Introduction: Navigating the Global Market for black alcantara material

Navigating the complexities of sourcing black alcantara material can pose significant challenges for B2B buyers, especially those in diverse markets such as Africa, South America, the Middle East, and Europe. With its unique blend of luxury, durability, and versatility, black alcantara is increasingly sought after for applications ranging from automotive interiors to high-end fashion. However, finding reliable suppliers, ensuring material authenticity, and understanding cost structures can be daunting tasks.

This comprehensive guide aims to demystify the global market for black alcantara material by providing actionable insights on various types of alcantara, including backed and unbacked options, and their specific applications across different industries. We will also delve into the critical aspects of supplier vetting, highlighting the importance of sourcing genuine products from reputable manufacturers, particularly those based in Italy, where the material is traditionally produced.

Additionally, the guide will outline cost considerations and potential pricing structures, empowering international B2B buyers to make informed purchasing decisions. By addressing these key areas, this resource equips businesses with the knowledge necessary to navigate the intricacies of the alcantara market confidently, ensuring that they can secure the best materials for their needs while optimizing their supply chain efficiency.

Table Of Contents

- Top 7 Black Alcantara Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for black alcantara material

- Understanding black alcantara material Types and Variations

- Key Industrial Applications of black alcantara material

- 3 Common User Pain Points for ‘black alcantara material’ & Their Solutions

- Strategic Material Selection Guide for black alcantara material

- In-depth Look: Manufacturing Processes and Quality Assurance for black alcantara material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘black alcantara material’

- Comprehensive Cost and Pricing Analysis for black alcantara material Sourcing

- Alternatives Analysis: Comparing black alcantara material With Other Solutions

- Essential Technical Properties and Trade Terminology for black alcantara material

- Navigating Market Dynamics and Sourcing Trends in the black alcantara material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of black alcantara material

- Strategic Sourcing Conclusion and Outlook for black alcantara material

- Important Disclaimer & Terms of Use

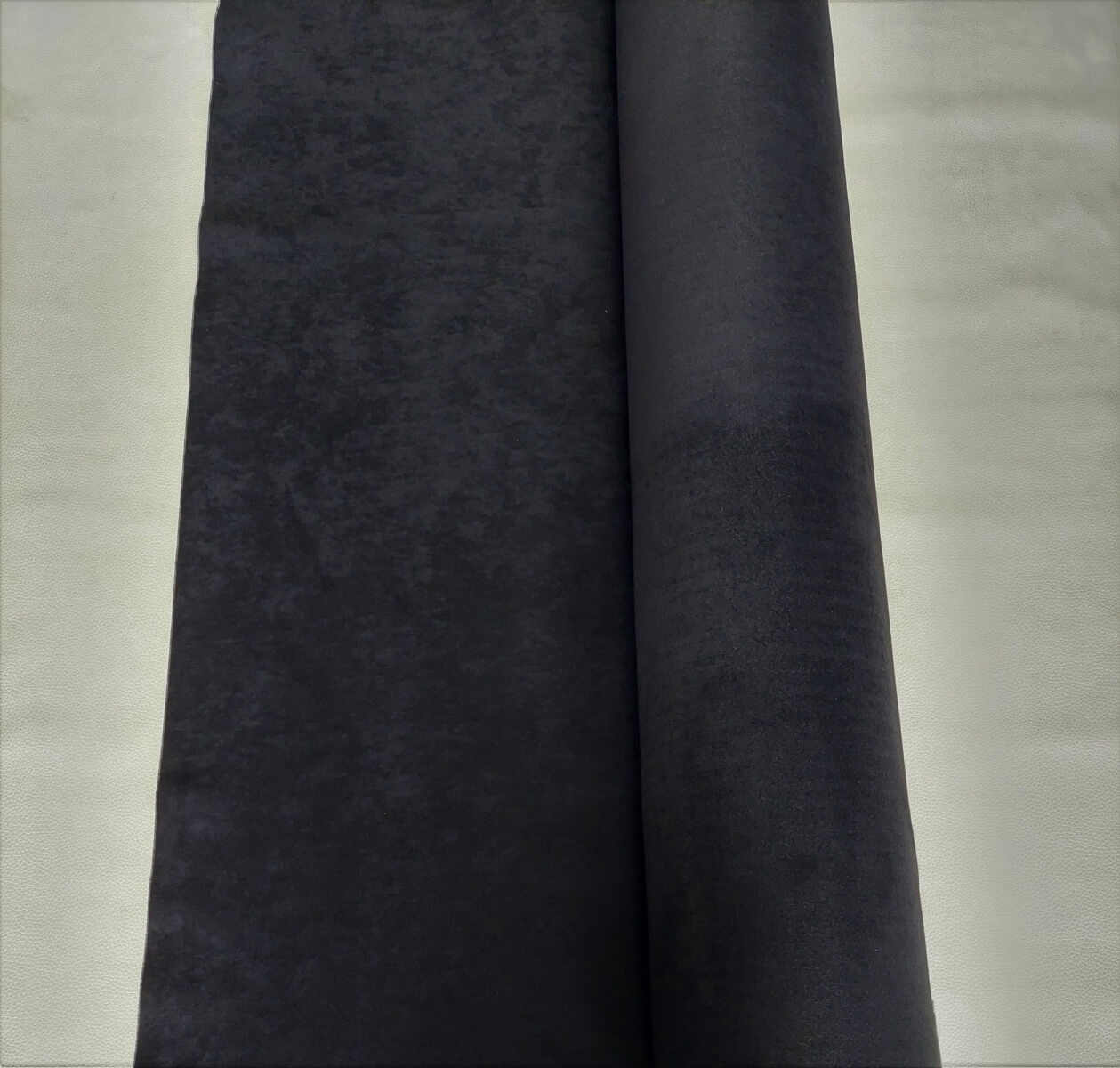

Understanding black alcantara material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alcantara Soft | Foam-backed, easy to clean, superior grip | Automotive interiors, furniture upholstery | Pros: Durable, comfortable, reduces glare. Cons: Higher cost than basic fabrics. |

| Alcantara Unbacked | Single-layer, high stretchability, lightweight | Automotive panels, headliners | Pros: Excellent for tight applications. Cons: Less durable compared to backed variants. |

| Alcantara Cover | Backed for added durability, thicker texture | Seating, high-end fashion | Pros: Enhanced durability, luxurious feel. Cons: Limited flexibility in tight spaces. |

