Introduction: Navigating the Global Market for custom leather sheath

In today’s global marketplace, sourcing custom leather sheaths presents a unique challenge for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The demand for high-quality, tailored leather sheaths is growing, driven by industries ranging from outdoor equipment to artisan crafts. However, the complexity of selecting the right supplier, understanding material quality, and ensuring compliance with regional standards can be daunting. This guide aims to demystify the process by providing a comprehensive overview of the custom leather sheath market.

Throughout this resource, we will explore various types of leather sheaths, their applications across different sectors, and critical factors to consider when vetting suppliers. We will delve into the intricacies of material selection, design options, and pricing structures, ensuring that buyers can make informed decisions that align with their business needs. Additionally, we will address the importance of establishing strong supplier relationships, particularly in regions where craftsmanship and local sourcing can significantly impact product quality.

By equipping B2B buyers with actionable insights and strategic recommendations, this guide empowers you to navigate the complexities of sourcing custom leather sheaths effectively. Whether you are based in Nigeria, Brazil, or elsewhere, our goal is to facilitate your procurement process, helping you secure products that not only meet your specifications but also enhance your brand’s reputation in the competitive global market.

Table Of Contents

- Top 8 Custom Leather Sheath Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather sheath

- Understanding custom leather sheath Types and Variations

- Key Industrial Applications of custom leather sheath

- 3 Common User Pain Points for ‘custom leather sheath’ & Their Solutions

- Strategic Material Selection Guide for custom leather sheath

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather sheath

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather sheath’

- Comprehensive Cost and Pricing Analysis for custom leather sheath Sourcing

- Alternatives Analysis: Comparing custom leather sheath With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather sheath

- Navigating Market Dynamics and Sourcing Trends in the custom leather sheath Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather sheath

- Strategic Sourcing Conclusion and Outlook for custom leather sheath

- Important Disclaimer & Terms of Use

Understanding custom leather sheath Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pancake Sheath | Flat design, typically with a top opening for easy access | Outdoor gear suppliers, knife retailers | Pros: Slim profile, easy to carry. Cons: Limited protection for the blade edge. |

| Vertical Sheath | Vertical carry design, often with a belt loop for attachment | Tactical gear companies, hunting outfitters | Pros: Secure fit, good for active use. Cons: May be bulkier than other types. |

| Cross Draw Sheath | Designed for horizontal carry across the body | Survival gear suppliers, custom knife makers | Pros: Quick access, comfortable to wear. Cons: Requires careful design for fit. |

| Multi-tool Sheath | Designed to hold multiple tools, often with additional pockets | Hardware suppliers, outdoor equipment retailers | Pros: Versatile, organized storage. Cons: Can be complex and costly to produce. |

| Custom Inlay Sheath | Features decorative inlays or tooling for aesthetic appeal | Artisan shops, luxury retailers | Pros: Unique designs, high-end appeal. Cons: Higher cost due to craftsmanship. |

What are the Characteristics of Pancake Sheaths?

Pancake sheaths are characterized by their slim, flat design that allows for easy access to the knife. Typically featuring a top opening, they are favored for their minimalist profile, making them ideal for outdoor enthusiasts who prioritize portability. When purchasing, businesses should consider the sheath’s material quality and stitching, as these factors influence durability and functionality. Pancake sheaths are particularly suitable for knife retailers looking to offer a lightweight option for customers who carry their knives daily.

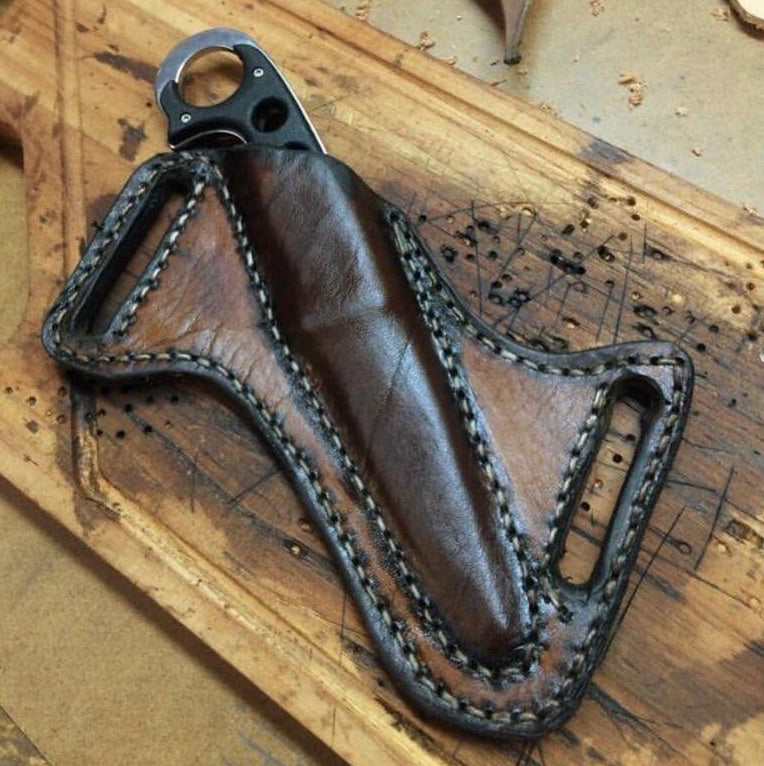

Illustrative image related to custom leather sheath

How Does a Vertical Sheath Serve B2B Needs?

Vertical sheaths are designed for a secure, upright carry, often incorporating a belt loop for easy attachment. This type is particularly popular among tactical gear companies and hunting outfitters, as it provides a stable and accessible solution for users in the field. When sourcing vertical sheaths, businesses should evaluate the retention mechanism and the sheath’s compatibility with various knife sizes. While they offer excellent security, potential buyers should be aware that their bulkier design may not appeal to all consumers.

What Makes Cross Draw Sheaths Unique?

