Introduction: Navigating the Global Market for coated leather

In the dynamic global market, sourcing high-quality coated leather can be a daunting challenge for B2B buyers, particularly those navigating the diverse landscapes of Africa, South America, the Middle East, and Europe. With an array of options available, distinguishing between genuine coated leather and inferior alternatives is crucial for ensuring product integrity and customer satisfaction. This guide serves as a comprehensive resource, delving into the various types of coated leather, their applications across industries, effective supplier vetting practices, and insights into cost considerations.

Understanding the nuances of coated leather is essential for making informed purchasing decisions. This guide will illuminate the characteristics that differentiate coated leather, such as its thickness and surface treatments, while also highlighting its applications in sectors ranging from fashion to automotive interiors. By providing actionable insights and best practices, we empower international B2B buyers to navigate the complexities of the market confidently.

Furthermore, this guide addresses common misconceptions surrounding leather types, ensuring that buyers can avoid pitfalls associated with misleading terminology. Whether you are a manufacturer seeking durable materials or a retailer aiming to enhance your product offerings, this resource will equip you with the knowledge needed to select the right coated leather solutions for your business needs, ultimately fostering successful partnerships and sustainable growth.

Table Of Contents

- Top 7 Coated Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for coated leather

- Understanding coated leather Types and Variations

- Key Industrial Applications of coated leather

- 3 Common User Pain Points for ‘coated leather’ & Their Solutions

- Strategic Material Selection Guide for coated leather

- In-depth Look: Manufacturing Processes and Quality Assurance for coated leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘coated leather’

- Comprehensive Cost and Pricing Analysis for coated leather Sourcing

- Alternatives Analysis: Comparing coated leather With Other Solutions

- Essential Technical Properties and Trade Terminology for coated leather

- Navigating Market Dynamics and Sourcing Trends in the coated leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of coated leather

- Strategic Sourcing Conclusion and Outlook for coated leather

- Important Disclaimer & Terms of Use

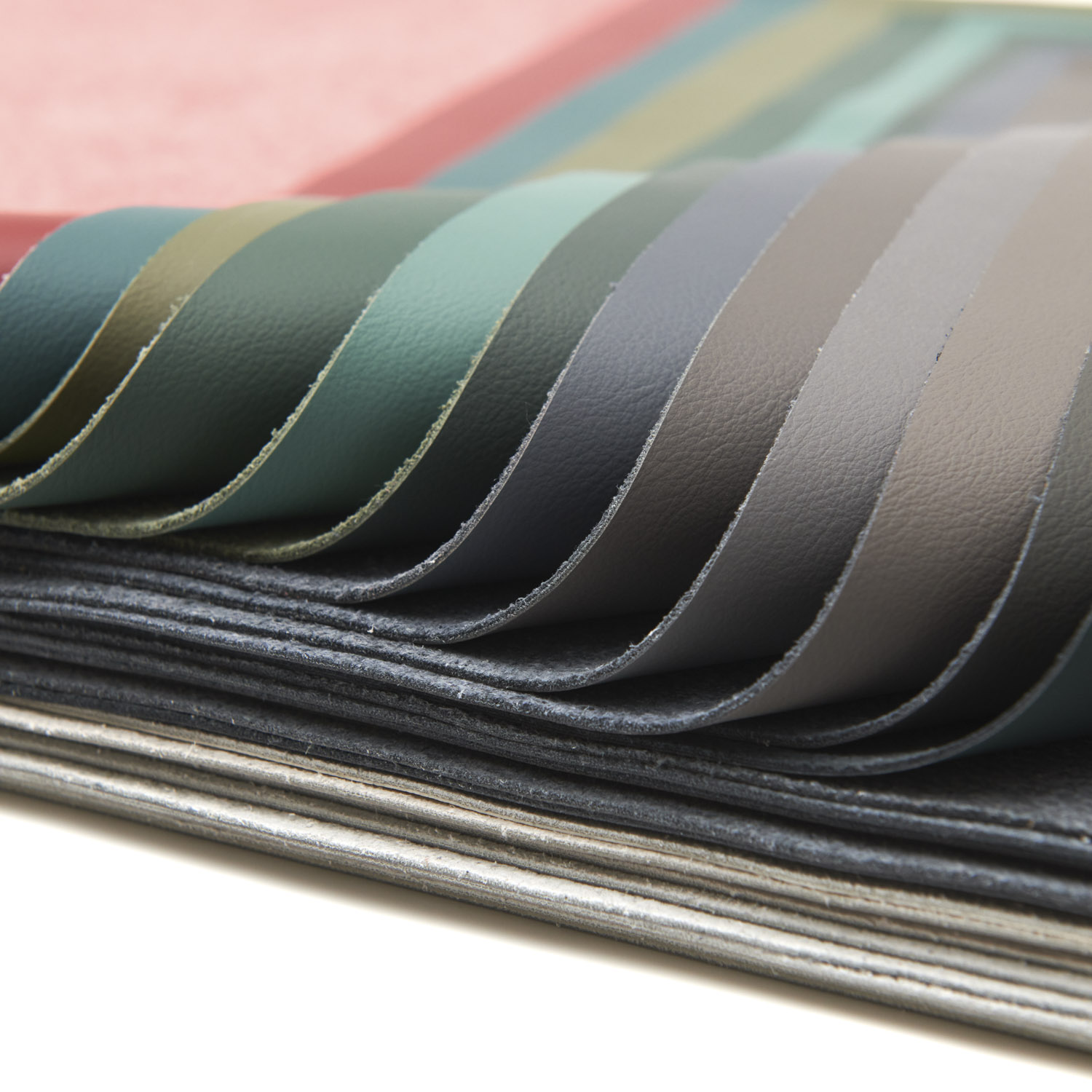

Understanding coated leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pigmented Coated Leather | Features a protective finish that enhances durability and color vibrancy. | Automotive interiors, furniture, accessories. | Pros: Highly durable, easy to maintain. Cons: Less breathable than untreated leather. |

| Patent Leather | Glossy finish with a high-shine appearance; often used for fashion items. | Fashion accessories, handbags, footwear. | Pros: Eye-catching, water-resistant. Cons: Can scuff easily, requires specific care. |

| Reptile-Effect Leather | Mimics the texture and appearance of reptile skins, often used in luxury products. | High-end fashion, luxury goods, upholstery. | Pros: Unique aesthetic appeal. Cons: Higher cost, niche market appeal. |

| Semi-Aniline Leather | Offers a balance of natural appearance with a light protective coating. | Premium furniture, automotive seating. | Pros: Retains natural look, more resistant to stains. Cons: Can be susceptible to wear if not maintained. |

| Corrected Grain Leather | Surface is sanded and treated for a uniform appearance; often dyed. | General leather goods, upholstery. | Pros: Cost-effective, consistent quality. Cons: Less natural feel, may lack unique character. |

What Are the Key Characteristics of Pigmented Coated Leather?

