Introduction: Navigating the Global Market for microfiber microsuede fabric

In the competitive landscape of textile sourcing, navigating the global market for microfiber microsuede fabric poses a unique challenge for B2B buyers. The quest for high-quality, durable, and cost-effective materials is paramount, especially when considering the diverse needs of various industries, from upholstery to fashion. This guide serves as a comprehensive resource, addressing critical aspects such as types of microsuede fabric, its multifaceted applications, effective supplier vetting processes, and cost considerations.

Microfiber microsuede fabric, known for its luxurious feel and practical benefits, offers an attractive alternative to genuine suede, making it a popular choice among manufacturers and retailers alike. As B2B buyers from Africa, South America, the Middle East, and Europe—regions with distinct market dynamics—explore their sourcing options, this guide equips them with essential insights to make informed purchasing decisions.

From understanding the nuances of fabric quality to identifying reliable suppliers, our guide empowers international buyers to confidently navigate the complexities of the microsuede market. By providing actionable information and expert recommendations, we aim to streamline the sourcing process, ensuring that businesses can meet their project requirements while maximizing value and efficiency.

Table Of Contents

- Top 9 Microfiber Microsuede Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for microfiber microsuede fabric

- Understanding microfiber microsuede fabric Types and Variations

- Key Industrial Applications of microfiber microsuede fabric

- 3 Common User Pain Points for ‘microfiber microsuede fabric’ & Their Solutions

- Strategic Material Selection Guide for microfiber microsuede fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for microfiber microsuede fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber microsuede fabric’

- Comprehensive Cost and Pricing Analysis for microfiber microsuede fabric Sourcing

- Alternatives Analysis: Comparing microfiber microsuede fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for microfiber microsuede fabric

- Navigating Market Dynamics and Sourcing Trends in the microfiber microsuede fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of microfiber microsuede fabric

- Strategic Sourcing Conclusion and Outlook for microfiber microsuede fabric

- Important Disclaimer & Terms of Use

Understanding microfiber microsuede fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Microsuede | Soft texture, suede-like appearance, stain-resistant | Upholstery, clothing, decorative items | Pros: Affordable, easy to clean; Cons: Less durable than heavy variants. |

| Heavy-Duty Microsuede | Thick, durable fabric, high abrasion resistance | Commercial upholstery, automotive interiors | Pros: Long-lasting, ideal for high-traffic areas; Cons: Heavier and may be costlier. |

| Vegan Microsuede | 100% synthetic, eco-friendly alternative to real suede | Eco-conscious fashion, furniture upholstery | Pros: Sustainable, animal-friendly; Cons: Perceived lower quality by some consumers. |

| Printed Microsuede | Customizable prints and patterns available | Fashion apparel, promotional items | Pros: Versatile design options; Cons: May have longer lead times for production. |

| Microfiber Suede Blend | Combination of microsuede and other fibers for varied texture | Home decor, cushions, and pet products | Pros: Enhanced texture, diverse applications; Cons: May require specialized cleaning. |

What are the characteristics of Standard Microsuede?

Standard microsuede is characterized by its soft texture and suede-like appearance, making it a popular choice for various applications. Its stain-resistant properties enhance its appeal, especially for upholstery in residential settings. B2B buyers should consider this fabric for projects that require a balance between aesthetics and affordability. However, while it is easy to clean, it may not withstand heavy use as well as more robust variants.

How does Heavy-Duty Microsuede differ from Standard Microsuede?

Heavy-duty microsuede is designed for durability, featuring a thicker weave that offers high abrasion resistance. This makes it particularly suitable for commercial upholstery and automotive interiors, where heavy usage is common. B2B buyers looking for long-lasting materials in high-traffic areas will find this option ideal. The trade-off may be a higher price point and increased weight, which could affect shipping and handling.

Illustrative image related to microfiber microsuede fabric

What makes Vegan Microsuede a viable option for eco-conscious buyers?

Vegan microsuede is a 100% synthetic fabric that serves as an eco-friendly alternative to genuine suede. This fabric is increasingly popular among brands that prioritize sustainability. B2B buyers in the fashion and home decor industries can leverage vegan microsuede to appeal to environmentally-conscious consumers. While it offers a sustainable choice, some may perceive it as lower quality compared to traditional materials, which could influence purchasing decisions.

Why choose Printed Microsuede for fashion and promotional items?

Printed microsuede allows for customizable designs and patterns, catering to brands that seek unique fabric options for fashion apparel and promotional items. This type of microsuede can enhance brand visibility and create distinctive product lines. However, B2B buyers should be aware that the production time for printed microsuede may be longer, impacting project timelines.

How does Microfiber Suede Blend enhance versatility in applications?

Microfiber suede blend combines microsuede with other fibers to create varied textures and enhance functionality. This type is particularly suitable for home decor, cushions, and pet products, offering a diverse range of applications. B2B buyers should consider the specific cleaning and maintenance requirements, as these blends may need specialized care. The ability to offer unique textures can be a significant selling point in competitive markets.

Key Industrial Applications of microfiber microsuede fabric

| Industry/Sector | Specific Application of microfiber microsuede fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas, chairs, and headboards | Offers durability and easy maintenance, enhancing product lifespan and customer satisfaction | Ensure fabric meets durability standards (e.g., abrasion resistance) and is available in desired colors and textures |

| Automotive | Interior car upholstery and seat covers | Provides a luxurious feel while being stain-resistant and easy to clean, appealing to consumers | Check for compliance with automotive standards and fire resistance ratings |

| Fashion and Apparel | Clothing items such as jackets and skirts | Combines style with comfort, allowing for versatile fashion applications at competitive prices | Look for suppliers with a wide range of colors and finishes to meet fashion trends |

| Home Decor | Decorative pillows, cushions, and throws | Enhances aesthetic appeal while being practical for high-traffic areas, increasing sales potential | Consider sourcing options that provide custom colors and patterns to match interior design trends |

| Pet Products | Pet beds and accessories | Durable and easy to clean, meeting the needs of pet owners seeking practical yet stylish solutions | Ensure the fabric is non-toxic and safe for pets, with options for various sizes and designs |

How is microfiber microsuede fabric utilized in furniture manufacturing?

