Introduction: Navigating the Global Market for custom leather gloves

In the ever-evolving landscape of global trade, sourcing high-quality custom leather gloves presents a unique challenge for B2B buyers. Whether you’re in the automotive sector, construction, or fashion, understanding the nuances of custom leather glove procurement is essential for ensuring product quality, worker safety, and brand reputation. This comprehensive guide will delve into the various types of custom leather gloves available, their applications across different industries, and the critical factors to consider when vetting suppliers. We will also explore cost considerations, customization options, and shipping logistics, providing you with the knowledge needed to make informed purchasing decisions.

For international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe—including key players from Brazil and Germany—this guide is designed to empower you in navigating the complexities of sourcing custom leather gloves. By equipping you with actionable insights and best practices, we aim to enhance your procurement strategy, ensuring that you can confidently select the right partners and products for your business needs. With this guide, you’ll not only streamline your sourcing process but also elevate your brand’s commitment to quality and craftsmanship in the competitive global market.

Table Of Contents

- Top 3 Custom Leather Gloves Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather gloves

- Understanding custom leather gloves Types and Variations

- Key Industrial Applications of custom leather gloves

- 3 Common User Pain Points for ‘custom leather gloves’ & Their Solutions

- Strategic Material Selection Guide for custom leather gloves

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather gloves

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather gloves’

- Comprehensive Cost and Pricing Analysis for custom leather gloves Sourcing

- Alternatives Analysis: Comparing custom leather gloves With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather gloves

- Navigating Market Dynamics and Sourcing Trends in the custom leather gloves Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather gloves

- Strategic Sourcing Conclusion and Outlook for custom leather gloves

- Important Disclaimer & Terms of Use

Understanding custom leather gloves Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Work Gloves | Heavy-duty leather, reinforced stitching, custom fit | Construction, manufacturing, agriculture | Pros: High durability, protective features. Cons: May lack flexibility for intricate tasks. |

| Driving Gloves | Lightweight, fine leather, often fingerless options | Automotive, luxury vehicle accessories | Pros: Enhanced grip, stylish appearance. Cons: Limited protection against impact. |

| Fashion Gloves | Variety of designs, colors, and finishes | Fashion retail, promotional giveaways | Pros: Customizable aesthetics, brand visibility. Cons: May not be suitable for heavy-duty use. |

| Safety Gloves | Protective features, often compliant with safety standards | Industrial, oil and gas, logistics | Pros: Meets regulatory requirements, high protection. Cons: Can be bulkier, affecting dexterity. |

| Specialty Gloves | Tailored for specific tasks (e.g., welding, cold weather) | Specialized industries (welding, cold storage) | Pros: Task-specific protection, enhanced performance. Cons: Higher cost and longer lead times. |

What Are the Characteristics of Custom Leather Work Gloves?

Custom leather work gloves are designed to provide maximum protection and durability in demanding environments. They often feature heavy-duty leather, reinforced stitching, and a custom fit to ensure comfort during extended use. These gloves are ideal for industries such as construction and manufacturing, where workers face various hazards. B2B buyers should consider the level of protection required, the specific tasks involved, and the comfort needs of their workforce when selecting these gloves.

How Do Driving Gloves Enhance User Experience?

Driving gloves are crafted from lightweight, high-quality leather, often featuring fingerless designs for improved tactile feedback. They are designed to enhance grip and provide comfort during long drives, making them popular in the automotive sector, especially for luxury vehicles. When purchasing driving gloves, B2B buyers should focus on the quality of the leather, customization options, and the aesthetic appeal that aligns with their brand or customer preferences.

What Makes Fashion Gloves a Unique B2B Offering?

Fashion gloves come in a variety of designs, colors, and finishes, making them an excellent choice for retail environments and promotional giveaways. Their customizable nature allows businesses to enhance brand visibility while offering stylish accessories to consumers. However, buyers should be mindful of the intended use, as these gloves may not provide the same level of protection as work or safety gloves, and may not be suitable for heavy-duty applications.

Why Are Safety Gloves Essential in Industrial Settings?

Safety gloves are specifically designed to meet regulatory standards and provide high levels of protection in industrial settings. These gloves often feature reinforced areas, cut resistance, and other protective features tailored to specific hazards in industries like oil and gas, construction, and logistics. B2B buyers must prioritize compliance with safety regulations and the specific risks faced by their workforce when selecting safety gloves, balancing protection with comfort and dexterity.

What Are the Benefits of Specialty Gloves for Specific Industries?

Specialty gloves are tailored for specific tasks, such as welding or cold weather applications, providing targeted protection and enhanced performance. These gloves are often designed with unique materials and features suited to their respective industries. B2B buyers should consider the specialized nature of their operations, the level of customization required, and the potential for increased costs associated with these tailored solutions when making purchasing decisions.

