Introduction: Navigating the Global Market for custom leather brand

Navigating the global market for custom leather branding presents a unique set of challenges for international B2B buyers, particularly when it comes to sourcing high-quality branding solutions that meet diverse regional needs. Whether you are looking to personalize leather goods for luxury markets in Europe or seeking durable branding tools for mass production in Africa and South America, understanding the nuances of custom leather branding is crucial. This guide provides an in-depth exploration of various branding options, including fire-heated and electric branding irons, as well as leather stamping tools, all tailored to meet specific business requirements.

By examining different types of custom branding tools, their applications across industries, and key factors for supplier vetting, this comprehensive resource empowers buyers to make informed decisions. Additionally, we delve into cost considerations, production timelines, and best practices for branding different leather types. This guide aims to equip B2B buyers from regions such as Saudi Arabia, Nigeria, and beyond with actionable insights and strategies, ensuring that they can confidently navigate the complexities of the custom leather market. Ultimately, our goal is to facilitate successful sourcing experiences that align with your business objectives, enhance brand identity, and drive customer loyalty.

Table Of Contents

- Top 5 Custom Leather Brand Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather brand

- Understanding custom leather brand Types and Variations

- Key Industrial Applications of custom leather brand

- 3 Common User Pain Points for ‘custom leather brand’ & Their Solutions

- Strategic Material Selection Guide for custom leather brand

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather brand

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather brand’

- Comprehensive Cost and Pricing Analysis for custom leather brand Sourcing

- Alternatives Analysis: Comparing custom leather brand With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather brand

- Navigating Market Dynamics and Sourcing Trends in the custom leather brand Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather brand

- Strategic Sourcing Conclusion and Outlook for custom leather brand

- Important Disclaimer & Terms of Use

Understanding custom leather brand Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Branding Irons | Utilizes electric heating for consistent temperature control | High-volume leather goods manufacturing | Pros: Quick heating, consistent results. Cons: Higher initial investment. |

| Fire-Heated Branding Irons | Requires manual heating with a flame source | Artisanal leather crafting | Pros: Cost-effective, versatile. Cons: Less control over heat, slower process. |

| Custom Embossing Stamps | Creates raised designs on leather surfaces | Custom leather goods, promotional items | Pros: Intricate designs possible, durable materials. Cons: May require specialized presses. |

| Curved Surface Branders | Designed for branding on non-flat surfaces | Sports equipment, bags, and accessories | Pros: Versatile for various shapes. Cons: May have a learning curve for effective use. |

| Heavy-Duty Branding Irons | Built for durability, ideal for thick leather | Industrial applications, heavy-duty items | Pros: Long-lasting, can handle tough materials. Cons: Heavier and less portable. |

What Are Electric Branding Irons and Their Benefits for B2B Buyers?

Electric branding irons are preferred for high-volume production due to their ability to maintain a consistent temperature, which is essential for achieving uniform branding results. They are especially suitable for manufacturers producing leather goods on a large scale, such as bags, wallets, and upholstery. B2B buyers should consider the upfront costs versus the efficiency gains, as these tools can significantly reduce labor time and improve output quality.

How Do Fire-Heated Branding Irons Work for Artisanal Leather Crafting?

Fire-heated branding irons are a traditional method for branding leather, utilizing a flame to heat the branding head. This type is often favored by artisans and small-scale producers who appreciate the craftsmanship involved. While they are generally more affordable, buyers must be cautious about heat control, as variations can affect the branding quality. This method is ideal for bespoke items and small batch productions where uniqueness is paramount.

What Are the Advantages of Custom Embossing Stamps in Leather Branding?