In the furniture manufacturing sector, microfiber microsuede fabric is predominantly used for upholstery on sofas, chairs, and headboards. Its luxurious texture mimics real suede while providing superior durability and ease of maintenance. This fabric is particularly beneficial in high-traffic environments, as it resists wear and is stain-resistant, addressing common concerns of furniture longevity. International buyers should prioritize sourcing fabrics that meet specific durability standards, ensuring they can offer high-quality products that enhance customer satisfaction.

Illustrative image related to microfiber microsuede fabric

What role does microfiber microsuede fabric play in the automotive industry?

In the automotive industry, microfiber microsuede fabric is utilized for interior car upholstery and seat covers. The fabric not only offers a premium look and feel but also provides practical benefits such as stain resistance and ease of cleaning, which are crucial for maintaining vehicle interiors. Buyers in this sector should verify that the fabric complies with automotive standards, including fire resistance, to meet safety regulations and enhance vehicle appeal to consumers.

How does the fashion industry benefit from microfiber microsuede fabric?

The fashion and apparel industry leverages microfiber microsuede fabric for a variety of clothing items, including jackets and skirts. This fabric’s softness and luxurious appearance allow designers to create versatile fashion pieces at competitive prices. Additionally, its lightweight nature and comfort make it suitable for various styles. B2B buyers should seek suppliers that offer a broad spectrum of colors and finishes to stay aligned with evolving fashion trends, ensuring they can meet diverse customer demands.

In what ways is microfiber microsuede fabric used in home decor?

Microfiber microsuede fabric is widely used in home decor for making decorative pillows, cushions, and throws. Its plush texture not only enhances the aesthetic appeal of living spaces but also provides practical benefits, such as easy maintenance and durability, making it ideal for high-traffic areas. Buyers in this sector should consider sourcing options that allow for custom colors and patterns to align with current interior design trends, ensuring they can offer unique and stylish products to their customers.

How is microfiber microsuede fabric relevant to pet products?

In the pet products sector, microfiber microsuede fabric is commonly used for pet beds and accessories. Its durability and ease of cleaning cater to the practical needs of pet owners who seek stylish yet functional solutions. Additionally, the fabric is often non-toxic, making it safe for pets. When sourcing, buyers should ensure that the fabric meets safety standards and offers a variety of sizes and designs to accommodate different pet needs, enhancing marketability in this growing industry.

3 Common User Pain Points for ‘microfiber microsuede fabric’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Quality of Microfiber Microsuede Fabric

The Problem:

B2B buyers often struggle with choosing the appropriate quality of microfiber microsuede fabric for their projects. With various suppliers offering different grades, it can be challenging to determine which fabric will meet durability and aesthetic requirements. This is particularly crucial for businesses in the upholstery industry, where the fabric’s longevity directly impacts customer satisfaction and brand reputation. Buyers may also face issues with discrepancies in product samples versus the final delivered goods, leading to potential project delays and increased costs.

Illustrative image related to microfiber microsuede fabric

The Solution:

To ensure that you source the right quality of microfiber microsuede fabric, it is essential to establish clear criteria based on your specific needs. Start by defining the intended application—whether for upholstery, clothing, or accessories—as different uses may require distinct fabric weights, textures, and finishes. Request samples from multiple suppliers and conduct a thorough comparison. Look for fabrics with high abrasion resistance (measured in double rubs using the Wyzenbeek method) and check for stain resistance properties, which are critical for high-traffic environments.

Additionally, ensure that you inquire about the fabric’s manufacturing process and the materials used, as these factors can significantly influence quality and sustainability. Engaging in conversations with suppliers about their quality control measures can also provide insights into their reliability. By developing a comprehensive understanding of your quality requirements and supplier capabilities, you can make informed decisions that align with your business goals.

Scenario 2: Challenges in Cleaning and Maintenance of Microfiber Microsuede Fabric

The Problem:

Microfiber microsuede fabric is praised for its ease of care, yet B2B buyers often encounter challenges in cleaning and maintaining this material, especially in high-usage settings like hotels, restaurants, or homes with pets. Misunderstandings about cleaning methods can lead to fabric damage, discoloration, or loss of texture, ultimately affecting the lifespan of the upholstery and resulting in costly replacements.

The Solution:

To mitigate cleaning challenges, it’s vital to establish and communicate clear cleaning guidelines to your team or end-users. Start by educating yourself on the specific cleaning codes for the fabric you’re sourcing. Many microfiber microsuede fabrics can be cleaned with a simple mixture of mild soap and water; however, some may require specific fabric cleaners designed for microfiber. Create a maintenance schedule that includes routine cleaning and deeper cleaning sessions, especially for high-traffic areas.

Illustrative image related to microfiber microsuede fabric

Additionally, consider providing training sessions or informational materials for staff or customers that detail proper cleaning techniques. This could include demonstrations on removing stains promptly and the importance of using the right cleaning agents to maintain the fabric’s integrity. By prioritizing proper care and maintenance, you can extend the life of the microsuede fabric and enhance customer satisfaction.

Scenario 3: Concerns About Color Consistency and Dye Lot Variations

The Problem:

B2B buyers frequently face issues with color consistency in microfiber microsuede fabric due to dye lot variations. This concern can be particularly problematic for projects requiring large quantities of fabric, such as commercial upholstery or large-scale production runs. When fabric colors differ slightly from batch to batch, it can lead to mismatched products, negatively impacting the overall aesthetic and quality of the finished items.

The Solution:

To address color consistency concerns, it’s crucial to establish a clear understanding of dye lot variations before placing large orders. Always request samples from the specific dye lot intended for your order and compare them with previously acquired samples to ensure they match your expectations. When ordering, communicate your need for color consistency clearly to the supplier and inquire about their dyeing processes and how they manage dye lot variations.

Illustrative image related to microfiber microsuede fabric

Implementing a quality assurance protocol where you inspect fabric upon delivery can also help catch any inconsistencies before they affect production. Additionally, consider keeping a small inventory of the fabric in different dye lots to accommodate future projects or repairs without compromising on color matching. By taking proactive measures, you can ensure that your final products maintain the desired color integrity, thereby enhancing customer trust and satisfaction.

Strategic Material Selection Guide for microfiber microsuede fabric

What Are the Key Properties of Microfiber Microsuede Fabric?