Key Industrial Applications of custom leather gloves

| Industry/Sector | Specific Application of custom leather gloves | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Автомобили | Custom driving gloves for professionals | Enhanced grip and control, comfort during long drives | Material durability, customization options, ergonomic design |

| Construction | Protective gloves for labor-intensive tasks | Safety compliance, reduced hand injuries | Compliance with safety standards, fit and flexibility |

| Agriculture | Gloves for handling livestock and machinery | Protection against abrasions, comfort for extended use | Breathability, water resistance, ease of cleaning |

| Food Processing | Gloves for food handling and preparation | Hygiene compliance, prevention of contamination | FDA compliance, easy maintenance, custom sizing |

| Oil & Gas | Protective gloves for hazardous environments | Enhanced safety, resistance to chemicals and heat | Material resistance to chemicals, certification standards |

How Are Custom Leather Gloves Used in the Automotive Industry?

In the automotive sector, custom leather gloves are essential for professional drivers, providing superior grip and comfort. These gloves enhance control over vehicle handling, particularly during long drives or racing conditions. Buyers in this industry should look for gloves made from high-quality materials like peccary or deerskin, which offer durability and a luxurious feel. Sourcing should focus on customization options that allow for personal touches, such as color and design, while ensuring ergonomic fit for optimal performance.

What Role Do Custom Leather Gloves Play in Construction?

In construction, custom leather gloves serve as protective gear for workers engaged in labor-intensive tasks. These gloves not only comply with safety regulations but also mitigate the risk of hand injuries from tools and heavy materials. Buyers must consider gloves that offer a balance between durability and dexterity, allowing for ease of movement while providing adequate protection. Sourcing should prioritize gloves that meet industry safety standards and offer features like reinforced stitching and grip-enhancing palm designs.

Why Are Custom Leather Gloves Important in Agriculture?

In agriculture, custom leather gloves are vital for tasks involving livestock handling and machinery operation. They protect against abrasions and provide comfort for extended periods of wear. Buyers in this sector should seek gloves that are breathable and water-resistant, ensuring they remain functional in various weather conditions. Sourcing considerations should include the gloves’ ease of cleaning, as hygiene is crucial when working with livestock and food products.

How Do Custom Leather Gloves Benefit Food Processing Operations?

In food processing, custom leather gloves are utilized to maintain hygiene and prevent contamination during food handling and preparation. These gloves ensure compliance with health regulations while providing comfort and dexterity for workers. Buyers need to ensure that the gloves are FDA compliant and easy to maintain, as frequent washing is often required. Custom sizing options can enhance fit and comfort, which is particularly important for employees who handle food products for long durations.

What Are the Key Features of Custom Leather Gloves in Oil & Gas Industries?

In the oil and gas industry, custom leather gloves are crucial for providing protection in hazardous environments. These gloves are designed to resist chemicals and heat, ensuring worker safety while handling equipment and materials. Buyers should focus on sourcing gloves that meet specific certification standards for safety and durability. Additionally, considerations should include the gloves’ material properties, such as resistance to punctures and abrasions, to ensure optimal performance in challenging conditions.

3 Common User Pain Points for ‘custom leather gloves’ & Their Solutions

Scenario 1: Sizing Challenges Leading to Poor Fit

The Problem: One of the most common pain points for B2B buyers of custom leather gloves is ensuring the right fit for their employees or clients. Inaccurate sizing can result in discomfort, decreased productivity, and even safety hazards, particularly in industries such as construction, automotive, or manufacturing where a proper grip is essential. Additionally, the lack of a standardized sizing chart across different manufacturers can exacerbate this issue, leading to confusion and potential dissatisfaction with the purchase.

The Solution: To mitigate sizing challenges, buyers should invest time in establishing a clear and standardized sizing protocol. This can be achieved by providing employees with hand tracing templates or sizing guides from the manufacturers. For instance, requesting suppliers to include a detailed sizing guide alongside their product offerings can help ensure accuracy. Additionally, consider ordering sample sizes to facilitate a fitting process before making bulk purchases. Encourage employees to measure their hand dimensions accurately and refer to the supplier’s size chart to select the most appropriate size. This proactive approach not only enhances comfort but also boosts morale and efficiency among users.

Scenario 2: Quality Concerns with Customization

The Problem: B2B buyers often face concerns regarding the quality and durability of custom leather gloves, especially when ordered in large quantities. When sourcing gloves for specific tasks, such as driving or heavy-duty work, the risk of receiving subpar products that do not meet industry standards can lead to safety issues and financial loss. Poor quality can manifest in the form of inadequate stitching, inferior leather, or lack of durability, which can ultimately damage the company’s reputation and lead to customer dissatisfaction.

The Solution: To ensure high-quality custom leather gloves, buyers should conduct thorough research on potential suppliers. Look for manufacturers with a strong reputation for craftsmanship and reliability. Request samples before committing to large orders, allowing you to assess the material quality and construction firsthand. Furthermore, inquire about the sourcing of the leather used and the production methods employed. Establishing a clear communication channel with suppliers to discuss quality expectations and standards can also help mitigate risks. Additionally, consider implementing a quality assurance process upon receiving shipments to verify that products meet the agreed-upon specifications.

