Introduction: Navigating the Global Market for custom leather stamp logo

Navigating the intricacies of the global market for custom leather stamp logos can be daunting for B2B buyers, particularly when seeking quality and reliability. With a plethora of suppliers scattered across continents, including Africa, South America, the Middle East, and Europe, the challenge lies in identifying the right partner who can deliver precise, high-quality products tailored to specific branding needs. This guide serves as a comprehensive resource for international buyers, detailing the various types of custom leather stamps available, their applications, and the essential criteria for vetting potential suppliers.

From understanding the differences between brass, steel, and aluminum stamps to exploring applications in leather embossing and branding, this guide empowers decision-makers to make informed choices. Additionally, it covers crucial aspects such as pricing structures, shipping considerations, and the importance of design specifications, ensuring that every buyer is equipped with the knowledge necessary to navigate this niche market effectively.

By addressing these key challenges and providing actionable insights, this guide aims to streamline the sourcing process for custom leather stamp logos, ultimately helping businesses enhance their branding efforts and establish a lasting impression in their respective markets.

Table Of Contents

- Top 7 Custom Leather Stamp Logo Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather stamp logo

- Understanding custom leather stamp logo Types and Variations

- Key Industrial Applications of custom leather stamp logo

- 3 Common User Pain Points for ‘custom leather stamp logo’ & Their Solutions

- Strategic Material Selection Guide for custom leather stamp logo

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamp logo

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamp logo’

- Comprehensive Cost and Pricing Analysis for custom leather stamp logo Sourcing

- Alternatives Analysis: Comparing custom leather stamp logo With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather stamp logo

- Navigating Market Dynamics and Sourcing Trends in the custom leather stamp logo Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamp logo

- Strategic Sourcing Conclusion and Outlook for custom leather stamp logo

- Important Disclaimer & Terms of Use

Understanding custom leather stamp logo Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Handheld Leather Stamps | Portable, easy to use; typically made from brass or steel. | Small-scale production, custom branding. | Pros: Cost-effective; Cons: Labor-intensive for large runs. |

| Custom Branding Irons | Electric or manual, ideal for heat stamping; durable construction. | Mass production, high-volume branding. | Pros: Quick application; Cons: Higher initial investment. |

| Leather Roll Dies | Designed for continuous patterns; mounted for press use. | Large batch production, decorative designs. | Pros: Efficient for volume; Cons: Requires press machinery. |

| Embossing Plates | Flat plates for creating raised designs; often used for logos. | High-end leather goods, luxury branding. | Pros: High detail; Cons: Less versatile for different designs. |

| Custom Cutting Dies | Used for cutting shapes as well as stamping; steel construction. | Prototyping, unique leather shapes. | Pros: Versatile; Cons: Need precise design specifications. |

What Are Handheld Leather Stamps and Their Applications?

