Introduction: Navigating the Global Market for custom leather stamping tools

In an increasingly competitive landscape, sourcing high-quality custom leather stamping tools can pose significant challenges for international B2B buyers. Whether you’re a manufacturer in Nigeria seeking to enhance your product line or a craftsman in Germany looking to elevate your craftsmanship, understanding the nuances of the market is essential. This comprehensive guide delves into the intricacies of the custom leather stamping tools market, covering a wide range of topics including types of tools available, their applications, and the critical aspects of supplier vetting.

By exploring the various features and benefits of these tools, along with actionable insights on pricing strategies and bulk purchasing options, this guide empowers you to make informed purchasing decisions. From the detailed assessment of materials used—such as premium brass and stainless steel—to the evaluation of design uniqueness, we aim to equip you with the knowledge to navigate this complex market effectively.

With a focus on international buyers from diverse regions such as Africa, South America, the Middle East, and Europe, this guide addresses the specific needs and preferences of these markets. Ultimately, our goal is to facilitate successful sourcing experiences, ensuring that you acquire the best tools to meet your business objectives and enhance your product offerings.

Table Of Contents

- Top 8 Custom Leather Stamping Tools Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather stamping tools

- Understanding custom leather stamping tools Types and Variations

- Key Industrial Applications of custom leather stamping tools

- 3 Common User Pain Points for ‘custom leather stamping tools’ & Their Solutions

- Strategic Material Selection Guide for custom leather stamping tools

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamping tools

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamping tools’

- Comprehensive Cost and Pricing Analysis for custom leather stamping tools Sourcing

- Alternatives Analysis: Comparing custom leather stamping tools With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather stamping tools

- Navigating Market Dynamics and Sourcing Trends in the custom leather stamping tools Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamping tools