Cross draw sheaths enable horizontal carry across the body, facilitating quick access to the knife without needing to adjust the sheath’s position. This design is especially useful for survival gear suppliers and custom knife makers, as it allows for rapid deployment in critical situations. When considering cross draw sheaths, B2B buyers should focus on the adjustability of the carry system and the sheath’s overall comfort. While they provide an innovative solution for accessibility, careful attention must be given to ensure a proper fit for the specific knife model.

Why Choose Multi-tool Sheaths for Your Business?

Multi-tool sheaths are specifically crafted to accommodate several tools, often featuring additional pockets for organization. This versatility makes them a valuable product for hardware suppliers and outdoor equipment retailers. When evaluating multi-tool sheaths, businesses should consider the layout of compartments and the materials used, as these factors affect usability and durability. Although they offer extensive storage capabilities, multi-tool sheaths may involve more complex designs, potentially leading to higher production costs.

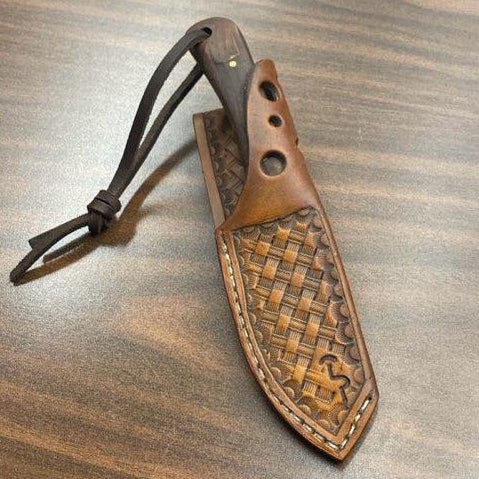

What are the Advantages of Custom Inlay Sheaths?

Custom inlay sheaths combine functionality with aesthetic appeal, often featuring intricate designs or unique materials. They are particularly sought after by artisan shops and luxury retailers, who want to offer distinctive products that stand out in the marketplace. When sourcing custom inlay sheaths, businesses should assess the craftsmanship and material sourcing to ensure quality. While they can attract a niche market willing to pay a premium, the complexity of their production can result in higher costs, which is a crucial consideration for buyers.

Key Industrial Applications of custom leather sheath

| Industry/Sector | Specific Application of custom leather sheath | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Equipment Retailers | Custom sheaths for knives and tools | Enhances product appeal and customer satisfaction | Quality of leather, customization options, and lead times |

| Military and Tactical Gear | Sheaths for survival knives and multi-tools | Provides durability and reliability in critical situations | Compliance with military standards, material specifications |

| Artisan and Craftsmanship | Bespoke sheaths for handcrafted knives | Supports artisan branding and showcases craftsmanship | Unique design capabilities, artisan partnerships, and pricing |

| Culinary Equipment Suppliers | Sheaths for chef knives | Protects valuable tools and enhances presentation | Material quality, customization for different knife sizes |

| E-commerce Platforms | Customizable sheaths for diverse markets | Attracts a wider audience and increases sales potential | Shipping logistics, international trade regulations, and costs |

How is Custom Leather Sheath Used in Outdoor Equipment Retailers?

In the outdoor equipment sector, custom leather sheaths are essential for enhancing the appeal of knives and tools. Retailers can offer personalized sheaths that not only protect the blades but also provide a unique selling proposition. This customization can solve issues related to blade protection during transport and usage, making it attractive to adventurers and outdoor enthusiasts. Buyers in this sector should consider the quality of leather and available customization options to ensure customer satisfaction.

Illustrative image related to custom leather sheath

What Role Does Custom Leather Sheath Play in Military and Tactical Gear?

Military and tactical gear manufacturers utilize custom leather sheaths for survival knives and multi-tools, ensuring that these critical tools are both accessible and secure. The durability of leather sheaths is vital in high-stakes environments where equipment reliability is paramount. Buyers should focus on compliance with military standards and specific material specifications to meet operational requirements, especially when sourcing from international suppliers.

How Can Artisans Benefit from Bespoke Sheaths?

Artisans and craftsmen benefit significantly from bespoke leather sheaths tailored for their handcrafted knives. These custom sheaths not only protect the knives but also enhance the overall aesthetic, reinforcing the artisan’s brand identity. Buyers in this niche should prioritize unique design capabilities and potential partnerships with artisans to create a compelling product offering that emphasizes quality craftsmanship.

Why Are Custom Sheaths Important for Culinary Equipment Suppliers?

Culinary equipment suppliers often use custom leather sheaths to protect high-value chef knives, ensuring they remain in pristine condition. These sheaths not only safeguard the blades but also elevate the presentation of culinary tools, appealing to professional chefs and cooking enthusiasts alike. Buyers in this sector should consider the material quality and customization options available for various knife sizes to meet diverse customer needs.

How Do E-commerce Platforms Leverage Custom Leather Sheath?

E-commerce platforms can attract a broader audience by offering customizable leather sheaths for various knives and tools. This flexibility not only increases sales potential but also allows customers to express their individuality through personalized products. When sourcing for this application, businesses must navigate shipping logistics, international trade regulations, and cost considerations to effectively serve a global market.

3 Common User Pain Points for ‘custom leather sheath’ & Their Solutions

Scenario 1: Sizing and Fit Issues with Custom Leather Sheaths

The Problem: One of the most common challenges B2B buyers face when ordering custom leather sheaths is ensuring a precise fit for their specific knives. Incorrect measurements can lead to sheaths that are either too loose, risking the knife falling out, or too tight, making it difficult to draw the knife. This issue is particularly prevalent when dealing with manufacturers who may not have a hands-on approach or clear guidelines for measuring. Buyers often find themselves frustrated, needing to return products or even re-order entirely, which can lead to increased costs and delays in fulfilling customer orders.

Illustrative image related to custom leather sheath

The Solution: To overcome sizing and fit issues, it is essential to develop a comprehensive measurement guide that outlines the exact specifications required for a custom leather sheath. Buyers should ensure that their suppliers provide a detailed checklist that includes the knife’s length, blade width at the widest point, handle width, and any unique features of the knife that may impact the sheath design. Additionally, providing high-quality images of the knife alongside the measurements can significantly enhance the accuracy of the order. Establishing a direct line of communication with the manufacturer is also crucial; buyers should not hesitate to ask questions or request clarification on the measurement process before placing an order. This proactive approach will help ensure that the final product meets the exact requirements, minimizing the need for returns or adjustments.