Microfiber microsuede fabric is primarily composed of ultra-fine polyester or nylon fibers. These fibers are densely woven to create a soft, luxurious texture that mimics real suede. The key properties of this material include its high abrasion resistance, typically rated at over 50,000 double rubs (Wyzenbeek method), making it suitable for high-traffic areas. Its stain resistance and ease of cleaning are other significant advantages, allowing for maintenance with mild soap and water or specialized fabric cleaners.

What Are the Pros and Cons of Using Polyester in Microsuede Fabric?

Pros: Polyester, the most common fiber used in microfiber microsuede, is known for its durability and resistance to shrinking and stretching. It is also lightweight, which makes it easy to handle during manufacturing and application. Additionally, polyester is cost-effective, making it an attractive option for bulk purchases.

Cons: However, polyester can be less breathable compared to natural fibers, which may lead to discomfort in warmer climates. Furthermore, while it is resistant to many chemicals, it can be susceptible to certain solvents, which may limit its use in specific applications.

Illustrative image related to microfiber microsuede fabric

How Does Nylon Contribute to the Performance of Microsuede Fabric?

Nylon is another fiber that can be used in microfiber microsuede fabric. It offers excellent strength and elasticity, contributing to the overall durability of the fabric.

Pros: The high tensile strength of nylon makes it resistant to tearing and abrasion, while its elasticity allows for a snug fit in upholstery applications. Additionally, nylon is less prone to fading, which is beneficial for products exposed to sunlight.

Cons: On the downside, nylon can be more expensive than polyester, which may impact the overall cost of the final product. It also has a lower resistance to heat, which could be a consideration for applications involving high temperatures.

What Should International Buyers Consider When Selecting Microsuede Fabric?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, several factors should be taken into account when selecting microfiber microsuede fabric. Compliance with international standards (e.g., ASTM, DIN, JIS) is crucial to ensure product quality and safety. For instance, buyers should verify that the fabric meets fire safety regulations, especially for upholstery in commercial settings.

Additionally, preferences for colorfastness and environmental sustainability are increasingly important. Many buyers are looking for vegan options, which align with growing consumer trends toward ethical sourcing.

Summary Table of Material Properties

| Material | Typical Use Case for microfiber microsuede fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Upholstery, clothing, home decor | Durable and cost-effective | Less breathable than natural fibers | Low |

| Nylon | High-end upholstery, outdoor applications | High strength and elasticity | More expensive, lower heat resistance | Med |

| Blended Fibers | Versatile applications in fashion and upholstery | Combines benefits of both fibers | Potentially higher manufacturing complexity | Med |

| Vegan Faux Suede | Eco-friendly furniture, accessories | Aligns with ethical consumerism | May have lower durability compared to traditional options | High |

This guide provides a comprehensive overview of the strategic selection of materials for microfiber microsuede fabric, emphasizing the importance of understanding the properties, advantages, and limitations of each option. By considering these factors, international B2B buyers can make informed decisions that align with their specific needs and market trends.

In-depth Look: Manufacturing Processes and Quality Assurance for microfiber microsuede fabric

What are the Main Stages in the Manufacturing Process of Microfiber Microsuede Fabric?

The manufacturing process of microfiber microsuede fabric involves several critical stages, each designed to ensure the creation of a high-quality product.

Material Preparation

The first stage in the manufacturing of microfiber microsuede involves the selection and preparation of raw materials. Typically, ultra-fine polyester or nylon fibers are chosen due to their durability and ability to mimic the luxurious feel of real suede. The fibers are processed to a specific diameter, often less than 1 denier, allowing for a denser and softer fabric. This stage may also involve dyeing the fibers to achieve the desired color and aesthetic appeal before they are woven.

Forming the Fabric

Once the materials are prepared, the next step is forming the fabric. This is primarily done through a weaving or knitting process where the fibers are densely interlaced. The weaving technique can significantly affect the texture and durability of the final product. For microsuede, techniques such as warp knitting or weft knitting are commonly employed, creating a fabric that not only looks and feels luxurious but also offers resilience against wear and tear.

Assembly and Finishing

After the fabric is formed, it undergoes assembly and finishing processes. This includes additional treatments such as brushing to enhance the nap, which contributes to the velvety texture. The fabric may also be treated with stain-resistant coatings to improve its usability in high-traffic areas. Other finishing techniques can include heat-setting, which stabilizes the fabric’s structure, and chemical treatments to improve durability and ease of maintenance.

What Quality Control Measures are Essential for Microfiber Microsuede Fabric?

Quality control (QC) is a vital component in the manufacturing of microfiber microsuede fabric, ensuring that the final product meets international standards and customer expectations.

Illustrative image related to microfiber microsuede fabric

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be aware of international quality standards, such as ISO 9001, which focuses on quality management systems. Compliance with ISO standards indicates that a manufacturer has met rigorous quality assurance protocols. Additionally, other certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the application of the fabric, particularly in sectors like automotive or upholstery.

What Are the Key QC Checkpoints in Fabric Production?

Quality control checkpoints are crucial at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting the raw materials upon arrival at the manufacturing facility. Key aspects include checking for fiber quality, color consistency, and any defects in the material.

-

In-Process Quality Control (IPQC): During the manufacturing process, samples are taken to ensure that the weaving and finishing processes are meeting quality standards. This may include checking the fabric’s weight, texture, and overall appearance.

-

Final Quality Control (FQC): Before the fabric is shipped to customers, a final inspection is conducted. This involves testing the fabric for durability, stain resistance, and colorfastness, often utilizing standardized testing methods like the Wyzenbeek test for abrasion resistance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers maintain high-quality standards, B2B buyers should implement several verification strategies.

What Are Effective Methods for Supplier Audits?

Conducting on-site audits is one of the most effective ways to assess a supplier’s quality control processes. During these audits, buyers can review documentation related to quality management systems, observe manufacturing practices, and inspect the facilities. This firsthand observation can provide insights into the supplier’s commitment to quality.

How Can Buyers Utilize Quality Reports and Third-Party Inspections?

