Introduction: Navigating the Global Market for red faux leather fabric

In an increasingly competitive global market, sourcing high-quality red faux leather fabric presents a unique challenge for B2B buyers seeking to balance aesthetic appeal with practicality. As businesses in Africa, South America, the Middle East, and Europe strive to meet consumer demand for stylish yet durable materials, understanding the nuances of faux leather becomes essential. This guide aims to demystify the complexities of red faux leather fabric, offering insights into various types, applications, and key considerations for supplier vetting.

From upholstery for commercial furniture to fashion-forward apparel, red faux leather is versatile and adaptable, making it a favored choice among manufacturers and designers alike. The guide will delve into the material’s unique properties, including its durability, ease of maintenance, and ethical advantages compared to genuine leather. Additionally, we will explore cost factors, industry trends, and sourcing strategies that empower international buyers to make informed decisions.

By equipping B2B stakeholders with comprehensive knowledge about red faux leather fabric, this guide serves as a valuable resource for optimizing procurement processes and enhancing product offerings. Whether you are a supplier in Germany or a manufacturer in Vietnam, understanding these dynamics will enable you to navigate the global market effectively and capitalize on the growing demand for high-quality, sustainable materials.

Table Of Contents

- Top 7 Red Faux Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for red faux leather fabric

- Understanding red faux leather fabric Types and Variations

- Key Industrial Applications of red faux leather fabric

- 3 Common User Pain Points for ‘red faux leather fabric’ & Their Solutions

- Strategic Material Selection Guide for red faux leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for red faux leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘red faux leather fabric’

- Comprehensive Cost and Pricing Analysis for red faux leather fabric Sourcing

- Alternatives Analysis: Comparing red faux leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for red faux leather fabric

- Navigating Market Dynamics and Sourcing Trends in the red faux leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of red faux leather fabric

- Strategic Sourcing Conclusion and Outlook for red faux leather fabric

- Important Disclaimer & Terms of Use

Understanding red faux leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vinyl Faux Leather | Waterproof, durable, flexible; high-shine finish | Upholstery, automotive, fashion accessories | Pros: Cost-effective, easy to clean. Cons: Can be less breathable than natural leather. |

| PU Faux Leather | Soft texture, eco-friendly, versatile | Apparel, bags, furniture upholstery | Pros: Soft feel, more environmentally friendly. Cons: May wear faster than vinyl. |

| Embossed Faux Leather | Textured surface mimicking real leather | High-end upholstery, fashion items | Pros: Aesthetic appeal, adds depth to designs. Cons: Can be more expensive than standard options. |

| Patent Faux Leather | Glossy, high-shine finish, eye-catching | Fashion apparel, accessories, decorative items | Pros: Stylish and modern look. Cons: Can scuff easily and may require special cleaning. |

| Marine Faux Leather | UV-resistant, waterproof, durable | Marine upholstery, outdoor furniture | Pros: Ideal for outdoor use, resistant to elements. Cons: Limited color options compared to others. |

What Are the Key Characteristics of Vinyl Faux Leather?

Vinyl faux leather is a synthetic option known for its waterproof and durable properties, making it suitable for a variety of applications including upholstery and automotive interiors. Its high-shine finish provides a visually appealing look, ideal for businesses looking to create a modern aesthetic. When purchasing, B2B buyers should consider the fabric’s ease of cleaning and maintenance, as well as its potential lack of breathability compared to natural materials.

How Does PU Faux Leather Stand Out in the Market?

PU faux leather is recognized for its soft texture and eco-friendly production methods, making it a popular choice for apparel and fashion accessories. Its versatility allows it to be used in various applications, from bags to furniture upholstery. Buyers should weigh the benefits of its softer feel against its durability, as it may wear faster than vinyl options. This makes it essential to assess the intended use and expected lifespan when making purchasing decisions.

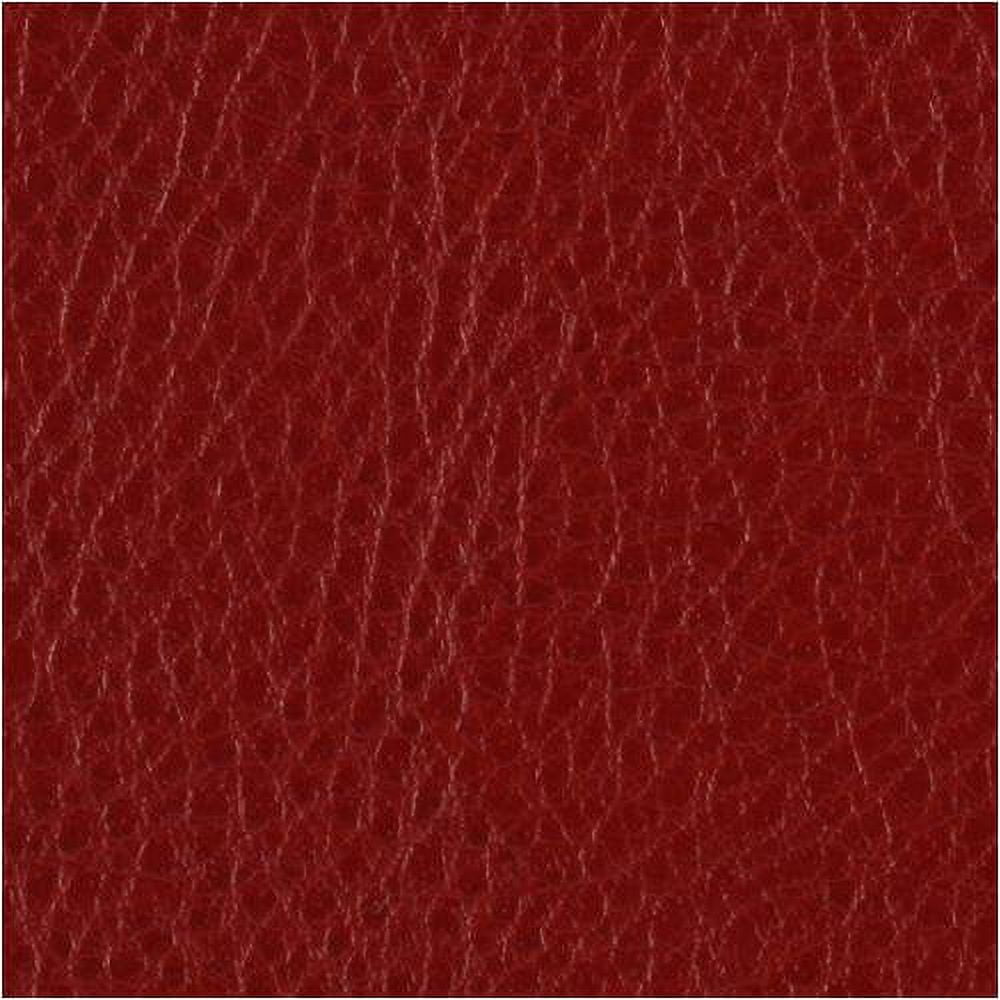

Why Choose Embossed Faux Leather for High-End Applications?