- Strategic Sourcing Conclusion and Outlook for custom leather stamping tools

- Important Disclaimer & Terms of Use

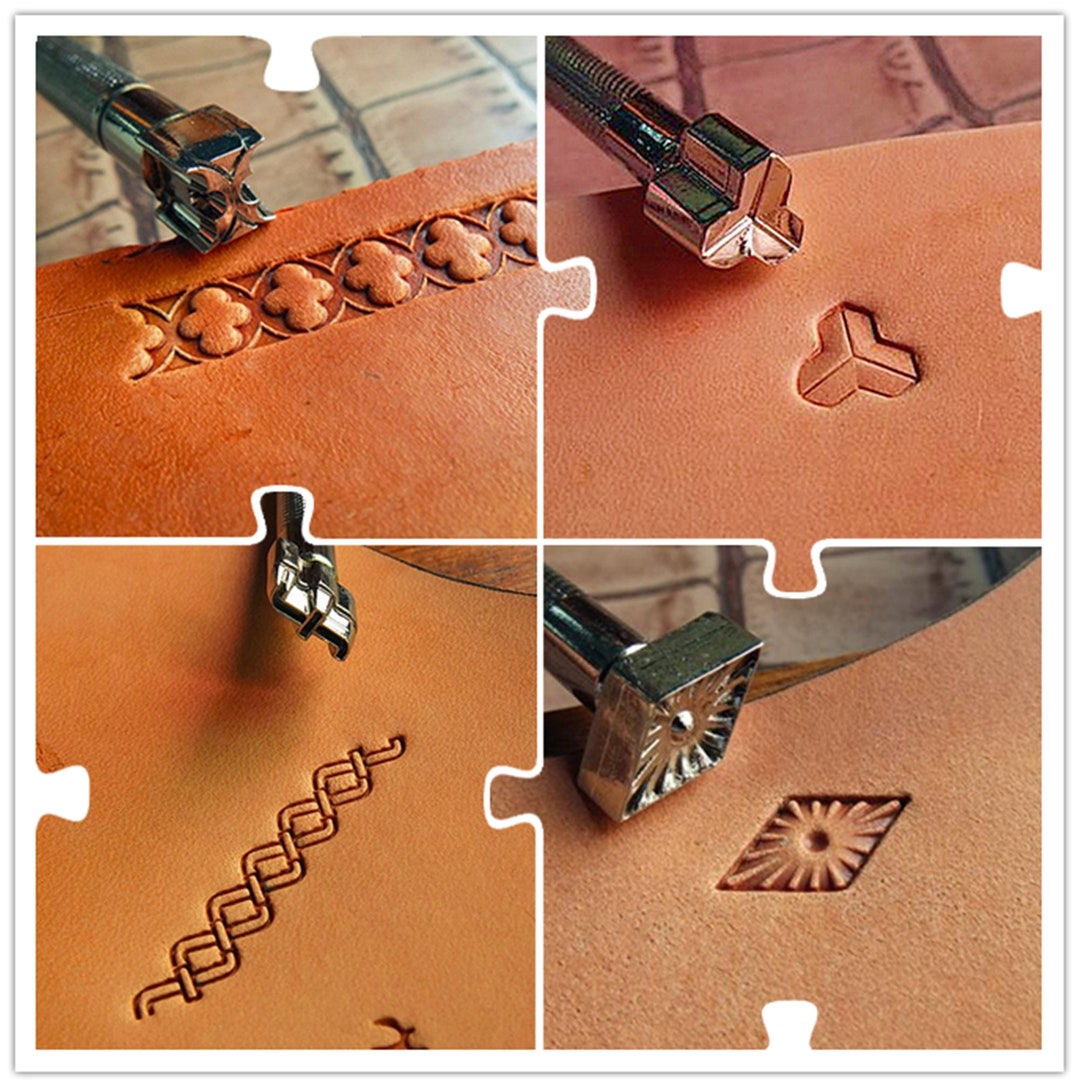

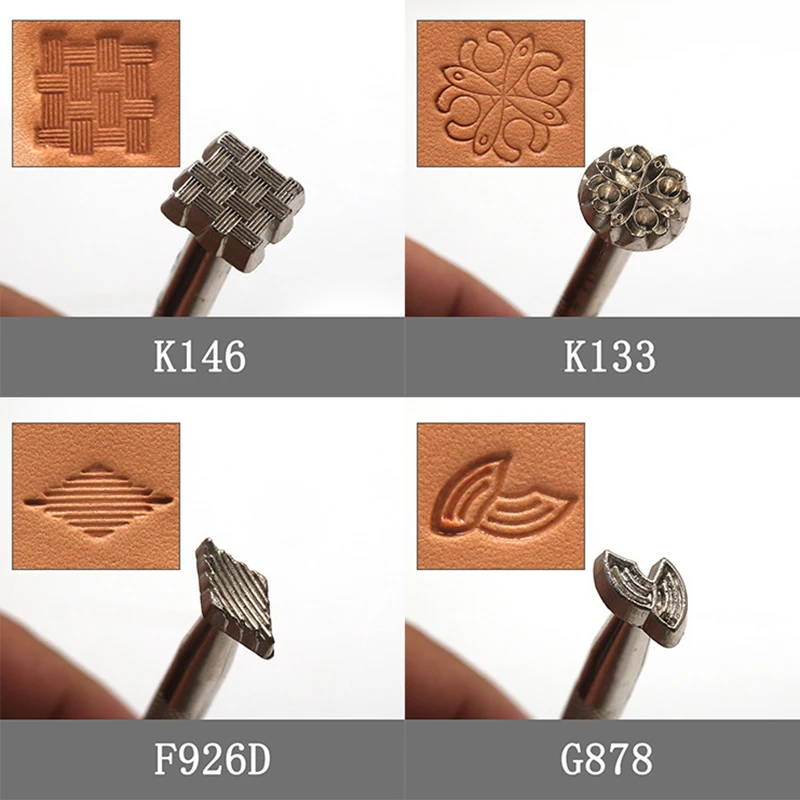

Understanding custom leather stamping tools Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alphabet Stamps | Includes A-Z and 0-9 characters; various fonts | Personalization of leather goods | Pros: Customization options; versatile use. Cons: Limited to text; may require multiple sets for different styles. |

| Decorative Stamps | Unique patterns and designs; includes geometric, floral, etc. | High-end leather products, fashion | Pros: Enhances aesthetic appeal; diverse designs. Cons: More expensive; may not suit all product types. |

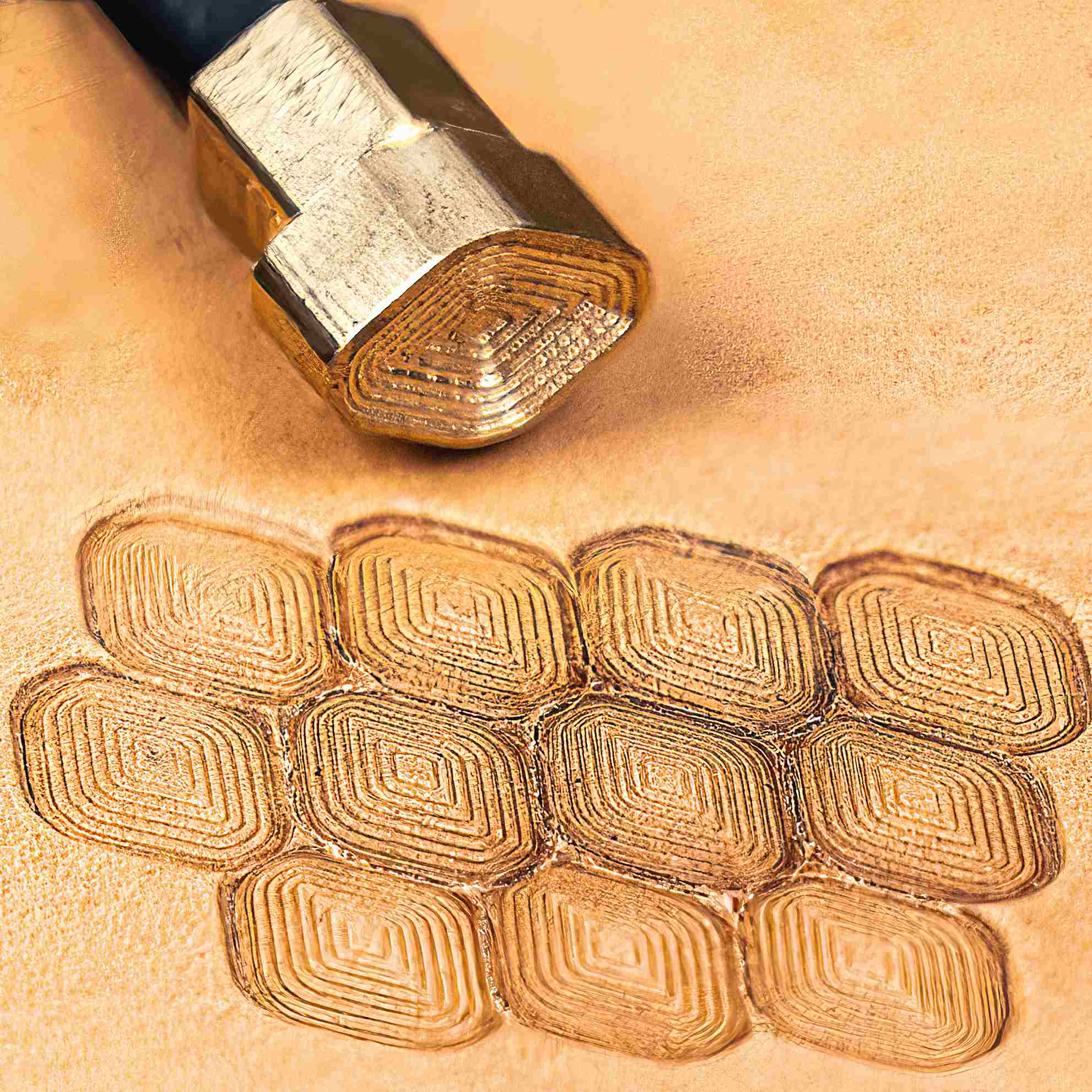

| Basket Weave Stamps | Patterns resembling basket weaves; various sizes | Crafting bags, belts, and wallets | Pros: Adds texture; popular in traditional crafts. Cons: Niche application; less versatile compared to other types. |

| Edge Cutter Stamps | Designed to create decorative edges; various shapes | Finishing leather products | Pros: Professional finish; easy to use. Cons: Limited to edge work; may need multiple sizes for different projects. |

| Custom Stamps | Tailored designs based on client specifications | Unique branding and marketing | Pros: Fully personalized; enhances brand identity. Cons: Higher cost; longer lead times for production. |

What Are Alphabet Stamps and Their Business Applications?

Alphabet stamps are essential tools for businesses seeking to personalize leather goods. These stamps feature letters and numbers in various fonts, enabling manufacturers to create unique branding or custom messages on products. They are widely used in the production of items like wallets, belts, and bags, where personalization can significantly enhance customer appeal. When considering B2B purchases, buyers should evaluate the range of fonts available and the durability of the materials used, as these factors can impact the final product quality.

