Introduction: Navigating the Global Market for custom leather shoes

Navigating the global market for custom leather shoes presents a unique challenge for B2B buyers, particularly when it comes to sourcing high-quality products that meet diverse regional preferences and standards. The demand for bespoke leather footwear is on the rise, driven by an increasing appreciation for craftsmanship and personalized style. This guide is designed to provide international buyers—especially those from Africa, South America, the Middle East, and Europe (including Brazil and Vietnam)—with the essential knowledge to make informed purchasing decisions.

Within these pages, we delve into the various types of custom leather shoes available, exploring their applications across different industries—from fashion retail to corporate environments. We also cover critical aspects such as supplier vetting processes, cost considerations, and the importance of quality assurance in sourcing. By equipping buyers with a comprehensive understanding of the market landscape, this guide empowers them to navigate complexities and make strategic purchasing choices that align with their business goals.

In an increasingly competitive global market, having access to reliable information and expert insights can significantly enhance your sourcing strategy. This guide aims to streamline your decision-making process, ensuring that you find the perfect custom leather shoes that resonate with your target market while maintaining the highest standards of quality and craftsmanship.

Table Of Contents

- Top 6 Custom Leather Shoes Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather shoes

- Understanding custom leather shoes Types and Variations

- Key Industrial Applications of custom leather shoes

- 3 Common User Pain Points for ‘custom leather shoes’ & Their Solutions

- Strategic Material Selection Guide for custom leather shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather shoes

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather shoes’

- Comprehensive Cost and Pricing Analysis for custom leather shoes Sourcing

- Alternatives Analysis: Comparing custom leather shoes With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather shoes

- Navigating Market Dynamics and Sourcing Trends in the custom leather shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather shoes

- Strategic Sourcing Conclusion and Outlook for custom leather shoes

- Important Disclaimer & Terms of Use

Understanding custom leather shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dress Shoes | Sleek design, often made from polished leather | Corporate settings, formal events | Pros: Timeless style, versatility; Cons: Can be expensive, requires care. |

| Casual Loafers | Slip-on style, often in softer leathers | Business casual environments | Pros: Easy to wear, comfortable; Cons: Less formal, may not suit all occasions. |

| Boots | Ankle or knee-high, rugged construction | Work environments, outdoor events | Pros: Durability, protection; Cons: Heavier, may require break-in period. |

| Custom Sneakers | Sporty designs, often with personalized features | Casual wear, promotional events | Pros: Trendy, customizable; Cons: Less formal, may not appeal to all demographics. |

| Specialty Shoes | Unique designs for specific purposes (e.g., orthopedic) | Niche markets, healthcare, fashion | Pros: Tailored to needs; Cons: Limited appeal, higher costs. |

What are the Key Characteristics of Dress Shoes?

Dress shoes are characterized by their sleek and polished appearance, often made from high-quality leather. They are designed for formal occasions and corporate environments, making them essential for businesses looking to maintain a professional image. When purchasing, B2B buyers should consider the quality of the leather, craftsmanship, and style to ensure they meet the expectations of their clientele. While dress shoes can be a significant investment, their timeless style and versatility make them a worthwhile addition to any formal wardrobe.

Illustrative image related to custom leather shoes

How Do Casual Loafers Stand Out in Custom Leather Footwear?

Casual loafers are designed for ease and comfort, featuring a slip-on style that appeals to a wide range of customers. They are ideal for business casual settings, offering a relaxed yet polished look. B2B buyers should focus on the choice of leather and construction quality, as these factors influence comfort and longevity. While loafers are versatile, they may not suit more formal occasions, which is a consideration for businesses aiming to cater to a diverse clientele.

What Makes Boots a Preferred Choice for Work Environments?

Boots are typically constructed with rugged materials and provide ankle or knee-high coverage, making them suitable for work environments that require durability and protection. They are popular in outdoor and industrial settings, where comfort and safety are paramount. When selecting custom boots, B2B buyers should assess the materials, insulation, and waterproofing features to ensure they meet specific operational needs. While boots offer great protection, they can be heavier and may require a break-in period, which should be communicated to end-users.

Why are Custom Sneakers Gaining Popularity Among B2B Buyers?

Custom sneakers combine sporty designs with the potential for personalization, making them an attractive option for businesses looking to promote their brand or cater to younger demographics. They are suitable for casual wear and promotional events, providing comfort without sacrificing style. B2B buyers should explore customization options, material choices, and trending designs to appeal to their target market. However, it’s important to note that sneakers may not be appropriate for formal settings, limiting their versatility.

Illustrative image related to custom leather shoes

What are Specialty Shoes and Their Market Applications?

Specialty shoes encompass a variety of unique designs tailored for specific purposes, such as orthopedic or fashion-forward styles. These shoes cater to niche markets, including healthcare professionals or fashion enthusiasts looking for distinctive footwear. B2B buyers should consider the intended audience and market demand when investing in specialty shoes, as they often come at a premium price. While they meet specific needs, their limited appeal may pose a challenge in broader markets, making targeted marketing strategies essential.