Embossed faux leather features a textured surface that closely mimics real leather, making it an excellent choice for high-end upholstery and fashion items. Its aesthetic appeal adds depth and sophistication to designs, which can attract discerning customers. However, B2B buyers should be mindful of the higher costs associated with this type of fabric and consider whether the investment aligns with their target market’s expectations.

What Are the Advantages and Disadvantages of Patent Faux Leather?

Patent faux leather is characterized by its glossy, high-shine finish that is particularly eye-catching, making it suitable for fashion apparel and accessories. This type of faux leather offers a stylish and modern look, appealing to businesses targeting trend-conscious consumers. However, it can scuff easily and may require special cleaning methods to maintain its appearance, which buyers should consider when evaluating its practicality for their specific applications.

What Makes Marine Faux Leather Ideal for Outdoor Use?

Marine faux leather is designed to be UV-resistant and waterproof, making it an excellent choice for outdoor furniture and marine upholstery. Its durability in harsh conditions ensures longevity, which is a significant advantage for B2B buyers in industries requiring weather-resistant materials. However, the range of color options may be more limited compared to other faux leathers, necessitating careful selection to meet design requirements.

Key Industrial Applications of red faux leather fabric

| Industry/Sector | Specific Application of red faux leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for chairs and sofas | Durable, aesthetically appealing products that attract consumers | Weight, texture, and ease of cleaning are critical factors. |

| Automotive | Interior detailing for vehicles | Enhances vehicle aesthetics and provides a cost-effective alternative to genuine leather | Consider UV resistance and durability under varying climates. |

| Fashion Retail | Apparel production, such as jackets and skirts | Offers a trendy, animal-friendly option that appeals to eco-conscious consumers | Ensure fabric availability in various shades and patterns. |

| Hospitality | Restaurant seating and decor | Provides a stylish, easy-to-maintain solution for high-traffic areas | Focus on stain resistance and ease of cleaning for longevity. |

| Event Planning | Decorative elements for events | Creates a vibrant atmosphere while being budget-friendly | Sourcing should prioritize lightweight options for easy transport and setup. |

How is red faux leather fabric utilized in furniture manufacturing?

In the furniture manufacturing sector, red faux leather fabric is prominently used for upholstery on chairs, sofas, and other seating solutions. Its durability and aesthetic appeal make it a preferred choice for manufacturers aiming to create stylish yet resilient products. This fabric can withstand wear and tear, making it ideal for both residential and commercial applications. International buyers, especially from regions like Africa and South America, should focus on sourcing high-quality fabric that meets specific weight and texture requirements, ensuring long-lasting performance in various environments.

What role does red faux leather play in the automotive industry?

Red faux leather fabric is increasingly utilized in the automotive industry for interior detailing, including seats, dashboards, and door panels. It provides an elegant look while serving as a cost-effective alternative to genuine leather. This fabric is particularly advantageous for manufacturers looking to meet the growing demand for sustainable materials. Buyers from the Middle East and Europe should consider sourcing options that emphasize UV resistance and durability, as vehicles in these regions often face harsh weather conditions.

How is red faux leather fabric transforming fashion retail?

In the fashion retail industry, red faux leather fabric is a staple for creating trendy apparel, including jackets, skirts, and accessories. Its ability to mimic the luxurious look of real leather at a lower price point appeals to a broad consumer base, particularly among eco-conscious shoppers. For B2B buyers in Europe and Vietnam, it is essential to ensure a consistent supply of fabric in various shades and patterns to meet diverse design needs and seasonal trends.

Why is red faux leather fabric essential in the hospitality sector?

In the hospitality industry, red faux leather fabric is widely used for restaurant seating and decor elements. Its stylish appearance enhances the ambiance while providing a practical solution for high-traffic areas that require easy maintenance. Buyers should prioritize sourcing fabrics that are stain-resistant and easy to clean, ensuring that they maintain a fresh appearance despite constant use. This is particularly relevant for businesses in Africa and South America, where durability and aesthetics are crucial for customer satisfaction.

How does red faux leather fabric enhance event planning?

For event planning, red faux leather fabric serves as a vibrant decorative element that can transform spaces for weddings, corporate events, and exhibitions. Its lightweight nature makes it easy to transport and set up, while its affordability allows planners to create visually appealing environments without exceeding budgets. Sourcing should focus on options that provide both aesthetic value and practicality, ensuring the fabric can withstand the demands of various events.

3 Common User Pain Points for ‘red faux leather fabric’ & Their Solutions

Scenario 1: Sourcing High-Quality Red Faux Leather Fabric for Upholstery Projects

The Problem: B2B buyers often struggle to find reliable suppliers who offer high-quality red faux leather that meets their specific needs for durability and aesthetics. With numerous options available, distinguishing between subpar products and premium materials can be overwhelming. Additionally, buyers in regions like Africa or South America may encounter challenges related to shipping times and product availability, leading to delays in their projects and potential financial losses.

The Solution: To ensure you source high-quality red faux leather fabric, start by identifying reputable suppliers with a proven track record in the industry. Look for suppliers that provide detailed product specifications, including the fabric’s weight, texture, and durability ratings. Request samples before making bulk purchases to assess the quality firsthand. Use your network to get recommendations or check online reviews. Additionally, consider suppliers that offer comprehensive shipping solutions, including tracking and reliable delivery timelines, to mitigate delays. For upholstery projects, opt for fabrics that are specifically designed for high-traffic areas, such as those labeled as “heavyweight” or “commercial-grade,” ensuring longevity and customer satisfaction.

