Introduction: Navigating the Global Market for leather lining

In the ever-evolving landscape of the leather industry, sourcing high-quality leather lining can be a pivotal challenge for international B2B buyers. As the demand for luxurious and durable materials grows, understanding the nuances of leather lining—its types, applications, and sourcing strategies—becomes essential for businesses aiming to enhance their product offerings. This comprehensive guide delves into the various types of leather lining available in the global market, including lambskin, cowhide, and goatskin, each offering unique characteristics that cater to specific applications, from fashion accessories to high-end footwear.

Moreover, this guide provides actionable insights on supplier vetting processes, ensuring that buyers can confidently select partners who adhere to quality standards and ethical practices. By exploring cost considerations and market trends, B2B buyers from diverse regions—including Africa, South America, the Middle East, and Europe—will be equipped with the knowledge necessary to make informed purchasing decisions. With an emphasis on quality, durability, and aesthetics, this resource empowers buyers to navigate the complexities of the leather lining market, ultimately enhancing their competitiveness and product appeal in a global marketplace.

Table Of Contents

- Top 7 Leather Lining Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather lining

- Understanding leather lining Types and Variations

- Key Industrial Applications of leather lining

- 3 Common User Pain Points for ‘leather lining’ & Their Solutions

- Strategic Material Selection Guide for leather lining

- In-depth Look: Manufacturing Processes and Quality Assurance for leather lining

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather lining’

- Comprehensive Cost and Pricing Analysis for leather lining Sourcing

- Alternatives Analysis: Comparing leather lining With Other Solutions

- Essential Technical Properties and Trade Terminology for leather lining

- Navigating Market Dynamics and Sourcing Trends in the leather lining Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather lining

- Strategic Sourcing Conclusion and Outlook for leather lining

- Important Disclaimer & Terms of Use

Understanding leather lining Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lambskin | Soft, lightweight, and supple; offers a luxurious feel | High-end garments, bags, and accessories | Pros: Luxurious appearance, soft texture. Cons: Less durable than other types. |

| Cowhide | Durable, thick, and resilient; strong structural integrity | Footwear, bags, and heavy-duty items | Pros: Highly durable, versatile. Cons: Heavier, can be less comfortable. |

| Goatskin | Flexible and pliable; offers a unique texture | Fashion items, gloves, and upholstery | Pros: Soft yet durable, versatile in applications. Cons: Can be more expensive. |

| Suede | Napped finish for a velvety texture; less formal appearance | Fashion accessories, interiors, and footwear | Pros: Luxurious feel, good for casual applications. Cons: More prone to staining. |

| Napa Leather | Premium quality, fine-grained finish; often aniline dyed | Luxury goods and high-quality products | Pros: Exceptional softness, rich appearance. Cons: Higher cost, requires care to maintain. |

What Are the Characteristics and Suitability of Lambskin Leather Lining?

Lambskin leather lining is recognized for its soft and lightweight qualities, making it a popular choice for high-end garments, bags, and accessories. Its luxurious feel adds a touch of elegance to any product. However, while lambskin offers a sophisticated aesthetic, it is less durable than other leather types, making it more suitable for items that prioritize appearance over heavy wear. B2B buyers should consider the intended use of the product and weigh the benefits of luxury against potential durability issues.

How Does Cowhide Leather Lining Compare in Terms of Durability?

Cowhide leather lining is known for its durability and thick texture, providing excellent structural integrity. This type is ideal for applications requiring robustness, such as footwear, bags, and heavy-duty items. Cowhide’s resilience ensures longevity, making it a cost-effective choice for businesses focusing on functional products. However, its heavier weight may affect the comfort of finished goods, which is a crucial consideration for B2B buyers targeting comfort-focused markets.

What Makes Goatskin Leather Lining a Versatile Option?

Goatskin leather lining stands out for its flexibility and unique texture, making it suitable for a wide range of applications, including fashion items, gloves, and upholstery. This leather type balances softness with durability, appealing to buyers looking for versatile solutions. While goatskin can be more expensive, its quality often justifies the investment, especially for products that require both aesthetic appeal and functional longevity.

Why Choose Suede Leather Lining for Fashion Accessories?

Suede leather lining features a napped finish that provides a velvety texture, making it a favored choice for fashion accessories, interiors, and footwear. Its luxurious feel adds a casual elegance to products. However, suede is more prone to staining and requires careful maintenance, which may deter some buyers. Businesses should consider their target market and product positioning when deciding to use suede, balancing the allure of its aesthetic against practical maintenance concerns.

What Are the Advantages of Using Napa Leather Lining?

Napa leather lining is celebrated for its premium quality and fine-grained finish, often dyed with aniline to enhance its appearance. This type is particularly suited for luxury goods and high-quality products, appealing to consumers seeking sophistication. While Napa leather offers exceptional softness and a rich look, it comes at a higher cost and requires diligent care to maintain its condition. B2B buyers should assess their market position and customer expectations when considering Napa leather for their product lines.

Key Industrial Applications of leather lining

| Industry/Sector | Specific Application of leather lining | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear | Lining for shoes and boots | Enhances comfort, durability, and aesthetic appeal of footwear. | Quality of leather (e.g., lambskin, goatskin), thickness, and softness. |

| Fashion and Apparel | Lining for jackets, bags, and garments | Provides structure, luxury feel, and protects skin from irritation. | Color options, flexibility, and compatibility with outer materials. |

| Automotive | Interior lining for car seats and interiors | Increases comfort and luxury, contributing to a premium user experience. | Compliance with safety standards, durability under various conditions. |

| Furniture | Lining for upholstered furniture | Adds durability and enhances aesthetic value, protecting against wear. | Fire resistance, ease of cleaning, and color matching with designs. |

| Bookbinding | Lining for covers and spines of books | Protects pages, adds elegance, and enhances longevity of books. | Availability of various textures, thickness, and environmental considerations. |

How is Leather Lining Utilized in the Footwear Industry?