How Do Decorative Stamps Enhance Leather Products?

Decorative stamps offer a variety of intricate patterns and designs, including floral and geometric motifs, which can elevate the aesthetic appeal of leather items. These tools are particularly valuable in the high-end fashion sector, where unique designs can set products apart in a competitive market. Buyers should consider the cost-effectiveness of these stamps, as they can be more expensive than standard options, but the potential for increased sales through enhanced product appeal can justify the investment.

Illustrative image related to custom leather stamping tools

What Are the Benefits of Using Basket Weave Stamps?

Basket weave stamps create textured patterns that are particularly popular in traditional leather crafting. They are often used in the production of bags, belts, and wallets, providing a tactile element that enhances the product’s overall appeal. For B2B buyers, the suitability of these stamps depends on their target market’s preferences and the types of products they manufacture. While basket weave stamps add a unique touch, they may not be suitable for all leather goods, limiting their versatility.

Why Choose Edge Cutter Stamps for Finishing Touches?

Edge cutter stamps are designed specifically for creating decorative edges on leather products, making them invaluable for businesses focused on high-quality finishing. These tools can provide a professional look to items like bags and belts, enhancing their marketability. Buyers should assess the variety of shapes and sizes available to ensure they can meet diverse product requirements. While edge cutter stamps are easy to use, their functionality is limited to edge work, which could necessitate additional tools for comprehensive leather crafting.

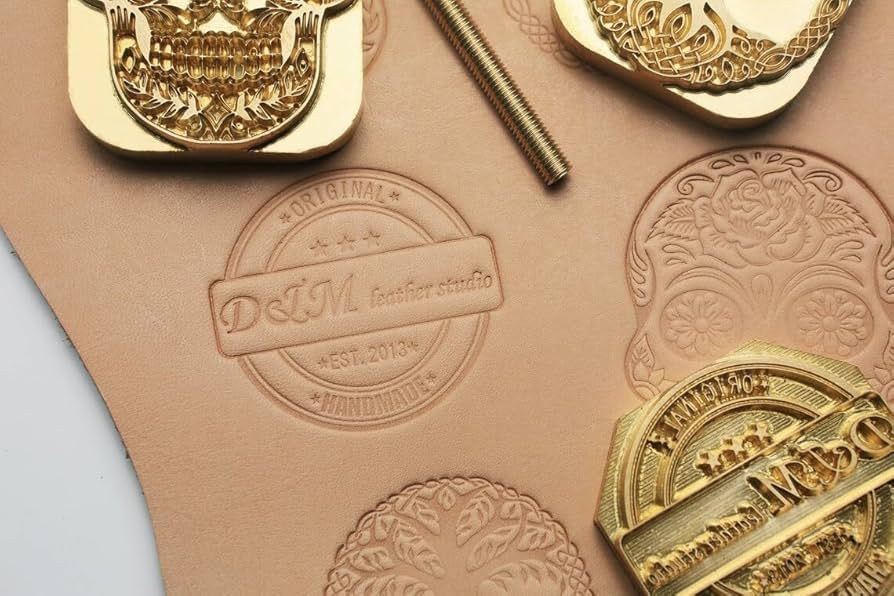

How Do Custom Stamps Contribute to Brand Identity?

Custom stamps offer businesses the opportunity to create unique designs tailored to their specific branding needs. This personalization is crucial for companies looking to stand out in a crowded marketplace. Custom stamps can be used for logos, special messages, or unique designs, making them a powerful tool for brand recognition. However, buyers should be prepared for higher costs and longer lead times associated with custom orders. Investing in these stamps can significantly enhance a brand’s identity and customer loyalty when executed effectively.

Illustrative image related to custom leather stamping tools

Key Industrial Applications of custom leather stamping tools

| Industry/Sector | Specific Application of custom leather stamping tools | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom branding on leather goods such as bags and shoes | Enhances brand identity and product differentiation | Quality of materials, design customization options, and production lead times |

| Automotive | Stamping leather interiors for vehicles | Adds luxury and personalization to vehicles | Durability of stamps, compatibility with various leather types, and precision in detail |

| Furniture and Home Décor | Decorative stamping on leather upholstery | Increases aesthetic appeal and market value | Availability of unique designs, production scalability, and cost-effectiveness |

| Craft and Hobby Supplies | Custom stamps for DIY leather projects | Empowers creativity and personalization for consumers | Range of stamp designs, ease of use, and affordability for bulk purchases |

| Leather Goods Manufacturing | Mass production of stamped leather products | Streamlines production and reduces labor costs | Consistency in quality, lead time for bulk orders, and after-sales support |

How Are Custom Leather Stamping Tools Used in the Fashion and Apparel Industry?

In the fashion sector, custom leather stamping tools are essential for branding and personalization. They allow businesses to imprint logos or unique designs on leather goods such as handbags and shoes, enhancing brand identity. This application helps solve the problem of product differentiation in a competitive market. Buyers in this sector should focus on sourcing high-quality materials that ensure clear and lasting impressions, as well as customization options that align with their brand aesthetics.

What Role Do Custom Leather Stamping Tools Play in the Automotive Industry?

In the automotive industry, custom leather stamping tools are utilized to create luxurious interiors. This includes stamping leather seats and trims with intricate designs or branding, which not only elevates the vehicle’s aesthetic but also enhances its market value. International buyers should consider the durability of the stamping tools and their compatibility with various leather types to ensure that the final product meets high-quality standards and customer expectations.

How Are Custom Leather Stamping Tools Beneficial for Furniture and Home Décor?

Custom leather stamping tools are employed in the furniture and home décor industry to add decorative elements to leather upholstery. This application increases the aesthetic appeal of products, making them more attractive to consumers and allowing manufacturers to command higher prices. For buyers, it is crucial to evaluate the availability of unique designs and the scalability of production to meet market demand while ensuring cost-effectiveness.

In What Ways Do Custom Leather Stamping Tools Enhance Craft and Hobby Supplies?

For craft and hobby enthusiasts, custom leather stamping tools enable the creation of personalized leather projects. These tools allow users to easily imprint designs, enhancing creativity and individuality in their crafts. Buyers in this sector should look for a variety of stamp designs and affordability, especially when purchasing in bulk, to ensure they can offer a wide range of products to their customers.

Illustrative image related to custom leather stamping tools

How Do Custom Leather Stamping Tools Streamline Production in Leather Goods Manufacturing?