Key Industrial Applications of custom leather shoes

| Industry/Sector | Specific Application of custom leather shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Bespoke footwear for high-end fashion lines | Enhances brand exclusivity and customer loyalty | Focus on craftsmanship, material quality, and design versatility |

| Hospitality | Custom shoes for staff uniforms | Improves employee comfort and brand image | Consider durability, comfort features, and aesthetic appeal |

| Corporate Business | Personalized executive footwear | Reflects professionalism and brand identity | Ensure fit, customization options, and material longevity |

| Healthcare | Specialized footwear for healthcare workers | Promotes employee well-being and reduces injury risk | Prioritize ergonomic design, breathability, and ease of cleaning |

| Sports and Recreation | Custom sports shoes for teams | Boosts performance and team cohesion | Look for specific performance features, durability, and style |

How Are Custom Leather Shoes Used in the Fashion Retail Industry?

In the fashion retail sector, custom leather shoes are integral for creating exclusive collections that reflect a brand’s identity. High-end retailers often seek bespoke footwear to differentiate themselves in a competitive market. These shoes not only enhance brand exclusivity but also foster customer loyalty, as consumers are increasingly drawn to unique, tailored products. International buyers should focus on craftsmanship, material quality, and the ability to adapt designs to their specific market needs, particularly in diverse regions like Africa and South America.

What Role Do Custom Leather Shoes Play in the Hospitality Industry?

In the hospitality industry, custom leather shoes are essential for staff uniforms, contributing to both aesthetics and functionality. Comfortable and stylish footwear can significantly improve employee satisfaction and retention while enhancing the overall guest experience. Moreover, well-designed shoes help project a professional image that aligns with the brand’s values. When sourcing for this application, businesses should prioritize durability and comfort features, ensuring that the shoes can withstand the demands of a fast-paced environment.

Why Are Custom Leather Shoes Important for Corporate Businesses?

Corporate businesses utilize personalized executive footwear to reinforce professionalism and brand identity. Custom leather shoes allow executives to present a polished image while ensuring comfort during long hours of wear. This personalized touch can enhance employee morale and foster a sense of belonging within the company. International buyers should ensure that sourcing options include a variety of fits and customization features, as well as materials that are durable yet comfortable for everyday use.

How Do Custom Leather Shoes Benefit Healthcare Workers?

In the healthcare sector, custom leather shoes are designed to meet the specific needs of healthcare professionals, promoting comfort and reducing injury risk during long shifts. These shoes often feature ergonomic designs and materials that allow for breathability and ease of cleaning. By investing in specialized footwear, healthcare facilities can enhance employee well-being, leading to improved job performance and reduced turnover. Buyers in this sector should prioritize sourcing shoes that combine functionality with style, ensuring they meet the rigorous demands of healthcare environments.

What Are the Advantages of Custom Leather Shoes in Sports and Recreation?

Custom sports shoes are increasingly popular among teams looking to boost performance and foster unity. Tailored footwear can enhance athletic performance by providing the necessary support and comfort for various sports activities. Additionally, custom designs can promote team branding and cohesion. When sourcing these shoes, businesses should focus on specific performance features, durability, and style, ensuring that the products meet the unique needs of athletes across different sports disciplines.

3 Common User Pain Points for ‘custom leather shoes’ & Their Solutions

Scenario 1: Sizing and Fit Issues for Custom Leather Shoes

The Problem:

B2B buyers often face significant challenges when it comes to the sizing and fit of custom leather shoes. This issue is particularly pronounced in international markets where standard sizing may differ from region to region. For example, a buyer in Africa may order sizes based on local standards, only to find that the shoes do not fit the intended recipients. This not only leads to dissatisfaction but can also result in costly returns and replacements, straining business relationships and affecting the bottom line.

Illustrative image related to custom leather shoes

The Solution:

To mitigate sizing and fit issues, buyers should prioritize accurate foot measurements and leverage advanced fitting technologies. It is advisable to partner with manufacturers that offer comprehensive measurement guides and fitting consultations. Buyers can also consider using 3D foot scanning technologies that provide precise foot dimensions, allowing for the production of shoes tailored to individual needs. Furthermore, establishing a clear communication channel with the manufacturer about sizing standards and potential variations can help set expectations and reduce the risk of fit issues. Regularly testing samples before placing bulk orders can also ensure that the final product meets the necessary specifications.

Scenario 2: Quality Control and Material Consistency in Custom Leather Shoes

The Problem:

Another common pain point for B2B buyers is ensuring consistent quality and material standards across custom leather shoe orders. In many cases, buyers may receive products that do not align with the expected quality due to variations in leather sources, tanning processes, or craftsmanship. This inconsistency can lead to a tarnished reputation if the shoes do not meet the quality standards required by end customers, especially in competitive markets.

The Solution:

To address quality control issues, it is essential for buyers to conduct thorough due diligence when selecting suppliers. Establishing partnerships with reputable manufacturers known for their craftsmanship and material sourcing can significantly reduce risks. Buyers should request detailed information about the leather types used, including origin and tanning methods, as well as production processes. Implementing a quality assurance program that includes regular audits of the manufacturing process and final product inspections can ensure that each batch of shoes meets the required standards. Additionally, maintaining open lines of communication with suppliers about quality expectations and addressing any discrepancies immediately can help foster a culture of accountability and continuous improvement.