Scenario 3: Long Lead Times Affecting Inventory Management

The Problem: Long lead times for the production and delivery of custom leather gloves can pose significant challenges for B2B buyers, particularly those in industries with fluctuating demand. Delays in receiving gloves can disrupt workflow, hinder project timelines, and create inventory shortages, leading to operational inefficiencies and lost revenue. This is especially critical for businesses that rely on seasonal labor or have specific project deadlines to meet.

The Solution: To address lead time issues, buyers should engage in proactive supply chain management. Start by assessing and choosing suppliers with a proven track record of timely deliveries and transparent communication regarding production timelines. Establish a clear timeline for your orders and communicate your expectations upfront. If possible, consider placing orders well in advance of peak seasons or project starts to buffer against potential delays. Additionally, explore the possibility of building a strategic partnership with a reliable supplier, which can facilitate better inventory management and quicker response times in urgent situations. Implementing a just-in-time inventory system can also help maintain optimal stock levels without overcommitting resources.

Strategic Material Selection Guide for custom leather gloves

What are the Key Properties of Common Materials Used in Custom Leather Gloves?

When selecting materials for custom leather gloves, it is essential to consider the unique properties of each type of leather. The most commonly used materials include goat leather, cowhide, peccary leather, and deerskin. Each material has distinct characteristics that affect performance, durability, and suitability for various applications.

Goat Leather: A Versatile Choice for Custom Gloves

Goat leather is renowned for its softness and flexibility, making it an excellent choice for gloves that require dexterity. It typically offers good abrasion resistance and can withstand various temperatures, providing comfort in diverse environments. However, goat leather may not be as durable as thicker leathers, which can limit its lifespan in high-stress applications.

Pros: Soft, flexible, good abrasion resistance.

Cons: Less durable than thicker leathers, potentially higher wear in demanding conditions.

Impact on Application: Suitable for tasks requiring high dexterity, such as driving or fine assembly work.

Considerations for International Buyers: Goat leather gloves may need to comply with specific quality standards, such as ASTM or DIN, depending on the target market.

Illustrative image related to custom leather gloves

Cowhide: The Durable Workhorse

Cowhide is one of the most widely used leathers in glove manufacturing due to its strength and durability. It offers excellent resistance to abrasion and puncture, making it ideal for heavy-duty applications. However, cowhide can be heavier and less flexible than other leathers, which may impact comfort during extended wear.

Pros: Highly durable, good abrasion and puncture resistance.

Cons: Heavier, less flexible, may require longer break-in periods.

Impact on Application: Ideal for industrial settings, construction, and heavy machinery operation.

Considerations for International Buyers: Buyers should ensure compliance with local safety standards and regulations, particularly in industries like construction and manufacturing.

Peccary Leather: Luxury and Performance Combined

Peccary leather, sourced from the peccary animal, is known for its luxurious feel and exceptional durability. It provides excellent grip and comfort, making it a favorite for high-end driving gloves. However, peccary leather is more expensive and may not be suitable for all budgets.

Pros: Luxurious feel, excellent grip, high durability.

Cons: High cost, limited availability, may require special care.

Impact on Application: Best suited for luxury markets, high-performance driving, and fashion-oriented applications.

Considerations for International Buyers: Buyers should be aware of ethical sourcing practices and potential import restrictions related to exotic leathers.

Illustrative image related to custom leather gloves

Deerskin: Softness Meets Comfort

Deerskin is prized for its softness and comfort, making it a popular choice for gloves designed for extended wear. It offers good insulation and is naturally breathable, which can be advantageous in varying climates. However, deerskin is less resistant to abrasion compared to cowhide or goat leather, which may limit its use in demanding environments.

Pros: Soft, comfortable, good insulation and breathability.

Cons: Less durable, lower abrasion resistance.

Impact on Application: Suitable for outdoor activities, driving, and casual use.

Considerations for International Buyers: Compliance with environmental regulations regarding leather sourcing is crucial, especially in regions with strict wildlife protection laws.

Summary Table of Material Selection for Custom Leather Gloves

| Материал | Typical Use Case for custom leather gloves | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Goat Leather | Driving, fine assembly work | Soft and flexible | Less durable than thicker leathers | Medium |

| Cowhide | Industrial, construction | Highly durable | Heavier, less flexible | Низкий |

| Peccary Leather | Luxury driving, fashion | Luxurious feel, excellent grip | High cost, limited availability | Высокий |

| Deerskin | Outdoor activities, casual use | Soft, comfortable | Lower abrasion resistance | Medium |

This guide provides a comprehensive overview of the materials used in custom leather gloves, aiding international B2B buyers in making informed decisions based on performance, application suitability, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather gloves

What Are the Main Stages of the Manufacturing Process for Custom Leather Gloves?

The manufacturing process for custom leather gloves involves several critical stages, each contributing to the final product’s quality and uniqueness. Understanding these stages will help B2B buyers appreciate the craftsmanship involved and make informed purchasing decisions.

How is Material Prepared for Custom Leather Gloves?

The journey begins with material preparation, where high-quality leather is sourced, often from reputable suppliers known for their sustainable practices. Common materials include goat leather, peccary, and deerskin, selected for their durability and aesthetic appeal. Before cutting, the leather undergoes conditioning to ensure it is supple and free of imperfections. Buyers should inquire about the source of the leather and any certifications that verify ethical sourcing practices.

