Introduction: Navigating the Global Market for custom leather punch

In today’s competitive landscape, sourcing custom leather punches poses a significant challenge for international B2B buyers. As the demand for high-quality leather products continues to rise across various sectors—including fashion, automotive, and furniture—businesses must ensure they have the right tools to achieve precision and efficiency in their production processes. This guide serves as an essential resource for navigating the global market for custom leather punches, offering insights into the types available, their diverse applications, supplier vetting processes, and cost considerations.

By consolidating critical information, this comprehensive guide empowers buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia—to make informed purchasing decisions. Understanding the nuances of custom leather punch production can streamline operations and enhance product quality, ultimately driving business growth.

Whether you are looking for basic hand punches or complex die-cutting solutions, this guide will help you identify reputable suppliers, evaluate pricing structures, and understand the manufacturing capabilities required to meet your specific needs. Equip yourself with the knowledge to transform your leather crafting endeavors into successful business ventures.

Table Of Contents

- Top 6 Custom Leather Punch Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather punch

- Understanding custom leather punch Types and Variations

- Key Industrial Applications of custom leather punch

- 3 Common User Pain Points for ‘custom leather punch’ & Their Solutions

- Strategic Material Selection Guide for custom leather punch

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather punch

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather punch’

- Comprehensive Cost and Pricing Analysis for custom leather punch Sourcing

- Alternatives Analysis: Comparing custom leather punch With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather punch

- Navigating Market Dynamics and Sourcing Trends in the custom leather punch Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather punch

- Strategic Sourcing Conclusion and Outlook for custom leather punch

- Important Disclaimer & Terms of Use

Understanding custom leather punch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cutting Punch | Designed for cutting leather, paper, and cardstock; custom shapes available | Mass production of leather goods; prototyping | Pros: High precision, quick turnaround. Cons: Higher initial cost for custom designs. |

| Clicking Die | Pre-sharpened steel construction; designed for high-volume cutting | Large-scale manufacturing of leather products | Pros: Durable, efficient for large runs. Cons: Requires upfront investment in dies. |

| Leather Stamping Tool | Customizable branding options; various heat methods available | Branding and personalization of leather goods | Pros: Versatile for different materials. Cons: May require additional equipment for heat application. |

| Hole Punch | Creates precise holes in various sizes; often used for hardware attachment | Leather goods assembly and accessory creation | Pros: Essential for functionality, easy to use. Cons: Limited to hole creation, less versatile. |

| Embossing Die | Creates raised designs on leather; custom designs possible | Decorative leather goods and high-end products | Pros: Enhances product aesthetics, unique branding. Cons: Higher cost and longer production time. |

What Are the Key Characteristics of Cutting Punches?

Cutting punches are essential tools for businesses engaged in producing leather goods, as they allow for precise cutting of materials into custom shapes. These punches can handle various materials, including leather and cardstock, making them versatile for different applications. B2B buyers should consider the balance between the initial investment and the potential for mass production, as custom designs may incur higher costs but yield significant returns in efficiency.

How Do Clicking Dies Enhance Production Efficiency?

Clicking dies are specifically designed for high-volume leather cutting. Made from pre-sharpened steel, these dies ensure durability and accuracy, crucial for manufacturers that require consistency across large batches. When purchasing, businesses should evaluate the cost of the die against their production needs, as the upfront investment can be offset by the increased speed and precision in manufacturing.

What Benefits Do Leather Stamping Tools Provide?

Leather stamping tools offer businesses the ability to create unique branding and decorative elements on leather products. With various customization options, including heat application methods, these tools cater to a wide range of branding needs. Buyers should consider the versatility of these tools, as they can be used across different materials, although additional equipment may be required for certain methods.