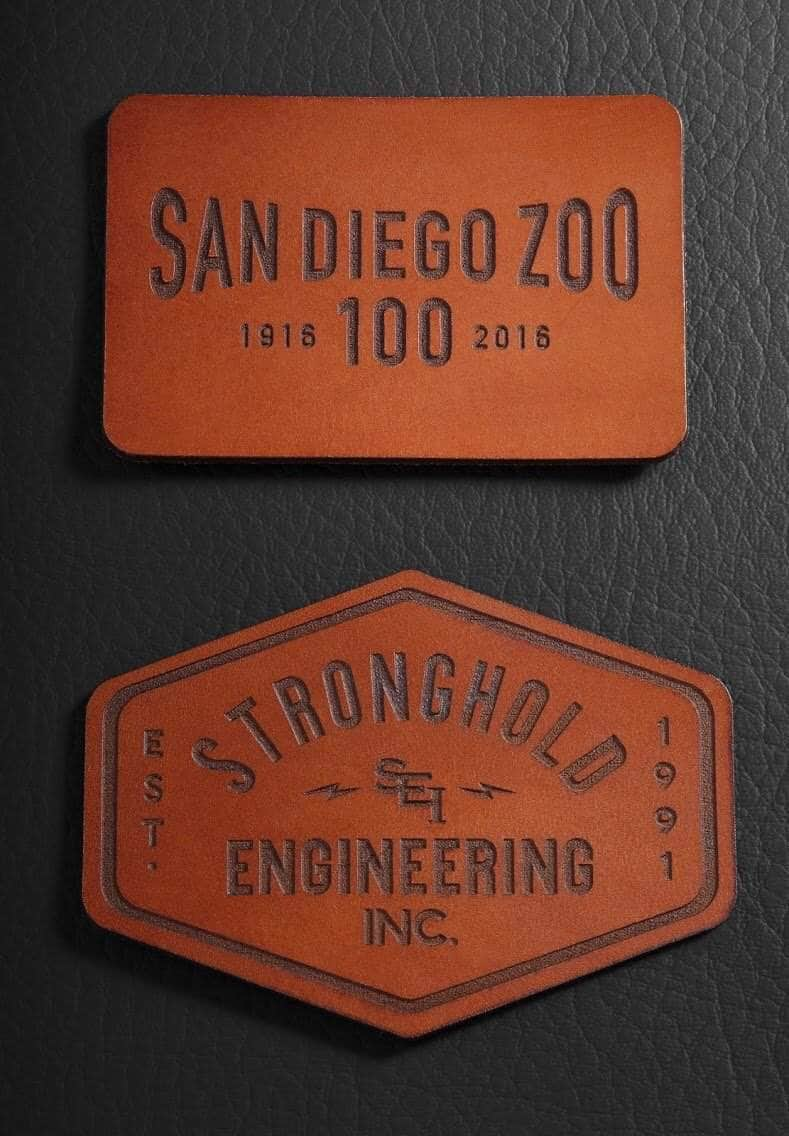

Custom embossing stamps allow for intricate designs and logos to be imprinted onto leather surfaces, making them ideal for promotional products and custom leather goods. These stamps are typically made from durable materials such as brass, ensuring longevity even with repeated use. B2B buyers should consider the type of press required for application, as some stamps may necessitate specialized equipment, which could impact overall cost and logistics.

Why Choose Curved Surface Branders for Non-Flat Leather Items?

Curved surface branders are specifically designed to accommodate the branding of items with non-flat surfaces, such as sports equipment or bags. This versatility makes them a valuable asset for companies that deal with a range of leather products. While they offer unique branding opportunities, users may face a learning curve to achieve the best results, necessitating training or practice to ensure effective branding.

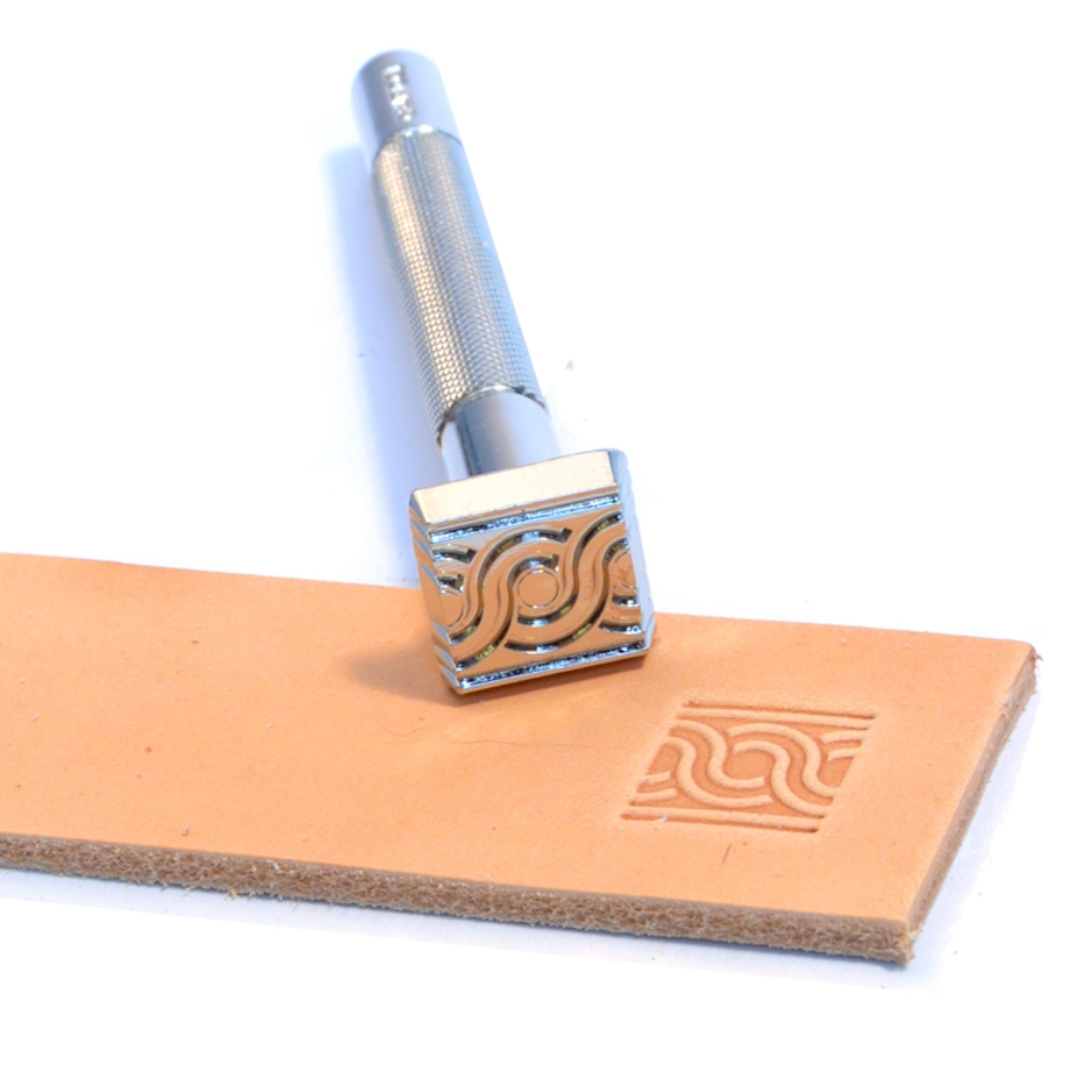

Illustrative image related to custom leather brand

What Are the Key Features of Heavy-Duty Branding Irons for Industrial Use?

Heavy-duty branding irons are constructed for durability and are particularly effective for branding thick, tough leather. These tools are essential in industrial applications where brands need to be applied to heavy-duty items like belts, boots, and furniture. Buyers should assess the weight and portability of these irons, as they may not be as easy to maneuver as lighter alternatives, but their longevity and effectiveness in demanding conditions often justify the trade-off.

