

Military applications require robust solutions for vehicle interiors, where perforated seat covers provide both durability and ease of maintenance in challenging environments. The ability to withstand extreme conditions is critical, as is compliance with specific military standards. Buyers in this sector must ensure that their suppliers can meet these stringent requirements while offering products that provide comfort and functionality for personnel in the field.

Illustrative image related to perforated seat covers

3 Common User Pain Points for ‘perforated seat covers’ & Their Solutions

Scenario 1: Difficulty in Achieving the Right Fit for Diverse Vehicle Models

The Problem: B2B buyers often face the challenge of sourcing perforated seat covers that fit a wide variety of vehicle models, especially when catering to fleets or diverse customer preferences. Many suppliers offer generic sizes, which can lead to ill-fitting covers that compromise both aesthetic appeal and functionality. This can result in increased returns and dissatisfied customers, ultimately affecting the buyer’s reputation and bottom line.

The Solution: To overcome the fitment issue, buyers should prioritize suppliers that specialize in custom-fit solutions, such as those employing advanced CAD/CAM technology for precise measurements. When sourcing perforated seat covers, ensure that the supplier provides a comprehensive range of patterns tailored specifically for different makes and models. It’s also beneficial to request samples or prototypes to test the fit and quality before placing larger orders. Furthermore, establishing a strong relationship with the supplier can facilitate better communication regarding specific customer needs, ensuring that the products meet the expectations for quality and fit.

Scenario 2: Concerns Over Durability and Maintenance in Challenging Environments

The Problem: In regions with extreme weather conditions or high wear and tear, such as those found in parts of Africa or South America, buyers often worry about the durability of perforated seat covers. Issues like fading, tearing, and difficulty in cleaning can lead to increased maintenance costs and customer dissatisfaction. Additionally, buyers need assurances that the products can withstand daily use without significant degradation.

The Solution: When selecting perforated seat covers, focus on materials known for their durability, such as high-grade vinyl or specialized fabric blends. Look for products that come with warranties to guarantee their longevity. It’s also advisable to choose covers with UV protection and water-resistant features to safeguard against environmental damage. Implementing a routine maintenance guide for customers can enhance product lifespan and satisfaction. Educating clients about proper cleaning techniques and recommended products can also help alleviate concerns regarding maintenance, ensuring that the seat covers remain in pristine condition over time.

Scenario 3: Balancing Aesthetics with Functionality

The Problem: Buyers frequently struggle with the challenge of balancing the visual appeal of perforated seat covers with their functional benefits. In sectors like luxury automotive or high-end transport services in Europe or the Middle East, customers expect both sophisticated design and practical features, such as breathability and comfort. This dual requirement can complicate the decision-making process for B2B buyers.

The Solution: To address this balance, buyers should collaborate with manufacturers that offer a variety of customizable options for perforated seat covers, including colors, patterns, and textures. It’s essential to evaluate the aesthetic impact of the covers in conjunction with their functional features. Buyers can arrange for mock-ups or visualizations to present to clients, highlighting how the chosen designs will complement the vehicle’s interior while providing necessary comfort and durability. Furthermore, consider showcasing case studies or testimonials from previous clients that successfully integrated these seat covers, emphasizing both their style and functionality. This approach not only instills confidence in potential buyers but also helps them make informed decisions that meet their customers’ expectations.

Strategic Material Selection Guide for perforated seat covers

When selecting materials for perforated seat covers, it is essential to consider various factors that influence performance, durability, and suitability for specific applications. This guide analyzes four common materials used in the manufacturing of perforated seat covers, providing insights that can aid international B2B buyers in making informed decisions.

What Are the Key Properties of Neoprene for Perforated Seat Covers?

Neoprene is a synthetic rubber known for its excellent temperature resistance and flexibility. It typically withstands temperatures ranging from -40°F to 200°F (-40°C to 93°C) and exhibits good resistance to water, oils, and UV rays. This material is particularly suitable for environments that require durability against spills and exposure to the elements.

Pros: Neoprene is highly durable, water-resistant, and provides a comfortable feel, making it ideal for vehicles exposed to moisture and heat. It also offers good cushioning, enhancing passenger comfort.

Illustrative image related to perforated seat covers

Cons: The manufacturing process can be complex, and the cost of high-grade neoprene can be on the higher side. Additionally, while it is resistant to many chemicals, it may not perform well against certain solvents.

Impact on Application: Neoprene’s water resistance makes it suitable for vehicles in humid climates, such as those found in parts of Africa and South America.

Considerations for International Buyers: Compliance with international standards such as ASTM D2000 for rubber materials is essential. Buyers in regions like Europe and the Middle East may also prefer materials that meet specific environmental regulations.

How Does Polyester Perform in Perforated Seat Covers?