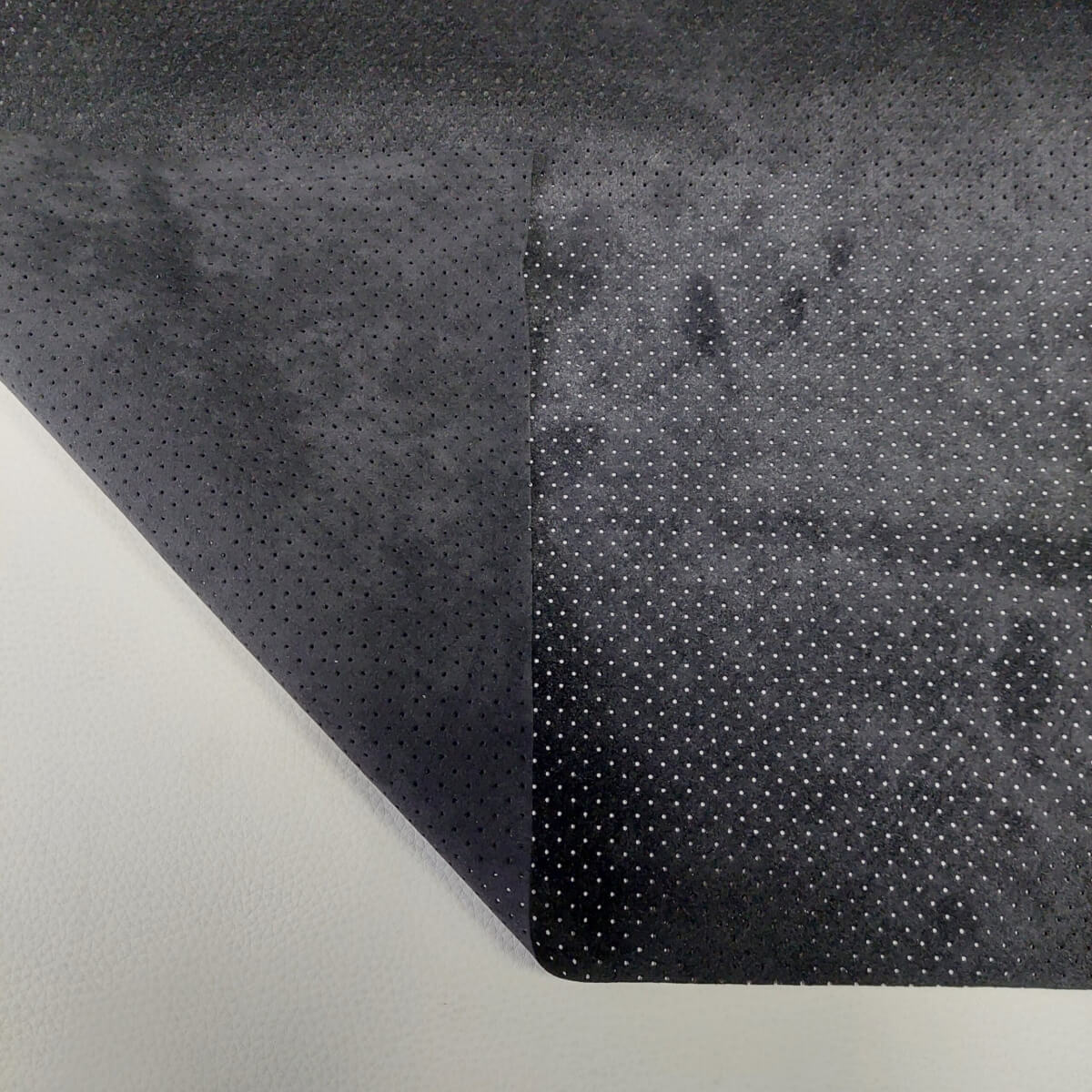

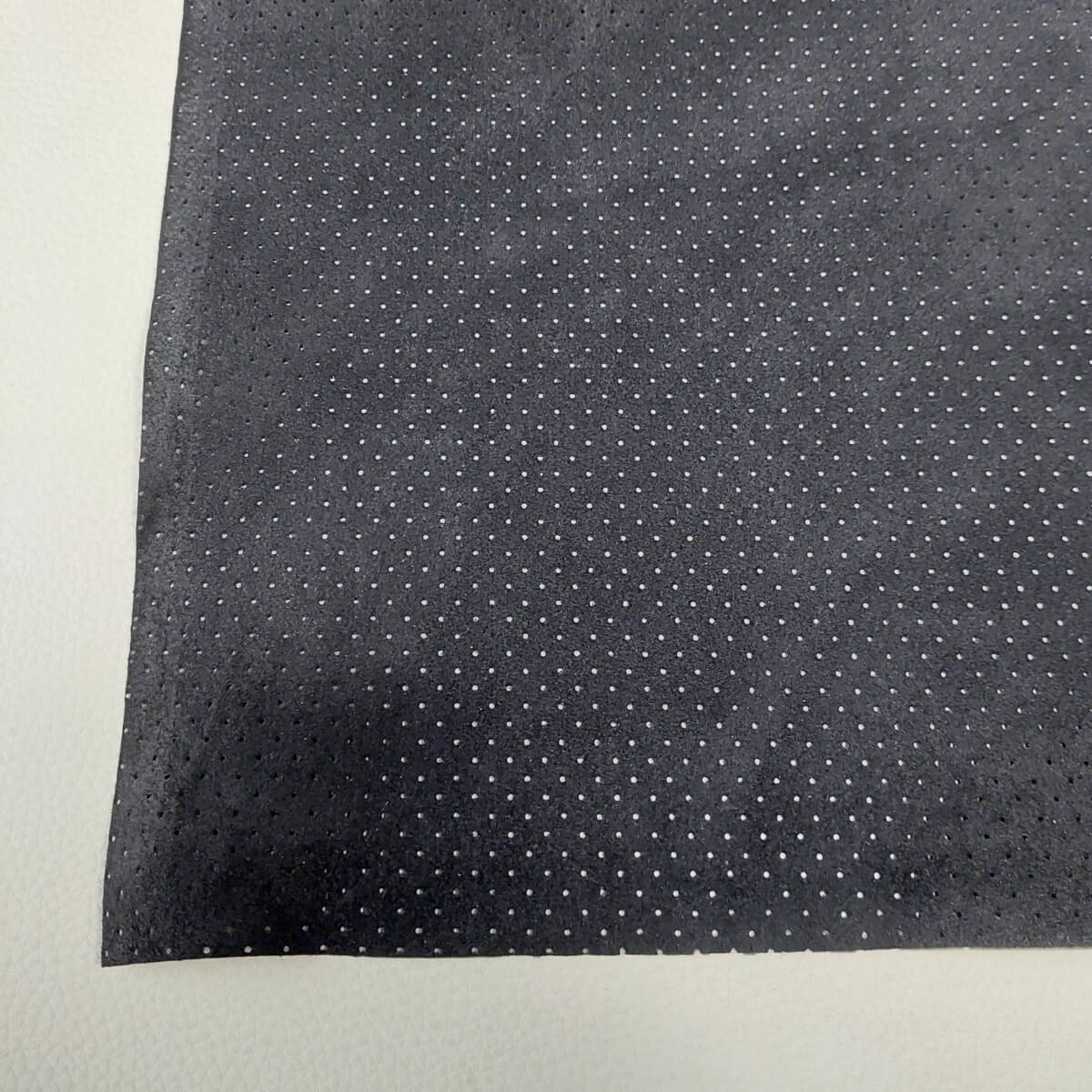

| Alcantara Perforated | Features small holes for breathability and style | Automotive, fashion accessories | Pros: Aesthetic appeal, lightweight. Cons: May not be suitable for all applications. |

| Alcantara EXO Outdoor | Weather-resistant, designed for outdoor use | Outdoor furniture, automotive exteriors | Pros: Resilient against elements, easy maintenance. Cons: Limited color options. |

What Are the Key Characteristics of Alcantara Soft?

Alcantara Soft is a foam-backed variant of Alcantara that combines comfort with practicality. Composed of 68% polyester and 32% polyurethane, it offers enhanced grip and is easy to clean, making it an excellent choice for automotive interiors and furniture upholstery. When considering a purchase, buyers should evaluate the intended use, as its durability and comfort make it ideal for high-traffic areas. However, its higher price point compared to standard fabrics may be a consideration for budget-conscious buyers.

How Does Alcantara Unbacked Differ from Other Variants?

Alcantara Unbacked is a lightweight, single-layer material known for its exceptional stretchability and flexibility. This type is particularly well-suited for applications requiring close-fitting designs, such as automotive panels and headliners. B2B buyers should note that while it offers superior adaptability, it may be less durable than backed options, potentially leading to increased wear in high-use environments. Understanding the specific application needs is crucial for making informed purchasing decisions.

What Advantages Does Alcantara Cover Provide?

Alcantara Cover is designed with a backing layer, enhancing its durability and making it suitable for high-end seating and fashion applications. This thicker variant provides a luxurious feel while maintaining the characteristic aesthetic of Alcantara. Buyers should consider its application requirements, as its added thickness may limit flexibility in certain projects. However, its robustness against wear and tear makes it a preferred choice for luxury markets.