Scenario 2: Material Quality and Durability Concerns

The Problem: B2B buyers are often concerned about the quality and durability of the leather used in custom sheaths. In industries like outdoor equipment or culinary tools, the sheath must withstand harsh conditions, including exposure to moisture, extreme temperatures, or heavy use. Buyers may have encountered suppliers who claim to use high-quality materials but deliver products that show signs of wear and tear much sooner than expected. This inconsistency can damage reputations and lead to significant financial losses.

The Solution: To address material quality and durability concerns, buyers should prioritize sourcing from reputable manufacturers who provide transparency about their materials and craftsmanship. Request samples of leather before making bulk orders to assess the tactile quality and durability firsthand. It’s beneficial to inquire about the specific types of leather used, such as English bridle leather or vegetable-tanned leather, and their suitability for the intended application. Additionally, buyers should ask about the manufacturing process, including stitching techniques and any protective treatments applied to the leather. Establishing a long-term relationship with a trusted supplier who stands behind their products with warranties or guarantees can also provide peace of mind regarding durability.

Scenario 3: Delays in Production and Delivery Timelines

The Problem: Timeliness is critical in B2B transactions, and delays in the production and delivery of custom leather sheaths can disrupt business operations. Buyers often face challenges when suppliers underestimate lead times or do not communicate effectively about production schedules. These delays can lead to stock shortages, missed sales opportunities, and unsatisfied customers, which can have a cascading effect on a business’s bottom line.

Illustrative image related to custom leather sheath

The Solution: To mitigate delays in production and delivery, buyers should establish clear expectations with suppliers at the outset of the ordering process. This includes discussing realistic timelines for production based on the complexity of the sheath design and the supplier’s current workload. Buyers should also request regular updates on the status of their orders and have contingency plans in place for urgent needs. Incorporating a buffer period into project timelines can provide an additional layer of protection against unforeseen delays. Furthermore, seeking suppliers that offer expedited services or have a proven track record of meeting deadlines can help ensure that delivery times align with the buyer’s operational needs. Building a collaborative relationship with suppliers, characterized by open communication, will also foster a more reliable partnership.

Strategic Material Selection Guide for custom leather sheath

What are the Key Properties of Common Materials Used for Custom Leather Sheaths?

When selecting materials for custom leather sheaths, several options stand out due to their unique properties and suitability for different applications. The following analysis covers four common materials: vegetable-tanned leather, chrome-tanned leather, synthetic leather, and exotic leathers. Each material has distinct characteristics that can influence the performance, durability, and overall quality of the sheath.

1. Vegetable-Tanned Leather

Key Properties: Vegetable-tanned leather is known for its natural tanning process, which uses tannins derived from plant sources. This type of leather is breathable, durable, and develops a beautiful patina over time. It typically withstands moderate temperatures and pressures, making it suitable for various outdoor applications.

Pros & Cons: The durability of vegetable-tanned leather is a significant advantage, as it can last for years with proper care. However, it is generally more expensive than other leathers and requires more complex manufacturing processes, including longer drying times. Its natural properties make it less resistant to water and stains unless treated.

Impact on Application: This leather is compatible with various media, including knives and tools, as it offers excellent protection against scratches and impacts. It is ideal for users who appreciate aesthetics and durability.

Illustrative image related to custom leather sheath

Considerations for International Buyers: Buyers from regions like Africa and South America may need to consider local climate conditions, as humidity can affect the leather’s longevity. Compliance with local standards regarding leather sourcing and environmental impact is also crucial.

2. Chrome-Tanned Leather

Key Properties: Chrome-tanned leather is processed using chromium salts, resulting in a more supple and water-resistant material. It can handle a wide range of temperatures and pressures, making it suitable for various applications, including outdoor and tactical uses.

Pros & Cons: The primary advantage of chrome-tanned leather is its flexibility and resistance to water and stains, which makes it easier to maintain. However, it may not develop the same aesthetic appeal as vegetable-tanned leather over time. Additionally, the manufacturing process can be less environmentally friendly, raising concerns for buyers focused on sustainability.

Impact on Application: This leather is particularly effective for sheaths that require frequent exposure to the elements, as its water resistance enhances longevity. It is also suitable for tactical applications where durability and ease of maintenance are paramount.

Considerations for International Buyers: Buyers in Europe and the Middle East may need to ensure compliance with EU regulations regarding chemical use in leather production. Understanding local preferences for leather types is also essential for market acceptance.

Illustrative image related to custom leather sheath

3. Synthetic Leather

Key Properties: Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to traditional leather. It is lightweight, water-resistant, and can be produced in various colors and textures.

Pros & Cons: The primary benefit of synthetic leather is its affordability and ease of maintenance. However, it may not provide the same level of durability and aesthetic appeal as genuine leather. Additionally, it can be less breathable, which may impact comfort during prolonged use.

Impact on Application: Synthetic leather is suitable for budget-conscious buyers or applications where aesthetics are less critical. It is often used in environments where exposure to moisture is frequent.

Considerations for International Buyers: Buyers from regions like Brazil may find synthetic leather appealing due to its lower cost. However, they should consider the environmental impact of synthetic materials and ensure compliance with local regulations regarding plastic products.

4. Exotic Leathers (e.g., Alligator, Ostrich)

Key Properties: Exotic leathers are prized for their unique textures and patterns, offering a high-end aesthetic. They are generally more durable and resistant to wear compared to standard leathers, though their temperature and pressure ratings can vary significantly based on the specific type.

Illustrative image related to custom leather sheath

Pros & Cons: The key advantage of exotic leathers is their luxury appeal, making them ideal for high-end markets. However, they come with a high price tag and may require specialized care to maintain their appearance. The manufacturing process can also be complex and time-consuming.

Impact on Application: Exotic leathers are suitable for custom sheaths intended for luxury knives or as fashion accessories. Their unique characteristics can enhance the perceived value of the product.

