Introduction: Navigating the Global Market for leather customized

In an increasingly competitive landscape, sourcing high-quality leather customized products can pose a significant challenge for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. Companies must navigate a complex supply chain that includes identifying reliable suppliers, ensuring product authenticity, and balancing cost with quality. This guide aims to demystify the global market for leather customization by offering a comprehensive overview of the types of products available, their applications across different industries, and best practices for supplier vetting.

B2B buyers will benefit from insights on how to assess quality, negotiate pricing, and understand the nuances of customization options, such as monogramming or unique design elements. Additionally, this guide will explore the importance of sustainability in leather sourcing, which is becoming increasingly vital for brands aiming to meet consumer demand for eco-friendly products. With actionable insights and data-driven recommendations, this resource empowers international buyers to make informed purchasing decisions that align with their business needs and values.

Whether you are looking to enhance your product offerings with bespoke leather goods or seeking reliable partners for bulk orders, this guide serves as an essential tool for navigating the complexities of the leather customization market. By leveraging the information provided, B2B buyers can confidently engage with suppliers and unlock the potential of personalized leather products to elevate their brand.

Table Of Contents

- Top 6 Leather Customized Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather customized

- Understanding leather customized Types and Variations

- Key Industrial Applications of leather customized

- 3 Common User Pain Points for ‘leather customized’ & Their Solutions

- Strategic Material Selection Guide for leather customized

- In-depth Look: Manufacturing Processes and Quality Assurance for leather customized

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather customized’

- Comprehensive Cost and Pricing Analysis for leather customized Sourcing

- Alternatives Analysis: Comparing leather customized With Other Solutions

- Essential Technical Properties and Trade Terminology for leather customized

- Navigating Market Dynamics and Sourcing Trends in the leather customized Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather customized

- Strategic Sourcing Conclusion and Outlook for leather customized

- Important Disclaimer & Terms of Use

Understanding leather customized Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Monogrammed Leather | Personalization with initials or names | Corporate gifts, promotional items | Pros: Enhances brand identity; Cons: Limited to basic personalization options. |

| Hand-Painted Leather | Unique artistic designs created by artisans | Luxury goods, personalized gifts | Pros: One-of-a-kind appeal; Cons: Higher cost and longer production time. |

| Embossed Leather | Textures and patterns created using heat and pressure | Fashion accessories, home decor | Pros: Durable and visually appealing; Cons: May require minimum order quantities. |

| Custom Cut Leather | Tailored shapes and sizes for specific needs | Industrial applications, bespoke items | Pros: Fits exact specifications; Cons: More complex logistics and planning required. |

| Upcycled Leather | Repurposed leather materials from various sources | Sustainable products, eco-friendly brands | Pros: Environmentally friendly; Cons: Quality may vary based on source. |

What are the Characteristics and Suitability of Monogrammed Leather?

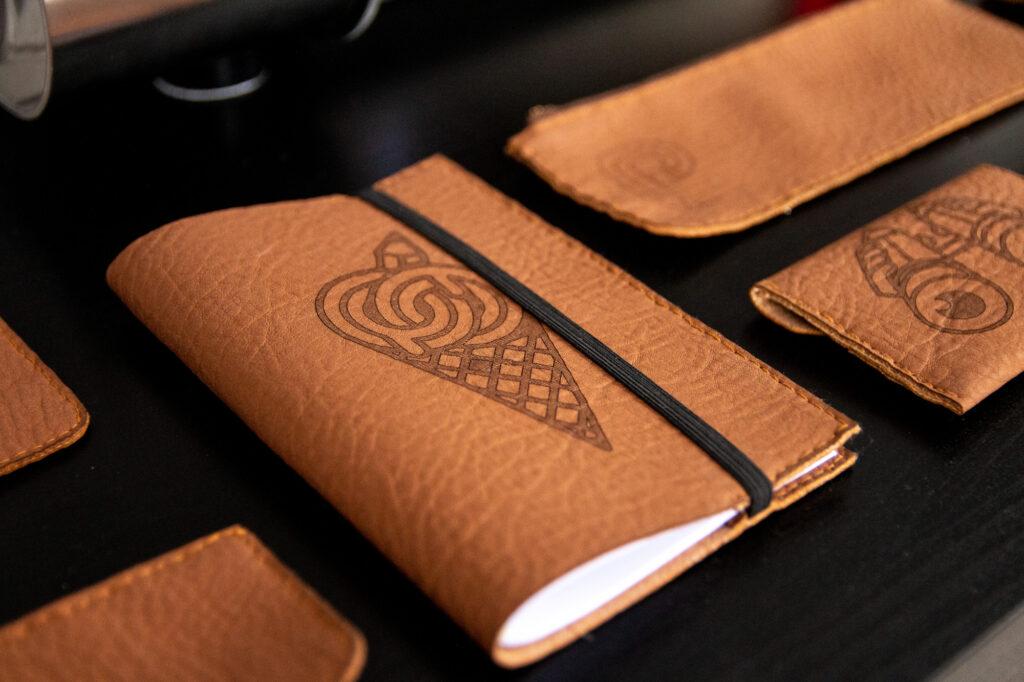

Monogrammed leather products are characterized by the addition of initials or names, often using debossing or embroidery techniques. This type of customization is highly suitable for corporate gifts and promotional items, where branding plays a crucial role. B2B buyers should consider the branding opportunities that monogramming provides, as it enhances brand identity and personalizes the customer experience. However, the options may be limited to text-based personalization, which might not appeal to all markets.

How Does Hand-Painted Leather Stand Out in the Market?

Hand-painted leather features unique, artistic designs applied by skilled artisans, making each piece a work of art. This type of leather is ideal for luxury goods and personalized gifts, appealing to consumers looking for exclusivity. B2B buyers should be aware that while the artistic value adds to the product’s appeal, it often comes at a higher price point and may require longer lead times. Thus, it is essential to balance cost with the unique selling proposition of the product.

