Introduction: Navigating the Global Market for fabric material shoes

Navigating the complex landscape of sourcing fabric material shoes can be a daunting challenge for international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. The sheer variety of textiles—from breathable mesh to durable canvas—coupled with varying quality standards and supplier reliability, can complicate decision-making. This guide addresses these challenges head-on, providing a comprehensive overview of the types of fabric materials available for shoe production, their applications in different footwear segments, and the nuances of selecting the right suppliers.

Throughout this guide, you will gain insights into the critical factors influencing the selection of fabric materials, including thread composition, weave patterns, and surface treatments. We will also explore the cost implications of sourcing these materials and offer strategies for vetting suppliers to ensure quality and compliance with international standards. By empowering you with this knowledge, we aim to facilitate informed purchasing decisions that align with your business objectives and market demands.

Whether you’re seeking sustainable materials for eco-friendly brands or high-performance fabrics for athletic footwear, this guide is your essential resource. Our goal is to support B2B buyers in making strategic choices that enhance product offerings and drive profitability in the competitive footwear market.

Table Of Contents

- Top 5 Fabric Material Shoes Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric material shoes

- Understanding fabric material shoes Types and Variations

- Key Industrial Applications of fabric material shoes

- 3 Common User Pain Points for ‘fabric material shoes’ & Their Solutions

- Strategic Material Selection Guide for fabric material shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric material shoes

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric material shoes’

- Comprehensive Cost and Pricing Analysis for fabric material shoes Sourcing

- Alternatives Analysis: Comparing fabric material shoes With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric material shoes

- Navigating Market Dynamics and Sourcing Trends in the fabric material shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric material shoes

- Strategic Sourcing Conclusion and Outlook for fabric material shoes

- Important Disclaimer & Terms of Use

Understanding fabric material shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cotton Canvas Shoes | Durable, breathable, and often vulcanized construction | Casual footwear, eco-friendly brands | Pros: Natural material, customizable, cost-effective. Cons: Less water-resistant, can be heavier. |

| Nylon Sneakers | Lightweight, high durability, and quick-drying | Sportswear, active lifestyle brands | Pros: Excellent strength-to-weight ratio, easy to clean. Cons: May lack breathability compared to natural fibers. |

| Polyester Running Shoes | Stretchable, moisture-wicking, and often blended with other materials | Athletic and performance footwear | Pros: Good UV resistance, colorfastness, and shape retention. Cons: Less eco-friendly, potential for odor retention. |

| Lycra-Blend Footwear | High elasticity and comfort, often used in linings | Fashion, performance, and comfort shoes | Pros: Enhanced fit and comfort, lightweight. Cons: Can be less durable than other fibers. |

| Air Mesh Shoes | Breathable, lightweight, and flexible with a 3D structure | Sports and casual footwear | Pros: Superior ventilation, moisture management. Cons: May require careful handling to maintain structure. |

What Are the Characteristics of Cotton Canvas Shoes?

Cotton canvas shoes are renowned for their durability and breathability, making them a popular choice for casual footwear. They are often produced using vulcanized construction, which enhances their longevity. B2B buyers should consider the environmental impact of sourcing cotton, as organic options are increasingly sought after. Customization options, such as colors and prints, can also be leveraged to align with brand identity. However, their weight and lower water resistance may limit their appeal in certain markets.

Why Are Nylon Sneakers Preferred for Active Lifestyle Brands?

Nylon sneakers are characterized by their lightweight and high durability, making them ideal for sports and active lifestyle applications. Their quick-drying properties are particularly advantageous for consumers engaged in outdoor activities. B2B buyers should evaluate the balance between cost and performance when sourcing nylon footwear, as the material’s strength-to-weight ratio often justifies a higher price point. While they are easy to clean, the potential lack of breathability compared to natural fibers can be a consideration for end-users.

How Do Polyester Running Shoes Enhance Athletic Performance?

Polyester running shoes are designed with performance in mind, featuring moisture-wicking properties and excellent stretchability. They are commonly blended with other materials to enhance comfort and fit. For B2B buyers, understanding the technical specifications of polyester blends is crucial, as these can impact the shoe’s performance metrics. While polyester shoes offer good UV resistance and colorfastness, their environmental footprint should be assessed against consumer demand for sustainability.

What Makes Lycra-Blend Footwear Comfortable Yet Challenging?

Lycra-blend footwear is recognized for its high elasticity and comfort, often used in linings to enhance the fit of shoes. This material is especially appealing to fashion and performance brands looking to provide lightweight options. B2B buyers should consider the trade-off between comfort and durability, as Lycra may not withstand heavy wear as effectively as other materials. The potential for high customization in design can attract buyers, but understanding the market’s durability expectations is essential.

Why Choose Air Mesh Shoes for Breathability?

Air mesh shoes offer superior breathability and moisture management, making them suitable for sports and casual footwear markets. Their lightweight and flexible nature enhances user comfort, particularly in warmer climates. B2B buyers should focus on the quality of mesh construction, as it can significantly impact the shoe’s longevity and performance. While air mesh shoes provide excellent ventilation, they may require careful handling to maintain their structure, which could influence manufacturing and shipping considerations.

Key Industrial Applications of fabric material shoes

| Industry/Sector | Specific Application of fabric material shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports and Fitness | Athletic footwear for running and training | Enhanced performance through lightweight, breathable materials; improved user comfort and support. | Look for moisture-wicking fabrics and durable construction to withstand rigorous use. |

| Healthcare | Non-slip shoes for medical professionals | Reduces risk of slips and falls; provides comfort during long shifts, enhancing employee productivity. | Prioritize easy-to-clean materials and slip-resistant soles. Compliance with healthcare standards is crucial. |

| Manufacturing | Safety shoes for factory workers | Protection against workplace hazards; improved comfort can lead to higher employee satisfaction and lower turnover. | Ensure compliance with safety regulations and consider sourcing from local suppliers to reduce lead times. |

| Retail | Fashionable casual shoes for consumers | Ability to offer trendy, lightweight options that appeal to a wide demographic; enhances brand image. | Focus on unique designs and sustainable materials to attract eco-conscious consumers. |

| Travel and Leisure | Lightweight shoes for travelers | Offers convenience and comfort for long-distance travel; easy to pack and carry. | Look for compact designs and quick-drying materials to cater to the traveling demographic. |

How Are Fabric Material Shoes Used in the Sports and Fitness Sector?