Considerations for International Buyers: Buyers in Europe may be more familiar with exotic leathers and their market demand. However, compliance with CITES regulations regarding the trade of exotic animal products is essential.

Summary Table of Material Selection for Custom Leather Sheaths

| Material | Typical Use Case for custom leather sheath | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Outdoor knives, traditional sheaths | High durability, develops patina | More expensive, requires care | High |

| Chrome-Tanned Leather | Tactical and outdoor sheaths | Water-resistant, flexible | Less aesthetic appeal, environmental concerns | Medium |

| Synthetic Leather | Budget-friendly sheaths | Affordable, easy to maintain | Less durable, less breathable | Low |

| Exotic Leathers | High-end luxury sheaths | Unique aesthetic, high durability | High cost, requires specialized care | High |

This guide aims to equip international B2B buyers with the necessary insights to make informed decisions regarding material selection for custom leather sheaths, ensuring that they meet both performance and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather sheath

What Are the Key Stages in the Manufacturing Process of Custom Leather Sheaths?

The manufacturing of custom leather sheaths involves several critical stages that ensure both functionality and aesthetic appeal. Each stage requires skilled craftsmanship and attention to detail.

Illustrative image related to custom leather sheath

Material Preparation: Sourcing and Selecting High-Quality Leather

The first step in the manufacturing process is the selection of high-quality leather. Most reputable manufacturers prefer English bridle leather due to its durability and appealing finish. The leather is sourced from trusted suppliers who comply with ethical practices.

Once sourced, the leather undergoes a preparation process, which includes conditioning and cutting to the required dimensions. This is crucial, as the quality of the leather directly impacts the final product’s performance and longevity.

Forming: Shaping the Leather to Fit Specific Designs

After preparation, the leather is formed into the desired shape. This process may include wet molding, where the leather is dampened and shaped around a knife or tool to ensure a snug fit. Techniques such as hand-stitching and tooling are often employed to add design elements and enhance durability.

The forming stage is where customization becomes most evident. Buyers can specify details such as sheath style, color, and carry orientation (right or left), ensuring that the final product meets their unique requirements.

Illustrative image related to custom leather sheath

Assembly: Bringing Together Components for Functionality

In the assembly phase, various components, such as buckles, snaps, and rivets, are added to the sheath. Each part is selected based on its intended use and must withstand significant wear and tear. High-quality hardware, often military-grade, is preferred to guarantee longevity and functionality.

This stage may also involve additional processes like lining the sheath with softer materials to protect the blade and enhance usability. Attention to detail during assembly is crucial, as any oversight can affect the sheath’s performance.

Finishing: Ensuring Quality and Aesthetic Appeal

The final stage in the manufacturing process is finishing. This involves dyeing, polishing, and applying protective coatings to enhance the leather’s appearance and durability. Manufacturers often use natural dyes and finishes to maintain the leather’s integrity while providing an attractive look.

Quality control is integrated into this stage to ensure that the finished product meets both aesthetic and functional standards.

What Quality Assurance Measures Are Critical for Custom Leather Sheaths?

Quality assurance (QA) is essential in the custom leather sheath manufacturing process to ensure that products meet international and industry-specific standards. This is particularly important for B2B buyers who rely on consistent quality for their businesses.

Illustrative image related to custom leather sheath

What International Standards Should B2B Buyers Consider?

For manufacturers aiming to serve international markets, adherence to standards such as ISO 9001 is crucial. This quality management standard ensures that organizations consistently provide products that meet customer and regulatory requirements.

Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the intended use of the sheath. These certifications demonstrate compliance with European and industry-specific regulations, enhancing buyer confidence.

What Are the Key Quality Control Checkpoints?

To maintain high-quality standards, manufacturers typically implement several checkpoints during the production process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. It ensures that the leather and other components meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC checks are performed at various stages to identify any defects or deviations from specifications. This helps mitigate issues early in the process.

-

Final Quality Control (FQC): Once production is complete, FQC involves a thorough inspection of the finished product. This includes checking dimensions, craftsmanship, and overall appearance to ensure that the product meets quality expectations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify a supplier’s quality control measures:

-

Conduct Audits: Regular audits can provide insight into a manufacturer’s processes and adherence to quality standards. Buyers should consider scheduling audits, either in-person or remotely, to evaluate compliance.

-

Request Quality Reports: Suppliers should be able to provide documentation that outlines their quality control processes and any relevant certifications. This may include test results, inspection reports, and compliance certificates.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturing process and final products. This is especially important for international buyers who may not have direct oversight.

What Are the Unique Quality Control Considerations for International Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control. Factors such as varying regulations, cultural expectations, and logistical complexities can influence product quality.

Illustrative image related to custom leather sheath

-

Understanding Regional Standards: Buyers should familiarize themselves with local regulations and standards that may differ from international norms. This knowledge is crucial for ensuring compliance and avoiding potential legal issues.

-

Language and Communication Barriers: Clear communication is vital in the B2B landscape. Buyers should ensure that they can effectively communicate their requirements and expectations to suppliers, possibly involving translators if necessary.

-

Logistics and Shipping Concerns: Shipping leather products internationally can present challenges, including customs regulations and potential damage during transit. Buyers should work with experienced logistics partners to mitigate these risks.

Conclusion

The manufacturing process and quality assurance of custom leather sheaths are critical elements that B2B buyers must understand. By focusing on the key stages of manufacturing and implementing rigorous quality control measures, buyers can ensure they receive high-quality products that meet their specifications. Additionally, understanding international standards and unique regional considerations will empower buyers to make informed decisions and foster successful supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather sheath’

This guide serves as a practical checklist for international B2B buyers seeking to procure custom leather sheaths. By following these steps, you can ensure that you choose a supplier who meets your specifications and quality requirements, ultimately resulting in a successful procurement process.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications for your custom leather sheath. This includes dimensions, style, leather type, and any specific features such as retention systems or carry options. Having a detailed specification helps suppliers understand your needs and minimizes miscommunication, ensuring the final product aligns with your expectations.

Illustrative image related to custom leather sheath

- Dimensions: Specify the length, width, and depth to accommodate the knife or tool.