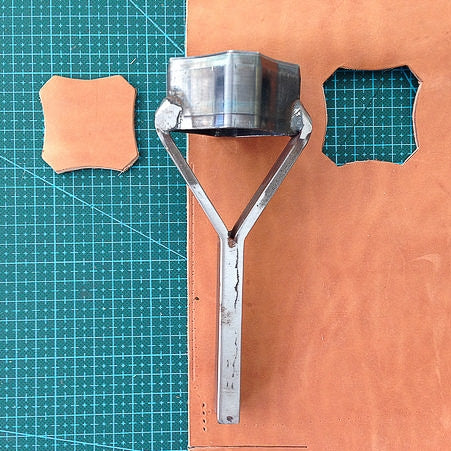

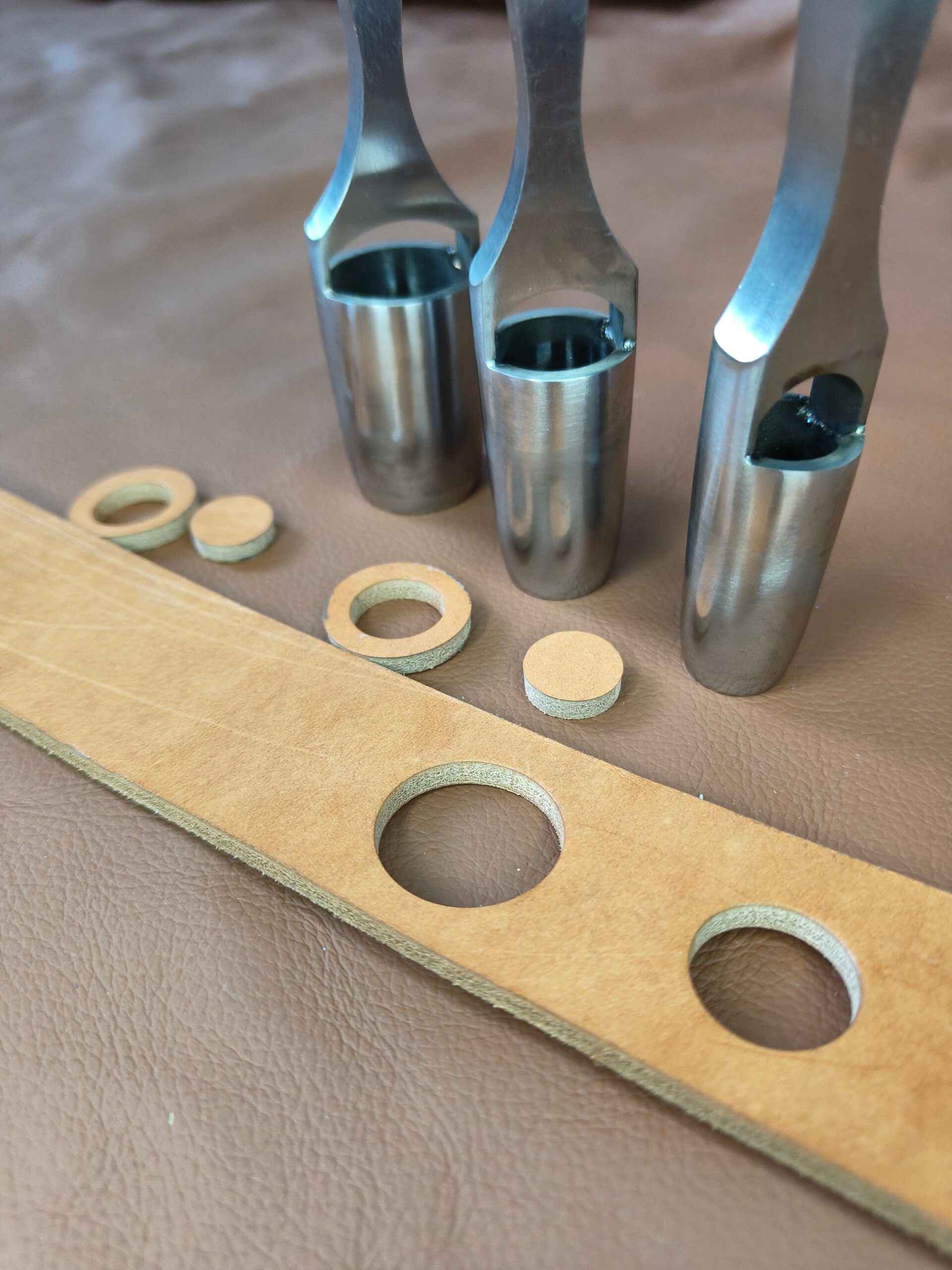

Illustrative image related to custom leather punch

Why Are Hole Punches Indispensable in Leather Goods Production?

Hole punches are vital for creating precise holes in leather, essential for attaching hardware and ensuring the functionality of leather products. They are user-friendly and can be employed in various manufacturing settings. However, businesses should be aware that while hole punches are crucial for assembly, they are limited in scope compared to other types of custom leather punches.

How Do Embossing Dies Contribute to Product Differentiation?

Embossing dies are used to create raised designs on leather, adding a distinctive aesthetic appeal to products. This customization can enhance branding and elevate the perceived value of leather goods. B2B buyers should weigh the unique branding opportunities against the higher costs and longer production times associated with embossed designs, ensuring alignment with their market positioning and customer expectations.

Key Industrial Applications of custom leather punch

| Industry/Sector | Specific Application of custom leather punch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom shapes for clothing and accessories | Enhances design uniqueness and brand differentiation | Precision in design, minimum order quantities, lead times |

| Автомобили | Leather components for upholstery | Improves quality and aesthetic appeal of interiors | Material compatibility, durability requirements |

| Footwear | Sole and upper leather cutting | Streamlines production processes and reduces waste | Customization options, size specifications |

| Мебель | Custom leather patches and upholstery | Increases product lifespan and aesthetic value | Bulk order capabilities, design accuracy |

| Craft and DIY | Personalized crafting tools | Supports creativity and personalization for end-users | Versatility in design, material options |

How is Custom Leather Punch Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, custom leather punches are utilized to create intricate shapes and patterns for clothing and accessories. This allows designers to incorporate unique elements that set their products apart in a competitive market. Buyers should focus on sourcing punches that offer precision and can accommodate various design complexities. Additionally, understanding minimum order requirements and lead times is crucial for timely product launches, especially in regions like Europe and South America where fashion trends can shift rapidly.

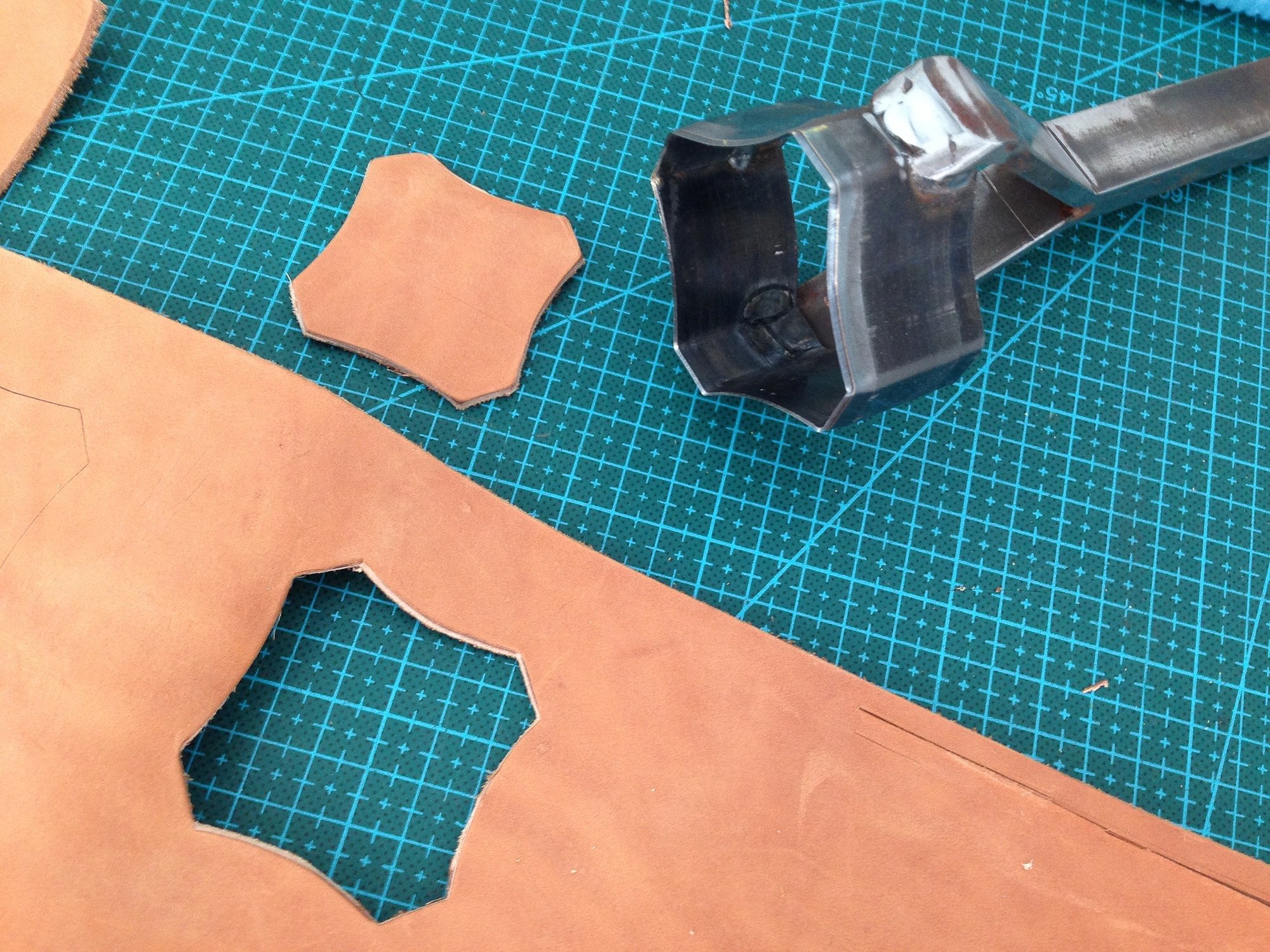

Illustrative image related to custom leather punch

What Role Does Custom Leather Punch Play in the Automotive Industry?