Key Industrial Applications of custom leather brand

| Industry/Sector | Specific Application of custom leather brand | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom branding on leather goods such as handbags, belts, and shoes. | Enhances brand identity and customer loyalty through unique, recognizable products. | Ensure high-quality materials that withstand wear and maintain brand visibility. |

| Automotive | Branding leather interiors and custom seat covers. | Adds a premium feel to vehicles, increasing perceived value and customer satisfaction. | Consider durability and maintenance requirements for high-traffic areas. |

| Furniture and Home Decor | Branding leather upholstery for furniture items. | Differentiates products in a competitive market, appealing to design-conscious consumers. | Focus on eco-friendly materials and finishes to attract environmentally aware buyers. |

| Sports Equipment | Branding leather sports gear like gloves and balls. | Creates a sense of ownership and team spirit among users, enhancing brand loyalty. | Look for lightweight materials that maintain performance under various conditions. |

| Promotional Products | Custom leather items for corporate gifting. | Strengthens business relationships and enhances brand visibility through unique promotional items. | Consider customization options and lead times to meet marketing campaign schedules. |

How is Custom Leather Branding Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, custom leather branding is pivotal for establishing brand identity. Designers often use branded leather goods—such as handbags, belts, and shoes—to create a distinct image. This branding enhances customer loyalty by making products instantly recognizable. For international buyers, especially in regions like Africa and Europe, sourcing high-quality materials is essential. The durability of the branding must match the craftsmanship of the leather goods to ensure longevity and maintain brand visibility.

What are the Applications of Custom Leather Branding in the Automotive Sector?

In the automotive industry, custom leather branding is applied to enhance the interiors of vehicles, particularly in luxury models. Branding on leather seats and trims adds a premium touch, elevating the vehicle’s perceived value. For buyers from regions like the Middle East and South America, it’s crucial to consider the durability of the branding, as these areas may have extreme weather conditions that affect leather quality. Additionally, ensuring that the branding process does not compromise the leather’s integrity is vital for long-term customer satisfaction.

How is Custom Leather Branding Utilized in Furniture and Home Decor?

Custom leather branding in furniture and home decor focuses on branding leather upholstery for sofas, chairs, and other furnishings. This application differentiates products in a crowded market, appealing to design-conscious consumers who value aesthetics and craftsmanship. International B2B buyers should prioritize eco-friendly materials and finishes, as sustainability is becoming a significant purchasing factor, particularly in Europe. Moreover, ensuring that the branding does not interfere with the leather’s texture or comfort is essential for maintaining product quality.

Illustrative image related to custom leather brand

What Role Does Custom Leather Branding Play in Sports Equipment?

In the sports equipment sector, custom leather branding is commonly seen on items like gloves and balls. This branding fosters a sense of ownership and team spirit among athletes, thereby enhancing brand loyalty. For international buyers, particularly in regions with a strong sports culture, sourcing lightweight and durable materials is critical. The branding process must ensure that the performance of the gear is not compromised, as athletes require high-quality equipment that can withstand rigorous use.

How is Custom Leather Branding Used in Promotional Products?

Custom leather branding is increasingly popular for promotional products, where businesses use branded leather items as corporate gifts. These unique items strengthen business relationships and enhance brand visibility among clients and partners. For B2B buyers, particularly in emerging markets like Nigeria and Saudi Arabia, it’s important to consider customization options that allow for individual branding needs. Additionally, sourcing should take into account lead times to align with marketing campaigns, ensuring timely delivery of promotional materials.

3 Common User Pain Points for ‘custom leather brand’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Branding Quality

The Problem: B2B buyers in the custom leather sector often struggle with achieving uniform branding quality across various products. This inconsistency can arise due to variations in leather types, heat settings, and branding tools used. For example, soft leather may require less heat than tougher materials, leading to burnt impressions on some pieces while others remain poorly branded. Such discrepancies can result in customer dissatisfaction, diminished brand reputation, and increased returns.

The Solution: To ensure consistent branding quality, buyers should invest in a comprehensive training program for their production teams. This training should cover the specifics of heat application for different leather types and the importance of dwell time. Furthermore, sourcing high-quality, adjustable branding irons that allow for precise temperature control can mitigate issues with overheating or underheating. Electric branding tools, particularly those with built-in temperature controllers, provide a reliable solution. Additionally, conducting test runs on sample pieces before full production can help identify the optimal settings for each leather type, ensuring that every branded item meets the desired quality standards.

Illustrative image related to custom leather brand

Scenario 2: High Volume Production Challenges

The Problem: Buyers seeking to produce large quantities of custom leather products often encounter bottlenecks in their branding processes. High-volume production can be hampered by inefficient branding methods, leading to increased labor costs and extended turnaround times. For instance, manual branding techniques can be time-consuming and prone to errors, resulting in wasted materials and resources.

The Solution: Implementing automated branding solutions can significantly enhance production efficiency. Buyers should consider investing in drill press-mounted branding irons or electric branding machines that allow for high-speed branding with consistent results. These tools can drastically reduce the time spent on each branded piece while maintaining quality. Moreover, establishing a standardized workflow that integrates these tools into the production line will streamline operations. Collaborating with suppliers who offer bulk pricing for branding tools and materials can also reduce costs and improve overall production efficiency.

Scenario 3: Design Limitations and Customization Issues

The Problem: Many B2B buyers face challenges when it comes to customizing designs for branding on leather products. Limited options for artwork, design complexity, and the capabilities of existing branding tools can hinder creativity. This limitation can be particularly frustrating for businesses looking to differentiate their products in competitive markets.

The Solution: To overcome design limitations, buyers should partner with suppliers who offer advanced customization options and a robust design support system. For instance, sourcing branding irons that allow for intricate designs or deep relief can significantly enhance branding capabilities. Companies should also explore digital design tools that enable them to create and visualize their branding concepts before production. Additionally, working closely with branding iron manufacturers to develop custom designs tailored to their specific needs can yield unique branding solutions. Regular feedback loops during the design phase can help ensure that the final product aligns with the brand’s vision and customer expectations.

