Introduction: Navigating the Global Market for nubuck leather material

In the ever-evolving landscape of B2B sourcing, navigating the global market for nubuck leather material presents both exciting opportunities and significant challenges. As international buyers from regions such as Africa, South America, the Middle East, and Europe grapple with sourcing high-quality nubuck leather for various applications—from luxury footwear to upscale upholstery—the need for a comprehensive understanding of this premium material becomes paramount. Nubuck leather, characterized by its velvety texture and durability, offers an elegant yet robust choice for discerning manufacturers and retailers.

This guide aims to equip you with essential insights into the diverse types of nubuck leather available, their unique applications across industries, and effective strategies for vetting suppliers. Moreover, we will delve into cost considerations, ensuring that you can make informed purchasing decisions while balancing quality and budget constraints. By demystifying the intricacies of nubuck leather sourcing, this resource empowers B2B buyers to confidently navigate their procurement processes, mitigate risks, and capitalize on the luxurious appeal of nubuck in their product offerings.

As you explore the nuances of this material, you will gain a clearer perspective on how to leverage nubuck leather’s attributes to meet market demands and enhance your brand’s reputation for quality and sophistication.

Table Of Contents

- Top 8 Nubuck Leather Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for nubuck leather material

- Understanding nubuck leather material Types and Variations

- Key Industrial Applications of nubuck leather material

- 3 Common User Pain Points for ‘nubuck leather material’ & Their Solutions

- Strategic Material Selection Guide for nubuck leather material

- In-depth Look: Manufacturing Processes and Quality Assurance for nubuck leather material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘nubuck leather material’

- Comprehensive Cost and Pricing Analysis for nubuck leather material Sourcing

- Alternatives Analysis: Comparing nubuck leather material With Other Solutions

- Essential Technical Properties and Trade Terminology for nubuck leather material

- Navigating Market Dynamics and Sourcing Trends in the nubuck leather material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of nubuck leather material

- Strategic Sourcing Conclusion and Outlook for nubuck leather material

- Important Disclaimer & Terms of Use

Understanding nubuck leather material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Nubuck | Soft, velvety texture; made from the grain layer of the hide | Footwear, bags, upholstery | Pros: Durable and stylish; Cons: Susceptible to staining. |

| Waterproof Nubuck | Treated for water resistance; maintains softness | Outdoor gear, high-end fashion footwear | Pros: Resistant to moisture; Cons: Higher cost due to treatment. |

| Vegetable-Tanned Nubuck | Eco-friendly tanning process; retains natural characteristics | Sustainable fashion, luxury goods | Pros: Biodegradable; Cons: May require more care. |

| Baby Calf Nubuck | Sourced from younger animals; softer and finer texture | High-end accessories, luxury footwear | Pros: Luxurious feel; Cons: Higher price point. |

| Upcycled Nubuck | Made from recycled leather materials; eco-conscious option | Sustainable products, niche markets | Pros: Cost-effective; Cons: Varied quality due to sourcing. |

What Are the Characteristics of Standard Nubuck Leather?

Standard nubuck is characterized by its soft, velvety texture, which results from lightly sanding the grain layer of the hide. This type of nubuck is widely used in the footwear and upholstery sectors due to its durability and aesthetic appeal. For B2B buyers, it is essential to consider the potential for staining, which can impact the longevity and appearance of the final product. When sourcing standard nubuck, ensure that the hides are of high quality to minimize imperfections.

Illustrative image related to nubuck leather material

Why Choose Waterproof Nubuck for Outdoor Applications?

Waterproof nubuck is treated to resist moisture while maintaining its soft texture. This makes it particularly suitable for outdoor gear and high-end fashion footwear that require both style and functionality. B2B buyers should prioritize suppliers who can guarantee the effectiveness of the waterproofing treatment, as this can significantly enhance the product’s usability in various weather conditions. While the price may be higher due to additional treatments, the investment often pays off in customer satisfaction and product longevity.

What Makes Vegetable-Tanned Nubuck a Sustainable Choice?

Vegetable-tanned nubuck is produced using natural tannins, making it an eco-friendly option for brands focused on sustainability. This type retains the natural characteristics of the leather, providing a unique appearance and feel. B2B buyers interested in sustainable fashion or luxury goods should consider vegetable-tanned nubuck for its biodegradability and lower environmental impact. However, it’s important to note that this type may require more care to maintain its appearance over time.

How Does Baby Calf Nubuck Compare to Other Types?

Baby calf nubuck is sourced from younger animals, resulting in a softer and finer texture compared to standard nubuck. This luxurious feel makes it ideal for high-end accessories and luxury footwear. B2B buyers should be aware that while the quality is superior, the price point is typically higher. When sourcing baby calf nubuck, it’s crucial to verify the authenticity and quality of the hides to ensure that they meet the standards expected in luxury markets.

What Are the Benefits of Upcycled Nubuck Leather?

Upcycled nubuck leather is created from recycled materials, offering an eco-conscious alternative for brands looking to minimize waste. This type can be a cost-effective option for sustainable products and niche markets. B2B buyers should consider the variability in quality due to the sourcing process and ensure that the upcycled nubuck meets their specific requirements. This approach not only supports sustainability but also appeals to environmentally conscious consumers.

