Introduction: Navigating the Global Market for leather tanning solution

Navigating the complexities of sourcing leather tanning solutions can be a daunting challenge for B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. As global demand for high-quality leather products continues to rise, understanding the nuances of different tanning methods, materials, and supplier capabilities is crucial for securing a competitive edge. This guide serves as a comprehensive resource, addressing key areas such as the various types of tanning solutions available, their specific applications, and insights into supplier vetting processes.

Moreover, we delve into cost considerations, enabling buyers to evaluate their options effectively and make informed purchasing decisions. By highlighting critical factors such as product quality, compliance with international standards, and sustainability practices, this guide empowers B2B buyers to navigate the global market confidently. With an eye towards emerging trends and technologies in the leather tanning industry, particularly in regions like Brazil and Vietnam, readers will gain actionable insights that can drive their business success. Whether you are a seasoned importer or a newcomer to the leather trade, this resource is designed to equip you with the knowledge needed to make strategic decisions and foster productive supplier relationships.

Table Of Contents

- Top 8 Leather Tanning Solution Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather tanning solution

- Understanding leather tanning solution Types and Variations

- Key Industrial Applications of leather tanning solution

- 3 Common User Pain Points for ‘leather tanning solution’ & Their Solutions

- Strategic Material Selection Guide for leather tanning solution

- In-depth Look: Manufacturing Processes and Quality Assurance for leather tanning solution

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather tanning solution’

- Comprehensive Cost and Pricing Analysis for leather tanning solution Sourcing

- Alternatives Analysis: Comparing leather tanning solution With Other Solutions

- Essential Technical Properties and Trade Terminology for leather tanning solution

- Navigating Market Dynamics and Sourcing Trends in the leather tanning solution Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather tanning solution

- Strategic Sourcing Conclusion and Outlook for leather tanning solution

- Important Disclaimer & Terms of Use

Understanding leather tanning solution Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vegetable Tanning | Utilizes tannins from plant sources; eco-friendly | High-end leather goods, accessories | Pros: Sustainable, soft feel. Cons: Longer process, less water resistance. |

| Chrome Tanning | Fast process using chromium salts; produces durable leather | Mass production, fashion industry | Pros: Quick, high durability. Cons: Environmental concerns, potential toxicity. |

| Synthetic Tanning | Uses synthetic chemicals; versatile and consistent quality | Various applications, including upholstery | Pros: Cost-effective, uniform results. Cons: Less traditional feel, potential for lower biodegradability. |

| Oil Tanning | Incorporates oils for softness and flexibility | Specialty leather goods, garments | Pros: Soft, pliable leather. Cons: Can be more expensive, requires careful handling. |

| Alum Tanning | Uses aluminum salts; simpler and safer process | Small-scale operations, hobbyists | Pros: Easy to use, less hazardous. Cons: Limited durability compared to other methods. |

What are the Characteristics of Vegetable Tanning Solutions?

Vegetable tanning is a traditional method that employs tannins extracted from plant sources such as tree bark, leaves, and fruits. This process is highly regarded for its eco-friendliness, making it suitable for high-end leather goods, accessories, and products where natural aesthetics are preferred. Buyers should consider the longer tanning time associated with this method, as well as the final product’s soft texture and ability to age beautifully. However, the leather produced may not be as water-resistant as other types, which could limit its applications in certain environments.

How Does Chrome Tanning Compare in Terms of Efficiency?

Chrome tanning is characterized by its rapid processing time, utilizing chromium salts to produce a durable and water-resistant leather. This method is prevalent in mass production and the fashion industry due to its efficiency and the strength of the leather it yields. B2B buyers should be aware of the environmental concerns linked to chromium, particularly regarding disposal and potential toxicity. Despite these drawbacks, the speed and durability of chrome-tanned leather make it an attractive option for businesses looking to meet high demand quickly.

What Advantages Do Synthetic Tanning Solutions Offer?

Synthetic tanning involves the use of synthetic chemicals to achieve consistent quality and versatility in leather production. This method is widely applicable across various industries, including upholstery and fashion, due to its cost-effectiveness. While synthetic tanning provides uniform results, B2B buyers should consider the potential trade-off in terms of the traditional leather feel and biodegradability. The ability to produce large quantities with less variability is a significant advantage for businesses focused on scaling operations.

Why Consider Oil Tanning for Specialty Products?

Oil tanning is a method that incorporates oils into the tanning process, resulting in exceptionally soft and pliable leather. This type of tanning is ideal for specialty leather goods and garments where flexibility and comfort are priorities. While the final product is highly desirable, B2B buyers should note that oil-tanned leather can be more expensive and requires careful handling to maintain its quality. The unique texture and appearance can justify the investment for businesses targeting niche markets.

What is the Role of Alum Tanning in the Leather Industry?

Alum tanning utilizes aluminum salts in a simpler and safer tanning process, making it accessible for small-scale operations and hobbyists. This method is particularly appealing for those new to leather tanning due to its ease of use and lower hazard levels compared to other methods. However, the leather produced through alum tanning may not offer the same durability as chrome or vegetable-tanned leather, which could limit its applications in more demanding environments. Buyers should weigh the benefits of safety and simplicity against the longevity of the final product when considering alum tanning solutions.