In the sports and fitness industry, fabric material shoes play a crucial role in enhancing athletic performance. Lightweight and breathable fabrics, such as mesh or specialized knits, allow for better airflow, reducing heat and moisture buildup. This improves comfort during long workouts. Buyers in this sector should prioritize sourcing materials that offer moisture-wicking properties and durability, as these shoes must withstand high-impact activities.

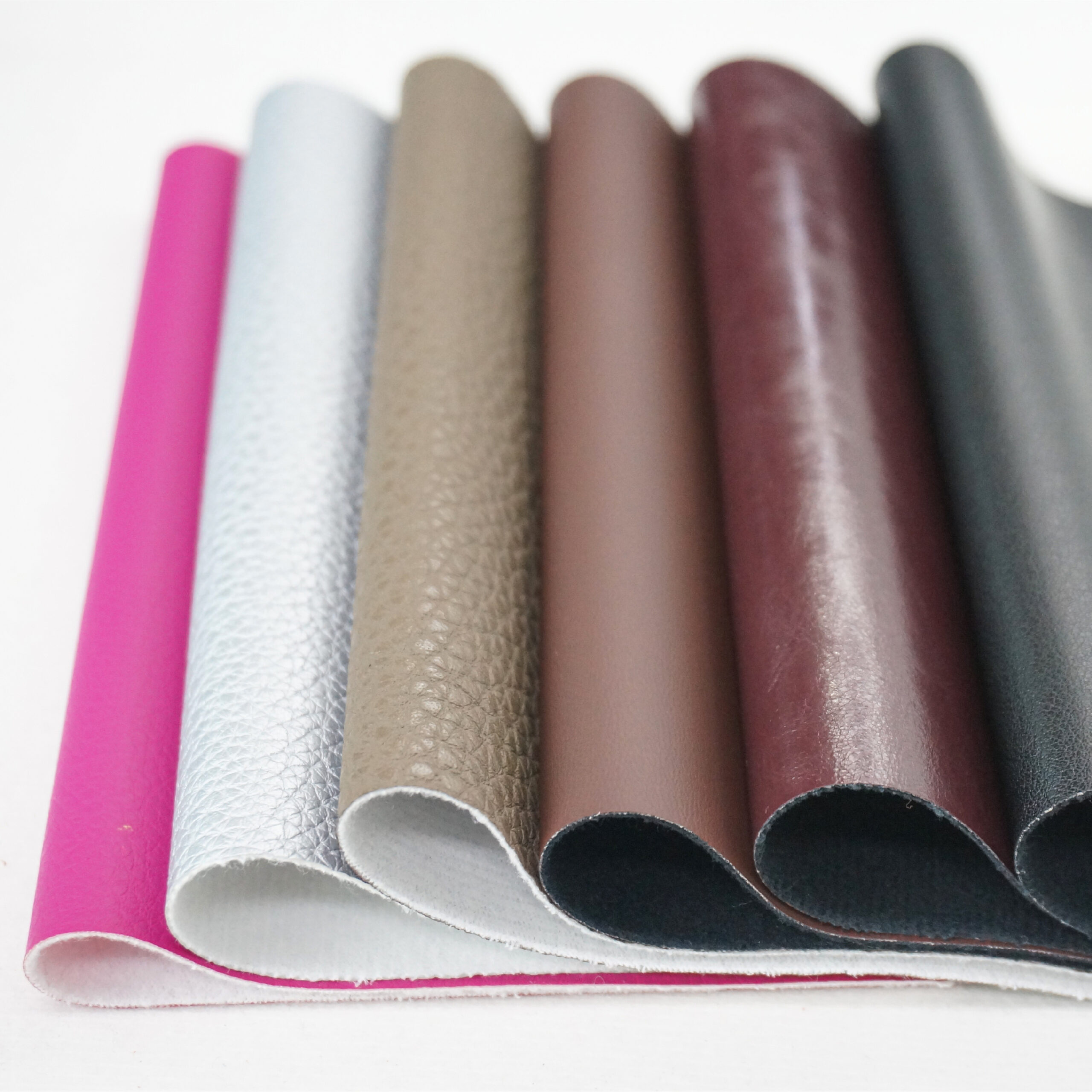

Illustrative image related to fabric material shoes

What Are the Benefits of Fabric Material Shoes in Healthcare?

In healthcare settings, fabric material shoes are essential for medical professionals who spend long hours on their feet. Non-slip fabric shoes provide the necessary grip to prevent accidents in slippery environments, while comfortable cushioning reduces fatigue. For international buyers, sourcing options should focus on easy-to-clean materials that comply with hygiene standards, ensuring that shoes maintain a professional appearance while being functional.

How Do Fabric Material Shoes Enhance Safety in Manufacturing?

In the manufacturing industry, fabric material shoes designed for safety can significantly reduce workplace injuries. These shoes often include reinforced toes and slip-resistant soles, providing essential protection against various hazards. Buyers should consider sourcing from suppliers who understand local safety regulations, ensuring that the shoes meet compliance standards. Additionally, comfort features can contribute to lower employee turnover by enhancing job satisfaction.

Why Are Fabric Material Shoes Important in Retail?

In the retail sector, fabric material shoes can be both fashionable and functional. Brands can leverage unique designs and sustainable materials to attract eco-conscious consumers, enhancing their market appeal. Buyers should focus on sourcing trendy fabrics that align with current fashion trends while ensuring quality to maintain customer satisfaction. The ability to offer lightweight options can also help retailers cater to a diverse demographic.

How Do Fabric Material Shoes Benefit Travelers and Leisure Enthusiasts?

For travelers, fabric material shoes provide the perfect blend of comfort and convenience. Lightweight designs make them easy to pack, while quick-drying materials are ideal for various travel scenarios. Buyers should prioritize sourcing shoes with versatile styles that can transition from casual to formal settings, ensuring they meet the diverse needs of travelers. Additionally, comfort features are essential for long-distance wear, enhancing the overall travel experience.

