Introduction: Navigating the Global Market for fire retardant furniture

In today’s global marketplace, sourcing fire retardant furniture poses a significant challenge for B2B buyers aiming to ensure safety and compliance in various environments, from hotels in Brazil to offices in Germany. As fire safety regulations evolve and consumer awareness grows, the demand for furniture that balances safety with aesthetic appeal has never been higher. This comprehensive guide delves into the diverse types of fire retardant furniture available, their applications across different sectors, and the critical importance of selecting reliable suppliers.

From understanding the nuances of flammability standards to evaluating costs and performance, this guide equips international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe—with the insights needed to make informed purchasing decisions. You’ll gain clarity on how to vet suppliers effectively, assess product certifications, and navigate regional regulations that affect fire safety standards.

By the end of this guide, you’ll not only be equipped with knowledge about the best practices for sourcing fire retardant furniture but also empowered to protect your clients and end-users from potential hazards while enhancing the overall appeal of their spaces. Join us as we explore the essential components of fire safety in furniture, ensuring your investments meet both compliance requirements and market expectations.

Table Of Contents

- Top 1 Fire Retardant Furniture Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fire retardant furniture

- Understanding fire retardant furniture Types and Variations

- Key Industrial Applications of fire retardant furniture

- 3 Common User Pain Points for ‘fire retardant furniture’ & Their Solutions

- Strategic Material Selection Guide for fire retardant furniture

- In-depth Look: Manufacturing Processes and Quality Assurance for fire retardant furniture

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fire retardant furniture’

- Comprehensive Cost and Pricing Analysis for fire retardant furniture Sourcing

- Alternatives Analysis: Comparing fire retardant furniture With Other Solutions

- Essential Technical Properties and Trade Terminology for fire retardant furniture

- Navigating Market Dynamics and Sourcing Trends in the fire retardant furniture Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fire retardant furniture

- Strategic Sourcing Conclusion and Outlook for fire retardant furniture

- Important Disclaimer & Terms of Use

Understanding fire retardant furniture Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Upholstered Furniture | Soft fabrics with fire-resistant treatments | Hospitality, Offices, Public Spaces | Pros: Comfortable, variety of styles. Cons: May still contain harmful chemicals. |

| Metal Furniture | Non-combustible materials, typically steel or aluminum | Industrial, Commercial Settings | Pros: Durable, low maintenance. Cons: Limited design options, can be heavy. |

| Wood Furniture | Treated with fire-retardant coatings | Residential, Offices, Retail | Pros: Aesthetic appeal, natural materials. Cons: Coatings can wear off, requires maintenance. |

| Modular Furniture | Configurable pieces that can be adapted for safety | Offices, Educational Institutions | Pros: Versatile, space-efficient. Cons: May require additional investment for safety features. |

| Composite Furniture | Made from engineered wood with fire-resistant properties | Commercial, Retail Spaces | Pros: Cost-effective, good for high-traffic areas. Cons: Environmental concerns regarding materials. |

What are the characteristics of Upholstered Furniture in B2B settings?

Upholstered furniture is characterized by its soft, cushioned surfaces and diverse fabric options that can be treated for fire resistance. Commonly used in hospitality, offices, and public spaces, this type of furniture provides a comfortable seating solution while maintaining aesthetic appeal. B2B buyers should consider the fire-retardant treatments, as some may still contain harmful chemicals. When purchasing, it’s crucial to verify compliance with local safety standards to ensure the well-being of end-users.

Why choose Metal Furniture for commercial environments?

Metal furniture, typically constructed from steel or aluminum, is non-combustible and ideal for industrial and commercial settings. Its durability and low maintenance make it a preferred choice for high-traffic areas. B2B buyers should weigh the advantages of longevity against the limited design options and potential weight issues. This type of furniture is particularly suitable for environments where fire safety is a priority, ensuring compliance with regulations without sacrificing structural integrity.

How does Wood Furniture balance aesthetics and safety?

Wood furniture is often treated with fire-retardant coatings to enhance safety while providing an aesthetic appeal that is hard to replicate with other materials. It is commonly used in residential, office, and retail environments. Buyers should consider the longevity of the fire-retardant treatment, as wear and tear can diminish effectiveness over time. Additionally, sourcing sustainably harvested wood can align with corporate social responsibility goals, making it an attractive option for B2B buyers focused on environmental impact.

What are the benefits of Modular Furniture in B2B applications?

Modular furniture consists of configurable pieces that can be adapted for various uses, making it a versatile solution for offices and educational institutions. Its space-efficient design allows for easy reconfiguration, catering to changing needs. B2B buyers should consider the initial investment required for safety features, as some modular options may not come with inherent fire-retardant properties. However, the flexibility and adaptability of modular furniture can lead to long-term cost savings and improved functionality.

Why is Composite Furniture a cost-effective option for businesses?

Composite furniture, made from engineered wood and often treated with fire-resistant properties, offers a cost-effective solution for commercial and retail spaces. Its ability to withstand high-traffic usage makes it suitable for environments where durability is essential. Buyers should be aware of environmental concerns regarding the materials used in composites, as they can impact sustainability goals. However, the affordability and practicality of composite furniture can provide significant value to B2B buyers looking to maximize their budget while ensuring safety standards are met.