Scenario 2: Ensuring Color Consistency Across Different Batches

The Problem: Another common issue B2B buyers face is color inconsistency when ordering red faux leather fabric in multiple batches. Variations in dye lots can lead to mismatched colors, which is particularly problematic for large-scale projects that require uniformity. This inconsistency can diminish the aesthetic appeal of finished products and may result in costly rework or returns.

The Solution: To tackle color consistency challenges, establish clear communication with your supplier about your color requirements. Specify the exact shade of red you need, and request color matching services if available. It’s advisable to order all your fabric from the same batch or dye lot, especially for larger projects. If possible, collaborate with suppliers who offer color-standardized samples or swatches, enabling you to verify that the fabric matches your expectations. Also, consider developing a long-term partnership with a single supplier to ensure that you can obtain consistent colors in future orders.

Scenario 3: Navigating Fabric Care and Maintenance Challenges

The Problem: B2B buyers often encounter difficulties regarding the care and maintenance of red faux leather fabrics, especially when used in environments like restaurants or hotels where spills and stains are common. Without proper knowledge of how to care for faux leather, buyers may find that the material degrades quickly, leading to a poor customer experience and increased replacement costs.

The Solution: To prevent maintenance issues, provide comprehensive care instructions to your team and clients. Emphasize that while red faux leather is generally easy to clean, it’s crucial to use the right cleaning agents to avoid damage. Recommend a mild soap solution and a soft cloth for regular cleaning. Additionally, inform your clients about the importance of promptly addressing spills to prevent staining. Consider offering a care package that includes the necessary cleaning materials along with your products. This proactive approach not only enhances the longevity of the fabric but also reinforces your commitment to quality service, helping to build long-term relationships with your customers.

Strategic Material Selection Guide for red faux leather fabric

When selecting red faux leather fabric for various applications, understanding the properties, advantages, and limitations of the materials involved is crucial for B2B buyers. Here’s an analysis of four common materials used in red faux leather fabric, tailored for international buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of PVC Faux Leather?

PVC (Polyvinyl Chloride) is one of the most widely used materials for faux leather due to its versatility and durability. It offers excellent resistance to moisture, making it suitable for both indoor and outdoor applications. PVC can withstand a range of temperatures and is resistant to UV light, which helps maintain its color over time.

Pros and Cons: The primary advantage of PVC faux leather is its cost-effectiveness, making it an attractive option for large-scale production. However, it can be less breathable than other materials, which may affect comfort in upholstery applications. Additionally, while PVC is durable, it can be prone to cracking over time if exposed to extreme temperatures.

Impact on Application: PVC faux leather is commonly used in furniture upholstery, automotive interiors, and fashion accessories. Its compatibility with various media, such as screen printing and embroidery, makes it a versatile choice for branding and customization.

How Does PU Faux Leather Compare to Other Materials?

PU (Polyurethane) faux leather is known for its soft texture and high-end appearance, closely resembling genuine leather. It offers good flexibility and is more breathable than PVC, making it a preferred choice for apparel and high-quality upholstery.

Pros and Cons: The key advantage of PU faux leather is its aesthetic appeal and comfort. It is also easier to clean and maintain compared to natural leather. However, PU tends to be more expensive than PVC and may not be as durable, particularly in high-wear applications.

Impact on Application: PU faux leather is ideal for fashion items such as jackets, bags, and high-end furniture. Its compatibility with dyeing processes allows for vibrant colors, which is particularly appealing for B2B buyers looking to create standout products.

What Are the Benefits of Using Microfiber Faux Leather?

Microfiber faux leather is a synthetic fabric made from ultra-fine polyester fibers. It is known for its softness, durability, and stain resistance. Microfiber is also lightweight and offers a luxurious feel, making it suitable for various applications.

Pros and Cons: The main advantage of microfiber faux leather is its high durability and resistance to wear and tear. It is also easy to clean and maintain, making it suitable for both residential and commercial use. However, it can be more expensive than traditional faux leather options and may require specific care instructions to maintain its appearance.

Impact on Application: Microfiber is often used in premium upholstery, automotive interiors, and fashion accessories. Its compatibility with high-quality printing techniques allows for intricate designs, which can enhance product appeal.

How Does Recycled Faux Leather Fit into Sustainable Practices?

Recycled faux leather is made from repurposed materials, often combining various synthetic fibers. This material is gaining popularity among environmentally conscious consumers and businesses due to its sustainable attributes.

Pros and Cons: The primary advantage of recycled faux leather is its reduced environmental impact, appealing to B2B buyers focused on sustainability. However, the quality may vary depending on the source materials, and it can be more expensive than traditional options.

Impact on Application: Recycled faux leather is suitable for eco-friendly fashion lines, upholstery, and accessories. Its unique textures and colors can differentiate products in a competitive market.

Summary Table of Material Selection for Red Faux Leather Fabric

| Material | Typical Use Case for red faux leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Upholstery, automotive interiors | Cost-effective and durable | Less breathable, prone to cracking | Low |

| PU | Fashion items, high-end upholstery | Soft texture, high-end appearance | More expensive, less durable | Medium |

| Microfiber | Premium upholstery, automotive interiors | High durability and stain resistance | More expensive, specific care needed | Medium |

| Recycled Faux Leather | Eco-friendly fashion and accessories | Reduced environmental impact | Variable quality, higher cost | High |

This analysis provides B2B buyers with a comprehensive understanding of the materials available for red faux leather fabric, helping them make informed decisions based on their specific needs and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for red faux leather fabric

What Are the Main Stages of Manufacturing Red Faux Leather Fabric?

The manufacturing process of red faux leather fabric involves several critical stages that ensure the final product meets the necessary quality and aesthetic standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The initial stage begins with the selection and preparation of raw materials. Faux leather is typically made from synthetic materials like polyurethane (PU) or polyvinyl chloride (PVC). During this phase, manufacturers focus on sourcing high-quality resins and additives to achieve desired properties such as durability, flexibility, and colorfastness. The materials undergo a thorough inspection to ensure they meet industry standards before being processed further.