Scenario 3: Limited Customization Options for Diverse Markets

The Problem:

B2B buyers often encounter limitations in the customization options available for custom leather shoes, which can be a significant barrier when attempting to cater to diverse markets. Cultural preferences, fashion trends, and local demands vary widely across regions, and a one-size-fits-all approach may not resonate with customers. This lack of flexibility can hinder a buyer’s ability to offer products that appeal to specific demographics, ultimately affecting sales and market penetration.

Illustrative image related to custom leather shoes

The Solution:

To overcome these limitations, buyers should seek manufacturers who are willing to offer extensive customization options. This includes not only size and fit adjustments but also variations in design, color, and materials. Engaging in collaborative product development with suppliers can lead to innovative solutions tailored to specific market needs. Additionally, conducting market research to understand regional preferences and trends can inform customization efforts. Buyers can also consider limited-edition releases or region-specific lines that highlight unique cultural elements, thereby enhancing their product offerings and ensuring they resonate with target audiences. By fostering strong partnerships with suppliers, buyers can also negotiate for more flexible customization terms and faster turnaround times for bespoke orders.

Strategic Material Selection Guide for custom leather shoes

What Are the Key Properties of Common Materials Used in Custom Leather Shoes?

When selecting materials for custom leather shoes, understanding the properties of different leathers is essential for optimizing performance and meeting market demands. Here, we analyze four commonly used materials: full-grain leather, suede, patent leather, and shell cordovan.

How Does Full-Grain Leather Perform in Custom Leather Shoes?

Full-grain leather is renowned for its durability and breathability. It retains the natural grain of the hide, providing a unique texture and appearance. This material is resistant to wear and develops a rich patina over time, enhancing its aesthetic appeal. Full-grain leather is suitable for formal and casual shoes alike, making it a versatile choice for various applications.

Illustrative image related to custom leather shoes

Pros include exceptional durability and comfort, while cons encompass a higher cost and potential for water absorption if not treated. For international B2B buyers, particularly those in Africa and South America, it is crucial to ensure compliance with local leather standards, such as ISO 17075 for testing leather properties.

What Advantages Does Suede Offer for Custom Leather Shoes?

Suede, made from the underside of the animal hide, is known for its soft texture and luxurious feel. It is lightweight and provides excellent comfort, making it a popular choice for casual footwear. Suede is also more pliable than full-grain leather, allowing for stylish designs.

However, suede has disadvantages such as lower water resistance and susceptibility to staining. Its maintenance requires regular care to preserve its appearance. Buyers from the Middle East and Europe should consider local climate conditions when choosing suede, as it may not perform well in humid environments without proper treatment.

Why Choose Patent Leather for Custom Leather Shoes?

Patent leather is characterized by its high-gloss finish, making it a popular choice for formal occasions. It is created by applying a coating to the leather, which provides a waterproof barrier. This material is easy to clean and maintain, making it suitable for dress shoes.

The key advantages of patent leather include its aesthetic appeal and ease of care, while the disadvantages involve limited breathability and potential for cracking over time. For B2B buyers, understanding local regulations regarding synthetic coatings is essential, especially in regions like Europe where environmental compliance is strict.

Illustrative image related to custom leather shoes

What Makes Shell Cordovan a Premium Choice for Custom Leather Shoes?

Shell cordovan is a unique leather derived from the fibrous flat muscle beneath the skin of a horse. It is known for its exceptional durability, rich color, and distinctive texture. Shell cordovan shoes are often considered luxury items due to the labor-intensive tanning process that can take up to six months.

The pros of shell cordovan include unmatched durability and a unique aesthetic that ages beautifully. However, it comes with a high cost and limited availability, making it less accessible for mass production. Buyers in Europe and the Middle East should be aware of the high demand and potential supply chain challenges when sourcing this material.

Summary of Material Selection for Custom Leather Shoes

| Material | Typical Use Case for custom leather shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Formal and casual shoes | Exceptional durability and breathability | Higher cost and water absorption potential | High |

| Suede | Casual footwear | Soft texture and comfort | Lower water resistance and staining risk | Medium |

| Patent Leather | Formal shoes | High-gloss finish and easy maintenance | Limited breathability and cracking risk | Medium |

| Shell Cordovan | Luxury shoes | Unmatched durability and unique aesthetic | High cost and limited availability | High |

This strategic material selection guide provides essential insights for B2B buyers in the custom leather shoe market, helping them make informed decisions based on material properties, advantages, limitations, and regional considerations.

Illustrative image related to custom leather shoes

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather shoes

The manufacturing process of custom leather shoes is a sophisticated blend of artistry and engineering, requiring a deep understanding of materials, techniques, and quality control measures. This section outlines the primary stages of manufacturing, the key techniques employed, and the rigorous quality assurance protocols that international B2B buyers should consider when sourcing custom leather footwear.

What Are the Main Stages in the Manufacturing Process of Custom Leather Shoes?

Material Preparation: What Goes Into Making Custom Leather Shoes?

The first step in the manufacturing of custom leather shoes involves the careful selection and preparation of high-quality materials. The choice of leather is paramount, with options ranging from calfskin to exotic leathers, each providing unique characteristics in terms of durability, texture, and appearance.