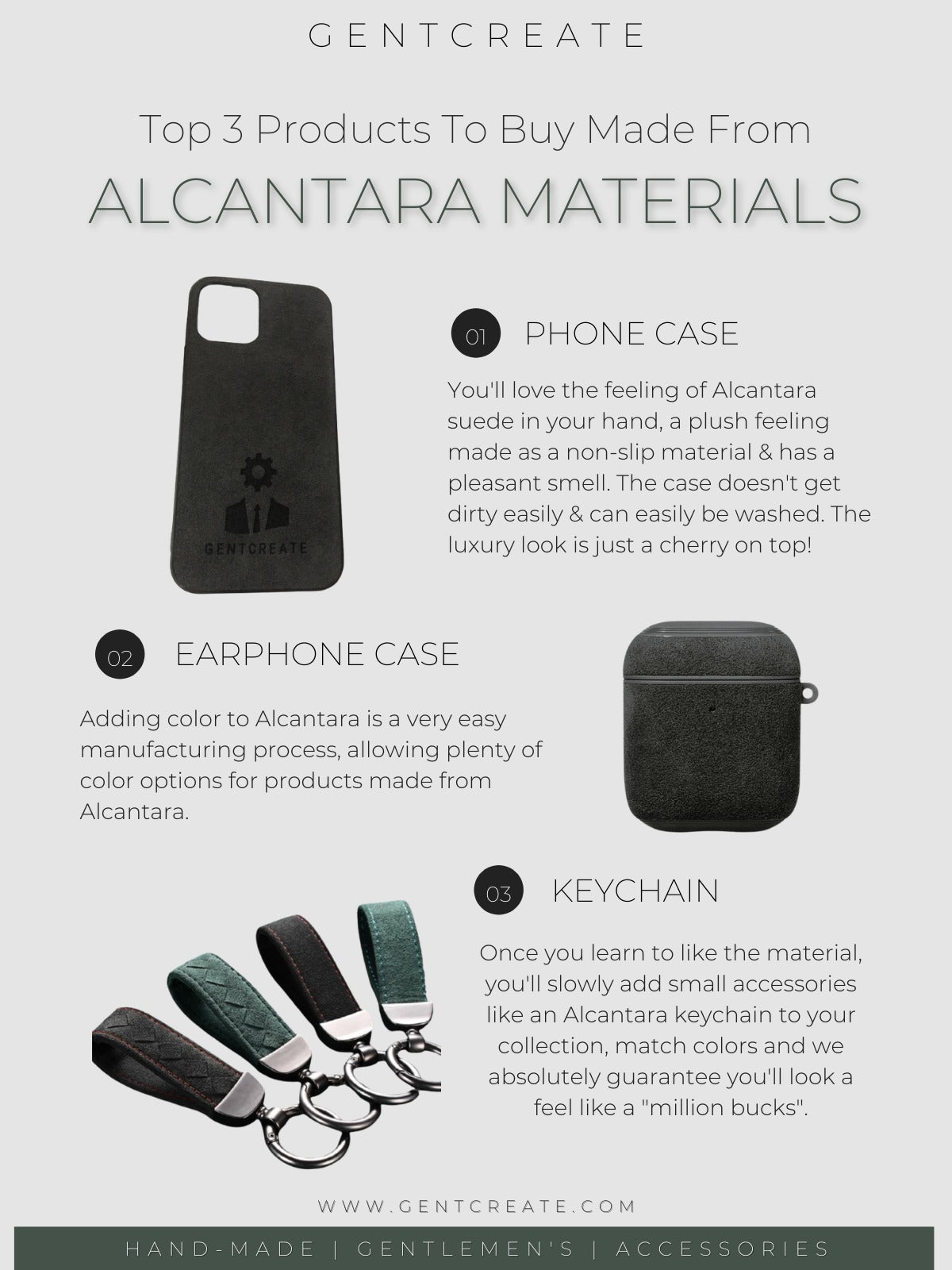

Why Choose Alcantara Perforated for Your Projects?

Alcantara Perforated features small holes that enhance breathability and aesthetic appeal, making it a popular choice for automotive interiors and fashion accessories. This variant allows for better airflow while retaining the luxurious look of Alcantara. When sourcing this material, B2B buyers should consider the specific functional requirements of their applications, as perforated fabrics may not suit all environments. The unique style may justify a higher price point for design-focused projects.

What Makes Alcantara EXO Outdoor a Unique Option?

Alcantara EXO Outdoor is specifically engineered to withstand outdoor conditions, making it ideal for outdoor furniture and automotive exteriors. Its weather-resistant properties ensure longevity and ease of maintenance, appealing to buyers in sectors focused on durability. However, its limited color options might restrict design choices. B2B buyers looking for resilient materials for outdoor applications will find this variant particularly advantageous, balancing functionality with aesthetic considerations.

Key Industrial Applications of black alcantara material

| Industry/Sector | Specific Application of black alcantara material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for luxury vehicle interiors | Enhances aesthetics and comfort; lightweight and durable | Ensure compliance with OEM specifications; sourcing from certified suppliers is crucial. |

| Furniture | High-end furniture coverings | Provides a premium look and feel; easy to clean | Consider fabric durability and maintenance requirements; verify color consistency. |

| Fashion & Apparel | Designer clothing and accessories | Offers a unique texture and luxurious appearance | Focus on material sourcing for sustainability; check for color and texture options. |

| Aviation | Aircraft interior design | Reduces weight while maintaining luxury; sound absorption | Prioritize fire resistance certifications; ensure compliance with aviation standards. |

| Interior Design | Wall coverings and decorative accents | Adds sophistication to interiors; versatile in design | Assess the fabric’s adaptability to different environments; ensure availability of samples. |

How is Black Alcantara Material Used in the Automotive Sector?

In the automotive industry, black alcantara material is predominantly used for upholstery in luxury vehicle interiors, including seats, door panels, and headliners. Its suede-like texture enhances the aesthetic appeal while offering durability and ease of maintenance. For international buyers, particularly from regions like Europe and the Middle East, sourcing genuine alcantara that meets OEM specifications is essential. This ensures that the material not only meets aesthetic standards but also complies with safety regulations, such as fire resistance.

Illustrative image related to black alcantara material

What are the Applications of Black Alcantara in Furniture?

In the furniture sector, black alcantara is utilized for high-end upholstery on sofas, chairs, and other furnishings. Its luxurious appearance and soft texture provide a sophisticated touch to interior spaces. Additionally, alcantara is easy to clean, making it a practical choice for both residential and commercial applications. Buyers should consider the fabric’s durability and maintenance needs, particularly in high-traffic areas, and ensure that they receive consistent color and texture throughout their orders.

How is Black Alcantara Material Employed in Fashion and Apparel?

The fashion and apparel industry leverages black alcantara for creating designer clothing and accessories. Its unique texture and luxurious feel make it a popular choice for high-end garments, bags, and footwear. For B2B buyers, particularly in South America and Africa, focusing on sustainable sourcing practices is becoming increasingly important. Buyers should also assess the availability of various color options and ensure that the material aligns with the latest fashion trends to meet consumer demands.

Why is Black Alcantara Important in Aviation?

In aviation, black alcantara is used in aircraft interior designs, particularly for seat coverings and cabin accents. Its lightweight nature contributes to overall fuel efficiency while providing a luxurious feel for passengers. Additionally, alcantara offers sound absorption properties that enhance passenger comfort. Buyers in this sector must prioritize sourcing materials that meet stringent aviation safety standards, including fire resistance and durability, to ensure compliance with regulatory requirements.

Illustrative image related to black alcantara material

How is Black Alcantara Used in Interior Design?

Interior designers utilize black alcantara for wall coverings and decorative accents, adding a sophisticated touch to both residential and commercial spaces. Its versatility allows it to be used in various design applications, from feature walls to bespoke furniture pieces. Buyers should consider the adaptability of alcantara to different environments, including its performance in varying humidity and temperature levels. Ensuring the availability of fabric samples can help designers and clients visualize the final outcome before making significant investments.

3 Common User Pain Points for ‘black alcantara material’ & Their Solutions

Scenario 1: Difficulty in Matching Color and Texture for Projects

The Problem: One common challenge B2B buyers face when sourcing black alcantara material is ensuring that the color and texture match their existing products or designs. Variations in color can occur due to differences in monitor settings and lighting conditions during photography, leading to discrepancies between what was ordered and what arrives. This can result in costly delays and dissatisfaction if the material does not align with the specifications required for high-end applications, such as automotive interiors or luxury furnishings.