Key Industrial Applications of fire retardant furniture

| Industry/Sector | Specific Application of fire retardant furniture | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Fire retardant upholstered furniture in hotels | Enhances guest safety and complies with local regulations | Certification of materials and compliance with fire safety standards |

| Healthcare | Fire retardant furniture in hospitals | Reduces fire risks in sensitive environments | Durability and ease of cleaning, along with fire safety certifications |

| Education | Fire retardant classroom furniture | Protects students and staff from fire hazards | Compliance with educational institution safety regulations |

| Commercial Offices | Fire retardant seating in office spaces | Ensures employee safety and minimizes liability risks | Aesthetic appeal and ergonomic design, alongside fire safety compliance |

| Public Sector | Fire retardant furniture in government buildings | Meets stringent safety regulations and enhances public safety | Long-term durability and maintenance support options |

How is Fire Retardant Furniture Used in the Hospitality Industry?

In the hospitality sector, fire retardant upholstered furniture is crucial for hotels and restaurants. It not only enhances guest safety but also ensures compliance with local fire safety regulations. Hotels, particularly in regions prone to wildfires or urban areas with strict fire codes, must invest in compliant furnishings. Buyers should prioritize sourcing furniture with certifications that verify fire safety standards, ensuring that they provide a safe environment for guests while minimizing liability.

Why is Fire Retardant Furniture Essential in Healthcare Facilities?

In hospitals and healthcare settings, the use of fire retardant furniture is vital due to the unique challenges posed by these environments. Patients, many of whom may have limited mobility, require safe surroundings. Fire retardant materials help to mitigate risks, particularly in high-traffic areas where quick evacuation may be necessary. Buyers in this sector must consider the durability of materials, ease of cleaning, and certifications that confirm compliance with fire safety standards to ensure patient and staff safety.

What Role Does Fire Retardant Furniture Play in Educational Institutions?

Educational institutions, from primary schools to universities, benefit significantly from fire retardant classroom furniture. This furniture helps to protect students and staff from potential fire hazards, fostering a safer learning environment. Buyers need to ensure that the furniture meets educational safety regulations and is designed for durability to withstand heavy use. Compliance with fire safety standards is non-negotiable, especially in regions with stringent regulations.

How Can Commercial Offices Benefit from Fire Retardant Seating?

In commercial office spaces, integrating fire retardant seating not only ensures employee safety but also mitigates liability risks for employers. This is particularly important in high-rise buildings where fire codes are stringent. Buyers should focus on the aesthetic appeal and ergonomic design of the furniture while ensuring it meets fire safety compliance. Fire retardant furniture in offices can also contribute to a positive corporate image, showing commitment to employee welfare.

Why is Fire Retardant Furniture Important for Public Sector Facilities?

For government buildings, fire retardant furniture is essential to meet stringent safety regulations and enhance public safety. These facilities often host large groups of people, making fire safety paramount. Buyers should consider long-term durability and maintenance support when sourcing furniture, as public sector budgets are often tight. Ensuring compliance with fire safety standards can protect both the public and the integrity of government operations.

3 Common User Pain Points for ‘fire retardant furniture’ & Their Solutions

Scenario 1: Navigating Compliance with Fire Safety Regulations

The Problem: B2B buyers, especially those operating in regulated markets, often grapple with navigating complex fire safety regulations that mandate the use of fire retardant materials. This can be particularly challenging in regions like Europe and North America, where compliance standards such as California’s TB 117 or the European Union’s REACH regulations dictate stringent testing and certification processes. Failure to comply not only jeopardizes safety but can also result in legal repercussions and significant financial losses.

The Solution: To effectively source compliant fire retardant furniture, buyers should first familiarize themselves with the specific regulations relevant to their region. Engaging with suppliers who are transparent about their testing processes and certification can streamline this effort. Request detailed documentation proving compliance with local and international standards. Additionally, establishing a robust communication channel with manufacturers can ensure any updates or changes in regulations are promptly addressed. Consider investing in third-party certification services to validate the fire safety claims of the furniture, which can enhance credibility with clients and stakeholders.

Illustrative image related to fire retardant furniture

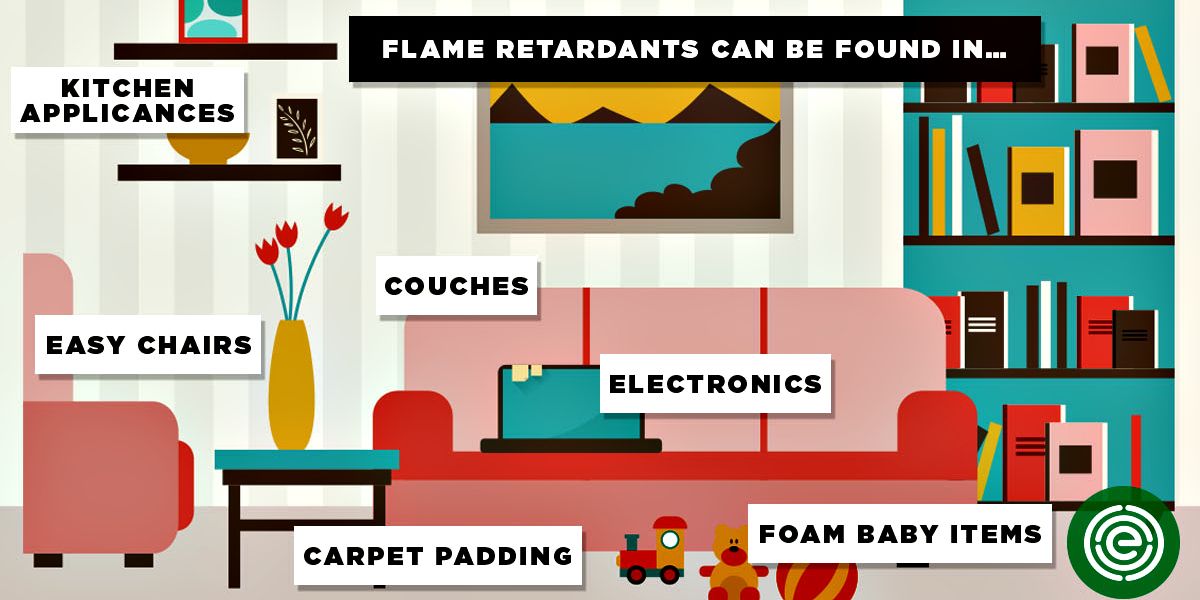

Scenario 2: Health Concerns Over Flame Retardant Chemicals

The Problem: Many B2B buyers face growing concerns regarding the health implications of traditional flame retardant chemicals used in furniture. Studies have linked these chemicals to adverse health effects, including hormone disruption and developmental issues in children. As health and environmental awareness increases, buyers must contend with the backlash from consumers and employees who demand safer, more sustainable products. This concern is particularly pronounced in industries like hospitality and education, where the health of occupants is paramount.