What Techniques Are Used in Forming Custom Leather Gloves?

Forming is the next stage, where the leather is cut into specific patterns based on glove designs. Advanced cutting techniques, such as die-cutting or laser cutting, ensure precision and minimize waste. This is followed by a meticulous process of shaping the leather to fit the contours of the hand. Hand-sewing techniques are often employed to assemble the pieces, allowing for greater flexibility and customization. B2B buyers should look for manufacturers that utilize skilled artisans, as this craftsmanship greatly impacts the glove’s fit and finish.

How is Assembly Conducted for Custom Leather Gloves?

During assembly, the cut leather pieces are stitched together. This stage may involve various stitching techniques, such as saddle stitching, which provides strength and durability. The assembly process can also include adding features like linings, padding, or closures, depending on the glove’s intended use. B2B buyers should ask about the specific assembly methods used, as these can influence both the performance and longevity of the gloves.

What Finishing Techniques Are Applied to Custom Leather Gloves?

Finishing is the final step in the manufacturing process, where gloves are treated to enhance their appearance and functionality. This can include polishing, dyeing, and applying protective coatings to ensure water resistance and stain protection. Additionally, quality checks are performed at this stage to ensure that each glove meets the required standards. Buyers should request information about the finishing techniques used, as these can significantly impact the product’s quality and marketability.

What Quality Assurance Standards Should B2B Buyers Expect for Custom Leather Gloves?

Quality assurance (QA) is critical in the manufacturing of custom leather gloves, ensuring that products meet specific standards and regulations. B2B buyers should be aware of the relevant international and industry-specific standards that govern quality.

Which International Standards Are Relevant for Quality Assurance in Custom Leather Gloves?

ISO 9001 is a widely recognized international standard for quality management systems. Manufacturers adhering to this standard demonstrate their commitment to quality and continuous improvement. Other standards, such as CE marking in Europe, indicate compliance with health, safety, and environmental protection standards. Buyers should verify that their suppliers maintain these certifications, as they are essential for ensuring product reliability and safety.

Illustrative image related to custom leather gloves

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are essential for maintaining product quality throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor adherence to production standards and identify any defects early.

- Final Quality Control (FQC): Before shipment, finished gloves undergo a comprehensive inspection to verify that they meet design specifications and quality standards.

B2B buyers should inquire about the specific QC procedures their suppliers implement to ensure consistent quality.

What Common Testing Methods Are Used to Ensure Quality in Custom Leather Gloves?

Manufacturers employ various testing methods to validate the quality of custom leather gloves. These methods may include:

- Tensile Strength Testing: Measures the durability of the leather and stitching.

- Water Resistance Testing: Ensures that gloves can withstand exposure to moisture without compromising quality.

- Dimensional Stability Testing: Assesses whether gloves maintain their shape and size after washing or use.

Buyers should request information about the testing methods employed by their suppliers, as this can provide insights into the product’s performance and longevity.

Illustrative image related to custom leather gloves

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is crucial for B2B buyers, especially when dealing with international suppliers. Here are effective strategies to ensure quality:

- Conduct Supplier Audits: Regular audits can help assess compliance with quality standards and operational practices. Buyers can perform these audits themselves or hire third-party inspection services.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including inspection reports and test results. This transparency is vital for building trust.

- Utilize Third-Party Inspection Services: Engaging third-party inspectors can provide an unbiased evaluation of the supplier’s quality control practices and product quality before shipment.

What Are the Quality Control Nuances for International B2B Buyers from Different Regions?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control practices. For instance:

- Regulatory Differences: Different regions may have varying regulations regarding leather goods. Buyers must ensure that their suppliers comply with local regulations to avoid legal complications.

- Cultural Expectations: Buyers from different cultures may have unique expectations regarding product quality and customer service. Understanding these cultural differences can facilitate better communication and collaboration with suppliers.

- Logistical Considerations: International shipping can introduce additional challenges, such as customs inspections and delays. Buyers should ensure that their suppliers are experienced in navigating these logistical complexities to maintain product quality during transport.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing custom leather gloves, ensuring they partner with reputable suppliers who prioritize quality and craftsmanship.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather gloves’

In the competitive landscape of B2B procurement, sourcing custom leather gloves requires a structured approach to ensure quality, compliance, and value. This guide provides a comprehensive checklist for international buyers, particularly from Africa, South America, the Middle East, and Europe, to facilitate informed decision-making throughout the sourcing process.

Illustrative image related to custom leather gloves

Step 1: Define Your Technical Specifications

Clearly outlining your requirements is essential for aligning with suppliers. Consider factors such as glove type (e.g., work, driving, fashion), materials (e.g., goat leather, peccary, deerskin), and any specific features (e.g., fingerless options, custom engraving). Precise specifications help suppliers understand your needs and provide accurate quotes.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in custom leather gloves. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers. Pay attention to their reputation, experience, and customer reviews to gauge reliability and quality.