Polyester is a versatile synthetic fabric known for its durability and resistance to shrinking and stretching. It can withstand a range of temperatures and is generally resistant to mildew and fading, making it a popular choice for automotive applications.

Pros: Polyester is lightweight, cost-effective, and offers a wide range of colors and patterns, allowing for aesthetic customization. Its durability makes it suitable for high-traffic vehicles.

Cons: While polyester is resistant to many environmental factors, it can be less breathable compared to other materials, potentially leading to discomfort in hot climates.

Impact on Application: Polyester’s affordability and durability make it suitable for family vehicles and commercial fleets, especially in regions with varying climates, such as the Middle East and South America.

Considerations for International Buyers: Buyers should ensure that the polyester used meets relevant fire safety standards, particularly in Europe, where regulations are stringent.

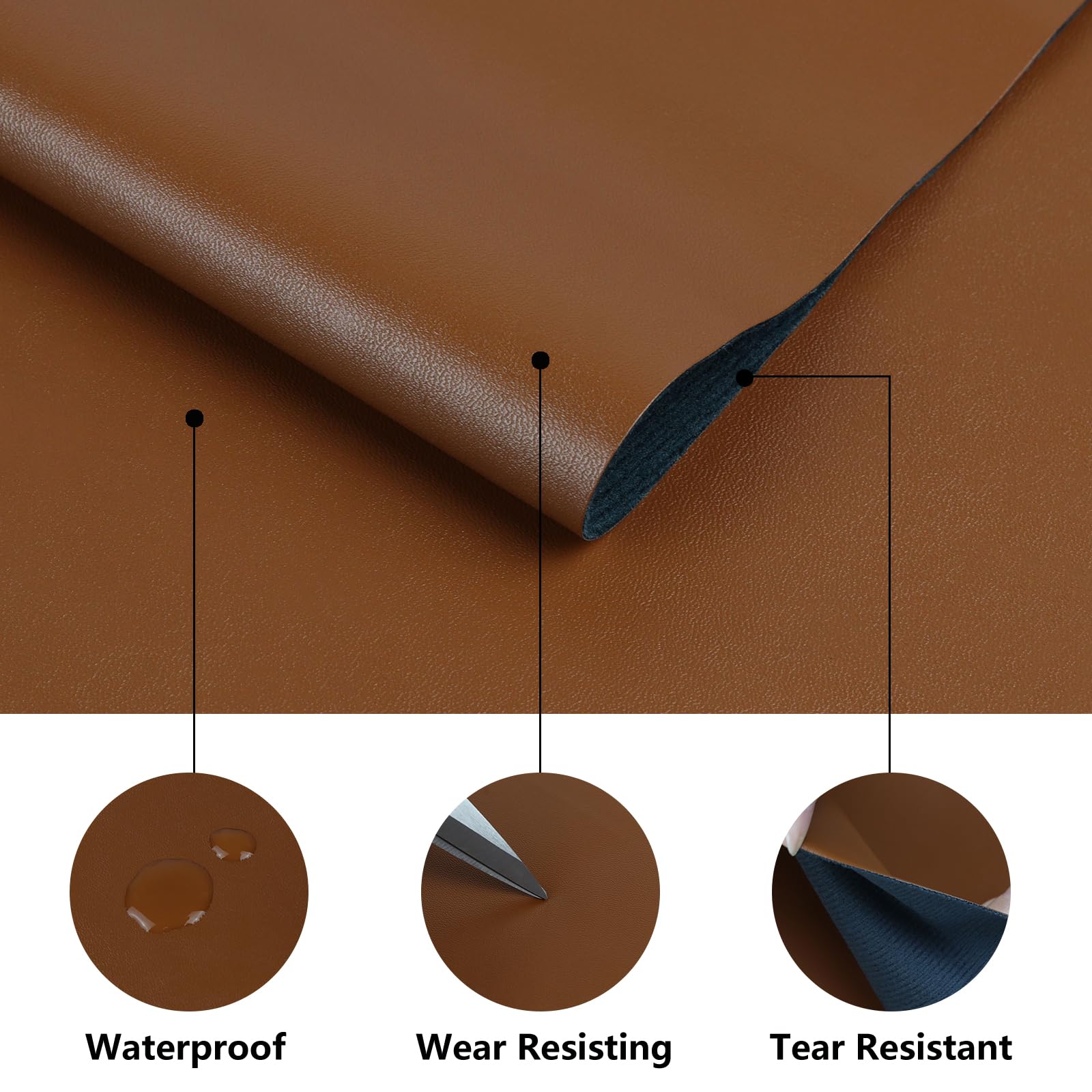

What Advantages Does Leatherette Offer for Perforated Seat Covers?

Leatherette, or synthetic leather, provides the luxurious appearance of genuine leather while being more affordable and easier to maintain. It is often made from PVC or polyurethane, which can be engineered to be water-resistant and durable.