The Solution: To address these health concerns, buyers should prioritize sourcing flame retardant furniture that utilizes non-toxic, eco-friendly alternatives. Opt for products certified as free from harmful chemicals, such as those adhering to the GREENGUARD or OEKO-TEX standards. Communicating the benefits of these safer options to stakeholders can aid in gaining internal support for purchasing decisions. Additionally, providing training for staff on the importance of choosing safer materials can foster a culture of health consciousness within the organization. Partnering with manufacturers who are committed to sustainability can also enhance brand reputation and appeal to environmentally conscious consumers.

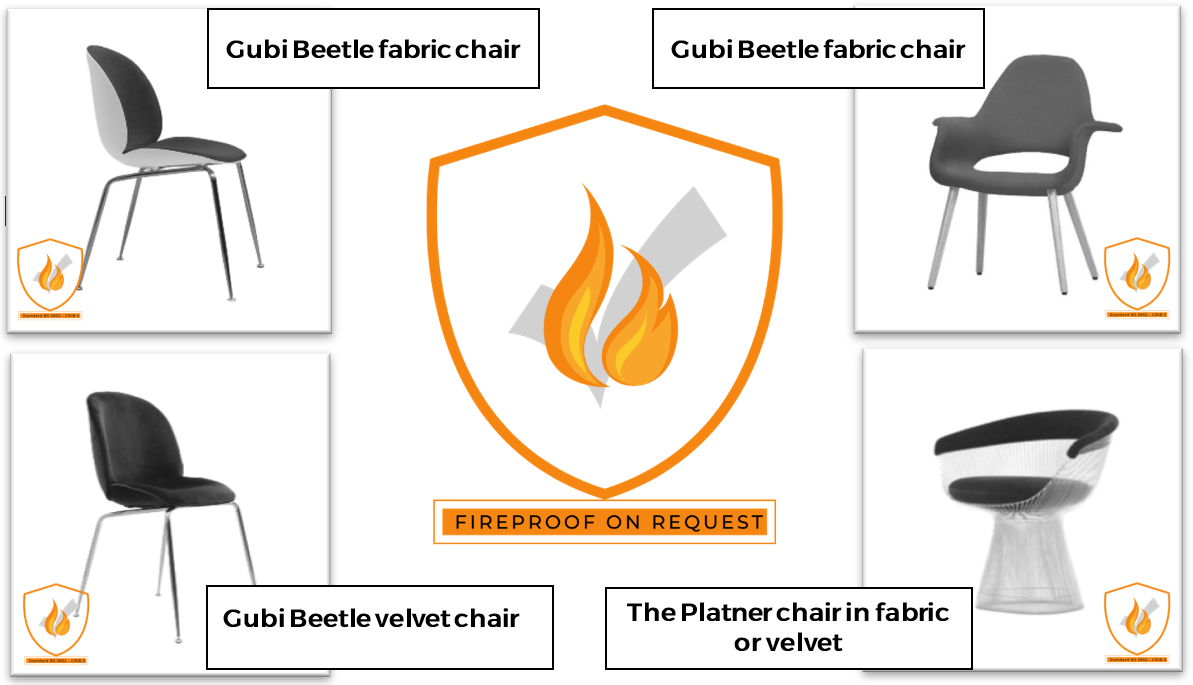

Scenario 3: Balancing Aesthetic Appeal with Fire Safety

The Problem: B2B buyers often find themselves at a crossroads when trying to balance the aesthetic appeal of furniture with the necessary fire safety standards. This is particularly evident in sectors such as interior design and hospitality, where the visual impact of furniture is crucial. Buyers may worry that prioritizing fire retardancy could compromise the design quality and overall ambiance of their spaces, leading to a dilemma that can hinder purchasing decisions.

The Solution: To strike a balance between aesthetics and fire safety, buyers should engage with suppliers who specialize in customizable fire retardant furniture. Many manufacturers now offer a range of stylish options that meet safety standards without sacrificing design. Buyers can request samples or prototypes to evaluate the look and feel before making bulk purchases. Collaborating with designers who are well-versed in fire safety can also ensure that the final selections not only comply with regulations but also enhance the desired aesthetic. Furthermore, utilizing innovative materials such as inherently flame-retardant fabrics can provide a solution that meets both safety and style requirements.

Strategic Material Selection Guide for fire retardant furniture

When selecting materials for fire retardant furniture, it’s essential to consider various factors such as performance properties, cost, and compliance with international standards. Below, we analyze four common materials used in fire retardant furniture, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Polyurethane Foam in Fire Retardant Furniture?

Polyurethane foam is a widely used material in the furniture industry due to its excellent cushioning properties. It can withstand temperatures up to 200°C (392°F) and offers good pressure resistance. However, its fire retardant versions often contain chemical additives that may pose health risks.

Pros: Polyurethane foam is lightweight, cost-effective, and provides excellent comfort and support. It can be molded into various shapes, making it suitable for diverse furniture designs.