Buyers should request quality reports that detail the results of various tests conducted on the fabric. Additionally, employing third-party inspection services can offer an unbiased evaluation of the fabric’s quality. These inspections often include checks for compliance with international standards and can validate the supplier’s claims regarding fabric durability and performance.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

When sourcing microfiber microsuede fabric from international suppliers, buyers from regions such as Africa, South America, the Middle East, and Europe must consider several nuances.

Illustrative image related to microfiber microsuede fabric

How Do Cultural Differences Impact Quality Expectations?

Cultural differences can influence quality expectations and communication. Buyers should ensure clear communication about quality requirements and specifications. Understanding local manufacturing practices and standards can also help in assessing potential suppliers.

What Are the Import Regulations and Compliance Requirements?

Each region may have specific import regulations and compliance requirements that can affect the quality assurance process. For example, European buyers must be aware of REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations when importing textiles. Ensuring that suppliers are compliant with these regulations can help prevent future legal complications.

Conclusion

The manufacturing processes and quality assurance practices for microfiber microsuede fabric are integral to delivering a high-quality product that meets the expectations of international B2B buyers. By understanding the stages of production, quality control measures, and verification processes, buyers can make informed decisions when selecting suppliers, ultimately ensuring that they receive durable and luxurious fabrics suitable for various applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber microsuede fabric’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of microfiber microsuede fabric, a versatile and durable material widely used in upholstery, clothing, and accessories. By following this step-by-step checklist, you can ensure that your sourcing process is efficient, cost-effective, and aligned with your project requirements.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the microfiber microsuede fabric you need, including weight, fiber content, and intended applications. This step is crucial as it sets the foundation for your sourcing process, ensuring that you communicate your needs effectively to suppliers.

– Considerations:

– Desired weight (e.g., 250 g/m² for durability).

– Fiber content (e.g., 100% polyester for vegan-friendly options).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in microfiber microsuede fabric. Utilize online directories, industry trade shows, and networking to compile a list of reputable vendors.

– Actions to Take:

– Check supplier reviews and ratings.

– Look for suppliers with a proven track record in your target market regions (Africa, South America, the Middle East, and Europe).

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that your selected suppliers have the necessary certifications and quality standards in place. Certifications can indicate compliance with international quality norms and ethical sourcing practices.

– Key Certifications to Look For:

– ISO certifications for quality management.

– OEKO-TEX Standard 100 for safety and environmental standards.

Step 4: Request Samples for Testing

Request fabric samples from shortlisted suppliers to evaluate the quality and performance of the microfiber microsuede. This step allows you to assess the texture, color fidelity, and durability before making a bulk purchase.

– Important Points:

– Test the fabric for stain resistance and ease of cleaning.

– Check for color consistency across different batches.

Illustrative image related to microfiber microsuede fabric

Step 5: Negotiate Terms and Pricing

Engage in discussions with potential suppliers to negotiate pricing, payment terms, and delivery timelines. Effective negotiation can lead to cost savings and better service agreements.

– Strategies:

– Compare quotes from multiple suppliers to ensure competitive pricing.

– Inquire about bulk order discounts and shipping costs.

Step 6: Assess Supply Chain Reliability

Evaluate the logistics and supply chain capabilities of your chosen supplier. A reliable supply chain is essential for timely delivery and consistent quality, especially for high-volume orders.

– Considerations:

– Review the supplier’s delivery history and capacity to meet your timelines.

– Understand their policies regarding order changes or cancellations.

Step 7: Establish a Quality Control Process

Once you have procured the fabric, establish a quality control process to ensure that the received goods meet your specifications. This step helps in minimizing defects and maintaining product quality.

– Implementation Steps:

– Set criteria for inspection upon delivery.

– Create a feedback loop with your supplier to address any quality issues promptly.

By following these steps, you can streamline your sourcing process for microfiber microsuede fabric, ensuring that you make informed decisions that meet your business needs and uphold quality standards.

Comprehensive Cost and Pricing Analysis for microfiber microsuede fabric Sourcing

What Are the Key Cost Components in Sourcing Microfiber Microsuede Fabric?

When sourcing microfiber microsuede fabric, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The cost of raw materials, primarily ultra-fine polyester or nylon fibers, significantly influences the overall price. Quality and sourcing of these materials can vary, affecting costs. For instance, premium fibers may command higher prices but offer enhanced durability and performance.

-

Labor: Labor costs encompass the workforce involved in fabric production, which can vary significantly by region. Countries with lower labor costs, such as Vietnam, may offer more competitive pricing compared to European nations like Germany, where labor is typically more expensive.

-

Manufacturing Overhead: This includes costs related to factory operation, utilities, and administrative expenses. Efficient manufacturing processes can help mitigate these costs, impacting the final pricing of the fabric.

-

Tooling: Depending on the complexity of the fabric design or any specific machinery required for production, tooling costs can add to the overall expense. Custom tooling for unique fabric patterns may further increase this cost.

-

Quality Control (QC): Implementing rigorous QC measures ensures the fabric meets specific standards, which can incur additional costs. However, investing in quality control can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping and handling costs are significant, especially for international transactions. Factors such as distance, shipping method, and customs duties can influence the final price delivered to the buyer.

-

Margin: Suppliers will add a profit margin to their costs, which can vary widely. Understanding the market dynamics and pricing strategies of suppliers can provide leverage during negotiations.

How Do Price Influencers Impact the Cost of Microsuede Fabric?

Several factors can influence the pricing of microfiber microsuede fabric:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically benefit from bulk pricing, reducing the per-unit cost. Buyers should negotiate MOQs that align with their purchasing capacity to optimize costs.

-

Specifications and Customization: Tailored specifications, such as specific colors, textures, or patterns, can increase costs. Standardized options usually come at a lower price point, while customization can lead to higher tooling and production costs.

-

Material Quality and Certifications: Fabrics that meet industry certifications (e.g., eco-friendly or hypoallergenic standards) may carry a premium price. Buyers should assess whether these certifications align with their market needs.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Established suppliers may charge more but offer guarantees on quality and delivery, while new entrants may provide lower prices to build their customer base.

-

Incoterms: The terms of shipment can affect costs significantly. Buyers should understand Incoterms to evaluate who bears the costs and risks associated with shipping, which can ultimately influence the total cost of ownership.