3 Common User Pain Points for ‘fabric material shoes’ & Their Solutions

Scenario 1: Sourcing High-Quality Fabric for Shoes

The Problem: B2B buyers often struggle with sourcing high-quality fabric materials for shoes that meet specific performance criteria. This is particularly challenging when dealing with international suppliers, as buyers may encounter inconsistencies in fabric quality, durability, and compliance with local regulations. For example, a buyer in Europe may find that a supplier from Asia provides fabric that does not hold up under rigorous testing for water resistance or UV protection, leading to costly returns and damaged relationships with retailers.

Illustrative image related to fabric material shoes

The Solution: To mitigate these risks, buyers should prioritize establishing strong partnerships with fabric suppliers who have a proven track record in the footwear industry. Conduct thorough research on suppliers, looking for certifications such as ISO or OEKO-TEX that indicate compliance with quality standards. Additionally, buyers should request samples and conduct in-house tests to evaluate the fabric’s performance against specific criteria before placing bulk orders. Implementing a clear and detailed fabric specification document can also help ensure that suppliers understand the required standards, reducing the likelihood of discrepancies.

Scenario 2: Navigating Import Duties and Regulations for Fabric Shoes

The Problem: Import duties can be a significant pain point for B2B buyers in the footwear industry, particularly when dealing with fabric material shoes. For instance, a buyer importing shoes with a textile surface area exceeding the threshold may face a steep 20% duty rate, impacting profit margins. This can be particularly problematic for buyers in regions like Africa and South America, where import regulations may be complex and vary significantly from country to country.

The Solution: To navigate these challenges, buyers should familiarize themselves with the import regulations specific to their target markets. This includes understanding the percentage of textile surface area that triggers higher duties and exploring potential exemptions or alternative classifications for their products. Buyers can also consider collaborating with a customs broker who specializes in footwear to ensure compliance and optimize duty payments. Another strategic approach is to explore local manufacturing options or partnerships to produce fabric shoes within the target market, thereby bypassing hefty import fees altogether.

Scenario 3: Ensuring Longevity and Performance of Fabric Shoes

The Problem: B2B buyers often face customer complaints regarding the longevity and performance of fabric shoes, particularly when they are not designed to withstand the intended use. For example, a retailer selling athletic shoes made from lightweight fabric may find that customers report issues with durability and support, leading to returns and negative reviews. This can be especially damaging in competitive markets where brand reputation is crucial.

Illustrative image related to fabric material shoes

The Solution: To enhance the performance and longevity of fabric shoes, buyers should invest in high-quality, durable materials and innovative fabric treatments. Buyers should look for fabrics with enhanced features such as abrasion resistance, water repellency, and breathability. Engaging with suppliers who offer advanced textile technologies, such as lamination or specialized coatings, can provide added durability without compromising comfort. Furthermore, conducting thorough wear tests with actual users can provide valuable insights into the performance of the shoes, allowing buyers to make informed decisions on the materials used and design modifications needed to meet customer expectations.

Strategic Material Selection Guide for fabric material shoes

What Are the Key Properties of Common Fabric Materials Used in Shoes?

When selecting fabric materials for shoes, understanding the properties and performance characteristics is essential for B2B buyers. Here, we analyze four common materials: polyester, nylon, cotton canvas, and lycra. Each material has distinct attributes that can influence the final product’s performance, durability, and suitability for various applications.

How Does Polyester Perform in Fabric Material Shoes?

Polyester is a widely used synthetic fiber known for its durability and resistance to shrinking and stretching. It has excellent moisture-wicking properties, making it suitable for athletic footwear. Polyester can withstand temperatures up to 150°C, although prolonged exposure may degrade its integrity.

Pros: Polyester is lightweight, cost-effective, and easy to dye, allowing for vibrant colors and patterns. Its durability makes it ideal for high-wear applications, such as sports shoes.

Cons: While polyester is resistant to many chemicals, it can be less breathable than natural fibers, potentially leading to discomfort in hot climates. Additionally, it may not have the same aesthetic appeal as natural fabrics.

Impact on Application: Polyester is compatible with a variety of shoe designs, particularly in athletic and casual footwear. However, it may not be suitable for high-end fashion applications where premium materials are preferred.

Considerations for International Buyers: Buyers should be aware of varying textile regulations and standards, such as ASTM in the U.S. and DIN in Germany. Polyester’s widespread use means it often meets global compliance standards, but buyers should verify specific certifications for their target markets.

Illustrative image related to fabric material shoes

What Advantages Does Nylon Offer for Shoe Fabrication?

Nylon is another synthetic fiber known for its strength and elasticity. It can endure high temperatures, typically around 200°C, and is resistant to abrasion, making it ideal for rugged footwear applications.

Pros: Nylon’s elasticity allows for a snug fit, enhancing comfort and performance in athletic shoes. It also dries quickly, making it suitable for outdoor and water-resistant footwear.

Cons: Nylon can be more expensive than polyester, impacting overall production costs. Its susceptibility to UV degradation can limit its lifespan if used in outdoor applications without proper treatment.

Impact on Application: Nylon’s properties make it favorable for performance-oriented shoes, such as running or hiking footwear. However, its cost may deter manufacturers focusing on budget-friendly options.

Considerations for International Buyers: Buyers should consider the import duties associated with nylon products, especially in regions with high tariffs on synthetic materials. Additionally, understanding local preferences for textile durability and performance can guide material selection.

Why Is Cotton Canvas a Staple in Fabric Material Shoes?

Cotton canvas is a natural fiber known for its breathability and comfort. It is commonly used in casual and vulcanized shoes due to its ability to withstand heat during the vulcanization process.

Pros: Cotton canvas is versatile, easily dyed, and can be treated for water resistance. Its natural fibers provide excellent breathability, making it suitable for warm climates.

Cons: Cotton canvas is less durable than synthetic options and can absorb moisture, which may lead to mildew if not properly treated. It may also require more complex manufacturing processes to achieve desired finishes.

Illustrative image related to fabric material shoes

Impact on Application: Cotton canvas is ideal for casual footwear and is often used in brands targeting eco-conscious consumers. However, its limitations in durability may restrict its use in high-performance applications.

Considerations for International Buyers: Buyers should be aware of the environmental regulations surrounding cotton production and the importance of sustainability in markets like Europe. Certifications such as Oeko-Tex can enhance marketability.

What Role Does Lycra Play in Fabric Material Shoes?