Pigmented coated leather is widely recognized for its robust protective finish, which not only enhances its color vibrancy but also significantly boosts its durability. This type of leather is commonly used in automotive interiors, furniture, and various accessories due to its resistance to wear and tear. For B2B buyers, the main consideration is its ease of maintenance and longevity, although it is less breathable than untreated leather, which may be a factor for specific applications.

How Does Patent Leather Stand Out in the Market?

Patent leather is distinguished by its high-gloss finish, making it particularly appealing for fashion items such as handbags and footwear. Its shiny surface is not only visually striking but also offers some water resistance. However, B2B buyers should be aware that while patent leather can attract attention, it is prone to scuffing and requires specialized care products to maintain its appearance. Therefore, understanding the care requirements is crucial for businesses looking to incorporate this material into their product lines.

Why Choose Reptile-Effect Leather for Luxury Products?

Reptile-effect leather is designed to mimic the texture and appearance of exotic reptile skins, making it a popular choice for high-end fashion and luxury goods. Its unique aesthetic appeal allows brands to differentiate their offerings in a competitive market. However, it tends to come with a higher price point and may cater to a niche audience, so B2B buyers should evaluate their target market’s preferences before making significant investments in this type of leather.

What Are the Benefits of Semi-Aniline Leather?

Semi-aniline leather strikes a balance between natural appearance and durability, featuring a light protective coating that helps resist stains while retaining the soft feel of genuine leather. This makes it an excellent choice for premium furniture and automotive seating. For B2B buyers, the key considerations include its aesthetic appeal and practicality, although they should note that it may still be susceptible to wear if not properly maintained.

How Is Corrected Grain Leather Used in Various Applications?

Corrected grain leather undergoes a process where its surface is sanded and treated to achieve a uniform appearance, often resulting in a more cost-effective option for general leather goods and upholstery. While it provides consistent quality, buyers should consider that it may lack the unique character and natural feel found in higher-grade leathers. Understanding the trade-offs between cost and quality is essential for B2B buyers looking to make informed purchasing decisions.

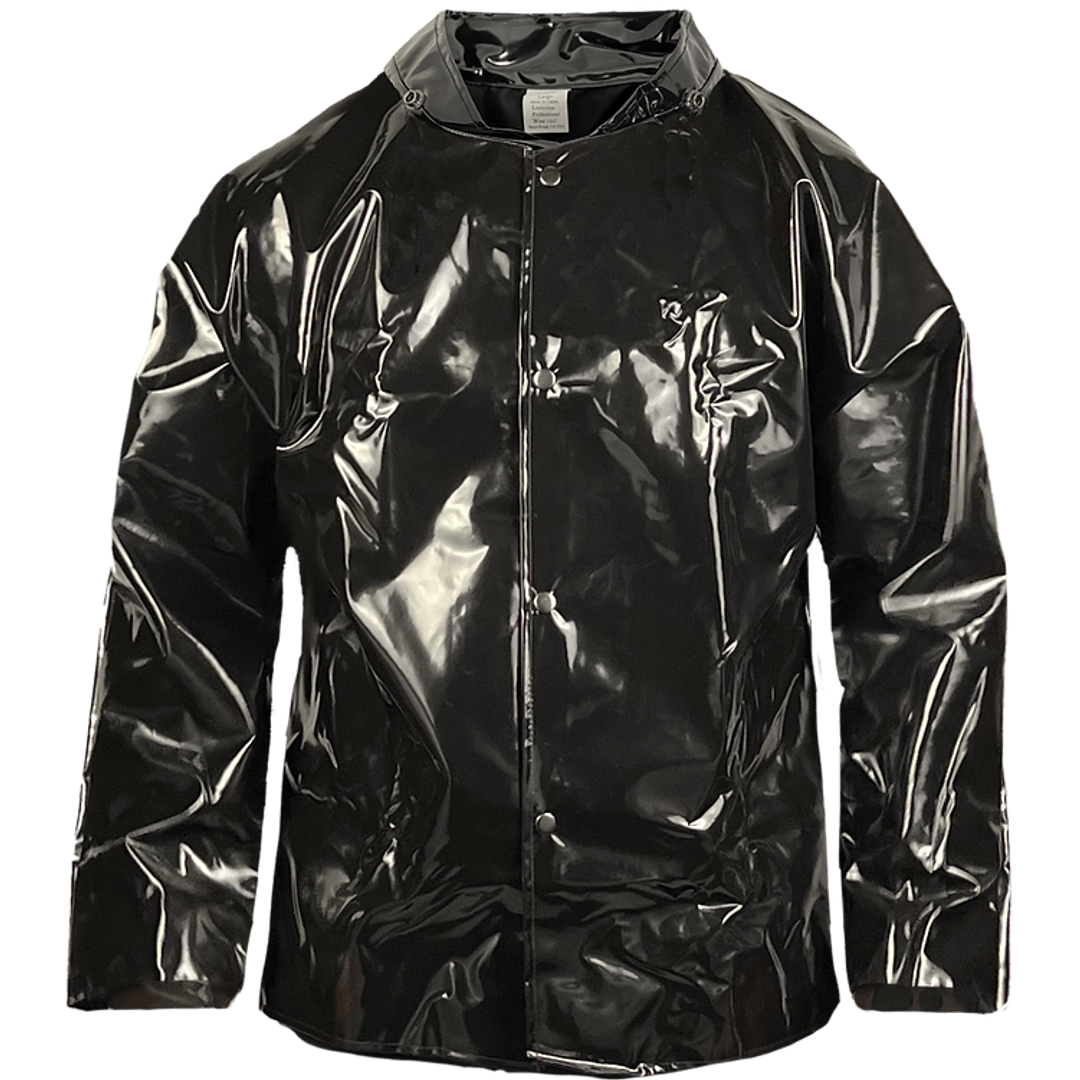

Illustrative image related to coated leather

Key Industrial Applications of coated leather

| Industry/Sector | Specific Application of Coated Leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior upholstery for cars | Enhances aesthetic appeal and durability of vehicle interiors | Ensure compliance with automotive standards and regulations |

| Fashion & Accessories | High-end handbags and footwear | Provides a luxurious look while being easy to maintain | Source from reputable manufacturers with quality assurance |

| Furniture | Upholstery for sofas and chairs | Adds elegance and longevity to furniture products | Look for eco-friendly coatings and durability guarantees |

| Sports Equipment | Protective gear and accessories | Offers durability and protection in high-impact environments | Verify material certifications and performance standards |

| Home Decor | Wall coverings and decorative items | Provides a unique texture and aesthetic to interiors | Consider sourcing from suppliers with sustainable practices |

How is Coated Leather Utilized in the Automotive Sector?