The Solution: To mitigate this issue, buyers should always request physical samples before placing larger orders. Many suppliers offer swatch samples that allow buyers to evaluate the actual material’s color and texture. This step is crucial, especially for projects with strict aesthetic requirements. Additionally, using tools like the EZMatch Swatch Scanner can help in ensuring that the selected fabric matches the intended design. When placing an order, specifying the need for consistent dye lots and checking supplier policies on color matching can further prevent discrepancies.

Scenario 2: Concerns About Durability and Maintenance of Alcantara

The Problem: Another pain point is the uncertainty regarding the durability and maintenance of black alcantara, especially in applications subjected to wear and tear, such as automotive seats and high-traffic furniture. Buyers often worry that the material might not withstand everyday use, leading to premature wear or fading, which could damage their brand reputation if the products fail to meet quality standards.

The Solution: To address these concerns, buyers should opt for foam-backed or multilayer alcantara options that provide enhanced durability. These variants are designed to resist wear and tear while maintaining a luxurious appearance. Furthermore, implementing a care and maintenance guide tailored to the specific alcantara variant can help end-users understand how to care for the material effectively. Regular cleaning with appropriate products will prolong its life and maintain its aesthetic appeal. Suppliers should provide detailed maintenance instructions and cleaning kits tailored for alcantara, which can be a value-add for buyers.

Illustrative image related to black alcantara material

Scenario 3: Managing Supply Chain Issues with Alcantara Sourcing

The Problem: Sourcing black alcantara material can be complicated by supply chain issues, especially in times of global disruptions. Buyers may experience delays in receiving materials, which can halt production schedules and lead to unmet customer demands. Additionally, fluctuations in pricing can impact budget planning, making it difficult for businesses to maintain profitability.

The Solution: To alleviate these supply chain issues, buyers should develop relationships with multiple suppliers to ensure a diverse source of materials. This strategy minimizes the risk of dependence on a single vendor and allows for more flexibility in procurement. Implementing a just-in-time inventory system can also help manage stock levels and reduce holding costs. Buyers should keep an eye on market trends and pricing forecasts for alcantara to adjust their purchasing strategies accordingly. Furthermore, establishing clear communication with suppliers about lead times and potential delays can enhance transparency and allow for better planning.

Strategic Material Selection Guide for black alcantara material

What Are the Key Properties of Black Alcantara Material?

Black Alcantara material is a synthetic suede made primarily from polyester and polyurethane, which endows it with several advantageous properties. The material typically features a thickness ranging from 0.83 mm to 1.3 mm, making it suitable for various applications, including automotive interiors and high-end fashion. Its temperature resistance allows it to maintain performance in diverse climates, which is particularly important for international buyers from regions with varying weather conditions. Additionally, Alcantara offers excellent durability, resisting wear and tear while maintaining its aesthetic appeal.

What Are the Advantages and Disadvantages of Black Alcantara Material?

When considering black Alcantara for B2B applications, it is essential to weigh its advantages against potential drawbacks.

Advantages:

– Durability: Alcantara is known for its high resistance to abrasion and fading, making it ideal for long-term use in automotive and furniture applications.

– Ease of Maintenance: The material is easy to clean, which is a significant advantage for sectors like automotive and hospitality, where hygiene is paramount.

– Aesthetic Appeal: The luxurious look and feel of Alcantara enhance the perceived value of products, appealing to high-end markets.

Disadvantages:

– Cost: Alcantara tends to be more expensive than traditional fabrics, which may impact budget-sensitive projects.

– Manufacturing Complexity: The production process for Alcantara can be more complex than for simpler textiles, potentially leading to longer lead times.

– Limited Media Compatibility: Alcantara may not be suitable for all applications, particularly those requiring extreme durability or exposure to harsh chemicals.

How Does Black Alcantara Material Impact Specific Applications?

Black Alcantara’s unique properties make it particularly suitable for various applications, including automotive interiors, fashion, and furniture. In the automotive sector, its ability to reduce glare and stay cool to the touch enhances driver and passenger comfort. For fashion and upholstery, its luxurious texture and appearance can elevate product lines, appealing to consumers seeking premium materials. However, international buyers should consider the specific requirements of their markets, such as compliance with local standards (e.g., ASTM, DIN, JIS) and preferences for sustainable materials.

What Should International B2B Buyers Consider When Sourcing Black Alcantara Material?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of several factors when sourcing black Alcantara. Compliance with local regulations regarding material safety and environmental impact is crucial. Additionally, understanding the supply chain dynamics, including shipping times and costs, is essential for timely project execution. Buyers should also consider the availability of samples to ensure color and texture match their specifications, as variations in display devices can lead to discrepancies in material appearance.

| Material | Typical Use Case for black alcantara material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Black Alcantara | Automotive interiors, luxury upholstery | High durability and aesthetic appeal | Higher cost compared to alternatives | High |

| Alcantara Soft (Foam-backed) | Furniture, automotive seating | Excellent grip and comfort | Limited chemical resistance | Medium |

| Alcantara for Panels | Automotive door panels, headliners | Superior workability and stretch | Not suitable for extreme conditions | High |

| Unbacked Alcantara Panel | Custom upholstery applications | Lightweight and flexible | Less durability compared to backed options | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for black alcantara material

What Are the Key Stages in the Manufacturing Process of Black Alcantara Material?

The manufacturing of black Alcantara material involves several intricate stages, each crucial for ensuring the high quality and performance associated with this premium fabric. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to black alcantara material

Material Preparation

The process begins with the selection of raw materials, typically a blend of polyester and polyurethane, which form the base of Alcantara. The fibers are carefully processed and dyed to achieve the desired color, in this case, a deep, rich black. This stage is vital as the quality of the raw materials directly impacts the final product’s durability and aesthetic appeal.

Forming

Once prepared, the fibers undergo a unique forming process. The fibers are spun into a fabric, employing advanced techniques that create a soft, suede-like texture. This stage often includes the use of foam backing for specific applications, enhancing the material’s comfort and usability, particularly in automotive and upholstery industries.

Assembly

During the assembly phase, the Alcantara fabric is cut and sewn into various shapes and sizes as per customer specifications. For automotive applications, this might involve creating seat covers, door panels, or headliners. Quality checks are implemented throughout this phase to ensure that the fabric meets dimensional and aesthetic requirements.

Illustrative image related to black alcantara material

Finishing

The final stage of manufacturing involves applying treatments that enhance the fabric’s properties, such as stain resistance and UV protection. The finishing process also includes rigorous inspections to ensure that the fabric maintains its luxurious feel and appearance. This is critical for B2B buyers who require assurance that the materials will perform well in demanding environments.

What Quality Assurance Standards Are Relevant for Black Alcantara Material?

Quality assurance is paramount in the production of black Alcantara material, particularly for B2B buyers who seek reliability and consistency. International standards such as ISO 9001 provide a framework for quality management systems that manufacturers must adhere to. This certification ensures that companies maintain high-quality processes, from material sourcing to final product delivery.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, depending on the end-use of the material. For instance, automotive applications may require compliance with specific safety and performance standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process. These checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins. This includes verifying the quality of fibers and dyes used in the manufacturing of black Alcantara.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are performed to monitor the consistency of the fabric’s texture, color, and physical properties. This stage is critical for identifying defects early, minimizing waste, and ensuring that production standards are upheld.

-

Final Quality Control (FQC): Once the black Alcantara fabric is fully assembled, a comprehensive final inspection is conducted. This includes evaluating the finished product for any defects, measuring dimensions, and testing for durability and performance attributes.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential to mitigate risks associated with product quality. Here are several strategies to ensure compliance with quality standards:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control systems firsthand. This includes reviewing documentation related to quality standards and testing procedures.