Key Industrial Applications of nubuck leather material

| Industry/Sector | Specific Application of nubuck leather material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | High-end shoes and boots | Offers a luxurious look and feel, enhancing brand prestige. | Ensure consistent quality and availability of premium hides. |

| Upholstery and Furniture | Sofas, chairs, and cushions | Provides durability and a sophisticated aesthetic for furniture. | Consider water-resistant treatments for longevity in high-use areas. |

| Fashion and Accessories | Handbags, wallets, and belts | Combines style with functionality, appealing to fashion-conscious consumers. | Source from reputable tanneries to ensure ethical practices. |

| Automotive Interiors | Car seats and interiors | Enhances luxury feel while maintaining durability and ease of cleaning. | Look for suppliers offering treated nubuck to resist stains and wear. |

| Sporting Goods | Premium sports equipment and apparel | Provides comfort and style, enhancing the user experience. | Verify the material’s performance characteristics for specific sports. |

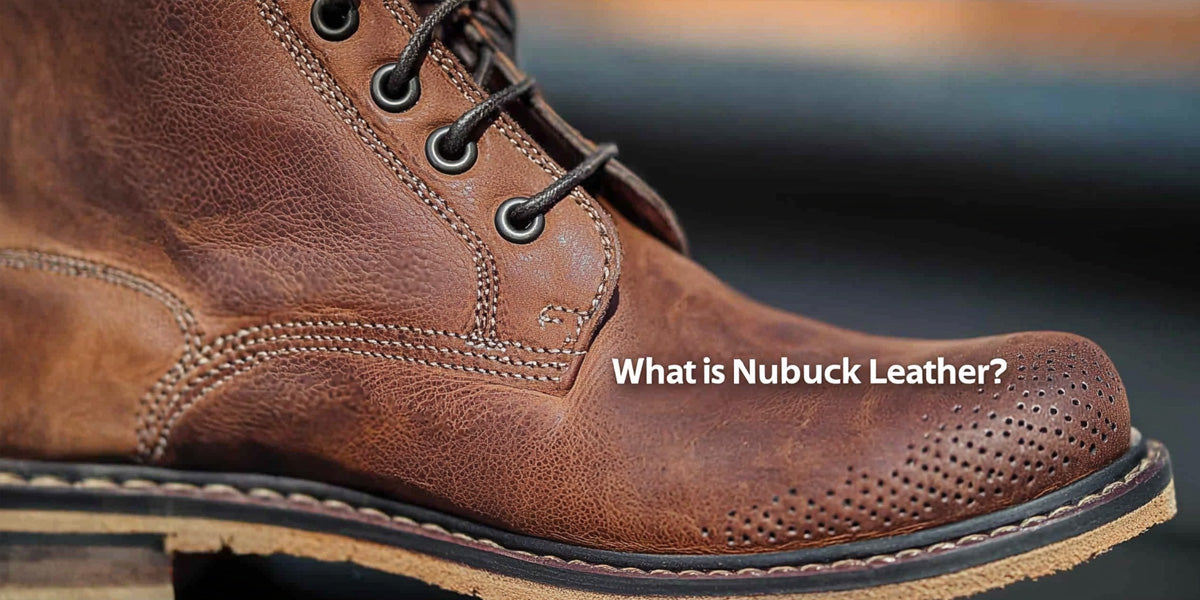

How is Nubuck Leather Used in Footwear Manufacturing?

Nubuck leather is a popular choice for high-end footwear, particularly in the production of stylish shoes and boots. Its velvety texture not only enhances aesthetic appeal but also offers durability, making it suitable for both casual and formal wear. For international buyers, especially in regions like Europe and the Middle East, sourcing high-quality nubuck is crucial to ensure that the final products meet luxury standards. Buyers should prioritize suppliers who can provide consistent quality and a range of color options.

Illustrative image related to nubuck leather material

What Role Does Nubuck Leather Play in Upholstery and Furniture?

In the upholstery sector, nubuck leather is prized for its soft feel and sophisticated appearance, making it an excellent choice for sofas, chairs, and cushions. Its durability ensures that it withstands everyday use while maintaining an elegant look. For B2B buyers from Africa and South America, it is essential to consider sourcing options that offer water-resistant treatments, as these can significantly enhance the material’s longevity in diverse climates and environments.

Why is Nubuck Leather Ideal for Fashion and Accessories?

The fashion industry utilizes nubuck leather extensively for products like handbags, wallets, and belts. Its luxurious appearance combined with its functional properties makes it appealing to fashion-forward consumers. International buyers should seek suppliers who adhere to ethical sourcing practices, as this can enhance brand reputation and consumer trust, particularly in markets that value sustainability and ethical manufacturing.

How is Nubuck Leather Beneficial in Automotive Interiors?

In automotive applications, nubuck leather is used for car seats and interiors, providing a touch of luxury that enhances the overall driving experience. Its durability and ease of maintenance make it suitable for high-end vehicles. Buyers from regions like the Middle East, where luxury vehicles are in demand, should prioritize suppliers that offer treated nubuck options to resist stains and wear, ensuring that the interiors remain pristine over time.

What are the Advantages of Nubuck Leather in Sporting Goods?

Nubuck leather is increasingly being used in premium sports equipment and apparel due to its unique combination of comfort, style, and durability. For B2B buyers in the sporting goods sector, it is essential to verify the material’s performance characteristics to ensure it meets the specific needs of athletes and active consumers. Sourcing from reputable suppliers who understand the demands of the sports industry can lead to better product performance and customer satisfaction.

3 Common User Pain Points for ‘nubuck leather material’ & Their Solutions

Scenario 1: Staining Concerns for Nubuck Leather Products

The Problem: B2B buyers in industries such as footwear, upholstery, or luxury goods often face significant challenges related to the staining susceptibility of nubuck leather. Given its delicate, velvety texture, nubuck can easily absorb liquids and dirt, leading to unsightly marks that compromise the aesthetic appeal of high-end products. This issue is particularly pressing for retailers in regions with humid climates, where moisture can exacerbate staining, making it a critical consideration during product selection and design.

Illustrative image related to nubuck leather material

The Solution: To mitigate staining concerns, buyers should look for nubuck leather that has undergone advanced treatment processes, such as waterproofing or stain-resistant finishes. Specifically, sourcing products like the Italia Nubuck Collection can provide a solution, as this line offers a luxurious, water-repellent nubuck that resists stains without sacrificing the soft feel and visual appeal of traditional nubuck. Additionally, incorporating protective sprays designed for nubuck leather into the product care guidelines can help maintain the leather’s appearance. Buyers should also educate their customers about proper cleaning methods and the importance of immediate stain treatment, ensuring that the products retain their high-end quality throughout their lifecycle.