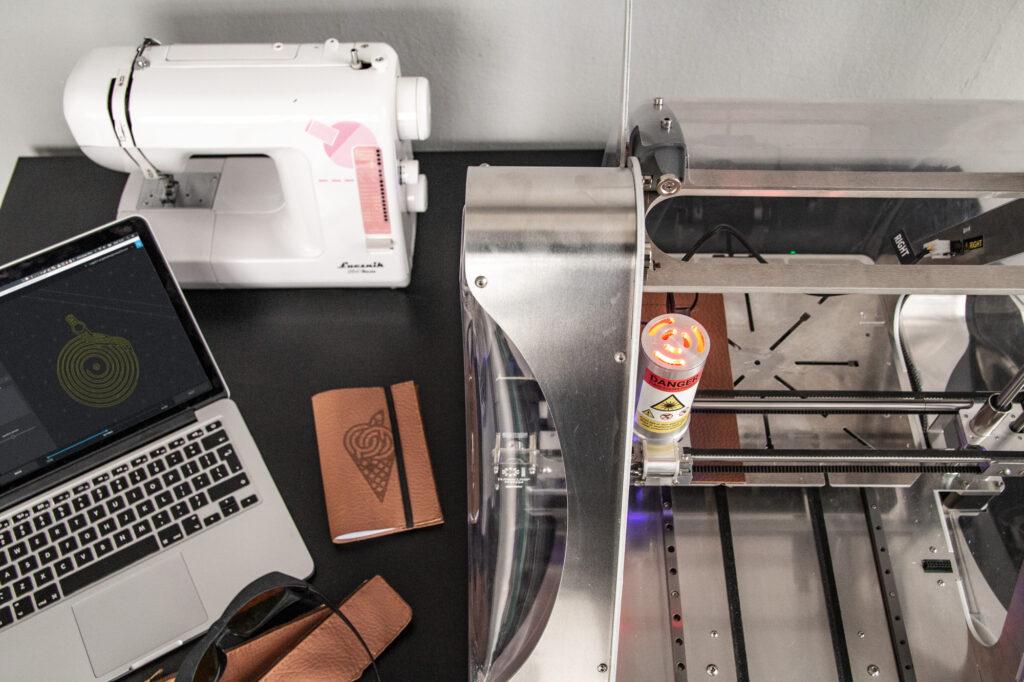

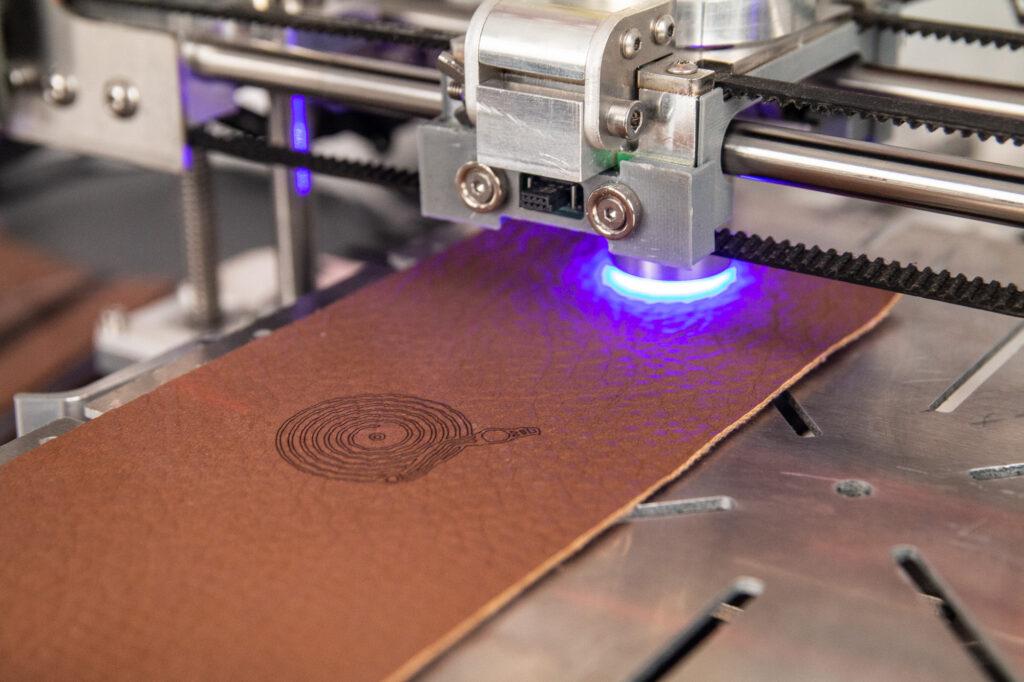

Illustrative image related to leather customized

What Makes Embossed Leather a Popular Choice?

Embossed leather is distinguished by textures and patterns created through heat and pressure techniques. This variation is popular in fashion accessories and home decor items, as it provides durability alongside visual interest. For B2B purchasers, the appeal lies in the product’s longevity and aesthetic value. However, buyers should note that embossed leather may have minimum order requirements, which could impact smaller businesses or startups.

Why Opt for Custom Cut Leather in Industrial Applications?

Custom cut leather is tailored to specific shapes and sizes, making it highly suitable for industrial applications and bespoke items. This type allows businesses to meet precise specifications, ensuring a perfect fit for their needs. B2B buyers must consider the complexity of logistics involved in sourcing custom cut leather, as it often requires careful planning and collaboration with suppliers. The benefits of exact fit and functionality can outweigh these challenges for many businesses.

How Does Upcycled Leather Contribute to Sustainable Business Practices?

Upcycled leather is sourced from repurposed materials, offering an environmentally friendly alternative in the leather goods market. This type is particularly appealing to brands focused on sustainability and eco-conscious consumers. B2B buyers should evaluate the quality consistency of upcycled materials, as the sourcing can vary widely. While the sustainable aspect is a significant advantage, potential variability in quality may pose challenges for businesses aiming for uniformity in their product offerings.

Key Industrial Applications of leather customized

| Industry/Sector | Specific Application of leather customized | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Customized leather garments and accessories | Enhances brand identity and customer loyalty through uniqueness | Sourcing quality leather, skilled artisans, and sustainable practices |

| Automotive | Personalized leather interiors for vehicles | Increases perceived value and customer satisfaction | Consideration of durability, luxury finishes, and design versatility |

| Corporate Gifts & Promotions | Customized leather office supplies and gifts | Strengthens corporate branding and employee/client relations | Focus on quality, customization options, and delivery timelines |

| Travel & Hospitality | Personalized leather luggage and travel accessories | Provides a premium experience for high-end clients | Need for durability, style, and compliance with international shipping standards |

| Home Decor | Customized leather furniture and home accessories | Adds luxury and personalization to interior spaces | Sourcing high-quality materials, craftsmanship, and design flexibility |

How Is Customized Leather Used in the Fashion & Apparel Industry?

In the fashion and apparel sector, customized leather garments and accessories allow brands to create unique offerings that resonate with consumers. This personalization can take the form of monogrammed bags or bespoke jackets, enhancing brand identity and fostering customer loyalty. International buyers must ensure that their suppliers can provide high-quality leather and skilled artisans who can execute intricate designs, as well as sustainable sourcing practices that align with ethical standards prevalent in regions like Europe and South America.

What Role Does Customized Leather Play in the Automotive Sector?

The automotive industry increasingly utilizes customized leather for vehicle interiors, offering personalized touches that elevate the driving experience. Options may include bespoke leather seats, steering wheels, and dashboard trims, which enhance the vehicle’s perceived value and overall customer satisfaction. Buyers in this sector should prioritize sourcing durable leather that meets industry standards for safety and longevity, while also considering aesthetic preferences that appeal to diverse markets across Africa and the Middle East.

How Can Businesses Leverage Customized Leather for Corporate Gifts?