Pros: Leatherette is easy to clean, resists stains, and offers a high-end look without the cost of genuine leather. Its perforated design enhances breathability while maintaining a stylish appearance.

Illustrative image related to perforated seat covers

Cons: While it is durable, leatherette may not be as breathable as natural leather, leading to potential discomfort in hot climates. Additionally, it may wear out faster than genuine leather under heavy use.

Impact on Application: Leatherette is ideal for luxury vehicles and commercial fleets where aesthetics are important, making it a popular choice in Europe and the Middle East.

Considerations for International Buyers: Compliance with environmental regulations regarding PVC use is critical, particularly in regions like Europe where sustainability is a growing concern.

Illustrative image related to perforated seat covers

How Does Ballistic Fabric Compare for Perforated Seat Covers?

Ballistic fabric is a heavy-duty nylon known for its exceptional strength and abrasion resistance. It is often used in military applications but has found a niche in automotive upholstery due to its durability.

Pros: Ballistic fabric is highly resistant to tears, punctures, and abrasions, making it ideal for vehicles that endure heavy wear and tear, such as those used in construction or by families with pets.

Cons: The cost of ballistic fabric can be higher than other materials, and its heavy nature may not provide the same level of comfort as softer fabrics.

Impact on Application: Ballistic fabric is particularly suitable for commercial vehicles and rugged environments, making it a preferred choice in regions with challenging conditions, such as parts of Africa.

Illustrative image related to perforated seat covers

Considerations for International Buyers: Buyers should be aware of compliance with safety and durability standards, such as those set by ASTM, to ensure product quality.

Summary Table of Material Selection for Perforated Seat Covers

| Material | Typical Use Case for perforated seat covers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Neoprene | SUVs in humid climates | Excellent water resistance | Higher manufacturing complexity | High |

| Polyester | Family vehicles and commercial fleets | Cost-effective and durable | Less breathable | Medium |

| Leatherette | Luxury vehicles and commercial fleets | High-end appearance and easy care | May wear out faster than leather | Medium |

| Ballistic Fabric | Heavy-use vehicles and rugged environments | Exceptional strength and durability | Higher cost and less comfort | High |

This analysis provides a comprehensive overview of the materials available for perforated seat covers, helping international B2B buyers make informed decisions that align with their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for perforated seat covers

What Are the Key Manufacturing Processes for Perforated Seat Covers?

The manufacturing of perforated seat covers involves several critical stages, ensuring the final product meets the high standards expected by B2B buyers. Each stage is designed to optimize quality, durability, and aesthetic appeal. Here’s a breakdown of the main processes involved:

1. Material Preparation: What Materials Are Used?

The journey begins with selecting high-quality materials that can withstand daily wear and tear while offering comfort. Common materials include:

- Synthetic Fabrics: Neosupreme and leatherette are popular for their durability and ease of maintenance.

- Breathable Mesh: This allows for air circulation, enhancing comfort during hot weather.

- Foam Padding: Used for additional comfort and support.

Once the materials are selected, they undergo pre-treatment processes such as cleaning and coating to enhance their performance characteristics, including stain resistance and UV protection.

2. Forming: How Are Seat Covers Shaped?

After preparing the materials, the next step is forming. This involves cutting the fabrics into specific patterns using advanced techniques:

- CAD/CAM Technology: Computer-Aided Design and Manufacturing systems are employed to create precise patterns tailored to various vehicle models. This ensures that each seat cover fits seamlessly and maintains the functionality of all seat features, including airbags.

- Perforation Techniques: To achieve the perforated design, manufacturers use laser cutting or die-cutting techniques, allowing for intricate designs that enhance both aesthetics and breathability.

3. Assembly: What Steps Are Involved in Putting It All Together?

The assembly process involves stitching the cut pieces together. Key techniques include:

- Double-Stitching: This method enhances durability and prevents fraying, ensuring the longevity of the seat covers.

- Reinforced Stitching: For high-stress areas, such as seams, reinforced stitching is used to provide additional strength.

- Attachment of Accessories: This stage may also include adding features like zippers, Velcro, or elastic bands for a snug fit.

4. Finishing: How Is the Product Prepared for Shipping?

The finishing stage focuses on the final touches that enhance the product’s appeal:

- Quality Inspection: Before packaging, each seat cover undergoes a thorough quality check to identify any defects.

- Cleaning and Packaging: Covers are cleaned to remove any dust or residues from the manufacturing process and then carefully packaged to prevent damage during transit.

What Quality Assurance Processes Are in Place for Perforated Seat Covers?

Quality assurance is a vital component of manufacturing perforated seat covers. It ensures that the products meet international standards and customer expectations. Here’s an overview of the quality assurance processes typically implemented:

Relevant International Standards: Which Certifications Should Buyers Look For?