Once selected, the leather undergoes a rigorous tanning process to enhance its longevity and aesthetic appeal. This process can be vegetable or chrome tanning, with the former being preferred for its environmentally friendly properties. Additionally, other materials such as linings, insoles, and soles are sourced, often from specialized suppliers to ensure quality consistency.

Forming: How Are Custom Leather Shoes Shaped?

After material preparation, the next stage is forming, where the leather is cut into specific patterns using precision cutting tools or die-cutting machines. This step is crucial as it determines the overall fit and style of the shoe.

Illustrative image related to custom leather shoes

The cut pieces are then shaped over a last—a mold that mimics the contours of a foot—using techniques like wet molding or heat molding. This shaping process can significantly affect comfort and fit, making it essential for manufacturers to use advanced technology and skilled craftsmanship.

Assembly: What Techniques Are Used to Construct Custom Leather Shoes?

The assembly stage involves stitching and bonding various components of the shoe together. Techniques like Goodyear welt construction are often employed in high-end custom leather shoes, providing enhanced durability and ease of resoling.

Skilled artisans perform hand-stitching for intricate designs, while machine stitching is used for more uniform seams. Adhesives may also be applied to secure certain parts, such as the sole and upper, ensuring a robust bond. The assembly process can take several weeks, depending on the complexity of the design and the level of craftsmanship involved.

Finishing: What Steps Are Taken to Perfect Custom Leather Shoes?

The finishing stage is where the shoes are polished, dyed, and treated to achieve the desired look and feel. This may involve multiple processes such as buffing, glazing, and applying protective coatings to enhance water resistance and shine.

Quality artisans pay close attention to detail during this phase, ensuring that every pair of shoes meets the highest standards of aesthetics and performance.

Illustrative image related to custom leather shoes

What Quality Assurance Protocols Should B2B Buyers Look for?

What Are the Relevant International Standards for Custom Leather Shoes?

Quality assurance in custom leather shoe manufacturing is critical, especially for international B2B buyers. Suppliers should comply with international quality management standards such as ISO 9001, which ensures that they have effective processes in place to meet customer requirements consistently.

Additionally, certifications like CE marking indicate compliance with European health, safety, and environmental protection standards. In some markets, adherence to industry-specific standards such as the American Podiatric Medical Association (APMA) guidelines may also be beneficial.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process with specific checkpoints:

-

Incoming Quality Control (IQC): This involves the inspection of raw materials upon arrival to ensure they meet specified quality standards.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted at various stages to monitor adherence to quality standards and specifications.

-

Final Quality Control (FQC): Once the shoes are completed, a thorough inspection is performed to assess overall quality, including fit, finish, and functionality.

Common testing methods include abrasion resistance testing, water resistance testing, and visual inspections for defects or inconsistencies.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers should conduct thorough due diligence. This includes:

-

Supplier Audits: Performing on-site audits to assess manufacturing processes, quality control measures, and overall operational capabilities.

-

Reviewing Quality Reports: Requesting detailed quality assurance reports from suppliers, including results from internal inspections and testing.

-

Third-Party Inspections: Engaging independent inspection agencies to conduct assessments of the supplier’s facilities and products, which can provide an unbiased evaluation of quality.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of regional nuances in quality standards and certifications.

Understanding local regulations and expectations is crucial, as compliance requirements may vary significantly between regions. For instance, buyers from the European market may prioritize CE certification, while those in the Middle East may look for compliance with local quality standards.

Moreover, language barriers and cultural differences can impact communication regarding quality expectations. It’s advisable for B2B buyers to establish clear specifications and maintain open lines of communication with suppliers to ensure mutual understanding of quality requirements.

Illustrative image related to custom leather shoes

In conclusion, the manufacturing processes and quality assurance protocols for custom leather shoes are intricate and critical for ensuring product excellence. B2B buyers must leverage these insights to make informed sourcing decisions, ensuring that the shoes they procure meet their standards for quality, durability, and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather shoes’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring custom leather shoes effectively. With a focus on quality, craftsmanship, and supplier reliability, this checklist will help you navigate the complexities of sourcing custom footwear tailored to your business needs. Follow these steps to ensure a successful procurement process that meets both your standards and your customers’ expectations.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your custom leather shoes, including design, material, sizing, and durability standards. This step is crucial as it sets the foundation for your sourcing process. Consider factors like:

– Material Type: Specify whether you require calf leather, suede, or specialty leathers like shell cordovan.

– Design Elements: Detail any specific design features, such as color, style (e.g., loafers, oxfords), and embellishments.

Illustrative image related to custom leather shoes

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers with a track record in producing high-quality custom leather shoes. This is essential to ensure that you partner with manufacturers who meet your specifications. Look for:

– Industry Experience: Suppliers should have significant experience in the footwear industry.

– Portfolio of Work: Review their previous projects or collections to gauge their craftsmanship and style.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications and adhere to industry standards. This step is critical for ensuring compliance with quality and ethical manufacturing practices. Check for:

– Quality Certifications: Look for ISO certifications or equivalent standards that confirm their commitment to quality.

– Sustainability Practices: Ensure they follow environmentally-friendly practices, especially if sourcing from regions with strict regulations.