Forming

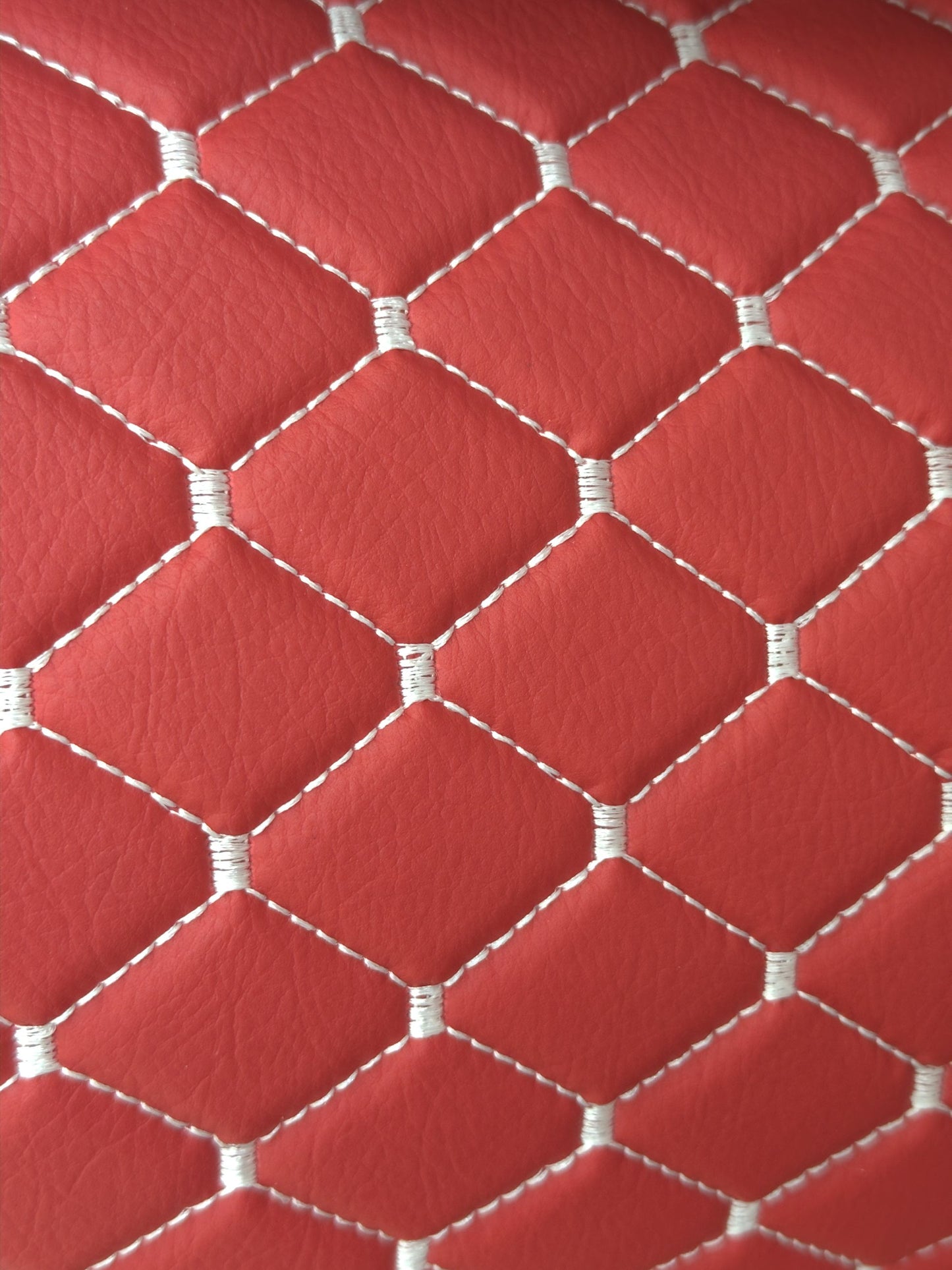

In the forming stage, the prepared materials are transformed into sheets or rolls of faux leather. This is often done through a process called calendering, where the raw materials are heated and pressed between rollers to create a smooth, uniform thickness. The color, in this case, red, is applied either during this phase or afterward, using dyeing techniques that ensure an even distribution and vibrancy of color. Manufacturers may also incorporate textures or patterns using embossing techniques, which enhance the visual appeal of the fabric.

Assembly

Once the faux leather sheets are formed, they are cut and assembled into desired shapes and sizes for various applications, such as upholstery or apparel. This stage involves precise cutting techniques to minimize waste and ensure consistency in dimensions. The assembly process may include stitching or bonding layers together, depending on the intended use of the fabric. Quality checks are crucial during this phase to verify that all pieces meet the design specifications.

Finishing

The finishing stage is essential for enhancing the fabric’s performance characteristics. Treatments such as UV protection, water resistance, and anti-scratch coatings may be applied to improve durability. Additionally, the surface may be polished to achieve a specific sheen or texture. Final inspections are conducted to assess the overall quality and ensure that the fabric meets both aesthetic and functional requirements.

What Quality Control Standards Are Relevant for Red Faux Leather Fabric?

Quality control (QC) is a vital aspect of the manufacturing process for red faux leather fabric, ensuring that the final product meets both international and industry-specific standards. Key standards include ISO 9001, which focuses on maintaining quality management systems, and CE marking, which indicates compliance with European safety standards.

International Standards and Certifications

-

ISO 9001: This is a globally recognized standard that establishes criteria for a quality management system. Manufacturers of faux leather fabric should be ISO 9001 certified to demonstrate their commitment to quality and continuous improvement.

-

CE Marking: For products intended for the European market, CE marking is essential. It indicates that the product meets EU safety, health, and environmental protection requirements. This is particularly relevant for upholstery fabrics that may come into contact with skin or be used in consumer products.

-

API Standards: For manufacturers supplying materials for specific industries, such as automotive or aerospace, adherence to American Petroleum Institute (API) standards may be necessary. These standards ensure that the materials can withstand rigorous conditions.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

To maintain high standards, manufacturers implement various quality control checkpoints throughout the production process. These checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Incoming Quality Control (IQC)

IQC involves inspecting raw materials upon arrival at the manufacturing facility. This step is crucial for verifying that materials meet specified quality standards before they enter the production process. B2B buyers should ensure that their suppliers have robust IQC procedures in place, including documentation of material specifications and supplier certifications.

Illustrative image related to red faux leather fabric

In-Process Quality Control (IPQC)

IPQC is conducted during the manufacturing process and involves regular inspections at various stages. This includes checking the thickness of the material, color consistency, and adherence to design specifications. Implementing IPQC helps identify and rectify issues early, reducing waste and ensuring product quality.