Illustrative image related to fire retardant furniture

Cons: The main drawback is its susceptibility to degradation over time, especially when exposed to moisture. Additionally, the fire retardant chemicals used may not be compliant with environmental regulations in certain regions.

Impact on Application: Polyurethane foam is suitable for residential and commercial applications, but buyers must ensure compliance with local regulations regarding chemical content.

How Does Polyester Fabric Perform as a Fire Retardant Material?

Polyester fabric is another common choice for upholstery in fire retardant furniture. It has a melting point around 250°C (482°F) and offers good resistance to abrasion and fading.

Pros: Polyester is durable, easy to clean, and resistant to wrinkling, making it a practical choice for high-traffic areas. Its affordability also makes it attractive for budget-conscious buyers.

Illustrative image related to fire retardant furniture

Cons: While inherently flame-resistant, polyester may require additional chemical treatments to meet specific fire safety standards, which can increase costs and complicate manufacturing.

Impact on Application: Polyester is suitable for both indoor and outdoor furniture, but international buyers should verify compliance with local flammability standards, such as ASTM or DIN.

What Are the Advantages of Using Metal Frames in Fire Retardant Furniture?

Metal frames, typically made from steel or aluminum, provide structural integrity and fire resistance. They can withstand high temperatures and are not prone to burning.

Pros: Metal frames are extremely durable, resistant to pests, and have a long lifespan. They also require minimal maintenance, making them a cost-effective choice over time.

Cons: The initial cost of metal frames can be higher than wood or plastic alternatives. Additionally, they can add significant weight to furniture, impacting shipping and handling.

Impact on Application: Metal frames are ideal for commercial settings where durability is paramount. Buyers should consider the weight and shipping costs when sourcing internationally.

How Do Natural Fibers Like Wool Contribute to Fire Retardant Furniture?

Wool is a natural fiber known for its fire-resistant properties. It has a high ignition temperature (around 570°C or 1,058°F) and does not melt, making it a safe choice for upholstery.

Pros: Wool is sustainable, biodegradable, and offers excellent insulation properties. It is also naturally resistant to moisture and dirt, making it suitable for various applications.

Illustrative image related to fire retardant furniture

Cons: The primary limitation is its higher cost compared to synthetic fibers. Additionally, wool may require special care to maintain its appearance and performance.

Impact on Application: Wool is particularly favored in European markets where sustainability is a priority. Buyers should ensure that the wool meets local standards for fire resistance.

| Material | Typical Use Case for fire retardant furniture | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Foam | Cushions and padding in sofas | Lightweight and cost-effective | Degrades over time; chemical concerns | Medium |

| Polyester Fabric | Upholstery for residential and commercial use | Durable and easy to clean | May require chemical treatments | Low |

| Metal Frames | Structural support for various furniture types | Extremely durable and low maintenance | Higher initial cost | High |

| Wool | Upholstery in high-end furniture | Sustainable and naturally fire-resistant | Higher cost; requires special care | High |

This strategic material selection guide provides critical insights for international B2B buyers, ensuring they make informed decisions that align with their market needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fire retardant furniture

What Are the Main Stages of Manufacturing Fire Retardant Furniture?

Manufacturing fire retardant furniture involves a series of well-defined stages, ensuring that products meet safety standards while maintaining aesthetic appeal and functionality. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Fire Retardant Furniture?

The manufacturing process begins with material preparation, where raw materials are selected based on fire safety standards. High-density foams, which are often treated with fire retardant chemicals or made from inherently fire-resistant materials, are commonly used. Additionally, textiles are chosen for their fire-resistant properties, often adhering to specific flammability standards like California’s TB 117-2013.

Illustrative image related to fire retardant furniture

During this stage, manufacturers may also conduct preliminary tests on materials to ensure they comply with international and regional safety standards. This is particularly crucial for B2B buyers in regions like Africa and South America, where regulations may vary significantly.

What Techniques Are Used in the Forming Stage?

The forming stage involves shaping the prepared materials into the desired furniture components. This can include cutting, molding, or sewing, depending on the type of furniture being produced. Techniques such as CNC machining for wood components or automated cutting for upholstery fabrics are commonly employed to ensure precision and reduce waste.

Additionally, the incorporation of flame retardant treatments during this stage is vital. Manufacturers may apply chemical treatments to foam or use specialized fabrics that have been treated to resist ignition. Understanding these techniques can help B2B buyers assess the quality and safety of the products they are considering.

How Is Fire Retardant Furniture Assembled?

Assembly is a critical phase where all components come together to create the final product. This typically involves:

- Joining Techniques: Various methods such as stapling, gluing, or using screws are employed to assemble furniture parts. The choice of technique can affect the furniture’s durability and safety.

- Quality Checks: During assembly, manufacturers often implement in-process quality control (IPQC) measures to ensure that each component meets safety standards. This can include visual inspections and functional tests, ensuring that the furniture not only looks good but also performs well under stress.

B2B buyers should inquire about the specific assembly techniques used by manufacturers, as these can impact the longevity and safety of the furniture.

Illustrative image related to fire retardant furniture

What Finishing Processes Are Commonly Used?

Finishing processes enhance the aesthetic appeal and durability of fire retardant furniture. This stage may include:

- Surface Treatments: Applying varnishes, stains, or protective coatings that are fire-resistant and enhance the furniture’s longevity.

- Textile Application: Upholstery fabrics are often treated with additional fire retardant finishes to ensure compliance with safety standards.

These finishing touches not only contribute to the visual appeal but also play a significant role in the overall safety of the furniture. B2B buyers should evaluate these processes to ensure the final products align with their brand values and safety requirements.