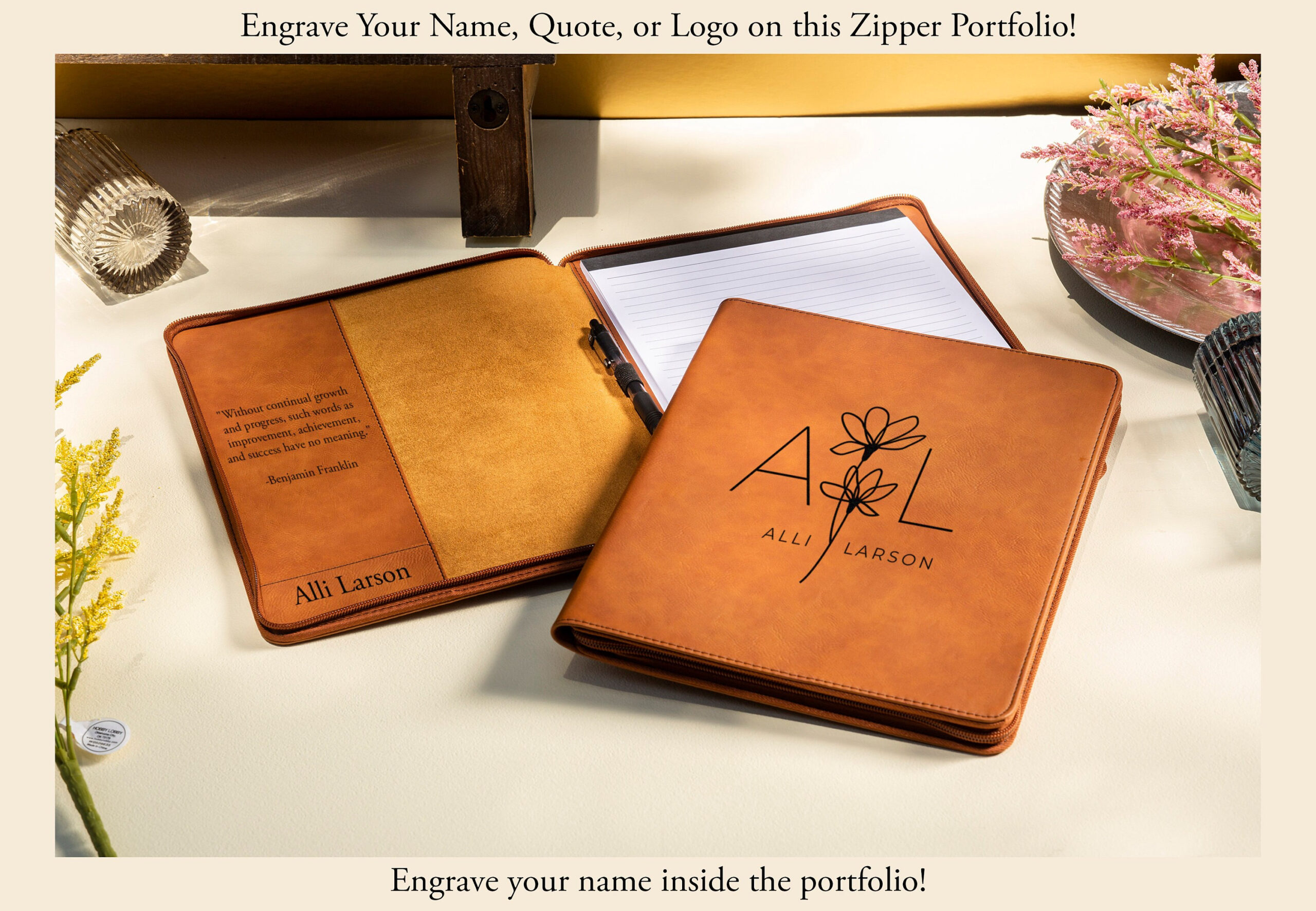

Customized leather office supplies and gifts serve as impactful promotional items that strengthen corporate branding and enhance relationships with clients and employees. Items like personalized leather notebooks, pen holders, and portfolios can convey a sense of professionalism and thoughtfulness. B2B buyers should focus on sourcing high-quality materials and versatile customization options, as well as ensuring timely delivery, particularly for events or milestones that require bulk orders.

In What Ways Does Customized Leather Enhance Travel & Hospitality Experiences?

In the travel and hospitality sector, personalized leather luggage and travel accessories provide a premium experience that can significantly enhance customer satisfaction. Customized items such as monogrammed luggage tags and bespoke travel bags not only serve practical purposes but also add a touch of luxury. Buyers should consider factors such as durability and style, ensuring that products comply with international shipping standards, especially when catering to a global clientele.

How Is Customized Leather Applied in Home Decor?

Customized leather furniture and home accessories are increasingly popular in the home decor market, offering a blend of luxury and personalization. Products such as leather couches, cushions, and decorative items allow consumers to express their individual style while enhancing the aesthetic of their living spaces. Buyers should prioritize sourcing high-quality materials and craftsmanship, as well as flexibility in design to meet diverse consumer preferences across different regions.

Illustrative image related to leather customized

3 Common User Pain Points for ‘leather customized’ & Their Solutions

Scenario 1: Navigating Quality Concerns in Customized Leather Products

The Problem: B2B buyers often face uncertainty regarding the quality of leather used in customized products. This is particularly pertinent when sourcing from international suppliers, where the risk of receiving subpar materials can lead to dissatisfaction among end customers. For instance, a company in Nigeria may order personalized leather goods for corporate gifts, only to find that the leather is not durable or lacks the expected aesthetic appeal. Such scenarios not only impact customer satisfaction but can also tarnish the company’s reputation.

The Solution: To mitigate quality concerns, B2B buyers should implement a rigorous vetting process for suppliers. Start by requesting samples of the leather to assess texture, durability, and craftsmanship. It’s also beneficial to establish relationships with suppliers who have a proven track record in the industry, particularly those who can provide certifications for their leather, such as full-grain or top-grain options. Additionally, consider visiting manufacturing facilities, if feasible, to observe production processes firsthand. Engaging with suppliers who are transparent about their sourcing and production practices can further ensure that the leather meets the required standards.

Scenario 2: Managing Long Lead Times for Customized Orders

The Problem: One of the most pressing issues for B2B buyers in the leather customization space is the extended lead times associated with personalized orders. Companies in South America, for example, may face delays due to production bottlenecks or shipping issues when placing bulk orders for customized leather items. This can disrupt planned marketing campaigns or client engagements, leading to lost opportunities and financial repercussions.

The Solution: To tackle lead time challenges, buyers should proactively negotiate clear timelines with suppliers at the outset. It is essential to establish a detailed project timeline that includes key milestones from order placement to delivery. Utilizing local suppliers when possible can also significantly reduce shipping times and related costs. Additionally, implementing a just-in-time inventory strategy can help maintain stock levels for frequently ordered items, allowing for quicker turnaround on personalized requests. Buyers should also consider maintaining an ongoing dialogue with suppliers to monitor production status and address any potential delays before they escalate.

Scenario 3: Ensuring Brand Consistency Across Customized Products

The Problem: Maintaining brand consistency can be a daunting task for companies looking to incorporate customized leather products into their branding strategy. A firm in Europe may wish to offer personalized leather items featuring their logo, but they struggle to ensure that the customization aligns with their brand’s identity in terms of color, style, and overall presentation. Inconsistencies can lead to a disjointed brand image, negatively affecting brand perception among clients and partners.