Final Quality Control (FQC)

FQC occurs once the manufacturing process is complete. This final inspection assesses the finished product against quality criteria, including appearance, durability, and compliance with regulatory standards. B2B buyers should request FQC reports to gain insights into the quality of the faux leather fabric before making a purchase.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, especially those operating in international markets such as Africa, South America, the Middle East, and Europe, must establish trust with their suppliers. Here are actionable steps to verify supplier QC practices:

Illustrative image related to red faux leather fabric

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should consider scheduling on-site visits to evaluate the production facilities, equipment, and quality control systems.

-

Request Quality Reports: Buyers should ask for detailed quality reports, including IQC, IPQC, and FQC results. These documents should outline the testing methods used and any corrective actions taken in response to quality issues.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can add an additional layer of assurance. These independent entities can conduct inspections and tests on behalf of buyers, providing unbiased assessments of product quality.

-

Check for Certifications: Verify that suppliers hold relevant certifications (e.g., ISO 9001, CE marking) that demonstrate their commitment to quality management. Certification bodies often provide online databases where buyers can confirm the validity of these credentials.

What Are the Nuances of Quality Control for International Buyers?

International B2B buyers face unique challenges and nuances regarding quality control. Understanding these can help streamline procurement processes and mitigate risks.

-

Regulatory Compliance: Different regions may have varying regulatory requirements for faux leather products. Buyers must familiarize themselves with local standards, such as REACH in Europe or other environmental regulations, to ensure compliance.

-

Cultural Differences: Cultural perceptions of quality can vary significantly between regions. Buyers should establish clear communication with suppliers to align expectations regarding product quality and performance.

-

Supply Chain Transparency: Given the complexity of global supply chains, buyers should seek suppliers who provide transparency in their sourcing and manufacturing processes. This transparency can enhance trust and confidence in product quality.

-

Language Barriers: Language differences can lead to misunderstandings regarding quality specifications and requirements. Buyers should ensure that all documentation is clearly translated and that there are designated points of contact for any inquiries.

By understanding the manufacturing processes and quality assurance standards for red faux leather fabric, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘red faux leather fabric’

When sourcing red faux leather fabric for your business, having a structured approach is crucial. This guide offers a practical checklist to help you navigate the procurement process effectively, ensuring that you select the right materials that meet your business needs.

Illustrative image related to red faux leather fabric

Step 1: Define Your Technical Specifications

Begin by clearly outlining the specifications you require for the red faux leather fabric. Consider factors such as thickness, texture, and intended use (e.g., upholstery, fashion, or accessories). Having precise specifications helps you communicate your needs to suppliers and ensures that the products you receive will meet your quality and performance standards.

- Texture & Finish: Decide whether you want a matte, glossy, or embossed finish.

- Weight & Durability: Specify whether you need lightweight fabric for clothing or heavier grades for upholstery.

Step 2: Research and Identify Suppliers

Conduct thorough research to identify potential suppliers of red faux leather fabric. Look for manufacturers and wholesalers who specialize in synthetic textiles and have a solid reputation in the industry.

- Industry Directories: Utilize platforms like Alibaba, ThomasNet, or local trade associations.

- Product Range: Ensure they offer a variety of styles and colors, particularly red, to meet your design needs.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to assess their credibility and reliability. Request company profiles, product samples, and references from previous clients to gauge their performance.

Illustrative image related to red faux leather fabric

- Certifications: Verify if they have relevant certifications (e.g., ISO, OEKO-TEX) that indicate quality and safety standards.

- Customer Feedback: Look for reviews or testimonials from other businesses that have sourced from them.

Step 4: Request Samples

Always request samples of the red faux leather fabric you are considering. This allows you to evaluate the quality, texture, and color accuracy before making a bulk order.

- Test for Durability: Check for resistance to tearing, water, and sunlight, especially if the fabric will be used outdoors.

- Color Match: Ensure the sample matches your desired shade of red, as colors can vary between batches.

Step 5: Discuss Pricing and Terms

Once you’ve identified suitable suppliers, initiate discussions about pricing, minimum order quantities, and payment terms. Understanding these details upfront can prevent misunderstandings later.

- Bulk Discounts: Inquire about discounts for large orders or repeat business.

- Payment Terms: Clarify the payment methods accepted and any conditions for deposits or credit.

Step 6: Review Shipping and Delivery Options

Evaluate the supplier’s shipping and delivery capabilities to ensure timely receipt of your orders. Understanding lead times and logistics is vital, especially if you are working on a tight schedule.

- Shipping Costs: Ask for detailed shipping costs and options (air, sea, etc.).

- Customs and Duties: Be aware of any potential customs fees or duties that may apply when importing fabric into your region.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the fabric’s quality upon arrival. This is crucial to ensure that the materials meet your specifications and to address any discrepancies promptly.

- Inspection Criteria: Develop a checklist to evaluate the quality of the fabric, including color, texture, and weight.

- Return Policy: Understand the supplier’s return policy in case the fabric does not meet your standards.

By following these steps, you can streamline your sourcing process for red faux leather fabric, ensuring that you secure high-quality materials that align with your business objectives.

Comprehensive Cost and Pricing Analysis for red faux leather fabric Sourcing

What Are the Key Cost Components in Sourcing Red Faux Leather Fabric?

When sourcing red faux leather fabric, understanding the cost structure is essential for effective budgeting and procurement. The main cost components include:

-

Materials: The primary raw materials for red faux leather include PVC or polyurethane, which dictate the fabric’s durability and aesthetic appeal. Prices for these materials can fluctuate based on global oil prices and supply chain disruptions.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs can offer competitive pricing, while regions with higher wage standards may reflect this in the final product cost. Labor efficiency also plays a critical role in overall manufacturing costs.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: If custom designs or specific textures are required, the tooling costs can add significantly to the initial investment. Custom molds for embossing or unique patterns will require upfront capital.

-

Quality Control (QC): Ensuring the quality of faux leather is vital. This can involve testing for durability, colorfastness, and compliance with international safety standards, adding to overall costs.

-

Logistics: Shipping costs can be substantial, especially for international orders. Factors such as distance, shipping method, and import duties must be considered.

-

Margin: Suppliers typically add a profit margin to cover their operational risks and ensure sustainability. Margins can vary widely depending on market competition and brand positioning.

How Do Price Influencers Affect the Cost of Red Faux Leather Fabric?