-

Requesting Quality Reports: Suppliers should provide comprehensive quality reports that detail the results of inspections and tests conducted throughout the manufacturing process. This transparency fosters trust and assures buyers of the product’s quality.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These services can conduct tests and inspections at various stages of production, ensuring compliance with international standards.

What Testing Methods Are Commonly Used for Black Alcantara Material?

Testing methods play a crucial role in verifying the performance and durability of black Alcantara material. Some common testing methods include:

-

Color Fastness Testing: This assesses how well the fabric retains its color when exposed to various elements, such as light, washing, and rubbing. For B2B buyers, high color fastness is essential, especially for applications in the automotive industry where sun exposure is prevalent.

-

Abrasion Resistance Testing: This measures the fabric’s durability by simulating wear and tear over time. The results provide insight into the expected lifespan of the material, helping buyers make informed decisions based on their specific application needs.

-

Flammability Testing: Ensuring that the fabric meets safety standards regarding flammability is vital, particularly for automotive and public transport applications. Compliance with relevant safety regulations can significantly affect marketability.

How Do Quality Control and Certification Nuances Affect International B2B Transactions?

International B2B transactions often come with unique challenges regarding quality control and certification nuances. For buyers in diverse markets like Africa, South America, the Middle East, and Europe, understanding these nuances is critical for successful procurement.

-

Regulatory Compliance: Different regions have varying regulations concerning material safety and environmental impact. It is essential for buyers to familiarize themselves with local laws and ensure that their suppliers comply with these regulations.

-

Cultural and Market Expectations: Quality perceptions can differ across regions. Buyers should communicate their specific quality expectations clearly to suppliers, ensuring that products meet both international standards and local market demands.

-

Supplier Relationships: Building strong relationships with suppliers can facilitate better communication regarding quality issues and certification requirements. Trust and transparency are key to navigating the complexities of international trade.

By understanding these aspects of manufacturing processes and quality assurance for black Alcantara material, B2B buyers can make informed decisions that align with their business needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘black alcantara material’

To streamline your procurement of black Alcantara material, this guide outlines essential steps for B2B buyers, ensuring you make informed decisions tailored to your specific needs.

Illustrative image related to black alcantara material

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify your technical requirements for black Alcantara. Consider factors such as thickness, backing type (foam-backed or unbacked), and intended application (e.g., automotive interiors or upholstery). Having precise specifications helps in narrowing down suppliers who can meet your exact needs.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers of black Alcantara. Focus on companies that specialize in genuine Alcantara sourced from Italy, as authenticity is crucial for quality assurance. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers.

Step 3: Evaluate Supplier Certifications and Quality Assurance

Verify that your shortlisted suppliers hold necessary certifications and adhere to quality standards. Look for certifications that ensure the material’s authenticity and compliance with industry regulations. This step is vital to mitigate risks associated with inferior products and to ensure that the materials will perform as expected.

Illustrative image related to black alcantara material

Step 4: Request Samples for Evaluation

Before placing a bulk order, request samples of black Alcantara from your chosen suppliers. Assess the samples for texture, color accuracy, and overall quality. This hands-on evaluation allows you to confirm that the material meets your aesthetic and functional requirements, reducing the likelihood of costly mistakes later on.

Step 5: Inquire About Pricing and Minimum Order Quantities

Engage suppliers to discuss pricing structures and minimum order quantities (MOQs). Understanding pricing tiers based on volume can lead to significant savings, especially for larger orders. Additionally, clarify any shipping costs and timelines to ensure they align with your project schedules.

Step 6: Review Terms of Sale and Payment Options

Carefully review the terms of sale, including return policies and warranty information. Ensure that your payment options are secure and flexible enough to accommodate your financial processes. This step is crucial to protect your investment and establish a positive relationship with your supplier.

Step 7: Establish Communication and Logistics Plans

Once you’ve selected a supplier, establish clear communication channels and logistics plans. Discuss order tracking, delivery timelines, and any potential delays. Maintaining open lines of communication will facilitate smoother transactions and help address any issues promptly, ensuring your supply chain remains uninterrupted.

By following these structured steps, B2B buyers can effectively navigate the sourcing process for black Alcantara material, ensuring quality, cost-effectiveness, and timely delivery tailored to their specific needs.

Illustrative image related to black alcantara material

Comprehensive Cost and Pricing Analysis for black alcantara material Sourcing

What Are the Key Cost Components in Black Alcantara Material Sourcing?

When sourcing black Alcantara material for B2B applications, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The base cost of Alcantara fabric varies widely based on quality and specifications. Prices can range from $3.00 to $154.00 per yard, depending on factors like thickness, backing, and treatment. Genuine Alcantara, typically sourced from Italy, commands a premium due to its brand reputation and quality.

-

Labor: Labor costs encompass the expenses associated with cutting, sewing, and finishing the fabric. This can vary significantly by region, with labor-intensive processes typically being more expensive in developed markets compared to emerging economies.

-

Manufacturing Overhead: This includes costs for utilities, equipment maintenance, and factory rent. Efficient manufacturing processes can mitigate overhead, but high-quality Alcantara production often necessitates specialized equipment and skilled labor.

-

Tooling: Custom tooling for specific designs or applications can add to the overall cost. For instance, producing Alcantara for automotive interiors may require specialized molds or patterns.

-

Quality Control (QC): Ensuring that the fabric meets specific standards requires investment in QC processes. This is particularly important for industries such as automotive and aviation, where quality standards are stringent.

-

Logistics: Shipping costs can vary based on the distance and method of transport. For international buyers, understanding Incoterms is essential, as they define responsibilities for shipping costs, insurance, and risk.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. This can vary based on market demand, competition, and the supplier’s positioning.

What Influences Pricing for Black Alcantara Material?

Several factors influence the pricing of black Alcantara material, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically yield better pricing due to economies of scale. Negotiating for bulk discounts can significantly lower per-unit costs.

-

Specifications and Customization: Custom colors, textures, or treatments can increase costs. Buyers should assess whether these specifications are essential for their application.

-

Materials and Quality Certifications: Higher-quality materials or those with specific certifications (such as environmental sustainability) may come at a premium. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more for their trusted products, but they often provide better service and quality assurance.

-

Incoterms: Understanding shipping terms (such as FOB, CIF, etc.) can affect overall costs. Buyers should clarify who bears the shipping responsibilities and associated costs.

How Can International B2B Buyers Optimize Costs When Sourcing Black Alcantara?

To achieve cost-efficiency when sourcing black Alcantara, consider the following tips:

-

Negotiate Pricing: Engage suppliers in negotiations to explore flexible pricing options, especially for large orders. Highlighting long-term partnership potential may also yield better terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, durability, and performance over time. A more expensive but durable Alcantara may offer better long-term value compared to cheaper alternatives.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and local taxes that can impact the final cost. It’s advisable to secure fixed pricing where possible.

-

Request Samples: Before placing large orders, request samples to evaluate the fabric quality. This helps avoid costly mistakes and ensures that the material meets your specifications.

-

Leverage Technology: Utilize online platforms to compare prices, materials, and suppliers. Some platforms offer tools for estimating shipping costs based on different suppliers and shipping methods.

In summary, understanding the comprehensive cost structure and price influencers when sourcing black Alcantara material can significantly enhance decision-making for B2B buyers across diverse regions. Make informed choices to ensure that your procurement process is both efficient and cost-effective.