- Leather Type: Choose from options like bridle leather, which is durable and aesthetically pleasing.

Step 2: Research Potential Suppliers

Conduct thorough research on suppliers specializing in custom leather sheaths. Look for companies with a solid reputation and proven track records in the industry. Reviews and testimonials from previous clients can offer insights into their reliability and craftsmanship quality.

- Industry Experience: Seek suppliers with extensive experience in creating custom sheaths for the type of knives or tools you use.

- Portfolio: Review their past work to assess the quality and variety of their designs.

Step 3: Evaluate Supplier Capabilities

Not all suppliers have the same capabilities. Assess whether potential suppliers can meet your specific needs, such as customization options, production capacity, and turnaround times. A supplier’s ability to deliver on time is crucial, especially if you have a specific deadline.

- Customization Options: Ensure they can accommodate unique designs or modifications.

- Production Capacity: Confirm they can handle your order volume without compromising quality.

Step 4: Verify Material Quality

The quality of leather and hardware used in the sheath directly affects durability and functionality. Request samples of the leather and hardware to examine their quality firsthand. Understanding the materials will help you gauge whether they meet your standards for performance and longevity.

- Leather Quality: Look for full-grain or top-grain leather, as these are more durable and aesthetically pleasing.

- Hardware: Ensure that any metal components are rust-resistant and robust.

Step 5: Request Prototypes

Once you’ve narrowed down your supplier options, request prototypes or mock-ups of your custom sheath. This step is vital for assessing fit, design, and functionality before final production. Prototypes allow you to make adjustments based on real-world use, ensuring the final product meets your needs.

- Fit Testing: Ensure the sheath fits the knife or tool as intended.

- Design Adjustments: Use the prototype to refine any design elements or features.

Step 6: Confirm Pricing and Payment Terms

Discuss pricing structures and payment terms upfront to avoid any surprises later in the procurement process. Be clear about what is included in the price, such as shipping, taxes, and any additional customization fees. Transparent financial discussions are key to maintaining a healthy supplier relationship.

- Cost Breakdown: Request a detailed breakdown of costs to understand what you are paying for.

- Payment Terms: Clarify payment schedules and acceptable methods to ensure smooth transactions.

Step 7: Establish Communication Protocols

Effective communication is essential throughout the procurement process. Set up clear channels and protocols for ongoing communication with your chosen supplier. Regular updates and feedback can help address any issues promptly and ensure that the project stays on track.

- Point of Contact: Designate a specific person for all communications to streamline the process.

- Update Frequency: Agree on how often you will receive updates on production status.

By following these steps, you can navigate the complexities of sourcing custom leather sheaths and secure a product that meets your business needs effectively.

Comprehensive Cost and Pricing Analysis for custom leather sheath Sourcing

What Are the Key Cost Components in Custom Leather Sheath Production?

When analyzing the cost structure of custom leather sheaths, several components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to custom leather sheath

-

Materials: The type of leather used significantly influences the price. For instance, high-quality English bridle leather commands a premium due to its durability and aesthetic appeal. Additional materials, such as hardware for closures or decorative elements, will also affect overall costs.

-

Labor: Skilled craftsmanship is essential for producing high-quality leather sheaths. Labor costs can vary depending on the complexity of the design and the level of expertise required. Customization often necessitates more time, thus increasing labor expenses.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Custom sheath manufacturers often have lower overhead costs if they operate on a small scale or utilize home-based workshops.

-

Tooling: The initial investment in tools and machinery for custom designs can be substantial. However, these costs are amortized over time, particularly for manufacturers producing a high volume of products.

-

Quality Control (QC): Ensuring that each sheath meets quality standards requires systematic inspection processes. This adds to labor costs but is essential for maintaining brand reputation and minimizing returns.

-

Logistics: Shipping costs must be factored in, especially for international orders. Import duties and taxes can also impact the final price for buyers outside the manufacturer’s country.

-

Margin: Profit margins for custom leather sheath manufacturers typically range from 20% to 50%, depending on the level of customization and market demand.

What Influences Pricing for Custom Leather Sheaths?

Several factors can influence the pricing of custom leather sheaths, particularly for B2B buyers in international markets.

-

Volume/MOQ: Larger orders often lead to lower unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can also impact pricing, with suppliers offering discounts for bulk purchases.

-

Specifications and Customization: The more intricate the design or specific the requirements, the higher the cost. Custom features, such as unique stitching patterns or specialized closures, will add to the overall price.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., eco-friendly practices) can elevate costs. Buyers should assess whether these certifications align with their market needs.

-

Supplier Factors: The geographical location of suppliers, their reputation, and operational efficiencies can affect pricing. Suppliers with established relationships in the leather industry may offer better rates.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. They dictate responsibilities for shipping, insurance, and tariffs, which can significantly affect total costs.

How Can B2B Buyers Optimize Costs When Sourcing Custom Leather Sheaths?

To ensure cost efficiency when sourcing custom leather sheaths, buyers should consider the following strategies:

-

Negotiate Effectively: Engaging in transparent discussions with suppliers about pricing, especially for larger orders, can yield favorable terms. Establishing long-term relationships can also lead to better pricing over time.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the longevity and durability of the sheath. A higher upfront cost might lead to lower overall expenses if the product lasts longer and requires fewer replacements.

-

Understand Pricing Nuances for International Purchases: Be aware of currency fluctuations and international shipping costs. These can impact the final price significantly, especially for buyers from regions like Africa or South America.

-

Research Market Trends: Keeping abreast of industry trends and pricing can help buyers make informed decisions. Understanding seasonal demand and material availability can also aid in timing purchases for the best rates.

-

Request Samples: Before placing large orders, request samples to assess quality and fit. This can prevent costly mistakes and ensure that the final products meet expectations.

Disclaimer on Indicative Prices

Prices for custom leather sheaths can vary significantly based on specifications and supplier location. The figures provided in this analysis are indicative and should be verified with individual suppliers for accurate quotes tailored to specific requirements.