B2B buyers should be aware of several international quality standards that manufacturers may adhere to, including:

- ISO 9001: This standard focuses on quality management systems, ensuring consistent product quality and customer satisfaction.

- CE Marking: Required in Europe, this certification indicates compliance with health, safety, and environmental protection standards.

- API Standards: For manufacturers supplying the automotive industry, adherence to American Petroleum Institute standards may be relevant, especially if the materials used have a petroleum base.

Quality Control Checkpoints: What Are the Key Stages?

Quality control (QC) is integrated into every stage of the manufacturing process. The key checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet predefined specifications before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify defects early, allowing for immediate corrective action.

- Final Quality Control (FQC): A thorough inspection of the finished products ensures they meet quality standards before shipment.

What Testing Methods Are Commonly Used to Ensure Quality?

To verify the quality of perforated seat covers, manufacturers may employ various testing methods:

- Durability Testing: Simulates wear and tear to assess the longevity of materials under stress.

- Colorfastness Testing: Ensures that colors remain vibrant after exposure to sunlight and washing.

- Breathability Testing: Measures the air permeability of the perforated materials to confirm comfort levels.

- Safety Testing: For airbag compatibility, tests ensure that the seat covers do not obstruct the deployment of side airbags.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers need to ensure that their suppliers maintain rigorous quality control standards. Here are practical steps for verification:

Illustrative image related to perforated seat covers

Conducting Supplier Audits: What Should Buyers Look For?

Buyers can schedule on-site audits to assess the manufacturing processes and quality control measures in place. Key areas to focus on include:

- Production Capabilities: Evaluate the technology and equipment used in manufacturing.

- Quality Control Procedures: Review documentation related to quality checks and compliance with international standards.

- Workforce Training: Ensure that the staff is adequately trained in quality management practices.

Requesting Quality Reports: What Documentation Is Essential?

Buyers should ask suppliers for detailed quality reports that outline:

- Test Results: Documentation of all testing methods used and their outcomes.

- Certifications: Copies of relevant certifications and standards compliance.

- Defect Rates: Historical data on defect rates and corrective actions taken.

Utilizing Third-Party Inspections: How Can They Help?

Engaging third-party inspection services can provide an impartial assessment of the supplier’s quality control processes. These services can conduct random inspections and provide reports that help buyers make informed decisions.

Conclusion: Why Quality Matters in the Perforated Seat Cover Industry

For international B2B buyers, particularly those in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the manufacturing and quality assurance processes for perforated seat covers is crucial. By focusing on the right materials, adhering to international standards, and implementing rigorous quality control measures, manufacturers can provide products that meet the high expectations of global buyers. Ensuring that suppliers maintain these standards through audits and documentation will further solidify partnerships and enhance product reliability in the competitive automotive accessories market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘perforated seat covers’

To effectively source perforated seat covers for your business, it’s essential to follow a structured approach. This checklist will guide you through the critical steps to ensure you select the right products and suppliers that meet your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the seat covers you procure meet your requirements. Consider factors such as material type (e.g., leatherette, neoprene), breathability, compatibility with airbags, and the specific dimensions needed for various vehicle models. Detailed specifications help suppliers provide accurate quotes and reduce the likelihood of errors during manufacturing.

Illustrative image related to perforated seat covers

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in perforated seat covers. Look for companies with a proven track record and positive reviews from previous clients. Utilize online platforms, trade shows, and industry directories to compile a list of potential vendors.

- Key Considerations:

- Supplier location and shipping capabilities.

- Their experience with international clients, especially in your target regions.

Step 3: Evaluate Supplier Capabilities

Before proceeding with any supplier, assess their production capabilities and quality control processes. Inquire about their manufacturing methods, materials used, and the technologies employed in creating custom-fit seat covers.

- What to Look For:

- Certifications for quality standards (e.g., ISO).

- Evidence of advanced CAD/CAM technology for precision fitting.

Step 4: Request Samples for Evaluation

Always request samples of the perforated seat covers before making a bulk purchase. This step allows you to evaluate the quality, comfort, and fit of the products. Pay attention to the stitching, material feel, and overall craftsmanship.

Illustrative image related to perforated seat covers

- Sample Assessment:

- Check for breathability and comfort.

- Verify the durability of the fabric under various conditions.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications that attest to the quality and safety of their products. Certifications can indicate compliance with international standards, which is particularly important for B2B transactions.

- Examples of Important Certifications:

- ISO 9001 for quality management.

- Specific automotive industry standards.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, initiate negotiations regarding pricing, payment terms, and delivery schedules. It’s crucial to have a clear understanding of all costs involved, including shipping and potential tariffs, to avoid unexpected expenses.

- Negotiation Tips:

- Discuss bulk purchase discounts.

- Clarify warranty terms and return policies.

Step 7: Establish a Long-Term Partnership

Consider the long-term potential of your relationship with the supplier. Building a strong partnership can lead to better pricing, priority service, and collaborative product development in the future.