Coated leather is widely used in the automotive industry, particularly for interior upholstery. Its durability and aesthetic appeal make it a preferred choice for seats, dashboards, and door panels. Coated leather provides a protective layer that resists stains and wear, which is crucial for maintaining vehicle interiors over time. International buyers should ensure that the coated leather meets specific automotive standards for safety and environmental impact, especially in regions with stringent regulations.

What Role Does Coated Leather Play in Fashion and Accessories?

In the fashion industry, coated leather is often utilized in the production of high-end handbags and footwear. Its glossy finish and variety of textures allow designers to create visually striking products that appeal to consumers. Coated leather is also easier to clean compared to traditional leather, making it a practical choice for everyday use. B2B buyers in fashion should prioritize sourcing from manufacturers that offer high-quality finishes and ethical production practices.

How is Coated Leather Applied in Furniture Design?

Coated leather is a popular choice for furniture upholstery, including sofas and chairs, due to its elegance and durability. It enhances the visual appeal of furniture while providing a surface that can withstand daily use. Buyers should look for coated leather that offers eco-friendly coatings and durability guarantees, ensuring that the furniture remains in good condition for years. Additionally, sourcing from suppliers with a reputation for quality can help ensure long-term satisfaction.

What Benefits Does Coated Leather Provide in Sports Equipment?

In the sports industry, coated leather is used in protective gear and accessories, such as gloves and pads. Its robustness and resistance to abrasion make it ideal for high-impact environments. Coated leather provides essential protection while maintaining flexibility and comfort for the user. B2B buyers should verify material certifications and performance standards to ensure that the coated leather meets the demands of sports applications, particularly in regions where safety standards are critical.

How is Coated Leather Used in Home Decor?

Coated leather finds its place in home decor, particularly in wall coverings and decorative items. Its unique texture and aesthetic qualities can significantly enhance the ambiance of a space. Buyers interested in this application should consider sourcing from suppliers that utilize sustainable practices, ensuring that the coated leather products not only look good but are also environmentally responsible. This aspect is increasingly important for consumers across Africa, South America, the Middle East, and Europe.

3 Common User Pain Points for ‘coated leather’ & Their Solutions

Scenario 1: Misunderstanding Coated Leather Specifications

The Problem:

B2B buyers often face confusion regarding the specifications of coated leather. Many suppliers may misrepresent the thickness and quality of the coating, leading to concerns about durability and authenticity. Buyers, particularly in regions like Africa and South America, may find it challenging to discern whether they are receiving true coated leather that meets their project requirements. This can result in costly mistakes, such as purchasing inferior products that don’t perform as expected or cause delays in production.

The Solution:

To effectively navigate this issue, buyers should prioritize working with reputable suppliers who provide clear documentation of their products. Request detailed technical specifications, including the total thickness of the leather and the exact thickness of the coating. A reputable supplier should also be able to explain how the coating enhances the leather’s durability while maintaining its aesthetic appeal. Additionally, establishing a relationship with manufacturers who are transparent about their production processes can provide buyers with confidence in their purchases. Conducting regular audits and quality checks on received materials can further mitigate risks, ensuring that the coated leather meets the agreed-upon standards.

Scenario 2: Difficulty in Maintenance and Longevity of Coated Leather

The Problem:

Another common pain point for B2B buyers is the maintenance of coated leather products. Coated leather, while visually appealing, can develop issues such as a matted finish over time, especially in high-traffic environments like automotive interiors or commercial furnishings. Buyers may find themselves struggling with how to maintain the leather’s original shine and durability, leading to dissatisfaction from end-users and potential financial losses due to premature replacements.

Illustrative image related to coated leather

The Solution:

To combat maintenance challenges, buyers should educate their teams on proper care techniques specific to coated leather. Suppliers can provide maintenance guidelines, including recommended cleaning products that do not harm the surface coating. For instance, a gentle damp cloth and a specialized patent leather lotion can restore the leather’s shine effectively. Implementing a maintenance schedule can also extend the life of the product; for example, encouraging regular cleaning and conditioning every few months can prevent the leather from becoming dull. Additionally, providing training sessions for staff on how to care for these materials can enhance product longevity and customer satisfaction.

Scenario 3: Environmental Concerns and Sourcing Sustainability

The Problem:

With increasing scrutiny on environmental practices, B2B buyers are often concerned about the sustainability of the materials they procure, including coated leather. Many manufacturers use chemical coatings that may not be eco-friendly, leading to potential backlash from consumers who prioritize sustainability. Buyers from Europe and the Middle East, in particular, face pressure to ensure that their suppliers adhere to environmental regulations and ethical sourcing practices.

The Solution:

Buyers can address these concerns by prioritizing suppliers who are committed to sustainable practices. This includes sourcing coated leather from manufacturers who utilize environmentally-friendly tanning processes and coatings. Requesting certifications, such as the Leather Working Group (LWG) certification, can help ensure that the leather meets environmental standards. Furthermore, engaging in discussions about the lifecycle of the leather and its potential recyclability can provide added value. By opting for suppliers who demonstrate a commitment to sustainability, buyers can align their purchasing decisions with market demands and enhance their brand reputation in the process.

Strategic Material Selection Guide for coated leather

What Are the Common Materials Used for Coated Leather?

Coated leather is a versatile material widely used in various industries, including fashion, automotive, and furniture. Understanding the different materials used in coated leather can help international B2B buyers make informed decisions. Here, we analyze four common materials used in coated leather, focusing on their properties, advantages, disadvantages, and considerations for buyers in Africa, South America, the Middle East, and Europe.

1. Polyurethane (PU) Coating

Key Properties: Polyurethane is known for its flexibility and resistance to abrasion. It can withstand moderate temperatures and is generally resistant to water and stains.

Illustrative image related to coated leather

Pros & Cons: PU-coated leather is durable and provides a high-quality finish, making it suitable for luxury goods. However, it can be more expensive than other coatings, and its manufacturing process may involve complex chemical treatments that can raise environmental concerns.

Impact on Application: PU coatings are ideal for products requiring a soft touch and aesthetic appeal, such as handbags and upholstery. However, they may not perform well in extreme conditions, such as high humidity or direct sunlight.

Considerations for B2B Buyers: Buyers should ensure that PU-coated leather complies with international standards such as ASTM and REACH, particularly regarding chemical safety and environmental impact.

Illustrative image related to coated leather

2. Polyvinyl Chloride (PVC) Coating

Key Properties: PVC is a robust material known for its excellent resistance to chemicals and moisture. It can endure high pressure and is less prone to cracking compared to other coatings.