In the footwear industry, leather lining is crucial for enhancing both comfort and durability. High-quality materials like lambskin and goatskin are often used to create a soft barrier between the foot and the shoe, reducing friction and preventing irritation. For B2B buyers, sourcing considerations include the leather’s thickness, softness, and quality, as these factors directly impact the end product’s comfort and longevity. Buyers from regions such as Africa and South America may also seek sustainable sourcing options to align with growing environmental concerns.

What Role Does Leather Lining Play in Fashion and Apparel?

In fashion and apparel, leather lining serves multiple purposes, from providing structure to adding a touch of luxury. It is commonly used in jackets, bags, and garments to protect the skin from direct contact with coarser outer materials. Buyers should consider the flexibility and color options of the leather to ensure compatibility with their designs. For international buyers, especially in Europe and the Middle East, understanding local trends and preferences can greatly enhance product appeal.

How is Leather Lining Applied in the Automotive Sector?

The automotive industry employs leather lining extensively for car interiors, particularly in seats and dashboards. This application not only enhances comfort but also elevates the overall aesthetic appeal, contributing to a premium user experience. Key sourcing considerations include compliance with safety standards and the leather’s ability to withstand various environmental conditions, such as heat and humidity. Buyers in regions like Saudi Arabia may prioritize materials that offer durability under extreme weather.

What Benefits Does Leather Lining Provide in Furniture Manufacturing?

In furniture manufacturing, leather lining adds both durability and aesthetic value to upholstered pieces. It protects against wear and tear, ensuring that furniture maintains its appearance over time. When sourcing leather for this application, considerations such as fire resistance and ease of cleaning become critical, especially in commercial settings. Buyers from South America and Africa may also look for locally sourced materials to support regional economies.

How is Leather Lining Used in Bookbinding?

Leather lining is an essential component in bookbinding, providing protection to the pages and enhancing the book’s overall elegance. This application requires specific sourcing considerations, including the availability of various textures and thicknesses to meet diverse customer needs. Additionally, environmental factors, such as the leather’s sourcing and treatment processes, are increasingly important for buyers in Europe, who may prioritize sustainable options.

3 Common User Pain Points for ‘leather lining’ & Their Solutions

Scenario 1: Quality Discrepancies in Leather Lining Materials

The Problem:

B2B buyers often face challenges when sourcing leather lining due to variations in quality. For instance, a manufacturer may receive leather that appears perfect but lacks the durability or softness expected for their specific application, such as high-end handbags or shoes. This inconsistency can lead to product returns, brand reputation damage, and ultimately, financial losses. Buyers in regions like Africa or South America may struggle even more, given the limited availability of premium leather vendors and the complexities of international shipping.

The Solution:

To mitigate quality discrepancies, B2B buyers should implement a rigorous supplier evaluation process. This includes requesting samples from multiple suppliers and conducting a comparative analysis of the leather’s texture, weight, and finish. Utilize quality certifications, such as ISO or specific tanning industry standards, to ensure the leather meets predetermined specifications. Establishing a long-term relationship with a reliable supplier can also yield better consistency over time. Additionally, consider investing in third-party inspections for bulk orders to confirm the leather meets your quality expectations before shipment.

Scenario 2: Understanding the Right Leather Type for Specific Applications

The Problem:

Another common challenge is selecting the appropriate leather type for specific lining applications. For example, a buyer may need a lining for luxury footwear but might mistakenly choose a leather that is too heavy or not breathable enough, leading to discomfort for the end-user. This is particularly critical in competitive markets like Europe, where customer expectations for quality and comfort are high.

The Solution:

To make informed choices, buyers should familiarize themselves with the various types of leather and their characteristics. For instance, lambskin is soft and lightweight, making it ideal for luxury items, while cowhide offers durability for more rugged products. Providing detailed specifications to suppliers, such as thickness, texture, and intended use, can help in sourcing the correct material. Additionally, engaging with leather experts or consultants can provide valuable insights on the latest trends and technologies in leather lining, enabling buyers to make well-informed decisions that enhance product quality.

Scenario 3: Cost Management in Sourcing Leather Lining

The Problem:

Cost management is a persistent concern for B2B buyers, especially when sourcing leather lining from international suppliers. Fluctuating prices, unexpected tariffs, and shipping costs can significantly affect the bottom line. Buyers in the Middle East and Asia may find themselves paying more than anticipated, impacting their pricing strategies and profit margins.

The Solution:

To better manage costs, buyers should adopt a strategic sourcing approach. This involves not only negotiating better terms with suppliers but also exploring alternative materials or blends that could reduce costs without compromising quality. Building a diverse supplier network can also provide flexibility to switch between vendors based on price fluctuations. Additionally, consider bulk purchasing or long-term contracts to lock in prices and reduce the impact of market volatility. Employing a cost-benefit analysis tool can help in comparing total costs from different suppliers, ensuring that budget constraints are met while maintaining product standards.

Strategic Material Selection Guide for leather lining

What Are the Key Properties of Common Leather Lining Materials?

When selecting leather lining materials, understanding their properties is crucial for ensuring product performance and longevity. Here, we analyze four common materials used in leather lining: lambskin, cowhide, goatskin, and suede. Each material offers unique characteristics that can significantly impact the final product.

How Does Lambskin Perform as a Leather Lining Material?

Lambskin is renowned for its softness and lightweight nature, making it an ideal choice for high-end products such as luxury handbags and jackets. Its supple texture provides a comfortable barrier against the skin, enhancing user experience. However, lambskin is less durable than other leathers, which may limit its suitability for products subjected to heavy wear.