What Are the Best Tips for Negotiating Microsuede Fabric Prices?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following tips to enhance negotiation outcomes:

-

Understand Total Cost of Ownership (TCO): Look beyond the initial price. Evaluate long-term costs associated with durability, maintenance, and potential waste. A slightly higher upfront cost for superior quality can lead to lower overall expenses.

-

Leverage Market Research: Familiarize yourself with current market prices and trends for microfiber microsuede fabric. Having data on hand can provide leverage during negotiations.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms. Long-term partnerships often result in more favorable conditions, including discounts on future orders.

-

Request Samples: Before committing to large orders, request samples to assess quality. This practice can also serve as a negotiation tool if the supplier is confident in their product.

-

Be Flexible: Consider adjusting order quantities or specifications to meet supplier thresholds for better pricing. Flexibility can lead to significant savings.

Disclaimer on Pricing Variability

Prices for microfiber microsuede fabric can vary widely based on numerous factors, including market demand, supplier pricing strategies, and regional economic conditions. It is advisable for buyers to conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

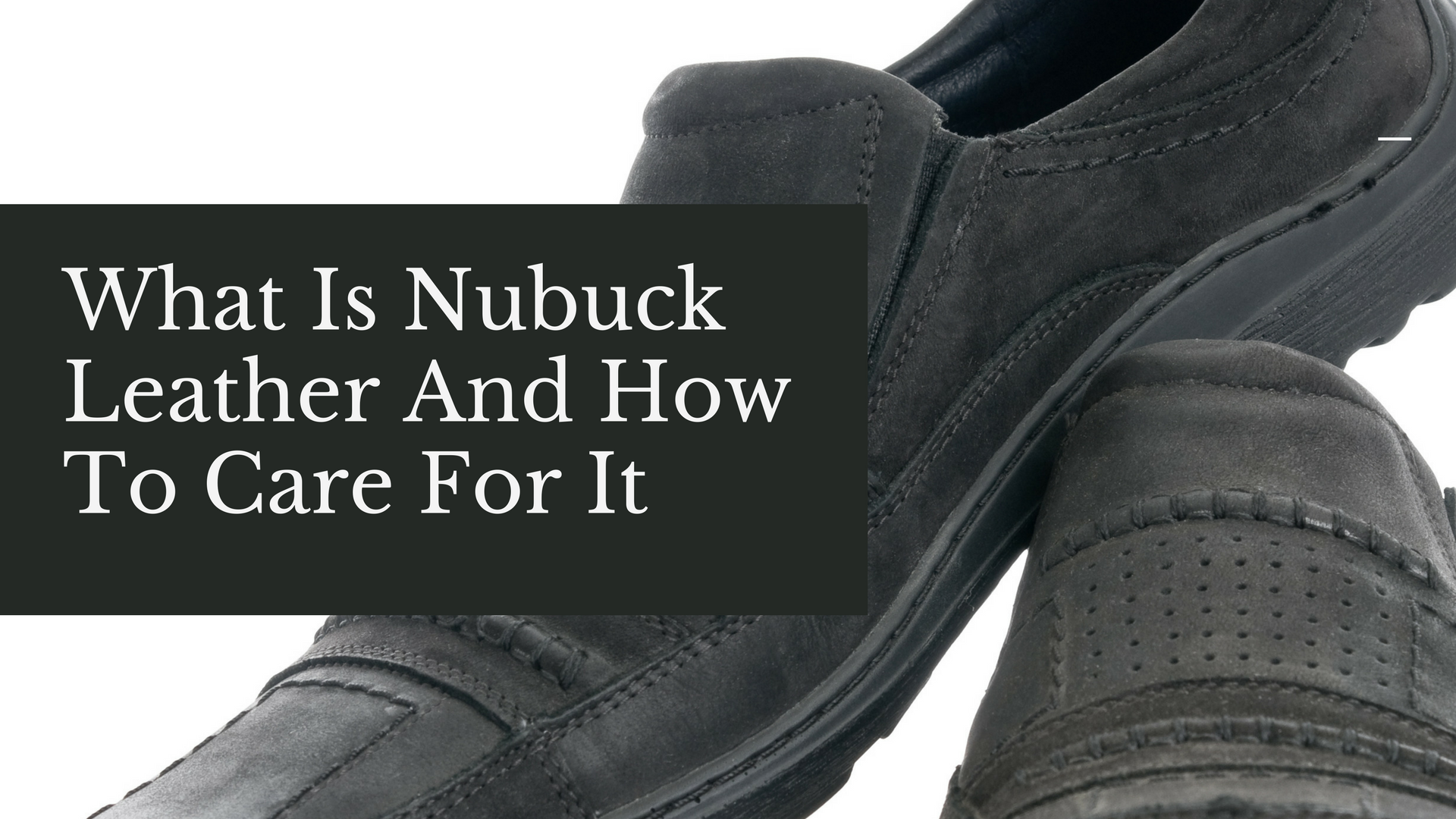

Alternatives Analysis: Comparing microfiber microsuede fabric With Other Solutions

Exploring Alternatives to Microfiber Microsuede Fabric

In the realm of upholstery and fabric solutions, microfiber microsuede fabric has gained significant traction due to its durability, versatility, and aesthetic appeal. However, buyers should consider alternative options that may better suit their specific needs, whether driven by budget constraints, desired performance characteristics, or particular applications. Below, we compare microfiber microsuede fabric with two viable alternatives: genuine suede and synthetic leather.

Illustrative image related to microfiber microsuede fabric

| Comparison Aspect | Microfiber Microsuede Fabric | Genuine Suede | Synthetic Leather |

|---|---|---|---|

| Performance | Highly durable, stain-resistant, soft texture | Durable but can stain easily; requires careful maintenance | Very durable, water-resistant, can mimic various textures |

| Cost | Affordable, often lower than genuine suede | Generally more expensive due to sourcing and processing | Mid-range, more affordable than genuine leather but pricier than microsuede |

| Ease of Implementation | Readily available by the yard, easy to sew and work with | Requires specialized care and may need professional installation | Easy to work with, available in various styles and colors |

| Maintenance | Easy to clean with mild soap and water | Requires specific cleaning products and techniques | Generally easy to clean; resistant to stains and spills |

| Best Use Case | High-traffic areas, pet-friendly environments, fashion apparel | High-end furniture, luxury items, and fashion | Automotive interiors, furniture, and fashion items requiring a leather-like finish |

In-Depth Look at Alternatives

1. Genuine Suede

Genuine suede is a natural leather product known for its luxurious feel and aesthetic appeal. While it offers a high-end look, its maintenance requirements can be a significant drawback. Suede is susceptible to stains and requires specialized cleaning products, making it less suitable for high-traffic areas or environments with children and pets. In terms of cost, genuine suede is generally more expensive than microfiber microsuede, which could be a limiting factor for B2B buyers focused on budget constraints.