Strategic Material Selection Guide for custom leather brand

What Are the Key Properties of Brass for Custom Leather Branding?

Brass is a popular choice for custom leather branding irons due to its excellent thermal conductivity and durability. With a high melting point of around 900°C, brass can withstand the heat required for effective branding without warping or degrading. Its corrosion resistance ensures longevity, making it suitable for high-volume applications. Additionally, the malleability of brass allows for intricate designs to be engraved, resulting in clear and precise branding marks.

Illustrative image related to custom leather brand

Pros and Cons of Using Brass

The primary advantages of brass include its durability and ability to retain heat, which facilitates consistent branding results. However, the cost of brass can be higher than other materials, which may affect budget considerations for international buyers. Furthermore, while brass is suitable for leather and wood, it may not perform as well on softer materials, which could limit its application in certain markets.

How Does Stainless Steel Compare for Leather Branding Applications?

Stainless steel is another viable option for custom leather branding due to its strength and resistance to rust and corrosion. It can handle high temperatures, making it suitable for branding applications that require extended use. The high tensile strength of stainless steel ensures that branding tools maintain their shape and effectiveness over time.

Pros and Cons of Using Stainless Steel

While stainless steel is incredibly durable and resistant to wear, it is typically more expensive than brass. Its rigidity can also make it challenging to engrave intricate designs, which may limit branding options. For international buyers, the weight of stainless steel tools can increase shipping costs, particularly for bulk orders.

What Are the Benefits of Using High-Density Resin for Branding Stamps?

High-density resin is a cost-effective alternative for custom leather branding, especially for low-volume applications. It is lightweight and easy to handle, making it suitable for smaller operations or startups. Resin stamps can be designed with intricate details and are often less expensive than metal options.

Pros and Cons of Using High-Density Resin

The main advantage of high-density resin is its affordability and ease of customization. However, its durability is limited compared to metal options, as it can wear out after repeated use. Additionally, resin stamps cannot withstand high temperatures, which restricts their use for branding leather that requires significant heat application. For international buyers, understanding the limitations of resin in terms of durability and application is crucial.

Illustrative image related to custom leather brand

What is the Role of Electric Branding Irons in Custom Leather Branding?

Electric branding irons offer a modern solution for custom leather branding, providing consistent heat application without the need for manual reheating. They are available in various sizes and styles, making them versatile for different branding needs. Electric branding tools can be particularly useful for high-volume production environments.

Pros and Cons of Using Electric Branding Irons

The key advantage of electric branding irons is their efficiency and ease of use, which can significantly enhance productivity. However, they typically come at a higher initial cost and may require specific electrical setups, especially in regions with different voltage standards. International buyers must consider compatibility with local electrical systems, especially in regions like Africa and the Middle East.

Summary Table of Material Selection for Custom Leather Branding

| Material | Typical Use Case for custom leather brand | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-volume branding for leather goods | Excellent heat retention and durability | Higher cost than other materials | High |

| Stainless Steel | Durable branding for various materials | Strong and corrosion-resistant | More expensive and heavier | High |

| High-Density Resin | Low-volume branding for intricate designs | Cost-effective and easy to customize | Limited durability and heat resistance | Low |

| Electric Branding Irons | High-efficiency branding in production | Consistent heat application | Higher initial cost and electrical setup needed | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers looking to optimize their custom leather branding processes. Understanding the properties, advantages, and limitations of each material will facilitate informed purchasing decisions tailored to specific market needs.

Illustrative image related to custom leather brand

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather brand

What Are the Main Stages of Manufacturing Custom Leather Products?

The manufacturing process for custom leather products is intricate and requires several key stages to ensure quality and precision. The main stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

The first step involves sourcing high-quality leather and other raw materials. B2B buyers should focus on suppliers that source leather from reputable tanneries, ensuring that the leather is treated and finished according to industry standards. This stage often includes inspecting the leather for defects, such as scars or irregularities, and cutting it into pre-defined shapes based on the product design.

What Techniques Are Used in Forming Custom Leather Products?

Forming techniques vary based on the intended use of the leather product. Common methods include:

- Die Cutting: A precise method to cut leather into specific shapes, ensuring consistency across production runs.

- Molding: For products requiring a specific shape, leather can be molded using heat and pressure. This technique is particularly useful for creating structured items like bags and wallets.

- Branding and Stamping: Custom branding irons are used to imprint logos or designs onto the leather. This process requires careful temperature control to avoid damaging the leather while ensuring a clear imprint.

How Is Assembly Conducted in Custom Leather Manufacturing?

Assembly involves stitching or bonding the various components of the product. Skilled artisans typically hand-stitch high-end leather products, providing durability and an artisanal touch. For mass production, sewing machines may be employed to speed up the process while maintaining quality. Ensuring the right thread type and stitch density is crucial to the product’s longevity.

What Quality Assurance Standards Are Relevant for Custom Leather Manufacturing?

Quality assurance is vital for maintaining consistency and meeting customer expectations. International standards like ISO 9001 are essential, as they provide a framework for quality management systems. In addition, industry-specific certifications such as CE (for products sold in the European market) and API (for oil and gas applications) can enhance credibility.

Illustrative image related to custom leather brand

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This step verifies that the raw materials, including leather and hardware, meet specified quality standards before they enter production.

- In-Process Quality Control (IPQC): During manufacturing, periodic inspections ensure that each stage adheres to quality standards. This can include checking stitching consistency and branding clarity.

- Final Quality Control (FQC): Before products are shipped, a thorough inspection is conducted to check for defects, ensuring that each item meets the buyer’s specifications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should consider several methods to verify a supplier’s quality control processes:

- Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing practices and QC measures. This is particularly important for international suppliers where standards may vary.