Lycra, or spandex, is a synthetic fiber known for its exceptional stretchability and recovery. It is often used in shoe linings and bindings to enhance fit and comfort.

Pros: Lycra provides a snug fit and excellent flexibility, making it ideal for performance footwear. It is also resistant to fading and retains its shape over time.

Illustrative image related to fabric material shoes

Cons: Lycra can be more expensive than other materials, which may increase production costs. Additionally, it may not be suitable for all shoe types, particularly those requiring more rigid structures.

Impact on Application: Lycra is commonly used in athletic and fashion footwear, where comfort and fit are paramount. Its unique properties can enhance the overall performance of the shoe.

Considerations for International Buyers: Buyers should consider the varying standards for synthetic materials in different regions. Ensuring compliance with regulations such as REACH in Europe can be crucial for market entry.

Illustrative image related to fabric material shoes

Summary Table of Fabric Materials for Shoes

| Material | Typical Use Case for fabric material shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Athletic and casual footwear | Durable, lightweight, vibrant colors | Less breathable than natural fibers | Low |

| Nylon | Performance-oriented shoes | Strong, elastic, quick-drying | More expensive, UV degradation risk | Medium |

| Cotton Canvas | Casual and vulcanized shoes | Breathable, comfortable, eco-friendly | Less durable, moisture absorption issues | Low |

| Lycra | Athletic and fashion footwear | Excellent stretch and fit | Higher cost, limited structural application | Medium |

This guide provides a comprehensive overview of fabric materials used in shoe manufacturing, equipping international B2B buyers with the necessary insights to make informed decisions tailored to their specific markets.

In-depth Look: Manufacturing Processes and Quality Assurance for fabric material shoes

What Are the Key Stages in the Manufacturing Process of Fabric Material Shoes?

The manufacturing process for fabric material shoes involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these stages is essential for B2B buyers looking to ensure the reliability and durability of their footwear products.

Material Preparation: How Are Fabric Components Selected and Processed?

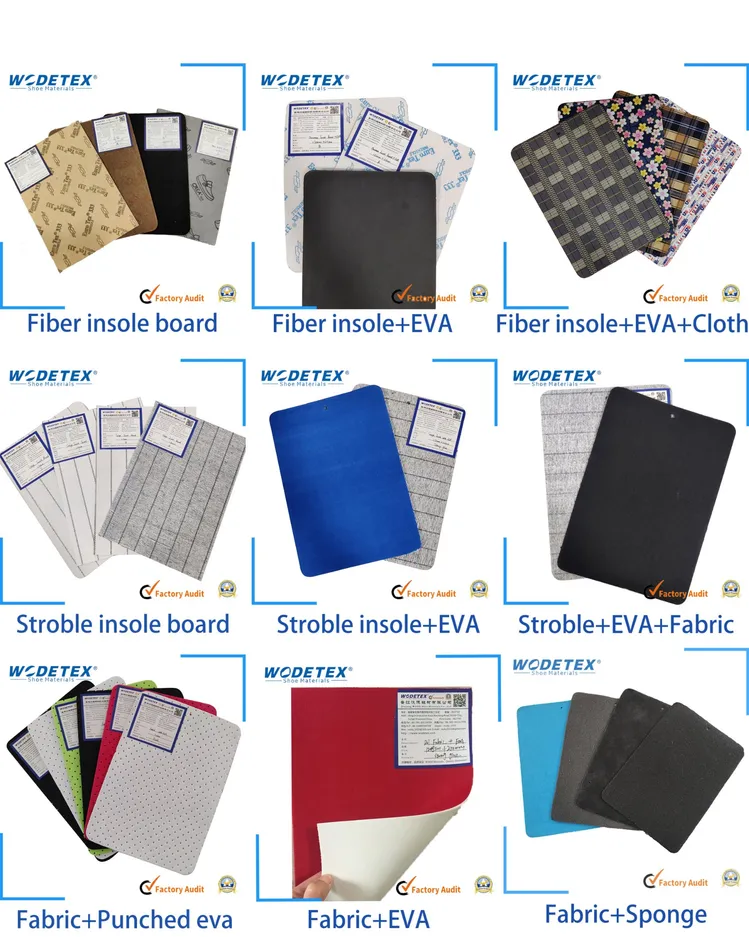

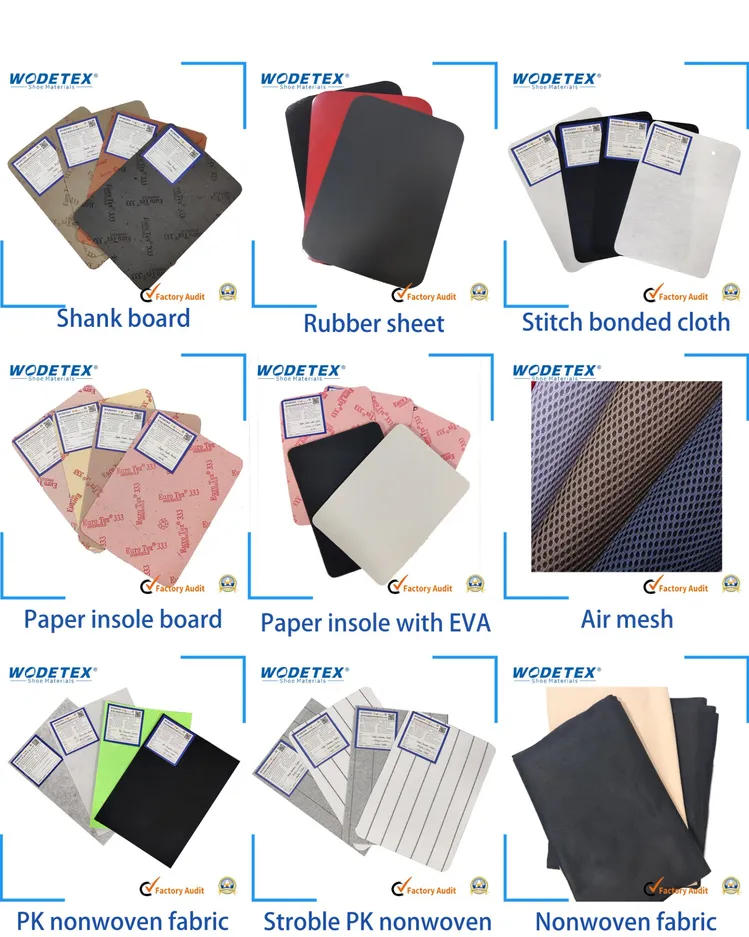

The first stage in manufacturing fabric material shoes is material preparation. This involves sourcing high-quality textiles, such as nylon, polyester, cotton, or specialized blends, which are chosen based on their intended use, durability, and aesthetic appeal.