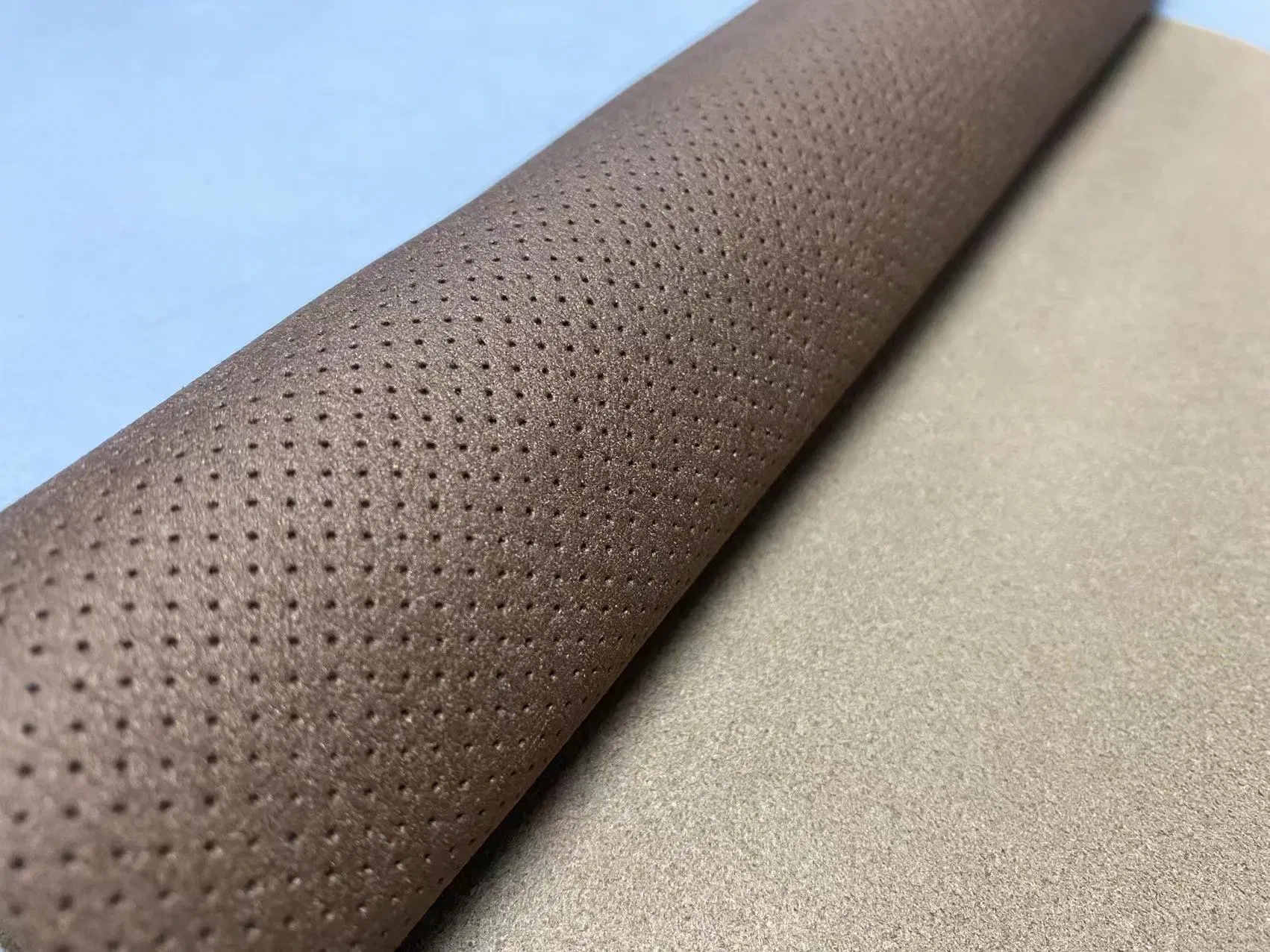

Illustrative image related to leather lining

From a B2B perspective, international buyers should consider the sourcing of lambskin, as it often requires compliance with animal welfare standards. Additionally, the material’s susceptibility to moisture can be a concern in humid climates, necessitating careful handling and storage.

What Advantages and Disadvantages Does Cowhide Offer for Leather Lining?

Cowhide is a robust and durable leather, making it suitable for products that demand longevity, such as work boots and heavy-duty bags. Its thickness provides excellent protection and structure, ensuring the lining retains its shape over time. However, cowhide can be heavier and less flexible than other options, which may affect the overall comfort and aesthetic of the final product.

For international buyers, cowhide must meet various compliance standards, such as ASTM for safety and performance. Additionally, its production involves more complex tanning processes, which can impact lead times and costs.

Illustrative image related to leather lining

Why Choose Goatskin for Leather Lining Applications?

Goatskin is a versatile material known for its resilience and flexibility. It strikes a balance between softness and durability, making it suitable for a wide range of applications, from clothing to accessories. Goatskin also tends to be more cost-effective than lambskin, providing a good compromise between quality and price.

However, goatskin may not provide the same level of luxury feel as lambskin, which could be a drawback for high-end products. International buyers should be aware of regional preferences, as goatskin is often favored in markets where durability is prioritized over luxury.

What Role Does Suede Play in Leather Lining Choices?

Suede, made from the underside of animal skin, offers a unique texture and luxurious feel, making it popular for lining high-fashion items. Its napped surface provides a soft touch, enhancing the overall comfort of products. However, suede is less resistant to stains and moisture, which can limit its application in certain environments.

For B2B buyers, understanding the maintenance requirements of suede is essential, especially in regions with high humidity or dust. Compliance with environmental regulations regarding suede tanning processes should also be considered, as these can vary significantly across different countries.

Summary Table of Leather Lining Materials

| Material | Typical Use Case for leather lining | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lambskin | Luxury handbags, jackets | Soft and lightweight | Less durable, moisture-sensitive | High |

| Cowhide | Work boots, heavy-duty bags | Durable and robust | Heavier, less flexible | Medium |

| Goatskin | Clothing, accessories | Versatile and cost-effective | Less luxurious feel than lambskin | Medium |

| Suede | High-fashion items | Luxurious texture | Less resistant to stains and moisture | Medium |

This analysis provides a comprehensive overview of the materials commonly used for leather lining, equipping international B2B buyers with the insights needed to make informed purchasing decisions. Understanding the properties, advantages, and limitations of each material will enable buyers to select the most suitable options for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for leather lining

What Are the Key Stages in the Manufacturing Process of Leather Lining?