Scenario 2: Sourcing Quality Nubuck Leather Materials

The Problem: When sourcing nubuck leather, B2B buyers often struggle with quality assurance due to varying standards among suppliers. Nubuck leather is derived from the top grain of hides, but the quality can differ significantly based on the processing methods and the origin of the hides. Buyers may find themselves receiving subpar materials that do not meet their specifications, leading to production delays and increased costs.

The Solution: To ensure the procurement of high-quality nubuck leather, buyers should establish strong relationships with reputable suppliers who provide transparency in their sourcing and processing methods. It’s beneficial to request samples before placing larger orders, allowing for a thorough evaluation of the texture, durability, and overall quality. Buyers can also consider suppliers who provide certifications or guarantees regarding the leather’s grade. Collaborating with suppliers who offer customizable options can further enhance the product line, allowing businesses to cater to specific market demands while ensuring consistent quality.

Scenario 3: Maintaining the Longevity of Nubuck Leather Products

The Problem: Nubuck leather, while durable, can lose its appeal if not properly cared for, leading to customer dissatisfaction and returns. B2B buyers, especially those in retail and hospitality, face the challenge of ensuring that their products remain in pristine condition over time, as improper care can lead to wear and tear that diminishes the leather’s luxurious appearance.

Illustrative image related to nubuck leather material

The Solution: To promote the longevity of nubuck leather products, businesses should implement a comprehensive care and maintenance program. This can include providing detailed care instructions with each product, highlighting the importance of regular brushing with a soft-bristled brush to maintain the nap and prevent dirt accumulation. Additionally, offering a range of specialized cleaning and conditioning products designed for nubuck leather can empower customers to take proactive measures in maintaining their purchases. Businesses should also consider hosting workshops or informational sessions on nubuck care for their customers, fostering loyalty and enhancing the customer experience by ensuring the durability and beauty of their nubuck leather items.

Strategic Material Selection Guide for nubuck leather material

What Are the Key Properties of Nubuck Leather?

Nubuck leather is primarily derived from the top grain of animal hides, typically from calves, goats, or deer. The unique sanding process exposes fine fibers, creating a soft, velvety texture. This material is known for its durability and luxurious appearance, making it suitable for high-end applications such as footwear, upholstery, and fashion accessories. Nubuck leather can withstand moderate pressure and wear, but it is more susceptible to staining compared to other leather types, necessitating careful handling and maintenance.

What Are the Pros and Cons of Using Nubuck Leather?

Pros:

- Durability: Nubuck leather retains the strength of full-grain leather, making it suitable for products that require longevity.

- Aesthetic Appeal: Its unique texture and matte finish provide a sophisticated look, appealing to luxury markets.

- Comfort: The soft fibers offer a comfortable feel, making it ideal for footwear and upholstery.

Cons:

- Staining: Nubuck is prone to stains and water damage, which can limit its use in certain environments.

- Maintenance: Requires regular cleaning and treatment to maintain its appearance and prolong its lifespan.

- Cost: Generally more expensive than other leather types due to the quality of the hides used and the manufacturing process.

How Does Nubuck Leather Impact Specific Applications?

Nubuck leather is particularly well-suited for applications where both aesthetics and durability are essential. In the footwear industry, it is often used for high-end shoes that require a soft touch without compromising strength. In upholstery, nubuck adds a luxurious feel to furniture while providing decent wear resistance. However, its susceptibility to staining means that it may not be the best choice for environments prone to spills or heavy use without proper treatment.

Illustrative image related to nubuck leather material

What Should International B2B Buyers Consider When Sourcing Nubuck Leather?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, several factors must be taken into account:

- Compliance and Standards: Familiarity with local regulations and international standards such as ASTM, DIN, or JIS is crucial. This ensures that the nubuck leather sourced meets the necessary quality and safety requirements.

- Climate Considerations: In regions with high humidity or rainfall, water-resistant treatments for nubuck leather may be essential. Buyers should inquire about the availability of treated options.

- Market Preferences: Understanding regional preferences for colors, textures, and finishes can help buyers select the right products for their target markets. For instance, Middle Eastern markets may favor darker hues, while European markets might lean towards more neutral tones.

- Supply Chain Logistics: Considerations regarding shipping times, tariffs, and local sourcing can impact the overall cost and availability of nubuck leather.

Summary Table of Nubuck Leather Material

| Material | Typical Use Case for nubuck leather material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nubuck Leather | High-end footwear, luxury upholstery | Durable yet soft texture | Susceptible to staining | High |

| Water-Resistant Nubuck | Outdoor footwear, furniture in humid areas | Enhanced stain and water resistance | Higher manufacturing complexity | High |

| Vegetable-Tanned Nubuck | Eco-friendly fashion accessories | Environmentally friendly | Longer tanning process | Medium |

| Upcycled Nubuck | Sustainable fashion products, bags | Cost-effective and eco-friendly | Quality may vary based on sourcing | Medium |

This analysis should provide valuable insights for B2B buyers looking to source nubuck leather, enabling informed decisions that align with their business needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for nubuck leather material

What Are the Key Stages in the Manufacturing Process of Nubuck Leather?

The production of nubuck leather involves several critical stages, each designed to enhance the quality and performance of the final product. Understanding these stages is essential for B2B buyers who seek reliable suppliers and high-quality materials.

Material Preparation: How Is Raw Hide Processed for Nubuck Leather?

The journey begins with the selection of high-quality raw hides, typically sourced from bovine, caprine, or cervine animals. The hides undergo rigorous cleaning to remove impurities such as dirt, hair, and fat. This initial stage is crucial as the quality of the raw material directly impacts the final product.