Illustrative image related to leather customized

The Solution: To ensure brand consistency, B2B buyers should create a comprehensive style guide that outlines specifications for customized products. This guide should detail preferred color palettes, logo placement, font styles, and material selections. When communicating with suppliers, share this guide to ensure that all customization adheres to brand standards. Regularly collaborating with suppliers and conducting quality checks on customized samples can further help in maintaining brand alignment. It may also be advantageous to establish a limited number of trusted suppliers who understand the brand ethos and can consistently deliver products that reflect the company’s identity accurately.

Strategic Material Selection Guide for leather customized

What are the Key Materials for Customized Leather Products?

When selecting materials for customized leather products, understanding the properties and implications of each option is crucial for B2B buyers. Here, we analyze four common materials used in leather customization: Full Grain Leather, Top Grain Leather, Suede, and Synthetic Leather. Each material has unique characteristics that can significantly affect product performance, durability, and market appeal.

How Does Full Grain Leather Perform in Customized Products?

Full grain leather is the highest quality leather available, made from the outer layer of the hide. It retains the natural grain, which provides unique patterns and textures. This material is renowned for its durability, breathability, and ability to develop a rich patina over time.

Pros: Full grain leather is exceptionally durable and resistant to wear and tear, making it suitable for high-end products like wallets and bags. Its natural look appeals to consumers seeking luxury items.

Cons: The cost of full grain leather is relatively high, which may impact pricing strategies. Additionally, its natural imperfections can be seen as flaws by some customers.

Illustrative image related to leather customized

Impact on Application: Full grain leather is compatible with various media, including embossing and dyeing, enhancing its customization potential.

Considerations for International Buyers: B2B buyers from regions like Europe and the Middle East often prefer full grain leather for its quality. Compliance with international standards such as ASTM and DIN is essential, especially concerning environmental regulations.

What Advantages Does Top Grain Leather Offer for Customization?

Top grain leather is the second-highest quality leather, made by sanding down the top layer of the hide. This process removes imperfections, resulting in a more uniform appearance.

Pros: It is more affordable than full grain leather while still offering good durability and a refined look. Top grain leather is easier to work with for manufacturers, allowing for more intricate designs.

Cons: While it is durable, it does not develop the same character over time as full grain leather. Additionally, it may be less resistant to moisture and scratches.

Impact on Application: Top grain leather is suitable for products requiring a polished finish, such as handbags and accessories.

Considerations for International Buyers: Buyers should ensure that top grain leather meets local quality standards and preferences, particularly in markets like Germany, where craftsmanship is highly valued.

How Does Suede Compare in Terms of Customization?

Suede is made from the underside of the hide, resulting in a soft, velvety texture. It is often used for fashion accessories and items that require a softer touch.

Illustrative image related to leather customized

Pros: Suede is lightweight and has a unique aesthetic appeal, making it popular for trendy products. It is also generally less expensive than full grain and top grain leather.

Cons: Suede is more susceptible to stains and damage from moisture, which limits its use in certain applications. Its durability is lower compared to other leather types.

Impact on Application: Suede is ideal for items like bags and shoes that prioritize style over ruggedness.

Illustrative image related to leather customized

Considerations for International Buyers: Buyers should be aware of the maintenance requirements for suede and ensure that products meet local market expectations, especially in humid regions.

What Role Does Synthetic Leather Play in Customized Products?

Synthetic leather, or faux leather, is made from plastic materials designed to mimic the look and feel of real leather. It has gained popularity due to ethical and environmental considerations.

Pros: Synthetic leather is generally more affordable and easier to clean than natural leather. It is also available in a wide range of colors and textures.

Cons: While it can be durable, synthetic leather often lacks the longevity and breathability of natural options. It may also not appeal to consumers who prioritize authenticity.

Impact on Application: Synthetic leather is versatile, suitable for various products, including budget-friendly options.

Illustrative image related to leather customized

Considerations for International Buyers: B2B buyers should consider local preferences for sustainable products, as markets in Africa and South America increasingly favor eco-friendly materials.

Summary Table of Material Selection for Customized Leather Products

| Material | Typical Use Case for leather customized | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | High-end wallets, bags, and belts | Exceptional durability and unique aesthetics | High cost and natural imperfections | High |

| Top Grain Leather | Handbags, accessories, and apparel | More affordable with a refined look | Less character and moisture resistance | Medium |

| Suede | Fashion bags, shoes, and accessories | Soft texture and lightweight | Susceptible to stains and less durable | Medium |

| Synthetic Leather | Budget-friendly bags, apparel, and upholstery | Affordable and easy to clean | Lacks authenticity and longevity | Low |

This guide aims to provide actionable insights for international B2B buyers, helping them make informed decisions when selecting materials for customized leather products.

In-depth Look: Manufacturing Processes and Quality Assurance for leather customized

What Are the Key Stages in the Manufacturing Process of Customized Leather Products?

The manufacturing of customized leather products involves several critical stages, each contributing to the overall quality and uniqueness of the final product. Understanding these stages can help B2B buyers make informed decisions when sourcing from suppliers.

Material Preparation: What is Involved in Sourcing and Preparing Leather?

The first step in the manufacturing process is material preparation, which includes sourcing high-quality leather. Leather can be sourced from various animal hides, such as cow, goat, or sheep, each offering different textures and durability levels. Buyers should look for suppliers who prioritize ethical sourcing and sustainability, as this can significantly impact brand reputation.

Once the leather is sourced, it undergoes a tanning process to enhance its durability and aesthetic appeal. Tanning can be done using vegetable-based or chrome-based methods, each offering unique characteristics. After tanning, the leather is conditioned and dyed, allowing for a range of colors and finishes, which is essential for customized products. B2B buyers should request samples to evaluate the leather’s quality and suitability for their needs.

How Are Customized Leather Goods Formed and Assembled?

The forming stage involves cutting the leather into specific shapes and sizes based on design specifications. This is often done using precision cutting tools or die-cutting methods to ensure consistency and accuracy. For customized products, additional techniques such as embossing or debossing may be employed to add logos or personalized elements.

Assembly follows forming, where the individual leather pieces are stitched or glued together. Skilled artisans often perform this stage to ensure that the craftsmanship meets high-quality standards. B2B buyers should inquire about the artisans’ experience and the techniques used, as this can affect the durability and aesthetic of the final product.

What Finishing Techniques Enhance the Quality of Customized Leather Products?

The finishing stage is crucial for enhancing the leather’s appearance and protecting it from wear and tear. This can involve applying protective coatings, polishing, or adding hardware such as zippers and buckles. Customization can also include hand-painted designs or unique stitching patterns, which not only make the product unique but can also justify a higher price point.