The manufacturing process for leather lining involves several critical stages, each contributing to the quality and functionality of the final product. Understanding these stages helps B2B buyers ensure they source high-quality materials that meet their specific needs.

1. Material Preparation: Sourcing and Selection

The first step in manufacturing leather lining is sourcing high-quality hides. Common types used include lambskin, cowhide, and goatskin. Suppliers often assess the hides for thickness, grain quality, and color consistency. This stage also involves tanning, which can be done through chrome or vegetable tanning processes, significantly affecting the leather’s properties. Tanning not only preserves the hides but also enhances their aesthetic and functional attributes.

2. Forming: Cutting and Shaping

Once the hides are prepared, the next step is cutting them into the desired shapes and sizes. Advanced cutting techniques, such as die cutting or laser cutting, are often employed to ensure precision and minimize waste. This process is essential for maintaining uniformity across batches, which is crucial for large-scale production. The cut pieces are then subjected to a quality check to ensure they meet predetermined specifications.

3. Assembly: Attaching the Lining

In the assembly phase, the leather lining is attached to the primary product, whether it be shoes, bags, or jackets. This can be achieved using various methods, including sewing, gluing, or a combination of both. Depending on the design, additional features like pockets or compartments may be integrated during this stage. The assembly process requires skilled labor to ensure the lining is not only functional but also aesthetically pleasing.

4. Finishing: Final Treatments and Quality Checks

The final stage involves finishing touches that enhance the leather’s appearance and durability. This may include buffing, applying protective coatings, or dyeing. Each piece is subjected to rigorous quality checks to ensure it meets the desired standards. This finishing process is crucial for providing the leather lining with a luxurious feel and ensuring longevity in use.

What International Standards Are Relevant for Quality Assurance in Leather Lining?

Quality assurance in the leather lining industry is governed by various international standards and practices. These standards ensure that products are safe, reliable, and of high quality, which is particularly important for B2B buyers in diverse markets.

ISO 9001: What It Means for Leather Lining Suppliers

ISO 9001 is a widely recognized standard for quality management systems. Suppliers adhering to this standard demonstrate their commitment to consistent quality and customer satisfaction. This certification involves regular audits and continuous improvement processes, making it a reliable indicator of quality for B2B buyers.

CE Marking: Ensuring Compliance with European Standards

For suppliers targeting the European market, CE marking is crucial. This certification indicates that the leather lining complies with health, safety, and environmental protection standards set by the European Union. B2B buyers should inquire about CE certification to ensure that products meet these stringent requirements.

Illustrative image related to leather lining

API Standards: Importance for Specific Applications

For industries such as automotive or aerospace, adherence to API (American Petroleum Institute) standards may be necessary. These standards ensure that materials used can withstand specific conditions and perform reliably. Buyers should verify the relevance of such certifications based on their application needs.

What Are the Key Quality Control Checkpoints in Leather Lining Manufacturing?

Implementing effective quality control (QC) measures is essential in the leather lining manufacturing process. Several checkpoints can help ensure that the final products meet quality standards.

Incoming Quality Control (IQC): Assessing Raw Materials

IQC involves inspecting incoming materials to ensure they meet specified criteria before production begins. This may include visual inspections, measurements, and testing for defects. Implementing stringent IQC processes helps mitigate risks associated with substandard materials, ultimately leading to higher-quality finished products.

In-Process Quality Control (IPQC): Monitoring Production

During the manufacturing process, IPQC is essential for maintaining quality standards. Regular checks at various stages of production help identify issues early, allowing for timely corrections. This might include monitoring cutting precision, stitching quality, and adherence to design specifications.

Final Quality Control (FQC): Ensuring Product Readiness

FQC is the last checkpoint before products are shipped to customers. This stage involves thorough inspections of the finished leather lining products, assessing them for defects, color consistency, and overall quality. Buyers should expect detailed reports on FQC processes to ensure transparency and accountability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers to ensure they are receiving high-quality leather lining products.

Conducting Supplier Audits: What to Look For

Conducting on-site audits is one of the most effective ways to assess a supplier’s quality control processes. During these audits, buyers should evaluate the supplier’s production methods, quality management systems, and compliance with international standards. This firsthand insight helps build trust and ensures that suppliers are committed to quality.

Illustrative image related to leather lining

Requesting Quality Reports: Importance of Documentation

Buyers should request detailed quality reports from suppliers, including documentation of IQC, IPQC, and FQC processes. These reports should outline inspection results, testing methods, and corrective actions taken for any defects found. Reviewing these documents can provide buyers with a clearer understanding of the supplier’s quality assurance measures.

Utilizing Third-Party Inspections: Ensuring Objectivity

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can conduct random sampling and testing of products, ensuring compliance with international standards. B2B buyers can leverage these inspections as an additional layer of assurance before finalizing their orders.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

When sourcing leather lining from international suppliers, buyers must navigate various nuances related to quality control and certification.

Understanding Regional Certification Requirements

Different regions may have specific certification requirements that must be met for leather lining products. For instance, buyers in Europe may prioritize CE marking, while those in the Middle East might focus on compliance with local standards. Understanding these regional nuances is crucial for avoiding compliance issues.

Adapting to Different Quality Expectations

Quality expectations can vary significantly across markets. For example, buyers from Africa may prioritize durability and cost-effectiveness, while those in Europe may emphasize luxury and aesthetic appeal. B2B buyers should clearly communicate their quality expectations to suppliers to ensure alignment.