Pros & Cons: PVC-coated leather is cost-effective and widely available, making it popular for mass-produced items. However, it is less breathable than PU, which can lead to discomfort in products like footwear. Its environmental impact during production and disposal is also a concern.

Impact on Application: PVC is commonly used in automotive interiors and outdoor furniture due to its durability and resistance to wear and tear. However, it may not be suitable for high-end fashion items that require a premium feel.

Considerations for B2B Buyers: Buyers should be aware of PVC’s compliance with local regulations, especially in regions with strict environmental laws. Ensuring that the material meets standards like DIN EN 71 for safety can mitigate risks.

3. Acrylic Coating

Key Properties: Acrylic coatings are known for their clarity and gloss finish. They offer good UV resistance and can maintain their color over time, making them suitable for outdoor applications.

Pros & Cons: Acrylic-coated leather is lightweight and provides a high level of aesthetic appeal. However, it may not be as durable as PU or PVC, making it less suitable for high-wear applications. The cost can also be moderate to high, depending on the quality.

Impact on Application: This type of coating is often used in fashion accessories and luxury items where appearance is paramount. However, it may not withstand harsh conditions, limiting its use in industrial applications.

Considerations for B2B Buyers: Buyers should assess the acrylic coating’s compatibility with specific applications, especially in regions with extreme weather conditions. Compliance with standards like JIS can also be crucial for market acceptance.

4. Silicone Coating

Key Properties: Silicone coatings provide excellent water resistance and flexibility. They can withstand high temperatures and are often used in applications requiring thermal stability.

Pros & Cons: Silicone-coated leather is highly durable and resistant to environmental factors, making it suitable for outdoor use. However, it can be more expensive to produce and may require specialized manufacturing techniques.

Impact on Application: This coating is ideal for products exposed to moisture and temperature variations, such as outdoor gear and automotive interiors. Its high performance can justify the higher cost in demanding applications.

Considerations for B2B Buyers: Buyers should ensure that silicone-coated leather meets relevant standards for safety and performance, particularly in industries like automotive and outdoor equipment where reliability is critical.

Summary Table

| Material | Typical Use Case for Coated Leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Handbags, Upholstery | High-quality finish, durable | More expensive, complex manufacturing | High |

| Polyvinyl Chloride (PVC) | Automotive Interiors, Outdoor Furniture | Cost-effective, widely available | Less breathable, environmental concerns | Low |

| Acrylic | Fashion Accessories, Luxury Items | Aesthetic appeal, UV resistant | Less durable, moderate to high cost | Med |

| Silicone | Outdoor Gear, Automotive Interiors | Excellent water resistance, flexible | Higher production cost, specialized techniques | High |

This analysis provides a comprehensive overview of the materials used in coated leather, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for coated leather

What Are the Key Stages in the Manufacturing Process of Coated Leather?

The manufacturing process of coated leather involves several critical stages, each contributing to the quality and functionality of the final product. Understanding these stages is essential for B2B buyers seeking reliable suppliers.

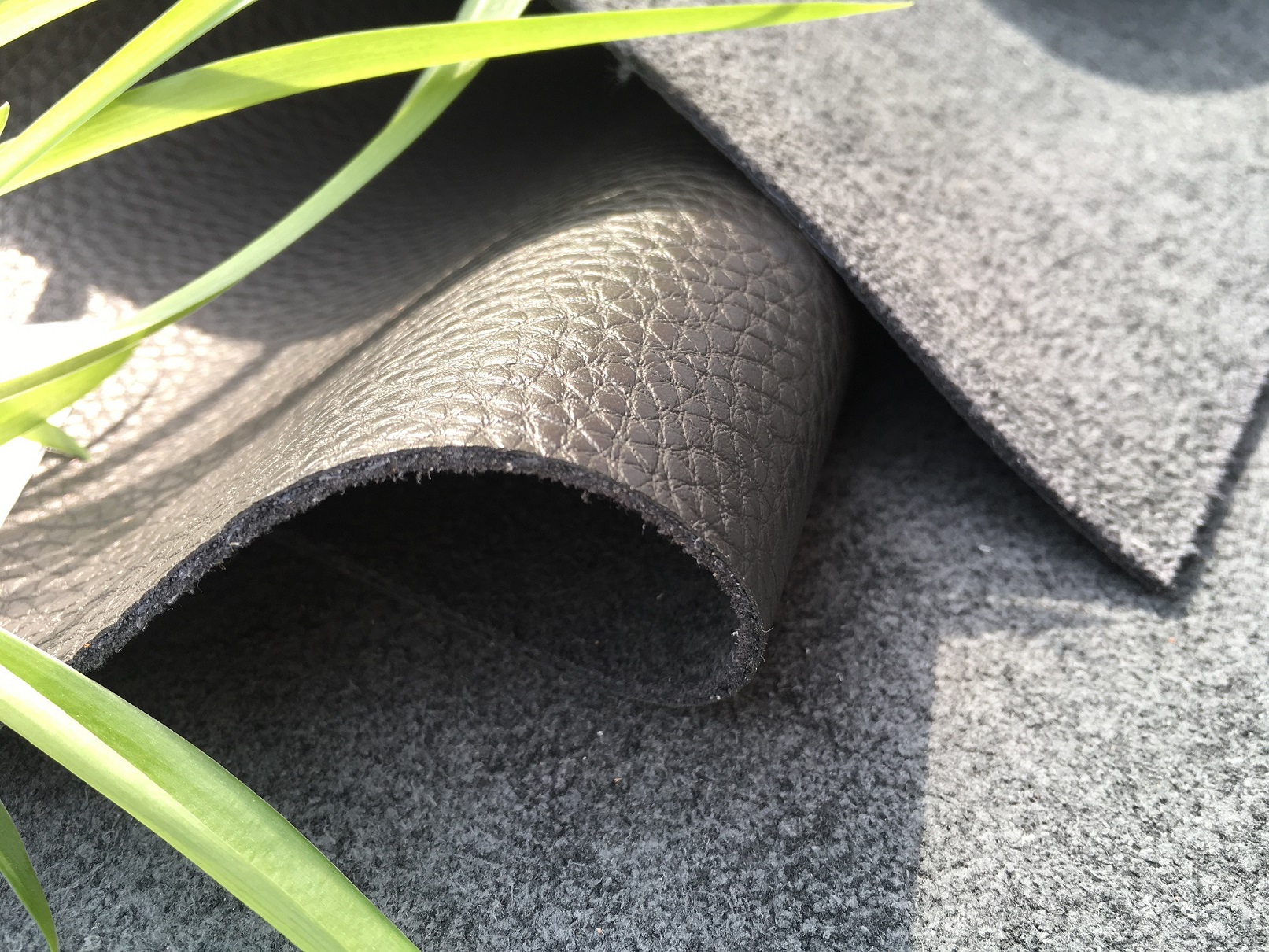

How is Material Prepared for Coated Leather?