- Partnership Benefits:

- Access to exclusive designs or materials.

- Enhanced communication for future orders and modifications.

By following this checklist, you can streamline your procurement process for perforated seat covers, ensuring that you make informed decisions that align with your business objectives.

Illustrative image related to perforated seat covers

Comprehensive Cost and Pricing Analysis for perforated seat covers Sourcing

What Are the Key Cost Components in Sourcing Perforated Seat Covers?

When analyzing the cost structure for perforated seat covers, several critical components must be considered. Materials play a significant role, with high-quality fabrics being essential for durability and comfort. Options like neoprene, leatherette, and ballistic materials vary in price, influencing the overall cost of the seat covers.

Labor costs will depend on the complexity of the design and the skill level required for manufacturing. Skilled labor is often necessary for custom-fit seat covers, which require precise tailoring to ensure functionality and aesthetics.

Manufacturing overhead includes expenses related to equipment, facility maintenance, and utilities. These costs can fluctuate based on production volume, making it crucial to understand how they affect pricing.

Illustrative image related to perforated seat covers

Tooling refers to the initial investment needed to create molds and patterns for custom seat covers. This is particularly relevant for B2B buyers looking for specialized designs, as the tooling costs can be amortized over larger orders.

Quality control (QC) is essential for ensuring that the products meet specified standards. This process incurs additional costs but is vital for maintaining brand reputation and customer satisfaction.

Logistics involves the transportation and distribution of the finished products, which can vary based on the geographic location of the supplier and the buyer. International shipping costs, customs duties, and tariffs must be factored into the total cost.

Margin is the profit that suppliers add on top of their costs. This can vary widely among suppliers and is influenced by the market demand and competition.

Illustrative image related to perforated seat covers

How Do Price Influencers Affect Perforated Seat Cover Costs?

Several factors can influence the pricing of perforated seat covers. Volume or minimum order quantities (MOQ) are significant; larger orders typically lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it essential for buyers to negotiate effectively.

Specifications and customization also play a critical role. Custom designs or unique materials can significantly increase costs, so understanding the balance between customization and budget is vital. Buyers should evaluate whether the added features justify the higher price.

Quality and certifications are crucial for buyers, especially in regions like Europe, where strict standards may apply. Products that meet specific certifications may carry a premium price, but they can also provide assurance of quality and compliance.

Illustrative image related to perforated seat covers

Supplier factors, such as their reputation, reliability, and production capabilities, can also impact pricing. Established suppliers may charge more but often provide better quality assurance and customer service.

Incoterms determine who is responsible for shipping costs and risks during transportation, which can significantly affect the overall pricing. Buyers should clarify these terms to avoid unexpected expenses.

What Are the Best Buyer Tips for Cost-Efficiency in Perforated Seat Covers Sourcing?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding negotiation tactics can lead to better pricing. Building a strong relationship with suppliers can often yield favorable terms and pricing adjustments.

Illustrative image related to perforated seat covers

Considering the Total Cost of Ownership (TCO) is essential when evaluating options. This includes not only the purchase price but also maintenance costs, longevity, and resale value. Higher upfront costs for quality materials may lead to lower overall costs in the long run.

Buyers should be aware of pricing nuances in international transactions. Currency fluctuations, regional tariffs, and import regulations can all affect final costs. Thorough research into local market conditions and supplier capabilities can help mitigate these risks.

Lastly, it is crucial to remember that prices provided by suppliers are often indicative and may vary based on market conditions, negotiations, and specific buyer requirements. Therefore, gathering multiple quotes and conducting a comprehensive analysis is recommended to ensure the best sourcing decisions are made.

Alternatives Analysis: Comparing perforated seat covers With Other Solutions

Understanding Alternative Solutions for Vehicle Seat Protection

When it comes to protecting vehicle interiors, perforated seat covers are a popular choice, known for their comfort and breathability. However, there are other viable alternatives that buyers should consider. This analysis will compare perforated seat covers with two alternative solutions: neoprene seat covers and ballistic fabric seat covers. By examining these options, B2B buyers can make informed decisions based on performance, cost, and suitability for their specific needs.

Illustrative image related to perforated seat covers

| Comparison Aspect | Perforated Seat Covers | Neoprene Seat Covers | Ballistic Fabric Seat Covers |

|---|---|---|---|

| Performance | Excellent breathability and comfort | Superior water resistance and cushioning | High durability and resistance to wear |

| Cost | Moderate ($370) | Moderate ($330) | Higher ($390) |

| Ease of Implementation | Easy installation, no special tools needed | Generally easy, but may require some adjustments | Installation can be more complex |

| Maintenance | Easy to clean, stain-resistant | Easy to clean, water-resistant | Easy to clean, highly resistant to stains |

| Best Use Case | Everyday vehicles needing comfort | Active lifestyles, water-prone environments | Heavy-duty use, families with pets or children |

What Are the Pros and Cons of Neoprene Seat Covers?