Several key factors influence the pricing of red faux leather fabric, particularly in a B2B context:

-

Volume/MOQ: Suppliers often offer discounts for bulk purchases. Minimum order quantities (MOQs) can impact per-unit pricing, making larger orders more cost-effective.

-

Specifications and Customization: Customization can lead to increased costs. Unique textures, colors, or patterns may require additional resources, affecting the final price.

-

Materials and Quality Certifications: The choice of materials directly impacts pricing. Fabrics with eco-friendly certifications or advanced durability features typically command higher prices.

-

Supplier Factors: Supplier reputation, reliability, and location can influence pricing. Well-established suppliers may offer more consistent quality but at a premium.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect the total cost.

What Are the Best Buyer Tips for Sourcing Red Faux Leather Fabric?

B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should consider the following tips to optimize their sourcing strategy:

Illustrative image related to red faux leather fabric

-

Negotiation: Engage suppliers in discussions about pricing and payment terms. Leveraging volume commitments can lead to better deals.

-

Cost-Efficiency: Analyze the total cost of ownership (TCO), which includes not only the purchase price but also shipping, handling, and potential waste or defects.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and import duties, which can affect the overall cost. Also, familiarize yourself with local market conditions to better negotiate prices.

-

Quality vs. Price: While lower prices are attractive, ensure that the quality meets your requirements. Conduct thorough evaluations of samples and supplier certifications.

-

Supplier Relationships: Building long-term relationships with reliable suppliers can lead to better pricing, priority during shortages, and improved service.

Disclaimer on Indicative Prices

It is important to note that prices for red faux leather fabric can vary significantly based on the factors discussed above. The costs mentioned in this analysis are indicative and subject to change based on market conditions and supplier negotiations. Always conduct thorough market research and supplier evaluations to ensure the best sourcing decisions for your business.

Alternatives Analysis: Comparing red faux leather fabric With Other Solutions

Understanding Alternatives for Red Faux Leather Fabric

When considering materials for upholstery, fashion, or decor, red faux leather fabric stands out for its aesthetic appeal and practical benefits. However, various alternatives exist that can also meet the demands of B2B buyers, particularly in international markets. This section compares red faux leather fabric with two viable alternatives: genuine leather and vinyl fabric, allowing buyers to make informed choices based on their specific needs.

| Comparison Aspect | Red Faux Leather Fabric | Genuine Leather | Vinyl Fabric |

|---|---|---|---|

| Performance | Durable, waterproof, flexible | Highly durable, breathable | Waterproof, tear-resistant |

| Cost | Generally lower cost | Higher cost | Typically low cost |

| Ease of Implementation | Easy to cut and sew | Requires special tools | Easy to cut and sew |

| Maintenance | Easy to clean, resistant to stains | Requires conditioning | Easy to clean, resistant to stains |

| Best Use Case | Fashion items, upholstery | High-end products, luxury items | Budget-friendly upholstery, outdoor use |

In-Depth Analysis of Alternatives

What Are the Pros and Cons of Genuine Leather Compared to Red Faux Leather Fabric?

Genuine leather is known for its luxury appeal and durability. It is breathable, which makes it comfortable for apparel and upholstery. However, the cost is significantly higher than that of red faux leather fabric, making it less accessible for budget-conscious projects. Additionally, genuine leather requires regular maintenance, such as conditioning, to preserve its quality and appearance. It is best suited for high-end applications where authenticity and longevity are paramount, such as luxury furniture or premium fashion items.

How Does Vinyl Fabric Compare to Red Faux Leather Fabric in Practical Use?

Vinyl fabric offers a similar aesthetic to faux leather and is often more affordable. It is waterproof and highly resistant to wear and tear, making it an excellent choice for outdoor furniture or environments where moisture is a concern. The ease of cleaning vinyl adds to its practicality. However, vinyl can lack the luxurious feel of red faux leather fabric and may not provide the same level of comfort for clothing applications. It is typically utilized for budget-friendly upholstery projects or in commercial settings where durability is prioritized.

Illustrative image related to red faux leather fabric

Conclusion: Which Material Should B2B Buyers Choose for Their Needs?

When selecting between red faux leather fabric, genuine leather, and vinyl fabric, B2B buyers should assess their project requirements, including budget, desired aesthetics, and maintenance capabilities. Red faux leather fabric is an excellent choice for those seeking a balance of cost-effectiveness and style. In contrast, genuine leather is ideal for high-end markets where authenticity is critical, while vinyl fabric serves well in cost-sensitive applications requiring durability and ease of care. Ultimately, the right choice will depend on the specific use case and the values prioritized by the buyer, whether they lean towards luxury, functionality, or affordability.

Essential Technical Properties and Trade Terminology for red faux leather fabric

What Are the Essential Technical Properties of Red Faux Leather Fabric?

Understanding the technical specifications of red faux leather fabric is crucial for B2B buyers looking to make informed purchasing decisions. Here are the key properties to consider:

1. Material Composition

Red faux leather is typically made from synthetic materials such as polyvinyl chloride (PVC) or polyurethane (PU). The choice between these materials can affect durability, flexibility, and environmental impact. PVC is generally more durable and cost-effective, while PU offers a more premium feel and is often more environmentally friendly. Buyers should assess their specific application needs to select the right material.

2. Weight and Thickness

Faux leather fabrics come in various weights, usually measured in grams per square meter (GSM) or ounces per square yard. Heavier fabrics (around 600 GSM and above) are ideal for upholstery, while lighter fabrics (around 300-400 GSM) may be suitable for clothing or accessories. Understanding the weight and thickness helps buyers determine the suitability of the fabric for their intended application, whether it be for furniture, apparel, or automotive interiors.

3. Abrasion Resistance

Abrasion resistance is a critical property for faux leather, especially for applications involving wear and tear, such as upholstery and automotive seating. This property is often assessed using the Martindale test, where a higher rub count indicates greater durability. Fabrics that withstand over 30,000 rubs are considered highly durable and suitable for heavy-use environments.

Illustrative image related to red faux leather fabric

4. Water Resistance

The water resistance of faux leather is an essential property for outdoor and indoor applications alike. Fabrics treated with water-repellent finishes can prevent moisture absorption, making them easier to clean and maintain. Buyers should inquire about the water resistance rating to ensure the fabric meets their performance requirements.