The first step in the manufacturing process is material preparation. This typically begins with selecting high-quality animal hides, which are often sourced from cattle, goats, or sheep. The hides undergo a curing process to prevent decay, followed by soaking and liming, which helps to remove hair and flesh residues.

Once cleaned, the hides are split into layers. The top layer, known as the grain layer, is used for coated leather, while the lower layers may be repurposed for other leather products. The grain layer retains the natural texture and strength of the hide, which is crucial for ensuring durability in the final product.

Illustrative image related to coated leather

What Techniques Are Used in Forming Coated Leather?

After preparation, the forming stage begins. This involves applying a surface coating to the leather. The coating can be made from various materials, including polyurethane or acrylic, which enhances the leather’s aesthetic appeal and durability.

The application process usually involves several techniques, such as spraying or rolling the coating onto the leather surface. The thickness of the coating is carefully controlled to ensure it does not exceed one-third of the total thickness of the leather, in accordance with industry standards. This balance is vital for maintaining the leather’s breathability and flexibility.

What Are the Key Steps in the Assembly of Coated Leather Products?

The assembly stage involves cutting the coated leather into specific shapes and sizes according to the product design. This can include items such as shoes, handbags, or upholstery. Precision cutting tools and dies are commonly used to ensure accuracy.

Following cutting, the leather pieces are sewn together, often using industrial sewing machines. Reinforcement techniques, such as double stitching or the use of bonding agents, may be employed to enhance durability in high-stress areas. Quality checks are essential at this stage to ensure that all components fit together correctly.

How is the Finishing Process Conducted for Coated Leather?

Finishing is the final stage in the manufacturing process, where additional treatments are applied to enhance the leather’s appearance and performance. This may include buffing, polishing, or applying protective topcoats. The goal is to achieve a visually appealing finish while ensuring that the leather is resistant to stains and water.

Innovative techniques such as embossing or printing can also be used to create unique textures and patterns on the leather surface. This customization can be an attractive selling point for B2B buyers looking for distinct products.

What Quality Assurance Measures Are Essential for Coated Leather?

Quality assurance (QA) is critical in the coated leather manufacturing process to ensure that the final products meet international standards and customer expectations. Several key measures and standards are widely recognized in the industry.

Illustrative image related to coated leather

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards ensures that manufacturers consistently produce high-quality products and can effectively manage customer satisfaction.

In addition to ISO standards, specific industry certifications such as CE marking (indicating conformity with health, safety, and environmental protection standards) and API (American Petroleum Institute) certifications for leather used in automotive applications may also be relevant depending on the intended use of the coated leather.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting the raw materials upon arrival to ensure they meet specified standards. Any subpar materials are rejected before the manufacturing process begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor adherence to quality standards. This includes checking the thickness of coatings, seam integrity, and overall craftsmanship.

-

Final Quality Control (FQC): Before products are shipped, a final inspection is performed. This ensures that finished goods meet all specifications and are free from defects.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

To ensure that suppliers adhere to quality assurance practices, B2B buyers should consider several verification methods:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can help identify any potential risks in the supply chain.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC practices and the results of previous inspections.

-

Third-Party Inspections: Engaging independent third-party inspection services can add an extra layer of assurance. These inspectors can verify compliance with industry standards and confirm that products meet specified quality benchmarks.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control in coated leather manufacturing.

Illustrative image related to coated leather

-

Cultural and Regulatory Differences: Different regions may have varying regulations and expectations regarding leather quality. Buyers should familiarize themselves with local standards and practices to ensure compliance and satisfaction.

-

Supply Chain Transparency: Establishing transparent communication with suppliers about their sourcing, manufacturing, and quality control processes can help mitigate risks associated with quality issues.

-

Sustainability Practices: Increasingly, buyers are looking for suppliers who adhere to sustainable practices in leather production. This includes using eco-friendly tanning processes and ensuring ethical treatment of animals.

By understanding the manufacturing processes and quality assurance measures for coated leather, B2B buyers can make informed decisions when selecting suppliers and ensure that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘coated leather’

To assist B2B buyers in successfully sourcing coated leather, this practical guide outlines essential steps for evaluating and procuring high-quality materials. By following this checklist, buyers can ensure they select the right suppliers and products that meet their specific requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications for the coated leather you require. This includes determining the type of finish, thickness, and intended application—whether for fashion, automotive, or furniture industries. By having precise specifications, you will better communicate your needs to suppliers and ensure the products align with your project requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in coated leather. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers. Focus on suppliers with a strong reputation and experience in the coated leather market, as this can greatly impact the quality and reliability of your procurement.

Illustrative image related to coated leather

Step 3: Evaluate Supplier Certifications

✅ Verify Supplier Certifications

It’s essential to check if your potential suppliers hold relevant certifications, such as ISO 9001 for quality management or environmental certifications like ISO 14001. These certifications indicate a commitment to quality and sustainability, ensuring that the leather is produced under ethical and environmentally friendly conditions. Ask for documentation and audit reports to verify compliance.

Step 4: Request Product Samples

📦 Obtain Samples of Coated Leather

Request samples of the coated leather from shortlisted suppliers to assess quality and suitability. Evaluate the samples for texture, finish, and durability, paying close attention to the coating thickness and overall appearance. This hands-on assessment will help you make informed decisions based on tangible evidence rather than solely relying on descriptions.

Step 5: Assess Production Capabilities

🏭 Inquire About Production Capacity

Understanding a supplier’s production capabilities is vital, especially if you anticipate bulk orders or have tight deadlines. Discuss lead times, minimum order quantities, and flexibility for customizations. A supplier with robust production capabilities can better meet your demands and ensure timely delivery.

Step 6: Review Pricing and Payment Terms

💰 Analyze Pricing Structures

Request detailed pricing from potential suppliers, including any additional costs such as shipping, duties, and taxes. Compare quotes while considering the quality of the product and the supplier’s reputation. Additionally, negotiate payment terms that align with your cash flow needs, ensuring that both parties are satisfied with the agreement.

Illustrative image related to coated leather

Step 7: Establish Communication Channels

📞 Set Up Clear Communication Protocols

Effective communication is crucial for a successful sourcing relationship. Establish points of contact and preferred communication methods early on. Regular updates and feedback loops can help address any concerns promptly and keep the project on track, fostering a collaborative partnership.