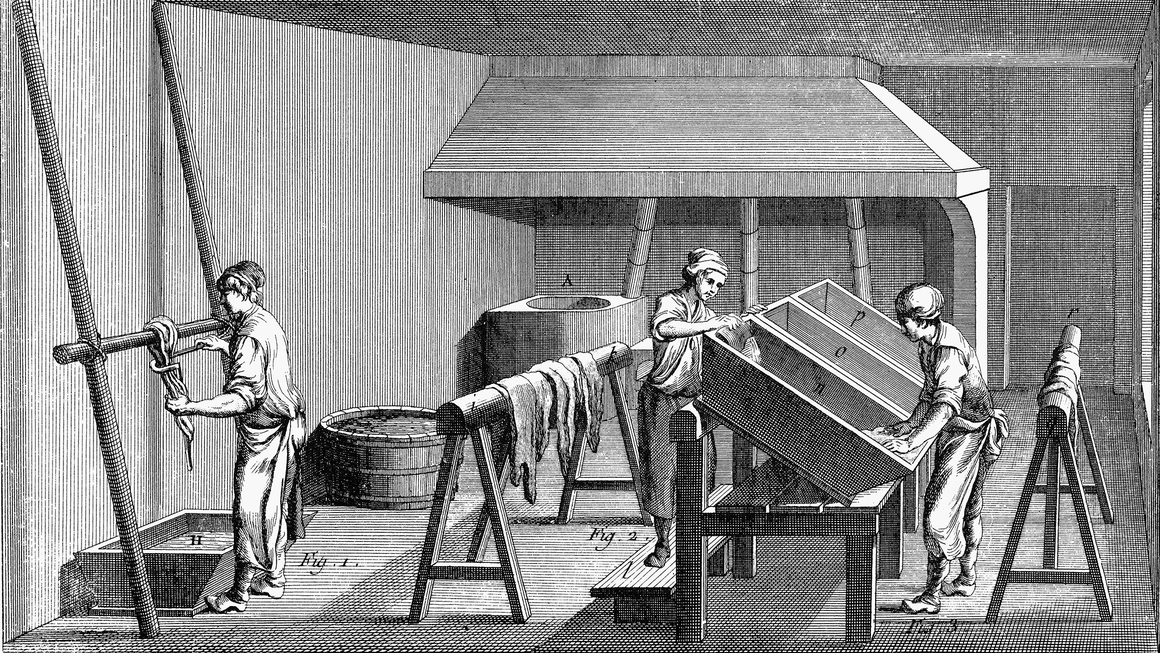

Illustrative image related to leather tanning solution

Key Industrial Applications of leather tanning solution

| Industry/Sector | Specific Application of leather tanning solution | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Production of high-quality leather garments | Enhanced product durability and aesthetic appeal | Sourcing sustainable and high-quality tanning agents |

| Automotive | Upholstery and interior leather materials | Increased comfort and luxury perception | Compliance with industry standards and regulations |

| Footwear | Tanning for shoe leather and accessories | Improved flexibility and wear resistance | Availability of diverse leather types and tanning techniques |

| Furniture | Leather finishes for high-end furniture production | Aesthetic enhancement and increased value | Sourcing eco-friendly tanning solutions to meet market demands |

| Craft and Hobby | DIY leather tanning kits for artisans and hobbyists | Empowerment of local craftsmanship and creativity | Accessibility of kits and instructional resources |

How is Leather Tanning Solution Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, leather tanning solutions are crucial for producing high-quality leather garments. These solutions ensure that the leather is not only durable but also aesthetically appealing, which is essential for fashion brands aiming to attract discerning customers. International buyers must consider sourcing sustainable and high-quality tanning agents that meet regional regulations and consumer preferences, particularly in markets like Europe where eco-consciousness is paramount.

What Role Does Leather Tanning Solution Play in Automotive Upholstery?

The automotive industry heavily relies on leather tanning solutions for upholstery and interior materials. These solutions provide a luxurious finish and enhance the comfort of vehicle interiors, significantly influencing consumer purchase decisions. For international buyers, compliance with automotive industry standards and regulations is critical when sourcing tanning solutions, especially in regions like the Middle East where luxury vehicles are in high demand.

How is Leather Tanning Solution Essential for Footwear Production?

In footwear manufacturing, leather tanning solutions are vital for creating leather that is both flexible and resistant to wear. This ensures that shoes not only look good but also last longer, providing better value to consumers. Buyers in this sector should focus on the availability of diverse leather types and various tanning techniques to cater to different styles and customer preferences, particularly in emerging markets such as Brazil and Vietnam.

Illustrative image related to leather tanning solution

Why is Leather Tanning Solution Important for Furniture Production?

Leather tanning solutions are integral to the production of high-end furniture, where they enhance the leather’s aesthetic and durability. This application not only elevates the perceived value of the furniture but also meets consumer demand for luxury home décor. When sourcing tanning solutions, businesses should prioritize eco-friendly options to align with the growing trend of sustainability in home furnishings, especially in Europe.

How Do Craft and Hobby Sectors Utilize Leather Tanning Solutions?

The craft and hobby sector benefits from leather tanning solutions through DIY kits that empower artisans and hobbyists to create their own leather products. These solutions simplify the tanning process, allowing users to produce quality leather goods at home. For international buyers, accessibility of these kits and the availability of instructional resources are key considerations, as they enhance the crafting experience and support local craftsmanship initiatives.

3 Common User Pain Points for ‘leather tanning solution’ & Their Solutions

Scenario 1: Navigating Inconsistent Quality in Tanning Processes

The Problem: Many B2B buyers in the leather tanning industry struggle with inconsistent quality of tanned leather. Variations in the tanning process can lead to unpredictable results, resulting in leather that is either too stiff, too oily, or lacks the desired softness and durability. This inconsistency not only affects product quality but also damages the reputation of businesses that rely on a steady supply of high-quality leather for their products.

Illustrative image related to leather tanning solution

The Solution: To mitigate this issue, buyers should seek out suppliers who offer comprehensive tanning kits that include standardized tanning agents and detailed instructions. For instance, using products like the PRO-1 Advanced Formula Tanning Oil can ensure uniform results, as it is designed to provide consistent stretch and finish across various hides. Buyers should establish a quality control protocol by testing small batches before full-scale production, allowing them to adjust the tanning process based on the specific properties of the hides they are working with. Additionally, investing in training for staff on best practices for leather tanning can further enhance consistency.