The automotive industry leverages custom leather punches for crafting leather components used in vehicle upholstery. This application enhances the aesthetic appeal and comfort of car interiors, providing a luxurious feel that can increase vehicle value. When sourcing, businesses must consider the compatibility of the punch with different leather types and the durability of the final product. Buyers from the Middle East and Africa, where luxury vehicles are highly sought after, should prioritize suppliers who can deliver high-quality, durable punches that meet stringent automotive standards.

How is Custom Leather Punch Beneficial for Footwear Manufacturing?

In footwear manufacturing, custom leather punches are essential for cutting out soles and upper components with precision. This not only streamlines the production process but also minimizes material waste, which is critical in maintaining cost efficiency. Buyers need to ensure that the punches can handle various leather thicknesses and that they offer customization options for unique shoe designs. Sourcing from reputable suppliers who can meet bulk order requirements is particularly important for manufacturers aiming to scale production in competitive markets.

How Does Custom Leather Punch Enhance Furniture Design?

For the furniture industry, custom leather punches are used to create leather patches and upholstery that enhance product longevity and aesthetic appeal. This application allows manufacturers to provide bespoke solutions tailored to customer preferences, thus increasing market competitiveness. Buyers should consider sourcing punches that can create complex designs and are compatible with various leather types. Ensuring that suppliers can handle bulk orders and deliver high-quality punches will be vital for meeting customer demand in diverse markets, including Europe and South America.

How Can Craft and DIY Sectors Utilize Custom Leather Punch?

The craft and DIY sectors benefit significantly from custom leather punches, which allow artisans to create personalized crafting tools and products. This application supports creativity and enables crafters to produce unique items that resonate with end-users. When sourcing, businesses should look for versatility in design and material options to accommodate various project needs. Given the rising popularity of DIY projects in regions like Africa and South America, suppliers who offer quick turnaround times and customization can capture a growing market segment effectively.

3 Common User Pain Points for ‘custom leather punch’ & Their Solutions

Scenario 1: Delays in Production Due to Customization Complexity

The Problem: B2B buyers often face significant delays in their production schedules when ordering custom leather punches. The complexity of designs can lead to extended lead times, especially if the supplier struggles to accurately interpret the specifications provided. Buyers may also find that their requests for intricate patterns are met with additional charges or longer wait times, which can disrupt their manufacturing timelines and ultimately affect their delivery commitments to clients.

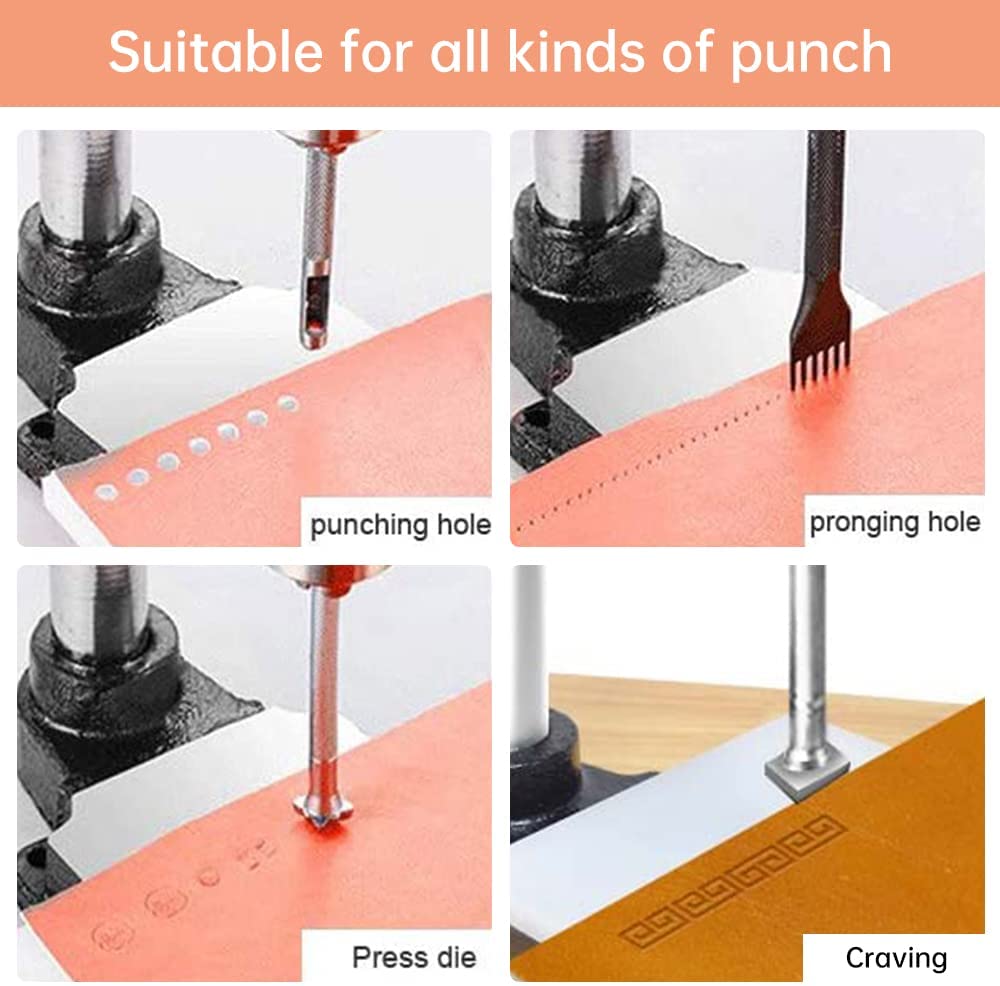

Illustrative image related to custom leather punch

The Solution: To mitigate these delays, buyers should ensure that they provide suppliers with highly detailed specifications, including CAD drawings or high-resolution images of the desired designs. Clearly outlining dimensions, materials, and any specific requirements (like the type of leather or thickness) can significantly reduce back-and-forth communication and streamline the production process. Additionally, working with suppliers known for their quick turnaround times, such as those who guarantee shipment within a few business days, can help maintain production schedules. Establishing a strong communication channel with the supplier can also facilitate quicker problem resolution and adjustments to design specifications.

Scenario 2: Inconsistent Quality Across Orders

The Problem: Another common pain point for B2B buyers is the inconsistency in quality across different orders of custom leather punches. Variations in the manufacturing process can lead to discrepancies in the cut quality, which affects the final product. This inconsistency can be especially problematic for businesses that rely on uniformity in their leather goods, as it can lead to increased waste and customer dissatisfaction.

The Solution: To ensure consistent quality, buyers should seek out suppliers that offer a quality assurance guarantee, such as a money-back promise if the product does not meet specified standards. Prior to placing a bulk order, it is advisable to request a sample run of the custom leather punch to verify the quality and consistency. Establishing a partnership with suppliers who utilize advanced manufacturing technologies, such as precision laser cutting or CNC machines, can also enhance uniformity. Furthermore, requesting regular updates and engaging in quality checks throughout the production process can help address any issues before the final product is shipped.