By following this checklist, B2B buyers can navigate the complexities of sourcing coated leather with confidence, ensuring they make informed decisions that align with their business objectives.

Comprehensive Cost and Pricing Analysis for coated leather Sourcing

What Are the Key Cost Components in Coated Leather Sourcing?

When sourcing coated leather, understanding the cost structure is essential for effective budgeting and negotiations. The primary cost components include:

-

Materials: The quality and type of leather significantly impact costs. Coated leather can vary based on the type of finish applied (e.g., patent or reptile-effect), with higher-end finishes commanding a premium. Additionally, the source of the leather—be it cowhide or exotic skins—will also affect pricing.

-

Labor: Labor costs encompass the wages paid to workers involved in tanning, coating, and finishing processes. Regions with lower labor costs may provide competitive pricing, but this could come at the expense of quality or compliance with international labor standards.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and administrative costs. Efficient manufacturing processes can help minimize overhead, impacting the final price of the coated leather.

-

Tooling: The initial setup and tooling costs for production can be substantial, especially for customized designs. These costs are often amortized over large production runs, meaning that higher volume orders will see a lower per-unit tooling cost.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can add to the cost but is vital for maintaining standards. Certifications such as ISO or specific leather quality certifications can also influence price.

-

Logistics: Transportation and shipping costs must be factored into the total cost. This includes freight charges, customs duties, and insurance. The choice of Incoterms can significantly influence logistics costs and risk allocation between buyers and suppliers.

-

Margin: Suppliers will add their profit margin, which can vary based on market conditions, competition, and perceived value. Understanding the market landscape can help buyers negotiate better terms.

What Influences Pricing in Coated Leather Sourcing?

Several factors influence the pricing of coated leather, which are critical for B2B buyers to consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate volume discounts when possible.

-

Specifications and Customization: Custom designs or specific finishes may incur additional costs. It’s essential to define specifications clearly to avoid unexpected pricing changes.

-

Material Quality and Certifications: High-quality materials and recognized certifications can increase costs but are often necessary for compliance and marketability in various regions.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role. Established suppliers may charge more for their products but often provide better quality and service.

-

Incoterms: The chosen Incoterms affect shipping responsibilities and costs. Understanding these terms can help buyers manage risks and costs effectively.

What Are Effective Buyer Tips for Negotiating Coated Leather Prices?

For international buyers, especially from regions such as Africa, South America, the Middle East, and Europe, negotiating effectively can lead to substantial savings:

-

Understand Total Cost of Ownership (TCO): Consider all costs associated with purchasing coated leather, including transportation, storage, and potential waste. A lower upfront cost may not equate to overall savings.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better prices and terms. Frequent communication and trust can foster loyalty and more favorable negotiation outcomes.

-

Be Clear About Specifications: Ensure that all product specifications are clearly defined in contracts to avoid misunderstandings that could lead to increased costs.

-

Stay Informed About Market Trends: Keeping abreast of industry trends and fluctuations in material costs can provide leverage during negotiations.

Disclaimer for Indicative Prices

Prices for coated leather can vary widely based on quality, supplier, and market conditions. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to establish a competitive price range for their specific needs.

Alternatives Analysis: Comparing coated leather With Other Solutions

In the ever-evolving landscape of material options, understanding the alternatives to coated leather is crucial for international B2B buyers. Coated leather, known for its aesthetic appeal and durability, may not always be the most suitable choice depending on specific requirements. This analysis will compare coated leather with two viable alternatives: synthetic leather and genuine leather, highlighting their respective advantages and disadvantages.

| Comparison Aspect | Coated Leather | Synthetic Leather | Genuine Leather |

|---|---|---|---|

| Performance | Durable and resistant to stains; however, may not be as breathable as genuine leather. | Offers a wide range of finishes and colors; can be less durable over time. | Highly durable, ages well, and develops a unique patina; breathability is superior. |

| Cost | Mid-range pricing, depending on quality and finish. | Generally lower-cost option, appealing for budget-conscious buyers. | Higher initial investment but can offer better long-term value. |

| Ease of Implementation | Straightforward application in various industries, especially fashion and automotive. | Easy to produce and customize, widely available. | Requires skilled craftsmanship, which can limit production scalability. |

| Maintenance | Low maintenance; requires basic cleaning and occasional polishing. | Variable maintenance depending on the type; can be prone to wear and tear. | High maintenance; needs regular conditioning to prevent drying out and cracking. |

| Best Use Case | Ideal for fashion accessories and automotive interiors where a glossy finish is desired. | Suitable for budget-friendly products like bags and footwear where high durability is less critical. | Best for luxury goods and high-end furniture where durability and aesthetics are paramount. |

What are the Advantages and Disadvantages of Synthetic Leather as an Alternative?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a viable alternative to coated leather. One of its primary advantages is cost; synthetic leather is typically less expensive than both coated and genuine leather, making it an attractive option for manufacturers looking to minimize expenses. Additionally, it is available in a vast array of colors and textures, allowing for high customization. However, synthetic leather may lack the durability and breathability found in natural materials, which can lead to quicker wear and a less luxurious feel over time.

How Does Genuine Leather Compare to Coated Leather?

Genuine leather is often regarded as the gold standard in materials due to its durability, breathability, and ability to develop a unique character over time. While it is a higher-cost option, many buyers consider it a worthwhile investment, especially in high-end applications. Genuine leather’s maintenance requirements are more demanding, as it needs regular conditioning to maintain its suppleness. Nonetheless, for luxury items or high-quality furniture, the longevity and aesthetic appeal of genuine leather can justify the initial investment.

Conclusion: How Should B2B Buyers Choose the Right Material?

Selecting the appropriate material for your needs requires a thorough understanding of your specific use case, budget constraints, and performance expectations. Coated leather offers a balance of aesthetics and durability, making it suitable for various applications, particularly in fashion and automotive industries. Conversely, synthetic leather may appeal to cost-sensitive projects, while genuine leather remains the top choice for luxury and durability. Assessing these factors will empower B2B buyers to make informed decisions that align with their business goals and customer expectations.

Essential Technical Properties and Trade Terminology for coated leather

What Are the Key Technical Properties of Coated Leather?

Understanding the technical properties of coated leather is crucial for B2B buyers looking to make informed purchasing decisions. The following properties are essential to consider:

1. Material Composition

Coated leather typically consists of genuine leather as its base, topped with a synthetic or natural coating. The composition can significantly affect durability, appearance, and maintenance requirements. Buyers should verify the percentage of genuine leather versus synthetic materials, as this will influence product quality and sustainability.

2. Thickness Specifications

The thickness of coated leather is a critical specification that impacts its strength and application suitability. Coated leather must have a surface coating that does not exceed one-third of the total thickness, specifically remaining above 0.15mm. This metric is essential for assessing durability and suitability for various applications, such as upholstery, footwear, and fashion accessories.