5. UV Resistance

For applications exposed to sunlight, UV resistance is vital to prevent fading and degradation. Fabrics treated with UV stabilizers can last longer and maintain color vibrancy, making them ideal for outdoor furniture or automotive interiors. Buyers should look for UV ratings or specific treatments that enhance this property.

6. Flexibility and Stretch

Flexibility refers to how well the fabric can conform to shapes without tearing or cracking. Stretch properties, particularly in fabrics intended for apparel, can enhance comfort and fit. Understanding these specifications helps buyers select the right faux leather for their applications, ensuring longevity and user satisfaction.

Illustrative image related to red faux leather fabric

Which Trade Terminology Should B2B Buyers Understand When Sourcing Red Faux Leather Fabric?

Familiarity with industry jargon can streamline the sourcing process. Here are some essential terms for B2B buyers:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company. In the context of faux leather, buyers might engage OEMs to create custom designs or specifications tailored to their needs, ensuring product differentiation in the market.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest order quantity a supplier will accept. Understanding MOQ is critical for buyers, as it can affect inventory management and cost efficiency. Larger orders may yield better pricing, but buyers must balance this with demand forecasts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. Including detailed specifications in the RFQ ensures that suppliers provide accurate quotes, which can facilitate comparison and negotiation.

Illustrative image related to red faux leather fabric

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including delivery, risk, and insurance. Familiarity with Incoterms helps buyers navigate logistics and understand their obligations and rights during the shipping process.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for planning and inventory management, especially for businesses with tight production schedules.

6. Certification Standards

Certification standards, such as OEKO-TEX or REACH, indicate compliance with safety and environmental regulations. Buyers should seek suppliers with appropriate certifications to ensure that the faux leather fabric meets industry standards for safety and sustainability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing red faux leather fabric, ensuring they select products that align with their business needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the red faux leather fabric Sector

What Are the Current Market Dynamics and Key Trends in the Red Faux Leather Fabric Sector?

The red faux leather fabric market is witnessing a dynamic transformation, driven by a variety of global factors. Increased consumer demand for stylish yet affordable alternatives to genuine leather has propelled the growth of faux leather, especially in upholstery and fashion applications. Emerging markets in Africa and South America are particularly noteworthy, as urbanization and rising disposable incomes lead to heightened demand for home furnishings and stylish apparel. Furthermore, regions like Europe, particularly Germany and Vietnam, are experiencing a surge in eco-conscious consumers who prioritize sustainable products, thereby influencing sourcing trends.

Technological advancements in fabric manufacturing are reshaping the landscape as well. Innovations in production processes, such as digital printing and advanced textile treatments, enhance the aesthetic appeal and durability of red faux leather. Additionally, B2B platforms are increasingly facilitating direct sourcing, allowing international buyers to connect with manufacturers and suppliers more efficiently. This shift towards digital sourcing is vital for companies looking to reduce lead times and optimize supply chains.

How Important Is Sustainability and Ethical Sourcing in the Red Faux Leather Fabric Industry?

Sustainability and ethical sourcing are paramount in today’s red faux leather fabric sector. The environmental impact of synthetic materials, primarily derived from petroleum, is a growing concern. However, the industry is evolving with the introduction of eco-friendly alternatives, such as bio-based polyurethane (PU) and recycled materials that minimize carbon footprints. For B2B buyers, prioritizing suppliers that adhere to sustainable practices is not just a trend; it’s a necessity that aligns with consumer expectations and regulatory frameworks.

Ethical supply chains are becoming increasingly significant as businesses strive to ensure transparency and responsible sourcing. Certifications such as Global Recycle Standard (GRS) and OEKO-TEX® Standard 100 are becoming essential for verifying the sustainability claims of faux leather products. Buyers should look for these certifications when sourcing red faux leather to ensure they are investing in environmentally responsible materials. Moreover, embracing ethical practices can enhance brand reputation and customer loyalty, particularly in markets that value sustainability.

Illustrative image related to red faux leather fabric

What Is the Evolution of Red Faux Leather Fabric and Its Relevance to B2B Buyers?

The evolution of red faux leather fabric reflects broader trends in consumer preferences and technological advancements. Initially developed as a cost-effective alternative to genuine leather, faux leather has undergone significant improvements in texture, durability, and appearance, making it a favored choice in diverse applications from upholstery to fashion. The introduction of advanced manufacturing techniques has allowed for a wider range of colors, including vibrant reds, and textures that closely mimic natural leather.

In the B2B context, this evolution is crucial as it enables businesses to meet diverse customer needs without compromising on quality. The rise of ethical consumerism has also prompted manufacturers to innovate further, focusing on sustainable materials and practices. Consequently, buyers are not only equipped with a versatile product but also the assurance that their sourcing decisions contribute positively to environmental and social outcomes. Understanding this historical context helps B2B buyers make informed decisions that resonate with current market trends and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of red faux leather fabric

-

How do I choose the right supplier for red faux leather fabric?

Selecting the right supplier involves thorough research and evaluation. Start by checking their reputation through reviews and testimonials. Look for suppliers who have experience in international trade, particularly with your target regions. Request samples to assess the quality of the red faux leather fabric. Additionally, verify their compliance with industry standards and certifications. Establish clear communication to gauge their responsiveness and willingness to accommodate your needs, which is crucial for a successful partnership. -

What are the common applications for red faux leather fabric?

Red faux leather is versatile and commonly used in various applications, including upholstery for furniture, automotive interiors, fashion items like jackets and bags, and decorative accents in commercial spaces. Its durability and aesthetic appeal make it suitable for both indoor and outdoor use. B2B buyers should consider the specific project requirements, such as wear resistance and ease of maintenance, when selecting the right type of faux leather. -

What is the minimum order quantity (MOQ) for red faux leather fabric?

MOQs can vary significantly among suppliers, typically ranging from 50 to 1,000 yards, depending on the manufacturer and the specific fabric type. It’s essential to inquire about MOQs when contacting potential suppliers. Some manufacturers may offer flexibility for smaller orders, especially for first-time buyers or trial runs. Understanding the MOQ will help you plan your inventory and budget effectively. -

What payment terms should I expect when sourcing red faux leather fabric?

Payment terms can differ based on the supplier and the nature of your agreement. Common terms include a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers might offer net 30 or net 60 terms for established buyers. Always clarify payment options, including wire transfers, letters of credit, or online payment systems, to ensure secure transactions and avoid potential disputes. -

How do I ensure quality assurance for red faux leather fabric?