Once the materials are sourced, they undergo processes such as dyeing and finishing. Dyeing can involve various methods, including piece dyeing and yarn dyeing, depending on the desired color and pattern. Additionally, finishing treatments like water resistance or anti-microbial treatments enhance the fabric’s performance. During this stage, suppliers may also apply sizing agents to add body and stability to the fabric, ensuring it meets the required specifications for shoe construction.

How Are Fabric Shoes Formed and Assembled?

The next phase is forming, where the prepared materials are cut into specific patterns for different shoe components, such as the upper, lining, and insole. Precision cutting is essential, as any discrepancies can lead to fit issues or increased waste.

Illustrative image related to fabric material shoes

Following cutting, the assembly process begins. This typically involves stitching or bonding the fabric components together using techniques like heat sealing or ultrasonic welding, which are increasingly popular for their ability to create strong, seamless joints. In some cases, fabric is laminated with additional layers, such as foam, to improve comfort and performance.

Quality control (QC) checkpoints during assembly, often referred to as In-Process Quality Control (IPQC), are crucial. These checkpoints ensure that assembly aligns with design specifications and that any defects are caught early in the process.

What Finishing Processes Are Applied to Fabric Shoes?

Finishing is the final stage of the manufacturing process, where the assembled shoes undergo several treatments to enhance their aesthetic and functional qualities. This may include polishing, applying protective coatings, or adding decorative elements.

During this stage, the shoes are also subjected to quality inspections, known as Final Quality Control (FQC). This ensures that the shoes meet all design specifications and quality standards before they are packaged for shipment.

What Quality Assurance Standards Are Relevant for Fabric Material Shoes?

Quality assurance is a critical component of manufacturing fabric material shoes, particularly for international markets. Understanding relevant international standards can help B2B buyers ensure that their suppliers maintain high-quality production practices.

ISO 9001 is one of the most recognized quality management standards globally, applicable to any organization seeking to improve its operational processes. Compliance with this standard indicates that the supplier has a robust quality management system in place, focusing on customer satisfaction and continuous improvement.

In addition to ISO standards, industry-specific certifications such as CE marking for products sold in the European Economic Area and API (American Petroleum Institute) standards for oil and gas industry applications may also apply, depending on the shoe’s intended use.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that each stage meets predefined quality standards. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials upon delivery. It ensures that fabrics and components meet the specified requirements before they enter the production line.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing stages, this checkpoint monitors the assembly process to identify any defects or inconsistencies in real-time.

-

Final Quality Control (FQC): This final inspection assesses the completed shoes against design specifications and quality standards, ensuring that they are ready for distribution.

What Common Testing Methods Are Used in Quality Assurance for Fabric Shoes?

To ensure the quality and durability of fabric material shoes, various testing methods are employed. Common tests include:

-

Tensile Strength Testing: Measures the fabric’s ability to withstand tension and is critical for ensuring durability.

-

Abrasion Resistance Testing: Assesses how well the fabric can withstand wear and tear, which is particularly important for footwear.

-

Water Resistance Testing: Evaluates the fabric’s ability to repel water, an essential factor for outdoor or performance footwear.

-

Colorfastness Testing: Determines how well the fabric retains its color when exposed to washing, sunlight, or rubbing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are some actionable strategies:

Illustrative image related to fabric material shoes

-

Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality assurance protocols, and compliance with international standards.

-

Request Quality Reports: Ask suppliers for detailed reports outlining their quality control measures, testing results, and any certifications they hold.

-

Engage Third-Party Inspectors: Utilize third-party inspection services to provide an unbiased assessment of the manufacturing process and finished products. This can be particularly beneficial for buyers in regions with stringent import regulations.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Different regions may have specific standards and regulatory requirements that suppliers must meet.

Buyers should familiarize themselves with import regulations that pertain to footwear, including any duties or tariffs based on the material composition of the shoes. For instance, textiles often incur high import duties, and understanding how to navigate these regulations can lead to significant cost savings.

Moreover, cultural differences in business practices and expectations regarding quality can impact supplier relationships. Establishing clear communication and understanding the local market can facilitate smoother transactions and ensure alignment on quality expectations.

By understanding the manufacturing processes and quality assurance standards for fabric material shoes, B2B buyers can make informed decisions, ensuring that they source high-quality products that meet the needs of their markets.

Illustrative image related to fabric material shoes

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric material shoes’

To assist B2B buyers in sourcing fabric material shoes effectively, this guide provides a structured checklist that outlines essential steps. By following these actionable items, buyers can ensure they select high-quality products and reliable suppliers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful sourcing. This includes deciding on the types of fabrics (e.g., cotton, polyester, nylon) and their characteristics, such as durability, water resistance, and stretchability. Knowing your desired specifications helps streamline the selection process and ensures that the final product meets your quality standards.

Step 2: Research Market Trends and Consumer Preferences

Understanding current market trends and consumer preferences is vital for selecting the right products. This involves analyzing popular styles, materials, and colors in your target regions, such as Europe and Africa. By aligning your offerings with consumer demands, you can enhance your market competitiveness and drive sales.

Step 3: Evaluate Potential Suppliers

Before making any commitments, it is essential to thoroughly vet potential suppliers. Request detailed company profiles, product samples, and references from other businesses in your industry. This step not only helps assess the supplier’s reliability but also provides insights into their production capabilities and quality control processes.

Illustrative image related to fabric material shoes

Step 4: Inspect Fabric Quality and Compliance

Conducting quality inspections is crucial to ensuring that the fabrics meet your specifications. Check for key attributes such as thread count, weave patterns, and surface treatments. Additionally, confirm that the materials comply with international standards and regulations, especially regarding import duties and safety certifications.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers, engage in pricing negotiations. Consider factors such as bulk order discounts, payment terms, and lead times. Establishing favorable terms can significantly impact your overall cost and profitability, making this step crucial for long-term partnerships.