Alternatives Analysis: Comparing custom leather sheath With Other Solutions

Understanding Alternative Solutions to Custom Leather Sheaths

In the competitive landscape of knife protection and storage, custom leather sheaths are a popular choice among B2B buyers. However, it’s essential to evaluate alternative solutions that may offer different benefits, such as versatility, cost-effectiveness, or ease of production. This analysis will compare custom leather sheaths with two viable alternatives: synthetic sheaths and Kydex sheaths, providing insights for international buyers in diverse markets.

| Comparison Aspect | Custom Leather Sheath | Synthetic Sheath | Kydex Sheath |

|---|---|---|---|

| Performance | High durability; excellent fit and aesthetic appeal. | Moderate durability; can vary in fit and aesthetic. | Very high durability; precision fit and functional design. |

| Cost | Higher initial investment (typically $100-$300). | Generally lower cost (around $30-$100). | Moderate cost (around $50-$150). |

| Ease of Implementation | Requires detailed customization and manual crafting. | Quick production; often ready-to-ship items available. | Fast production; can be molded to fit specific knives. |

| Maintenance | Requires regular conditioning to prevent drying and cracking. | Minimal maintenance; easy to clean. | Low maintenance; resistant to moisture and wear. |

| Best Use Case | Ideal for collectors or high-end knife users seeking aesthetic value. | Suitable for budget-conscious buyers or casual users. | Best for tactical applications where durability and quick access are needed. |

Evaluating Synthetic Sheaths as an Alternative

Synthetic sheaths, often made from materials like nylon or polyester, offer a cost-effective solution for knife storage. They provide reasonable protection and are lightweight, making them easy to carry. However, the performance may not match that of custom leather sheaths, particularly regarding fit and aesthetic appeal. Synthetic options can vary in quality, which may affect durability over time. For B2B buyers in regions like Africa or South America, where budget constraints might be significant, synthetic sheaths can be an attractive alternative despite their limitations in aesthetics and durability.

Illustrative image related to custom leather sheath

Understanding Kydex Sheaths and Their Advantages

Kydex sheaths are made from a thermoplastic material that can be molded to the shape of the knife. This creates a highly durable and secure fit, ideal for tactical and outdoor use. Kydex sheaths are also resistant to moisture and wear, making them suitable for environments where exposure to the elements is a concern. While they offer excellent performance, their aesthetic appeal may not match that of custom leather options. Kydex sheaths strike a balance between cost and functionality, making them ideal for businesses that prioritize performance in demanding conditions.

How to Choose the Right Knife Sheath Solution for Your Needs

When considering the best sheath solution for your business, assess your specific needs and priorities. Custom leather sheaths are perfect for those valuing craftsmanship and aesthetics, while synthetic and Kydex alternatives provide practical options for various use cases and budgets. B2B buyers should evaluate factors such as the intended use of the knife, budget constraints, and the desired level of customization before making a decision. By aligning your choice with your operational requirements, you can ensure that your investment in knife sheaths will enhance your overall product offering and customer satisfaction.

Essential Technical Properties and Trade Terminology for custom leather sheath

What are the Key Technical Properties of Custom Leather Sheaths?

When considering a custom leather sheath, understanding the technical properties is vital for ensuring quality and functionality. Here are several critical specifications that play a significant role in the selection process:

-

Material Grade

The quality of leather used in custom sheaths can vary significantly. High-grade materials, such as English bridle leather or vegetable-tanned leather, offer durability, flexibility, and resistance to wear. For B2B buyers, opting for superior material grades is essential to ensure that the sheath will withstand rigorous use and maintain its aesthetic appeal over time. -

Thickness

The thickness of the leather directly impacts the sheath’s strength and protection level. Common thicknesses range from 4 to 8 ounces, with thicker leather providing better protection for the blade. Understanding thickness is crucial for B2B buyers, as it affects both the sheath’s weight and its ability to protect the knife during transport. -

Stitching Method

The stitching technique used in crafting the sheath is another critical property. Hand-stitched sheaths, for example, typically offer superior strength and durability compared to machine-stitched options. B2B buyers should consider the stitching method as it affects the longevity of the product and its resistance to wear and tear. -

Retention System

A well-designed retention system ensures that the knife remains securely in place while allowing for easy access. Common systems include friction fits, snaps, or Velcro closures. For businesses, understanding the retention mechanism is vital to meet user preferences and operational needs, especially in high-mobility environments. -

Customization Options

The ability to customize aspects such as color, style, and additional features (like belt loops or attachment points) is a significant selling point. Customization allows businesses to cater to specific market demands and enhance their branding. This flexibility can differentiate a product in competitive markets.

What are Common Terms in the Custom Leather Sheath Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some key terms related to custom leather sheaths:

Illustrative image related to custom leather sheath

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of custom leather sheaths, an OEM might create sheaths for knife brands, emphasizing the importance of quality control and brand consistency. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. This is crucial for B2B buyers to understand, as it can impact inventory management and cash flow. Knowing the MOQ helps businesses plan their orders effectively. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. In the custom leather sheath market, submitting an RFQ can help buyers compare pricing and terms, ensuring they receive competitive offers from different manufacturers. -

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers, as they clarify costs, risks, and logistics involved in shipping custom leather sheaths across borders. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. This is particularly important in the custom leather sheath industry, where production may require specific crafting times. B2B buyers should assess lead times to ensure that their supply chain remains efficient and responsive to market demands. -

Bespoke Design

This term refers to products that are tailor-made to meet specific customer requirements. In the context of custom leather sheaths, bespoke design emphasizes the importance of client input in creating a product that perfectly fits their needs. Understanding bespoke options can enhance customer satisfaction and loyalty.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing custom leather sheaths, ensuring they meet both quality standards and market demands.

Navigating Market Dynamics and Sourcing Trends in the custom leather sheath Sector

What Are the Key Market Dynamics and Trends in the Custom Leather Sheath Sector?

The custom leather sheath market has seen significant growth driven by a rising demand for personalized, high-quality products. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly looking for unique solutions that reflect their specific needs and preferences. This trend is fueled by the growing popularity of outdoor activities and a resurgence in traditional craftsmanship, where consumers value the artistry and durability of handmade products.