Illustrative image related to custom leather punch

Scenario 3: High Costs Associated with Custom Designs

The Problem: The cost of custom leather punches can be a significant concern for B2B buyers, particularly when intricate designs are involved. Buyers may encounter unexpected fees for design alterations, die creation, and additional setup costs, which can strain budgets and affect pricing strategies for their end products. This financial unpredictability can deter businesses from pursuing custom designs altogether, limiting their creative potential.

The Solution: To navigate these cost challenges, buyers should engage in upfront discussions with suppliers about all potential fees associated with their custom orders. Requesting a detailed quote that outlines costs for design creation, production, and any additional services can provide clarity and help avoid surprise charges. Additionally, buyers can explore bulk order discounts or loyalty programs that some suppliers offer to mitigate costs. Investing time in understanding the supplier’s pricing structure and discussing alternative design options that may be more cost-effective can also lead to significant savings while still achieving the desired aesthetic.

Strategic Material Selection Guide for custom leather punch

What Are the Key Materials for Custom Leather Punches?

When selecting materials for custom leather punches, B2B buyers must consider several factors that influence performance, durability, and cost. The following analysis focuses on four common materials used in the manufacturing of leather punches: steel, brass, aluminum, and polymer composites.

How Does Steel Perform in Custom Leather Punch Manufacturing?

Steel is the most widely used material for custom leather punches due to its exceptional strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications. Steel punches typically have a high corrosion resistance when treated, which extends their lifespan in various environments.

Pros: Steel punches are highly durable, can handle intricate designs, and are suitable for mass production. They offer excellent precision in cutting and stamping, making them ideal for high-quality leather products.

Cons: The main drawback of steel is its weight, which can make handling more cumbersome. Additionally, untreated steel is prone to rust, necessitating protective coatings, which can increase manufacturing complexity and costs.

Impact on Application: Steel punches are compatible with a wide range of leather types, including thick and heavy materials. However, buyers should ensure that the specific steel grade used meets international standards for quality and safety.

What Advantages Does Brass Offer for Leather Punches?

Brass is another popular choice for custom leather punches, particularly for decorative applications. It is known for its aesthetic appeal and resistance to corrosion, making it a good option for punches that will be frequently exposed to moisture.

Pros: Brass punches are lightweight and offer good durability. They are particularly effective for intricate designs and decorative stamping due to their ability to hold fine details.

Cons: While brass is resistant to corrosion, it is softer than steel, which can lead to wear over time, especially in high-volume applications. Additionally, brass punches may require more frequent replacement, which can increase long-term costs.

Impact on Application: Brass is suitable for lighter leather and is often used in fashion accessories and decorative items. Buyers should consider the specific application to ensure that brass meets performance expectations.

Why Choose Aluminum for Custom Leather Punches?

Aluminum is valued for its lightweight properties and corrosion resistance. It is often used in applications where weight is a concern, such as portable leatherworking tools.

Pros: Aluminum punches are easy to handle and transport, making them ideal for small-scale or mobile operations. They are also resistant to rust and can be anodized for additional durability.

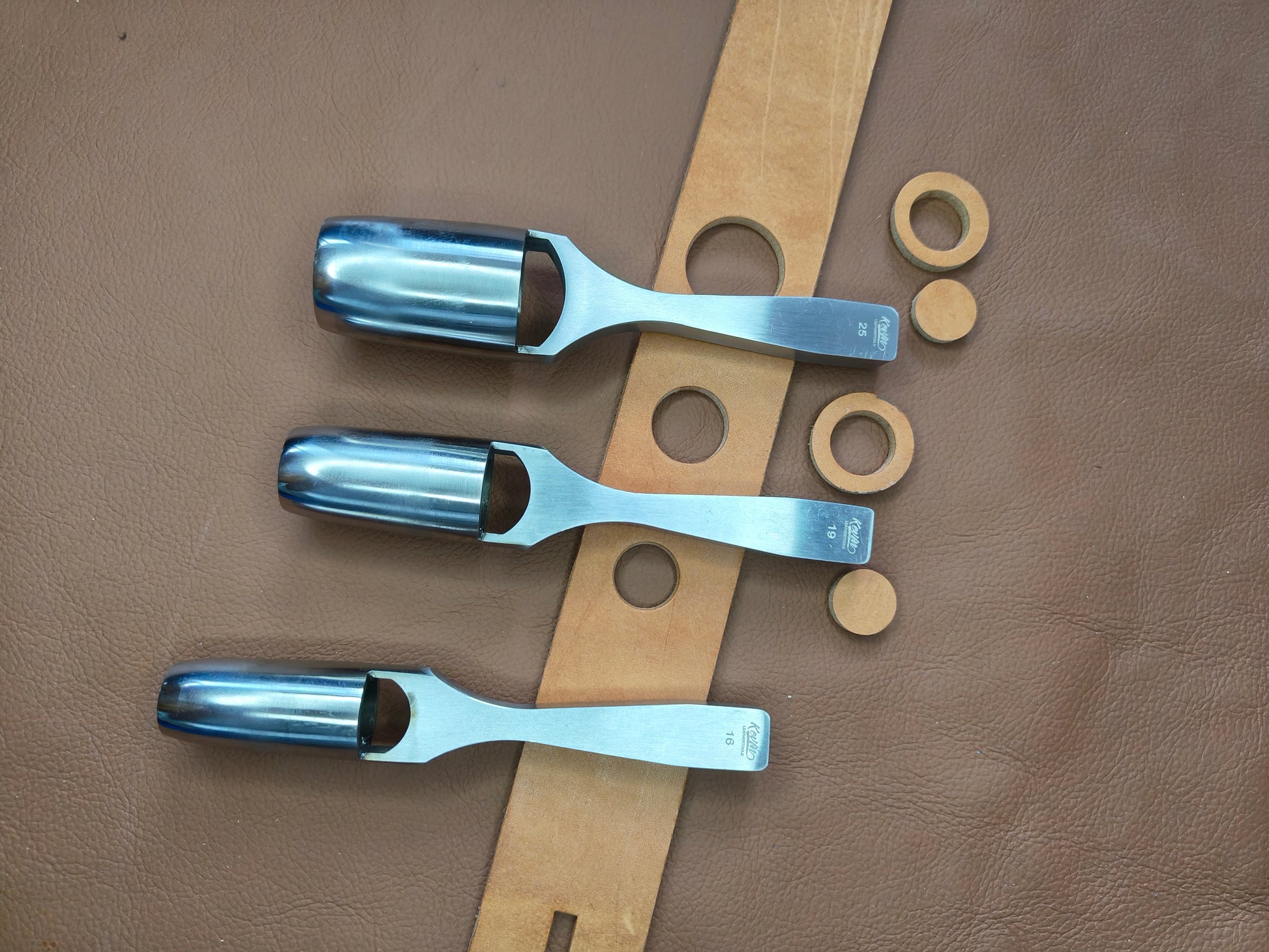

Illustrative image related to custom leather punch

Cons: The main limitation of aluminum is its lower strength compared to steel, which may not be suitable for heavy-duty leather applications. Additionally, aluminum can be more expensive than steel, depending on the alloy used.

Impact on Application: Aluminum punches are best suited for lighter leather or smaller projects. Buyers should assess whether the application requires the strength of steel or if aluminum will suffice.