In leather goods manufacturing, custom leather stamping tools are vital for mass production processes. They facilitate the efficient stamping of designs across numerous products, significantly reducing labor costs and production times. When sourcing for this application, businesses should prioritize consistency in quality, the lead time for bulk orders, and reliable after-sales support to maintain production efficiency and product quality.

3 Common User Pain Points for ‘custom leather stamping tools’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Impressions with Custom Stamps

The Problem: One of the primary challenges faced by B2B buyers of custom leather stamping tools is achieving consistent quality in the impressions made on leather. When working with large batches of products, inconsistencies can lead to damaged materials and wasted resources, affecting overall production efficiency. Buyers often struggle with tools that do not provide clear, even impressions, leading to dissatisfaction from end customers and potentially harming brand reputation.

The Solution: To ensure consistent impressions, it is crucial to invest in high-quality, precision-engineered stamping tools made from durable materials such as brass or stainless steel. B2B buyers should prioritize suppliers who offer comprehensive specifications and detailed product descriptions. Additionally, implementing a standardized stamping technique across the production team can help maintain uniformity. For instance, training staff on the correct amount of pressure to apply and ensuring that the leather is properly prepared before stamping can significantly improve results. Buyers may also consider using stamping templates or guides to assist in positioning the tools accurately, further enhancing consistency in output.

Scenario 2: Challenges in Sourcing High-Quality Custom Stamping Tools

The Problem: Many B2B buyers, especially from regions with less access to specialized tools, face difficulties in sourcing high-quality custom leather stamping tools. They may encounter subpar products that do not meet their specifications, leading to frustration and financial losses. Poor-quality tools not only result in inferior product quality but also increase maintenance costs and downtime, as they may require frequent replacements.

Illustrative image related to custom leather stamping tools

The Solution: Buyers should conduct thorough research before committing to a supplier. This includes checking reviews, requesting samples, and verifying the supplier’s credentials and experience in the leather stamping industry. Engaging with industry forums and trade shows can also provide valuable insights and recommendations from other businesses. Furthermore, establishing direct communication with suppliers to discuss specific needs and quality expectations can result in more tailored solutions. B2B buyers should look for suppliers that provide warranties and clear return policies, ensuring that they can replace or return tools that do not meet their standards.

Scenario 3: Limited Design Options for Custom Stamping Tools

The Problem: B2B buyers often find themselves limited by the design options available for custom leather stamping tools. A lack of variety can stifle creativity and hinder the ability to produce unique, differentiated products that stand out in the market. This is particularly challenging for businesses looking to cater to niche markets or those that require bespoke designs to meet specific customer preferences.

The Solution: To overcome this limitation, buyers should seek suppliers who offer a wide range of customizable options, including various designs, sizes, and shapes. It’s beneficial to partner with manufacturers that allow for bespoke design services, enabling businesses to create unique stamps tailored to their branding or product line. Furthermore, buyers should explore collaborative design opportunities with their suppliers, allowing them to input ideas and feedback during the development of new tools. By fostering these partnerships, businesses can expand their creative capabilities and ensure that their stamping tools align with their branding strategy. Additionally, leveraging digital design tools can facilitate the visualization of custom designs before production, ensuring that the final product meets expectations.

Strategic Material Selection Guide for custom leather stamping tools

What Are the Key Materials for Custom Leather Stamping Tools?

When selecting materials for custom leather stamping tools, it is crucial to consider their properties, advantages, and limitations. This analysis focuses on four common materials: brass, stainless steel, carbon steel, and aluminum. Each material offers unique characteristics that can significantly impact the performance and suitability of the tools in various applications.

How Does Brass Perform in Leather Stamping Tools?

Brass is a popular choice for leather stamping due to its excellent machinability and resistance to corrosion. It can withstand moderate temperatures and pressures, making it suitable for most stamping applications. Brass tools provide clear and crisp impressions on leather, enhancing the aesthetic appeal of the final product.

Pros: Brass is durable and offers a good balance between cost and performance. It is relatively easy to manufacture and can be polished to achieve a high-quality finish.

Cons: While brass is resistant to corrosion, it can tarnish over time, requiring maintenance to preserve its appearance. Additionally, brass tools may not be suitable for high-temperature applications.

Impact on Application: Brass tools are compatible with various leather types, including vegetable-tanned and chrome-tanned leather. However, buyers should ensure that the brass used meets international standards for quality and safety.

What Are the Benefits of Stainless Steel for Leather Stamping Tools?

Stainless steel is renowned for its exceptional durability and resistance to corrosion, making it an ideal material for leather stamping tools that require longevity. It can withstand high temperatures and pressures, ensuring consistent performance over time.

Pros: Stainless steel tools are less likely to rust or corrode, which is particularly beneficial for humid environments. They also provide a clean and precise impression, enhancing the quality of the stamped leather.

Cons: The primary drawback of stainless steel is its higher cost compared to other materials. Additionally, manufacturing stainless steel tools can be more complex and time-consuming.

Impact on Application: Stainless steel is compatible with a wide range of leather types and is often preferred for high-end leather goods. International buyers should verify that the stainless steel used complies with relevant standards such as ASTM or DIN.

Why Choose Carbon Steel for Custom Leather Stamping Tools?

Carbon steel is another viable option for leather stamping tools, offering a good balance between strength and cost. It has excellent hardness and wear resistance, making it suitable for heavy-duty applications.

Pros: Carbon steel tools can produce sharp impressions and are often less expensive than brass or stainless steel. They are also relatively easy to sharpen and maintain.

Cons: One of the main disadvantages of carbon steel is its susceptibility to rust and corrosion, especially in humid environments. Regular maintenance, such as oiling, is necessary to prolong its lifespan.

Impact on Application: Carbon steel tools are effective for stamping various leather types but may not be suitable for environments with high moisture levels. Buyers should consider protective coatings to enhance durability.

How Does Aluminum Compare in Leather Stamping Tools?

Aluminum is a lightweight and cost-effective material that can be used for leather stamping tools. While it may not be as durable as brass or stainless steel, it offers unique advantages in specific applications.

Illustrative image related to custom leather stamping tools

Pros: Aluminum is easy to machine and can be produced in various shapes and sizes. Its lightweight nature makes it easier to handle during the stamping process.

Cons: The primary limitation of aluminum is its lower strength and wear resistance compared to other metals. It may not provide the same level of impression quality as heavier materials.

Impact on Application: Aluminum tools are best suited for lighter stamping tasks or for use in educational settings. International buyers should ensure that the aluminum used meets industry standards for quality and safety.