Conclusion

Navigating the complexities of manufacturing processes and quality assurance for leather lining requires an informed approach. By understanding the key stages in production, relevant international standards, and effective quality control measures, B2B buyers can make educated decisions when sourcing leather lining products. Verifying supplier practices through audits, quality reports, and third-party inspections further enhances confidence in product quality, ultimately leading to successful business partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather lining’

To assist B2B buyers in the procurement of leather lining, this guide outlines a structured checklist aimed at ensuring quality, compliance, and suitability for your specific needs. By following these steps, you can effectively navigate the sourcing process, minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing the right leather lining. Determine the type of leather (e.g., lambskin, cowhide, goatskin) based on the end product’s requirements, such as durability, flexibility, and aesthetic appeal. Consider the thickness, weight, and finish that will best complement your products.

Illustrative image related to leather lining

- Thickness Range: Identify whether you need light (1-2 oz) or heavier (2-3 oz) leather.

- Type of Finish: Decide between aniline, suede, or other finishes that align with your brand’s quality standards.

Step 2: Research and Identify Potential Suppliers

Invest time in researching potential suppliers who specialize in leather lining. Look for manufacturers with a strong reputation in the industry and those who have experience exporting to your target markets, particularly in regions like Africa, South America, the Middle East, and Europe.

- Supplier Directories: Utilize platforms like Alibaba, Global Sources, or industry-specific directories.

- Trade Shows: Attend leather and textile trade shows to meet suppliers and evaluate their offerings firsthand.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, it’s vital to verify their certifications. This step ensures that the leather lining meets international standards for quality and sustainability, which is particularly important for markets with strict regulations.

- Sustainability Certifications: Look for certifications like LWG (Leather Working Group) or ISO standards.

- Quality Assurance: Confirm that suppliers conduct regular quality checks and can provide evidence of compliance.

Step 4: Request Samples

Once you have shortlisted suppliers, request samples of their leather lining products. Evaluating samples allows you to assess the quality, texture, and suitability for your specific applications, ensuring they meet your expectations before placing a bulk order.

Illustrative image related to leather lining

- Sample Size: Ask for sufficient material to test in your production environment.

- Comparison: Compare samples from different suppliers to gauge variations in quality and price.

Step 5: Negotiate Pricing and Terms

Engage in discussions about pricing, payment terms, and delivery schedules. Effective negotiation can yield better pricing structures and favorable terms that align with your budget and cash flow requirements.

- Volume Discounts: Inquire about discounts for bulk orders.

- Payment Flexibility: Explore payment options that could ease financial strain, such as installment payments or letters of credit.

Step 6: Assess Production Capacity and Lead Times

Understanding a supplier’s production capacity and lead times is crucial for planning your inventory and meeting market demands. Ensure that they can deliver on time without compromising quality.

- Production Timeline: Confirm the time required for producing your order size.

- Flexibility: Assess their ability to handle urgent orders or changes in demand.

Step 7: Establish Clear Communication Channels

Effective communication is essential throughout the sourcing process. Establish a reliable point of contact within the supplier’s organization to facilitate smooth interactions and prompt resolution of any issues.

Illustrative image related to leather lining

- Regular Updates: Set expectations for updates on production status and shipping.

- Language and Cultural Considerations: Be mindful of language barriers and cultural differences that may affect communication.

By adhering to this comprehensive sourcing checklist, B2B buyers can ensure a successful procurement process for leather lining, ultimately leading to high-quality products and satisfied customers.

Comprehensive Cost and Pricing Analysis for leather lining Sourcing

When sourcing leather lining for various products, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis delves into the key cost components, price influencers, and provides actionable buyer tips to enhance purchasing decisions.

What Are the Key Cost Components in Leather Lining Sourcing?

Materials: The primary cost driver in leather lining is the raw material itself. Prices vary significantly based on the type of leather, such as lambskin, goatskin, or calfskin, with softer, high-quality options like lambskin generally commanding a premium. For instance, lambskin leather can range from $43.20 to $72.00 per square foot, while calf lining is priced around $85.00 for 12-14 square feet.

Illustrative image related to leather lining

Labor and Manufacturing Overhead: Labor costs depend on the region of production and the complexity of the manufacturing process. Skilled artisans are often required for high-quality leather lining, which can increase labor expenses. Manufacturing overhead, including utilities, equipment maintenance, and factory rent, also contributes to the overall cost.

Tooling and Quality Control (QC): Initial tooling costs for cutting and shaping leather can be significant, especially for custom orders. Quality control is essential in ensuring the leather meets the desired specifications, which can add to the labor costs but is critical for maintaining product quality.

Logistics: Transportation and shipping costs can vary widely based on the supplier’s location and the buyer’s destination. For international shipments, factors such as customs duties, insurance, and freight charges must be considered in the total cost.

Margin: Suppliers typically add a profit margin to cover their expenses and risks. This margin can fluctuate based on market demand, competition, and the perceived value of the leather lining.

What Influences the Pricing of Leather Lining?

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing based on their demand forecast.

Specifications and Customization: Custom specifications—such as thickness, color, and texture—can impact pricing. Standardized products are usually more cost-effective than bespoke options.

Quality and Certifications: Higher quality leathers that come with certifications (such as eco-friendly or organic certifications) may cost more. Buyers should weigh the benefits of these certifications against their budget.

Supplier Factors: The supplier’s reputation, location, and production capabilities can significantly affect pricing. Established suppliers may charge more due to their reliability and quality assurance processes.

Illustrative image related to leather lining

Incoterms: Understanding the terms of shipping (Incoterms) is vital as they define the responsibilities of buyers and sellers in international transactions. Incoterms can influence costs related to shipping, insurance, and customs clearance.

What Tips Can Help Buyers Negotiate Better Prices for Leather Lining?

-

Negotiate Based on Total Cost of Ownership: Instead of focusing solely on the upfront price, consider the total cost of ownership, which includes maintenance, durability, and potential waste. This perspective can provide leverage in negotiations.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Consistent orders and clear communication about expectations can foster trust and loyalty.