Step 4: Request Samples

Before placing large orders, request samples of the custom leather shoes you intend to order. This is vital for assessing quality and craftsmanship firsthand. Pay attention to:

– Material Quality: Evaluate the leather’s texture, finish, and overall appearance.

– Construction Quality: Inspect stitching, sole attachment, and comfort to ensure they meet your expectations.

Step 5: Negotiate Terms and Conditions

Engage in discussions with your chosen suppliers to negotiate pricing, lead times, and payment terms. Clear agreements at this stage can prevent misunderstandings later. Consider:

– Minimum Order Quantities (MOQs): Understand the supplier’s MOQs and how they align with your business needs.

– Delivery Timelines: Confirm production and shipping timelines to ensure timely delivery to your market.

Step 6: Establish a Quality Control Process

Implement a quality control process to monitor the production of your custom leather shoes. This step is crucial for maintaining high standards throughout the manufacturing process. Key points to consider include:

– Inspection Points: Define specific stages during production where inspections will take place.

– Feedback Mechanism: Establish a system for providing feedback to the supplier based on quality assessments.

Step 7: Build a Long-term Relationship

Focus on building a long-term relationship with your supplier for ongoing collaboration and better pricing terms in the future. Strong partnerships can lead to improved communication and responsiveness. Consider:

– Regular Check-ins: Schedule periodic meetings to discuss performance and address any issues.

– Collaborative Design: Work together on future designs to create unique offerings that cater to your target market.

By following this checklist, B2B buyers can effectively source custom leather shoes that meet their business requirements while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for custom leather shoes Sourcing

When considering sourcing custom leather shoes, understanding the comprehensive cost structure is crucial for B2B buyers. The pricing of these shoes is influenced by multiple factors, from the quality of materials used to the complexity of customization requests. Here, we break down the cost components and pricing influencers, offering actionable insights for international buyers.

What Are the Key Cost Components in Custom Leather Shoe Production?

-

Materials: The choice of leather significantly impacts the cost. Premium materials such as calfskin or shell cordovan from reputable tanneries can elevate the price. Additionally, sourcing eco-friendly or certified leathers may incur higher costs but can appeal to conscious consumers.

-

Labor: Crafting custom leather shoes is a labor-intensive process, often requiring skilled artisans. The labor costs vary by region; for instance, labor in Vietnam may be less expensive than in Europe, but the skill level and craftsmanship quality must be considered.

-

Manufacturing Overhead: This includes the costs associated with factory operations, utilities, and maintenance. Efficient production processes can help mitigate these costs, but buyers should be aware that high-quality production facilities may charge a premium.

-

Tooling: Custom molds and lasts necessary for shoe production involve initial tooling costs. These costs can be amortized over larger order quantities, making them more manageable for bulk orders.

-

Quality Control (QC): Rigorous QC processes ensure that each pair meets specific standards. This might involve additional inspections and testing, which can contribute to the overall cost but is essential for maintaining brand reputation.

-

Logistics: Shipping costs can vary greatly depending on the destination and Incoterms. Air freight is faster but more expensive than sea freight. Understanding the total logistics cost is vital for accurate budgeting.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure sustainability. The margin can vary based on market demand, brand positioning, and competition.

How Do Pricing Influencers Affect Custom Leather Shoe Costs?

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically lead to lower per-unit costs due to economies of scale. Buyers should inquire about MOQs to avoid unnecessary expenses.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should clearly communicate their requirements to get precise quotes.

-

Material Quality and Certifications: The level of certification (e.g., eco-friendly, fair trade) can impact pricing. Suppliers with recognized certifications may charge more due to their commitment to sustainable practices.

-

Supplier Factors: Established suppliers with a strong reputation may command higher prices. However, they often provide better quality assurance and customer service, which can lead to long-term savings.

-

Incoterms: Understanding shipping terms can affect the total cost. Buyers should negotiate terms that minimize their exposure to unexpected charges, especially in international transactions.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

-

Negotiate Effectively: Leverage your purchasing power and market knowledge during negotiations. Be clear about your budget and requirements, and don’t hesitate to seek competitive quotes from multiple suppliers.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the shoes, including durability, maintenance, and potential resale value. Investing in higher-quality shoes may reduce replacement costs over time.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, tariffs, and import duties that could impact the final price. Establishing relationships with local suppliers can mitigate some of these risks.

-

Request Sample Orders: Before committing to a large order, request samples to assess quality and fit. This can help avoid costly mistakes in the final order.

Disclaimer on Indicative Prices

Pricing for custom leather shoes can vary widely based on the factors outlined above. This analysis provides a framework for understanding potential costs, but buyers should always obtain specific quotes tailored to their unique requirements and market conditions.

Illustrative image related to custom leather shoes

Alternatives Analysis: Comparing custom leather shoes With Other Solutions

Understanding Alternatives to Custom Leather Shoes

When considering footwear options for businesses, custom leather shoes offer a unique combination of quality, style, and durability. However, various alternatives exist that might meet the needs of B2B buyers in different contexts. This section explores how custom leather shoes compare to other viable solutions, enabling buyers to make informed decisions based on their specific requirements.

| Comparison Aspect | Custom Leather Shoes | Alternative 1: Mass-Produced Shoes | Alternative 2: Synthetic Leather Shoes |

|---|---|---|---|

| Performance | High durability and comfort; tailored fit | Variable quality; generally less durable | Good durability; less breathable |

| Cost | Higher initial investment; long-term value | Lower cost per pair | Moderate cost; often cheaper than leather |

| Ease of Implementation | Longer lead time due to customization | Readily available; minimal wait time | Readily available; minimal wait time |

| Maintenance | Requires regular care for longevity | Minimal care; easy to maintain | Moderate maintenance; depends on quality |

| Best Use Case | Formal events, high-end fashion, corporate settings | Casual wear, bulk purchases | Budget-friendly options, casual or semi-formal settings |

What Are the Pros and Cons of Mass-Produced Shoes?