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications to ensure compliance with international standards. Look for certifications related to quality management (ISO 9001), environmental practices (ISO 14001), and ethical labor practices. These certifications can serve as indicators of a supplier’s commitment to quality and sustainability.

Step 4: Request Samples

Requesting samples is a critical step to assess the quality of the gloves. Evaluate the craftsmanship, material quality, and overall finish of the samples. This hands-on experience will allow you to determine if the supplier meets your quality standards and design expectations before placing a larger order.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, initiate negotiations on pricing and terms. Discuss volume discounts, payment terms, and delivery timelines. Clear communication during this stage can lead to more favorable conditions and help establish a mutually beneficial relationship.

Illustrative image related to custom leather gloves

Step 6: Establish a Communication Plan

Effective communication is vital for successful collaboration. Set up a plan detailing how you will communicate with the supplier throughout the production process. Consider regular updates, feedback mechanisms, and points of contact to address any concerns promptly.

Step 7: Finalize Contracts and Agreements

Before proceeding with the order, ensure that all agreements are documented in a formal contract. This should include specifications, pricing, delivery schedules, and quality assurance processes. A well-defined contract protects both parties and sets clear expectations, minimizing the risk of misunderstandings.

By following this structured checklist, B2B buyers can navigate the sourcing process for custom leather gloves with confidence, ensuring they select the right supplier to meet their specific needs while fostering long-term partnerships.

Comprehensive Cost and Pricing Analysis for custom leather gloves Sourcing

What Are the Key Cost Components of Custom Leather Gloves?

When sourcing custom leather gloves, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to custom leather gloves

-

Materials: The type of leather used significantly impacts costs. Goat, peccary, and deerskin are common choices, with varying price points depending on quality and availability. Specialty leathers may incur higher costs but offer enhanced durability and aesthetic appeal.

-

Labor: Labor costs are influenced by the skill level of artisans. Handcrafted gloves, which involve meticulous stitching and personalization, generally command higher labor costs than machine-produced alternatives. In regions where skilled labor is limited, expect to pay a premium.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Factories in regions with lower operational costs may offer more competitive pricing.

-

Tooling: Customization often requires specialized tooling, which can add to initial costs. Buyers should inquire about these costs upfront, as they can vary based on the complexity of the design.

-

Quality Control (QC): Effective QC processes ensure that products meet specifications and quality standards. Robust QC measures may increase costs but can prevent costly returns and dissatisfaction down the line.

-

Logistics: Shipping and handling costs can vary widely based on distance, shipping method, and volume. Buyers should consider Incoterms to understand responsibilities for shipping and customs duties.

-

Margin: Suppliers typically apply a margin to cover their overhead and profit. Understanding the margin structure can help buyers assess whether a price is competitive.

How Do Price Influencers Affect Custom Leather Gloves?

Several factors influence the pricing of custom leather gloves, including volume, specifications, material quality, supplier reputation, and logistical considerations.

-

Volume/MOQ: Purchasing in bulk can lead to significant cost savings. Many suppliers offer tiered pricing, where larger orders result in lower per-unit costs. Understanding Minimum Order Quantities (MOQ) is crucial for budget planning.

-

Specifications and Customization: Custom features such as monograms, unique color combinations, or specific design elements can increase costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., eco-friendly or sustainable sourcing) can raise prices. However, investing in quality can enhance the product’s lifespan and appeal.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers may charge more due to their proven track record, but they often provide better service and quality assurance.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms like DAP (Delivered at Place) or FOB (Free on Board) dictate who bears shipping costs and risks, influencing the total price.

What Are Effective Buyer Tips for Negotiating Prices on Custom Leather Gloves?

B2B buyers should adopt strategic approaches to ensure cost-efficiency and favorable terms when sourcing custom leather gloves.

-

Negotiate Terms: Don’t hesitate to negotiate pricing, especially on larger orders. Suppliers may offer discounts for bulk purchases or long-term contracts.

-

Evaluate Total Cost of Ownership: Consider all costs, including shipping, import duties, and potential returns. A lower initial price may not always equate to better value if ongoing costs are high.

-

Research Market Prices: Understanding the market landscape can empower buyers during negotiations. Comparing quotes from multiple suppliers can reveal competitive pricing and help identify red flags.

-

Consider Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and exclusive offers. Look for suppliers who are willing to adapt to your specific needs.

-

Be Aware of Regional Nuances: International buyers, particularly from Africa, South America, the Middle East, and Europe, should be mindful of regional factors such as currency fluctuations and local regulations that can affect pricing.

Disclaimer

Prices for custom leather gloves can vary widely based on the aforementioned factors. This analysis provides a general overview; actual costs may differ based on specific requirements and supplier agreements. Always conduct thorough research and obtain detailed quotes tailored to your specific needs.