Scenario 2: Dealing with Environmental Compliance and Sustainability Concerns

The Problem: With growing global awareness of environmental issues, many B2B buyers face pressure to comply with stringent regulations regarding the use of chemicals in leather tanning. Traditional tanning methods can involve harmful substances, leading to potential legal issues and reputational damage. Buyers need solutions that not only meet regulatory requirements but also align with sustainable practices to appeal to eco-conscious consumers.

The Solution: Buyers should prioritize sourcing tanning solutions that are eco-friendly and compliant with local and international environmental regulations. For example, opting for vegetable tanning agents or synthetic alternatives that are free from harmful chemicals can significantly reduce environmental impact. Establishing partnerships with suppliers who specialize in sustainable tanning solutions, such as those offering the PRO-MAXX TAN system, can provide a competitive edge. Additionally, buyers should conduct regular audits of their tanning processes to ensure compliance and seek certifications that can enhance their brand’s reputation in sustainability.

Illustrative image related to leather tanning solution

Scenario 3: Managing Supply Chain Disruptions and Material Shortages

The Problem: Global supply chain disruptions can lead to significant delays in the availability of leather tanning supplies, impacting production schedules and customer satisfaction. B2B buyers often find themselves scrambling to source tanning agents and tools, leading to increased costs and potential loss of business opportunities.

The Solution: To combat supply chain challenges, buyers should diversify their sourcing strategies by establishing relationships with multiple suppliers across different regions. This approach minimizes reliance on a single source and helps ensure that materials are available even during disruptions. Additionally, buyers can consider investing in bulk purchasing agreements with reliable suppliers to secure favorable terms and pricing. Staying informed about market trends and engaging in proactive communication with suppliers can also provide insights into potential shortages, allowing buyers to adjust their inventories accordingly. Implementing a just-in-time inventory system can further optimize stock levels, ensuring that buyers have the necessary materials on hand without overcommitting resources.

Strategic Material Selection Guide for leather tanning solution

What Are the Key Materials Used in Leather Tanning Solutions?

When selecting materials for leather tanning solutions, several key components play a crucial role in determining the quality, durability, and suitability of the final product. Below are four common materials used in leather tanning, analyzed from a B2B perspective.

What Are the Key Properties of Chrome Tanning Agents?

Chrome tanning agents, primarily based on chromium salts, are among the most widely used materials in the leather tanning industry. They provide excellent durability and resistance to heat and water, making them suitable for various leather applications. Chrome-tanned leather can withstand high temperatures and is less prone to degradation over time.

Pros: Chrome tanning results in a soft, pliable leather that maintains its shape and color. It is also cost-effective and widely available, making it a popular choice among manufacturers.

Illustrative image related to leather tanning solution

Cons: The environmental impact of chrome tanning is significant, as chromium can be toxic if not managed properly. Compliance with environmental regulations, such as REACH in Europe, is essential for international buyers.

Impact on Application: Chrome-tanned leather is ideal for high-performance applications, including automotive interiors and footwear, but may not be suitable for products that require a more natural finish.

How Do Vegetable Tanning Agents Compare in Performance?

Vegetable tanning agents, derived from plant sources such as tree bark and leaves, offer a more environmentally friendly alternative to chrome tanning. They are known for their ability to produce leather with a unique texture and natural finish.

Pros: The leather produced through vegetable tanning is biodegradable and has a rich, natural appearance. It is often preferred for high-end leather goods and artisanal products.

Cons: The tanning process is slower and can be more labor-intensive, leading to higher production costs. Additionally, vegetable-tanned leather may not be as water-resistant as chrome-tanned leather.

Illustrative image related to leather tanning solution

Impact on Application: This type of leather is well-suited for luxury items, such as handbags and belts, where aesthetics and environmental considerations are paramount.

What Are the Benefits of Synthetic Tanning Agents?

Synthetic tanning agents, including acrylic and polymer-based solutions, are gaining popularity due to their versatility and performance. These agents can be engineered to provide specific properties, such as enhanced flexibility or resistance to UV light.

Pros: Synthetic agents can offer consistent results and can be tailored to meet specific performance criteria. They are often more affordable than traditional tanning methods.

Cons: The environmental impact of synthetic agents can vary, and some may not be biodegradable. Additionally, there may be concerns about the long-term durability of synthetic-tanned leather compared to traditional methods.

Illustrative image related to leather tanning solution

Impact on Application: Synthetic tanning is suitable for a wide range of products, from fashion items to industrial applications, where performance and cost-effectiveness are critical.

What Are the Considerations for Aldehyde Tanning Agents?

Aldehyde tanning agents, particularly those based on glutaraldehyde, are used to produce leather that is soft and water-resistant. This method is often favored for its low environmental impact compared to chrome tanning.

Pros: Aldehyde-tanned leather is known for its softness and flexibility, making it ideal for garments and upholstery. It also has a lower environmental footprint.

Illustrative image related to leather tanning solution

Cons: The production process can be more complex, and the costs may be higher than traditional methods. Additionally, aldehyde-tanned leather may not have the same level of durability as chrome-tanned leather.

Impact on Application: This type of leather is often used in high-quality garments and specialty products where softness and comfort are essential.