Mass-produced shoes are often seen as a convenient alternative to custom leather shoes. They are readily available and come at a significantly lower price point, making them attractive for businesses looking to outfit large teams without a substantial financial commitment. However, the quality can be inconsistent, and they typically lack the tailored fit and durability of custom options. For businesses in need of a practical, short-term solution, mass-produced shoes can work well, but they may not provide the lasting value that custom leather shoes offer.

How Do Synthetic Leather Shoes Compare?

Synthetic leather shoes present another alternative, often marketed as a more affordable and environmentally friendly option. These shoes tend to be lighter and easier to clean compared to traditional leather. However, they may not offer the same level of breathability or comfort, particularly in warmer climates. While they can serve well in casual or semi-formal environments, businesses seeking a sophisticated image may find that synthetic options lack the prestige associated with genuine leather.

Making the Right Choice for Your Business Needs

In summary, selecting the right footwear solution depends on various factors such as budget, intended use, and the desired image of your brand. Custom leather shoes excel in performance and longevity, making them ideal for formal settings or businesses aiming to convey a high-end image. Conversely, mass-produced and synthetic leather shoes may be more suitable for casual environments or budget-conscious buyers. Understanding these alternatives allows B2B buyers to align their footwear choices with their operational needs and brand identity, ensuring a balanced approach to procurement that addresses both quality and cost.

Essential Technical Properties and Trade Terminology for custom leather shoes

What Are the Key Technical Properties of Custom Leather Shoes?

When sourcing custom leather shoes, understanding specific technical properties is crucial for ensuring quality and durability. Here are some essential specifications:

Illustrative image related to custom leather shoes

1. Material Grade

The material grade refers to the quality of the leather used in the shoes. High-grade materials, such as full-grain or top-grain leather, are preferred for their durability and aesthetic appeal. For B2B buyers, opting for higher-grade materials can lead to lower return rates and enhanced customer satisfaction, ultimately impacting sales positively.

2. Tolerance

Tolerance in shoe manufacturing pertains to the allowable deviation in dimensions and specifications during production. This is critical for ensuring a proper fit and overall comfort. For international buyers, understanding tolerance levels can help mitigate issues related to sizing discrepancies, especially when dealing with diverse markets and varying foot shapes.

3. Construction Method

The method of construction significantly affects the shoe’s quality and longevity. Common methods include Goodyear welted and Blake stitched, each offering different benefits. Goodyear welted shoes are known for their durability and ease of resoling, which can be a selling point for buyers focusing on long-term investments in footwear.

4. Breathability

Breathability refers to the ability of the shoe material to allow moisture and air to circulate. This is especially important in warmer climates where comfort is paramount. Buyers targeting regions with hot weather should prioritize shoes that offer excellent breathability to enhance user comfort and prevent premature wear.

5. Weight

The weight of the shoe can affect comfort and usability. Lighter shoes are typically preferred for casual wear, while heavier models may be favored for formal occasions. For B2B buyers, understanding the target market’s preferences regarding weight can guide purchasing decisions and inventory management.

Illustrative image related to custom leather shoes

What Are Common Trade Terms in the Custom Leather Shoe Industry?

Navigating the B2B landscape requires familiarity with specific trade terminology. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products based on the specifications provided by another company, often under that company’s brand. In the custom leather shoe industry, OEM partnerships can help brands access specialized manufacturing capabilities without investing in their own production facilities.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to produce or sell. Understanding MOQ is essential for buyers to manage inventory and ensure they meet the supplier’s requirements without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent by potential buyers to suppliers requesting pricing and terms for a specific quantity of goods. Utilizing RFQs can help businesses compare prices, terms, and conditions from multiple suppliers, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps businesses understand shipping costs, risks, and responsibilities, facilitating smoother trade agreements.

Illustrative image related to custom leather shoes

5. Lead Time

Lead time refers to the period between placing an order and receiving the products. For custom leather shoes, lead times can vary significantly based on complexity and production capacity. Buyers should account for lead times in their planning to ensure timely delivery and inventory management.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ultimately enhancing their procurement strategies and ensuring the successful sourcing of custom leather shoes.

Navigating Market Dynamics and Sourcing Trends in the custom leather shoes Sector

What Are the Key Market Dynamics and Trends Influencing Custom Leather Shoes?

The custom leather shoes sector is witnessing a remarkable transformation, driven by several global factors. Increased consumer awareness regarding quality and craftsmanship has fueled demand for bespoke footwear, particularly among discerning buyers in regions like Africa, South America, the Middle East, and Europe. These markets are increasingly favoring products that offer personalized features and superior durability. Moreover, the rise of e-commerce platforms has facilitated access to a wider range of custom options, allowing international B2B buyers to explore diverse suppliers and products from different geographical locations.