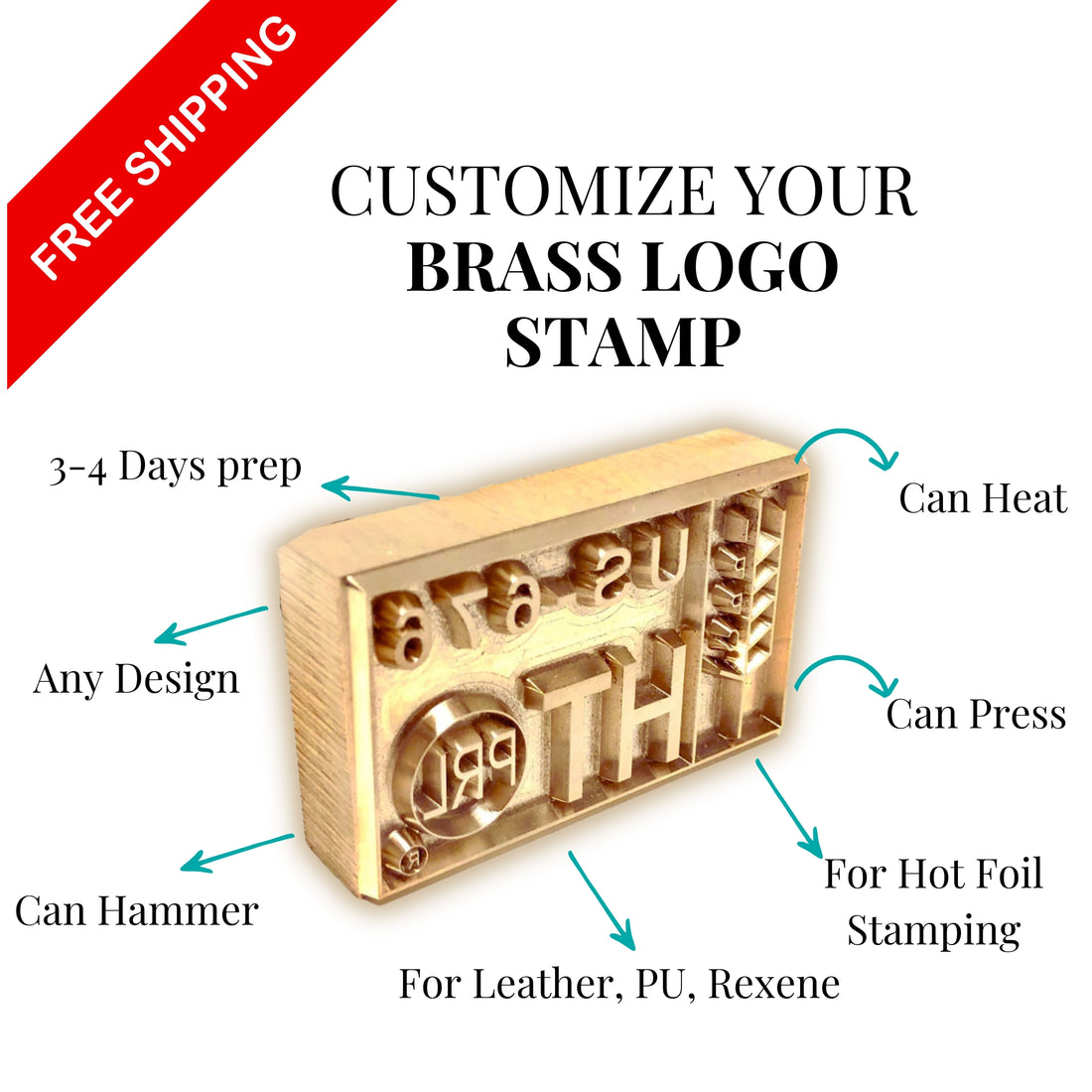

Handheld leather stamps are portable tools typically made from brass or steel, making them user-friendly for artisans and small businesses. They are ideal for custom branding on leather goods, such as wallets, belts, and bags. When considering a purchase, buyers should evaluate the production scale, as these stamps are more suited for lower volumes due to the manual effort required.

How Do Custom Branding Irons Enhance Production?

Custom branding irons can be electric or manual and are specifically designed for heat stamping leather, making them durable and efficient for mass production. They are particularly advantageous for businesses looking to brand large quantities of products quickly. Buyers should consider the upfront cost versus the long-term benefits of increased production speed and consistency in branding.

What Are the Benefits of Using Leather Roll Dies?

Leather roll dies are designed for creating continuous patterns and are mounted on presses for efficiency. They are particularly useful in large batch production where consistency and speed are crucial. Businesses focusing on decorative designs or large-scale manufacturing should assess their machinery compatibility and the volume of production needed when investing in roll dies.

Illustrative image related to custom leather stamp logo

Why Choose Embossing Plates for High-End Products?

Embossing plates are flat and used to create raised designs, making them ideal for high-end leather goods and luxury branding. They offer high detail and precision, enhancing the aesthetic value of products. However, buyers should consider their limited versatility, as they are best suited for specific designs rather than varied applications.

How Do Custom Cutting Dies Facilitate Unique Designs?

Custom cutting dies serve a dual purpose of cutting shapes and stamping designs, typically made from steel for durability. They are essential for prototyping and creating unique leather shapes that stand out in the marketplace. When purchasing, businesses must provide precise design specifications, ensuring that the die meets their unique requirements for both cutting and stamping.