- Quality Reports: Requesting detailed QC reports can help buyers understand the frequency and types of inspections performed during production.

- Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of product quality and compliance with international standards.

What Are the Common Testing Methods for Quality Assurance in Leather Products?

Testing methods for leather products vary but typically include:

- Physical Tests: These assess the leather’s durability, flexibility, and resistance to wear and tear. Common tests include abrasion resistance and tensile strength tests.

- Chemical Tests: These tests evaluate the leather’s resistance to various substances, including water, oil, and heat. This is crucial for products intended for specific environments or uses.

- Visual Inspections: A thorough visual inspection is essential for detecting surface defects, color consistency, and overall aesthetic appeal.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification. Different markets may have varying expectations regarding product safety and environmental standards. For instance, European buyers may prioritize compliance with REACH regulations regarding chemical safety, while buyers in the Middle East may focus on durability and design aesthetics.

Additionally, understanding local customs regulations and import standards can prevent delays or additional costs. Buyers should establish clear communication channels with suppliers to ensure that all quality standards are met and that any certifications are provided in a timely manner.

Conclusion

The manufacturing processes and quality assurance protocols for custom leather products are multifaceted and require a keen understanding of both the production techniques and the necessary quality standards. By focusing on these aspects, B2B buyers can ensure they source high-quality leather products that meet their specific requirements and stand up to the rigors of international trade. Engaging in thorough due diligence, including audits, quality reports, and understanding local regulations, will facilitate successful partnerships and enhance product satisfaction in competitive markets.

Illustrative image related to custom leather brand

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather brand’

In today’s competitive market, sourcing a custom leather brand requires careful consideration and strategic planning. This guide provides a practical checklist to help B2B buyers navigate the procurement process effectively, ensuring they secure the best products for their business needs.

Step 1: Define Your Branding Requirements

Start by outlining your specific branding needs, including the type of leather, the branding method (e.g., electric vs. fire-heated), and the design specifications. Clearly defined requirements will help you communicate effectively with suppliers and ensure that you receive products that meet your standards. Consider the following:

– Material Type: Different leathers react differently to branding techniques.

– Design Complexity: Simple logos may require different tools than intricate designs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in custom leather branding. Look for manufacturers with a strong reputation and relevant experience. This step is crucial as it sets the foundation for successful partnerships. Focus on:

– Supplier Reviews: Check online reviews and testimonials from other businesses.

– Portfolio: Review their past work to gauge the quality and creativity of their branding solutions.

Step 3: Evaluate Supplier Certifications

Verify that your selected suppliers have the necessary certifications and compliance with international standards. This ensures that they meet quality and ethical production practices, which is increasingly important in global trade. Pay attention to:

– ISO Certifications: Look for suppliers with ISO certifications that demonstrate quality management.

– Sustainability Practices: Consider suppliers that follow environmentally friendly processes.

Step 4: Request Samples and Prototypes

Before finalizing your order, request samples or prototypes to assess the quality and effectiveness of the branding tools. This hands-on evaluation allows you to determine if the products meet your expectations. Key aspects to examine include:

– Branding Quality: Ensure the branding is clear and durable on the leather.

– Ease of Use: Assess whether the tools are user-friendly and suitable for your production scale.

Illustrative image related to custom leather brand

Step 5: Discuss Production Capabilities and Timelines

Engage in discussions with suppliers about their production capabilities and lead times. Understanding their capacity to meet your demand is vital for planning your inventory and marketing strategies. Consider:

– Production Volume: Ensure they can handle your required quantities.

– Delivery Times: Clarify how long it will take for your order to be completed and shipped.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, negotiate pricing and payment terms. Effective negotiation can lead to cost savings and favorable conditions for future orders. Focus on:

– Bulk Discounts: Inquire about price reductions for larger orders.

– Payment Terms: Establish clear payment schedules that align with your cash flow.

Step 7: Finalize Agreements and Place Orders

After agreeing on terms, ensure all aspects are documented in a formal agreement. This protects both parties and clarifies expectations. Be meticulous about including:

– Delivery Expectations: Clearly outline shipping dates and logistics.

– Quality Assurance Clauses: Include terms regarding product quality and return policies.

By following these steps, B2B buyers can effectively source custom leather branding tools that meet their business needs while fostering strong supplier relationships.

Illustrative image related to custom leather brand

Comprehensive Cost and Pricing Analysis for custom leather brand Sourcing

What Are the Key Cost Components in Custom Leather Brand Sourcing?

Understanding the cost structure of custom leather branding is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of leather significantly influences costs. High-quality leather, such as full-grain or top-grain, commands higher prices compared to lower grades. Additionally, the type of branding equipment (e.g., electric versus fire-heated irons) and the materials used for these tools (brass, steel, etc.) also affect overall costs.

-

Labor: Skilled labor is required for crafting custom branding tools and executing branding processes. Labor costs vary based on geographic location, with regions offering lower labor costs impacting the overall price. This is particularly relevant for buyers in regions like Africa and South America, where labor may be less expensive than in Europe or the Middle East.

-

Manufacturing Overhead: This includes costs related to the facilities, utilities, and administrative expenses necessary for production. Efficient production facilities can reduce overhead costs, which can be a negotiating point for buyers.

-

Tooling: Custom branding tools require initial investment in tooling, which can be amortized over larger production runs. The setup for custom designs may involve higher upfront costs, which could be mitigated through higher order volumes.

-

Quality Control (QC): Ensuring the quality of leather products and branding marks is critical. QC processes add to the cost but are essential for maintaining brand integrity, especially for businesses exporting to international markets where quality standards may vary.

-

Logistics: Shipping and handling costs can vary widely based on the origin and destination of the products, as well as the chosen Incoterms. Buyers should factor in potential customs duties and taxes when calculating total costs.

-

Margin: Supplier profit margins are influenced by competition, production costs, and perceived value in the market. Understanding the typical margins in the custom leather industry can provide a basis for negotiation.