What Role Do Polymer Composites Play in Leather Punch Production?

Polymer composites are emerging as a viable alternative for custom leather punches, especially in applications that require flexibility and lightweight characteristics. These materials can be engineered to provide specific properties, such as impact resistance and flexibility.

Illustrative image related to custom leather punch

Pros: Polymer composites are resistant to corrosion and can be molded into complex shapes, allowing for innovative designs. They are lightweight and can reduce production costs due to lower material waste.

Cons: The durability of polymer punches can be a concern, especially in high-volume applications. They may not withstand the same levels of pressure as metal punches, leading to limitations in their use.

Impact on Application: Polymer composites are suitable for specific applications, such as crafting or prototyping, where flexibility and ease of use are prioritized. Buyers should evaluate the intended use to determine if polymers meet their needs.

Summary Table of Material Properties for Custom Leather Punches

| Материал | Typical Use Case for Custom Leather Punch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty leather cutting and stamping | Exceptional durability and strength | Heavier and may rust without treatment | Высокий |

| Brass | Decorative leather items and accessories | Aesthetic appeal and corrosion resistance | Softer, may wear out quickly | Medium |

| Aluminum | Portable leatherworking tools | Lightweight and easy to handle | Lower strength than steel | Medium |

| Polymer Composites | Crafting and prototyping | Flexibility and innovative design | Limited durability in high-volume use | Низкий |

This strategic material selection guide provides B2B buyers with essential insights into the most common materials used for custom leather punches, helping them make informed decisions that align with their specific needs and market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather punch

What Are the Key Stages in the Manufacturing Process of Custom Leather Punches?

The manufacturing of custom leather punches involves several critical stages, each designed to ensure precision, quality, and durability. Understanding these stages is essential for B2B buyers seeking reliable suppliers for their leatherworking needs.

1. Material Preparation: What Materials Are Used and How Are They Processed?

The first step in manufacturing custom leather punches is selecting the right materials. Typically, high-grade steel or brass is used due to their durability and ability to retain sharp edges. The material is sourced from reputable suppliers who adhere to industry standards.

Once the material is selected, it undergoes a preparation process that may include cutting it to size, surface treatment to remove impurities, and pre-conditioning for optimal performance. This stage is crucial as it lays the groundwork for the quality and effectiveness of the final product.

2. Forming: How Are Custom Designs Created?

The forming process utilizes advanced techniques such as CNC (Computer Numerical Control) machining and die casting. CNC machining allows for high precision in creating complex shapes and designs based on customer specifications. CAD (Computer-Aided Design) software is often employed to create a digital blueprint, ensuring accuracy before production begins.

Illustrative image related to custom leather punch

In the case of die casting, the material is melted and poured into a mold that reflects the desired shape of the punch. This method is particularly effective for mass production, enabling manufacturers to produce multiple units quickly while maintaining uniformity.

3. Assembly: What Steps Ensure All Components Fit Correctly?

For leather punches that require multiple components, assembly is a vital stage. This involves fitting together the punch head, handle, and any additional features such as springs or locks. Quality assurance measures are implemented during assembly to ensure that all parts fit perfectly and function as intended.

During this stage, manufacturers may also perform functional tests to verify that the punch operates smoothly and efficiently. Any discrepancies or defects are addressed immediately to prevent issues in later stages.

4. Finishing: How Is the Product Prepared for Delivery?

The finishing stage includes surface treatments such as polishing, coating, or painting to enhance durability and aesthetic appeal. This process not only improves the product’s appearance but also protects it from corrosion and wear, extending its lifespan.

Illustrative image related to custom leather punch

Quality control checks are essential during finishing to ensure that the final product meets established specifications. This may involve visual inspections, dimensional checks, and performance tests.

What Quality Assurance Measures Are Employed in Custom Leather Punch Manufacturing?

Quality assurance is paramount in the manufacturing of custom leather punches, ensuring that products meet both international standards and customer expectations.

International Standards: Which Certifications Should Buyers Look For?

Many manufacturers adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Certification to this standard indicates that a company has established processes for consistent product quality and customer satisfaction.

In addition to ISO, industry-specific certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for oil and gas applications can further assure buyers of product reliability.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards. This includes checking for defects, dimensions, and material properties.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are performed to catch any deviations from the desired specifications. This stage often includes tests for dimensional accuracy and functionality.

-

Final Quality Control (FQC): Once the product is finished, a final inspection is conducted to verify that all quality standards are met before shipping. This may involve comprehensive testing, including durability and performance assessments.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

When sourcing custom leather punches, B2B buyers should take proactive steps to verify supplier quality assurance practices. Here are several effective methods:

1. Conducting Supplier Audits: What Should Be Included?

Audits allow buyers to assess a supplier’s manufacturing processes and quality control measures. Key areas to evaluate include:

- Compliance with international standards (ISO, CE)

- The effectiveness of quality control checkpoints

- Documentation practices and traceability of materials

2. Requesting Quality Assurance Reports: What Information Is Valuable?

Buyers should request detailed quality assurance reports that outline the results of inspections and tests conducted at various stages of production. This documentation provides insights into the supplier’s commitment to maintaining high-quality standards.

3. Engaging Third-Party Inspection Services: How Can They Help?

Utilizing third-party inspection services can add an extra layer of confidence in the quality of the products being sourced. These independent entities can conduct thorough inspections and testing, providing unbiased reports on the supplier’s adherence to quality standards.

What Are the QC and Certification Nuances for International Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certifications is crucial. Different regions may have specific requirements or expectations regarding quality standards.

For instance, European buyers may place a higher emphasis on CE marking, while buyers from the Middle East may prioritize compliance with local industry regulations. It’s essential for buyers to communicate their specific requirements clearly to suppliers to ensure alignment.

Moreover, cultural differences can influence quality expectations and communication styles. Building a strong relationship with suppliers through regular communication can help bridge these gaps and enhance the overall purchasing experience.

Conclusion: Why Is Understanding Manufacturing Processes and QC Important for B2B Buyers?

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for custom leather punches is essential for B2B buyers. By familiarizing themselves with each stage of production and the associated quality control measures, buyers can make informed decisions and select suppliers that align with their quality expectations. This knowledge not only enhances procurement strategies but also helps in fostering long-term partnerships that ensure product reliability and satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather punch’

In the pursuit of sourcing a custom leather punch, it’s essential to follow a structured approach that ensures quality, efficiency, and cost-effectiveness. This guide provides a practical checklist tailored for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications of your custom leather punch. This includes dimensions, shapes, and any specific features required. A well-defined specification helps prevent misunderstandings and ensures that suppliers can meet your exact needs.

- Consider material requirements: Identify whether you need heavy-duty steel, brass, or other materials, as this impacts durability and performance.

- Include usage details: Specify how you plan to use the punch—whether for mass production or small batches—affecting the design complexity.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in custom leather punches. Look for manufacturers with a strong track record and positive customer feedback.

Illustrative image related to custom leather punch

- Evaluate their portfolio: Review past projects to assess their design capabilities and quality of work.