2. Synthetic Leather

Synthetic leather, often referred to as faux leather or vegan leather, provides a versatile and cost-effective alternative to both genuine suede and microfiber microsuede. It offers durability and a water-resistant surface, making it ideal for automotive interiors and commercial applications. Synthetic leather can mimic the appearance of various textures, including suede, but may lack the breathability of natural materials. It is generally easy to maintain and clean, which is a significant advantage for businesses in need of low-maintenance solutions.

Conclusion: How to Choose the Right Fabric Solution

When selecting the right fabric for your needs, consider the specific requirements of your project, including budget, maintenance capacity, and performance characteristics. Microfiber microsuede fabric stands out for its affordability and ease of care, making it an excellent choice for high-traffic and pet-friendly environments. However, if you prioritize luxury and aesthetics, genuine suede may be worth the investment, provided you are prepared to manage its upkeep. Alternatively, synthetic leather can offer a balance of durability and style, making it a practical choice for various applications. Understanding the unique benefits and drawbacks of each option will empower B2B buyers to make informed decisions tailored to their specific operational needs.

Illustrative image related to microfiber microsuede fabric

Essential Technical Properties and Trade Terminology for microfiber microsuede fabric

What Are the Key Technical Properties of Microfiber Microsuede Fabric?

Microfiber microsuede fabric possesses several essential technical properties that significantly impact its usability and performance in various applications. Understanding these properties is crucial for B2B buyers looking to make informed purchasing decisions.

-

Material Composition

Microfiber microsuede is primarily composed of ultra-fine polyester or nylon fibers. The synthetic nature of these materials mimics the luxurious feel of genuine suede while providing enhanced durability. For businesses, choosing the right composition is vital for ensuring product longevity and maintaining quality, especially in high-traffic environments. -

Weight (GSM)

The weight of microsuede fabric is typically measured in grams per square meter (GSM). A standard microsuede fabric may range from 180 to 300 GSM, with heavier weights offering increased durability and a more substantial feel. For manufacturers and upholstery businesses, selecting the appropriate weight is essential for determining the fabric’s suitability for various applications, from furniture to apparel. -

Abrasion Resistance

Abrasion resistance is a critical measure of durability, often tested using the Wyzenbeek method. A high abrasion resistance rating (e.g., 50,000 double rubs) indicates that the fabric can withstand significant wear and tear. For B2B buyers, understanding this property helps in selecting fabrics that will perform well in environments subject to heavy use, such as commercial upholstery. -

Cleaning Code

The cleaning code indicates the recommended cleaning method for the fabric. For microsuede, a common code is “W,” meaning it can be cleaned with water. This property is particularly important for buyers in sectors like hospitality or healthcare, where ease of maintenance is essential for hygiene and aesthetic upkeep. -

Width

Microfiber microsuede fabric is usually available in widths of 58-60 inches. Understanding the width is crucial for buyers to estimate material requirements accurately for their projects, reducing waste and optimizing costs. -

Colorfastness

Colorfastness refers to the fabric’s ability to retain its color when exposed to light and washing. High colorfastness ratings are essential for products that will be frequently laundered or exposed to sunlight, ensuring that the fabric maintains its appearance over time.

What Are Common Trade Terms in the Microsuede Fabric Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms associated with microfiber microsuede fabric:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or products that are marketed under another company’s brand. In the context of microsuede fabric, OEMs may produce custom fabric designs or blends for specific brands. Understanding OEM relationships can help buyers identify potential suppliers for unique fabric requirements. -

MOQ (Minimum Order Quantity)

MOQ is the minimum amount of product a supplier is willing to sell. For microsuede fabric, MOQs can vary significantly between suppliers and may affect pricing and availability. Knowing the MOQ is crucial for buyers to ensure they can meet their production needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. When sourcing microsuede fabric, submitting an RFQ allows buyers to compare offers from multiple suppliers, ensuring competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding these terms is vital for B2B transactions involving microsuede fabric, as they dictate shipping responsibilities, risk, and costs associated with the delivery of goods. -

Dye Lot

A dye lot refers to a specific batch of fabric dyed at the same time. Variations can occur between dye lots, making it important for buyers to order sufficient quantities from the same lot to ensure color consistency across their products. -

Sample Swatch

A sample swatch is a small piece of fabric provided to potential buyers to evaluate color, texture, and quality before making a larger purchase. Requesting swatches is a standard practice that enables buyers to make more informed decisions, reducing the risk of dissatisfaction with the final product.

Navigating Market Dynamics and Sourcing Trends in the microfiber microsuede fabric Sector

What Are the Current Market Dynamics and Key Trends in the Microfiber Microsuede Fabric Sector?

The microfiber microsuede fabric market is witnessing robust growth globally, driven by increasing demand for durable and versatile materials in various industries, particularly upholstery, fashion, and automotive sectors. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek affordable alternatives to genuine suede, microsuede stands out due to its luxurious appearance and enhanced durability. The fabric’s stain-resistant properties make it particularly appealing for high-traffic applications, catering to the needs of households with children and pets.

Emerging trends in B2B sourcing include the rise of e-commerce platforms that facilitate direct procurement from manufacturers, enabling buyers to access a broader range of products with competitive pricing. Additionally, the integration of technology in supply chain management, such as AI and data analytics, is streamlining inventory management and forecasting, allowing businesses to respond swiftly to market fluctuations. As manufacturers focus on customization and personalization, the ability to order microsuede fabric by the yard is becoming increasingly popular, minimizing waste and optimizing resource use.

Furthermore, sustainability is becoming a critical factor in sourcing decisions. Buyers are increasingly inclined to partner with suppliers who demonstrate a commitment to environmentally-friendly practices and materials. The shift towards circular economy principles is influencing market dynamics, as businesses seek to align their operations with sustainable practices.