Step 6: Finalize Logistics and Shipping Arrangements

Logistics play a vital role in the procurement process. Collaborate with suppliers to determine shipping options, delivery timelines, and customs requirements. Efficient logistics management ensures that your products arrive on time and in good condition, which is critical for maintaining customer satisfaction.

Step 7: Plan for Post-Purchase Evaluation

After the purchase, implement a system for evaluating the quality and performance of the shoes. Gather feedback from end-users and monitor sales data to assess product acceptance in the market. This evaluation will inform future sourcing decisions and help refine your product offerings.

By adhering to this structured checklist, B2B buyers can navigate the complexities of sourcing fabric material shoes with confidence, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for fabric material shoes Sourcing

What Are the Key Cost Components for Sourcing Fabric Material Shoes?

When sourcing fabric material shoes, understanding the cost structure is essential for effective budgeting and pricing strategy. The primary components of cost include:

-

Materials: The choice of textiles significantly influences the overall cost. Common materials such as nylon and polyester are generally more economical than specialty fabrics like high-tech mesh or organic cotton. Additionally, treatments such as waterproofing or UV resistance can increase material costs.

-

Labor: Labor costs vary by region and complexity of the shoe design. In countries with lower labor costs, such as some regions in Africa and South America, the overall production cost may be reduced. However, specialized craftsmanship for high-quality shoes may require higher-skilled labor, impacting labor expenses.

-

Manufacturing Overhead: This includes costs related to factory operation, utilities, and equipment maintenance. Overhead can vary significantly based on the location of the manufacturing facility, with European factories often incurring higher overhead costs compared to those in Asia or South America.

-

Tooling: Initial costs for molds and machinery setup are crucial, especially for custom designs. This can be a significant upfront investment but is often amortized over larger production volumes.

-

Quality Control (QC): Implementing rigorous QC processes is vital, particularly for B2B buyers who require consistent quality. The costs associated with QC can vary based on the complexity of the product and the standards set by the buyer.

-

Logistics: Shipping costs, including freight and insurance, can fluctuate based on destination and shipping terms. Import duties, which can be significant for textile products, should also be factored into the logistics costs.

-

Margin: Finally, the supplier’s desired profit margin will affect the final price. Understanding the market rates and competitive landscape can help buyers gauge acceptable margins.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence the pricing of fabric material shoes:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQ) that can impact pricing. Larger orders typically lead to lower per-unit costs due to economies of scale.

-

Specifications and Customization: Customized designs or specifications can lead to higher costs. Buyers should weigh the benefits of unique features against the additional expenses incurred.

-

Material Quality and Certifications: The quality of materials and any associated certifications (e.g., eco-friendly labels) can drive costs up. Buyers should assess whether these certifications align with their brand values and customer expectations.

-

Supplier Factors: The reputation, reliability, and production capacity of suppliers can affect pricing. Engaging with established suppliers may yield better quality but at a higher price.

-

Incoterms: Understanding shipping terms is critical. Different Incoterms (e.g., FOB, CIF) can shift the responsibility and costs associated with logistics, influencing the total price.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing?

To maximize cost efficiency in sourcing fabric material shoes, consider the following strategies:

-

Negotiation: Effective negotiation can lead to better pricing. Establishing long-term relationships with suppliers may also provide leverage for more favorable terms.

-

Total Cost of Ownership (TCO): Focus on the TCO rather than just upfront costs. This includes considering maintenance, durability, and potential returns or replacements.

-

Pricing Nuances for International Buyers: International buyers, particularly from Africa, South America, and the Middle East, should be aware of currency fluctuations, import duties, and regional market demands that can impact pricing. Conducting thorough market research can provide insights into competitive pricing strategies.

-

Monitor Supply Chain Dynamics: Stay informed about global supply chain trends, which can affect availability and pricing. Flexibility in sourcing locations may also mitigate risks associated with regional disruptions.

Disclaimer on Indicative Prices

It’s important to note that prices for fabric material shoes can vary widely based on numerous factors outlined above. This analysis provides a framework for understanding potential costs but should not be taken as definitive pricing. Buyers are encouraged to conduct thorough research and obtain quotes tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing fabric material shoes With Other Solutions

Understanding Alternatives in Footwear Solutions

When exploring footwear options, particularly for B2B applications, it is crucial to evaluate various materials and technologies available in the market. Fabric material shoes offer unique advantages, but alternative solutions may also meet specific business needs or target customer preferences. This analysis compares fabric material shoes against two alternative solutions: leather shoes and synthetic shoes, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Fabric Material Shoes | Leather Shoes | Synthetic Shoes |

|---|---|---|---|

| Performance | Lightweight, breathable, flexible | Durable, excellent support | Water-resistant, versatile |

| Cost | Generally lower cost | Higher upfront investment | Moderate cost |

| Ease of Implementation | Easier to source and produce | Requires skilled labor | Generally straightforward |

| Maintenance | Low maintenance, machine washable | Requires conditioning and care | Low maintenance, easy to clean |

| Best Use Case | Casual and athletic footwear | Formal and high-end applications | Sports and outdoor activities |

What Are the Advantages and Disadvantages of Leather Shoes?

Leather shoes are renowned for their durability and classic appeal. They provide excellent support and can adapt well to various foot shapes, making them a popular choice for formal settings. However, the upfront costs can be significantly higher than fabric options, and they require more skilled craftsmanship for production. Additionally, leather demands regular maintenance, including conditioning and polishing, to maintain its appearance and longevity. These characteristics make leather shoes ideal for businesses focusing on upscale markets or requiring a formal aesthetic.

How Do Synthetic Shoes Compare?

Synthetic shoes, often made from materials such as polyurethane or PVC, offer a different set of benefits. They are generally water-resistant, making them suitable for outdoor and sports activities. Their production process is typically less complex than leather, leading to a moderate cost that can appeal to budget-conscious buyers. However, while synthetic shoes are often easier to clean and maintain, they may not offer the same level of breathability and comfort as fabric material shoes. Businesses targeting active consumers or those in need of functional footwear may find synthetic options appealing.

Conclusion: Which Footwear Solution is Right for Your Business?