Emerging technologies are also influencing the sourcing landscape. Digital platforms and custom order systems are streamlining the purchasing process, allowing buyers to specify their requirements more precisely. Moreover, advancements in materials science are leading to the development of innovative leather alternatives that can meet both functional and aesthetic needs. Buyers are encouraged to leverage these digital tools to enhance their procurement strategies and better connect with suppliers who can meet niche market demands.

Illustrative image related to custom leather sheath

Furthermore, the rise of e-commerce has facilitated access to global suppliers, enabling businesses in emerging markets to explore a broader range of options. This has created a more competitive landscape, compelling suppliers to differentiate their offerings through enhanced customization options, rapid turnaround times, and superior customer service. As the market evolves, international B2B buyers should remain attentive to these trends to capitalize on emerging opportunities and align their sourcing strategies accordingly.

How Does Sustainability Impact Sourcing in the Custom Leather Sheath Market?

Sustainability is becoming increasingly pivotal in the custom leather sheath sector, as both consumers and businesses prioritize ethical sourcing and environmental responsibility. The leather industry is often scrutinized for its environmental impact, particularly regarding deforestation and water usage associated with traditional tanning processes. Consequently, B2B buyers are urged to seek suppliers who utilize sustainable practices, such as sourcing leather from certified tanneries that adhere to strict environmental standards.

The importance of ethical supply chains cannot be overstated. Buyers should look for partners who can demonstrate transparency in their sourcing practices, ensuring that materials are sourced responsibly and that labor conditions are fair. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) can serve as indicators of a supplier’s commitment to sustainability.

Additionally, the demand for eco-friendly alternatives is on the rise. Suppliers are increasingly offering products made from vegetable-tanned leather or synthetic materials that mimic leather without the environmental drawbacks. By incorporating these sustainable options into their product lines, businesses can appeal to a growing segment of environmentally-conscious consumers, enhancing their market positioning and customer loyalty.

Illustrative image related to custom leather sheath

What Is the Historical Context of the Custom Leather Sheath Market?

The custom leather sheath market has its roots in traditional craftsmanship, where leatherworking was an essential skill among various cultures for thousands of years. Initially, leather sheaths were crafted for functional purposes, primarily to protect blades and tools used in daily life. Over time, as outdoor activities such as hunting and fishing gained popularity, the demand for specialized and durable sheaths grew, leading to the emergence of custom designs.

In recent decades, the revival of interest in handmade goods has further propelled the custom leather sheath market. Artisans and small-scale manufacturers have capitalized on this trend by offering bespoke solutions that combine practicality with personalized aesthetics. This evolution reflects broader consumer preferences for unique, high-quality products that stand out in a mass-produced world. Today, the market is characterized by a blend of traditional techniques and modern innovations, offering B2B buyers a rich landscape of options to explore.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather sheath

-

How do I ensure the quality of custom leather sheaths from suppliers?

To guarantee quality, start by vetting suppliers thoroughly. Look for manufacturers with a proven track record and positive reviews from previous clients. Request samples to assess craftsmanship and materials firsthand. It’s also beneficial to inquire about their production processes, including leather sourcing and stitching techniques. Establish clear quality assurance metrics in your contract, specifying acceptable standards for durability, aesthetics, and functionality. A reliable supplier should be willing to accommodate quality checks and provide detailed information about their craftsmanship. -

What are the key customization options for leather sheaths?

Customization options for leather sheaths can vary significantly by supplier but typically include dimensions, leather type, color, stitching style, and closure mechanisms. You may also request specific features like knife retention systems, belt attachments, or inlays. When placing an order, provide detailed specifications, including knife measurements and desired aesthetics. Engaging in a collaborative design process with the manufacturer can help ensure that the final product aligns with your vision and meets functional requirements. -

What are the minimum order quantities (MOQs) for custom leather sheaths?

Minimum order quantities for custom leather sheaths can vary widely depending on the supplier and the complexity of your design. Typically, MOQs may range from 10 to 50 units for custom orders, but some manufacturers may accommodate smaller orders at a higher price per unit. When negotiating, clarify your needs and explore options for trial orders or smaller batches, especially if you are a new buyer or testing a new market. Be sure to discuss pricing tiers based on volume to maximize your budget. -

What payment terms should I expect when ordering custom leather sheaths?

Payment terms for custom leather sheath orders can differ among suppliers. Common practices include a deposit upfront (often 30-50%) with the balance due upon completion or delivery. Some suppliers may offer net payment terms, allowing you to pay after receiving the goods. Always negotiate terms that align with your financial capabilities and risk tolerance. Ensure that these terms are clearly outlined in your contract, including any penalties for late payments or conditions for refunds. -

How do I manage logistics for shipping custom leather sheaths internationally?

Managing logistics for international shipping involves several critical steps. First, verify the supplier’s shipping capabilities and their experience with international orders. Choose a reliable shipping method that balances cost and delivery speed, considering customs regulations in your country. It’s essential to understand all applicable import duties and taxes to avoid unexpected expenses. Using a freight forwarder can simplify the process, offering expertise in documentation and compliance. Always track shipments to ensure timely delivery and address any issues that arise during transit. -

What are the common quality assurance practices for leather sheaths?

Quality assurance in leather sheath production typically involves several practices. Suppliers should conduct inspections at various stages of production, including raw material sourcing, during manufacturing, and before shipping. Common checks include assessing leather quality, stitching integrity, and overall craftsmanship. Request documentation of quality tests or certifications from your supplier to ensure compliance with industry standards. Establishing clear communication about your expectations and conducting periodic audits can further enhance quality assurance throughout the production process. -

How can I verify a supplier’s credibility in the custom leather sheath market?

Verifying a supplier’s credibility involves several steps. Start by checking their business history, including years in operation and client testimonials. Look for industry certifications or affiliations that demonstrate their commitment to quality and ethical practices. Conduct online research for reviews on platforms like Trustpilot or social media to gauge customer experiences. Additionally, request references from previous clients and consider visiting their production facility if feasible. These steps will help you assess their reliability and ability to meet your specific needs. -

What types of leather are recommended for durability in custom sheaths?