Summary Table of Material Selection for Leather Tanning Solutions

| Material | Typical Use Case for leather tanning solution | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Chrome Tanning Agents | Automotive interiors, footwear | Excellent durability and pliability | Environmental concerns, toxicity | Medium |

| Vegetable Tanning Agents | Luxury handbags, artisanal products | Biodegradable, rich natural finish | Higher production costs, slower process | High |

| Synthetic Tanning Agents | Fashion items, industrial applications | Customizable performance | Potential environmental impact | Medium |

| Aldehyde Tanning Agents | Garments, specialty products | Softness and comfort | Higher complexity and cost | Medium |

This guide provides a strategic overview of the materials commonly used in leather tanning solutions, enabling international B2B buyers to make informed decisions based on performance, environmental impact, and cost considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for leather tanning solution

What Are the Main Stages of the Manufacturing Process for Leather Tanning Solutions?

The manufacturing process for leather tanning solutions involves several critical stages that ensure the quality and effectiveness of the final product. Understanding these stages is essential for B2B buyers who aim to source high-quality tanning agents and kits.

Material Preparation

The first stage in the manufacturing process involves the careful selection and preparation of raw materials. This typically includes various tanning agents such as vegetable, chrome, or synthetic compounds. Each type of tanning agent has distinct properties that affect the leather’s final characteristics, such as flexibility, durability, and water resistance.

Illustrative image related to leather tanning solution

Materials must be pre-treated to remove impurities, with the hides and skins being cleaned and soaked to facilitate the tanning process. This is often accompanied by a pickling stage where the pH levels are adjusted to optimize the tanning agent’s effectiveness.

Forming

Once the raw materials are prepared, they undergo the forming stage, where the tanning solution is applied to the hides. This can be done through various techniques, including immersion tanning, where hides are submerged in tanning solutions for extended periods, or spray methods for more controlled application.

Advanced formulations may also involve multiple stages of application, where different agents are layered to achieve specific qualities in the leather. For example, a base tanning solution might be followed by an oil or wax finish to enhance the leather’s suppleness and water resistance.

Assembly

In the assembly stage, tanning solutions are combined with other essential components, such as softening agents, oils, and protective treatments. This can be done either in bulk or in specialized kits that provide all necessary components for a complete tanning process.

For B2B buyers, purchasing an all-inclusive tanning kit can streamline operations, particularly for smaller tanneries or individual craftsmen. These kits often include everything from the tanning solution to tools for hide preparation, ensuring a comprehensive approach to leather tanning.

Illustrative image related to leather tanning solution

Finishing

The final stage of the manufacturing process is finishing, which involves drying, conditioning, and sometimes dyeing the tanned leather. This stage is crucial for enhancing the leather’s aesthetic and functional qualities.

Quality control in this phase often includes testing for physical properties such as tensile strength, stretchability, and water resistance. Proper finishing ensures that the leather meets industry standards and buyer specifications.

How Is Quality Assurance Implemented in Leather Tanning Solutions?

Quality assurance is vital in the leather tanning industry, ensuring that products meet international standards and buyer expectations. B2B buyers should be aware of the various quality control measures that manufacturers implement throughout the tanning process.

What International Standards Are Relevant for Leather Tanning Solutions?

Many manufacturers adhere to international quality standards, with ISO 9001 being one of the most recognized. This standard focuses on ensuring consistent quality management systems that enhance customer satisfaction.

Illustrative image related to leather tanning solution

In addition to ISO standards, industry-specific certifications such as CE marking (indicating conformity with health, safety, and environmental protection standards) and API (American Petroleum Institute) standards for chemical products may also apply, depending on the tanning agents used.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure product integrity.

-

Incoming Quality Control (IQC): This initial checkpoint examines the quality of raw materials upon arrival, ensuring that only suitable materials are used in production.

-

In-Process Quality Control (IPQC): During the tanning and finishing processes, samples are regularly tested for consistency in pH levels, viscosity, and other critical parameters to prevent quality deviations.

-

Final Quality Control (FQC): Once the tanning solutions are completed, they undergo final testing for performance metrics, including stretchability, water resistance, and colorfastness.

What Testing Methods Are Commonly Used for Leather Tanning Solutions?

Manufacturers employ various testing methods to ensure the quality and effectiveness of tanning solutions. Common tests include:

-

Physical Property Testing: Assessing tensile strength, elongation, and tear resistance to confirm that the leather meets required performance standards.

-

Chemical Testing: Evaluating pH levels, the presence of harmful substances, and the concentration of tanning agents to ensure compliance with safety regulations.

-

Environmental Testing: Conducting assessments to ensure that the tanning process meets environmental standards, particularly for chemical waste management.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying a supplier’s quality control measures is critical. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes and quality assurance practices. This helps buyers assess compliance with international standards.

-

Requesting Quality Reports: Buyers should request detailed quality reports and documentation of testing methods and results. This transparency is vital for evaluating the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. This is particularly important for buyers in regions with strict import regulations.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Quality control and certification nuances can vary significantly across regions, particularly for buyers from Africa, South America, the Middle East, and Europe. Here are key considerations:

Illustrative image related to leather tanning solution

-

Regional Regulations: Buyers should familiarize themselves with local regulations regarding chemical use, environmental impact, and product safety. Non-compliance can lead to import restrictions.

-

Certification Recognition: Not all certifications are recognized universally. Buyers should confirm which certifications are applicable in their region and ensure that their suppliers hold the necessary credentials.

-

Cultural Differences in Quality Expectations: Different markets may have varying expectations for leather quality. B2B buyers must communicate their specific requirements clearly to suppliers to avoid misunderstandings.

By understanding the manufacturing processes and quality assurance measures in the leather tanning industry, B2B buyers can make informed decisions that align with their operational needs and market standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather tanning solution’

In the world of leather tanning, sourcing the right solutions is critical for achieving quality results. This step-by-step guide is designed to assist B2B buyers in effectively procuring leather tanning solutions that meet their specific needs, ensuring both quality and compliance with industry standards.