Neoprene seat covers are renowned for their robust water resistance, making them ideal for environments where spills and moisture are common. They provide a snug fit and excellent cushioning, which enhances passenger comfort. However, while neoprene offers superior protection against water, it may not breathe as well as perforated seat covers, potentially leading to heat retention in hot climates. Additionally, while the cost is slightly lower, the installation process can sometimes be more involved, requiring adjustments for a perfect fit.

How Do Ballistic Fabric Seat Covers Stand Out?

Ballistic fabric seat covers are designed for extreme durability, making them suitable for contractors or families with pets and children. Their high resistance to abrasion and puncture ensures that they can withstand heavy use without showing signs of wear. While they are more expensive than both perforated and neoprene options, their longevity and protective capabilities make them a worthwhile investment for specific applications. However, the installation may require more effort, and the material can be less comfortable than softer alternatives.

Conclusion: Choosing the Right Seat Cover Solution

In selecting the ideal seat cover solution, B2B buyers should consider their specific needs and usage scenarios. Perforated seat covers excel in providing comfort and breathability, making them suitable for everyday use in passenger vehicles. For those in environments prone to moisture, neoprene offers robust water resistance and comfort. Meanwhile, ballistic fabric seat covers are optimal for high-usage scenarios, providing unparalleled durability. By evaluating performance, cost, and maintenance requirements, buyers can confidently choose the solution that best fits their operational needs and enhances their vehicle’s longevity.

Essential Technical Properties and Trade Terminology for perforated seat covers

What Are the Key Technical Properties of Perforated Seat Covers?

Material Grade

The quality of the material used in perforated seat covers is paramount for durability and comfort. Common materials include high-grade vinyl, neoprene, and leatherette. These materials must meet specific industry standards to ensure they can withstand daily wear and tear, UV exposure, and spills. B2B buyers should prioritize materials that offer a balance between aesthetic appeal and functionality, as this impacts both customer satisfaction and long-term vehicle value.

Breathability

Perforated designs enhance airflow, making seats more comfortable in various climates. This property is particularly relevant for regions with extreme temperatures, as it reduces heat buildup and moisture retention. For buyers, selecting breathable seat covers can lead to improved user experience and reduced complaints regarding discomfort, which can positively influence brand reputation.

Custom Fit Tolerance

Precision in fit is crucial for the effectiveness of seat covers. A tolerance specification indicates how closely the seat cover aligns with the vehicle’s original seat dimensions. A snug fit ensures that the covers do not shift during use, maintaining functionality like seat adjustments and airbag deployment. Buyers should inquire about the manufacturing process to ensure that the covers are tailored to specific vehicle makes and models.

Installation Ease

Perforated seat covers should be designed for straightforward installation, often requiring no special tools. Manufacturers may include installation kits with their products, enhancing user convenience. For B2B buyers, ease of installation can reduce labor costs and time, making it a key consideration when selecting products for bulk purchase.

Durability Ratings

Durability ratings reflect a product’s resistance to wear, tear, and environmental factors. Common tests include abrasion resistance and water repellency. Buyers should look for products with clear durability ratings to ensure they are investing in long-lasting solutions, particularly for high-traffic vehicles or those used in harsh conditions.

Illustrative image related to perforated seat covers

What Are Common Trade Terms in the Perforated Seat Cover Industry?

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are used in another company’s end product. In the context of seat covers, OEM specifications ensure that the covers fit precisely and function correctly with the vehicle’s original design. Buyers should seek OEM-compatible products to guarantee quality and performance.

MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units that a supplier is willing to sell in a single order. Understanding MOQ is crucial for B2B buyers as it can affect inventory management and cash flow. Buyers should negotiate MOQs that align with their sales forecasts to avoid overstocking or stockouts.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. In the context of perforated seat covers, B2B buyers should prepare RFQs that clearly outline their requirements, including material specifications, quantities, and delivery timelines. This ensures that they receive accurate and competitive pricing from suppliers.

Illustrative image related to perforated seat covers

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery conditions. Understanding Incoterms is vital for B2B buyers involved in cross-border trade, as they determine who bears the cost and risk at various stages of the shipping process. Familiarity with these terms can help buyers negotiate better shipping agreements.

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. This is particularly important for B2B buyers who need to plan inventory and sales strategies. Understanding lead times helps buyers manage expectations and ensures that they can meet customer demands promptly.

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and lifespan of the product. For perforated seat covers, warranties can range from one to several years, depending on the material and construction. Buyers should consider warranty terms as they reflect the manufacturer’s confidence in their product and can protect against defects and failures, offering peace of mind in bulk purchases.