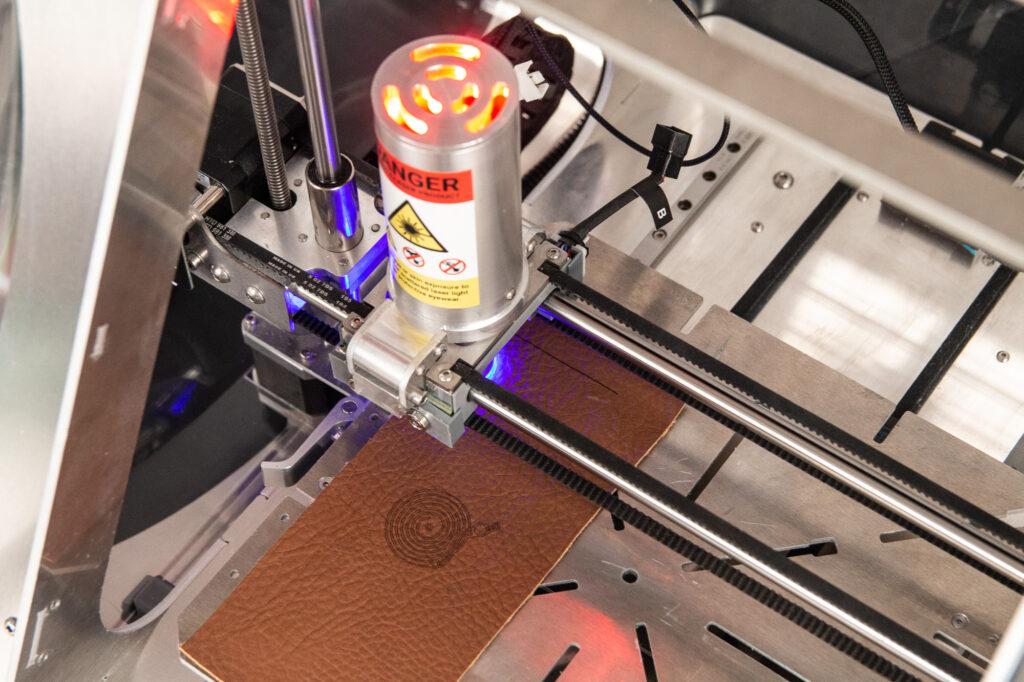

Illustrative image related to leather customized

Quality assurance during this stage ensures that the product meets the desired specifications. Buyers should seek suppliers who implement rigorous finishing processes to maintain quality.

What Quality Assurance Standards Should B2B Buyers Consider for Customized Leather Products?

Quality assurance (QA) is vital in the leather manufacturing industry, particularly for customized products where client specifications are paramount. International standards, such as ISO 9001, provide a framework for effective quality management systems. Compliance with these standards indicates that a supplier has established protocols for maintaining quality throughout the manufacturing process.

How Do Industry-Specific Standards Affect Quality Assurance?

In addition to general ISO standards, industry-specific certifications like CE marking for consumer safety or API standards for specific applications can be relevant. B2B buyers should ensure that their suppliers comply with these standards, as it reflects their commitment to quality and safety.

What Are the Key Quality Control Checkpoints in Leather Manufacturing?

Quality control (QC) is implemented at various checkpoints during the manufacturing process, including:

Illustrative image related to leather customized

-

Incoming Quality Control (IQC): This is where raw materials, such as leather hides, are inspected upon arrival. Buyers should confirm that their suppliers conduct thorough inspections to catch any defects early.

-

In-Process Quality Control (IPQC): During the forming and assembly stages, ongoing inspections ensure that the manufacturing process adheres to quality standards. Regular audits and checks can prevent defects from progressing to the final product.

-

Final Quality Control (FQC): This stage involves a comprehensive inspection of the finished product before shipment. Buyers should request detailed reports on FQC results to ensure that products meet their specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control processes is essential for B2B buyers, especially when dealing with international suppliers. Here are some actionable steps:

-

Request Documentation: Suppliers should provide documentation demonstrating compliance with quality standards, including ISO certifications and internal QC reports.

-

Conduct Audits: Buyers can perform on-site audits to evaluate the manufacturing processes and quality control measures in place. This hands-on approach allows for a deeper understanding of the supplier’s capabilities.

-

Utilize Third-Party Inspection Services: Engaging independent third-party inspectors can provide an unbiased assessment of the supplier’s quality practices. These inspectors can verify compliance with international standards and identify any potential issues.

What Challenges Do B2B Buyers Face in Quality Assurance Across Different Regions?

When sourcing customized leather products from different regions, B2B buyers may encounter various challenges related to quality assurance. Differences in manufacturing practices, availability of quality raw materials, and local regulations can affect product quality.

For example, buyers from Africa may face challenges related to supply chain logistics, while those in Europe may prioritize sustainability and ethical sourcing. Understanding these regional differences can help buyers tailor their quality assurance expectations and select suppliers that align with their values.

Illustrative image related to leather customized

Conclusion: Why is Quality Assurance Crucial for the Success of Customized Leather Products?

In the competitive landscape of customized leather goods, robust manufacturing processes and stringent quality assurance practices are essential for maintaining product quality and customer satisfaction. B2B buyers should prioritize suppliers who demonstrate a commitment to quality through established manufacturing protocols and compliance with international standards. By doing so, buyers can ensure that they receive high-quality products that meet their specific needs, ultimately enhancing their brand reputation and customer loyalty.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather customized’

This guide provides a comprehensive checklist for B2B buyers looking to procure customized leather products. As the demand for personalized leather goods continues to rise across various markets, understanding how to effectively source these products can lead to enhanced customer satisfaction and brand loyalty.

Step 1: Identify Your Target Market Needs

Understanding your target market’s preferences is crucial. Different regions, such as Africa, South America, the Middle East, and Europe, have unique cultural influences that can dictate the style and functionality of leather goods. Conduct market research to identify trends, popular designs, and potential price points that resonate with your audience.

Illustrative image related to leather customized

- Consider regional preferences: Look into local styles and preferences that can influence product design.

- Analyze competition: Study what similar businesses are offering to find gaps in the market.

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications of the leather products you wish to source. This includes details such as leather type, thickness, texture, color, and any customization options like embossing or stitching.

- Material quality: Ensure the leather meets industry standards for durability and aesthetics.

- Customization options: Specify the types of personalization that will appeal to your target customers, such as monogramming or custom artwork.

Step 3: Research and Evaluate Potential Suppliers

Conduct thorough research to identify suppliers who specialize in customized leather goods. Evaluate their reputations, product offerings, and manufacturing capabilities.

- Request samples: Before making a decision, ask for product samples to assess quality firsthand.

- Check reviews and references: Look for testimonials from other businesses that have sourced from these suppliers to gauge reliability.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers comply with industry regulations and standards. This is particularly important in international trade, where compliance can vary significantly.

- Certifications to look for: ISO certifications or other relevant quality assurance certifications can indicate a supplier’s commitment to quality.

- Sustainability practices: Inquire about the supplier’s sourcing practices to ensure they align with ethical and environmental standards.

Step 5: Negotiate Terms and Conditions

Once you’ve selected potential suppliers, negotiate terms that work for both parties. This includes pricing, lead times, minimum order quantities, and payment terms.

- Be clear about expectations: Ensure that all terms are documented to avoid misunderstandings later.

- Consider long-term relationships: Building a good rapport can lead to better pricing and terms in the future.

Step 6: Establish Quality Control Measures

Implement quality control measures to ensure the products meet your standards before they reach your customers. This step is vital in maintaining brand reputation.