Step 1: Define Your Technical Specifications

Clearly outline your requirements before beginning the sourcing process. This includes the type of leather you intend to tan, the volume of hides, and the desired finish. Knowing your specifications helps narrow down potential suppliers and ensures you select the most appropriate products for your tanning needs.

Illustrative image related to leather tanning solution

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify suppliers that specialize in leather tanning solutions. Look for companies with established reputations and positive reviews from other B2B buyers. Utilize industry-specific forums, trade shows, and directories to gather insights and compile a list of potential vendors.

Step 3: Evaluate Supplier Certifications and Compliance

Before making a commitment, verify that potential suppliers meet relevant industry standards and regulations. Check for certifications such as ISO 9001 for quality management or environmental compliance certifications. This step is crucial as it ensures that the products you procure are safe, effective, and environmentally responsible.

Step 4: Request Product Samples and Technical Data Sheets

To assess the quality of the tanning solutions, request samples and detailed technical data sheets from shortlisted suppliers. Analyze the samples for consistency, ease of use, and effectiveness in achieving the desired leather finish. Technical data sheets should provide information on application methods, safety precautions, and performance characteristics.

Step 5: Inquire About Product Availability and Lead Times

Confirm that the supplier can meet your required quantities and delivery schedules. Inquire about their inventory levels and lead times for production and shipping. Understanding these logistics is essential to ensure that your tanning operations remain uninterrupted and that you can meet your market demands.

Step 6: Evaluate Pricing and Payment Terms

Compare the pricing structures of different suppliers while considering the overall value offered. Look for transparent pricing without hidden costs and inquire about bulk purchase discounts. Additionally, discuss payment terms to ensure they align with your financial processes and cash flow requirements.

Step 7: Establish a Long-term Partnership

Once you have selected a supplier, consider establishing a long-term relationship. A reliable supplier can provide ongoing support, updates on new products, and industry insights that can enhance your tanning processes. Building a partnership fosters better communication and can lead to more favorable terms and conditions over time.

By following this checklist, B2B buyers can streamline their sourcing process for leather tanning solutions, ensuring they choose products that align with their operational needs and quality standards.

Comprehensive Cost and Pricing Analysis for leather tanning solution Sourcing

What Are the Key Cost Components in Leather Tanning Solutions?

When sourcing leather tanning solutions, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include:

-

Materials: The quality of tanning agents, oils, and tools directly impacts the cost. For instance, professional-grade tanning oils can range from $25 to $79 per gallon, depending on the formulation and intended use. High-quality chemicals often lead to better leather quality, which is essential for meeting customer expectations.

-

Labor: Skilled labor is necessary for both the manufacturing process and quality control. Labor costs can vary significantly based on geographic location. In regions with lower labor costs, such as some areas in South America or Africa, sourcing may be more cost-effective, but ensure that skill levels are adequate to maintain quality standards.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Overhead can vary widely among suppliers, especially between local manufacturers and larger international firms.

-

Tooling: Investment in specialized tools and equipment for leather tanning can be substantial. For example, fleshing and shaving tools are critical for ensuring the quality of the hide, and these can add to initial costs.

-

Quality Control (QC): Rigorous quality control measures are vital to ensure that the final product meets specifications. This often requires additional labor and testing materials, which can add to the overall costs.

-

Logistics: Transportation costs can be significant, especially for international shipments. Factors such as distance, mode of transport, and local regulations can influence pricing.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on competition, market demand, and supplier reputation.

How Do Price Influencers Affect Leather Tanning Solution Costs?

Several factors influence the pricing of leather tanning solutions:

-

Volume/MOQ: Many suppliers offer tiered pricing based on volume. Higher order quantities can lead to significant savings, making it beneficial for larger buyers or those with ongoing needs.

-

Specifications and Customization: Custom formulations or specific tanning techniques can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Quality and Certifications: Products certified for environmental compliance or those using premium materials may carry a higher price tag. Certifications can also be a selling point for buyers targeting eco-conscious markets.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their perceived quality and service level.

-

Incoterms: Understanding the terms of sale is essential. Different Incoterms (e.g., FOB, CIF) can significantly impact the total landed cost, including shipping, insurance, and duties.

What Are the Best Buyer Tips for Cost-Efficiency in Leather Tanning Solutions?

To maximize value when sourcing leather tanning solutions, buyers should consider the following strategies:

Illustrative image related to leather tanning solution

-

Negotiation: Engage suppliers in negotiations to secure better pricing, especially for bulk orders. Establishing a long-term relationship may lead to favorable terms.

-

Total Cost of Ownership: Consider all associated costs, including logistics, storage, and potential wastage. A lower initial price may not always translate to the best value if hidden costs are high.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations and tariffs, which can affect total costs. Additionally, cultural differences in business practices may influence negotiations.

-

Research and Benchmarking: Conduct thorough market research to compare prices across different suppliers. This will help identify fair pricing and provide leverage during negotiations.

-

Trial Orders: Before committing to large orders, consider placing trial orders to assess product quality and supplier reliability. This reduces risk and helps ensure that the supplier meets your standards.