Emerging technologies are reshaping sourcing strategies, with innovations such as 3D printing and AI-driven design tools enhancing customization capabilities. These advancements not only streamline production processes but also reduce lead times, enabling suppliers to meet changing consumer preferences more effectively. Additionally, there is a growing trend toward integrating sustainable practices within the manufacturing process, as buyers prioritize suppliers who demonstrate a commitment to ethical sourcing and environmental stewardship.

How Is Sustainability Shaping the Custom Leather Shoes Market?

The environmental impact of the leather industry is under scrutiny, compelling businesses to adopt more sustainable practices. For international B2B buyers, understanding the importance of ethical supply chains is crucial. Sourcing from manufacturers who utilize environmentally friendly tanning processes, such as vegetable tanning, can significantly reduce harmful emissions and waste.

Moreover, the demand for ‘green’ certifications and sustainable materials is on the rise. Buyers are increasingly seeking suppliers who offer leather sourced from certified tanneries that adhere to strict environmental standards. Additionally, the use of recycled materials and biodegradable packaging is becoming essential for brands aiming to enhance their sustainability credentials. By aligning with suppliers who prioritize these practices, international buyers can not only meet regulatory requirements but also appeal to a growing segment of eco-conscious consumers.

How Has the Custom Leather Shoes Sector Evolved Over Time?

The evolution of custom leather shoes dates back centuries, rooted in artisan craftsmanship and tailored solutions. Historically, bespoke footwear was a luxury reserved for the elite, characterized by meticulous handwork and the use of high-quality materials. As industrialization took hold, mass production began to dominate the market, leading to a decline in personalized offerings.

However, the late 20th century saw a resurgence of interest in bespoke craftsmanship, driven by a renewed appreciation for individuality and quality. Today, the custom leather shoes sector is experiencing a renaissance, where traditional techniques are harmoniously blended with modern technology. This evolution not only caters to the aesthetic and functional needs of consumers but also reflects a broader trend towards personalization and sustainability in the fashion industry. For B2B buyers, understanding this historical context can enhance their appreciation of product value and supplier capabilities.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather shoes

-

1. How do I ensure the quality of custom leather shoes from suppliers?

To guarantee the quality of custom leather shoes, it is crucial to conduct thorough supplier vetting. Start by requesting samples to evaluate craftsmanship, materials, and overall aesthetics. Look for suppliers with certifications and positive reviews from previous clients. Additionally, consider visiting the manufacturing facility, if feasible, to observe production processes firsthand. Establish clear quality assurance standards and set expectations for inspections during production and before shipment to minimize risks. -

2. What are the key factors to consider when choosing a supplier for custom leather shoes?

When selecting a supplier, assess their experience in the industry, production capacity, and specialization in custom leather shoes. Evaluate their compliance with international labor standards and environmental regulations. Communication is vital; choose a supplier who is responsive and can provide detailed information about their processes. Finally, check for flexible customization options and willingness to accommodate your specific requirements, such as designs, materials, and branding. -

3. What customization options are typically available for custom leather shoes?

Customization options vary by supplier but often include choices in materials (e.g., full-grain leather, suede), colors, styles (e.g., loafers, oxfords), and sizes. Some suppliers may offer unique features like personalized embossing, custom lasts for fit, or specialized soles for specific functions. Discuss your vision with the supplier to explore all available options. Always request visual prototypes or digital mock-ups to ensure the design aligns with your expectations before production begins. -

4. What is the minimum order quantity (MOQ) for custom leather shoes?

Minimum order quantities for custom leather shoes can vary significantly based on the supplier and the complexity of the design. Typically, MOQs range from 50 to 500 pairs per style. Larger orders may qualify for better pricing and more favorable terms. If your requirements are lower than a supplier’s MOQ, consider negotiating or exploring other suppliers who specialize in smaller runs. Always clarify MOQs upfront to avoid misunderstandings later in the sourcing process. -

5. What payment terms should I expect when sourcing custom leather shoes?

Payment terms can differ widely among suppliers, but common practices include a deposit (usually 30-50%) before production and the balance upon completion or prior to shipping. Some suppliers may offer credit terms based on your business relationship and order history. It’s essential to discuss and negotiate payment terms early in the process to ensure clarity and mutual agreement. Additionally, consider using secure payment methods to protect your investment. -

6. How can I handle logistics for importing custom leather shoes?

Managing logistics for importing custom leather shoes involves several steps. First, determine the best shipping method based on your timeline and budget—air freight for speed or sea freight for cost-efficiency. Work with a freight forwarder to navigate customs clearance, ensuring all required documentation is in order. Be aware of import duties and taxes applicable in your country. Establish clear communication with your supplier about shipping schedules to avoid delays. -

7. What quality assurance practices should be implemented for custom leather shoes?

Implementing robust quality assurance practices is crucial for maintaining standards. Start by defining quality benchmarks based on material specifications and craftsmanship. Conduct regular inspections during production, and consider third-party audits if necessary. Request detailed reports and photographs of the production process from your supplier. Before shipment, a final inspection should be carried out to verify that the products meet your quality standards, reducing the risk of returns or dissatisfaction. -

8. How do I resolve issues with defective custom leather shoes after delivery?

To address issues with defective custom leather shoes, first document the defects with clear photographs and detailed descriptions. Contact your supplier immediately to discuss the issues and provide evidence. Most reputable suppliers will have a return or replacement policy in place. Clearly communicate your expectations for resolution, whether it be a refund, replacement, or repair. Maintain open lines of communication to facilitate a swift resolution and preserve your business relationship.