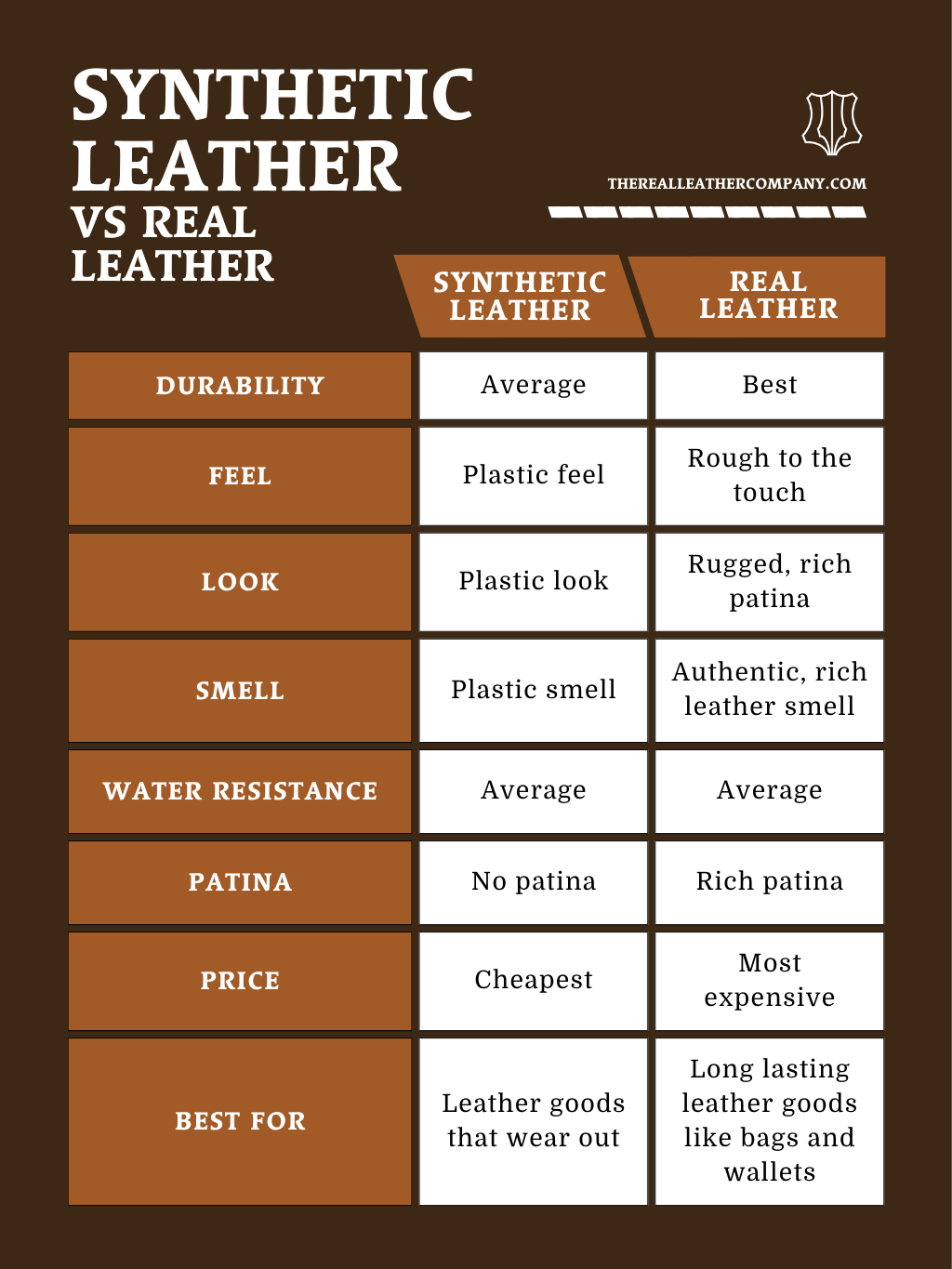

Alternatives Analysis: Comparing black alcantara material With Other Solutions

When evaluating the suitability of black Alcantara material for specific applications, it is essential to consider alternative solutions that may offer different benefits or cost structures. This analysis aims to compare black Alcantara against two viable alternatives: synthetic leather and traditional suede. Understanding these options can help B2B buyers make informed decisions based on their specific needs and requirements.

| Comparison Aspect | Black Alcantara Material | Synthetic Leather | Traditional Suede |

|---|---|---|---|

| Performance | High durability, stain-resistant, and versatile in applications | Good durability, less breathable than Alcantara | Soft and luxurious feel, but less durable |

| Cost | $55.00 per linear foot | $20.00 – $50.00 per yard | $25.00 – $100.00 per yard |

| Ease of Implementation | Requires specialized sewing techniques | Easy to cut and sew, widely available | Requires careful handling and maintenance |

| Maintenance | Easy to clean and maintain | Generally easy to clean but can stain | Requires regular conditioning and care |

| Best Use Case | Automotive interiors, luxury goods | Fashion accessories, upholstery | High-end clothing, luxury upholstery |

What are the Pros and Cons of Synthetic Leather Compared to Black Alcantara?

Synthetic leather, often made from polyurethane or PVC, offers a cost-effective alternative to black Alcantara. Its pricing typically ranges from $20 to $50 per yard, making it attractive for budget-conscious projects. However, while synthetic leather mimics the look of real leather, it often lacks the breathability and durability of Alcantara. It is suitable for fashion accessories and upholstery where a leather-like appearance is desired, but it may not perform as well in high-stress environments, such as automotive interiors.

Illustrative image related to black alcantara material

How Does Traditional Suede Stack Up Against Black Alcantara?

Traditional suede, derived from the underside of animal hides, provides a soft and luxurious feel that many consumers appreciate. Its cost can vary widely, ranging from $25 to $100 per yard, depending on quality and source. While suede offers aesthetic appeal, it requires more maintenance compared to Alcantara, as it can easily absorb stains and may need regular conditioning to maintain its texture and appearance. Suede is best suited for high-end clothing and luxury upholstery but may not withstand the rigors of automotive applications as effectively as Alcantara.

Conclusion: How Should B2B Buyers Choose the Right Material for Their Needs?

When selecting the right material for a project, B2B buyers should carefully assess their specific requirements, including performance, cost constraints, and intended use. Black Alcantara stands out for its durability and ease of maintenance, making it ideal for luxury automotive interiors and high-end products. In contrast, synthetic leather may appeal to those prioritizing cost-effectiveness, while traditional suede offers an upscale aesthetic at the expense of durability. By understanding the strengths and weaknesses of each option, buyers can make informed choices that align with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for black alcantara material

What Are the Essential Technical Properties of Black Alcantara Material?

When considering black Alcantara material for various applications, understanding its technical properties is crucial for making informed purchasing decisions. Here are some key specifications that B2B buyers should be aware of:

Illustrative image related to black alcantara material

1. Material Composition

Alcantara is a synthetic fabric composed primarily of 68% polyester and 32% polyurethane. This combination offers the luxurious feel of suede while providing enhanced durability and ease of maintenance. Understanding the composition is vital, as it influences the material’s performance in different environments, particularly for automotive and interior design applications.

2. Thickness

The thickness of black Alcantara can vary, typically ranging from 0.83 mm to 1.3 mm for unbacked versions, and up to 1.3 mm for backed options. Thickness affects the material’s flexibility, durability, and suitability for various applications such as upholstery, automotive interiors, and high-end fashion. Buyers should consider the appropriate thickness based on their specific use cases, balancing aesthetics with functionality.

3. Width

Standard widths for black Alcantara are generally 56 inches (142 cm) to 61 inches. The width of the roll is essential for calculating material requirements for large-scale projects. For B2B buyers, understanding width specifications helps in minimizing waste and optimizing material usage.

Illustrative image related to black alcantara material

4. Backing Options

Alcantara can come in various backing options, including unbacked, foam-backed, and multilayer configurations. Each type serves different purposes; for example, foam-backed Alcantara offers additional cushioning and sound absorption, making it suitable for automotive interiors. B2B buyers must select the right backing based on the intended application to ensure performance and comfort.

5. Care and Maintenance

One of Alcantara’s advantages is its ease of cleaning. It is recommended to use mild detergents and avoid harsh chemicals to maintain its appearance. Understanding care requirements is vital for B2B buyers in industries like automotive, where maintaining a pristine interior is crucial for customer satisfaction and brand reputation.

6. Color Fastness

Black Alcantara is designed to resist fading and discoloration over time, maintaining its luxurious appearance even in high-traffic areas. This property is particularly significant for B2B buyers in sectors where visual appeal is paramount, such as automotive, furniture, and fashion.