In summary, understanding the comprehensive cost structure and pricing influencers of leather tanning solutions is essential for B2B buyers. By leveraging these insights, buyers can make informed decisions that enhance their sourcing strategies and overall profitability. Please note that prices mentioned are indicative and may vary based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing leather tanning solution With Other Solutions

Exploring Alternatives to Leather Tanning Solutions

In the leather industry, the choice of tanning solution is crucial for achieving the desired quality, durability, and aesthetic of the final product. However, several alternatives exist that can cater to diverse needs and preferences among B2B buyers. Understanding these alternatives helps businesses make informed decisions that align with their operational requirements and market demands.

| Comparison Aspect | Leather Tanning Solution | Alternative 1: Synthetic Tanning Agents | Alternative 2: Natural Tanning Methods |

|---|---|---|---|

| Performance | High-quality, supple leather with excellent stitch holding ability | Can produce consistent results, but may lack the natural feel | Offers unique textures and characteristics, but results can vary |

| Cost | Moderate to high, depending on the kit or solution | Generally lower initial costs, but may require additional materials | Often cost-effective but may involve longer processing times |

| Ease of Implementation | Kits are user-friendly for both beginners and professionals | Requires knowledge of chemical handling; safety precautions necessary | Labor-intensive, requiring more time and skill |

| Maintenance | Low maintenance; products are designed for durability | Requires careful storage and handling of chemicals | Requires more frequent upkeep and monitoring of natural materials |

| Best Use Case | Ideal for high-quality leather goods and crafts | Suitable for mass production where consistency is key | Best for artisanal or traditional leather products with unique qualities |

What Are the Advantages and Disadvantages of Synthetic Tanning Agents?

Synthetic tanning agents are increasingly popular due to their ability to produce consistent quality leather at a lower cost. They often utilize chemicals that can be easily controlled and measured, which helps in achieving uniform results. However, these agents can sometimes result in a less natural feel compared to traditional methods. Additionally, they require careful handling due to potential health hazards associated with chemical exposure, making them less suitable for smaller operations or those without proper safety protocols.

How Do Natural Tanning Methods Compare?

Natural tanning methods, such as vegetable tanning, use organic materials to achieve a unique finish and texture. This approach is highly regarded for producing environmentally friendly leather that develops a rich patina over time. However, the process can be labor-intensive and time-consuming, often requiring specialized knowledge and skills. While the initial costs may be lower, the longer processing times can lead to increased operational costs in a commercial setting. Natural tanning is best for artisans focused on high-quality, bespoke leather products.

Illustrative image related to leather tanning solution

Making the Right Choice for Your Leather Tanning Needs

When choosing the appropriate tanning solution, B2B buyers should evaluate their specific needs, including the type of leather products they intend to produce, their budget constraints, and their operational capabilities. For businesses focused on high-quality leather goods, investing in a comprehensive leather tanning solution may provide the best results. Conversely, those seeking cost-effective and efficient mass production might lean towards synthetic tanning agents. Meanwhile, enterprises aiming for artisanal craftsmanship may find natural tanning methods align best with their brand ethos. Ultimately, understanding these alternatives will empower buyers to select the solution that best fits their business objectives.

Essential Technical Properties and Trade Terminology for leather tanning solution

What Are the Key Technical Properties of Leather Tanning Solutions?

When considering leather tanning solutions, understanding the critical technical properties can significantly impact product quality and usability. Here are essential specifications that B2B buyers should prioritize:

-

Material Grade

– Definition: This refers to the quality of the tanning agents and materials used in the tanning process. Higher-grade materials often yield superior leather.

– Importance: A higher material grade ensures consistency in the tanning process and results in leather that is more durable, flexible, and resistant to environmental factors. For businesses, investing in quality materials can reduce waste and enhance customer satisfaction. -

Tanning Agent Concentration

– Definition: This specifies the percentage of active tanning agents in the solution. Common agents include chromium salts, vegetable tannins, and synthetic alternatives.

– Importance: The concentration affects the effectiveness of the tanning process. A higher concentration can lead to better penetration into the hide, ensuring a more complete and uniform tanning. Businesses must balance concentration with cost-efficiency to optimize production. -

pH Level

– Definition: The pH level of the tanning solution can significantly influence the leather’s final properties.

– Importance: Maintaining an optimal pH is crucial for achieving desired leather characteristics such as softness and color retention. Inconsistent pH levels can lead to defects, necessitating additional processing and costs for the manufacturer. -

Water Resistance

– Definition: This property measures how well the tanned leather can withstand water exposure without damage.

– Importance: Water resistance is vital for leather intended for outdoor use or products exposed to moisture. For B2B buyers, understanding water resistance helps in selecting materials appropriate for specific applications, thereby preventing product failures. -

Flexibility and Stretchability

– Definition: These properties describe the leather’s ability to bend and stretch without breaking.

– Importance: Flexibility and stretchability are critical for applications in fashion and upholstery. Leather that retains its shape while allowing for movement is more desirable, thus affecting customer satisfaction and marketability.

What Are Common Trade Terms in the Leather Tanning Industry?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are key terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to companies that produce parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help businesses identify reliable suppliers and manage product sourcing effectively, ensuring they get quality materials that meet their specifications. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers plan their purchasing strategy and manage inventory effectively. It can also influence negotiations, particularly for smaller businesses looking to minimize upfront costs. -

RFQ (Request for Quotation)

– Definition: A document used to solicit price and other terms from suppliers for specific goods or services.

– Relevance: An RFQ allows buyers to compare offers from multiple suppliers, ensuring they secure the best price and terms for their leather tanning solutions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Relevance: Understanding Incoterms is crucial for managing logistics and shipping costs, which can significantly affect the overall pricing of leather products. Proper knowledge can prevent disputes and ensure smoother transactions. -

Lead Time

– Definition: The time taken from placing an order to the delivery of goods.

– Relevance: Lead time affects production schedules and inventory management. Buyers must factor in lead times when planning their supply chain to avoid delays in product availability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing leather tanning solutions, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the leather tanning solution Sector

What Are the Current Market Dynamics and Key Trends in the Leather Tanning Solutions Sector?