What Are the Key Quality Assurance Standards for Fire Retardant Furniture?

Quality assurance (QA) is paramount in the manufacturing of fire retardant furniture. Various international standards, such as ISO 9001, provide frameworks for ensuring consistent quality and safety in manufacturing processes.

Which International and Industry-Specific Standards Should Buyers Be Aware Of?

- ISO 9001: This standard focuses on quality management systems and helps ensure that manufacturers maintain high-quality processes throughout production.

- CE Marking: For furniture sold in the European market, CE marking indicates compliance with safety standards, including flammability requirements.

- API Standards: Relevant in specific regions, these standards may apply to certain materials used in fire retardant furniture.

Understanding these standards can help B2B buyers assess whether potential suppliers are committed to quality and safety in their manufacturing processes.

What QC Checkpoints Are Critical in the Manufacturing Process?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that fire retardant furniture meets the necessary safety and quality standards. Key checkpoints include:

- Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet specified safety standards before they enter production.

- In-Process Quality Control (IPQC): Continuous monitoring during the assembly phase helps identify and rectify issues in real-time, ensuring that products do not deviate from quality standards.

- Final Quality Control (FQC): A thorough inspection of the finished product before shipment, which may include flammability tests, structural integrity checks, and visual inspections for defects.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is essential to ensure the reliability of fire retardant furniture. Here are effective strategies:

Illustrative image related to fire retardant furniture

- Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control measures firsthand.

- Reports: Requesting documentation of quality control processes, including test results and compliance certifications, can provide insights into the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection agencies to evaluate production facilities and quality control practices can provide an unbiased assessment of a supplier’s capabilities.

What Nuances Should International Buyers Consider When Sourcing Fire Retardant Furniture?

When sourcing fire retardant furniture, international buyers from regions like Africa, South America, the Middle East, and Europe should be aware of several nuances:

- Regional Regulations: Different countries may have varying regulations concerning fire safety standards. Understanding these regulations is crucial for compliance.

- Cultural Preferences: Fire retardant furniture may need to meet specific aesthetic preferences or functional requirements based on regional tastes and market demand.

- Logistical Considerations: Shipping and handling practices can affect the quality of furniture upon arrival. Buyers should ensure that suppliers have robust logistics in place to protect products during transit.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing fire retardant furniture that meets safety standards and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fire retardant furniture’

To aid B2B buyers in the procurement of fire retardant furniture, this guide offers a structured checklist that emphasizes safety, compliance, and product integrity. The following steps will help you navigate the complexities of sourcing furniture that meets fire safety standards while ensuring the health and safety of users.

Step 1: Identify Your Compliance Requirements

Understanding the regulations governing fire safety in furniture is crucial. Different regions may have specific standards, such as TB 117 in California or the European Union’s EN 1021. Ensure you are familiar with these regulations, as they dictate the necessary certifications and testing your furniture must meet.

- Research Local Regulations: Investigate the legal requirements in your target market, considering factors like import regulations and safety standards.

- Consult Industry Guidelines: Reference resources from recognized safety organizations to grasp the implications of these standards on your procurement process.

Step 2: Define Your Technical Specifications

Establishing clear technical specifications will guide your selection process. Consider factors such as the materials used, the intended use of the furniture, and the level of fire resistance required.

- Material Selection: Choose materials that are inherently fire-resistant or have been treated with safe flame retardants.

- Performance Criteria: Specify performance criteria, such as how long the furniture should withstand flames, based on the intended environment (e.g., commercial vs. residential).

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your specifications and compliance needs. Request detailed company profiles, product samples, and references from other clients.

- Check for Certifications: Look for suppliers with relevant certifications from recognized testing bodies to validate their claims about fire resistance.

- Review Case Studies: Ask for examples of past projects that demonstrate the supplier’s capability in delivering compliant products.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples to conduct your own assessments. This step is vital to ensure the furniture meets your quality and safety expectations.

- Conduct Fire Safety Tests: If possible, perform fire safety tests on samples to verify their performance against your specified standards.

- Assess Durability and Comfort: Evaluate the samples for durability and comfort, ensuring they meet both safety and user experience needs.

Step 5: Verify Supplier Certifications

Confirm that your chosen suppliers hold all necessary certifications and comply with international safety standards. This step is essential for mitigating risks associated with non-compliance.

- Review Third-Party Testing Reports: Ensure that any claims about fire retardancy are backed by independent testing.

- Monitor Changes in Regulations: Stay updated on any changes in fire safety regulations that may affect supplier compliance.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate terms that protect your interests. This includes payment terms, delivery timelines, and warranty conditions.

- Include Safety Clauses: Ensure that contracts include clauses related to compliance with fire safety standards and recourse in case of non-compliance.

- Establish Clear Timelines: Set realistic timelines for delivery and installation to avoid disruptions in your operations.

Step 7: Implement a Continuous Evaluation Process

After procurement, establish a process for ongoing evaluation of your furniture’s performance and safety compliance. This is crucial for maintaining standards in your facility.

Illustrative image related to fire retardant furniture

- Conduct Regular Inspections: Schedule periodic inspections to assess the condition and safety of your furniture.

- Solicit User Feedback: Gather feedback from users to identify any issues related to comfort or safety, allowing for timely interventions.

By following this comprehensive checklist, B2B buyers can confidently source fire retardant furniture that meets both safety standards and the specific needs of their environments.

Comprehensive Cost and Pricing Analysis for fire retardant furniture Sourcing

What Are the Key Cost Components in Fire Retardant Furniture Manufacturing?

When sourcing fire retardant furniture, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Fire retardant fabrics and foams tend to be more expensive due to their specialized treatment processes. The use of sustainable or certified materials can also increase costs but may align with regulatory requirements and consumer preferences.