- Check industry experience: Suppliers with experience in your specific region may better understand local market demands and shipping logistics.

Step 3: Request Samples and Prototypes

Before placing a bulk order, request samples or prototypes of the custom leather punch. This step is critical to evaluate the quality and precision of the product.

- Assess the craftsmanship: Check for sharpness, durability, and how well the punch performs on different leather types.

- Test usability: Ensure that the punch meets your operational needs and is easy to use in your production environment.

Step 4: Verify Supplier Certifications and Compliance

Ensure that the suppliers adhere to relevant quality and safety standards. This is particularly important when dealing with international suppliers, as regulations may vary by region.

- Request certification documents: Look for ISO certifications or other industry-specific credentials that validate their manufacturing processes.

- Inquire about compliance: Confirm that the materials used comply with local environmental regulations, especially if exporting to regions with strict standards.

Step 5: Discuss Pricing and Payment Terms

Engage suppliers in discussions about pricing, payment terms, and any additional costs related to shipping or customs. Transparency in these discussions can prevent unexpected expenses later on.

Illustrative image related to custom leather punch

- Compare quotes: Obtain detailed quotes from multiple suppliers to ensure competitive pricing.

- Negotiate payment terms: Discuss options such as upfront payments, deposits, or payment upon delivery to manage cash flow effectively.

Step 6: Clarify Lead Times and Production Capacity

Understanding the lead times and production capacity of your chosen supplier is vital for planning your inventory and production schedules.

- Confirm turnaround times: Ask about production timelines for custom orders, especially if you have tight deadlines.

- Evaluate capacity for scaling: Ensure the supplier can handle increased orders in the future if your demand grows.

Step 7: Establish Clear Communication Channels

Effective communication is essential throughout the sourcing process. Establish clear channels for ongoing discussions and updates.

- Choose preferred communication methods: Whether email, phone, or video calls, ensure that both parties are comfortable with the communication medium.

- Set regular check-ins: Schedule periodic updates to monitor progress and address any issues promptly.

By following this structured checklist, B2B buyers can streamline their sourcing process for custom leather punches, ensuring they receive high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for custom leather punch Sourcing

When sourcing custom leather punches, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. This section delves into the various cost components, price influencers, and practical tips for negotiating favorable terms.

Illustrative image related to custom leather punch

What Are the Key Cost Components in Custom Leather Punch Sourcing?

-

Materials: The choice of materials significantly impacts the overall cost. High-quality steel or brass is commonly used for durability, but prices can vary based on the metal’s grade and sourcing location. Expect to pay more for premium materials that offer extended lifespan and performance.

-

Labor: Labor costs are influenced by the complexity of the punch design and the skill level required for production. Regions with lower labor costs may offer competitive pricing, but this can sometimes compromise quality. It’s essential to evaluate the craftsmanship and experience of the workforce involved.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Suppliers with advanced manufacturing capabilities may have higher overhead costs but could provide faster turnaround times and better precision.

-

Tooling Costs: The creation of custom dies or molds involves initial tooling costs. This can range from $100 to $500 or more, depending on the intricacy of the design. Buyers should consider these costs as part of their initial investment, especially for bespoke designs.

-

Quality Control (QC): Ensuring that each punch meets specified standards requires QC processes, which can add to the overall cost. Suppliers who implement rigorous QC measures may charge a premium, but this investment can save buyers from defects and rework expenses in the long run.

-

Logistics: Shipping costs are particularly relevant for international buyers. Factors such as the shipping method, distance, and Incoterms (e.g., FOB, CIF) will affect total logistics costs. Buyers should factor in potential customs duties and import taxes based on their local regulations.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins in the industry can help buyers gauge whether a quote is competitive.

How Do Price Influencers Affect Custom Leather Punch Costs?

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Suppliers may have MOQs that can influence total costs, so negotiating lower minimums can be beneficial for smaller businesses.

-

Specifications and Customization: Highly customized designs or intricate specifications will invariably increase costs. Buyers should be clear about their design requirements and be prepared for varying quotes based on complexity.

-

Materials and Quality Certifications: The choice of materials and certifications can influence pricing. For example, punches made from certified materials that comply with international standards may carry a higher price tag, but they ensure safety and reliability.

-

Supplier Factors: Reputation, experience, and location of the supplier can influence prices. Established suppliers with a strong track record may charge more due to their reliability and service quality.

What Are the Best Negotiation Tips for B2B Buyers?

-

Research and Benchmarking: Understand the market rates for different types of punches by comparing multiple suppliers. This data can provide leverage during negotiations.

-

Total Cost of Ownership: Consider not just the purchase price but also the long-term costs associated with maintenance, potential reorders, and quality issues. A slightly higher upfront cost may lead to savings over time if the product lasts longer.

-

Explore Flexible Payment Terms: Negotiating payment terms can improve cash flow. Some suppliers may offer discounts for upfront payments or extended payment periods for larger orders.

-

Quality vs. Cost Balance: While it’s tempting to choose the cheapest option, ensure that the quality aligns with your needs. Sometimes investing in a more expensive product can be more cost-effective in the long run.

-

Communicate Clearly: Provide detailed specifications and expectations upfront to minimize misunderstandings and avoid additional costs down the line.

Заключение

Navigating the costs and pricing of custom leather punches requires careful consideration of multiple factors. By understanding the cost components, recognizing price influencers, and employing effective negotiation strategies, B2B buyers can secure favorable agreements that meet their operational needs. As with any procurement process, maintaining open communication and fostering strong supplier relationships can lead to successful long-term partnerships.

Alternatives Analysis: Comparing custom leather punch With Other Solutions

When evaluating the options for leatherworking, particularly in the realm of cutting and punching, it’s essential to understand the various alternatives available. Custom leather punches are a popular choice for many businesses, but there are other methods and tools that may better suit specific needs. Below, we compare custom leather punches against two viable alternatives: die-cutting machines and laser cutting technology.

| Comparison Aspect | Custom Leather Punch | Die-Cutting Machines | Laser Cutting Technology |

|---|---|---|---|

| Performance | High precision for detailed designs; limited to specific shapes. | Can handle large volumes; precise but may require setup adjustments. | Exceptional precision; can create intricate designs quickly. |

| Cost | Moderate initial investment; long-term savings on repeated use. | Higher upfront costs for machines; cost-effective for bulk production. | High initial investment; operational costs can vary based on material and power usage. |

| Ease of Implementation | Simple to use; requires minimal training for operators. | Requires more training; setup can be complex. | User-friendly with proper training; software familiarity is needed. |

| Maintenance | Low maintenance; occasional sharpening needed. | Regular maintenance required; parts may need replacement over time. | Generally low maintenance; software updates are common. |

| Best Use Case | Ideal for custom, low-volume projects where detail is crucial. | Best for high-volume production with consistent patterns. | Suitable for complex designs and rapid prototyping in various materials. |

What Are the Advantages and Disadvantages of Die-Cutting Machines?

Die-cutting machines offer a robust alternative to custom leather punches, especially for businesses focused on high-volume production. These machines can efficiently cut multiple pieces at once, significantly speeding up the manufacturing process. However, they often come with a steep learning curve and require initial setup and calibration, which can be time-consuming. Additionally, while they are cost-effective for bulk orders, the upfront investment can be substantial for smaller businesses.