The leather tanning solutions market is experiencing notable growth driven by increasing consumer demand for high-quality leather products across various industries, including fashion, automotive, and furniture. Globalization has facilitated access to diverse markets, particularly in Africa, South America, the Middle East, and Europe, where buyers are seeking innovative tanning solutions. Key trends influencing this sector include the adoption of advanced tanning technologies, such as synthetic and eco-friendly agents that enhance the quality and durability of leather while reducing environmental impact. Furthermore, the integration of digital platforms for sourcing and procurement is transforming traditional supply chains, enabling buyers to access a wider range of products and suppliers with greater efficiency.

Illustrative image related to leather tanning solution

Emerging technologies, such as artificial intelligence and data analytics, are reshaping the decision-making process for B2B buyers, allowing for better forecasting and inventory management. As international buyers, particularly from regions like Brazil and Vietnam, navigate this evolving landscape, understanding local market dynamics, regulatory environments, and consumer preferences will be crucial. Additionally, there is a growing emphasis on customization and personalization in leather products, prompting tanneries to innovate their offerings to meet specific buyer needs.

How Does Sustainability and Ethical Sourcing Impact the Leather Tanning Solutions Market?

Sustainability has become a pivotal focus within the leather tanning sector, as environmental concerns gain traction among consumers and businesses alike. The tanning process can have significant ecological repercussions, including water pollution and resource depletion. Consequently, B2B buyers are increasingly prioritizing suppliers that adhere to sustainable practices and offer environmentally friendly tanning solutions. This shift is not only driven by regulatory requirements but also by the growing consumer demand for ethically sourced products.

Buyers should look for suppliers that possess certifications such as the Leather Working Group (LWG) certification or other eco-labels that attest to their commitment to sustainable practices. Utilizing ‘green’ materials, such as vegetable-based tanning agents, can significantly reduce the environmental footprint of leather production. Furthermore, ethical sourcing practices ensure that raw materials are obtained from suppliers who uphold fair labor standards and animal welfare, which enhances brand reputation and consumer trust.

What Is the Historical Context of the Leather Tanning Solutions Industry?

The evolution of the leather tanning industry dates back thousands of years, with ancient civilizations utilizing natural methods to preserve hides. Traditionally, tanning processes relied on natural resources, such as tannin from tree bark, which provided a sustainable approach to leather production. However, the industrial revolution ushered in synthetic tanning agents that allowed for mass production and greater efficiency, albeit with increased environmental concerns.

In recent decades, the industry has witnessed a paradigm shift towards sustainability and ethical practices, responding to consumer demand for transparency and responsibility. Today, B2B buyers are encouraged to consider the historical context of tanning methods as they seek suppliers that balance innovation with respect for traditional practices and environmental stewardship. Understanding this evolution can inform sourcing decisions and align buyer strategies with current market expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of leather tanning solution

-

1. How do I solve common leather tanning issues?

To address common leather tanning issues, such as uneven tanning or odor, start by ensuring you follow the manufacturer’s instructions for the tanning solution accurately. Using high-quality, compatible products and maintaining proper pH levels during the tanning process is crucial. If problems persist, consider consulting with experts or suppliers who can provide tailored advice based on your specific materials and conditions. Regular quality checks and testing smaller batches can also help mitigate issues before scaling up production. -

2. What is the best tanning solution for achieving high-quality leather?

The best tanning solution depends on the specific type of leather you aim to produce. For a soft, supple finish, consider using a combination of synthetic and natural tanning agents that provide durability and flexibility. Popular options include vegetable-based tannins for traditional leathers and chrome-based solutions for quicker processing. Research suppliers that offer customizable solutions to meet the desired specifications for your leather products, ensuring you achieve the quality required for your target market. -

3. How can I vet suppliers for leather tanning solutions?

When vetting suppliers, focus on their reputation, certifications, and experience in the leather tanning industry. Request samples of their products to assess quality and compatibility with your processes. It’s also beneficial to read customer reviews and case studies. Look for suppliers who offer technical support and training, as this indicates a commitment to customer success. Additionally, consider their production capacity and lead times to ensure they can meet your demand consistently. -

4. What are the minimum order quantities (MOQ) for leather tanning products?

Minimum order quantities can vary significantly among suppliers, often ranging from a few liters for small-scale operations to several hundred liters for larger industrial clients. When discussing MOQs, consider your production needs and the supplier’s capability to provide flexibility. Some suppliers may offer lower MOQs for first-time buyers or trial orders, which can be a good opportunity to test the products without committing to larger quantities. -

5. What payment terms should I expect when sourcing leather tanning solutions?

Payment terms can vary widely by supplier and region, but common practices include upfront payments, 30% deposits with the balance upon delivery, or net 30/60 terms. It’s crucial to clarify payment methods accepted, such as bank transfers, letters of credit, or credit terms. Establishing clear payment terms in your contracts can help avoid misunderstandings and ensure smoother transactions. Always ensure that the payment terms align with your cash flow needs and operational capabilities. -

6. How do I ensure quality assurance in leather tanning processes?

To ensure quality assurance, implement a robust quality control system that includes regular inspections at various stages of the tanning process. Collaborate with suppliers who adhere to international quality standards and are willing to provide documentation and certifications. Additionally, training staff in proper tanning techniques and maintaining equipment can help minimize defects. Utilize customer feedback and market research to continuously improve your processes and address any emerging quality issues. -

7. What logistics considerations are important when sourcing tanning solutions internationally?

When sourcing leather tanning solutions internationally, consider shipping costs, customs regulations, and import duties that may affect your overall budget. Choose suppliers who have experience with international shipping and can provide reliable delivery timelines. It’s also important to understand the storage requirements for tanning agents, as some may be sensitive to temperature or humidity. Establishing clear logistics channels and communication with your supplier can help streamline the process and avoid delays. -

8. Can I customize leather tanning solutions to fit my specific needs?

Many suppliers offer customizable tanning solutions to cater to the unique requirements of your leather production. This may include variations in tanning agents, additives for specific finishes, or formulations tailored for different types of hides. Engage with your supplier early in the process to discuss your specific needs and request samples for testing. Customization can enhance the quality of your final products and set you apart in competitive markets, particularly in regions with diverse leather crafting traditions.