How Do Price Influencers Affect Custom Leather Brand Sourcing?

Several factors can influence the pricing of custom leather branding solutions:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should discuss MOQs with suppliers to optimize pricing.

-

Specifications and Customization: Custom designs or specific branding requirements may increase costs. Clarity in design specifications can minimize revisions and unexpected expenses.

-

Materials and Quality Certifications: The choice of materials not only affects cost but also impacts the final product’s durability and marketability. Certifications for sustainable practices or quality standards may add to costs but can enhance brand reputation.

-

Supplier Factors: Supplier reputation, reliability, and production capacity can significantly affect pricing. Buyers should evaluate potential suppliers based on their track record and ability to meet quality and delivery standards.

-

Incoterms: The chosen Incoterms dictate the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs. Understanding these terms can help buyers manage costs effectively.

What Buyer Tips Can Enhance Cost-Efficiency in Custom Leather Sourcing?

-

Negotiation Strategies: Build strong relationships with suppliers to foster open communication. Discuss potential discounts for bulk orders or long-term contracts to secure better pricing.

-

Evaluating Total Cost of Ownership (TCO): Look beyond initial costs. Consider long-term factors such as durability, maintenance, and potential resale value when assessing the overall value of products.

-

Pricing Nuances for International Markets: Understand regional pricing dynamics, including local market demand and competition. Buyers from Africa, South America, the Middle East, and Europe should be aware of how currency fluctuations can impact pricing.

-

Stay Informed on Market Trends: Keeping abreast of industry trends can provide insights into pricing changes and help buyers make informed purchasing decisions.

Disclaimer for Indicative Prices

The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier pricing strategies, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing custom leather brand With Other Solutions

Exploring Viable Alternatives to Custom Leather Branding Solutions

When considering custom leather branding, it’s essential for B2B buyers to explore various alternatives that can achieve similar branding outcomes. This analysis will compare custom leather branding with alternative methods, providing insights into their respective benefits and drawbacks.

Illustrative image related to custom leather brand

| Comparison Aspect | Custom Leather Brand | Laser Engraving | Embossing Stamps |

|---|---|---|---|

| Performance | High-quality, permanent marks | Precise, detailed designs | Durable impressions, limited detail |

| Cost | Moderate to high (starting ~$69) | Higher initial investment (from ~$300) | Lower cost (starting ~$50) |

| Ease of Implementation | Requires heat source and skill | Requires specialized equipment and training | Simple to use with a press |

| Maintenance | Moderate (requires cleaning) | Low (occasional software updates) | Low (durable materials) |

| Best Use Case | Custom logos on leather goods | Intricate designs on various materials | Simple branding on leather and other substrates |

What Are the Pros and Cons of Laser Engraving?

Laser engraving is a highly precise method that utilizes laser technology to etch designs into materials. The main advantage of this technique is its ability to produce intricate and detailed designs that can be replicated consistently. However, the initial investment in laser engraving equipment can be significant, making it less accessible for small businesses. Additionally, the process can be slower for larger runs compared to traditional branding methods. Overall, laser engraving is best suited for businesses looking to create detailed artwork on a variety of materials, including leather, wood, and glass.

How Does Embossing Stamps Compare to Custom Leather Branding?

Embossing stamps are a traditional method for marking leather that involves pressing a heated stamp into the material. This technique is relatively low-cost and easy to implement, making it an attractive option for small-scale operations or businesses just starting with leather branding. However, embossing stamps typically offer less detail than custom leather branding or laser engraving, making them more suitable for simpler designs. They can be used effectively for branding items like wallets, belts, and other leather goods where a straightforward logo or mark is sufficient.

Conclusion: How to Choose the Right Branding Solution for Your Business

When selecting a branding solution, B2B buyers should consider their specific needs, including the complexity of designs, budget constraints, and production volume. Custom leather branding provides a high-quality, professional look for intricate designs, while laser engraving offers precision for detailed artwork at a higher cost. On the other hand, embossing stamps present a cost-effective option for simpler branding needs. By evaluating these factors, businesses can make informed decisions that align with their branding objectives and operational capabilities.

Essential Technical Properties and Trade Terminology for custom leather brand

What Are the Key Technical Properties of Custom Leather Brands?

When engaging with custom leather branding, understanding the technical properties of the products is essential for making informed purchasing decisions. Below are critical specifications that buyers should consider:

1. Material Grade

The material used for branding irons significantly affects durability and performance. Common materials include brass, stainless steel, and high-density resin. Brass is often preferred for its longevity and ability to withstand high temperatures, making it ideal for high-volume applications. In contrast, high-density resin is more cost-effective but suitable for lower volume tasks. Choosing the right material ensures that the branding tool can endure repeated use without compromising quality.

Illustrative image related to custom leather brand

2. Heat Retention

Heat retention is a crucial property for branding tools. Branding irons are designed to maintain a consistent temperature to achieve clear, crisp impressions. Irons with thicker branding heads tend to retain heat longer, reducing the need for constant reheating. This is particularly important in high-volume settings where efficiency is key. Understanding heat retention helps buyers select the right tool for their specific branding needs, whether for soft leather or thicker materials.

3. Branding Depth

The depth of the branding mark can vary based on the design and type of branding tool. A deeper branding mark provides more visibility and longevity, especially on textured surfaces. For example, deeply engraved branding heads can accommodate intricate designs and logos, making them suitable for complex branding tasks. Buyers should evaluate their branding requirements to ensure the selected tool achieves the desired depth and clarity.

4. Temperature Control

Temperature control features are vital for achieving optimal branding results. Tools that come with built-in temperature control units allow users to adjust heat settings according to the leather type being branded. Different leathers require varying temperatures; for instance, softer leathers may need less heat compared to firmer ones. This adaptability ensures quality branding, minimizing the risk of damaging the material.