Illustrative image related to custom leather gloves

Alternatives Analysis: Comparing custom leather gloves With Other Solutions

Understanding Alternative Solutions for Custom Leather Gloves

When evaluating custom leather gloves, it is essential to consider alternative solutions that can serve similar functions or meet comparable needs. This analysis will explore how custom leather gloves stack up against other options, such as synthetic gloves and work gloves made from alternative materials, allowing B2B buyers to make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | Custom Leather Gloves | Synthetic Gloves | Work Gloves (Cotton/Polyester) |

|---|---|---|---|

| Performance | High durability and comfort; offers excellent grip and protection. | Good grip; may not be as durable in harsh conditions. | Moderate durability; suitable for light to moderate tasks. |

| Cost | Higher initial investment; value reflects quality and longevity. | Lower cost; economical for bulk purchases. | Generally low-cost; ideal for large-scale needs. |

| Ease of Implementation | Requires customization, which can take time. | Readily available in various sizes and styles. | Easy to source and distribute, widely available. |

| Maintenance | Requires special care to maintain quality; may need conditioning. | Low maintenance; easy to clean. | Simple maintenance; machine washable. |

| Best Use Case | Ideal for specialized tasks requiring high precision and comfort. | Suitable for general use and disposable applications. | Best for bulk use in less specialized environments. |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Synthetic Gloves?

Synthetic gloves, typically made from materials like nitrile or latex, provide a cost-effective alternative to custom leather gloves. They are lightweight and often designed for specific tasks, such as medical or food handling. While they can offer good grip and flexibility, their durability may be compromised in extreme conditions. They are also less comfortable for extended wear, which can be a significant disadvantage for users needing prolonged protection.

How Do Work Gloves Made from Cotton or Polyester Compare?

Work gloves made from cotton or polyester are an economical choice for businesses needing a large quantity of gloves for general tasks. They offer decent protection against minor abrasions but lack the durability and comfort of leather options. These gloves are easily washable and can be replaced affordably, making them suitable for low-risk environments. However, for tasks requiring enhanced dexterity or protection, these gloves may fall short, leading to potential safety concerns.

Illustrative image related to custom leather gloves

Conclusion: Choosing the Right Solution for Your Needs

When selecting between custom leather gloves and alternative solutions, B2B buyers should consider several factors, including the specific application, budget constraints, and desired performance levels. Custom leather gloves offer unparalleled durability and comfort, making them ideal for specialized tasks where precision is paramount. In contrast, synthetic gloves and cotton/polyester work gloves may serve well for general purposes or disposable needs at a lower cost. Ultimately, the best choice hinges on balancing quality, cost, and the intended use to ensure optimal performance in your business operations.

Essential Technical Properties and Trade Terminology for custom leather gloves

What Are the Key Technical Properties of Custom Leather Gloves?

When sourcing custom leather gloves, understanding their technical properties is essential for making informed purchasing decisions. Here are several critical specifications to consider:

1. Material Grade

The grade of leather used in gloves significantly impacts their durability, comfort, and aesthetic appeal. Common materials include goat leather, deerskin, and peccary. Higher-grade leathers are typically more resistant to wear and tear, offering better longevity for industrial or personal use. B2B buyers should prioritize sourcing gloves made from premium materials, as this ensures better performance and customer satisfaction.

2. Stitching Quality

The stitching method and thread type contribute to the glove’s overall strength and flexibility. Hand-sewn gloves often feature stronger seams compared to machine-sewn options. It’s vital to assess the stitching technique, as high-quality stitching minimizes the risk of unraveling, especially in high-stress applications. This specification is particularly important for buyers seeking gloves for heavy-duty use, as it directly affects the product’s lifespan.

3. Sizing Tolerance

Accurate sizing is crucial for both comfort and functionality. Custom gloves should adhere to specific sizing tolerances to ensure a proper fit. This is particularly important in B2B transactions, where bulk orders may involve various hand sizes. A sizing guide, including hand measurement templates, can help buyers ensure they are ordering the right sizes, reducing the risk of returns and enhancing customer satisfaction.

4. Breathability and Comfort

Breathability refers to the leather’s ability to allow air circulation, which affects comfort during extended wear. Gloves made from naturally breathable leathers provide better moisture management, making them suitable for various climates and activities. Buyers should inquire about the breathability of the leather to ensure that the gloves will be comfortable for their intended use, whether for work or leisure.

5. Customization Options

Customization is a key selling point for many B2B buyers. Options may include color variations, monograms, and personalized features. Understanding the extent of customization available allows buyers to create a unique product that meets their specific branding or functional needs. This is particularly relevant for businesses looking to enhance their corporate identity or offer bespoke products to their customers.

Which Trade Terminology Should B2B Buyers Know?

Familiarizing yourself with industry-specific terminology is essential for effective communication in the custom leather glove market. Here are some common terms:

Illustrative image related to custom leather gloves

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then branded and sold by another company. In the leather glove industry, this means sourcing gloves from a manufacturer who produces them under your brand name. Understanding OEM relationships can help buyers negotiate better terms and quality standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers who need to assess whether they can meet the supplier’s minimum requirement. Understanding MOQ helps in inventory planning and managing cash flow, especially for smaller businesses or startups.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. In the custom leather glove industry, submitting an RFQ can help buyers compare quotes from different manufacturers, ensuring they receive the best deal for their specifications.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They clarify who pays for shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers, as they can significantly impact overall costs and risk management.