3. Finish Type

The finish applied to coated leather can vary widely, influencing both aesthetic appeal and functional properties. Common finishes include glossy, matte, and embossed textures. Understanding the finish type is vital for buyers, as it can determine the leather’s resistance to stains, water, and wear, affecting the product’s longevity.

4. Color Fastness

Color fastness is a measure of a material’s ability to retain its color when exposed to light, washing, and other environmental factors. For coated leather, this property is particularly important as it affects the product’s visual appeal over time. Buyers should inquire about testing standards (e.g., ISO 105) to ensure the leather meets their requirements for color retention.

5. Flexibility and Softness

The flexibility and softness of coated leather can vary based on the type of coating and the leather quality beneath. These properties are essential for applications where comfort and ease of movement are required, such as in automotive interiors or fashion items. Buyers should assess these attributes to ensure the material meets their specific application needs.

What Are Common Trade Terms Used in Coated Leather Transactions?

Familiarity with industry jargon is crucial for effective communication and negotiation in the coated leather market. Here are several key terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on the specifications provided by another company, typically a brand or retailer. For coated leather buyers, working with an OEM can ensure that products are tailored to specific design and quality requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to plan their purchasing strategy, especially when entering new markets or testing product lines.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. This process helps buyers gather competitive pricing and terms, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with these terms is vital for B2B buyers to understand shipping costs, risks, and responsibilities associated with the delivery of coated leather products.

5. Tannery Certification

Certification from recognized tanning organizations can assure buyers of the quality and sustainability practices of leather suppliers. Certifications may include compliance with environmental standards and ethical sourcing, which are increasingly important in global markets.

Illustrative image related to coated leather

6. Sample Approval

This term refers to the process where buyers request a sample of the coated leather before placing a larger order. Sample approval is critical for assessing the quality, texture, and finish of the material, ensuring it meets the buyer’s expectations before committing to a bulk purchase.

Understanding these properties and terms will empower B2B buyers to navigate the coated leather market more effectively, ensuring they make well-informed purchasing decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the coated leather Sector

What Are the Current Market Trends in the Coated Leather Sector?

The coated leather market is experiencing notable growth, driven by increasing demand across various industries, including fashion, automotive, and upholstery. Key trends include the rise of innovative coatings that enhance durability while providing aesthetic appeal. International B2B buyers, particularly in emerging markets like Africa, South America, and Southeast Asia, are increasingly looking for suppliers that offer high-quality coated leather products with competitive pricing.

Digital transformation is also reshaping the sourcing landscape. Companies are leveraging B2B e-commerce platforms to streamline procurement processes, allowing for quicker decision-making and reduced lead times. Moreover, the integration of artificial intelligence and data analytics enables businesses to better predict market trends and consumer preferences, enhancing inventory management and product offerings.

As global consumers become more discerning, there is a marked shift towards premium coated leather products that balance quality and sustainability. Buyers from Europe and the Middle East are particularly focused on sourcing from manufacturers that emphasize craftsmanship and offer customization options. Understanding these dynamics is essential for B2B buyers to navigate the complexities of the coated leather market effectively.

How Is Sustainability Influencing B2B Sourcing Decisions in Coated Leather?

Sustainability has become a cornerstone of the coated leather sector, impacting sourcing decisions for B2B buyers. The environmental implications of leather production, including water consumption and chemical runoff, are prompting businesses to seek suppliers committed to ethical practices. This shift is particularly relevant for buyers in Europe and North America, where regulatory pressures and consumer expectations regarding sustainability are high.

To meet these demands, many manufacturers are adopting eco-friendly tanning processes and sourcing raw materials from certified sustainable farms. Green certifications, such as the Leather Working Group (LWG) certification, are increasingly recognized as indicators of responsible sourcing. Buyers should prioritize suppliers who can demonstrate compliance with these standards, as it not only mitigates risk but also enhances brand reputation.

Moreover, the demand for alternative, sustainable materials is growing. While traditional coated leather remains popular, buyers are exploring innovations like plant-based or recycled materials that offer a lower environmental footprint. Emphasizing sustainability in sourcing strategies not only aligns with corporate social responsibility goals but can also lead to long-term cost savings through improved efficiency and waste reduction.

What Is the Historical Context of Coated Leather in B2B Markets?

Coated leather has evolved significantly since its inception, reflecting both technological advancements and changing consumer preferences. Historically, the use of coatings began in the 19th century to enhance leather’s durability and appearance, allowing manufacturers to offer products that were not only functional but also visually appealing. This evolution has made coated leather a staple in various industries, including automotive and fashion.

Illustrative image related to coated leather

The introduction of synthetic coatings, such as polyurethane, revolutionized the market by enabling manufacturers to produce leather that could withstand wear and tear while maintaining aesthetic quality. As a result, coated leather has become synonymous with luxury and durability, appealing to international B2B buyers seeking high-quality materials.

Understanding this historical context is vital for B2B buyers, as it highlights the continuous innovation within the sector. By recognizing the evolution of coated leather, businesses can better assess current offerings and anticipate future trends, ensuring they remain competitive in a rapidly changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of coated leather

-

How do I choose the right supplier for coated leather?

Selecting the right supplier for coated leather involves a thorough vetting process. Start by checking the supplier’s reputation through online reviews and industry references. Request samples to evaluate the quality of their coated leather, ensuring it meets your specifications for thickness and finish. Additionally, assess their production capabilities, lead times, and adherence to international standards. It’s also beneficial to verify their certifications for sustainability and quality assurance, which can impact your brand’s reputation and compliance with regulations in your target market. -

What are the typical minimum order quantities (MOQs) for coated leather?

Minimum order quantities (MOQs) for coated leather can vary significantly depending on the supplier and the specific product. Generally, MOQs may range from 50 to 500 square meters. It is essential to discuss your requirements directly with potential suppliers, as many are willing to negotiate MOQs for larger contracts or long-term partnerships. Understanding your own production needs will help you communicate effectively and ensure that the MOQ aligns with your business strategy. -

What payment terms should I expect when sourcing coated leather internationally?

Payment terms for international transactions involving coated leather can vary by supplier and region. Common practices include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer letters of credit or payment upon delivery as alternatives. Always clarify payment terms in the contract to avoid misunderstandings and ensure secure transactions. Consider using escrow services for larger orders to protect both parties during the transaction process. -

How can I ensure the quality of coated leather products?