5. Tolerance Levels

Tolerance levels refer to the acceptable variations in dimensions and performance of branding tools. High tolerance levels ensure that branding irons produce consistent results every time. For B2B buyers, understanding tolerance levels is critical in selecting tools that meet industry standards and produce uniform impressions across multiple products.

What Are Common Trade Terms in the Custom Leather Branding Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation efficiency. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products for another company to sell under its brand name. In the custom leather branding industry, buyers may work with OEMs to develop unique branding tools tailored to their specifications. Understanding OEM relationships can provide insights into product quality and customization options.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cost-effectiveness. Knowing the MOQ helps in budgeting and planning purchases, especially for businesses that require large quantities of branding tools.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a detailed quote for specific products or services. In the custom leather branding sector, submitting an RFQ can clarify pricing, lead times, and customization options, allowing buyers to make informed decisions based on competitive offers.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for B2B buyers engaging in cross-border purchases of custom leather products. Understanding Incoterms helps clarify shipping costs, risks, and delivery responsibilities.

Illustrative image related to custom leather brand

5. Lead Time

Lead time refers to the duration between placing an order and receiving the goods. In the custom leather branding industry, lead times can vary based on complexity, material availability, and production capacity. Awareness of lead times allows buyers to plan their inventory and marketing strategies accordingly.

Understanding these technical properties and trade terminology not only enhances operational efficiency but also fosters better supplier relationships, ultimately contributing to the success of a custom leather branding business.

Navigating Market Dynamics and Sourcing Trends in the custom leather brand Sector

What Are the Key Trends Driving the Custom Leather Brand Market?

The custom leather brand market is experiencing significant evolution driven by various global factors. The increasing demand for personalized products is one of the foremost trends, as consumers seek unique items that reflect their identity and style. This trend is particularly pronounced in regions like Africa and South America, where artisan craftsmanship holds cultural significance. Additionally, technological advancements in manufacturing, such as digital printing and automated cutting, are streamlining production processes, enabling brands to offer customized solutions more efficiently.

International B2B buyers are also influenced by the rising importance of e-commerce platforms that facilitate global trade. These platforms allow businesses to source custom leather products from diverse suppliers, enhancing competition and driving innovation. Moreover, the adoption of data analytics is helping companies understand market demands better, allowing for more targeted marketing strategies and inventory management.

Emerging markets, especially in the Middle East, are capitalizing on luxury consumption trends, where custom leather goods are perceived as status symbols. Thus, international buyers need to be aware of regional preferences and cultural nuances when sourcing products. The landscape is further complicated by fluctuating raw material prices and supply chain disruptions, which necessitate agile sourcing strategies.

How Is Sustainability Shaping the Future of Custom Leather Branding?

Sustainability has become a pivotal concern within the custom leather brand sector, influencing sourcing decisions and consumer preferences. As environmental consciousness rises, buyers are increasingly looking for suppliers that prioritize sustainable practices. This includes sourcing leather from tanneries that utilize eco-friendly methods, such as vegetable tanning, which minimizes harmful chemical usage.

Moreover, ethical sourcing has gained traction, with businesses expected to ensure transparency throughout their supply chains. This involves verifying that leather is obtained from reputable sources that uphold animal welfare standards. Certifications such as the Leather Working Group (LWG) certification can guide buyers in identifying responsible suppliers.

In addition to ethical sourcing, the market is seeing a rise in the use of alternative materials, such as plant-based leathers and recycled products. These innovations cater to environmentally conscious consumers and help brands differentiate themselves in a competitive marketplace. As buyers prioritize sustainability, they should seek partnerships with suppliers who align with these values, fostering long-term relationships built on shared ethical commitments.

What Is the Historical Context of Custom Leather Brands?

The history of custom leather branding can be traced back to ancient civilizations, where leather was prized for its durability and versatility. Initially, leather goods were crafted for functional purposes, but over time, artisans began to incorporate decorative elements, leading to the rise of branding as a means of personal expression.

In the modern era, the custom leather sector gained momentum during the industrial revolution, with advancements in manufacturing techniques allowing for more intricate designs and wider distribution. The late 20th century saw a resurgence of interest in handcrafted goods, fueled by a desire for authenticity in a mass-produced world. Today, this blend of tradition and innovation continues to shape the industry, providing B2B buyers with unique opportunities to engage with both artisanal craftsmanship and cutting-edge technology.

Illustrative image related to custom leather brand

Understanding these historical trends is crucial for international buyers, as they navigate a market characterized by diverse influences and evolving consumer expectations. By recognizing the roots of custom leather branding, businesses can better appreciate the value of quality, craftsmanship, and sustainability in their sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather brand

-

How do I ensure quality when sourcing custom leather products?

To ensure quality when sourcing custom leather products, start by vetting potential suppliers thoroughly. Request samples to assess the craftsmanship, material quality, and durability. Look for certifications or quality assurance processes that the supplier follows, and check reviews or testimonials from previous clients. Establish clear quality control measures, including specifications for materials and finishes, and discuss these expectations upfront. This proactive approach will help mitigate risks and ensure you receive high-quality products that meet your standards. -

What is the best way to customize my leather branding?

The best way to customize your leather branding is to work closely with your supplier to define your vision. Provide high-quality artwork or logos, and be clear about the desired size and placement on the leather. Many suppliers offer design mock-ups before production, allowing you to make adjustments. Additionally, inquire about different branding methods, such as heat branding or embossing, to determine which best suits your product and branding strategy. -

What are the common minimum order quantities (MOQs) for custom leather products?

Minimum order quantities (MOQs) for custom leather products can vary significantly by supplier and product type. Typically, MOQs range from 50 to 500 units, depending on the complexity of the customization and the materials used. It’s essential to discuss MOQs with potential suppliers early in the negotiation process. Some suppliers may offer flexibility for first-time buyers or smaller businesses, so don’t hesitate to inquire about options that fit your purchasing needs. -

What payment terms should I expect when sourcing custom leather products?