Key Industrial Applications of custom leather stamp logo

| Industry/Sector | Specific Application of custom leather stamp logo | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Branding leather goods like bags, wallets, and belts | Enhances brand identity and perceived value | Material durability, precision in design, and production speed |

| Automotive | Custom stamping for leather car interiors | Adds a luxury feel and personalization to vehicle interiors | Compatibility with different leather types and customization options |

| Hospitality | Stamping leather menus, coasters, and key fobs | Elevates customer experience and brand consistency | Quality of embossing, design clarity, and lead time for orders |

| Crafts & DIY | Custom stamps for artisan leather goods | Differentiates products in a competitive market | Availability of various stamp sizes and materials |

| Industrial Manufacturing | Stamping for leather components in machinery | Ensures traceability and compliance with quality standards | Precision engineering and ability to handle bulk orders |

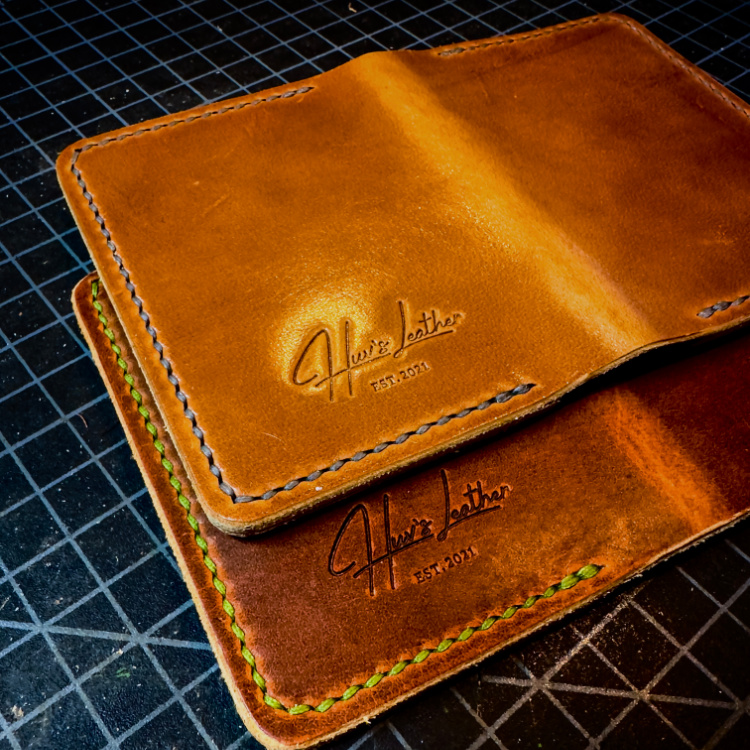

How is Custom Leather Stamp Logo Used in the Fashion & Accessories Industry?

In the fashion and accessories sector, custom leather stamp logos are essential for branding items like bags, wallets, and belts. They serve to elevate the perceived value of products by providing a professional touch that resonates with consumers. For international B2B buyers, it’s crucial to consider the durability of materials used in stamping, as well as the precision of the design to ensure brand consistency across multiple product lines.

Illustrative image related to custom leather stamp logo

What Role Does Custom Leather Stamping Play in the Automotive Sector?

Within the automotive industry, custom leather stamps are used to brand leather interiors in vehicles. This application not only enhances the aesthetic appeal but also adds a layer of personalization that customers appreciate. Buyers in this sector should focus on sourcing stamps that are compatible with various leather types and can withstand the rigors of automotive use, ensuring longevity and quality in branding.

How Can Hospitality Businesses Benefit from Custom Leather Stamps?

In hospitality, custom leather stamps are commonly used for menus, coasters, and key fobs, significantly enhancing the customer experience. By incorporating stamped leather items, businesses can create a cohesive brand identity that leaves a lasting impression on guests. Buyers should prioritize high-quality embossing and clarity in design to maintain a professional appearance, while also considering lead times to ensure timely delivery for events and peak seasons.

Why Are Custom Leather Stamps Important for Crafts & DIY?

Artisans in the crafts and DIY sector utilize custom leather stamps to differentiate their handmade products. A unique stamp can serve as a maker’s mark, providing authenticity and value to each piece. For B2B buyers, it’s essential to consider the availability of various stamp sizes and materials to accommodate diverse crafting needs, ensuring versatility and creativity in product offerings.

Illustrative image related to custom leather stamp logo

How Does Custom Leather Stamping Contribute to Industrial Manufacturing?

In industrial manufacturing, custom leather stamps are used for marking leather components in machinery, which aids in traceability and compliance with quality standards. This application is vital for maintaining operational efficiency and ensuring that components meet industry regulations. Buyers should seek precision-engineered stamps that can handle bulk orders, allowing for streamlined production processes and consistent quality across all stamped items.