-

Research Market Trends: Stay informed about market prices and trends in leather sourcing. This knowledge can provide leverage in negotiations and help buyers identify the best times to purchase.

-

Be Flexible with Specifications: If possible, be open to alternative leather types or colors that may be more cost-effective. Flexibility can lead to significant savings.

-

Consider Local Sourcing: For buyers in regions like Africa and South America, local sourcing can reduce logistics costs and delivery times. Engaging with regional suppliers may also offer competitive pricing and better understanding of local market dynamics.

Conclusion

Sourcing leather lining requires a nuanced understanding of the cost structure and pricing dynamics. By considering material quality, supplier relationships, and market trends, international buyers can make informed decisions that optimize their purchasing strategy. Remember that prices are indicative and can fluctuate based on various factors, so continuous market evaluation is essential for maintaining cost efficiency.

Alternatives Analysis: Comparing leather lining With Other Solutions

Introduction to Alternatives in Leather Lining Solutions

In the realm of leather products, lining is essential for enhancing comfort, durability, and aesthetic appeal. While leather lining is a popular choice, various alternatives exist that can cater to different needs and preferences. This analysis will compare leather lining with synthetic linings and fabric linings, providing B2B buyers with comprehensive insights into their performance, cost-effectiveness, and suitability for various applications.

Comparison Table

| Comparison Aspect | Leather Lining | Synthetic Lining | Fabric Lining |

|---|---|---|---|

| Performance | High durability, comfort | Good durability, lower comfort | Moderate durability, soft feel |

| Cost | Medium to high | Generally low | Low to medium |

| Ease of Implementation | Moderate (requires skilled labor) | Easy (machine-compatible) | Easy (machine-compatible) |

| Maintenance | Requires regular conditioning | Low maintenance, easy to clean | Moderate maintenance |

| Best Use Case | High-end products, luxury items | Budget-friendly items, casual wear | Casual apparel, accessories |

Detailed Breakdown of Alternatives

1. Synthetic Lining

Synthetic lining, often made from materials like polyester or nylon, provides a cost-effective alternative to leather. It is lightweight and resistant to moisture, making it suitable for various applications, particularly in budget-friendly products. However, while synthetic materials may offer decent durability, they typically lack the luxurious feel and breathability of leather, potentially leading to discomfort in prolonged wear. Additionally, synthetic linings can wear out more quickly than leather, especially under heavy use.

Illustrative image related to leather lining

2. Fabric Lining

Fabric linings, made from cotton, silk, or blends, are known for their softness and comfort. They are often used in casual apparel and accessories, providing a pleasant tactile experience. Fabric linings are generally more affordable than leather, making them attractive for budget-conscious consumers. However, they may not offer the same level of durability or structure as leather, which can affect the overall longevity of the product. Maintenance can also be a concern, as fabric may require more frequent cleaning to keep it looking fresh.

Conclusion: Choosing the Right Lining Solution for Your Needs

When selecting a lining solution, B2B buyers must consider several factors, including the intended application, target market, and budget constraints. Leather lining excels in high-end products where durability and luxury are paramount, while synthetic and fabric linings may be more suitable for budget-friendly or casual items. Understanding the pros and cons of each option will enable buyers to make informed decisions that align with their product offerings and customer expectations. Ultimately, the right choice will depend on balancing quality, cost, and the desired characteristics of the final product.

Essential Technical Properties and Trade Terminology for leather lining

Understanding the key technical properties and industry terminology of leather lining is crucial for B2B buyers in sectors like fashion, accessories, and upholstery. This knowledge aids in making informed purchasing decisions and ensuring product quality and compliance.

Illustrative image related to leather lining

What Are the Key Technical Properties of Leather Lining?

1. Material Grade

Material grade refers to the quality classification of leather based on factors such as source animal, processing methods, and overall integrity. Higher grades, like full-grain leather, offer superior durability and aesthetic appeal, making them ideal for high-end products. In contrast, lower grades may be more cost-effective but can compromise on quality. For B2B buyers, selecting the appropriate grade impacts both product longevity and customer satisfaction.

2. Weight and Thickness

Weight is typically measured in ounces per square foot (oz/sq ft), while thickness is expressed in millimeters (mm) or ounces. For example, lining leather weights can range from 1.5 oz to 2 oz. Lighter weights are often preferred for applications requiring flexibility, such as clothing, while heavier weights provide sturdiness for items like bags. Buyers must consider these specifications to ensure the leather meets the functional demands of their products.

3. Tannage Type

Tannage refers to the chemical process used to preserve the leather, with chrome and vegetable tanning being the most common methods. Chrome-tanned leather is known for its durability and resistance to moisture, making it suitable for various applications. Conversely, vegetable-tanned leather is often favored for its environmental friendliness and natural finish. Understanding the tanning type helps buyers evaluate the leather’s performance and suitability for specific uses.

4. Cutting Coefficient

The cutting coefficient is a measure of how easily leather can be cut and shaped during manufacturing. A higher cutting coefficient indicates better efficiency and yield during production, which is essential for cost management. For B2B buyers, this property affects production timelines and waste, directly impacting profitability.

Illustrative image related to leather lining

5. Color Fastness

Color fastness refers to the leather’s ability to retain its color when exposed to light, water, and abrasion. This property is vital for maintaining product aesthetics over time, especially in consumer-facing goods. Buyers should ensure that the leather lining meets color fastness standards to avoid product returns and enhance customer satisfaction.

What Are Common Trade Terms in the Leather Lining Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce goods for other brands under their specifications. In the leather industry, this often pertains to manufacturers creating leather linings for footwear, bags, or garments based on a buyer’s design. Understanding OEM relationships can help buyers leverage quality and customization in their products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their production needs while ensuring they can meet demand without overstocking.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and availability for specific products. In the context of leather lining, an RFQ can help buyers compare multiple suppliers and secure the best terms. This process is vital for budgeting and planning in procurement.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Common terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the cost and risk during transit. For B2B buyers, understanding Incoterms is essential for managing logistics and ensuring compliance with international trade regulations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, streamline their procurement processes, and foster successful partnerships in the leather lining industry.