5. Lead Time

Lead time refers to the time taken from placing an order until delivery. In the context of custom leather gloves, this can vary based on the complexity of customization and the manufacturer’s capacity. Knowing the lead time helps buyers plan their inventory and manage customer expectations effectively.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing custom leather gloves, ensuring they choose products that meet their operational needs and quality standards.

Navigating Market Dynamics and Sourcing Trends in the custom leather gloves Sector

What Are the Current Market Dynamics and Key Trends in Custom Leather Gloves?

The custom leather gloves market is experiencing a notable evolution driven by increasing consumer demand for personalized products and a growing emphasis on quality and craftsmanship. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking unique offerings that combine functionality with aesthetic appeal. The rise of e-commerce platforms and digital configurators is enabling buyers to customize products to their specifications, enhancing the purchasing experience. This trend is particularly strong in markets such as Germany and Brazil, where consumers appreciate both style and performance.

Emerging technologies, such as 3D printing and AI-driven design tools, are transforming the production process. These innovations allow manufacturers to create bespoke gloves with high precision and reduced lead times, catering to the fast-paced demands of global markets. Additionally, automation in supply chains is improving efficiency, helping suppliers manage inventory better and reduce costs. As a result, businesses can offer competitive pricing while maintaining high standards of quality.

Illustrative image related to custom leather gloves

Another significant trend is the growing inclination towards multifunctional gloves that serve diverse purposes—from industrial applications to luxury fashion. This versatility is appealing to B2B buyers who seek products that can meet various market needs. Overall, the custom leather gloves sector is adapting to these dynamic market forces, providing opportunities for international buyers to source innovative and high-quality products.

How Important Is Sustainability and Ethical Sourcing in Custom Leather Gloves?

Sustainability is becoming a paramount consideration in the custom leather gloves market. As global awareness of environmental issues rises, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable practices. The leather industry, traditionally associated with significant environmental impacts, is undergoing transformations to mitigate these effects. Buyers are now more inclined to partner with manufacturers who utilize eco-friendly tanning processes, which minimize chemical usage and reduce water consumption.

Moreover, the demand for ‘green’ certifications is on the rise. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential criteria for B2B buyers seeking assurance of sustainable practices. By sourcing from certified suppliers, companies can enhance their brand image and appeal to environmentally conscious consumers.

Additionally, there is a growing trend toward using alternative materials, such as plant-based leathers or recycled materials, in the production of custom leather gloves. These innovations not only reduce environmental impact but also cater to a niche market segment that values sustainability. In summary, integrating sustainability into sourcing strategies is not just a trend but a necessity for B2B buyers looking to thrive in the evolving market landscape.

What Is the Historical Context Behind Custom Leather Gloves?

The history of custom leather gloves dates back centuries, with origins rooted in craftsmanship and functionality. Initially, gloves served practical purposes, providing protection for hands in various trades and during harsh weather conditions. Over time, they evolved into symbols of status and style, particularly in European fashion.

In the 18th and 19th centuries, custom gloves became a hallmark of luxury, often handcrafted by skilled artisans. This era saw a rise in specialized glove-making techniques, with an emphasis on fit and design. The introduction of industrial processes in the 20th century changed the landscape, making gloves more accessible but often sacrificing quality for mass production.

Today, the custom leather gloves market is witnessing a renaissance, blending traditional craftsmanship with modern technology. Buyers are increasingly drawn to bespoke offerings that reflect personal style and preferences, creating a rich tapestry of opportunities for businesses in this sector. The evolution from practical utility to luxury item illustrates the enduring appeal of custom leather gloves in both historical and contemporary contexts.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather gloves

-

1. How do I choose the right supplier for custom leather gloves?

When selecting a supplier for custom leather gloves, prioritize those with a proven track record in quality craftsmanship and timely delivery. Look for manufacturers with certifications that ensure ethical sourcing and production standards. Request samples to assess the material quality and craftsmanship. Additionally, consider their ability to accommodate your specific customization needs and their responsiveness to inquiries. Don’t hesitate to ask for references or reviews from other businesses to gauge their reliability. -

2. What are the typical minimum order quantities (MOQs) for custom leather gloves?

Minimum order quantities can vary significantly among suppliers, often ranging from 50 to 500 pairs depending on the customization options and materials used. Larger MOQs may yield better pricing, while smaller orders could incur additional setup fees. It’s important to discuss your requirements with potential suppliers to find a balance that meets your needs while ensuring cost-effectiveness. Always confirm the MOQ during initial discussions to avoid misunderstandings later. -

3. How can I ensure the quality of custom leather gloves?

To ensure the quality of custom leather gloves, start by requesting detailed product specifications, including the type of leather used, stitching techniques, and finishing options. Implement a quality assurance process that includes pre-production samples and regular communication with the supplier during manufacturing. Consider arranging for third-party inspections if shipping internationally, which can provide an unbiased assessment of product quality before shipment. Establishing clear quality standards in your contract can also help maintain consistency. -