-

Labor: Labor costs vary by region and can be influenced by the skill level required for manufacturing fire retardant furniture. Skilled labor is often necessary for tasks such as sewing and quality control, which can raise production costs.

-

Manufacturing Overhead: This encompasses fixed costs related to running a manufacturing facility, including utilities, rent, and equipment maintenance. Efficient production processes can help mitigate these costs.

-

Tooling: Initial tooling costs for molds and machinery can be substantial, particularly for custom designs. These expenses are amortized over production runs, making larger orders more cost-effective.

-

Quality Control (QC): Given the safety implications of fire retardant furniture, rigorous QC processes are essential. This includes testing materials for compliance with safety standards, which can add to overall costs.

-

Logistics: Shipping and handling costs must be factored in, especially for international buyers. The complexity of logistics can vary depending on the distance, mode of transport, and whether the products are shipped as bulk or individually packaged.

-

Margin: Manufacturers typically apply a markup to cover their costs and ensure profitability. This margin can vary widely based on market competition and perceived product value.

How Do Price Influencers Affect Fire Retardant Furniture Sourcing?

Several factors can influence pricing in the fire retardant furniture market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit prices due to economies of scale. Buyers should negotiate MOQs to align with their purchasing capacity.

-

Specifications and Customization: Customized designs or specifications can significantly increase costs. Buyers should weigh the benefits of customization against potential price hikes.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., fire safety standards) can lead to increased costs. Buyers should assess the trade-off between cost and compliance with safety regulations.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their proven quality and service levels.

-

Incoterms: Understanding shipping terms (Incoterms) is crucial for international buyers. Different terms can affect the overall cost, including who is responsible for shipping, insurance, and tariffs.

What Tips Can Help Buyers Navigate Pricing for Fire Retardant Furniture?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigating the complexities of fire retardant furniture pricing can be challenging. Here are some actionable tips:

-

Negotiate Effectively: Don’t hesitate to negotiate pricing, especially for larger orders. Suppliers may offer discounts for bulk purchases or long-term contracts.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just upfront costs. Consider longevity, maintenance, and potential regulatory compliance costs in your purchasing decisions.

-

Understand Pricing Nuances: Be aware that prices can vary significantly based on regional market conditions. Research local competitors and market trends to gauge fair pricing.

-

Request Samples: Before making large purchases, request samples to evaluate quality. This helps ensure that the products meet your specifications and justifies the price.

-

Stay Informed About Regulations: Keep abreast of changes in fire safety regulations in your target markets, as compliance can influence pricing and sourcing decisions.

Disclaimer on Indicative Prices

Pricing in the fire retardant furniture market can fluctuate based on various factors, including market demand, material costs, and geopolitical conditions. The insights provided here are intended to guide buyers but should not be viewed as fixed prices. Always consult suppliers for the most current pricing and terms.

Illustrative image related to fire retardant furniture

Alternatives Analysis: Comparing fire retardant furniture With Other Solutions

When considering fire safety in furniture, B2B buyers have several options beyond traditional fire retardant furniture. This analysis explores viable alternatives, helping businesses make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Fire Retardant Furniture | Natural Fiber Furniture | Intumescent Coatings |

|---|---|---|---|

| Performance | Limited effectiveness in real fire scenarios; may not significantly slow down fire spread | Naturally less flammable but still requires careful use in high-risk areas | Highly effective; forms a protective layer that expands and insulates during a fire |

| Cost | Generally higher due to specialized treatments | Typically lower; natural materials can be cost-effective | Initial costs can be higher due to application and material costs |

| Ease of Implementation | Requires specific manufacturing processes; compliance with regulations needed | Easier to source and manufacture without special processes | Requires professional application; may need periodic reapplication |

| Maintenance | Requires careful handling to avoid damage; may degrade over time | Low maintenance; natural materials may need occasional cleaning or treatment | Needs periodic inspection and reapplication to ensure effectiveness |

| Best Use Case | Suitable for environments with strict fire safety regulations (e.g., public spaces) | Ideal for residential and low-risk commercial environments | Best for high-risk industries such as manufacturing or warehouses |

What Are the Pros and Cons of Natural Fiber Furniture?

Natural fiber furniture, made from materials like cotton, wool, and linen, is often considered a sustainable alternative. Pros include lower costs and reduced environmental impact, as these materials are biodegradable and generally less harmful to health. However, they may not be suitable for high-risk fire environments, as they can still ignite and spread flames quickly if not treated properly. While they are easier to source and manufacture, their inherent properties may require additional fire safety measures for compliance with certain regulations.

How Do Intumescent Coatings Work as an Alternative?

Intumescent coatings provide a robust solution for fire protection by expanding when exposed to heat, creating an insulating barrier that protects underlying materials from flames. This technology is highly effective in various applications, including industrial and commercial settings. However, the initial cost of these coatings can be higher than traditional options, and their application often requires skilled professionals. Additionally, regular inspections and reapplication are necessary to maintain their protective qualities, which can increase long-term maintenance costs.

How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate fire safety solution, B2B buyers should assess their specific needs based on the environment in which the furniture will be used. For high-risk areas, investing in intumescent coatings may provide superior protection, while natural fiber furniture could be suitable for low-risk settings or residential use. Fire retardant furniture may be necessary for compliance with stringent regulations, especially in commercial spaces. Ultimately, understanding the unique requirements of each environment, budget constraints, and long-term maintenance considerations will guide buyers toward the most effective choice for their organization.

Essential Technical Properties and Trade Terminology for fire retardant furniture

What Are the Essential Technical Properties of Fire Retardant Furniture?