Illustrative image related to black alcantara material

What Are Common Trade Terms Related to Black Alcantara Material?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms associated with black Alcantara material:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Alcantara, OEMs often use this material for luxury vehicle interiors. Understanding OEM relationships can help buyers identify quality sources and ensure they are sourcing genuine products.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units that a supplier is willing to sell. This term is vital for B2B buyers, as it helps in budgeting and inventory management. Knowing the MOQ for black Alcantara can assist in planning purchases, especially for large-scale projects.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific quantities of materials, including black Alcantara. This process is essential for comparing suppliers and ensuring competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to manage shipping logistics, costs, and risk.

5. SKU (Stock Keeping Unit)

SKU is a unique identifier for each distinct product and service that can be purchased. For black Alcantara, each variation (e.g., color, thickness, backing type) has its own SKU, facilitating inventory management and order accuracy.

By understanding these technical properties and trade terms, B2B buyers can navigate the procurement process for black Alcantara more effectively, ensuring they meet their project requirements while optimizing costs and quality.

Navigating Market Dynamics and Sourcing Trends in the black alcantara material Sector

What Are the Current Market Dynamics and Key Trends Impacting Black Alcantara Material?

The global market for black Alcantara material is experiencing dynamic growth, driven by several key factors. As industries such as automotive, fashion, and interior design increasingly prioritize luxury and performance, the demand for high-quality synthetic fabrics like Alcantara is on the rise. Notably, regions such as Europe, the Middle East, and emerging markets in Africa and South America are witnessing a surge in consumer preferences for premium materials that offer both aesthetic appeal and functional benefits.

Current B2B sourcing trends highlight a shift towards digital platforms that facilitate easier access to suppliers and real-time inventory management. International buyers are leveraging online marketplaces to compare prices, quality, and delivery options, making informed decisions more efficiently. Furthermore, the introduction of innovative manufacturing technologies, such as 3D printing and smart textiles, is reshaping how Alcantara is produced and utilized, allowing for custom solutions that meet specific client needs.

Illustrative image related to black alcantara material

Sustainability is also becoming a pivotal theme in market dynamics, with buyers increasingly favoring suppliers who adhere to ethical sourcing practices and sustainable production methods. As a result, Alcantara manufacturers are investing in eco-friendly production processes and certifications to align with global sustainability goals.

How Does Sustainability and Ethical Sourcing Impact the Black Alcantara Material Sector?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the black Alcantara material sector. The environmental impact of synthetic materials, including Alcantara, necessitates a focus on eco-friendly production methods. Manufacturers are increasingly adopting practices that minimize waste and reduce carbon footprints, making sustainable Alcantara a viable option for environmentally conscious businesses.

Ethical supply chains are also gaining importance, with buyers seeking transparency regarding the sourcing and production processes. This includes ensuring that raw materials are responsibly sourced and that labor practices meet international standards. Certifications such as OEKO-TEX and Global Recycled Standard can serve as indicators of a supplier’s commitment to sustainability, offering buyers peace of mind when selecting materials.

Illustrative image related to black alcantara material

Furthermore, the integration of recycled materials into the production of Alcantara is emerging as a trend that not only supports sustainability but also appeals to a growing market segment that values eco-friendly products. By prioritizing suppliers with strong sustainability credentials, B2B buyers can enhance their corporate responsibility initiatives while meeting consumer demand for greener products.

What Is the Brief History and Evolution of Black Alcantara Material?

Black Alcantara material has evolved significantly since its inception in the 1970s. Originally developed as a synthetic alternative to suede, it gained popularity for its luxurious feel and durability. The material’s versatility has allowed it to penetrate various industries, particularly automotive and fashion, where it is favored for its aesthetic qualities and performance attributes.

Over the years, advancements in manufacturing technologies have further refined the production of Alcantara, enhancing its properties such as stain resistance, ease of cleaning, and color retention. As consumer preferences shift towards sustainable and ethically produced materials, the Alcantara industry is responding by innovating and adapting to meet the demands of the modern market. This evolution positions black Alcantara as a key player in the global fabric market, appealing to B2B buyers seeking high-quality, sustainable solutions.

Illustrative image related to black alcantara material

Frequently Asked Questions (FAQs) for B2B Buyers of black alcantara material

-

1. How do I choose the right black alcantara material for my project?

Choosing the right black alcantara material involves considering several factors, including the intended application, desired texture, and durability. For automotive interiors, opt for unbacked or foam-backed varieties that provide stretch and comfort. If the application is high-traffic or requires easy maintenance, select a version that is easy to clean and resistant to wear. Additionally, always request samples to assess color accuracy and texture before making a bulk order. -

2. What are the available thicknesses and widths for black alcantara material?

Black alcantara material typically comes in various thicknesses ranging from 0.8 mm to 1.3 mm, depending on the specific product type. The standard width is usually around 56 to 61 inches (142 to 155 cm). It’s essential to choose the correct thickness and width based on your specific requirements, whether for upholstery, automotive applications, or fashion products. Always verify these specifications with suppliers to ensure they meet your project needs. -

3. What are the minimum order quantities (MOQs) for black alcantara material?

Minimum order quantities for black alcantara can vary significantly among suppliers. While some may allow orders as small as one linear foot, others may require a minimum of one yard or more. It’s advisable to check individual supplier policies and negotiate if you have specific quantity needs. Be aware that ordering in larger quantities often yields cost savings and more favorable pricing tiers. -

4. What payment terms should I expect when sourcing black alcantara material internationally?

Payment terms for international orders can vary widely based on the supplier and your negotiating power. Common terms include full payment upfront, a deposit with the balance upon delivery, or net 30/60 days after receipt of goods. Always clarify payment options before placing an order, and consider using secure payment methods such as letters of credit or escrow services to protect your investment, especially with new suppliers. -

5. How can I ensure the quality of black alcantara material before purchasing?

To ensure quality, always request samples before committing to a large order. This allows you to inspect the fabric’s texture, color accuracy, and overall quality. Additionally, inquire about the supplier’s quality assurance processes, certifications, and whether they have a return policy for defective products. Building a relationship with reputable suppliers who prioritize quality control can significantly reduce the risk of receiving subpar materials. -

6. What are the best practices for shipping black alcantara material internationally?

When shipping black alcantara material internationally, it’s crucial to select a reliable logistics partner experienced in handling textiles. Ensure that the material is properly packaged to prevent damage during transit. Be aware of customs regulations and potential tariffs in your destination country to avoid unexpected costs. Additionally, consider choosing an Incoterm that specifies who is responsible for shipping costs and risks. -

7. Can black alcantara material be customized for specific projects?

Yes, many suppliers offer customization options for black alcantara, including color variations, thickness adjustments, and even unique textures. When seeking customization, provide detailed specifications and be prepared for potential lead times. Discuss your requirements with suppliers early in the negotiation process to ensure they can meet your needs and to facilitate a smoother production timeline. -

8. What are the common applications for black alcantara material in various industries?

Black alcantara is widely used in the automotive industry for interior applications such as seats, door panels, and headliners due to its durability and luxurious feel. Beyond automotive, it is popular in fashion for accessories, upholstery, and home décor. Its versatility also extends to high-end electronics, where it is used for device covers and cases. Understanding the various applications can help you identify potential markets and uses for your sourced materials.