Once cleaned, the hides are soaked in a solution that may include chemicals to soften the leather and make it pliable. This process, known as liming, prepares the hides for tanning, which is essential for durability. The tanning process for nubuck often employs vegetable tanning agents, which are more environmentally friendly and enhance the leather’s natural characteristics.

Illustrative image related to nubuck leather material

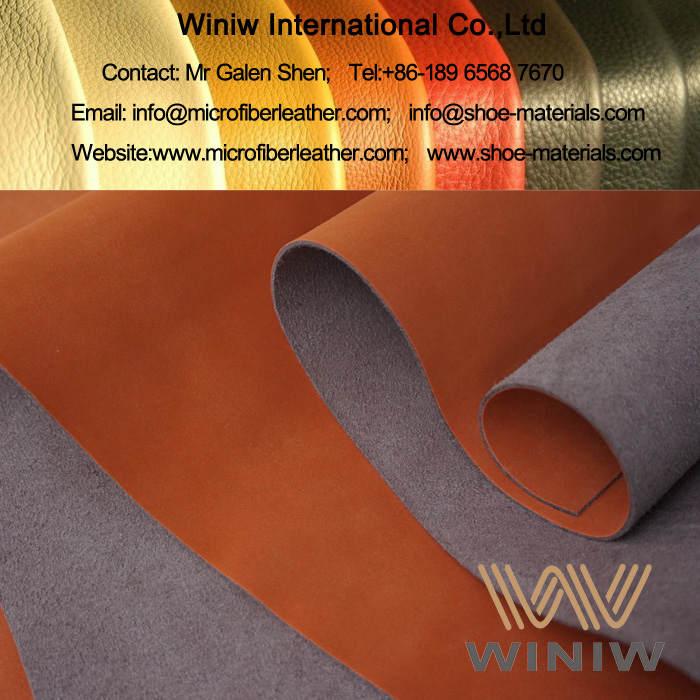

Forming: What Techniques Are Used to Create Nubuck Leather?

After tanning, the hides are dried and then subjected to a unique buffing process. This is where nubuck distinguishes itself from other leather types. The outer grain layer is lightly sanded using fine-grained sandpaper or pumice, creating a soft, velvety nap while retaining the hide’s inherent strength. The depth and uniformity of the sanding are critical, as they affect the final texture and appearance.

The hides may also undergo a process known as milling, where they are tumbled in a drum to soften the leather further and enhance its texture. This stage is vital for ensuring a consistent feel across the entire hide, which is especially important for high-end applications in footwear and upholstery.

Assembly: How Are Nubuck Leather Products Constructed?

The assembly of nubuck leather products varies depending on the intended use. For footwear, patterns are cut from the hide, and components such as linings, insoles, and outsoles are attached using adhesives and stitching. In upholstery, larger sections of nubuck are sewn together to create furniture coverings.

Quality craftsmanship is paramount during assembly, as any flaws in stitching or bonding can compromise the product’s integrity. Manufacturers often employ skilled artisans who are familiar with the nuances of working with nubuck leather, ensuring a high standard of workmanship.

Finishing: What Treatments Are Applied to Enhance Nubuck Leather?

The finishing stage is critical for adding protective layers to nubuck leather. Traditional nubuck is known for its susceptibility to stains; however, modern treatments can significantly improve its durability. Water-repellent and stain-resistant coatings can be applied, making the leather suitable for a broader range of applications, including family-friendly environments.

Illustrative image related to nubuck leather material

Additionally, finishes may include aniline dyes, which enhance the color while allowing the natural grain to show through, adding to the leather’s appeal. The choice of finishing treatments can influence the leather’s texture, sheen, and resistance to wear and tear.

What Are the Quality Assurance Measures for Nubuck Leather?

Quality assurance is a vital aspect of nubuck leather production, ensuring that the final products meet international standards and customer expectations. For B2B buyers, understanding these measures can help in selecting reliable suppliers.

Which International Standards Are Relevant for Nubuck Leather?

Compliance with international standards such as ISO 9001 is crucial for manufacturers seeking to establish credibility in the global market. ISO 9001 sets the framework for a quality management system, ensuring consistent product quality and continuous improvement.

In addition to ISO standards, manufacturers may also adhere to industry-specific certifications such as CE for products sold in Europe and API for those in the oil and gas industry. These certifications demonstrate a commitment to quality and safety, which is particularly important for buyers in regulated markets.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) in nubuck leather production involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial inspection assesses the quality of raw hides before processing begins. Suppliers should provide documentation to verify the source and quality of materials.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the quality of the sanding, tanning, and finishing processes. This helps identify any issues early on, minimizing waste and ensuring consistency.

-

Final Quality Control (FQC): Before products are shipped, a comprehensive inspection is carried out to check for defects, color consistency, and adherence to specifications. Buyers should inquire about the methods used for FQC to ensure that only top-quality products are delivered.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control measures of potential suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, equipment, and quality control practices firsthand. This is an effective way to ensure that suppliers adhere to international standards.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports that outline the results of IQC, IPQC, and FQC checks. These reports provide insight into the supplier’s quality management practices and any corrective actions taken.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This adds an additional layer of assurance for buyers, especially when dealing with suppliers in different regions.

What Nuances Should International Buyers Consider for Nubuck Leather?

When sourcing nubuck leather from international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances:

-

Regulatory Compliance: Different regions have varying regulations regarding leather production and environmental impact. Buyers should ensure that suppliers comply with local laws and international standards to avoid potential legal issues.

-

Cultural Considerations: Understanding cultural practices in leather production can impact the quality and characteristics of nubuck leather. For example, traditional tanning methods may vary, affecting the leather’s final properties.

-

Supply Chain Transparency: Establishing clear communication with suppliers about sourcing, processing, and quality control practices is vital. Transparency helps build trust and ensures that both parties are aligned on quality expectations.

By carefully considering these factors, B2B buyers can make informed decisions when sourcing nubuck leather, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nubuck leather material’

To effectively source nubuck leather material, it’s essential to follow a structured approach. This guide provides a step-by-step checklist tailored for B2B buyers, ensuring you make informed decisions while procuring this premium leather type.