Top 8 Leather Tanning Solution Manufacturers & Suppliers List

1. Advanced Tanning Solutions – Tan-a-Buckskin

Domain: advancedtanningsolutions.com

Registered: 2015 (10 years)

Introduction: {“product_name”: “Tan-a-Buckskin”, “price”: “$149.95”, “description”: “An all-inclusive deluxe tanning kit specifically designed for tanning buckskin, hair-off leather from deer, elk, bison, or cow hides. Contains a full set of products and tools to tan from start to finish, using the same tan and oil products as commercial tanneries for high quality buckskin leather.”, “coverage”: “Tans approxima…

2. FNT Post – Trapper’s Hide Tanning Formula

Domain: fntpost.com

Registered: 2006 (19 years)

Introduction: [{‘name’: “Trapper’s Hide Tanning Formula”, ‘price’: ‘$8.95’, ‘size’: ‘8 oz.’, ‘description’: ‘Allows easy home tanning of all fur skins and deer hides. Produces a soft, supple Indian-style tan in 5-7 days. One bottle will tan two medium sized fur skins or one deer hide.’}, {‘name’: “Trapper’s Hide Tanning Formula (5 Bottles)”, ‘price’: ‘$39.95’, ‘size’: ‘5 Bottles’, ‘description’: ‘Same as above,…

3. Pro1 Performance Chemicals – Leather Tanning Solutions

Domain: pro1performancechemicals.com

Registered: 2011 (14 years)

Introduction: This company, Pro1 Performance Chemicals – Leather Tanning Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Reddit – Tanning Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Lecithin: Used as a substitute for brains in tanning, it is cheap, shelf-stable, and does not attract flies. It is food-grade and safe for pets. 2. Permatan 2000: Recommended as one of the best tanning solutions. 3. Lubristretch 2000: Used in conjunction with Permatan 2000. 4. Lipa Solv 77: Another product from Trubond Tanning that is recommended. 5. Yellow granular lecithin: Purchased from Bul…

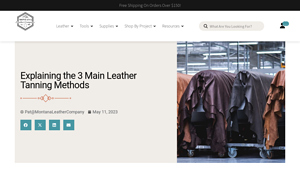

5. Montana Leather – Tanning Methods Explained

Domain: montanaleather.com

Registered: 2000 (25 years)

Introduction: The text explains three main leather tanning methods: chrome tanning, vegetable tanning, and non-chrome tanning. Chrome tanning uses chromium salts to create flexible leather quickly, but has environmental concerns. Vegetable tanning uses natural plant materials, resulting in high-quality leather with a distinct appearance, but is less water-resistant. Non-chrome tanning includes methods like brai…

6. TruBond – Taxidermy Tanning Solutions

Domain: trubondtanning.com

Registered: 2011 (14 years)

Introduction: TruBond Tanning Products, LLC offers a range of tanning products and accessories designed for taxidermy. Key features include: softer back skin with less work, more supple taxidermy tan with great stretch, and efficient oils, degreasers, and surfactants. The company emphasizes customer support with knowledgeable staff, including tanning developer Aubrey Young and award-winning taxidermist Justin P…

7. Tannit – Hide Tanning Solution

Domain: huntsmart.com

Registered: 1999 (26 years)

Introduction: {“name”: “Tannit Hide Tanning Solution”, “sku”: “TCR600”, “price”: “$29.99”, “description”: “Used by professional taxidermists for years, Tannit is now available for the do-it-yourself sportsman. A single application tanning solution for skins of all fur-bearing animals. One 16 oz. bottle will tan and preserve two average size deer, numerous small animals, or one elk.”, “size”: “16 oz.”, “note”: “…

8. Silvateam – Leather Tanning Solutions

Domain: silvateam.com

Registered: 2001 (24 years)

Introduction: Silvateam offers a range of leather tanning solutions including: plant-based extracts (chestnut, quebracho, tara, gambier, myrobalan), synthetic tannins, special extracts, tanning auxiliaries, oils and fatliquors, resins, and beamhouse chemicals. The company provides products for various tanning processes such as vegetable tanning, wet white tanning, and wet blue tanning. Main applications include…

Strategic Sourcing Conclusion and Outlook for leather tanning solution

How Can Strategic Sourcing Enhance Your Leather Tanning Operations?

In the competitive landscape of leather tanning, strategic sourcing emerges as a pivotal element for B2B buyers aiming to optimize their procurement processes. By aligning with reputable suppliers who provide high-quality tanning kits and agents, businesses can ensure consistency in product quality and operational efficiency. The integration of advanced tanning solutions, such as those offered by industry leaders, equips manufacturers with the necessary tools to produce superior leather products that meet market demands.

Buyers should prioritize sourcing solutions that offer comprehensive kits tailored for various hides, enabling flexibility and scalability in production. Engaging with suppliers that emphasize sustainable practices can also enhance brand value and appeal to environmentally conscious consumers, a growing trend in international markets.

Looking ahead, the leather tanning industry is poised for innovation, driven by technological advancements and changing consumer preferences. International B2B buyers from regions like Africa, South America, the Middle East, and Europe should capitalize on these trends by fostering strategic partnerships and investing in cutting-edge tanning solutions. Embrace the future of leather tanning—explore your sourcing options today to remain competitive and responsive to evolving market needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to leather tanning solution

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.