When sourcing fire retardant furniture, understanding key technical properties can significantly influence purchasing decisions. Here are several critical specifications:

-

Material Grade

The material grade of upholstery and padding is crucial in determining fire resistance. Furniture typically uses specific grades of foam, fabrics, and wood that comply with fire safety standards. For instance, high-density polyurethane foam can provide better resistance to ignition compared to lower-grade materials. B2B buyers should prioritize materials that meet or exceed local flammability regulations to ensure safety and compliance. -

Flammability Standards Compliance

Compliance with recognized flammability standards, such as California’s TB 117-2013, is essential. This standard mandates that furniture withstand specific ignition sources without catching fire. Understanding these regulations helps buyers ensure that the furniture they procure meets necessary safety requirements, thus protecting end-users and reducing liability. -

Burn Rate

The burn rate measures how quickly a material ignites and how fast flames spread. Furniture with a low burn rate is preferable, as it indicates a slower ignition and flame spread. This property is particularly important in commercial settings where safety is paramount, such as hotels or public spaces. Buyers should inquire about burn rate metrics when evaluating products. -

Chemical Treatment

Many fire retardant furniture products undergo chemical treatments to enhance their fire resistance. It is essential for buyers to understand what chemicals are used, as some may have health implications or may not be compliant with evolving regulations. Sourcing furniture that uses safer, non-toxic treatments can align with sustainability goals and health-conscious consumer preferences. -

Durability and Lifecycle

The durability of fire retardant furniture is a vital consideration for B2B buyers. Products should maintain their fire-resistant properties over time, even with regular use. A longer lifecycle reduces the frequency of replacements, thus optimizing total cost of ownership. Buyers should request documentation on expected lifespan and performance metrics.

What Are Common Trade Terms Associated with Fire Retardant Furniture?

Familiarity with industry terminology can enhance communication and negotiation processes. Here are some common terms relevant to fire retardant furniture:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the furniture industry, understanding OEM relationships can help buyers identify reliable suppliers and ensure consistent quality across products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers, as it affects inventory management and budgeting. Understanding MOQ helps in planning purchases and ensuring that stock levels meet demand without over-committing resources. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price proposals from suppliers. In the context of fire retardant furniture, an RFQ can help buyers compare costs and specifications across various manufacturers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with terms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is crucial for B2B buyers to understand shipping costs and risk management throughout the supply chain. -

Sustainability Certification

This term refers to the process by which products are evaluated for their environmental impact. Certifications such as GREENGUARD indicate that the furniture meets strict chemical emissions limits, making it a safer choice for indoor environments. Buyers should prioritize sustainability certifications to align with eco-friendly initiatives and consumer preferences.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing fire retardant furniture, ensuring safety, compliance, and value for their investment.

Navigating Market Dynamics and Sourcing Trends in the fire retardant furniture Sector

What Are the Current Market Dynamics and Key Trends in Fire Retardant Furniture?

The fire retardant furniture market is shaped by several global drivers, including increasing safety regulations, consumer demand for safer products, and a growing awareness of environmental health. In regions like Europe, where stringent regulations such as the EU’s REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) are in place, manufacturers are compelled to innovate and adopt safer materials. This trend is also reflected in emerging markets across Africa and South America, where a rising middle class is prioritizing health and safety in their purchasing decisions.

Technology is playing a pivotal role in the sourcing landscape, with advancements in materials science leading to the development of flame retardant alternatives that are both effective and environmentally friendly. International B2B buyers are increasingly looking for suppliers that leverage these technologies, including bio-based flame retardants and improved manufacturing processes that minimize harmful emissions. Furthermore, the COVID-19 pandemic has accelerated digital transformation in the B2B sector, prompting suppliers to enhance their online presence and e-commerce capabilities to meet the evolving needs of international buyers.

Another significant trend is the focus on customization and flexibility in product offerings. Buyers are seeking tailored solutions that fit specific market requirements, allowing for variations in design, size, and functionality. This demand for customization presents opportunities for manufacturers to differentiate themselves in a competitive market while catering to diverse consumer preferences across various regions.

How Is Sustainability and Ethical Sourcing Shaping the Fire Retardant Furniture Market?

Sustainability is no longer just a buzzword; it is a fundamental aspect of business strategy in the fire retardant furniture sector. The environmental impact of traditional flame retardants, which have been linked to health issues, is driving a shift towards more sustainable materials. International B2B buyers are prioritizing suppliers who can demonstrate a commitment to reducing their carbon footprint and using renewable resources in their products.

Illustrative image related to fire retardant furniture

Ethical sourcing is also gaining traction, with businesses increasingly held accountable for their supply chain practices. Buyers are actively seeking manufacturers who can provide transparency regarding their sourcing of materials and adherence to fair labor practices. Certifications such as GREENGUARD and OEKO-TEX are becoming essential indicators for buyers looking to ensure that their furniture not only meets fire safety standards but also aligns with environmental and social governance (ESG) criteria.

Additionally, the adoption of green certifications and eco-friendly materials is influencing purchasing decisions. Manufacturers that utilize non-toxic flame retardants or sustainable materials, such as recycled or rapidly renewable resources, are positioned favorably in the marketplace. This trend reflects a broader consumer movement towards health-conscious and environmentally responsible products, which is increasingly impacting B2B procurement strategies.

How Has the Fire Retardant Furniture Sector Evolved Over Time?

The evolution of the fire retardant furniture sector has been significantly influenced by regulatory changes and advancements in material science. The introduction of California’s Technical Bulletin 117 in 1975 marked a pivotal moment, as it mandated the use of flame retardants in upholstered furniture to enhance fire safety. However, the harmful effects associated with many of these chemicals led to increased scrutiny and eventual reforms in flammability standards.