Illustrative image related to leather customized

- Set inspection criteria: Define what constitutes acceptable quality and communicate this to your supplier.

- Conduct inspections: Consider third-party inspections if dealing with international suppliers to ensure compliance with your specifications.

Step 7: Plan for Logistics and Distribution

Finally, develop a logistics plan to manage the distribution of your customized leather products. This involves selecting shipping methods, understanding tariffs, and planning for inventory management.

- Shipping options: Evaluate different shipping methods for cost-effectiveness and reliability.

- Inventory management: Ensure that you have a system in place to track inventory levels and manage stock efficiently.

By following this structured checklist, B2B buyers can streamline their sourcing process for customized leather products, ensuring they meet market demands and maintain high-quality standards.

Comprehensive Cost and Pricing Analysis for leather customized Sourcing

What Are the Key Cost Components in Leather Customized Sourcing?

When sourcing customized leather products, it is vital to understand the various cost components that contribute to the overall pricing. The primary elements include:

Illustrative image related to leather customized

-

Materials: The type of leather used significantly impacts cost. Full-grain leather, for example, is more expensive than corrected grain leather due to its superior quality and durability. Additionally, the sourcing region may influence material prices; leather from Europe often commands a premium due to stringent quality standards.

-

Labor: Skilled artisanship is crucial in leather customization. Labor costs vary by region, with countries in Europe typically having higher wage standards compared to those in Africa or South America. The complexity of the design also affects labor costs; intricate patterns or personalized features require more time and expertise.

-

Manufacturing Overhead: This encompasses the costs associated with running a production facility, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, which is especially important for B2B buyers looking to maximize profit margins.

-

Tooling: Initial setup for custom designs may require specific tools or molds, leading to one-time costs that should be factored into the pricing structure. These costs can be amortized over larger order volumes, making it essential to consider minimum order quantities (MOQs).

-

Quality Control (QC): Implementing robust QC measures ensures that the final product meets the required specifications and quality standards. This adds to the cost but can prevent expensive returns and customer dissatisfaction.

-

Logistics: Transporting leather goods involves significant costs, particularly for international shipments. Factors such as shipping method, distance, and customs duties can greatly influence the final price.

-

Margin: Suppliers typically include a profit margin within their pricing. Understanding the margins applied by different suppliers can help buyers identify competitive pricing options.

How Do Price Influencers Impact Leather Customized Products?

Several factors influence the pricing of customized leather products, including:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide tiered pricing based on order volume. Higher quantities can result in lower per-unit costs, making it beneficial for buyers to negotiate bulk orders.

-

Specifications and Customization: The degree of customization affects cost. Simple designs may incur lower costs, while highly personalized items, such as engraved initials or unique color requests, can increase the price.

-

Material Quality and Certifications: Premium materials that are sustainably sourced or certified can lead to higher prices. Buyers should assess whether the additional costs align with their brand values and target market.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role. Established suppliers with a history of quality may charge higher prices but offer peace of mind regarding product consistency and delivery timelines.

-

Incoterms: Understanding the terms of trade (e.g., FOB, CIF) is essential for calculating total costs. Buyers should be aware of who bears the risk and costs at different stages of the shipping process.

What Tips Can Help Buyers Optimize Costs in Leather Customized Sourcing?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, optimizing costs in leather customized sourcing involves several strategies:

-

Negotiation: Engage suppliers in discussions regarding pricing and terms. Highlighting potential long-term partnerships can encourage suppliers to offer better rates or favorable payment terms.

-

Total Cost of Ownership: Evaluate the total cost beyond the initial purchase price. Consider shipping, customs, and potential returns when assessing the overall expenditure.

-

Pricing Nuances for International Buyers: Be mindful of currency fluctuations and international tariffs that can impact overall costs. Establishing contracts in stable currencies may reduce risk.

-

Supplier Diversification: Exploring multiple suppliers can provide leverage in negotiations and help identify competitive pricing. It also mitigates risks associated with relying on a single source.

Disclaimer on Indicative Prices

Prices in the leather customized market can fluctuate due to various factors, including market demand, material availability, and geopolitical influences. Therefore, it is advisable for buyers to conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing leather customized With Other Solutions

Exploring Alternatives to Leather Customized Products

In the evolving landscape of personalized goods, B2B buyers often seek alternatives to leather customized products. Understanding these alternatives is crucial for making informed purchasing decisions that align with business goals, budget constraints, and customer preferences. This analysis compares leather customized solutions with synthetic materials and other personalized gift options, examining various factors that can influence choice.

Illustrative image related to leather customized

| Comparison Aspect | Leather Customized | Synthetic Materials | Personalized Fabric Products |

|---|---|---|---|

| Performance | Durable, age beautifully, high quality | Less durable, may not age well | Moderate durability, fabric quality varies |

| Cost | Higher initial investment | Generally lower cost | Mid-range pricing |

| Ease of Implementation | Requires skilled craftsmanship | Easier to mass-produce | Simple production processes |

| Maintenance | Requires regular care | Easy to clean and maintain | Machine washable options available |

| Best Use Case | Premium gifts, corporate branding | Budget-friendly promotional items | Casual gifts, events, and giveaways |

What Are the Advantages and Disadvantages of Synthetic Materials Compared to Leather Customized Products?

Synthetic materials, such as polyurethane and PVC, present a cost-effective alternative to leather. These materials are easier to produce and can be manufactured in large quantities, making them ideal for businesses with tight budgets. However, they often lack the durability and aesthetic appeal of leather, which can affect long-term customer satisfaction. Moreover, synthetic options may not provide the same level of prestige that leather products typically convey, which can be a drawback for businesses aiming to project a luxury image.

How Do Personalized Fabric Products Compare to Leather Customized Solutions?

Personalized fabric products, like custom-printed bags or apparel, offer a versatile option for businesses looking to provide unique gifts or promotional items. They are generally more affordable than leather and can be produced quickly, making them suitable for events or short-term campaigns. However, the durability of fabric items can be a concern, as they may not hold up as well over time compared to leather. Additionally, fabric products may lack the perceived value associated with leather, which could impact brand reputation in more upscale markets.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between leather customized products and alternative solutions, B2B buyers should consider several factors: performance, cost, ease of implementation, maintenance, and the specific use case. Leather offers a premium option that can enhance brand image and customer loyalty, but it comes at a higher price point. Conversely, synthetic materials and personalized fabric products present budget-friendly alternatives that may be more suitable for promotional use or casual gifting. Ultimately, the right choice will depend on the buyer’s target audience, branding strategy, and long-term objectives. Making an informed decision will ensure that the selected products resonate with customers while aligning with the business’s financial and operational goals.

Essential Technical Properties and Trade Terminology for leather customized

What Are the Key Technical Properties of Customized Leather Products?

When sourcing customized leather products, understanding the technical properties is crucial for making informed purchasing decisions. Below are some essential specifications that play a significant role in the quality and performance of leather goods.