3 Common User Pain Points for ‘custom leather stamp logo’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Quality in Leather Stamps

The Problem: Many B2B buyers face the challenge of ensuring that their custom leather stamps consistently produce high-quality impressions. This is particularly important for brands aiming to convey a professional image through their products. Issues such as uneven pressure during stamping, variations in leather thickness, or insufficient engraving depth can lead to subpar results, frustrating businesses that depend on these stamps for branding. The inconsistency can tarnish brand reputation and lead to wasted materials and increased costs.

The Solution: To overcome these quality control issues, it is essential to work closely with experienced manufacturers who understand the nuances of leather stamping. Buyers should ensure they specify the type of leather being used and the intended application for the stamp (e.g., wet stamping vs. heat embossing). Request samples and proofs before finalizing the order to verify that the stamp meets your quality standards. Additionally, consider investing in a robust stamping mechanism, such as a hydraulic press, which provides even pressure across the stamping surface, ensuring consistent results across all products. Regular maintenance of stamping tools and machinery can also help sustain quality over time.

Illustrative image related to custom leather stamp logo

Scenario 2: Navigating the Complexity of Design Specifications

The Problem: Many B2B buyers struggle with the technical aspects of designing a custom leather stamp logo. Translating a logo into a stamp-friendly format can be challenging, especially when considering factors like engraving depth, size, and material compatibility. Inexperienced buyers may not realize that certain designs may not reproduce well on leather, leading to frustration and delays in the production process.

The Solution: To navigate this complexity, buyers should engage with suppliers that offer design assistance. A reputable manufacturer will provide guidance on file formats and design requirements, often preferring vector files (AI or PDF) over raster formats (JPG). When submitting designs, include detailed specifications such as desired dimensions and depth of engraving. It can be beneficial to collaborate with the supplier’s design team to refine the logo, ensuring it translates effectively into a stamp. Additionally, investing time in creating a clear design brief can streamline communication and reduce the back-and-forth, ultimately speeding up the production timeline.

Scenario 3: Managing Long Lead Times and Urgent Needs

The Problem: In the fast-paced world of B2B transactions, many buyers face the issue of long lead times when ordering custom leather stamps. Delays can occur due to complex designs, high demand, or inefficient production processes. For companies that need to meet tight deadlines for product launches or promotional events, these delays can be detrimental, impacting sales and customer satisfaction.

The Solution: To manage lead times effectively, buyers should prioritize suppliers that specialize in quick turnaround times. When sourcing custom leather stamps, inquire about the production timelines upfront and opt for manufacturers who can guarantee fast shipping options. Some companies offer next-day shipping for urgent orders, which can be a lifesaver in critical situations. Additionally, establishing a good relationship with a reliable supplier can lead to priority service for future orders. Consider maintaining a small inventory of standard stamps that can be used for common branding needs, allowing for flexibility and reducing reliance on custom orders during peak periods.

Strategic Material Selection Guide for custom leather stamp logo

What Are the Key Materials for Custom Leather Stamps?

When selecting materials for custom leather stamps, understanding the properties, advantages, and limitations of each option is crucial for achieving optimal performance. Here, we analyze four common materials used in the production of custom leather stamps: brass, steel, aluminum, and plastic.