Illustrative image related to custom leather punch

How Does Laser Cutting Technology Compare?

Laser cutting technology stands out for its precision and versatility. It can handle a wide range of materials, including leather, and produce intricate designs that are difficult to achieve with traditional methods. The speed of laser cutting can also enhance productivity, making it an excellent choice for businesses looking to innovate. However, the initial investment in laser cutting equipment can be high, and operational costs may fluctuate based on electricity consumption and maintenance needs. Moreover, familiarity with design software is essential, which might require additional training for staff.

Conclusion: How to Choose the Right Leather Cutting Solution for Your Business

Selecting the right cutting solution for leatherwork depends heavily on your specific operational needs and production goals. For businesses focusing on custom, low-volume projects, custom leather punches may be the most suitable option due to their precision and lower investment. In contrast, companies aiming for mass production should consider die-cutting machines for their efficiency and cost-effectiveness. Lastly, for those seeking versatility and the ability to create complex designs quickly, investing in laser cutting technology could provide the best long-term benefits. Ultimately, understanding these alternatives allows B2B buyers to make informed decisions that align with their production strategies and market demands.

Essential Technical Properties and Trade Terminology for custom leather punch

What Are the Key Technical Properties of Custom Leather Punches?

When evaluating custom leather punches, several technical properties are crucial for ensuring quality, precision, and efficiency in production. Understanding these specifications can significantly impact your decision-making process.

Illustrative image related to custom leather punch

1. Material Grade

The most common materials used in manufacturing leather punches include high-carbon steel and hardened steel. High-carbon steel offers excellent durability and sharpness, making it ideal for cutting through tough leather. Hardened steel, often used for more intricate designs, provides longevity and resistance to wear. The choice of material directly affects the tool’s lifespan and its performance in high-volume production scenarios.

2. Tolerance

Tolerance refers to the allowable deviation from a specified dimension. In the context of leather punches, tighter tolerances are essential for achieving accurate cuts and maintaining consistency across multiple pieces. A tolerance of ±0.1 mm is often standard in the industry, ensuring that each punch produces uniform results. For B2B buyers, understanding tolerance levels helps assess the quality of the tooling and its suitability for specific applications.

3. Blade Protrusion Height

The blade protrusion height indicates how far the cutting edge extends from the base of the punch. This dimension is critical because it determines the depth of the cut. A standard protrusion height ranges from 5 mm to 10 mm, allowing for various leather thicknesses. When selecting a custom leather punch, confirming the appropriate blade height ensures that it can effectively handle the leather types you intend to use.

4. Die Thickness

The thickness of the die, typically ranging from 3 mm to 4 mm, plays a vital role in the punch’s durability and cutting efficiency. Thicker dies are generally more robust and can withstand higher pressures during the cutting process. This factor is particularly important for businesses that engage in large-scale production, as it impacts both the quality of the cut and the overall production speed.

5. Production Lead Time

Understanding the production lead time is essential for B2B buyers, particularly those with tight deadlines. Custom leather punches can have varying lead times based on complexity and manufacturing capabilities. A typical lead time for custom dies is around 2-4 weeks, depending on the supplier’s capacity and the intricacy of the design. Knowing this helps in planning inventory and production schedules effectively.

Illustrative image related to custom leather punch

What Trade Terminology Should B2B Buyers Know When Sourcing Custom Leather Punches?

Familiarity with industry jargon can facilitate smoother negotiations and clearer communication with suppliers. Here are some essential terms to understand:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the leather punch industry, working with an OEM can help ensure that the tools you receive meet specific quality and design standards. This relationship is crucial for businesses that want to maintain brand integrity while outsourcing manufacturing.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For custom leather punches, MOQs can vary significantly, often ranging from 50 to 100 units. Understanding MOQs helps buyers assess their production needs and budget accordingly, ensuring they do not overcommit to quantities that exceed their requirements.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other details for specific products. In the context of custom leather punches, submitting an RFQ allows businesses to compare quotes from multiple suppliers, fostering competitive pricing and better service terms.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, insurance, and risks associated with the delivery of custom leather punches.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that align with their production needs and operational goals. This knowledge not only enhances procurement strategies but also strengthens supplier relationships, ultimately contributing to the success of your leather goods business.

Navigating Market Dynamics and Sourcing Trends in the custom leather punch Sector

What Are the Key Market Dynamics and Trends Influencing the Custom Leather Punch Sector?

The custom leather punch sector is experiencing a transformative phase fueled by several global drivers. Increasing demand for personalized leather goods and accessories is a primary catalyst, particularly among B2B buyers seeking differentiation in competitive markets across Africa, South America, the Middle East, and Europe. Additionally, advancements in manufacturing technology, such as precision die cutting and CAD design, are enabling faster production cycles and customization capabilities, allowing businesses to respond swiftly to customer demands.

Emerging trends include the rise of e-commerce platforms tailored for B2B transactions, facilitating easier access to suppliers and enhancing supply chain efficiencies. Buyers are also gravitating towards suppliers who can offer comprehensive support, from initial design consultation to rapid prototyping and delivery. This shift underscores the importance of agile supply chains capable of adapting to fluctuating market conditions, which is particularly relevant for international buyers looking to optimize their sourcing strategies.

How Does Sustainability and Ethical Sourcing Influence the Custom Leather Punch Market?

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the custom leather punch sector. The environmental impact of leather production, particularly concerning water usage and chemical treatments, has led to a growing demand for eco-friendly practices. Buyers are increasingly prioritizing suppliers who utilize sustainable materials and processes, such as vegetable-tanned leather and recycled components.

Incorporating ‘green’ certifications into the supply chain can significantly enhance a company’s reputation and marketability. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) serve as benchmarks for ethical sourcing. Businesses that can demonstrate a commitment to sustainability not only attract environmentally-conscious buyers but also mitigate risks associated with regulatory compliance and consumer backlash. This trend toward sustainability is not merely a passing phase; it is reshaping the purchasing criteria for international buyers, particularly in regions where environmental standards are becoming stricter.

What Is the Evolution of the Custom Leather Punch Sector?

The custom leather punch sector has evolved significantly over the past few decades, driven by technological advancements and changing consumer preferences. Traditionally, leather punching was a labor-intensive process that relied on manual tools and templates, limiting customization options and production scalability. However, the advent of computer-aided design (CAD) and automated cutting machines has revolutionized the industry, enabling high precision and rapid turnaround times for custom orders.

As the market matured, the focus shifted towards providing tailored solutions that cater to diverse customer needs, from artisanal workshops to large-scale manufacturers. Today, businesses not only offer a variety of designs but also emphasize the importance of customer collaboration in the design process. This evolution has fostered a dynamic marketplace that prioritizes quality, efficiency, and customization, positioning the custom leather punch sector as a vital component of the broader leather goods industry.

In summary, understanding the market dynamics, embracing sustainability, and recognizing the sector’s evolution are crucial for B2B buyers navigating the custom leather punch landscape. By leveraging these insights, businesses can make informed sourcing decisions that align with their strategic goals and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather punch

-

How do I choose the right custom leather punch for my needs?