Step 1: Define Your Technical Specifications

Start by clearly outlining the specifications required for your project. This includes the type of nubuck leather (e.g., calfskin, goat, or deer hides), thickness, and any specific treatments such as waterproofing or stain resistance. Establishing these criteria upfront helps in narrowing down potential suppliers who can meet your exact needs.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify suppliers that specialize in nubuck leather. Look for suppliers with a strong market presence and positive reviews from other B2B buyers. Utilize platforms like industry-specific trade shows or online marketplaces to gather a list of potential vendors.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Ensure that the suppliers you consider have a proven track record in delivering high-quality nubuck leather.

- Check for Certifications: Look for certifications that indicate adherence to quality standards, such as ISO or environmental certifications.

- Assess Production Capabilities: Inquire about the production capacity and lead times to ensure they can meet your demand.

Step 4: Request Samples

Request samples of nubuck leather from shortlisted suppliers. Evaluating physical samples allows you to assess the texture, color, and overall quality of the leather. This step is crucial, as it helps verify that the product meets your specifications before placing a bulk order.

Step 5: Negotiate Pricing and Terms

Once you are satisfied with the samples, initiate negotiations regarding pricing, payment terms, and delivery schedules. Ensure that you discuss potential discounts for bulk orders or long-term partnerships. Clear communication at this stage can lead to more favorable terms and better overall value.

Illustrative image related to nubuck leather material

Step 6: Understand Shipping and Logistics

Before finalizing your order, clarify the shipping options and logistics arrangements with your supplier. Understand the shipping costs, delivery timelines, and any customs duties that may apply, especially for international shipments. Having this information will help you plan your inventory and manage costs effectively.

Step 7: Establish a Quality Control Process

Finally, set up a quality control process to ensure that the nubuck leather received meets your standards. This can include inspections upon arrival and ongoing assessments during production runs. Establishing quality benchmarks helps in maintaining consistency and reliability in your supply chain.

By following these steps, B2B buyers can successfully navigate the sourcing process for nubuck leather, ensuring they acquire high-quality materials that meet their business needs.

Comprehensive Cost and Pricing Analysis for nubuck leather material Sourcing

Nubuck leather is a premium material that commands attention in various industries, including fashion, upholstery, and accessories. Understanding the comprehensive cost structure and pricing analysis for sourcing nubuck leather is vital for B2B buyers to make informed purchasing decisions.

What Are the Key Cost Components for Nubuck Leather?

When evaluating the costs associated with nubuck leather, several components come into play:

-

Materials: The primary cost driver is the quality of the hide used. Nubuck is derived from the top grain of the hide, which is more expensive than lower-grade leathers. Premium hides, such as those from calves, goats, or deer, are preferred for their durability and texture, significantly influencing the material cost.

-

Labor: The labor involved in processing nubuck is specialized. Skilled artisans perform the sanding and buffing processes to achieve the desired texture, which requires time and expertise. This skilled labor contributes to higher overall costs.

-

Manufacturing Overhead: Facilities that produce nubuck leather often incur significant overhead costs due to the need for specialized equipment and quality control measures. This includes maintaining equipment used for sanding and finishing the hides.

-

Tooling and Equipment: The equipment necessary for the sanding process, such as machines equipped with fine-grained sandpaper, represents a considerable investment. Tooling costs are amortized over production runs and can vary based on the scale of production.

-

Quality Control (QC): Ensuring the final product meets industry standards requires robust QC processes. This includes inspecting hides for imperfections and ensuring consistency in texture and finish, which adds to the overall cost.

-

Logistics: The logistics of sourcing nubuck leather, including shipping and handling, can be complex, especially for international buyers. Factors such as import duties, customs clearance, and transportation costs must be accounted for in the final pricing.

-

Margin: Suppliers typically build a profit margin into their pricing structure. This margin can vary based on the supplier’s market position, brand reputation, and the perceived value of their products.

What Influences Nubuck Leather Pricing for B2B Buyers?

Several factors influence the pricing of nubuck leather that buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better prices.

-

Specifications and Customization: Customization options, such as specific colors or finishes, can increase costs. Buyers should clarify their requirements to avoid unexpected expenses.

-

Quality Certifications: Hides that come with quality certifications or sustainability credentials may carry a premium price. Buyers should evaluate the importance of these certifications for their business needs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: The choice of Incoterms affects the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for budgeting.

What Are the Best Negotiation Strategies for Nubuck Leather?

B2B buyers should approach negotiations with a clear understanding of their needs and the market landscape. Here are some tips for achieving cost-efficiency:

-

Leverage Volume: If planning to order in bulk, use this as a bargaining chip to negotiate lower prices or better payment terms.

-

Research Market Prices: Familiarize yourself with current market prices for nubuck leather. This knowledge empowers buyers to negotiate effectively and ensures they are not overpaying.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but the long-term costs associated with the material, including maintenance, durability, and potential waste.

-

Build Relationships with Suppliers: Establishing a strong relationship with suppliers can lead to better pricing and terms in the long run. Communication and trust are essential in B2B relationships.

Final Thoughts on Nubuck Leather Pricing

As a high-quality material, nubuck leather pricing reflects its premium nature and the complexities involved in its production. International buyers, particularly from Africa, South America, the Middle East, and Europe, should carefully analyze these cost components and factors to make informed sourcing decisions. Pricing nuances vary by region and supplier, so maintaining an adaptable and well-informed approach will yield the best outcomes.