Illustrative image related to custom leather stamp logo

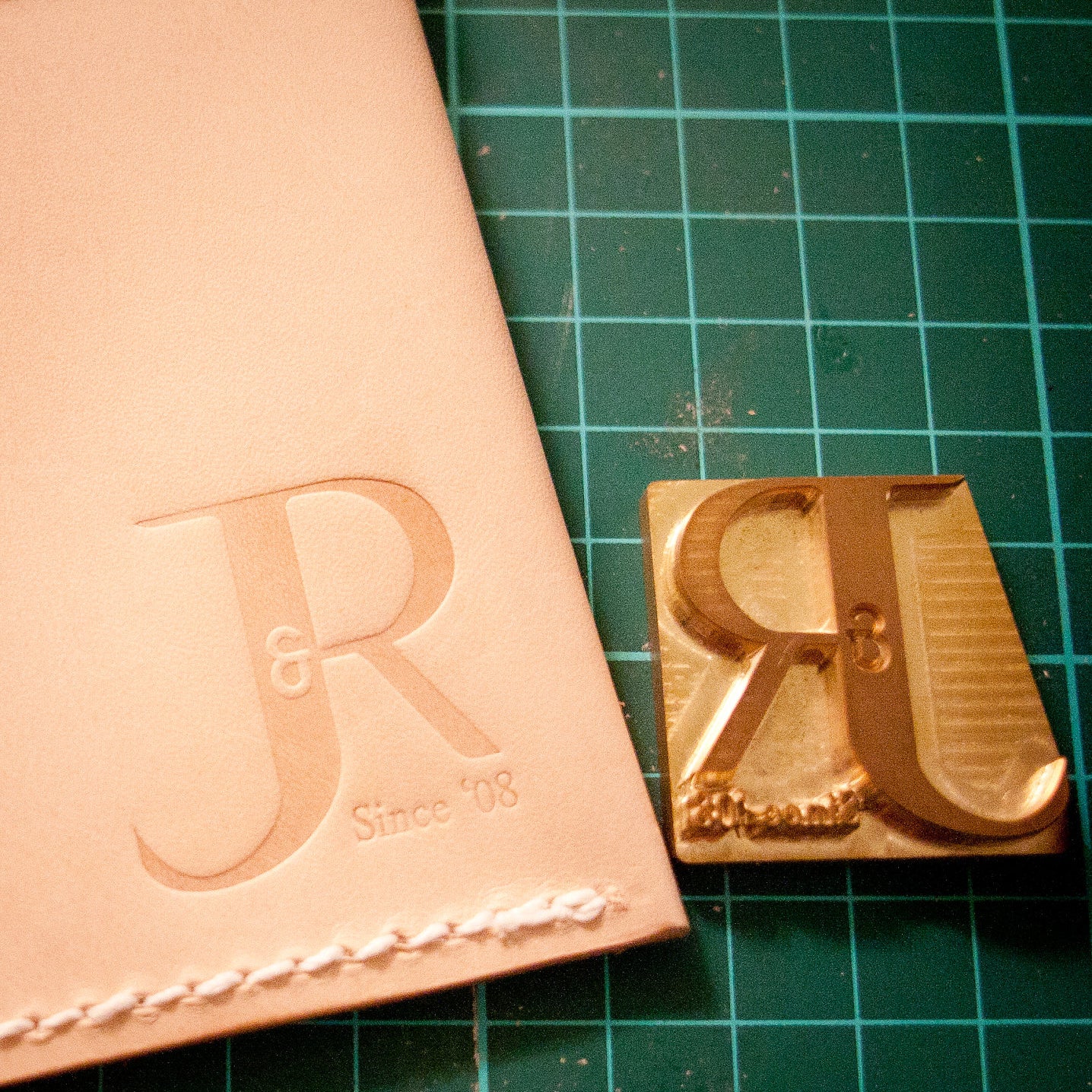

How Does Brass Perform as a Material for Custom Leather Stamps?