Choosing the right footwear solution depends on various factors, including target market, budget, and desired performance characteristics. Fabric material shoes provide a lightweight, cost-effective option suitable for casual and athletic contexts, while leather shoes cater to more formal requirements, and synthetic shoes excel in functionality for active use. By evaluating these alternatives against specific business needs and customer preferences, B2B buyers can make informed decisions that align with their strategic goals and market demands.

Essential Technical Properties and Trade Terminology for fabric material shoes

What Are the Key Technical Properties of Fabric Material Shoes?

When sourcing fabric material shoes, understanding the essential technical properties is crucial for ensuring product quality and performance. Here are several critical specifications to consider:

1. Fiber Composition

Fiber composition refers to the types of fibers used in the shoe’s construction, such as cotton, polyester, or nylon. Each fiber has unique properties that affect the shoe’s durability, breathability, and comfort. For instance, polyester is known for its strength and resistance to shrinking, while cotton offers natural breathability. B2B buyers must assess fiber composition to align with customer preferences and market demands.

Illustrative image related to fabric material shoes

2. Denier

Denier is a unit of measurement that indicates the thickness of the thread used in the fabric. A higher denier value typically signifies a thicker, stronger fabric, while a lower value indicates lightweight fabric. Common deniers for fabric material shoes range from 420D to 600D. Understanding denier is essential for evaluating the strength and durability of the shoe, impacting its performance in various conditions.

3. Weave Pattern

The weave pattern describes how the fibers are interlaced to create the fabric. Common patterns include plain, twill, and satin, each offering different aesthetic qualities and performance characteristics. For example, a twill weave provides enhanced durability and resistance to wear. Selecting the appropriate weave pattern can significantly influence the shoe’s appeal and functionality, making it a vital consideration for B2B buyers.

4. Surface Treatments

Surface treatments are applied to fabric to enhance its properties, such as water resistance or UV protection. Treatments like Durable Water Repellent (DWR) can make shoes suitable for various environments, thereby broadening market appeal. B2B buyers should prioritize fabrics with suitable surface treatments to meet specific consumer needs and enhance product longevity.

5. Backing Material

Backing material refers to the additional layer applied to the fabric to improve its structure and performance. Common backing types include PU (polyurethane) and PVC (polyvinyl chloride). PU is lighter and more flexible, while PVC offers greater durability and waterproofing. Understanding the backing material is crucial for assessing the shoe’s overall quality and suitability for targeted markets.

What Are Common Trade Terms in the Fabric Shoe Industry?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several common terms used in the fabric shoe industry:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the context of fabric shoes, an OEM may manufacture the shoes based on a buyer’s specifications. Understanding OEM relationships can help B2B buyers ensure they are sourcing quality products that meet their brand standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the fabric shoe market, MOQs can vary significantly between manufacturers. B2B buyers must consider MOQ when planning their inventory and production schedules, as it impacts cash flow and storage.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is a critical step in the procurement process, allowing buyers to compare offers and select the best supplier for their needs. A well-structured RFQ can streamline negotiations and ensure that all essential specifications are considered.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping goods. They specify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers to mitigate risks and clarify responsibilities in international transactions.

Illustrative image related to fabric material shoes

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. In the fabric shoe industry, lead times can vary based on production schedules, material availability, and shipping logistics. B2B buyers should account for lead times in their planning to ensure timely delivery to customers.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing fabric material shoes, ultimately enhancing their competitive edge in the marketplace.

Navigating Market Dynamics and Sourcing Trends in the fabric material shoes Sector

What Are the Key Market Trends Influencing Fabric Material Shoes?

The global fabric material shoes market is witnessing significant growth, driven by increasing consumer demand for lightweight, comfortable, and fashionable footwear. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate this evolving landscape, several key trends are emerging. Firstly, the rise of e-commerce and digital platforms has revolutionized sourcing, enabling buyers to access a broader range of suppliers and materials. Technologies such as 3D printing and AI-driven design tools are also gaining traction, allowing manufacturers to create custom designs efficiently while minimizing waste.

Moreover, the integration of smart textiles—fabrics embedded with sensors—offers an innovative edge, especially in sports and performance footwear. As buyers seek to differentiate their offerings, understanding these advancements can inform more strategic sourcing decisions. Importantly, the fabric material shoes market is increasingly influenced by regional preferences; for instance, European consumers may prioritize sustainability and ethical production, while buyers in Africa and South America may focus on cost-effectiveness and durability. This dynamic necessitates that B2B buyers remain agile, adapting their sourcing strategies to align with local market demands.

How Is Sustainability Shaping Sourcing Decisions in the Fabric Material Shoes Sector?

Sustainability has become a cornerstone of the fabric material shoes sector, with buyers increasingly aware of the environmental impact of their sourcing decisions. The footwear industry is notorious for its resource-intensive processes, and the rise of eco-conscious consumers has prompted brands to seek out sustainable materials and ethical supply chains. B2B buyers must prioritize suppliers that offer ‘green’ certifications, such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which indicate adherence to stringent environmental and social criteria.

Additionally, innovative materials like recycled polyester, organic cotton, and biodegradable options are becoming more prevalent. These materials not only reduce the environmental footprint but also resonate with consumers’ growing preference for sustainable products. By investing in ethical sourcing, buyers can enhance brand reputation, appeal to a broader audience, and potentially unlock new market opportunities. As sustainability trends evolve, staying informed about certifications and sourcing methods will be critical for B2B buyers aiming to lead in the fabric material shoes market.

What Is the Historical Context of Fabric Material Shoes and Its Relevance Today?

The evolution of fabric material shoes dates back centuries, with early forms of footwear primarily constructed from natural fibers such as leather and canvas. However, the advent of synthetic materials in the mid-20th century revolutionized shoe design, offering greater durability and versatility. The introduction of nylon and polyester allowed for lightweight, water-resistant options that appealed to both consumers and manufacturers.

Today, the significance of this historical context lies in the ongoing innovation within the sector. Modern advancements in textile technology have led to the development of breathable, moisture-wicking fabrics and sustainable alternatives that reflect contemporary consumer values. Understanding this evolution equips B2B buyers with insights into current material trends and consumer preferences, enabling them to make informed decisions that align with market demands. This historical perspective underscores the importance of adaptability in sourcing strategies, as the industry continues to evolve in response to technological advancements and shifting consumer attitudes.