Summary of Material Selection for Custom Leather Stamping Tools

| Material | Typical Use Case for custom leather stamping tools | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General leather stamping | Good machinability and corrosion resistance | Can tarnish over time | Medium |

| Stainless Steel | High-end leather goods | Exceptional durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Heavy-duty stamping applications | Sharp impressions and cost-effective | Susceptible to rust and corrosion | Low |

| Aluminum | Lightweight stamping tasks | Lightweight and easy to machine | Lower strength and wear resistance | Low |

This guide provides a comprehensive overview of the materials used in custom leather stamping tools, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamping tools

What Are the Main Stages of Manufacturing Custom Leather Stamping Tools?

Manufacturing custom leather stamping tools involves several critical stages, each designed to ensure the tools meet high-quality standards while being tailored to specific customer needs. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to custom leather stamping tools

Material Preparation: Sourcing and Selection

The manufacturing process begins with selecting high-quality materials, primarily brass and stainless steel, known for their durability and resistance to wear. Suppliers often source materials that meet international standards to ensure consistency and performance. This stage may also involve inspecting materials for defects or impurities, which can significantly affect the final product’s quality.

Forming: Techniques for Crafting Precision Tools

Once the materials are prepared, the next stage is forming. This involves various techniques such as machining, stamping, and forging. Computer Numerical Control (CNC) machining is particularly favored for its precision, allowing for intricate designs and consistent results. Forming techniques ensure that each stamping tool is shaped according to the desired specifications, allowing for clear and accurate impressions on leather surfaces.

Assembly: Bringing Components Together

After forming, the components of the stamping tools are assembled. This stage may involve attaching handles to the stamped heads, ensuring that they are securely fastened for optimal use. Quality checks during assembly are crucial, as any misalignment can lead to poor performance. Automated systems may be employed to streamline this process, reducing the risk of human error.

Finishing: Quality and Aesthetic Enhancements

The finishing stage is where the tools are polished and coated, if necessary, to enhance their durability and appearance. This may involve surface treatments to prevent rust and improve the visual appeal of the tools. Quality assurance checks are also essential at this stage to ensure that each tool meets the required aesthetic and functional standards.

Illustrative image related to custom leather stamping tools

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a vital aspect of the manufacturing process for custom leather stamping tools. Implementing effective QA measures ensures that the final products not only meet but exceed customer expectations.

What International Standards Should B2B Buyers Consider?

Many manufacturers adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards indicates that a manufacturer has established quality processes and is committed to continuous improvement. Additionally, industry-specific certifications, such as CE marking for products sold in Europe, can further assure buyers of compliance with safety and performance standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring production processes to identify and rectify any deviations from quality standards.

- Final Quality Control (FQC): Conducting thorough inspections of finished products before they are packaged and shipped.

These checkpoints help identify issues at various stages, allowing manufacturers to take corrective actions promptly.

What Testing Methods Are Commonly Used in Quality Assurance?

Testing methods vary but typically include:

- Dimensional Inspection: Ensuring that the tools meet specified dimensions and tolerances.

- Functional Testing: Verifying that the stamping tools perform as intended, producing clear impressions on leather.

- Durability Testing: Subjecting tools to stress tests to assess their longevity and resistance to wear.

Manufacturers may also employ third-party testing services to validate their quality assurance processes, adding an extra layer of credibility.

Illustrative image related to custom leather stamping tools

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial. Here are several strategies:

- Supplier Audits: Conducting audits of manufacturing facilities to assess their adherence to quality standards and practices.

- Quality Reports: Requesting detailed quality assurance reports that outline testing methods, results, and compliance with standards.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate products before shipment. This can help mitigate risks associated with quality discrepancies.

What Are the Quality Assurance Nuances for International B2B Buyers?

International buyers should be aware of specific nuances in quality assurance that may differ by region. For example, certain countries may have unique regulatory requirements that impact product specifications. Buyers should familiarize themselves with local standards and ensure that suppliers are compliant. Additionally, language barriers can pose challenges in communication regarding quality standards, so establishing clear channels for dialogue is essential.

Conclusion: Ensuring Quality in Custom Leather Stamping Tools

In conclusion, the manufacturing processes and quality assurance measures for custom leather stamping tools are multifaceted and essential for delivering high-quality products. By understanding these processes, international B2B buyers can make informed decisions, ensuring that they partner with reliable suppliers who prioritize quality and adherence to standards. As the demand for custom leather tools continues to grow across various markets, maintaining a focus on manufacturing excellence and rigorous quality control will be vital for success in this industry.

Illustrative image related to custom leather stamping tools

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamping tools’

Introduction

Sourcing custom leather stamping tools can significantly enhance your production capabilities and product offerings. This guide provides a step-by-step checklist to ensure you select the right tools and suppliers, minimizing risks and maximizing quality in your leather crafting operations.

Step 1: Define Your Technical Specifications

Before initiating your search, clarify what types of leather stamping tools you need. Consider factors such as the design patterns, sizes, and materials required for your projects. This step is crucial as it helps narrow down suppliers who can meet your specific needs.

- Design Patterns: Determine if you need alphabet stamps, geometric patterns, or custom designs.

- Material Preferences: Decide between brass, stainless steel, or other materials based on durability and imprint quality.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in leather stamping tools. Utilize industry directories, trade shows, and online platforms to gather a list of candidates.

- Online Reviews: Look for reviews and testimonials from previous clients to gauge reliability.

- Industry Reputation: Prioritize suppliers known for their craftsmanship and customer service.

Step 3: Evaluate Supplier Certifications and Quality Standards

Verification of supplier certifications is critical to ensuring product quality and compliance with international standards. Check for ISO certifications or other relevant quality assurance processes.

- Quality Control Processes: Inquire about their manufacturing processes and quality checks.

- Material Certifications: Ensure that the materials used are certified for safety and durability, especially if your products are intended for consumer use.

Step 4: Request Samples

Before making a bulk purchase, request samples of the stamping tools. This step allows you to assess the quality, design clarity, and overall functionality of the tools.

- Test Imprints: Use the samples on various leather types to evaluate how well they perform.

- Design Accuracy: Check if the imprints match your design specifications and expectations.

Step 5: Compare Pricing and Payment Terms

Once you have shortlisted suppliers, compare their pricing structures and payment terms. Look beyond just the initial cost; consider long-term value and service.

- Volume Discounts: Inquire about bulk purchase discounts or loyalty programs that could reduce costs.

- Payment Flexibility: Evaluate payment options that suit your cash flow, including deposits and credit terms.