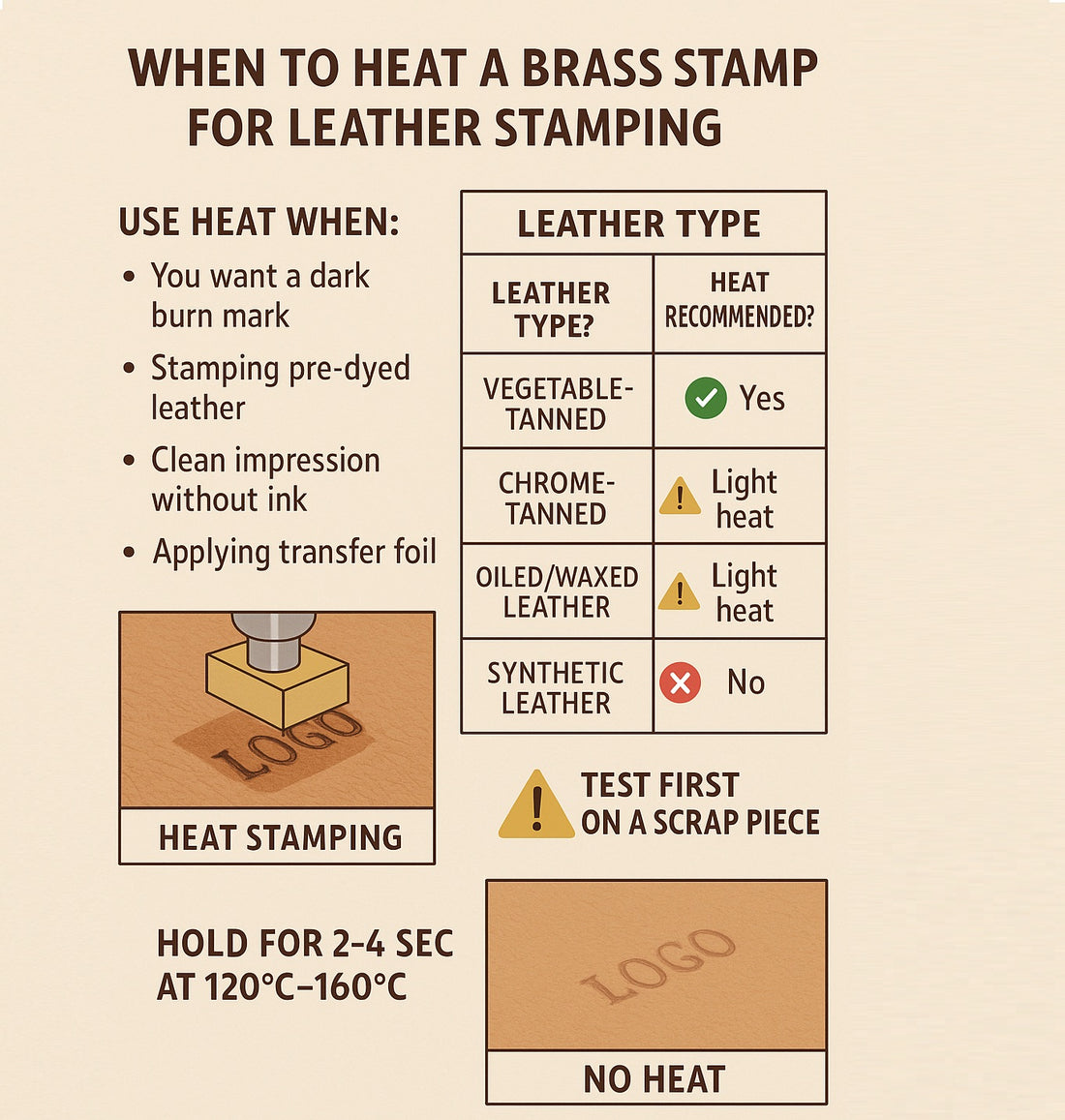

Brass is a popular choice for custom leather stamps due to its excellent thermal conductivity and resistance to corrosion. It can withstand high temperatures, making it suitable for both wet and heat stamping applications. The durability of brass ensures that stamps maintain their shape and detail over time, providing consistent results.

Pros: Brass stamps are known for their longevity and ability to produce high-quality impressions. They are less likely to rust when exposed to moisture, making them ideal for stamping vegetable-tanned leather.

Cons: The primary drawback is the cost; brass is generally more expensive than aluminum. Additionally, while brass is robust, it can be softer than steel, which may lead to wear over time if not properly cared for.

Impact on Application: Brass is particularly effective for detailed designs and logos, ensuring clarity in the stamped image. For international buyers, compliance with material standards such as ASTM B453 (for brass) is essential to ensure quality and safety.

What Are the Benefits of Using Steel for Custom Leather Stamps?

Steel is another commonly used material for custom leather stamps, known for its exceptional strength and durability. It can withstand significant pressure, making it suitable for high-volume stamping operations.

Illustrative image related to custom leather stamp logo

Pros: Steel stamps are highly resistant to wear and can produce sharp, clear impressions. They are ideal for heavy-duty applications where longevity is a concern.

Cons: The main disadvantage of steel is its susceptibility to rust if not properly maintained. Additionally, steel stamps can be heavier and may require more robust stamping equipment.

Impact on Application: Steel is suitable for a variety of leather types, including chrome-tanned leather. Buyers in regions with high humidity, such as parts of Africa and South America, should consider protective coatings to prevent rusting.

Why Choose Aluminum for Custom Leather Stamps?

Aluminum is a cost-effective alternative for custom leather stamps, offering a lightweight option that is easy to handle. While it may not match the durability of brass or steel, it is still a viable choice for less demanding applications.