Disclaimer: Prices for nubuck leather can fluctuate based on market conditions, availability, and supplier pricing strategies. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing nubuck leather material With Other Solutions

Exploring Alternatives to Nubuck Leather Material

When considering materials for upholstery, footwear, or accessories, nubuck leather stands out for its unique texture and durability. However, various alternatives may better suit specific requirements based on performance, cost, and maintenance needs. This section explores viable alternatives to nubuck leather, comparing them across several critical aspects.

| Comparison Aspect | Nubuck Leather Material | Suede | Synthetic Leather |

|---|---|---|---|

| Performance | Durable, water-resistant (when treated), luxurious feel | Soft but less durable, prone to wear | Highly durable, resistant to stains and water |

| Cost | Generally high due to quality hides | Moderate, depending on quality | Typically lower, but varies by brand and quality |

| Ease of Implementation | Requires skilled craftsmanship | Similar to nubuck, but less complex | Easier to cut and sew, less skilled labor needed |

| Maintenance | Requires special care to avoid stains | Difficult to clean; needs special treatment | Low maintenance; easy to clean with just soap and water |

| Best Use Case | High-end products like shoes and furniture | Fashion items, casual footwear | Mass-produced items, budget-friendly alternatives |

What Are the Pros and Cons of Suede as an Alternative to Nubuck Leather?

Suede, like nubuck, is a type of leather but is made from the inner layer of the hide. It is known for its softness and plush texture, making it appealing for fashion items and casual footwear. However, suede is generally less durable than nubuck and is more susceptible to stains and water damage. For B2B buyers, while suede can be a cost-effective option for certain product lines, the maintenance requirements may offset initial savings, especially in high-traffic applications.

How Does Synthetic Leather Compare to Nubuck Leather?

Synthetic leather, often referred to as faux leather or vegan leather, is made from plastic materials and designed to mimic the look and feel of real leather. One of its significant advantages is durability; it often withstands wear and tear better than natural leathers. Additionally, synthetic leather is easier to maintain, requiring only a simple wipe-down to keep it clean. However, it lacks the authentic texture and patina that nubuck leather offers, which may be a crucial factor for high-end products. Buyers looking for budget-friendly and low-maintenance materials may find synthetic leather appealing, but those targeting luxury markets may prefer the authentic feel of nubuck.

Illustrative image related to nubuck leather material

Conclusion: How to Choose the Right Material for Your Needs?

Choosing between nubuck leather and its alternatives hinges on your specific application and target market. Nubuck leather is ideal for high-end products where quality and aesthetic appeal are paramount. In contrast, suede may be suitable for fashion-forward items where softness is prioritized, albeit with caution regarding durability. Synthetic leather offers a practical alternative for budget-conscious businesses aiming for durability and ease of care. Ultimately, B2B buyers should consider the trade-offs of performance, cost, and maintenance to select the material that aligns best with their brand values and customer expectations.

Essential Technical Properties and Trade Terminology for nubuck leather material

What Are the Key Technical Properties of Nubuck Leather Material?

Nubuck leather is distinguished by several technical properties that are vital for B2B buyers to understand. Here are some of the most important specifications:

-

Material Grade

Nubuck leather is typically categorized into different grades based on the quality of the hide and the finishing process. The highest grades are often derived from full-grain leather, ensuring durability and a luxurious finish. Understanding material grades helps buyers select the appropriate quality for their specific applications, whether it be high-end fashion, upholstery, or automotive interiors. -

Thickness and Weight

Nubuck leather thickness generally ranges from 1.0 mm to 2.5 mm (approximately 0.04 to 0.10 inches). The weight of the leather can also vary, impacting its suitability for different products. For example, lighter nubuck is preferred for footwear, while heavier options are ideal for upholstery. Buyers should consider the thickness and weight based on the intended use to ensure product performance and longevity. -

Durability and Wear Resistance

Nubuck is known for its exceptional durability, attributed to its top-grain origin. While it is more susceptible to staining compared to other leathers, advancements in treatment processes have led to the development of water-resistant and stain-resistant nubuck options. Buyers should assess the durability specifications to ensure the leather meets their industry standards, especially for products subjected to heavy wear. -

Finish Type

The finish of nubuck leather can significantly impact its appearance and performance. Common finishes include aniline, semi-aniline, and pigmented, each offering varying degrees of protection and aesthetic appeal. Understanding finish types allows buyers to choose the right nubuck for their design and functional requirements. -

Color Fastness

Color fastness refers to the resistance of leather to fading and discoloration when exposed to light, moisture, and other environmental factors. Nubuck leather must meet specific color fastness standards, particularly for applications in fashion and upholstery. This property is crucial for maintaining the visual appeal of products over time. -

Environmental Considerations

As sustainability becomes increasingly important in the leather industry, buyers should be aware of the environmental implications of nubuck production. This includes the tanning processes used, whether they are chrome-tanned or vegetable-tanned, and the sourcing of hides. Understanding these factors can aid in making eco-friendly procurement decisions.

What Are Common Trade Terms Related to Nubuck Leather Material?

Familiarity with industry jargon is essential for B2B buyers in the nubuck leather market. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company. In the leather industry, this term is crucial for businesses looking to create custom leather goods, as it defines the relationship between manufacturers and brands. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to determine their purchasing strategy and ensure they meet the supplier’s requirements without overcommitting to inventory. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to provide pricing for specific products or services. In the context of nubuck leather, this allows buyers to compare prices and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. For nubuck leather transactions, understanding these terms is essential to clarify shipping, insurance, and delivery obligations, thereby reducing risks in international logistics. -

Tannage

Tannage is the process of treating raw hides to produce leather. Different tanning methods, such as chrome or vegetable tanning, affect the leather’s properties, including durability, flexibility, and environmental impact. Buyers should be aware of the tanning method used to align with their quality and sustainability standards. -

Finishing

Finishing refers to the processes applied to leather after tanning to enhance its appearance and performance. This may include dyeing, coating, or buffing. Knowledge of finishing techniques is important for buyers to ensure the final product meets their aesthetic and functional expectations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring nubuck leather, ensuring they meet both quality and market demands.

Navigating Market Dynamics and Sourcing Trends in the nubuck leather material Sector

What Are the Current Market Dynamics and Key Trends in the Nubuck Leather Sector?