Step 6: Assess Shipping and Delivery Options

Understanding the logistics involved is vital for timely production. Discuss shipping methods, costs, and delivery timelines with potential suppliers.

- Shipping Costs: Factor in how shipping will impact your overall budget.

- Delivery Times: Confirm lead times to ensure they align with your production schedules.

Step 7: Establish a Long-Term Relationship

After selecting a supplier, focus on building a strong relationship for future collaboration. Regular communication and feedback can enhance your partnership and ensure continuous improvement.

- Feedback Mechanism: Create a system for providing feedback on product performance and service.

- Future Orders: Discuss potential future needs and how the supplier can accommodate them.

By following this checklist, you can effectively navigate the sourcing process for custom leather stamping tools, ensuring you make informed decisions that align with your business goals.

Illustrative image related to custom leather stamping tools

Comprehensive Cost and Pricing Analysis for custom leather stamping tools Sourcing

What Are the Key Cost Components in Sourcing Custom Leather Stamping Tools?

Understanding the cost structure for custom leather stamping tools is essential for B2B buyers looking to make informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly influences pricing. High-quality brass and stainless steel are common in durable stamping tools, which can cost more than lower-grade alternatives. Buyers should consider whether the material used aligns with their quality requirements.

-

Labor: Skilled labor is necessary for the precision crafting of leather stamping tools. Labor costs vary by region and can be influenced by local wage standards, expertise levels, and the complexity of the design.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, rent, and equipment maintenance. A well-established manufacturer may have lower overhead costs due to optimized processes, which could lead to more competitive pricing.

-

Tooling: Custom designs often require specific tooling, which can add to initial costs. However, these costs may be amortized over large production runs, making bulk orders more cost-effective in the long term.

-

Quality Control (QC): Ensuring that each tool meets quality standards incurs costs. Rigorous QC processes may increase the price but provide assurance of product reliability, which is particularly crucial for B2B buyers in competitive markets.

-

Logistics: Shipping costs can vary widely depending on the destination, order size, and chosen shipping method. Buyers should factor in freight charges, duties, and potential delays when budgeting.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions and supplier reputation. Understanding this aspect can aid in negotiation.

How Do Price Influencers Affect the Cost of Custom Leather Stamping Tools?

Several factors can influence the pricing of custom leather stamping tools, making it crucial for buyers to analyze these elements before making a purchase.

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer price breaks for larger orders. Understanding the MOQ can help buyers optimize their purchasing strategy to achieve better pricing.

-

Specifications and Customization: Customization options, such as unique designs or specialized sizes, can increase costs. Buyers should weigh the benefits of customization against the additional expense.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO standards) can enhance durability and performance but also raise the price. Buyers need to assess whether these features justify the additional costs.

-

Supplier Factors: Reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge more but can offer peace of mind regarding the quality of tools.

-

Incoterms: The chosen Incoterms can affect logistics costs and responsibilities. Understanding the implications of terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can help buyers avoid unexpected charges.

What Are Effective Buyer Tips for Negotiating Custom Leather Stamping Tool Prices?

When sourcing custom leather stamping tools, particularly for international B2B transactions, consider the following tips to enhance cost-efficiency:

-

Negotiate Terms: Leverage volume purchasing to negotiate better pricing, flexible payment terms, or additional services such as free shipping.

-

Total Cost of Ownership (TCO): Look beyond the initial price. Consider the TCO, which includes maintenance, durability, and potential reordering costs over time. Investing in higher-quality tools may reduce overall expenses.

-

Understand Pricing Nuances: Different regions may have distinct pricing norms based on local demand, manufacturing capabilities, and supply chains. Researching these can provide leverage in negotiations.

-

Stay Informed: Keep abreast of market trends, material costs, and supplier developments. This knowledge can strengthen negotiation positions and help identify the best sourcing opportunities.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, improved service, and access to exclusive deals or new products.

By carefully analyzing these factors, B2B buyers can make more informed decisions, ultimately leading to better procurement outcomes in the competitive landscape of custom leather stamping tools.

Alternatives Analysis: Comparing custom leather stamping tools With Other Solutions

Understanding Alternatives to Custom Leather Stamping Tools

When considering tools for customizing leather goods, it’s crucial to evaluate alternatives to custom leather stamping tools. This analysis focuses on comparing traditional stamping techniques, laser engraving, and heat stamping. Each method has its unique characteristics, advantages, and drawbacks, which can significantly influence your decision as a B2B buyer.

Illustrative image related to custom leather stamping tools

| Comparison Aspect | Custom Leather Stamping Tools | Traditional Stamping Techniques | Laser Engraving | Heat Stamping |

|---|---|---|---|---|

| Performance | High precision and versatility | Moderate precision, more manual effort | Extremely high precision, intricate designs | Good for simple designs, less detail |

| Cost | Moderate to high (varies by tool) | Low initial cost, but labor-intensive | High initial investment, low operating costs | Moderate initial cost, low running costs |

| Ease of Implementation | Requires training but straightforward | Simple to use but labor-intensive | Requires skilled operators and software | Easy to implement with proper equipment |

| Maintenance | Low maintenance if used correctly | Moderate; tools need regular upkeep | Low; mainly software updates | Low; requires minimal upkeep |

| Best Use Case | Custom designs for various leather products | Simple patterns on larger pieces | Detailed, intricate designs, high volume | Bulk production of simple, repetitive designs |

In-Depth Look at Alternative Solutions

What Are the Pros and Cons of Traditional Stamping Techniques?

Traditional stamping techniques involve using manual stamps to imprint designs onto leather. While this method is cost-effective and straightforward, it can be labor-intensive and may lead to inconsistencies in design quality. It is ideal for artisans who focus on small batches or bespoke items where uniqueness is paramount. However, the physical effort and time required can limit scalability for larger operations.

How Does Laser Engraving Compare to Custom Leather Stamping Tools?

Laser engraving is a modern alternative that uses high-powered lasers to create intricate designs on leather. This method offers unparalleled precision and can produce complex patterns that would be challenging with traditional tools. However, the initial investment in laser equipment can be significant, and it requires skilled operators familiar with the technology. Laser engraving is best for businesses that demand high detail and consistency, especially in larger production runs.

What Are the Advantages and Disadvantages of Heat Stamping?

Heat stamping involves using heat and pressure to imprint designs onto leather, typically with pre-made plates. This method is relatively easy to implement and is effective for creating simple, repetitive designs. The initial setup costs are moderate, but like traditional stamping, it may not offer the level of detail achievable with custom stamping or laser engraving. Heat stamping is ideal for businesses focused on high-volume production of standard designs.