Quality assurance can be achieved through several steps. First, request samples before placing a bulk order to evaluate the fabric’s texture, durability, and color consistency. Consider conducting third-party inspections at the supplier’s facility or upon arrival of the goods. Establish clear quality standards and specifications in your purchase agreement. Continuous communication with the supplier during production can also help address any issues proactively. -

What logistics considerations should I keep in mind when importing red faux leather fabric?

Logistics play a crucial role in the timely delivery of your order. Confirm shipping options offered by the supplier, including sea, air, or land freight, and understand the associated costs. Familiarize yourself with customs regulations and import duties in your country to avoid unexpected expenses. Collaborate with a reliable freight forwarder to streamline the shipping process and ensure compliance with all international trade requirements. -

Can I customize red faux leather fabric for my specific needs?

Many suppliers offer customization options, including color matching, texture variations, and specific widths or finishes. If you have unique requirements, communicate these clearly with potential suppliers. Be prepared to provide detailed specifications and, if necessary, agree on a minimum order quantity for custom products. Customization can enhance your brand identity and ensure that the fabric meets your project’s aesthetic and functional needs. -

What are the environmental considerations when sourcing faux leather fabric?

When sourcing faux leather, it’s vital to consider the environmental impact of the materials used. Look for suppliers who utilize eco-friendly processes and materials, such as water-based adhesives and recycled plastics. Certifications like OEKO-TEX or Global Recycle Standard can indicate sustainable practices. By choosing environmentally responsible suppliers, you not only support sustainability but also enhance your brand’s reputation among eco-conscious consumers.

Top 7 Red Faux Leather Fabric Manufacturers & Suppliers List

1. OnlineFabricStore – Vinyl & Faux Leather Fabrics

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: This company, OnlineFabricStore – Vinyl & Faux Leather Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Naugahyde – Red Faux Leather Upholstery Vinyl

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Red Faux Leather Upholstery Vinyl available from industry leading brands including Naugahyde and Boltaflex. Order by the yard or roll at wholesale prices. Various options available with different stock levels and prices. Examples include: AM39 Naugahyde ALL-AMERICAN AM 39 AMERICAN BEAUTY at $27.95 per yard, LDR18 LANDERS RED at $14.95 per yard, and 6077123 SIMON RED at $24.95 per yard. Additional …

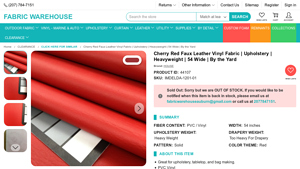

3. Fabric Warehouse – Cherry Red Faux Leather Vinyl Fabric

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Cherry Red Faux Leather Vinyl Fabric”, “Type”: “Upholstery”, “Weight”: “Heavyweight”, “Width”: “54 inches”, “Sold By”: “By the Yard”, “Fiber Content”: “PVC / Vinyl”, “Pattern”: “Solid”, “Color Theme”: “Red”, “Primary Color Code”: “#9c3437”, “Discount”: “40%”, “SKU”: “IMDELDA-1201-01”, “Stock Status”: “Out of Stock”, “Uses”: [“Upholstery”, “Tabletop”, “Bag Making”], “Features”: [“…

4. Etsy – Red Matte Pleather

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Red Matte Pleather, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. H&T Fabrics – RED Faux Leather Vinyl Upholstery Fabric

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”RED Faux Leather Vinyl Upholstery Fabric”,”Width”:”54 in.”,”Sold By”:”The Yard”,”Seller”:”H&T Fabrics”,”Seller Rating”:”97.4% positive”,”Condition”:”New”,”Quantity Available”:”More than 10 available”,”Price”:”US $20.99 or Best Offer”,”Shipping Cost”:”US $29.46″,”Location”:”New York, NY, United States”,”Returns”:”30 days returns, buyer pays for return shipping”,”Fiber Content”:”Syn…

6. Modelli Fabrics – Red Faux Leather Fabric, Monza 1289

Domain: modellifabrics.com

Registered: 2009 (16 years)

Introduction: {“name”: “Red Faux Leather Fabric, Monza 1289”, “colors”: [“Natural Brown / Taupe”, “Yellow”, “Orange / Warm Red”, “Cool Red”, “Pink”, “Purple / Lilac”, “Blue”, “Teal”, “Warm Green”, “Cool Green”, “Grey / Black”], “uses”: [“Anti-Microbial”, “Caravan / Motorhome / Boat”, “Conservatory”, “Contract Use (BS 7176 Compliant)”, “Contract Use (with extra FR coating)”, “Curtaining / Blinds”, “Domestic Upho…

7. Burlap Fabric – 54 Red Leather-like Upholstery Vinyl

Domain: burlapfabric.com

Registered: 2004 (21 years)

Introduction: {“name”:”54 Red Leather-like Upholstery Vinyl”,”model”:”FL-RED”,”price”:”$11.99″,”original_price”:”$15.00″,”discount”:”20%”,”width”:”54 inches”,”shipping_weight”:”2 lbs”,”description”:”54″ Red Leather-Like Upholstery Vinyl is a striking, resilient fabric that adds a vibrant splash of color to any project. With its rich texture and easy-to-clean surface, this fabric combines bold style with practic…

Strategic Sourcing Conclusion and Outlook for red faux leather fabric

In conclusion, the strategic sourcing of red faux leather fabric presents significant opportunities for international B2B buyers. This versatile material, known for its aesthetic appeal and durability, is increasingly favored in various applications, from upholstery to fashion. Key takeaways include the importance of selecting reliable suppliers that offer high-quality, sustainable options at competitive prices. By leveraging wholesale purchasing strategies, buyers can ensure they maintain a robust inventory while reducing costs.

Furthermore, as the demand for ethically sourced materials rises, engaging with suppliers who prioritize eco-friendly practices will not only enhance brand reputation but also align with global sustainability trends. B2B buyers from regions such as Africa, South America, the Middle East, and Europe should remain proactive in exploring innovative faux leather solutions that meet evolving consumer preferences.

Illustrative image related to red faux leather fabric

Looking ahead, the market for red faux leather fabric is poised for growth, driven by an expanding range of applications and a shift towards sustainable practices. By acting now and establishing strong supplier partnerships, businesses can position themselves advantageously in this dynamic landscape, ensuring they meet the demands of a diverse customer base.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.