The global nubuck leather market is experiencing a notable surge, driven by increasing demand from various industries, including footwear, upholstery, and fashion accessories. Key trends shaping this market include a growing preference for premium materials that combine aesthetics with durability. Nubuck leather, known for its luxurious texture and resilience, is emerging as a favored choice for high-end products. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly sourcing nubuck leather to meet the rising consumer expectations for quality and sophistication.

Technological advancements in production processes are also influencing the market. Innovations such as automated sanding and buffing techniques enhance the quality and consistency of nubuck leather, making it more accessible for manufacturers. Additionally, the introduction of water-repellent and stain-resistant treatments, such as those found in the Italia Nubuck Collection, is appealing to buyers seeking functional yet stylish materials. These advancements not only improve the product’s performance but also expand its applications across diverse sectors.

Furthermore, sustainability is becoming a crucial consideration for international buyers. The demand for ethically sourced and environmentally friendly materials is reshaping sourcing strategies. As buyers increasingly prioritize transparency in the supply chain, suppliers of nubuck leather must adapt to these evolving expectations to remain competitive.

How Are Sustainability and Ethical Sourcing Impacting the Nubuck Leather Market?

Sustainability and ethical sourcing are becoming paramount in the nubuck leather industry, reflecting a broader shift in consumer values towards environmentally responsible products. The environmental impact of leather production has raised concerns, prompting buyers to seek suppliers who prioritize eco-friendly practices. This includes the use of vegetable tanning methods, which minimize harmful chemicals, and sourcing hides from suppliers that adhere to strict environmental regulations.

Moreover, certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are gaining traction among B2B buyers. These certifications assure that the leather is produced sustainably and ethically, which is increasingly essential for companies aiming to enhance their brand reputation and appeal to conscientious consumers. Buyers from regions like Europe and the Middle East are particularly inclined to prioritize suppliers with these certifications, as they align with regional regulatory standards and consumer expectations.

In addition, the rise of the circular economy encourages the use of upcycled nubuck leather, which reduces waste and promotes sustainable practices. By choosing suppliers that offer recycled or upcycled materials, international buyers can play a significant role in mitigating the environmental footprint of their products.

What is the Historical Context of Nubuck Leather in the B2B Sector?

Nubuck leather has a rich history that dates back centuries, initially gaining popularity in the 19th century as artisans began to refine their tanning techniques. The process of sanding the top grain of leather to create a soft, velvety texture was perfected, leading to nubuck’s recognition as a premium material. Historically, nubuck was predominantly used for footwear, but its versatility soon saw it being adopted in various applications, including upholstery and fashion accessories.

In the B2B context, the evolution of nubuck leather reflects a growing appreciation for high-quality materials that blend luxury with functionality. As manufacturing processes advanced and global trade expanded, nubuck leather became more accessible to international buyers. Today, it stands as a symbol of sophistication and durability, meeting the demands of diverse markets while continuing to evolve with consumer preferences and technological innovations. This historical backdrop underscores the importance of nubuck leather in the modern B2B landscape, highlighting its enduring appeal and market potential.

Frequently Asked Questions (FAQs) for B2B Buyers of nubuck leather material

-

How do I ensure the quality of nubuck leather before purchasing?

To guarantee the quality of nubuck leather, request samples from potential suppliers. Examine the leather for consistency in texture, color, and absence of imperfections. A reputable supplier should be transparent about the source of their hides and provide certification regarding the tanning process. Additionally, inquire about their quality assurance processes, including any testing for durability and resistance to staining. Establishing a clear communication channel with the supplier will help clarify any concerns about the quality of the material. -

What are the best applications for nubuck leather in various industries?

Nubuck leather is highly versatile, making it suitable for a range of applications. In the fashion industry, it is commonly used for high-end footwear, handbags, and accessories due to its luxurious feel. In furniture, nubuck serves as a stylish upholstery option that adds sophistication to couches and chairs. Additionally, its durability makes it ideal for automotive interiors. When sourcing, consider your target market’s preferences and the specific characteristics of nubuck that align with your product offerings. -

What should I consider when negotiating payment terms with suppliers?

When negotiating payment terms, assess factors such as order size, supplier trustworthiness, and your financial capabilities. Common terms include upfront deposits, net 30 or 60 days, and payment upon delivery. Ensure to discuss currency options, as international transactions may involve exchange rate considerations. It is advisable to use secure payment methods, such as letters of credit or escrow services, to protect both parties. Always document agreed terms in a contract to avoid misunderstandings. -

Are there minimum order quantities (MOQs) for nubuck leather?

Minimum order quantities for nubuck leather can vary significantly between suppliers and depend on the type of leather and customization options. It’s common for suppliers to set MOQs to cover production costs and ensure profitability. When sourcing, inquire about MOQs upfront, and consider whether they align with your business needs. If you have specific requirements, such as color or finish, communicate these to the supplier early in the negotiation process to find a mutually beneficial arrangement. -

How can I customize nubuck leather for my products?

Customization options for nubuck leather can include color selection, texture variations, and specific finishes (e.g., waterproofing). Discuss your requirements with suppliers, as many offer custom dyeing and treatment services. It is essential to provide clear specifications and, if possible, visual references to ensure the final product meets your expectations. Be prepared for potential lead times associated with custom orders and verify that the supplier has experience with the specific modifications you require. -

What logistics considerations should I keep in mind when importing nubuck leather?

When importing nubuck leather, consider factors such as shipping methods, duties, and compliance with local regulations. Choose a reliable shipping partner experienced in handling leather products, ensuring they understand the importance of maintaining the material’s quality during transit. It’s crucial to be aware of any import tariffs that may apply to your shipments, which can affect your overall cost. Additionally, ensure that you have all necessary documentation, including invoices and certificates of origin, to facilitate customs clearance. -

How do I vet potential suppliers of nubuck leather?