Illustrative image related to microfiber microsuede fabric

How Important Is Sustainability and Ethical Sourcing in the Microsuede Fabric Industry?

Sustainability and ethical sourcing are paramount in today’s textile industry, particularly within the microfiber microsuede fabric sector. The environmental impact of synthetic fabrics, including microfiber, has raised concerns about pollution and waste. Consequently, B2B buyers are prioritizing suppliers that adhere to eco-friendly practices, such as using recycled materials and implementing sustainable manufacturing processes.

In this context, certifications play a crucial role. Buyers are increasingly seeking out products that are certified by recognized environmental standards, which validate the sustainability claims of manufacturers. Certifications like OEKO-TEX and Global Recycled Standard (GRS) assure buyers of the environmental integrity of the materials used. Additionally, the demand for vegan alternatives is on the rise, as consumers and businesses alike become more conscious of animal welfare. Microsuede, being a synthetic alternative to traditional suede, fits perfectly into this trend.

Moreover, ethical supply chains are becoming a focal point for B2B buyers. Transparency in sourcing and production processes not only enhances brand reputation but also builds trust with end consumers. Companies that prioritize ethical practices are likely to attract partnerships with conscientious buyers who value social responsibility alongside product quality.

How Has the Microfiber Microsuede Fabric Sector Evolved Over Time?

The evolution of microfiber microsuede fabric can be traced back to the late 20th century when advancements in synthetic fiber technology allowed for the creation of materials that mimic the look and feel of natural suede. Initially, the adoption of microsuede was primarily seen in the upholstery and automotive industries, where its durability and ease of maintenance were significant advantages over traditional fabrics.

As consumer preferences shifted towards more sustainable and affordable options, the appeal of microsuede expanded into fashion and home décor markets. Innovations in dyeing and finishing techniques have further enhanced the fabric’s aesthetic qualities, making it a popular choice for high-end applications. Today, the versatility of microfiber microsuede is evident, as it is utilized in a wide array of products, from clothing to decorative items, reflecting a significant evolution in design and functionality.

In summary, the microfiber microsuede fabric sector continues to adapt to market demands, emphasizing sustainability, technological integration, and ethical sourcing, while providing international B2B buyers with a reliable and luxurious material option.

Frequently Asked Questions (FAQs) for B2B Buyers of microfiber microsuede fabric

1. How do I ensure the quality of microfiber microsuede fabric when sourcing?

To ensure the quality of microfiber microsuede fabric, request samples from potential suppliers before placing a bulk order. Look for certifications that indicate compliance with international standards, such as ISO. Additionally, inquire about the fabric’s weight, fiber content, and abrasion resistance (measured in double rubs). Establish a quality assurance process that includes on-site inspections or third-party audits to verify that the fabric meets your specifications before shipment.

2. What is the best application for microfiber microsuede fabric in upholstery?

Microfiber microsuede fabric is ideal for high-traffic upholstery applications due to its durability and stain resistance. It is commonly used for sofas, chairs, headboards, and decorative cushions. This fabric mimics the luxurious appearance of real suede while offering easier maintenance, making it suitable for both residential and commercial settings. Additionally, its soft texture enhances comfort, making it a preferred choice for furniture in hotels and lounges.

Illustrative image related to microfiber microsuede fabric

3. How can I customize microfiber microsuede fabric for my business needs?

Customization options for microfiber microsuede fabric often include selecting specific colors, patterns, and finishes. Many suppliers offer dyeing services to match your brand colors or unique designs. When discussing customization, specify your minimum order quantity (MOQ) and lead times, as these can vary. It’s advisable to request a prototype or sample of the customized fabric to ensure it meets your expectations before final production.

4. What are typical payment terms when sourcing microfiber microsuede fabric internationally?

Payment terms can vary significantly by supplier and region. Common arrangements include a 30% deposit upon order confirmation and the balance due before shipment. Some suppliers may offer net 30 or net 60 terms for established business relationships. It’s essential to clarify these terms upfront and consider using secure payment methods such as letters of credit or escrow services to protect your transaction, especially in international dealings.

5. What is the minimum order quantity (MOQ) for microfiber microsuede fabric?

The MOQ for microfiber microsuede fabric can vary widely depending on the supplier and the level of customization required. Generally, MOQs can range from 50 to 500 yards. It’s advisable to discuss your specific needs with suppliers to understand their policies. Smaller businesses may benefit from partnering with wholesalers who can accommodate lower MOQs, allowing for more flexibility in sourcing.

6. How do I vet suppliers for microfiber microsuede fabric?

To vet suppliers, start by researching their reputation through online reviews and industry forums. Request references from other businesses that have sourced fabric from them. Check for certifications that ensure compliance with safety and quality standards. Conducting a factory visit or utilizing third-party inspection services can also help verify their operational capabilities and quality control processes.

7. What logistics considerations should I keep in mind when importing microfiber microsuede fabric?

When importing microfiber microsuede fabric, consider shipping methods, lead times, and customs regulations. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders but takes longer. Ensure you understand the import duties and taxes applicable in your country. Partnering with a reliable logistics provider can streamline the process and help navigate any potential challenges with customs clearance.

Illustrative image related to microfiber microsuede fabric

8. How can I maintain the quality of microfiber microsuede fabric during storage and transport?

To maintain the quality of microfiber microsuede fabric, store it in a cool, dry place away from direct sunlight to prevent fading and deterioration. Use protective covers or packaging during transport to avoid physical damage. Ensure that the fabric is rolled or folded properly to prevent creasing. If the fabric is exposed to moisture, allow it to dry completely before storage to prevent mold or mildew growth.