For durable custom leather sheaths, high-quality leather types such as full-grain and top-grain leather are recommended. Full-grain leather is the most robust option, retaining its natural texture and developing a unique patina over time. Top-grain leather is also durable but has a sanded surface for a more uniform appearance. Consider the intended use of the sheath when selecting leather; for outdoor or rugged applications, opt for thicker leather. Always inquire about the leather’s source and tanning process to ensure it meets your durability and aesthetic requirements.

Top 8 Custom Leather Sheath Manufacturers & Suppliers List

1. Lazy 3 Leather Co – Custom Knife Sheath

Domain: lazy3leatherco.com

Registered: 2019 (6 years)

Introduction: Custom Knife Sheath Request from Lazy 3 Leather Company. Regular price: $235.00 USD. Handcrafted from high-quality US sourced English bridle leather. Made to order and tailored to specific requests. Information needed for custom order includes: knife length, blade width at widest point, handle width, style of sheath, leather color (options: brown, black, natural, t-latigo, chestnut), and right or …

2. Leather by Storm – Key Products

Domain: leatherbystorm.com

Registered: 2024 (1 years)

Introduction: Key Products: The Drifter ($95.00), The Expedition ($140.00), The Rumor ($125.00), The Traveler ($125.00), The Pioneer ($125.00), The Revelation ($275.00), The Frontiersman ($140.00), The Vagabond ($90.00). All products are custom built to order and made from high quality English Bridle leathers with military grade hardware. Each item is hand stitched and comes with a Full Lifetime Warranty.

3. Diomedes Industries – Custom Knife Sheaths

Domain: diomedesindustries.com

Registered: 2016 (9 years)

Introduction: Custom sheaths designed for various knives, tailored to individual needs and preferences. Key examples include: 1. Nicole Apelian’s Cross Draw: Pancake-style sheath with a ¾ top opening and unique closure system, designed for a Bolo/Kukri blade. 2. Melissa Miller’s Baldric System: Extra-long baldric strap and sheath setup for versatility in challenging environments. 3. A Lined Bowie Sheath: Made w…

4. Custom Cowboy Shop – Diamondback Full Elk Handle Knife

Domain: customcowboyshop.com

Registered: 2000 (25 years)

Introduction: [{‘name’: ‘3 3/4″ Diamondback Full Elk Handle Knife’, ‘price’: ‘$250.00’}, {‘name’: ‘2 3/4″ Blade Knife – Coffee Colored Wood and Bone Handle’, ‘price’: ‘$126.00’}, {‘name’: ‘2 3/4″ Blade Knife – Coffee Colored Wood Handle’, ‘price’: ‘$84.00’}, {‘name’: ‘2 3/4″ Blade Belt Knife Bone and Walnut Wood Handle’, ‘price’: ‘$142.00’}, {‘name’: ‘2 1/4″ Blade Knife – Full Elk Handle’, ‘price’: ‘$122.00’}, …

5. Ramos Customs – Handcrafted Leather Sheaths

Domain: ramoscustoms.com

Registered: 2012 (13 years)

Introduction: Custom leather sheaths handcrafted since 2010 in Northern New Jersey. Made from high-quality, vegetable-tanned leather sourced from top American tanneries. 100% handmade, offering a unique and tailored experience. Small batch production for custom knife makers. Custom laser engraving available. Commitment to craftsmanship with a promise to repair or replace if issues arise.

6. Grommets Leathercraft – Leather Pocket Sheath

Domain: grommetsleathercraft.com

Registered: 2017 (8 years)

Introduction: Sheaths available in various styles and materials including leather and Kydex. Price range for products varies from $50.00 to $200.00. Specific products include: 1. Leather Pocket Sheath for the Benchmade Dacian ($75.00 – $90.00) 2. Handmade leather Scabbard for the Albion I:33 ($125.00 – $200.00) 3. Medieval Hook Belt ($75.00) 4. Handmade Leather Axe Frog ($50.00) 5. Handmade Leather Cauldron Bag…

7. Grizzle Leather – Knife Sheaths

Domain: rgrizzleleather.com

Registered: 2008 (17 years)

Introduction: Knife Sheaths and Other Gear: Prices vary based on knife size and material (cowhide, exotic, horsehide). Standard cowhide prices listed; exotics and custom work incur additional charges. 1. Grizzle Special: Pouch style sheath, hard rolled horsehide, 2/3 oz veg tanned cowhide lining. Price: $125 (without firesteel loop), $145 (with firesteel loop) for 4″-5″ blades. Dangler style available for addit…

8. Seward Leather – Custom Leather Knife Sheaths

Domain: sewardleather.com

Registered: 2019 (6 years)

Introduction: Seward Leather offers custom leather knife sheaths made in Austin, Arkansas. Key features include: 1. Custom designs tailored to fit individual knives. 2. Options for carved, exotic, utility, and tooled sheaths. 3. Unique sheath designs that synchronize with the knife’s aesthetics. 4. Custom mixed die colors to complement the knife. 5. No pre-payment required; customers are billed only upon comple…

Strategic Sourcing Conclusion and Outlook for custom leather sheath

In the evolving landscape of custom leather sheaths, strategic sourcing emerges as a cornerstone for international B2B buyers looking to enhance their product offerings. By prioritizing high-quality materials, such as English bridle leather, and collaborating with reputable manufacturers, buyers can ensure they receive durable and aesthetically pleasing products that meet specific customer needs. Understanding the nuances of customization—from sheath style and color to carry orientation—enables businesses to cater to diverse markets, particularly in regions such as Africa, South America, the Middle East, and Europe.

As the demand for bespoke craftsmanship grows, leveraging partnerships with skilled artisans can provide competitive advantages. Not only does this foster innovation, but it also enhances brand reputation through quality assurance and customer satisfaction.

Illustrative image related to custom leather sheath

Looking ahead, the potential for growth in this niche market is substantial. Companies that embrace strategic sourcing and maintain open communication with suppliers will be better positioned to adapt to changing consumer preferences and market trends. Engage with trusted suppliers today to explore how custom leather sheaths can elevate your product line and satisfy your clientele’s evolving expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to custom leather sheath

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.