Navigating Market Dynamics and Sourcing Trends in the leather lining Sector

What Are the Key Trends Shaping the Leather Lining Market?

The leather lining market is experiencing significant growth, driven by a surge in demand across various sectors, including fashion, automotive, and furniture. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly sourcing high-quality leather lining to enhance product durability and aesthetics. Notably, the trend towards customization and personalization is gaining traction, prompting suppliers to offer a diverse range of leather types, colors, and finishes. Additionally, advancements in technology, such as digital printing and automation, are revolutionizing the manufacturing process, allowing for faster production times and reduced costs.

Illustrative image related to leather lining

Another emerging trend is the rise of e-commerce platforms that facilitate direct sourcing from manufacturers. Buyers are leveraging these platforms to access a broader selection of materials and suppliers, streamlining the procurement process. Furthermore, the market is witnessing an increase in demand for lightweight and thin leather linings, particularly in the fashion industry, where comfort and style are paramount. As global supply chains evolve, B2B buyers must stay attuned to shifting market dynamics, including fluctuating raw material prices and trade regulations, to make informed sourcing decisions.

How Is Sustainability Influencing Leather Lining Sourcing Decisions?

Sustainability has become a pivotal consideration for B2B buyers in the leather lining sector. The environmental impact of leather production, particularly in relation to water usage and chemical waste, has prompted many companies to seek out sustainable sourcing options. Ethical supply chains are gaining importance, with buyers increasingly prioritizing suppliers that adhere to environmentally friendly practices. This includes the use of vegetable-tanned leather and chrome-free processes, which mitigate harmful effects on the environment.

Buyers are also looking for certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certification, which assure them of the sustainability and ethical practices of their suppliers. By integrating sustainable materials into their products, companies can not only reduce their environmental footprint but also appeal to a growing consumer base that values eco-friendly practices. As a result, B2B buyers are encouraged to establish partnerships with suppliers that prioritize sustainability, thereby enhancing their brand reputation and meeting regulatory requirements.

Illustrative image related to leather lining

What Is the Historical Context of Leather Lining in B2B Markets?

The use of leather lining dates back centuries, originally serving functional purposes in clothing and armor. Over time, the leather lining industry has evolved significantly, transitioning from traditional tanning methods to modern processes that emphasize quality and sustainability. The introduction of synthetic alternatives in the late 20th century posed challenges for natural leather, but the unique qualities of leather—such as its durability, breathability, and aesthetic appeal—have kept it in demand.

In recent years, the resurgence of handcrafted and artisanal products has reignited interest in high-quality leather linings, particularly in luxury markets. This evolution reflects a broader trend in consumer preferences, where quality and authenticity are increasingly valued over mass production. B2B buyers today are not only sourcing leather linings for their functionality but also for the rich heritage and craftsmanship associated with genuine leather, making it a compelling choice in an increasingly competitive marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of leather lining

-

How do I choose the right leather lining for my product?

Selecting the appropriate leather lining involves considering several factors, such as the intended use, desired aesthetics, and durability requirements. For products like bags or shoes, lambskin offers a soft touch and luxury, while cowhide is ideal for more durable applications. Additionally, evaluate the leather’s weight, thickness, and finish to ensure it aligns with your product’s specifications. Consulting with suppliers who specialize in leather can provide insights into the best options based on your specific needs. -

What types of leather are commonly used for lining?

Common types of leather used for lining include lambskin, goatskin, and cowhide. Lambskin is preferred for its softness and luxurious feel, making it ideal for high-end products. Goatskin is valued for its flexibility and durability, suitable for various applications. Cowhide offers strength and resilience, making it a great choice for items that require a tougher lining. Each type has unique characteristics that can enhance the functionality and appearance of your products. -

What is the minimum order quantity (MOQ) for leather lining?

Minimum order quantities for leather lining can vary significantly depending on the supplier and the type of leather. Generally, MOQs can range from 20 to 100 square feet or more, especially for custom orders. It’s important to discuss your needs with potential suppliers to understand their specific requirements and flexibility regarding MOQs. Some suppliers may offer smaller sample orders, allowing you to test the leather before committing to larger quantities. -

How can I ensure the quality of leather lining from suppliers?

To ensure the quality of leather lining, conduct thorough research on potential suppliers. Request samples to assess the leather’s texture, durability, and finish. Additionally, inquire about the supplier’s quality assurance processes and certifications. It’s also beneficial to read reviews and testimonials from other B2B buyers. Establishing a clear communication channel for quality expectations can help mitigate risks associated with sourcing leather from international suppliers. -

What payment terms should I expect when sourcing leather lining internationally?

Payment terms can vary by supplier and region, but common practices include a deposit upfront (often 30-50%) with the balance due upon delivery or after inspection. Some suppliers may offer flexible terms based on your business relationship or order size. It’s crucial to negotiate terms that work for both parties and consider using secure payment methods like letters of credit or escrow services for larger transactions to protect your investment. -

How do I handle logistics and shipping for international leather lining orders?

Managing logistics for international orders involves selecting reliable shipping partners and understanding customs regulations. Discuss shipping options with your supplier, including freight forwarders who can assist with documentation and customs clearance. Consider the shipping time, costs, and insurance for high-value orders. It’s also wise to familiarize yourself with import duties and taxes in your country to avoid unexpected expenses upon arrival. -

Can I customize leather lining colors and finishes?

Yes, many suppliers offer customization options for leather lining, including color, finish, and texture. When discussing your project, specify your requirements, and ask for samples of custom colors or finishes to ensure they meet your expectations. Customization may affect MOQs and lead times, so it’s essential to plan accordingly and communicate your needs early in the sourcing process. -

What certifications should I look for when sourcing leather lining?