Illustrative image related to leather customized

1. Material Grade

Material grade refers to the quality of the leather used in manufacturing. Grades can range from full-grain leather, which retains the natural grain and character of the hide, to corrected grain leather, which undergoes extensive processing. Full-grain leather is highly valued for its durability and aesthetics, making it ideal for high-end products. Recognizing the material grade helps buyers assess the longevity and appearance of the final product.

2. Tanning Process

The tanning process determines the leather’s softness, flexibility, and resistance to wear. Vegetable tanning is eco-friendly and yields a softer feel, while chrome tanning offers faster production and greater durability. Buyers should consider the tanning method when selecting products, as it directly impacts the leather’s suitability for various applications, such as fashion items or functional goods.

3. Thickness

Leather thickness is measured in ounces or millimeters and can significantly affect the product’s durability and feel. Thicker leather (typically over 4 ounces) is robust and suitable for items like bags and belts, while thinner leather (1-3 ounces) is often used for wallets and accessories. Understanding thickness aids in determining the appropriate applications for different leather goods.

4. Finish

The finish of leather refers to the surface treatment applied to enhance its appearance and protect it from wear and moisture. Common finishes include aniline, semi-aniline, and pigmented. Aniline leather showcases the hide’s natural beauty but may be less resistant to stains, whereas pigmented leather is more durable and easier to maintain. Buyers should align their finish selection with the intended use and maintenance expectations of the product.

5. Colorfastness

Colorfastness is the ability of leather to retain its color when exposed to light, water, and friction. This property is critical for ensuring that customized leather products maintain their appearance over time, especially in items that will be frequently handled or exposed to the elements. Buyers should inquire about colorfastness testing results to ensure that the products will meet their aesthetic and functional needs.

Illustrative image related to leather customized

What Are Common Trade Terms Used in the Customized Leather Industry?

Navigating the leather industry requires familiarity with specific jargon that can influence procurement processes. Understanding these terms can facilitate smoother transactions and clearer communications.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce goods that can be branded by another company. In the leather industry, this often relates to manufacturers who create customized leather products for brands. Recognizing OEM relationships can help buyers identify reliable sources and understand the production capabilities of potential suppliers.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it affects inventory management and cash flow. Understanding MOQ helps businesses plan their purchases according to their demand forecasts and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and other details for specific products. This term is essential for buyers looking to compare costs and services among different manufacturers. A well-prepared RFQ can streamline the sourcing process and ensure that all necessary information is gathered for decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. They define aspects such as shipping responsibilities, risk transfer, and payment obligations. Familiarity with Incoterms helps buyers understand their obligations in international transactions and can prevent misunderstandings during shipping and delivery.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. This term is crucial for supply chain management, as it impacts inventory levels and project timelines. Buyers should assess lead times when planning their purchases to ensure that they meet their operational requirements.

By understanding these essential technical properties and trade terminology, B2B buyers can make more informed decisions when sourcing customized leather products, ultimately enhancing their purchasing strategies and supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the leather customized Sector

What Are the Current Market Dynamics and Key Trends in the Leather Customized Sector?

The leather customized sector is witnessing a surge driven by increasing consumer demand for personalization and quality craftsmanship. Factors such as rising disposable incomes, especially in emerging markets in Africa and South America, are fueling this growth. International B2B buyers are increasingly seeking unique, high-quality leather goods that reflect their brand identity or serve as memorable gifts. This shift towards individuality is supported by technological advancements in manufacturing, such as 3D printing and digital design tools, which enable businesses to offer tailored products efficiently.

Illustrative image related to leather customized

Moreover, the sector is seeing a trend towards online sourcing platforms that facilitate global trade. For instance, B2B marketplaces are evolving to incorporate advanced filtering options, allowing buyers to find suppliers who can meet specific customization needs. Additionally, the integration of AI in inventory management is helping suppliers optimize their stock based on consumer trends, thus enhancing the responsiveness of the supply chain.

In Europe, particularly in Germany, there is a growing emphasis on artisanal craftsmanship, with brands focusing on limited-edition pieces that emphasize quality over quantity. Meanwhile, in regions like Nigeria, local artisans are leveraging traditional techniques to create customized leather products that appeal to both domestic and international markets. This blend of modern technology and traditional craftsmanship is becoming a hallmark of the leather customized sector.

How Is Sustainability and Ethical Sourcing Impacting the Leather Customized Industry?

Sustainability is becoming a core consideration for B2B buyers in the leather customized sector. As consumers become more environmentally conscious, they are demanding transparency in the sourcing of materials. Ethical supply chains are gaining importance, with businesses increasingly scrutinizing their suppliers to ensure compliance with environmental standards.

The environmental impact of leather production is significant, primarily due to water usage and chemical processes involved in tanning. As a response, many suppliers are adopting ‘green’ certifications and sourcing materials that minimize ecological harm. For example, vegetable-tanned leather, which uses natural tannins instead of harmful chemicals, is gaining popularity among environmentally conscious brands.

Furthermore, the rise of circular economy principles is prompting businesses to consider end-of-life management for leather products. This includes initiatives for recycling and upcycling, which not only reduce waste but also create new revenue streams for companies. B2B buyers who prioritize sustainability can leverage these practices to enhance their brand reputation and meet the growing consumer demand for responsible products.

Illustrative image related to leather customized

What Is the Historical Context of the Leather Customized Sector for B2B Buyers?

The leather customized sector has evolved significantly over the years, transitioning from a purely artisanal craft to a dynamic industry driven by consumer preferences and technological advancements. Historically, leather goods were primarily produced for functionality, with customization limited to monograms or initials. However, as consumer expectations shifted towards personalization and quality, the industry adapted by integrating advanced manufacturing techniques.

In the late 20th century, the globalization of trade opened new markets, allowing artisans and brands from various regions to access international buyers. This period saw an increase in the diversity of leather products, with unique styles and craftsmanship emerging from different cultures. Today, the leather customized sector is characterized by a blend of traditional techniques and modern innovations, offering international B2B buyers a wide array of options that cater to varying tastes and preferences.

As the market continues to evolve, the focus on sustainability and ethical sourcing will likely shape future trends, further enhancing the appeal of customized leather products in the global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of leather customized

1. How do I ensure the quality of customized leather products?

To ensure the quality of customized leather products, start by vetting suppliers thoroughly. Request samples to assess the leather’s texture, finish, and durability. Look for certifications that indicate adherence to industry standards, such as ISO or Leather Working Group certifications. Establish clear communication about your quality expectations and consider conducting factory visits if feasible. Additionally, inquire about the supplier’s quality assurance processes, such as inspections at various production stages, to ensure that the final product meets your standards.

2. What is the best way to find reliable suppliers of customized leather goods?

Finding reliable suppliers for customized leather goods involves researching and utilizing multiple channels. Start with online B2B marketplaces like Alibaba or Global Sources, where you can filter by ratings and reviews. Attend trade shows and leather expos to connect with manufacturers and artisans directly. Leverage industry networks and forums for recommendations. Always perform due diligence by checking references and requesting samples before placing larger orders to ensure the supplier meets your quality and reliability standards.