Illustrative image related to fabric material shoes

Frequently Asked Questions (FAQs) for B2B Buyers of fabric material shoes

-

How do I ensure the quality of fabric material shoes from suppliers?

To ensure quality, conduct thorough supplier vetting, including requesting samples of their fabric material shoes. Evaluate the materials used, stitching quality, and overall craftsmanship. Consider visiting the manufacturing facility if possible, or rely on third-party quality assurance inspections. Establish clear quality standards and specifications in your contract, and maintain open communication with the supplier throughout production to address any issues promptly. -

What are the key factors to consider when sourcing fabric material shoes?

When sourcing, consider the type of fabrics used, such as polyester, cotton, or nylon, which affect durability and comfort. Evaluate the supplier’s production capacity, lead times, and compliance with international labor and environmental standards. Additionally, assess customization options, minimum order quantities (MOQ), and payment terms to ensure they align with your business needs. Lastly, factor in logistics and shipping costs to get a comprehensive view of the total expenditure. -

What is the best fabric type for durability in fabric material shoes?

Polyester and nylon are among the best fabric types for durability, offering strength and resistance to wear and tear. Cotton, while comfortable, may not provide the same level of durability unless treated or reinforced. For specialized applications, consider high-tech options like ripstop nylon, which is designed to prevent tearing, or treated cotton for added water resistance. Always match the fabric choice with the intended use of the shoes to optimize performance. -

How can I customize fabric material shoes for my brand?

Customization options often include selecting fabric colors, patterns, and textures, as well as adding your brand logo or other design elements. Discuss your specific requirements with potential suppliers, ensuring they have the capabilities to meet your design vision. Some manufacturers may offer design services or collaborate with you on prototypes. Be clear about your expectations regarding lead times and costs associated with custom orders. -

What are the typical minimum order quantities (MOQ) for fabric material shoes?

Minimum order quantities can vary significantly based on the supplier and the complexity of your order. Typically, MOQs can range from 100 to 1,000 pairs for standard designs. For custom designs, the MOQ may be higher due to additional setup costs. Always negotiate MOQs with suppliers and consider the potential for future orders to build a long-term partnership, which could lead to more favorable terms. -

What payment terms should I expect when sourcing fabric material shoes?

Payment terms can differ among suppliers, but common practices include a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers may offer net 30 or net 60 terms for established relationships. Ensure that you clarify payment methods accepted, including wire transfers, credit cards, or letters of credit, and be aware of any additional fees that may apply to international transactions. -

How do import duties affect the cost of fabric material shoes?

Import duties vary by country and can significantly impact the total cost of fabric material shoes. For example, shoes with a textile surface area exceeding 51% may incur a 20% duty rate in certain markets. It’s crucial to understand the specific regulations of your country and the country of origin for the shoes. Consulting with a customs broker can provide clarity and help you navigate import duties effectively to avoid unexpected costs. -

What logistics considerations should I keep in mind when importing fabric material shoes?

Logistics is vital in ensuring timely delivery and cost-effectiveness. Consider the shipping methods available, such as air freight for faster delivery or sea freight for cost savings on larger shipments. Factor in transit times, customs clearance processes, and potential delays. Establish a reliable logistics partner familiar with international shipping regulations to streamline the process. Also, ensure you have proper insurance coverage for your shipments to mitigate risks during transit.

Top 5 Fabric Material Shoes Manufacturers & Suppliers List

1. Shoemakers Academy – Essential Textiles for Shoe Design

Domain: shoemakersacademy.com

Registered: 2022 (3 years)

Introduction: Textiles for Shoe Design: Understanding fabrics is essential for shoe design. Key textiles include nylon, polyester, lycra, and cotton canvas. Important considerations are thread size (measured in denier), fiber composition, weave pattern, backing material, sizing, and surface treatments. Common deniers range from 110D for lightweight fabric to 1000D for boots. Fiber types include cotton, wool, ny…

2. Adidas – Textile Upper Shoes

Domain: adidas.com

Registered: 1995 (30 years)

Introduction: This company, Adidas – Textile Upper Shoes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Etsy – Unique Shoe Fabrics

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Unique Shoe Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Footwear etc. – Ultimate Guide to Shoe Materials

Domain: footwearetc.com

Registered: 1995 (30 years)

Introduction: The Ultimate Guide to Selecting Footwear/Shoe Materials provides insights on various shoe materials available at Footwear etc. Key materials discussed include: BIRKIBUC (durable, animal-free, soft, easy to clean), BIRKO-FLOR (comfortable, soft, durable, easy to maintain), CANVAS (lightweight, breathable, versatile), and others like COTTON, EVA, FABRIC, LEATHER, MESH, NUBUCK, NYLON, PATENT LEATHER,…

5. Vans – Premium Canvas Sneakers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Canvas Sneakers: Generally considered more breathable, but some synthetic canvases may not breathe well. Example: Vans ‘premium’.

2. Leather Sneakers with Textile/Synthetic Lining: Geox Regio sneakers with 76% textile and 24% synthetic lining, featuring patented ‘Respira’ holes on the sole.

3. Leather Sneakers with Unknown Lining: Ecco Soft 7 or Ecco Soft 60.

4. High-Quality Leather Sneakers: C…

Strategic Sourcing Conclusion and Outlook for fabric material shoes

As the demand for fabric material shoes continues to rise globally, strategic sourcing becomes essential for B2B buyers looking to optimize their supply chains. By understanding the diverse range of textiles available—from durable synthetics like polyester and nylon to classic natural fibers such as cotton—companies can make informed decisions that align with both market trends and consumer preferences.

Investing in high-quality materials not only enhances product durability but also enables brands to differentiate themselves in a competitive marketplace. Moreover, awareness of import duties and sourcing regulations across regions, particularly in Africa, South America, the Middle East, and Europe, can lead to significant cost savings.

Looking ahead, it is crucial for international buyers to remain agile and responsive to evolving consumer trends, such as sustainability and innovation in textile technology. By prioritizing strategic partnerships and staying informed about advancements in fabric materials, businesses can position themselves for success in the dynamic footwear industry. Take action now—explore new sourcing opportunities and elevate your product offerings to meet the demands of today’s discerning consumers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.