4. What payment terms should I expect when ordering custom leather gloves?

Payment terms for custom leather gloves typically vary by supplier but may include options such as a deposit upfront (usually 30-50%) with the balance due upon delivery or net payment terms (e.g., net 30 days). Ensure that you understand the payment options available and any potential fees associated with international transactions. Using secure payment methods that offer buyer protection can mitigate risks, especially when dealing with new suppliers. -

5. How long does it take to receive custom leather gloves after placing an order?

The lead time for custom leather gloves can range from 4 to 12 weeks, depending on factors such as the complexity of customization, supplier capacity, and shipping logistics. It’s essential to discuss timelines during the initial negotiation phase and factor in additional time for potential delays, such as customs clearance. Establishing a clear timeline in your purchase agreement can help manage expectations and ensure timely delivery. -

6. What are the shipping options for international orders of custom leather gloves?

International shipping options for custom leather gloves generally include standard and express services through major carriers like UPS, DHL, or FedEx. Suppliers may offer different shipping terms, including DAP (Delivered At Place), which means you’ll be responsible for import duties and taxes. Always clarify shipping costs, delivery times, and who bears responsibility for damages during transit. Ensure that the supplier provides tracking information for better visibility during shipping. -

7. How do I handle customization requests for unique designs?

When handling customization requests for unique designs, communicate clearly with your supplier about your specific requirements, including materials, colors, and sizing. Providing detailed sketches or design mock-ups can facilitate the process. Many suppliers offer configurators or design consultations to help refine your vision. Be open to suggestions from the supplier’s design team, as their expertise can enhance the functionality and aesthetics of the gloves. -

8. What should I know about import regulations when sourcing custom leather gloves?

When sourcing custom leather gloves internationally, familiarize yourself with the import regulations of your country, including tariffs, taxes, and any restrictions on leather products. Consult with a customs broker if necessary to ensure compliance with local laws. Understanding these regulations can help prevent unexpected costs and delays upon arrival. Additionally, ensure that your supplier provides all necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance.

Top 3 Custom Leather Gloves Manufacturers & Suppliers List

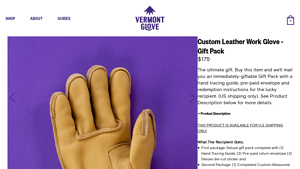

1. Vermont Glove – Custom Leather Work Glove Gift Pack

Domain: vermontglove.com

Registered: 2018 (7 years)

Введение: {“product_name”:”Custom Leather Work Glove – Gift Pack”,”price”:”$175″,”shipping”:”U.S. shipping only”,”gift_pack_contents”:{“first_package”:[“Hand Tracing Guide”,”Pre-paid return envelope”,”Deluxe die-cut sticker”],”second_package”:[“Completed Custom-Measured & Monogrammed pair of Vermonter gloves”,”Custom canvas glove bag”,”Leather Conditioner”,”Carpenter pencil”]},”how_it_works”:”1. Buy the Bes…

2. Opinari – Custom Made Driving Gloves

Domain: opinari-drivers.com

Registered: 2017 (8 years)

Введение: Custom Made Driving Gloves Service, handcrafted in Italy. Free delivery for orders over €150, free Express shipping outside Europe. Available collections include Classic collection, Modern collection, Winter collection, and Travel series. Accessories include bags, sweaters, tees, and gift cards.

3. Sullivan Glove – Work Collection

Domain: sullivanglove.com

Registered: 1999 (26 years)

Введение: Collection: Work

– 100% Made in the USA

– Free Shipping in USA on all orders over $50

– Products include:

1. Buffalo Roper – $85.00 (Sold out)

2. Deerskin Roper – $85.00 (Sold out)

3. Deerskin Gardener – $85.00 (Sold out)

4. Elk Roper – $85.00 (Sold out)

5. Goat Roper – $75.00 (Sold out)

6. Buffalo Roper: Lined – $95.00 (Sold out)

7. Elk Roper: Lined – $95.00 (Sold out)

8. Goat Rop…

Strategic Sourcing Conclusion and Outlook for custom leather gloves

In the evolving landscape of custom leather gloves, strategic sourcing remains a critical component for international B2B buyers looking to enhance their offerings. By focusing on quality materials, skilled craftsmanship, and personalized service, companies can differentiate themselves in a competitive market. The demand for bespoke solutions, especially from regions like Africa, South America, the Middle East, and Europe, underscores the importance of understanding local preferences and market dynamics.

Illustrative image related to custom leather gloves

Investing in strategic sourcing not only ensures superior product quality but also fosters long-term partnerships with suppliers who share a commitment to excellence. Buyers are encouraged to leverage innovative technologies, such as online configurators, to create unique products that resonate with their customer base.

Looking ahead, the global market for custom leather gloves is poised for growth, driven by an increasing appreciation for artisan craftsmanship and personalized products. As you navigate this landscape, consider the impact of your sourcing decisions on brand reputation and customer loyalty. Embrace the opportunity to collaborate with skilled artisans and explore diverse materials, ensuring that your product offerings remain relevant and desirable. Engage with suppliers today to secure your place in this thriving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.