To guarantee the quality of coated leather products, establish a quality assurance (QA) process that includes inspecting samples prior to bulk production. Implement regular quality checks during the manufacturing process and request certifications that demonstrate compliance with international standards. Additionally, consider using third-party inspection services to verify product quality before shipment. Clear communication with your supplier regarding your quality expectations is essential for ensuring that the final product meets your specifications. -

What customization options are available for coated leather?

Many suppliers offer customization options for coated leather, including variations in color, texture, and finish. Discuss your specific requirements with potential suppliers, as some may provide additional services such as embossing, printing, or applying unique coatings to enhance durability or aesthetics. Be sure to request samples of customized products to evaluate the quality and ensure they align with your brand’s vision and market demands. -

What are the common uses of coated leather in different industries?

Coated leather is widely used across various industries, including fashion, automotive, and furniture. In fashion, it is popular for bags, shoes, and accessories due to its stylish appearance and durability. The automotive industry favors coated leather for upholstery because it provides a luxurious feel while being easy to clean and maintain. In furniture, coated leather is used for sofas and chairs, combining comfort with aesthetic appeal. Understanding the specific applications can help you tailor your sourcing strategy to meet market needs. -

How do I handle logistics when importing coated leather?

Logistics for importing coated leather involve several steps, including selecting a reliable freight forwarder familiar with the leather industry. Ensure that all shipping documents are in order, including invoices, packing lists, and certificates of origin. Familiarize yourself with import regulations and tariffs in your country to avoid unexpected costs. Additionally, consider warehousing options if you need to store inventory before distribution. Effective communication with your supplier and logistics partner is crucial for a smooth shipping process. -

What are the environmental considerations when sourcing coated leather?

When sourcing coated leather, it’s important to consider the environmental impact of both the production process and the materials used. Look for suppliers who adhere to sustainable practices, such as using eco-friendly tanning methods and minimizing waste. Certifications like the Leather Working Group (LWG) can indicate a commitment to sustainability. Additionally, consider the lifecycle of the product, as genuine leather is biodegradable, while synthetic alternatives may not be. Engaging with suppliers who prioritize environmental responsibility can enhance your brand’s image and appeal to eco-conscious consumers.

Top 7 Coated Leather Manufacturers & Suppliers List

1. Dr. Martens – Kiev Smooth Leather Backpack

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Kiev Smooth Leather Backpack from Dr. Martens; described as 100% leather but made from PU-coated version of classic smooth leather; PU-coated leather is considered faux leather; tends to crack over time; not recommended for heavy use; straps may rip easily; alternative option is Milled Nappa Soft Leather Backpack, which has wider, more comfortable straps and better durability.

2. Flattered – Coated Leather Collection

Domain: flattered.com

Registered: 2001 (24 years)

Introduction: This company, Flattered – Coated Leather Collection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Leather Repair Company – Comprehensive Leather Care Solutions

Domain: leatherrepaircompany.com

Registered: 2007 (18 years)

Introduction: Leather Repair Company offers a variety of leather care products and services, including: 1. Leather Cleaning & Stain Removal 2. Leather Protection 3. Leather Repairs for holes, rips, scratches, scuffs, and burns 4. Leather Colour Restoration and Recolouring 5. Applicators & Accessories 6. Care & Restoration Kits 7. Sneakers/Trainers Care & Customisation 8. Leather Cleaning Service 9. Leather Repa…

4. AutoGeek – Coated Leather Guide

Domain: autogeekonline.net

Registered: 2006 (19 years)

Introduction: Coated leather is leather that has been surfaced with a polyurethane coating. 95% of all car leather is coated leather. There are four types of automotive leather: 1) Aniline (Unfinished) – very expensive, absorbs water, stays cool in summer and warm in winter. 2) Alcantara – found in expensive sports cars, looks like suede, requires specific care. 3) Semi-Aniline/finished – has a protective coat,…

5. Uniqlo – Coated Short Jacket

Domain: uniqlo.com

Registered: 1998 (27 years)

Introduction: {‘product_id’: ‘480060’, ‘product_name’: ‘Coated Short Jacket’, ‘material’: ‘Faux Leather’, ‘color’: ’09 BLACK’, ‘available_sizes’: [‘XXS’, ‘XS’, ‘S’, ‘M’, ‘L’, ‘XL’, ‘XXL’], ‘features’: [‘Soft fabric with a matte appearance’, ‘Short jacket with a shirt collar’, ‘Quilted padding lining for warmth’, ‘Compact fit for a stylish look’], ‘fit’: ‘Regular’, ‘pockets’: ‘With Pockets’, ‘washing_instruction…

6. Puracy – PU Coated Leather Care

Domain: puracy.com

Registered: 2013 (12 years)

Introduction: Coated leather furniture is made from polyurethane, providing a durable and easy-to-clean surface. To clean PU coated leather, use a handheld vacuum to remove debris, then clean with a solution of warm water and a few drops of Natural Dish Soap applied with a microfiber towel. For regular maintenance, a Natural Surface Cleaner can be used, ensuring it has a neutral or slightly basic pH to avoid da…

7. Leather Magic – Leather Conditioner for Coated Leather

Domain: leathermagic.com

Registered: 1997 (28 years)

Introduction: Leather Conditioner for Coated Leather SKU: LM-1006-8 Price: $14.95 Available Sizes: 4 oz., 8 oz., 16 oz., 32 oz., Gallon Use On: Top Grained or Protected Leather (Auto Upholstery, Furniture, Leather Jackets & Clothing, Luggage & Handbags, Horse Tack & Saddles, Sports Equipment) Key Features: – Made from original oils used in leather tanning (fat-liquors) – Protects leather from cracking, excessiv…

Strategic Sourcing Conclusion and Outlook for coated leather

Coated leather presents a unique opportunity for international B2B buyers looking to enhance their product offerings with a material that combines durability, aesthetic appeal, and versatility. As outlined, the strategic sourcing of coated leather can significantly impact product quality and customer satisfaction. By understanding the nuances of leather types, including the definitions and classifications, buyers can make informed decisions that align with market demands.

Illustrative image related to coated leather

Investing in coated leather not only enhances product lines in industries such as automotive, fashion, and furniture but also promotes sustainability. Unlike synthetic alternatives, genuine leather has a lower environmental impact, breaking down more efficiently over time. As buyers in Africa, South America, the Middle East, and Europe seek to differentiate their offerings, the emphasis on sourcing high-quality coated leather becomes paramount.

Looking ahead, it is essential to stay abreast of trends in coated leather innovations and consumer preferences. Engaging with reputable suppliers who can guarantee quality and compliance with international standards will be crucial. By prioritizing strategic sourcing, buyers can position themselves advantageously in a competitive market, ensuring they meet the evolving demands of consumers. Take the next step in your sourcing strategy—partner with trusted leather suppliers today to capitalize on the enduring appeal of coated leather.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.