Illustrative image related to custom leather stamp logo

Pros: Aluminum is less expensive and easier to machine, allowing for quick production times. It is also resistant to corrosion, making it suitable for various environments.

Cons: The primary limitation is its lower durability compared to brass and steel. Aluminum stamps may wear out faster, especially with intricate designs or high-volume use.

Impact on Application: Aluminum is best suited for simple designs and lower-volume applications. International buyers should ensure that the aluminum used complies with standards such as ASTM B221.

Illustrative image related to custom leather stamp logo

How Does Plastic Compare as a Material for Custom Leather Stamps?

Plastic, particularly high-density polyethylene (HDPE), is an emerging option for custom leather stamps. While not as traditional as metal options, it offers unique benefits for specific applications.

Pros: Plastic stamps are lightweight, inexpensive, and resistant to moisture. They can be easily produced in various shapes and sizes, making them versatile for different stamping needs.

Cons: The main drawback is their reduced durability compared to metal stamps. Plastic may not withstand high pressure or heat, limiting its use in more demanding applications.

Impact on Application: Plastic stamps are ideal for temporary or low-volume applications, such as promotional items. Buyers should be aware of the material’s limitations and ensure compliance with relevant standards for safety and quality.

Summary Table of Material Selection for Custom Leather Stamps

| Material | Typical Use Case for custom leather stamp logo | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-detail logos on vegetable-tanned leather | Excellent thermal conductivity and durability | Higher cost, softer than steel | High |

| Steel | Heavy-duty stamping, high-volume production | Exceptional strength and wear resistance | Susceptible to rust without maintenance | Med |

| Aluminum | Simple designs, low-volume applications | Lightweight and cost-effective | Lower durability, wears out faster | Low |

| Plastic | Temporary stamps, promotional items | Inexpensive and moisture-resistant | Reduced durability, limited pressure resistance | Low |

This strategic material selection guide provides B2B buyers with essential insights into the best materials for custom leather stamps, helping them make informed decisions based on their specific needs and applications.

Illustrative image related to custom leather stamp logo

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamp logo

What Are the Main Stages in the Manufacturing Process of Custom Leather Stamp Logos?

The manufacturing process for custom leather stamp logos involves several critical stages, each essential for ensuring high-quality end products. The primary stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Custom Leather Stamps?

The journey begins with material selection, typically involving high-grade metals such as solid brass, aluminum, or steel. Brass is often favored for its durability and resistance to rust, making it ideal for leather applications. The selected material is cut to size, ensuring that it meets the specifications required for the final product. This initial step may also include cleaning and treating the materials to ensure optimal adhesion during the engraving process.

What Techniques Are Used in the Forming Stage?

In the forming stage, precision is paramount. Techniques such as CNC (Computer Numerical Control) machining are commonly employed to create intricate designs. This technology allows for high precision and repeatability, crucial for creating detailed logos that maintain their integrity across multiple uses. The forming process may also involve engraving, where the design is etched into the surface of the metal to create a clear and lasting impression on leather.

How is the Assembly Process Conducted for Custom Leather Stamps?

After forming, the assembly process may involve attaching handles or securing the stamp face to a press mechanism. For handheld stamps, a removable steel handle is often included to facilitate ease of use. Each component is inspected for quality and compatibility to ensure that the final product will function effectively and meet the buyer’s specifications.

What Finishing Techniques Are Applied to Custom Leather Stamps?

Finishing techniques play a vital role in the aesthetics and functionality of the custom leather stamp. This stage may involve polishing the metal surfaces to remove any burrs or rough edges, ensuring a smooth stamping experience. Additionally, stamps may undergo surface treatments to enhance their durability and resistance to wear. Proper finishing not only enhances the visual appeal but also contributes to the longevity of the stamp, which is particularly important for B2B buyers looking for reliable products.

Illustrative image related to custom leather stamp logo

What Quality Assurance Standards Are Relevant for Custom Leather Stamps?

Quality assurance (QA) is a critical aspect of the manufacturing process, especially for international B2B buyers. Compliance with international standards such as ISO 9001 ensures that the manufacturing processes meet global quality management principles. ISO 9001 focuses on consistent quality, customer satisfaction, and continual improvement, making it a benchmark for suppliers.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch potential defects early. These checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before production begins. Suppliers should provide certificates of authenticity or material specifications to ensure compliance with quality standards.