Illustrative image related to custom leather stamping tools

How Can B2B Buyers Choose the Right Leather Customization Method?

When selecting the right solution for leather customization, B2B buyers should assess their specific needs, including the desired level of detail, production volume, and budget constraints. Custom leather stamping tools offer a balance of precision and versatility, making them suitable for various applications. However, if a business requires intricate designs or high production rates, exploring laser engraving or heat stamping may be more advantageous. Ultimately, the right choice will align with the company’s operational goals and customer demands.

Essential Technical Properties and Trade Terminology for custom leather stamping tools

What Are the Key Technical Properties of Custom Leather Stamping Tools?

When considering custom leather stamping tools, understanding their technical properties is crucial for ensuring quality and efficiency in production. Below are some essential specifications that B2B buyers should be familiar with:

-

Material Grade: The most common materials for leather stamping tools are brass and stainless steel. Brass is often preferred for its durability and ability to maintain a sharp edge, while stainless steel offers superior corrosion resistance. Choosing the right material affects the longevity and performance of the tools, making it a critical factor in procurement decisions.

-

Design Precision: This refers to the accuracy of the tool’s design in relation to the final imprint on the leather. High-precision tools ensure that designs are replicated accurately, which is vital for branding and product quality. Buyers should consider tools that offer tight tolerances to minimize variations in impressions.

-

Stamp Size and Shape: The dimensions of the stamping tools (e.g., 16x13mm for interlocking shapes) are important for compatibility with different leather projects. Buyers should evaluate the range of sizes available and ensure they align with their specific design requirements.

-

Finish Quality: The finish of the tool affects both its aesthetic appeal and functionality. A well-finished tool not only provides a cleaner imprint but also reduces the risk of leather tearing or fraying during stamping. This is particularly important for high-end leather goods where quality is paramount.

-

Weight and Balance: The weight of the stamping tool influences user comfort and control during operation. A well-balanced tool allows for more precise stamping, reducing the risk of errors. Buyers should assess the ergonomics of tools, especially for high-volume production environments.

What Are Common Trade Terms in the Leather Stamping Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms related to custom leather stamping tools:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that are sold under another company’s brand. In the leather stamping industry, OEMs can provide customized tools tailored to a buyer’s specifications, facilitating brand consistency and quality.

-

MOQ (Minimum Order Quantity): This is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to ensure they meet the supplier’s requirements while also managing inventory effectively. This is especially relevant for businesses looking to scale production without overcommitting resources.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This process allows buyers to compare pricing, terms, and conditions across different suppliers, ultimately aiding in informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that are used in international sales contracts. Understanding Incoterms is essential for negotiating shipping responsibilities and costs, which can significantly impact the overall price of leather stamping tools.

-

Lead Time: This term refers to the time taken from placing an order to receiving the goods. For B2B buyers, understanding lead times is critical for planning production schedules and ensuring timely delivery to customers.

Being well-versed in these technical properties and trade terminology will empower B2B buyers to make informed decisions when sourcing custom leather stamping tools, ultimately enhancing their product offerings and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the custom leather stamping tools Sector

What are the Key Trends Influencing the Custom Leather Stamping Tools Market?

The global market for custom leather stamping tools is witnessing robust growth, driven by several key factors. Increased demand for personalized leather goods in fashion, accessories, and home décor is a primary driver. As consumers prioritize unique and custom-made products, businesses in Africa, South America, the Middle East, and Europe are recognizing the need for high-quality stamping tools that can deliver intricate designs and branding options.

Emerging technologies are also reshaping the sourcing landscape. Digital design tools and 3D printing are becoming prevalent, allowing manufacturers to create bespoke tools tailored to specific customer needs. This trend is especially significant in regions like Germany, where technological innovation is highly valued. Furthermore, the rise of e-commerce platforms has facilitated easier access for international buyers, enabling them to source tools directly from manufacturers without geographical constraints.

Sourcing trends are shifting towards more collaborative relationships between buyers and suppliers. Companies are increasingly looking for partners who can provide not just tools, but also insights into design trends and market demands. This emphasis on collaboration fosters innovation and helps businesses remain competitive in a dynamic market.

How is Sustainability Influencing the Custom Leather Stamping Tools Sector?

Sustainability is becoming a critical consideration in the sourcing of custom leather stamping tools. The environmental impact of leather production and tool manufacturing has led to a growing demand for ethically sourced materials and ‘green’ certifications. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using vegetable-tanned leather or recycled materials in their products.

Ethical supply chains are essential, as they not only reduce environmental harm but also enhance brand reputation. Buyers from regions like Nigeria and Brazil are particularly attuned to the importance of sustainability, as consumers in these markets are becoming more eco-conscious. Furthermore, suppliers who adopt transparent sourcing practices and actively participate in social responsibility initiatives are likely to attract more business from international buyers.

Illustrative image related to custom leather stamping tools

The availability of certifications, such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certification, provides a framework for buyers to assess the sustainability of their suppliers. By prioritizing suppliers with these certifications, businesses can ensure they are contributing positively to the environment while meeting the growing consumer demand for sustainable products.

What is the Historical Context of Custom Leather Stamping Tools?

The history of custom leather stamping tools can be traced back to ancient civilizations, where artisans crafted tools for decorative and functional purposes. Over the centuries, these tools evolved from simple designs to intricate stamps used in various leather applications, including clothing, accessories, and furniture.

In the modern era, the industrial revolution brought significant advancements in manufacturing processes, enabling mass production of leather stamping tools. This evolution made high-quality tools more accessible to artisans and businesses alike. Today, the custom leather stamping tools sector is characterized by a blend of traditional craftsmanship and modern technology, allowing for the creation of bespoke tools that meet the demands of contemporary markets.

As the market continues to evolve, understanding this historical context is crucial for B2B buyers looking to appreciate the craftsmanship behind these tools and the innovations that have shaped their development. By recognizing the heritage of custom leather stamping tools, buyers can make informed decisions that honor both tradition and modernity.

Illustrative image related to custom leather stamping tools

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamping tools

-

How do I ensure the quality of custom leather stamping tools?

To guarantee the quality of custom leather stamping tools, it’s crucial to conduct thorough research on potential suppliers. Look for manufacturers with a strong reputation for craftsmanship, preferably with certifications or positive reviews from previous clients. Request samples to assess the durability and performance of the tools. Additionally, inquire about the materials used, such as high-grade brass or stainless steel, which indicate longevity and reliability. -

What are the best practices for sourcing custom leather stamping tools internationally?