3. What customization options are typically available for leather products?

Customization options for leather products can vary widely among suppliers. Common options include embossing or debossing logos, monogramming initials, and selecting specific colors and finishes. Some manufacturers may also offer hand-painted designs or unique stitching patterns. Discuss your specific requirements with potential suppliers to understand their capabilities and limitations. It’s also wise to inquire about the minimum order quantity (MOQ) for custom designs, as this can affect your purchasing decisions.

4. How do I determine the minimum order quantity (MOQ) for customized leather items?

Minimum order quantities (MOQ) for customized leather items depend on the supplier’s production capabilities and the complexity of the customization. Typically, MOQs can range from a few dozen to several hundred units. When negotiating with suppliers, clarify the MOQ for different product types and customization levels. Consider discussing your needs and exploring the possibility of lower MOQs for initial orders or samples to establish a relationship before committing to larger purchases.

5. What payment terms should I expect when ordering customized leather products?

Payment terms for customized leather products can vary by supplier and region. Common practices include a deposit (often 30-50%) upfront, with the balance due upon completion or before shipping. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) for established clients. It’s essential to negotiate terms that align with your cash flow needs while ensuring protection against potential risks. Always confirm accepted payment methods, such as bank transfers or letters of credit, to facilitate smooth transactions.

6. How can I manage logistics and shipping for international orders of customized leather goods?

Managing logistics for international orders of customized leather goods requires careful planning. Start by discussing shipping options with your supplier, as they may have preferred freight forwarders or shipping partners. Consider the incoterms (e.g., FOB, CIF) that best suit your needs and ensure clarity on who handles customs clearance and duties. Evaluate shipping times and costs, and factor in potential delays. Keeping open lines of communication with your supplier during the shipping process can help address any issues that may arise.

7. What quality assurance measures should I implement for customized leather orders?

Implementing quality assurance measures for customized leather orders begins with setting clear specifications and expectations with your supplier. Request pre-production samples to verify quality before full-scale production. Consider third-party inspections at various production stages, particularly for larger orders. Establish a clear process for addressing defects or issues upon receipt, including return policies and remedies. Regular communication with your supplier regarding quality expectations can also foster a proactive approach to quality management.

8. How can I effectively communicate my customization needs to suppliers?

Effective communication of customization needs to suppliers involves being clear and detailed. Start with a comprehensive product brief that outlines your specifications, including dimensions, materials, colors, and any unique design elements. Use visual aids such as sketches or reference images to convey your vision accurately. Establish a feedback loop to clarify any uncertainties and ensure that both parties are aligned on expectations. Regular check-ins throughout the production process can help address any changes or challenges in real-time.

Top 6 Leather Customized Manufacturers & Suppliers List

1. Leatherology – Personalized Leather Gifts

Domain: leatherology.com

Registered: 2007 (18 years)

Introduction: Leatherology offers personalized leather gifts including wallets, padfolios, handbags, travel accessories, and home office items. Key product categories include women’s and men’s wallets (bifold, trifold, card holders, money clips), handbags (crossbodies, totes, shoulder bags, mini bags, backpacks), travel bags (duffle bags, laptop bags), and home office accessories (portfolios, journals, desk acc…

2. Holtz Leather – The Trifecta Personalized Leather Tri-Fold Wallet

Domain: holtzleather.com

Registered: 2015 (10 years)

Introduction: {“products”:[{“name”:”The Trifecta Personalized Leather Tri-Fold Wallet with ID Slot”,”price”:”$109.00″},{“name”:”The Maria Fine Leather Tote Bag”,”price”:”$449.00″},{“name”:”Personalized Bridle Leather Men’s Casual Belt – Square Nickel or Brass Buckle”,”price”:”$105.00″},{“name”:”Tennessee Whiskey Barrel Stave Towel Hanger Wall Hook”,”price”:”$35.00″},{“name”:”The Monticello Fine Leather Personal…

3. Ox and Pine – Personalized Leather Journals

Domain: oxandpine.com

Registered: 2017 (8 years)

Introduction: Personalized Leather Gifts including Journals, Accessories, Wedding items, Wallets & Bags, Hats & Patches, Corporate Swag, and Top Gifts. Key products include: Personalized Leather Journal (from $49.00), Personalized Leather Journal w/ Snap (from $49.00), Personalized Leather Luggage Tags ($15.00), Small Leather Cord Wrap ($7.00), Leather Cord Wrap for Laptop Chargers ($9.00), Classic Personalized…

4. Odin Leather Goods – Customizable Products

Domain: odinleathergoods.com

Registered: 2012 (13 years)

Introduction: Customizable w/ Personalization; Products: 1. Odin Leather Goods Luggage Marker 3-Pack – Sale price $24.00; 2. Odin Leather Goods Leather & Steel Valet Tray (Personalization Available) – Sale price From $75.00; 3. Odin Leather Goods Turnkey Custom Leather Drink Coasters – Wholesale – Sale price From $450.00; Made in Texas; Family Owned; Premium leather goods including bags, wallets, belts, and acc…

5. Northwind Supply – Personalized Leather Gifts

Domain: northwindsupply.com

Registered: 2016 (9 years)

Introduction: Personalized Leather Gifts and Accessories. USA Made. Fast Shipping. Over 30,000+ Positive Reviews. Products include: Molded Leather Valet Tray, Leather Plant Hanger, Bottle Opener, Square Felt Coasters Set, Travel Leather Passport Cover, Leather AirTag Case, Leather Luggage Tag, Luxury Dopp Kit, Custom Patches, Folded Card Case, Folded Catchall Tray, Sustainable Felt Mousepad. Key products with p…

6. Leathersmith Designs – Custom Leather Products

Domain: leathersmithdesigns.com

Registered: 2000 (25 years)

Introduction: Custom Leather Products & Leather Craft Supplies including:

– Belt Pouches

– Belts (Personalized, Money, Design, Plain, Studded)

– Cellular Cases (Rugged, Soft Leather Smartphone, iPhone Cases)

– Change Purses & Wallets

– Dog Collars (Personalized, Plain, Studded)

– Dog Leashes (Personalized, Plain, Braided, Specialty, Studded)

– Guitar Straps (Classic Series, Inlay Series, Wide Bass, Etched Serie…

Strategic Sourcing Conclusion and Outlook for leather customized

In today’s competitive market, strategic sourcing of customized leather products offers significant advantages for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. By prioritizing partnerships with reputable suppliers who emphasize quality craftsmanship and personalization options, businesses can enhance their product offerings and create unique, brand-aligned experiences for their customers.

The demand for personalized leather goods is growing, driven by consumer preferences for individuality and exclusivity. This trend presents an opportunity for international buyers to invest in high-quality, customizable products that resonate with their target markets. Key takeaways include the importance of understanding market trends, selecting reliable suppliers, and leveraging customization capabilities to differentiate your offerings.

As you look to the future, consider how strategic sourcing in the leather industry can elevate your brand. Engage with suppliers who share your vision for quality and customization, and explore innovative personalization techniques that can set your products apart. By doing so, you will not only meet the evolving demands of consumers but also position your business for sustainable growth in the global marketplace. Embrace this opportunity to refine your sourcing strategy and lead in the dynamic world of customized leather products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.