Top 6 Custom Leather Shoes Manufacturers & Suppliers List

1. TLB Mallorca – Custom-Made Men’s Shoes

Domain: tlbmallorca.com

Registered: 2016 (9 years)

Introduction: Custom-made men’s shoes | Made in Spain | Main Collection | TLB Mallorca | Free shipping for orders over 160€ | Free size change | Categories: Oxfords, Wingtip, Derby, Boots, Chelsea boots, Chukka boots, Monk Straps, Loafers, Unlined Styles | Collections: Shell Cordovan, MTO, Artista, Main Collection, Sacchetto loafers, Kiowa loafers, Comfort Sneakers | Guides available: Last guide, Style guide, S…

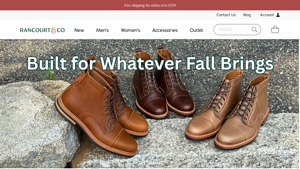

2. Rancourt & Co. – Handcrafted Footwear

Domain: rancourtandcompany.com

Registered: 2010 (15 years)

Introduction: Rancourt & Co. offers handcrafted and custom shoes made in Maine, with a focus on quality craftsmanship and timeless design. Their product range includes men’s and women’s shoes such as loafers, mocs, boots, oxfords, derbies, sneakers, and slippers. They feature a best-selling handcrafted footwear collection made with genuine handsewn moccasin construction, premium leathers, and in-stock favorites…

3. Adelante Shoes – The Granada & The Elena

Domain: adelanteshoes.com

Registered: 2016 (9 years)

Introduction: [{‘name’: ‘The Granada’, ‘price’: ‘$350.00’, ‘colors’: [‘Caramel’, ‘Black’, ‘Denim Blue’, ‘Desert’, ‘Mahogany’, ‘Pomegranate’, ‘Cemento’, ‘Spruce’, ‘Plum’]}, {‘name’: ‘The Elena’, ‘price’: ‘$365.00’, ‘colors’: [‘Black’, ‘Oatmeal’, ‘Denim Blue’, ‘Desert’, ‘Pomegranate’, ‘Caramel’, ‘Mahogany’, ‘Cemento’, ‘Spruce’, ‘Plum’]}, {‘name’: ‘The Cozy Havana’, ‘price’: ‘$375.00’, ‘colors’: [‘Caramel’, ‘Black…

4. Leolo – Bespoke Custom Shoes

Domain: leoloshoes.com

Registered: 2020 (5 years)

Introduction: Leolo Bespoke Custom Shoes, Custom Shoe Order $1,600.00, Fully bespoke process, Handmade shoes designed, created, and tailored for you, Commitment to humanity and sustainability, Traditional craftsmanship and individuality.

5. Girotti – Custom-Made Shoes

Domain: girotti.com

Registered: 2004 (21 years)

Introduction: GIROTTI is an Italian brand specializing in custom-made shoes for both women and men. Key features include:

– Customizable design options: colors, materials, and decorations can be changed.

– Free delivery and returns, along with a free remake if shoes do not fit.

– Sustainable shoe brand using chrome-free and metal-free materials.

– Premium quality shoes inspired by Italian heritage.

– A wid…

6. Hockerty – Custom Dress Shoes

Domain: hockerty.com

Registered: 2016 (9 years)

Introduction: Custom dress shoes starting from $199, handcrafted in Spain. Available styles include Oxford Shoes, Derby Shoes, Monk Strap Shoes, Penny Loafers, Horsebit Loafers, Tassel Loafers, Chukka Boots, Dress Boots, Chelsea Boots, and Custom Sneakers. Customization options include materials (Italian leather, suede, velvet), colors, toe shapes, broguing, laces, and personalized details like engraved initial…

Strategic Sourcing Conclusion and Outlook for custom leather shoes

In the evolving landscape of custom leather shoes, strategic sourcing emerges as a pivotal element for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. By prioritizing high-quality materials and skilled craftsmanship, businesses can enhance their product offerings and build strong brand loyalty. The meticulous processes involved in crafting custom leather shoes, such as selecting premium leathers and employing experienced artisans, underscore the importance of investing in reliable suppliers who uphold excellence.

What key advantages can strategic sourcing provide for your business? By establishing partnerships with reputable manufacturers, companies can ensure consistent quality, optimize lead times, and leverage innovative designs tailored to market demands. This proactive approach not only drives profitability but also positions businesses as leaders in the competitive footwear market.

Looking ahead, it is crucial for international B2B buyers to embrace the potential of custom leather shoes. By tapping into emerging markets and collaborating with skilled artisans, businesses can unlock new opportunities for growth and innovation. Engage with trusted suppliers today to elevate your product line and meet the evolving expectations of discerning consumers.

Illustrative image related to custom leather shoes

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.