Top 7 Black Alcantara Material Manufacturers & Suppliers List

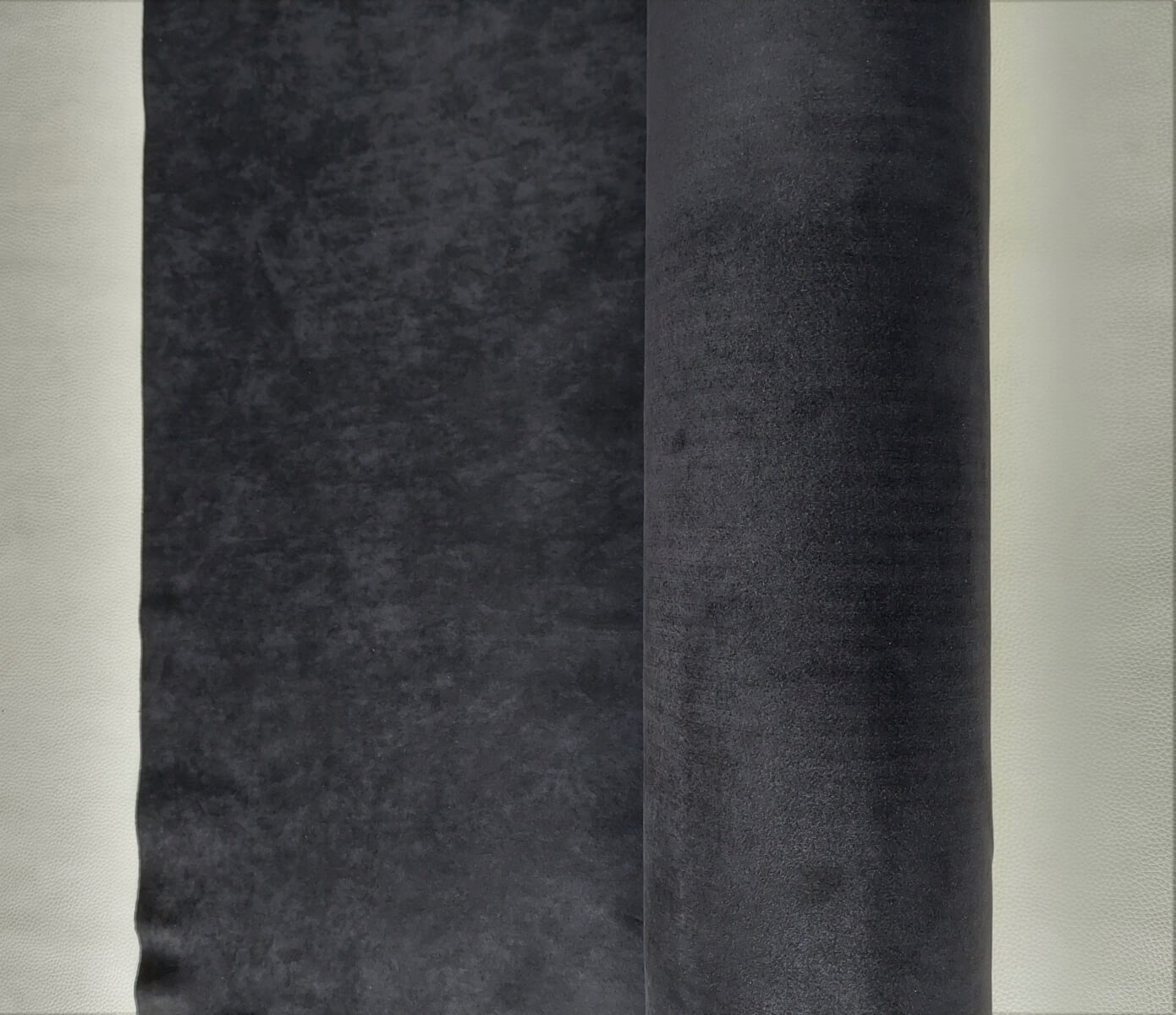

1. Relicate – Alcantara by the Linear Foot

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: Alcantara by the Linear Foot – Price: $55.00; Available in various colors including 9040 Black, 9002 Anthracite, 9052 Dark Charcoal, 2957 Chic Grey, and more; Options: Unbacked, Backed, Perforated, EXO, Multilayer; Width: ≥ 56″ (≥ 142 cm); Backed Thickness: 1.0-1.3 mm; Unbacked Thickness: 0.83 – 0.1 mm; EXO Thickness: ≤ 1.3 mm; Multilayer Thickness: 1.2 ± 0.2 mm; Ships in 1-2 business days; Genuin…

2. DLT Corporation – Alcantara Soft

Domain: dltcorporation.com

Registered: 2009 (16 years)

Introduction: Alcantara Soft is a foam-backed, Italian synthetic suede composed of 68% Polyester and 32% Polyurethane. It is easy to clean, offers more grip and durability, reduces glare on the windshield, and remains cool to the touch. Available colors include Pearl White, Silver Grey, Orion Grey, Sand Grey, Mouse Grey, Basalt, Slate Grey, Dark Grey, Charcoal Black, Deep Black, Raw Amber, Dark Brown, Brombeer,…

3. OEM Auto Fabric – ALCANTARA – BLACK

Domain: oemautofabric.com

Registered: 2018 (7 years)

Introduction: {“Product Name”: “ALCANTARA – BLACK”, “Material”: “Genuine Alcantara”, “Color”: “Black”, “Width”: “61 inches”, “Price Range”: “$3.00 – $120.00”, “SKU”: “ALCANTARA-BLACK”, “Categories”: [“Bodycloth”, “Specialty Fabrics”], “Tags”: [“Alcantara”, “Suede”]}

4. Upholstery Supply USA – Alcantara for Panels – Anthracite Black

Domain: upholsterysupplyusa.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “Alcantara for Panels – Anthracite Black (#9002)”, “Price”: “$135.00 per Yard”, “Quantity Discounts”: {“1 to 9”: “$135.00”, “10 to 24”: “$130.00”, “25+”: “$125.00”}, “Material Type”: “Genuine Alcantara Textile”, “Origin”: “Made in Italy”, “Applications”: “Automotive Interior including door panels, headliners, and more.”, “Roll Width”: “56 inches”, “Thickness”: “1.0 mm”, “Care Inst…

5. Carwow – Alcantara Upholstery

Domain: carwow.co.uk

Registered: 2011 (14 years)

Introduction: Alcantara is a synthetic textile made from a blend of polyester and polyurethane, developed in the 1970s by a Japanese chemist and manufactured by the Italian company Alcantara. It is a suede-like fabric commonly used in car interiors for upholstery on seats, dashboards, arm rests, door cards, transmission tunnels, sun visors, and headliners. Pros include better grip than leather or plastic, flame…

6. Alcantara – Craft Fabric

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Alcantara Craft Fabric available in various sizes and colors, including Black, Charcoal, Dark Grey, and Deep Black. Products include square foot options (12″ x 12″), yard options (36″ x 52″), and larger fabric rolls (1 meter x 150 cm). Prices range from approximately $10.99 to $1,800.00, with shipping costs varying by item. Most items are brand new and made in Italy, suitable for applications like…

7. Alcantara – High-Quality Upholstery Material

Domain: upholsterysupplyonline.com

Registered: 1999 (26 years)

Introduction: Alcantara Black is a high-quality upholstery material sold by the yard, measuring 60 inches wide, priced at $110.00. It is a 100% Italian brand known for its versatility, suitable for customizing seats, chairs, dashboards, door panels, steering wheels, and columns. The product is lightweight, weighing 1 lb, with SKU 9040-Black. Shipping is available worldwide, and returns are accepted only for man…

Strategic Sourcing Conclusion and Outlook for black alcantara material

In today’s competitive landscape, strategic sourcing of black Alcantara material represents a significant opportunity for international B2B buyers. This premium fabric, renowned for its durability and aesthetic appeal, is highly sought after in sectors ranging from automotive to luxury interiors. Key considerations for sourcing include understanding the material’s specifications, such as thickness and backing options, which directly influence performance and application suitability.

By partnering with reputable suppliers that guarantee genuine Alcantara made in Italy, buyers can ensure quality and consistency in their products. Moreover, utilizing bulk purchasing strategies can lead to cost efficiencies, particularly when engaging with suppliers who offer tiered pricing based on volume.

Looking ahead, the demand for sustainable and innovative materials is on the rise. Buyers from Africa, South America, the Middle East, and Europe should leverage this trend by exploring Alcantara’s eco-friendly attributes, positioning themselves as leaders in their respective markets. Embrace the opportunity to enhance your product offerings with Alcantara’s unmatched quality and style. Start your sourcing journey today to capitalize on this versatile material and secure a competitive edge in your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to black alcantara material

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.