Navigating Market Dynamics and Sourcing Trends in the perforated seat covers Sector

What Are the Current Market Dynamics and Key Trends in Perforated Seat Covers?

The global market for perforated seat covers is witnessing significant growth, driven by increasing consumer demand for vehicle personalization and protection. Key trends include the rise of custom-fit solutions tailored to specific vehicle models, which enhance both aesthetics and functionality. As international buyers, particularly from Africa, South America, the Middle East, and Europe, seek to improve the interior quality of their vehicles, the emphasis on breathable materials has become paramount. Perforated designs not only provide a sophisticated look but also allow for better air circulation, making them ideal for diverse climates.

Technological advancements in manufacturing processes, such as CAD/CAM technology, are enhancing the precision and efficiency of production. This allows manufacturers to offer a broader range of patterns and styles, catering to diverse market preferences. Additionally, the increasing integration of smart technologies in vehicles is prompting the development of seat covers that are compatible with advanced features like airbags and heated seats. For B2B buyers, understanding these dynamics is essential for making informed purchasing decisions and aligning with market trends.

Illustrative image related to perforated seat covers

How Is Sustainability Influencing the Sourcing of Perforated Seat Covers?

Sustainability is increasingly becoming a critical consideration in the sourcing of perforated seat covers. The environmental impact of manufacturing processes and materials used in these products is under scrutiny, prompting many manufacturers to adopt greener practices. B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainability through ethical sourcing, reduced carbon footprints, and the use of eco-friendly materials.

Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX provide assurance that materials used in seat covers meet stringent environmental and social criteria. Buyers are encouraged to inquire about the sourcing of materials and the sustainability practices of their suppliers, as this can significantly influence brand reputation and consumer trust. As the demand for eco-conscious products grows, those who align their sourcing strategies with sustainability goals are likely to gain a competitive edge in the market.

What Is the Evolution of Perforated Seat Covers in the Automotive Industry?

The evolution of perforated seat covers in the automotive industry reflects broader trends in consumer preferences and technological advancements. Initially, vehicle interiors were primarily functional, with limited options for personalization. However, as consumer expectations shifted towards enhanced comfort and style, manufacturers began to explore innovative materials and designs.

Perforated seat covers emerged as a popular choice due to their ability to combine aesthetics with practicality. The introduction of synthetic materials offered durability and ease of maintenance, making these covers suitable for a wide range of applications, from luxury vehicles to everyday family cars. Over the years, the integration of custom-fit designs has further transformed the market, allowing buyers to select options that perfectly match their vehicle’s specifications. This evolution underscores the importance of continuous innovation in meeting the diverse needs of international B2B buyers in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of perforated seat covers

-

How can I ensure the quality of perforated seat covers before purchasing?

To ensure quality, request samples from potential suppliers. Inspect the materials, stitching, and overall finish. Consider suppliers who provide warranties and detailed product specifications. Additionally, check for certifications related to quality standards, such as ISO or similar. It’s also beneficial to read reviews or testimonials from other businesses that have sourced from the supplier to gauge their reliability and product quality. -

What are the key features to look for in perforated seat covers?

When selecting perforated seat covers, prioritize materials that offer durability, breathability, and comfort. Look for custom-fit designs that ensure easy installation and compatibility with your vehicle’s airbag systems. Features like stain resistance and UV protection are also important for maintaining aesthetics over time. Finally, consider the availability of various colors and patterns for customization to suit your branding needs. -

What is the typical minimum order quantity (MOQ) for perforated seat covers in B2B transactions?

The MOQ for perforated seat covers can vary by supplier and often ranges from 50 to 500 units, depending on customization options and production capabilities. It’s advisable to communicate your requirements directly with suppliers to negotiate terms that work for both parties. Some suppliers may offer lower MOQs for specific patterns or materials, especially for new customers or bulk orders. -

What payment terms should I expect when sourcing perforated seat covers internationally?

Payment terms can differ widely among suppliers, but common arrangements include a 30% upfront deposit with the balance due before shipment. Some suppliers may also accept letters of credit or escrow services for added security. It’s crucial to clarify payment methods, currency exchange rates, and any potential fees associated with international transactions to avoid misunderstandings. -

How do I vet suppliers for perforated seat covers effectively?

Vetting suppliers involves researching their background, production capabilities, and customer feedback. Request references and case studies of previous clients to assess their reliability. Additionally, consider visiting their manufacturing facilities if possible or using third-party inspection services to evaluate their processes. Certifications and compliance with international standards can also indicate a reputable supplier. -

What logistics considerations should I keep in mind when importing perforated seat covers?

Logistics involves planning for shipping, customs clearance, and delivery timelines. Be aware of the shipping methods available (air, sea, etc.) and their associated costs. Ensure that the supplier provides necessary documentation for customs, such as invoices and certificates of origin. Understanding local import regulations in your country is crucial to avoid delays or additional charges. -

Can I customize the design of perforated seat covers to align with my brand?