By 2013, California revised its regulations, allowing for safer alternatives that do not rely on toxic flame retardants. This change set a precedent that has resonated globally, prompting manufacturers across Europe, Africa, and South America to rethink their approaches to fire safety in furniture design. As awareness of health and environmental impacts grows, the industry continues to shift towards safer, more sustainable practices, shaping a new landscape for international B2B buyers seeking responsible sourcing options.

Illustrative image related to fire retardant furniture

Frequently Asked Questions (FAQs) for B2B Buyers of fire retardant furniture

-

How do I ensure the fire safety of the furniture I source?

To ensure the fire safety of the furniture you source, start by verifying compliance with relevant fire safety standards in your target market. For example, furniture sold in the European Union must meet EN 1021-1 and EN 1021-2 standards. Request documentation from suppliers that demonstrates their products have been tested and certified according to these standards. Additionally, consider sourcing from manufacturers who provide transparent information about materials used and any flame retardants, ensuring they are compliant with regulations that restrict harmful substances. -

What are the key factors to consider when selecting a supplier for fire retardant furniture?

When selecting a supplier for fire retardant furniture, consider their reputation, manufacturing capabilities, and compliance with international safety standards. Evaluate their experience in producing fire retardant furniture and their ability to provide certifications. Additionally, assess their capacity for customization to meet your specific requirements and their commitment to sustainable practices. Request samples and conduct quality assessments to ensure the products meet your expectations before finalizing any agreements. -

What customization options are available for fire retardant furniture?

Many manufacturers offer customization options for fire retardant furniture, including fabric selection, color choices, and design modifications. When discussing customization, communicate your specific needs, such as dimensions, style, and material preferences. Ensure that the supplier can accommodate your requirements while still adhering to fire safety standards. Additionally, inquire about the lead time for custom orders, as this can vary significantly between suppliers. -

What is the minimum order quantity (MOQ) for fire retardant furniture?

Minimum order quantities (MOQs) for fire retardant furniture can vary widely depending on the supplier and the type of furniture. Generally, MOQs can range from a few pieces to several dozen. When negotiating with suppliers, clarify their MOQ policies and explore options for smaller initial orders, especially if you are testing the market. Building a strong relationship with your supplier can also provide opportunities for more flexible ordering terms as your business grows. -

What payment terms should I expect when sourcing fire retardant furniture?

Payment terms for sourcing fire retardant furniture can differ based on the supplier’s policies and the nature of the transaction. Common terms include a deposit upfront (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer credit terms for repeat customers. Always clarify payment methods accepted, such as bank transfers, letters of credit, or payment platforms, and ensure that the terms are documented in your purchase agreement to avoid misunderstandings. -

How can I verify the quality of fire retardant furniture before purchasing?

To verify the quality of fire retardant furniture, request product samples to assess materials, construction, and comfort firsthand. Additionally, review the supplier’s quality assurance processes and certifications, such as ISO 9001. Conduct factory visits if possible, or hire third-party inspection services to evaluate production practices. Look for reviews or testimonials from other B2B buyers to gauge the supplier’s reliability and product performance in real-world applications. -

What logistics considerations should I keep in mind when importing fire retardant furniture?

When importing fire retardant furniture, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Confirm that your supplier can provide necessary documentation for customs clearance, including certificates of conformity to fire safety standards. Evaluate shipping costs and choose a freight forwarder experienced in handling furniture shipments to ensure safe and timely delivery. Additionally, factor in potential tariffs or import duties that may apply to your shipment. -

How can I stay updated on regulations regarding fire retardant materials in furniture?

To stay informed about regulations regarding fire retardant materials in furniture, regularly consult industry publications, government websites, and standards organizations relevant to your market. Join professional associations or networks that focus on furniture manufacturing and safety standards. Attending trade shows and conferences can also provide insights into emerging trends and regulatory changes. Engaging with your suppliers and manufacturers can help ensure that you are aware of compliance requirements and product innovations.

Top 1 Fire Retardant Furniture Manufacturers & Suppliers List

1. The Hartford – Fire-Resistant Furniture

Domain: thehartford.com

Registered: 1995 (30 years)

Introduction: Fire-resistant furniture designed to reduce fire hazards, particularly upholstered items like chairs, couches, and mattresses. Recommended standards include the Upholstered Furniture Action Council (UFAC) program and California Bureau of Home Furnishings (CAL 117 or 133). These products are made to be more resistant to ignition, although they are still combustible. Safety tips include maintaining …

Strategic Sourcing Conclusion and Outlook for fire retardant furniture

In today’s competitive market, strategic sourcing of fire retardant furniture is not just a compliance measure but a significant driver of business value. By prioritizing products that adhere to updated safety standards and avoid harmful flame retardants, businesses can enhance their brand reputation and attract health-conscious consumers. The transition from traditional flame retardants to safer alternatives reflects a growing demand for sustainable and eco-friendly solutions, particularly in regions like Africa, South America, the Middle East, and Europe.

International B2B buyers must consider the implications of regulatory changes and consumer preferences in their sourcing strategies. Engaging with manufacturers who comply with the latest safety regulations and offer transparent product information can lead to better purchasing decisions. Additionally, investing in fire retardant furniture that aligns with health and safety standards can mitigate potential liabilities and enhance customer trust.

As we look to the future, the market for fire retardant furniture is poised for growth, driven by innovation and increased awareness of environmental impacts. Now is the time for businesses to reassess their sourcing strategies, prioritize sustainable options, and position themselves as leaders in the fire safety furniture sector. Embrace this opportunity to not only meet regulatory demands but to also foster a safer environment for consumers and communities alike.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.