When sourcing leather lining, look for certifications that indicate ethical and sustainable practices, such as the Leather Working Group (LWG) certification. This certification assesses the environmental impact of leather production. Additionally, certifications for chemical safety, like REACH compliance, ensure that the leather meets health and environmental standards. Requesting these certifications can help ensure that your sourcing aligns with your company’s sustainability goals and ethical practices.

Top 7 Leather Lining Manufacturers & Suppliers List

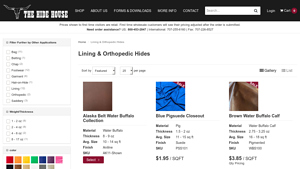

1. Hide & Leather House – Leather Lining for Orthopedic Use

Domain: hidehouse.com

Registered: 1996 (29 years)

Introduction: Leather Lining for Orthopedic Use from Hide & Leather House in Napa. Available hides include Goat, Calf, Sheep, Water-Buffalo-Calf, Cow, and Pig. Options for applications include Orthopedic, Lining, and more. Various finishes such as Aniline, Semi-Aniline, Suede, and Pigmented. Sizes range from 1 – 10 sq ft to 18 – 30 sq ft. Tannage options include Chrome and Veg. Temper options include Medium, So…

2. District Leathers – Slate Blue Stretch Lamb Suede

Domain: districtleathers.com

Registered: 2016 (9 years)

Introduction: This company, District Leathers – Slate Blue Stretch Lamb Suede, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

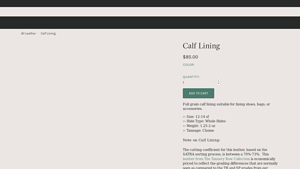

3. The Tannery Row – Calf Lining

Domain: thetanneryrow.com

Registered: 2011 (14 years)

Introduction: {“name”: “Calf Lining”, “price”: “$85.00”, “description”: “Full grain calf lining suitable for lining shoes, bags, or accessories.”, “size”: “12-14 sf”, “hide_type”: “Whole Hides”, “weight”: “1.25-2 oz”, “tannage”: “Chrome”, “cutting_coefficient”: “70%-73%”, “color_options”: [“Black”, “Faggio”, “Ivory”, “Tan”]}

4. American Bench Craft – Leather Lining Solutions

Domain: americanbenchcraft.com

Registered: 2014 (11 years)

Introduction: Leather lining is a thin piece of leather attached to the interior of leather products such as bags, jackets, or shoes. It provides structure, shape, and protects the user’s skin from direct contact with the leather. Types of leather used for lining include: 1. Lambskin – Soft, lightweight, supple, smooth, and delicate. 2. Cowhide – Durable, strong, tough, thick, and resilient. 3. Goatskin – Flexi…

5. BuyLeatherOnline – Affordable Leather Goods

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Introduction: {“price_range”:”$0.00 – $60.00″,”colors”:[{“name”:”White”,”count”:8},{“name”:”Talc”,”count”:1},{“name”:”Ivory – Off-White”,”count”:5},{“name”:”Beige – Natural”,”count”:13},{“name”:”Sand Beige”,”count”:5},{“name”:”Pinky Beige – Powder”,”count”:4},{“name”:”Greenish Beige – Kaki”,”count”:1},{“name”:”Lime”,”count”:1},{“name”:”Light Yellow”,”count”:2},{“name”:”Yellow”,”count”:3},{“name”:”Mustard”,”coun…

6. Samuel Hubbard – Premium Leather Linings

Domain: samuelhubbard.com

Registered: 2013 (12 years)

Introduction: Leather shoe linings are crucial for comfort and durability. Types include: 1. Textile Linings: Common in inexpensive shoes, absorb moisture quickly, wear out faster, and lead to odor. 2. Leather Linings: Durable, breathable, comfortable, conform to feet, and reduce chafing. Premium leather improves with age, while inexpensive leather may crack. 3. Shearling: Sourced from sheep, offers insulation …

7. Beckett Simonon – Types of Shoe Linings

Domain: beckettsimonon.com

Registered: 2012 (13 years)

Introduction: Types of Shoe Linings: 1. Leather Shoe Lining: Breathable, odor-controlling, moisture-wicking, and temperature-regulating. Ideal for sweaty feet and wearing without socks. Look for 100% full-grain leather. 2. Fleece Shoe Lining: Soft, warm, and cozy, mimicking lambs wool. Typically made from recycled plastic, not suited for refined footwear. 3. Polyester Shoe Lining: Common in cheaply made shoes, …

Strategic Sourcing Conclusion and Outlook for leather lining

What Are the Key Insights for B2B Buyers in Leather Lining Sourcing?

In today’s competitive landscape, strategic sourcing of leather lining is vital for enhancing product quality and customer satisfaction. Buyers should prioritize sourcing from reputable suppliers who offer a diverse range of materials, such as lambskin, goatskin, and calf lining, to meet varying aesthetic and functional needs. Understanding the unique characteristics of each type of leather—such as durability, softness, and visual appeal—will allow businesses to create superior products that stand out in the market.

How Can Strategic Sourcing Improve Your Leather Product Offerings?

Investing in high-quality leather lining not only reinforces the structure and longevity of products but also enhances comfort and luxury appeal. By leveraging strategic sourcing practices, companies can optimize their supply chains, reduce costs, and ensure consistent quality. Establishing strong relationships with suppliers can lead to better pricing and access to exclusive materials, crucial for maintaining a competitive edge.

What’s Next for International B2B Buyers?

As the global demand for premium leather products continues to rise, now is the time for international B2B buyers from regions like Africa, South America, the Middle East, and Europe to act. Engage with suppliers who understand your market needs and can provide tailored solutions. Embrace innovation in sourcing practices to stay ahead in a dynamic industry. The future of leather lining is bright—make it a part of your strategic vision today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.