Choosing the right custom leather punch involves assessing your specific requirements, such as the type of leather you will be working with and the designs you wish to create. Start by determining the size and shape of the punch you need. Consult with suppliers to discuss your project details, including the complexity of designs and production volume. Additionally, ensure the supplier can accommodate your material specifications and has a track record of delivering high-quality punches that meet your standards. -

What is the average turnaround time for custom leather punches?

The turnaround time for custom leather punches can vary significantly depending on the supplier and the complexity of the design. Generally, expect a timeframe of 2 to 4 weeks from the initial order to delivery. Some suppliers offer expedited services for an additional fee, which can reduce this time to as little as a few days for simple designs. Always confirm the lead time with your supplier before placing an order to align your production schedule accordingly. -

What factors affect the pricing of custom leather punches?

Pricing for custom leather punches is influenced by several factors, including the complexity of the design, the size of the punch, and the materials used. Intricate designs typically require more time and precision to manufacture, resulting in higher costs. Additionally, minimum order quantities (MOQ) may apply, which can also impact pricing. It’s advisable to request quotes from multiple suppliers to compare costs and ensure you are getting the best value for your investment. -

What are the minimum order quantities (MOQ) for custom leather punches?

Minimum order quantities for custom leather punches vary by supplier. Some may accept small orders for prototypes or limited runs, while others may have a minimum of 100 pieces or more. Be sure to clarify the MOQ with potential suppliers during your initial discussions. Understanding MOQ is crucial to ensure it aligns with your production needs and budget constraints. -

How can I ensure the quality of custom leather punches before making a large order?

To ensure quality, request samples or prototypes from suppliers before committing to a large order. This allows you to assess the punch’s performance and precision. Additionally, inquire about the materials used and manufacturing processes. Look for suppliers with a strong reputation and positive reviews, and consider asking for references from other businesses that have used their products. Quality assurance checks during production can also be discussed to minimize risks. -

What payment terms should I expect when ordering custom leather punches?

Payment terms for custom leather punches can differ widely among suppliers. Common arrangements include full payment upfront, partial payment upon order confirmation, or payment upon delivery. When dealing with international suppliers, consider payment methods that offer security, such as letters of credit or escrow services. It’s essential to clarify payment terms in your contract to avoid any misunderstandings. -

What logistics considerations should I keep in mind when importing custom leather punches?

When importing custom leather punches, consider shipping costs, customs duties, and import regulations specific to your country. Ensure that your supplier provides accurate documentation for customs clearance. Additionally, factor in potential delays in shipping and customs processing times. Working with a logistics partner familiar with international trade can help streamline this process and mitigate risks. -

How do I vet suppliers for custom leather punches in international markets?

Vetting suppliers requires thorough research and due diligence. Start by checking their online presence, including customer reviews and ratings. Request references from previous clients to gauge their reliability and product quality. Assess their manufacturing capabilities and certifications to ensure they meet international standards. If possible, visit the supplier’s facility or conduct virtual meetings to discuss your requirements and establish trust before making an order.

Top 6 Custom Leather Punch Manufacturers & Suppliers List

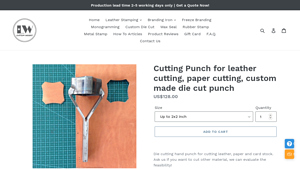

1. LW Leathers – Cutting Punch

Domain: lwleathers.com

Registered: 2012 (13 years)

Введение: Cutting Punch for leather cutting, paper cutting, custom made die cut; Regular price: US$128.00; Sizes available: Up to 2×2 inch, Up to 3×3 inch; Larger sizes available via Steel Rule Die Cuts; Production lead time: 2-5 working days; Custom die cutting mold can be made ready to ship in 2-3 working days; Rush orders can ship in 2 working days (additional cost applies); Standard price includes a sim…

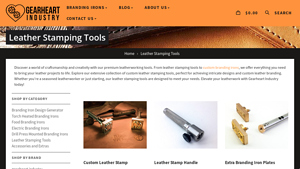

2. Gearheart Industry – Custom Leather Stamp

Domain: gearheartindustry.com

Registered: 2013 (12 years)

Введение: Custom Leather Stamping Tools, Made in the USA; Premium leatherworking tools for intricate designs and custom branding; Suitable for seasoned leatherworkers and beginners; Products include: Custom Leather Stamp ($119.00), Leather Stamp Handle ($21.00), Extra Branding Iron Plates (starting at $65.00); Features interchangeable leather stamping heads with electric branding irons; Emphasis on quality,…

3. Etsy – Handmade Leather Punches

Domain: etsy.com

Registered: 2004 (21 years)

Введение: This company, Etsy – Handmade Leather Punches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Weaver Leather Supply – Custom Leather Cutting Dies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Введение: Custom Leather Clicker & Cutting Dies by Weaver Leather Supply are made from hardened, pre-sharpened steel for quality and dependability. They are available in 3 mm and 4 mm thicknesses, with heights of 3/4″ or 1-1/4″. The dies are guaranteed to meet specifications or your money back. Each die is constructed with attention to detail and stamped with the date of manufacture. The company offers a cl…

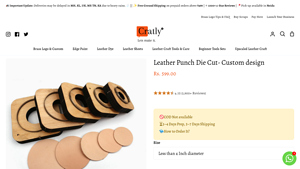

5. Cratly – Leather Punch Die Cut

Domain: cratly.com

Registered: 2014 (11 years)

Введение: Product Name: Leather Punch Die Cut – Custom design

Price: ₹599.00

Rating: 4.75 (1,900+ Reviews)

Shipping: 3-4 Days Prep, 5-7 Days Shipping

Material: Steel + Wood

Die Cut Height: 24mm (Blade Protrusion Height: 6mm)

Usage: Suitable for leather patterns, tags, special shaped name cards, DIY cards, and mass production.

Production Time: Ships in 3-5 business days after artwork or proof approval.

Order…

6. Custom Brand – Leather Embossing Stamp

Strategic Sourcing Conclusion and Outlook for custom leather punch

In summary, strategic sourcing of custom leather punches is a critical component for businesses aiming to enhance their production efficiency and product quality. By leveraging the capabilities of specialized manufacturers, B2B buyers can access high-precision cutting tools tailored to their specific design requirements. This not only streamlines the production process but also ensures that products meet the highest standards of craftsmanship, which is vital for competitiveness in diverse markets.

For buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing custom leather punches is essential. Factors such as minimum order quantities, lead times, and design specifications should be meticulously considered to optimize procurement strategies. Engaging with suppliers who offer robust support services and quick turnaround times can significantly impact your operational efficiency.

Illustrative image related to custom leather punch

Looking ahead, as the demand for custom leather goods continues to rise globally, now is the time to invest in quality cutting tools that can elevate your offerings. Embrace the opportunity to connect with reputable suppliers and explore innovative solutions that will drive your business forward in an increasingly competitive landscape. Take the next step in your sourcing journey today and unlock the potential of custom leather punches to enhance your product line.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.