Vetting suppliers is crucial for ensuring quality and reliability. Start by checking supplier reviews and ratings from other B2B buyers. Request references and case studies showcasing their previous work, particularly in your industry. Conduct virtual or in-person visits to their production facilities if possible, to assess their operations and quality control processes. Additionally, ensure that suppliers comply with international standards and certifications related to leather production, which can provide further assurance of their credibility. -

What are the best practices for maintaining nubuck leather in end products?

To maintain the quality of nubuck leather, it is essential to educate your customers on proper care practices. Recommend regular brushing with a soft bristle brush to remove dirt and restore the nap. Advise against exposing nubuck to water and recommend using a protective spray designed for nubuck to enhance stain resistance. For deeper stains, professional cleaning is often the best option. Providing care instructions can enhance customer satisfaction and prolong the lifespan of nubuck leather products.

Top 8 Nubuck Leather Material Manufacturers & Suppliers List

1. Leather Hide Store – Italia Nubuck Collection

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Nubuck is a top grain leather that has been lightly sanded and brushed to create a supple, velvety-like surface. It is compared to suede, but is a stronger upholstery grade leather. Traditional nubuck is susceptible to staining, but the Italia Nubuck Collection offers a waterproof and highly stain-resistant option. Italia Nubuck is described as a sublime, velvety soft Italian leather that is kid-f…

2. BuyLeatherOnline – Nubuck Leather

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Introduction: Nubuck leather is a premium material known for its velvety texture and exceptional durability. It is made from the grain layer of the hide, sanded or buffed to create a soft, suede-like surface. Nubuck retains the strength and longevity of full-grain leather while offering a luxurious, matte finish. Ideal for high-end footwear, accessories, and upholstery, it exudes sophistication and timeless ele…

3. Olpr – Nubuck Leather

Domain: olpr.com

Registered: 2006 (19 years)

Introduction: Nubuck is a type of leather with a brushed and buffed surface, featuring a frosted, velvety texture reminiscent of peach fuzz. It is made from the top grain of hides, typically from calves, goats, or deer. The production process involves sanding the hide to create a napped finish, resulting in a durable and soft material. Nubuck is known for its matte finish and slight nap, making it tough yet ten…

4. Carl Friedrik – Nubuck Leather

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: Nubuck is a premium velvety leather made by sanding down the outer layer of an animal’s hide, typically calfskin. It is known for its soft, luxurious texture and durability, making it suitable for high-end footwear, bags, wallets, and furniture. Nubuck is characterized by its pronounced nap, which gives it a rugged aesthetic. It is breathable, low maintenance, and retains its original color when w…

5. Manuel Dreesmann – Nubuck Leather Goods

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: Nubuck leather insights and comparisons to vegetable tanned leather. Worldwide free shipping over 100€. Product categories include MacBook sleeves, wallets, bags (tote bags, envelope bags, neck pouches, Sealife collection, woven bags, handbags), small leather goods (wallets, glasses cases, key wallets, belts, bracelets), device sleeves (MacBook sleeves, iPad sleeves), home & travel accessories, an…

6. SB Foot – Nubuck Leather

Domain: maverickleathercompany.com

Registered: 2009 (16 years)

Introduction: {‘name’: ‘SB Foot – Nubuck – Natural’, ‘description’: “SB Foot Nubuck leather in a natural tan color, this is most likely a nubuck crust that was never dyed or finished. ‘Crust’ is a term used for hides that have reached an early, yet final stage in the tanning process, the first of which they are considered a stable leather product. From this point hides are typically treated with oils, waxes, ta…

7. Montana Leather – Suede & Nubuck Leather

Domain: montanaleather.com

Registered: 2000 (25 years)

Introduction: Suede & Nubuck Leather | Suede Cowhide Split Leather. Free Shipping on Orders over $150! Available Colors: Beige, Black, Blue, Brown, Burgundy, Green, Grey, Pink, Purple, Red, Tan, Turquoise, White, Yellow. Tannage: Chrome Tanned. Thickness: 2-3 oz, 3-4 oz, 4-5 oz, 6-7 oz, 7-8 oz. Leather Types: Cow, Deer. Features: Soft, velvety look; unique rough “fleshy” sides; suitable for fashion garments and…

8. Classy Leather Bags – Nubuck Leather Collection

Domain: classyleatherbags.com

Registered: 2020 (5 years)

Introduction: Nubuck leather is a luxurious and durable type of leather made from goat, calfskin, and deerskin, originally from elk or deer. It has a soft, velvety texture and is known for its aesthetic appeal and comfort. Nubuck leather is breathable, requires less maintenance than other leathers, and ages gracefully. It is commonly used in footwear, accessories, clothing, and furniture upholstery. Key benefit…

Strategic Sourcing Conclusion and Outlook for nubuck leather material

In the evolving landscape of leather sourcing, nubuck leather stands out as a premium choice for B2B buyers seeking both aesthetic appeal and durability. This top-grain leather, known for its soft, velvety texture, offers a unique blend of elegance and resilience, making it ideal for high-end footwear, upholstery, and accessories. Strategic sourcing of nubuck leather enables businesses to leverage its superior qualities while mitigating potential risks associated with quality variations and supply chain disruptions.

Illustrative image related to nubuck leather material

Buyers should prioritize partnerships with reputable suppliers who can guarantee consistent quality and offer innovative treatments, such as water-resistance and stain-proofing, which enhance the material’s usability in diverse markets. As global demand for sustainable and luxurious materials continues to rise, investing in high-quality nubuck leather can differentiate products in competitive sectors.

Looking ahead, international buyers from regions like Africa, South America, the Middle East, and Europe should seize the opportunity to explore new sourcing avenues and forge strong relationships with manufacturers. By doing so, they can not only secure a reliable supply of nubuck leather but also contribute to the growth of sustainable practices in the leather industry. Take the next step today—invest in nubuck leather to elevate your product offerings and meet the evolving needs of your clientele.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.