When sourcing custom leather stamping tools internationally, establish clear communication with suppliers about your specifications and quality expectations. Utilize platforms that facilitate B2B transactions, ensuring they have good trade ratings. Consider attending trade shows or industry expos to meet potential suppliers face-to-face. It’s also beneficial to vet suppliers through third-party assessments or by checking references from other businesses in your region. -

What customization options are available for leather stamping tools?

Many manufacturers offer a range of customization options, including unique designs, sizes, and finishes. Depending on your needs, you can request specific patterns or logos to be integrated into the tools. Before placing a bulk order, ensure you receive a prototype or a detailed mock-up to confirm that the design meets your expectations. Discuss lead times for custom orders to align with your production schedules. -

What is the minimum order quantity (MOQ) for custom leather stamping tools?

The MOQ for custom leather stamping tools varies by supplier but typically ranges from 50 to 100 units. Some manufacturers may offer flexibility on MOQs, especially for first-time orders or if you commit to future purchases. Always clarify the MOQ during negotiations, as this can significantly impact your cost per unit and overall budgeting for your project. -

What payment terms should I expect when ordering internationally?

Payment terms can differ significantly between suppliers, but common practices include a deposit upfront (often 30-50%) and the balance upon shipment. Some suppliers may offer net payment terms, allowing you to pay within a specified period after delivery. It’s vital to discuss and agree on payment methods, such as wire transfers, credit cards, or payment platforms like PayPal, to ensure security and compliance with international trade regulations. -

How do I handle shipping and logistics for international orders?

For international orders, it’s essential to coordinate logistics well in advance. Discuss shipping options with your supplier, including freight forwarding and express shipping services. Understand the costs associated with shipping, customs duties, and insurance. Establish a reliable logistics partner familiar with your destination country to streamline the process and avoid unexpected delays. -

What are the best ways to vet suppliers for custom leather stamping tools?

Vetting suppliers involves checking their business credentials, industry experience, and customer reviews. Request references from previous clients and verify their production capabilities through site visits or third-party inspections. Additionally, assess their responsiveness and willingness to communicate clearly, as this can indicate their commitment to customer service and quality. -

How do I manage quality assurance (QA) for custom leather stamping tools?

Implementing a quality assurance process involves setting clear specifications and standards before production begins. Request regular updates and samples during production to ensure the tools meet your requirements. Consider conducting a final inspection before shipment, either personally or through a third-party QA service, to verify that the tools conform to your quality standards. This proactive approach can help mitigate issues and ensure you receive high-quality products.

Top 8 Custom Leather Stamping Tools Manufacturers & Suppliers List

1. Stamp Leather Co – Premium Leather Crafting Tools

Domain: stampleather.co

Registered: 2023 (2 years)

Introduction: Stamp Leather Co offers a variety of premium leather crafting tools, including:

1. **Basket Weave Leather Stamps**:

– LT001: Scaled Grid Basket Weave – $33.00 USD

– LT230: Interlocking Shapes Basket Weave (16x13mm) – $33.00 USD

– LT005: Interlaced Basket Weave – $22.00 USD

– LT339: Diamond Arrangement Basket Weave (16x7mm) – $35.00 USD

– LT231: Interlock Basket Weave (16x13mm) – $3…

2. LW Leathers – Leather Stamps

3. Buckeye Engraving – Custom Leather Stamps

Domain: buckeyeengraving.com

Registered: 2015 (10 years)

Introduction: Custom Leather Stamps made by Buckeye Engraving, available in steel, brass, or aluminum. Customization options include original designs using artwork, signatures, or sketches. High detail engraving with deep background clearance. Heavy-duty removable steel handle for hand stamps; press leather stamps include only the custom engraved stamp face. Hand made in the USA. Suitable for vegetable-tanned a…

4. Infinity Stamps – Leather Stamping Solutions

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: Leather Stamps – Infinity Stamps Inc. offers a variety of leather stamping products including: Handheld Stamps, Plate Stamps, Pin Marking Devices, Roll Dies, Maker Stamps, Hot Stamps, and Steel Type Stamps & Holders. All products are made in the USA and the company has been family-owned for over 25 years. Customers can contact a stamping specialist at 818-576-1188 or fill out a contact form for in…

5. Leather Stamp Maker – Custom Brass Stamps

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Leather & Custom Brass Stamps by Leather Stamp Maker. All custom stamps ship next business day. Made in the USA. Custom brass stamps, cutting dies, lettersets, and more. Custom stamps are CNC milled from solid brass, available up to 1″ thickness and custom size. Compatible with branding irons and standard presses. Custom leather cutting dies made from solid steel, usable with mechanical, hydraulic…

6. Steel Stamps Inc. – Custom Leather Stamps

Domain: steelstampsinc.com

Registered: 2009 (16 years)

Introduction: Custom Leather Stamps available at Steel Stamps Inc. include various categories such as Custom Jewelry Stamps, Custom Steel Stamps for Knife Makers, Blacksmiths, and Farriers, as well as Custom Locksmith Stamps and Industrial Markings. The collection features Leather Design Stamps, Sheridan Flowers/Leaves, Leather State Stamps, Jewelry Design Stamps, and multiple series like Pro Series Designs, Tr…

7. Leather Stamps – Quality Custom Options

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom leather stamps, good price point, quality stamp, options include Leatherstampstools on Etsy, Springfield Leather (makes stamps from PDF designs), leatherstampmaker (offers free quotes and proof, quick turnaround).

8. Custom Brand – Leather Embossing Stamp

Strategic Sourcing Conclusion and Outlook for custom leather stamping tools

In navigating the landscape of custom leather stamping tools, strategic sourcing emerges as a pivotal factor for B2B buyers seeking quality, durability, and unique designs. Understanding the diverse offerings—from basket weave to decorative edge cutter stamps—enables businesses to make informed decisions that align with their production needs and market demands. The emphasis on premium materials, such as brass and stainless steel, ensures that tools not only provide clear impressions but also stand the test of time, fostering long-term partnerships and brand integrity.

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the opportunity to leverage superior craftsmanship is significant. By investing in high-quality stamping tools, businesses can enhance their product offerings, meeting the rising consumer expectations for customized leather goods.

Looking ahead, as the global market evolves, the demand for innovative and sustainable leather crafting tools will continue to rise. Now is the time to engage with reliable suppliers and explore tailored solutions that can elevate your brand. Take the next step in your sourcing strategy—connect with trusted manufacturers today to secure your competitive edge in the leather industry.

Illustrative image related to custom leather stamping tools

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.