Yes, many manufacturers offer customization options for perforated seat covers, including colors, patterns, and logos. Discuss your specific design requirements with potential suppliers to ensure they can accommodate your branding needs. Keep in mind that custom designs may impact MOQs and lead times, so plan accordingly to align with your project timelines. -

What quality assurance measures should be in place for perforated seat covers?

Quality assurance should include thorough inspections during production and before shipment. Suppliers should implement quality control processes to check for defects in materials and workmanship. It’s advisable to establish criteria for acceptable quality levels and to conduct random sampling of products upon receipt. Additionally, consider including clauses in your contract that allow for returns or exchanges in case of quality issues.

Top 5 Perforated Seat Covers Manufacturers & Suppliers List

1. Coverking – Perforated Vinyl Custom Seat Covers

Domain: carcoverusa.com

Registered: 2005 (20 years)

Introduction: Coverking Perforated Vinyl Custom Seat Covers, Price: $369.99, Specialized Patterns, Best for heated and cooled seats, Made from high-grade vinyl, Soft and supple yet tough, Resists UV damage, stains, mildew, and rot, Good water resistance, Easy to clean, Tight fit to resist slippage, Soft Real Leather Feel, High durability, Perfect fitting, Precision design for full seat functionality, Includes c…

2. Ruff Tuff – Perforated Sof-Touch Seat Covers

Domain: rufftuff.com

Registered: 1996 (29 years)

Introduction: Perforated Sof-Touch Custom Seat Covers for various vehicles including cars, trucks, SUVs, and UTVs. Available for makes/models such as Chevrolet, Dodge/Ram, Ford, GMC, Honda, Jeep, Lexus, Nissan, Subaru, Tesla, and Toyota. Features include: Inserts only made from Perforated Sof-Touch fabric, available in multiple colors and trims (e.g., Black, Sandstone, Salsa, Medium Gray), with options for diam…

3. Coverking – Perforated Leatherette Seat Covers

Domain: carcoverworld.com

Registered: 2002 (23 years)

Introduction: Product Name: Coverking Perforated Leatherette Seat Covers

Material: High-grade vinyl, soft and supple like real leather

Features: 100% breathable, perforated design suitable for heated and cooled seats, UV damage resistance, stain and mildew resistance, good water resistance, easy to clean

Fit: Custom-fit for specific vehicle models, tight fit to resist slippage

Installation: Installation kit inc…

4. Clazzio – Perforated Genuine Leather Seat Kits

Domain: clazzio.com

Registered: 2009 (16 years)

Introduction: Leather Type: Perforated Genuine Leather; Warranty: 3 Year Warranty on leather seat kits; Whole Seat Leather: Only the INSERT is leather; Body Material: High Quality PVC for durability and factory fit; Thickness: 1/2 inch memory foam for added comfort; Installation Time: 2-3 hours for most vehicles; Professional Installation: Available through Authorized Clazzio Dealers, prices range from $100-$50…

5. Ruff Tuff – Perforated Sof-Touch Camo Seat Covers

Domain: realtruck.com

Registered: 1998 (27 years)

Introduction: {‘name’: ‘Ruff Tuff Perforated Sof-Touch Camo Seat Covers’, ‘price’: ‘From $453.95’, ‘rating’: ‘3.0 (1)’, ‘made_in’: ‘USA’, ‘features’: [‘Custom made for your vehicle’, ‘Perforated Sof-Touch constructed out of leatherette’, ‘Camo constructed out of 500 denier polyester/nylon blend’, ‘Water, abrasion, and UV resistant’, ‘Available in 5 Perforated Sof-Touch colors and 16 camo colors’, ‘Includes map …

Strategic Sourcing Conclusion and Outlook for perforated seat covers

In conclusion, the strategic sourcing of perforated seat covers presents a unique opportunity for B2B buyers to enhance vehicle interiors while ensuring durability and comfort. As highlighted, investing in high-quality, custom-fit covers not only protects against wear and tear but also elevates the aesthetic appeal of vehicles. The advanced materials and precision engineering utilized in these products result in a seamless integration with existing seat functionality, including safety features like airbags.

International buyers from Africa, South America, the Middle East, and Europe should leverage strategic sourcing to identify reputable suppliers that offer tailored solutions to meet specific regional demands. This approach will not only optimize procurement costs but also enhance customer satisfaction by providing superior products that resonate with local preferences and climate conditions.

Looking ahead, the market for perforated seat covers is poised for growth, driven by increasing consumer demand for personalized and functional automotive accessories. Buyers are encouraged to act proactively, exploring partnerships with manufacturers that prioritize quality and innovation. By doing so, they can position themselves competitively in a rapidly evolving marketplace, ensuring long-term success and customer loyalty.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.