Payment terms for custom leather products often vary based on the supplier’s policies and your business relationship. Common terms include a deposit (usually 30-50%) paid upfront, with the balance due upon completion or prior to shipping. For larger orders or established relationships, you may be able to negotiate more favorable terms, such as extended payment schedules. Always clarify payment methods accepted (e.g., bank transfers, credit cards) and ensure that all terms are documented to avoid misunderstandings. -

How do I handle logistics for international shipping of custom leather goods?

Handling logistics for international shipping of custom leather goods requires careful planning. Choose a reliable freight forwarder familiar with customs regulations in your destination country. Ensure that all necessary documentation, such as invoices, packing lists, and certificates of origin, are prepared to facilitate smooth customs clearance. Discuss shipping options with your supplier, including express services for urgent orders or sea freight for cost-effective bulk shipments. Additionally, factor in lead times for production and shipping to manage your inventory effectively. -

What should I consider when vetting suppliers for custom leather products?

When vetting suppliers for custom leather products, consider their experience and specialization in leather goods. Review their portfolio to assess the quality and range of products they offer. Check for industry certifications that indicate compliance with standards, such as ISO or ethical sourcing practices. Communication is crucial, so evaluate their responsiveness and willingness to collaborate on your design requirements. Finally, consider visiting their facilities if possible, or arrange virtual tours to gain insight into their manufacturing processes. -

What are the key benefits of using custom leather branding for my business?

Custom leather branding offers numerous benefits, including enhanced brand recognition and a premium feel that can elevate your product’s perceived value. It allows for unique personalization that can resonate with your target audience, making your products stand out in a competitive market. Additionally, custom branding can foster customer loyalty, as it creates a connection between the product and the brand’s identity. Furthermore, high-quality leather branding can lead to repeat business, as customers are often willing to pay more for distinctive, branded items. -

How can I ensure compliance with international trade regulations when sourcing leather products?

To ensure compliance with international trade regulations when sourcing leather products, familiarize yourself with the legal requirements of both your country and the supplier’s country. This includes understanding tariffs, import/export restrictions, and any specific regulations related to leather goods. Work with a legal expert or trade consultant to navigate complex trade laws and ensure that all necessary documentation is in place. Additionally, ensure that your supplier adheres to ethical sourcing practices and can provide certifications if required, which can help mitigate risks associated with non-compliance.

Top 5 Custom Leather Brand Manufacturers & Suppliers List

1. Branding Irons – Custom Branding Solutions

Domain: brandingirons.com

Registered: 1999 (26 years)

Introduction: Branding Irons for Leather, Family owned and operated for over 25 years, Made in the USA, Call 818-576-1101 to speak to a branding specialist, Custom Branding Iron Quote, Livestock Branding Irons, Curved Custom Branding Iron, Extra Large Custom Branding Irons, Custom Interchangeable Branding Irons, Buy Online, Custom Branding Irons, Light Duty Branding Irons, Heavy Duty Branding Irons, Basic Pre-M…

2. Gearheart Industry – Custom Leather Stamping Tools

Domain: gearheartindustry.com

Registered: 2013 (12 years)

Introduction: Custom Leather Stamping Tools, Made in the USA; Branding Irons: Torch Heated, Electric, Food, Mounted; Branding Iron Design Generator; Leather Stamping Tools; Accessories; Prices: Custom Leather Stamp as low as $119.00, Leather Stamp Handle $21.00, SmartBrand Branding System as low as $412.00, SmartBrand Drill Press Branding System as low as $522.00, Extra Branding Iron Plates as low as $65.00.

3. BrandNew – Custom Leather Branding Irons

Domain: brandnew.net

Registered: 1998 (27 years)

Introduction: Leather Branding Irons are fully customizable branding irons made with any artwork, logo, or text. They feature an extra deep relief, allowing for branding on leather and rough, uneven surfaces. Key details include:

– Material: Milled from brass

– High relief depth: 0.1″ to 0.15″ (depending on specific artwork)

– Standard production time: 2 weeks, plus shipping

– Starting price: $106.28

– Siz…

4. Custom Brand – Leather Embossing Stamp

5. LW Leathers – Custom Leather Stamps & Branding Irons

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: Custom Leather Stamp, Branding Iron & Die Cut – Production lead time: 2-5 working days. Custom orders can be ready to ship in 2-3 working days. Custom Branding Irons for leather and wood, Freeze Branding Irons for livestock, Leather Stamps, Steel Rule Cutting Dies, Electric Branding Iron Tools. All products made by CNC with solid brass for durability, withstand heating up to 1700°F / 900°C. Featur…

Strategic Sourcing Conclusion and Outlook for custom leather brand

How Can Strategic Sourcing Enhance Your Custom Leather Brand?

In the competitive landscape of custom leather branding, strategic sourcing emerges as a critical factor for success. By carefully selecting suppliers who offer high-quality materials and innovative branding tools—such as electric branding irons and custom embossing stamps—businesses can enhance their product offerings and brand identity. Leveraging these resources not only improves the quality of the final product but also ensures consistency and reliability, crucial elements for building long-term relationships with clients across diverse regions.

International B2B buyers from Africa, South America, the Middle East, and Europe must prioritize partnerships with suppliers that provide tailored solutions to meet specific market needs. This includes considering factors such as production timelines, customization capabilities, and customer support. Emphasizing collaboration with manufacturers who understand regional preferences and requirements will significantly enhance market penetration and customer satisfaction.

As you look to the future, consider investing in innovative branding technologies and sustainable materials that resonate with your target audience. Engaging with suppliers who prioritize ethical practices can also enhance your brand reputation. Make informed sourcing decisions today to position your custom leather brand for growth and success in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to custom leather brand

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.