Top 9 Microfiber Microsuede Fabric Manufacturers & Suppliers List

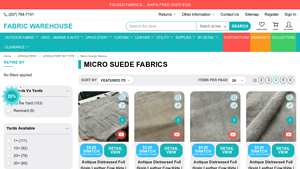

1. Fabric Warehouse – MicroSuede Upholstery Fabrics

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: MicroSuede Fabrics for Upholstery

– Types: By the Yard, Remnants

– Available Yards: 1+, 10+, 20+, 30+

– Colors: Beige, Black, Blue, Brown, Gold, Gray, Green, Ivory, Khaki, Orange, Pink, Purple, Red, Silver, Tan

– Upholstery Fabric Weight: Extra Heavy Weight, Heavy Weight, Lightweight, Medium/Heavyweight, Medium Weight

– Drapery Fabric Weight: Heavy Weight, Light Weight, Medium Weight, Too Heavy Fo…

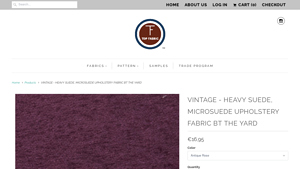

2. Top Fabric – Microsuede Upholstery Fabric

Domain: topfabric.com

Registered: 2003 (22 years)

Introduction: Microsuede Fabric – Heavy Suede, 58/60″ wide, 100% polyester, 30000 double rubs, available in various colors, suitable for upholstery, drapery, and crafts.

3. Fabric Wholesale Direct – Microsuede Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: Microsuede Fabric By The Yard | Free Shipping On Orders $99+ | Available in various colors and patterns | Suitable for multiple applications including apparel, upholstery, and home decor.

4. Folio Fabrics – Microfiber & Microsuede Collection

Domain: foliofabrics.com

Registered: 2013 (12 years)

Introduction: Microfiber & Microsuede Fabric collection ideal for upholstery, drapery, and decorative accents. Offers a soft, luxurious feel with durability and easy care. Plush textures create an inviting ambiance. Key products include: 1. Dotson Cobalt – $40/yard 2. Davis Cream – $44/yard 3. Camaro Oat – $38/yard 4. Hartford Pewter – $46/yard 5. Dotson Slate – $40/yard 6. Dotson Onyx – $40/yard 7. Lydia Rosew…

5. Fashion Fabrics Club – Microsuede Collection

Domain: fashionfabricsclub.com

Registered: 1999 (26 years)

Introduction: Microsuede fabric available in a variety of colors and styles for upholstery and apparel. Key details include:

– Fiber Content: Polyester (16), Polyester – Lycra (2), Polyester – Rayon (1)

– Categories: Activewear (2), Apparel Fabric (19), Blazer (1), Blouse – Dress Weight Fabric (2), Bottom Weight Fabric (1), Dancewear Fabric (2), Fabric By The Bolt – Wholesale Fabric (6), Knit Fabrics (3), Mic…

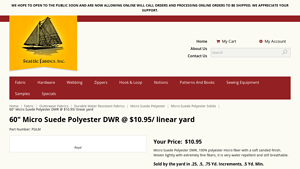

6. Seattle Fabrics – 60 Micro Suede Polyester DWR

Domain: seattlefabrics.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “60” Micro Suede Polyester DWR”, “Price”: “$10.95/linear yard”, “Part Number”: “FSILM”, “Fiber Content”: “100% Polyester Microfiber”, “Finish”: “Soft sanded finish, Durable Water Resistant (DWR)”, “Fabric Width”: “58/59 inches”, “Construction”: “155 x 88 Yarns”, “Yarn Size”: “75D x 150D”, “Total Weight”: “3.99 ounces per square yard”, “Colors Available”: [“Burgundy Red”, “Royal”, …

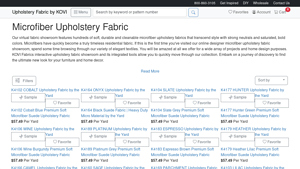

7. KOVI Fabrics – Microfiber Upholstery Fabric

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Microfiber Upholstery Fabric from KOVI Fabrics offers a wide selection of soft, durable, and cleanable fabrics suitable for various home design projects. Key features include:

– Made from synthetic materials like polyester or nylon.

– Available in strong neutrals and bold colors.

– Timeless residential fabric with a soft, smooth texture.

– Easy to clean and maintain, often machine-washable.

– Stai…

8. Big Z Fabric – Microfiber Suede vs. Real Suede

Domain: blog.bigzfabric.com

Registered: 2010 (15 years)

Introduction: Microfiber Suede: Crafted from synthetic fibers like polyester or nylon; affordable; durable and resistant to wear and tear; easy to clean and maintain, often machine washable; better water resistance; hypoallergenic. Real Suede Fabric: Derived from the inner layer of animal hides (cows, sheep, goats); luxurious appearance; more expensive; durable but requires careful maintenance; sensitive to wat…

9. My Textile Fabric – Suede Fabric

Domain: mytextilefabric.com

Registered: 2011 (14 years)

Introduction: Suede Fabric | Microsuede | 40 Colors | 60″ Wide | Faux Suede | Upholstery Weight, Tablecloth, Bags, Pouches, Cosplay, Costume | Continuous Yards | $8.99 per yard | Minimum order of 2 yards | Fabric by the Bolt available (65 yards) | 3″x3″ Sample Swatch available | Fabric weight: approximately 225 grams per square meter | Fabric content: 100% polyester | Solid fabric | Imported | Dry clean only | …

Strategic Sourcing Conclusion and Outlook for microfiber microsuede fabric

What Are the Key Benefits of Strategic Sourcing for Microsuede Fabric?

In summary, strategic sourcing of microfiber microsuede fabric offers B2B buyers numerous advantages, particularly in terms of cost-effectiveness, durability, and versatility. The synthetic nature of microsuede not only mimics the luxurious appearance of genuine suede but also ensures ease of maintenance and longevity, making it an ideal choice for high-traffic applications. As buyers consider their procurement options, it is crucial to evaluate suppliers based on quality, customer service, and the ability to meet specific project needs.

How Can International Buyers Leverage Microsuede Fabric?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, the growing demand for sustainable and durable fabrics presents an opportunity for strategic partnerships. Engaging with reputable suppliers who offer a variety of colors and finishes can enhance product offerings and cater to diverse market needs.

Illustrative image related to microfiber microsuede fabric

What Is the Future Outlook for Microsuede Fabric in the Global Market?

As trends evolve towards eco-friendly and vegan materials, the outlook for microfiber microsuede remains robust. Buyers are encouraged to explore the latest innovations and sustainable practices within the industry. By doing so, they can not only enhance their product lines but also position themselves as leaders in the competitive textile market. Take action today—connect with suppliers, assess your sourcing strategies, and capitalize on the potential of microsuede fabric to elevate your business offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.