-

In-Process Quality Control (IPQC): During the forming and assembly stages, IPQC checks are implemented to monitor production processes and ensure that they adhere to the defined specifications. This may include measuring dimensions and inspecting engravings for accuracy.

-

Final Quality Control (FQC): Once the stamping process is complete, FQC inspections focus on the final product’s performance and visual quality. This includes testing the stamp’s ability to create clear and detailed impressions on leather.

What Common Testing Methods Are Used in Quality Control?

Common testing methods employed during the quality assurance phase for custom leather stamps include:

-

Dimensional Inspection: Utilizing calipers and gauges to ensure that the dimensions of the stamp meet specified tolerances.

-

Engraving Depth Testing: Measuring the depth of engravings to confirm that they align with the design requirements, ensuring the logo will be visible and distinct on leather.

-

Durability Testing: Conducting wear tests to evaluate how well the stamp performs over time, especially under various stamping conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps to ensure supplier reliability:

Illustrative image related to custom leather stamp logo

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facility’s processes, equipment, and quality management systems firsthand. This can provide insights into the supplier’s commitment to quality.

-

Quality Assurance Reports: Requesting detailed QA reports can help buyers understand the QC measures in place. These reports should include information on testing methods, results, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s products and processes. This is particularly beneficial for international buyers who may not be able to visit the supplier’s facility.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers must navigate various nuances related to quality control. Different regions may have specific regulations or industry standards that suppliers must adhere to, such as CE marking in Europe or API standards in the oil and gas sector. Understanding these nuances can help buyers make informed decisions and avoid compliance issues.

In conclusion, the manufacturing processes and quality assurance measures for custom leather stamps are vital components that influence the product’s quality, durability, and performance. By understanding these processes and implementing thorough verification practices, international B2B buyers can ensure they partner with reliable suppliers that meet their standards for quality and excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamp logo’

In the quest to procure a custom leather stamp logo, a structured approach can significantly enhance your sourcing process. This checklist will guide international B2B buyers through essential steps to ensure they select the right supplier for their needs, particularly focusing on quality, efficiency, and cost-effectiveness.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline what you need from your custom leather stamp. Consider the size, material (brass, steel, aluminum), and design intricacies of your logo.

– Material Choice: Brass is popular for its durability and resistance to rust, while aluminum offers a cost-effective solution.

– Size and Depth: Specify the dimensions and engraving depth required to ensure your logo appears as intended on the leather.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers specializing in custom leather stamps. Look for companies with a proven track record in the industry and positive customer reviews.

– Supplier Location: Consider suppliers from regions known for high-quality leather goods, such as Europe or the USA, as they often adhere to stricter manufacturing standards.

– Portfolio Review: Examine their previous work to gauge their capabilities and the quality of their custom stamps.

Step 3: Request Samples and Quotes

Once you have shortlisted suppliers, request samples of their previous work along with quotes for your specific requirements. This step allows you to evaluate the craftsmanship and pricing.

– Sample Evaluation: Assess the quality of the sample—check for clarity in the logo design and overall finish.

– Cost Comparison: Obtain detailed quotes that break down costs for production, shipping, and any additional fees for rush orders.

Step 4: Evaluate Production Capabilities

Understanding a supplier’s production capabilities is vital to ensure they can meet your deadlines and quality standards.

– Turnaround Time: Inquire about their standard production time and options for expedited service.

– Technology Used: Suppliers using CNC machines or advanced engraving techniques tend to offer higher precision and quality.

Step 5: Verify Quality Control Processes

Quality assurance should be a non-negotiable aspect of your supplier evaluation. Ask about their quality control measures to ensure consistency in production.

– Inspection Procedures: Determine whether they conduct inspections at various stages of production.

– Certification Standards: Suppliers with ISO certifications or similar quality assurance frameworks are often more reliable.

Step 6: Understand Shipping and Logistics

Discuss shipping options and logistics to avoid unexpected delays once your order is placed.

– Shipping Methods: Confirm the shipping methods available and estimated delivery times based on your location.

– Customs and Duties: Be aware of any potential customs fees or regulations that might affect the delivery of your products, especially when dealing with international suppliers.

Step 7: Establish Clear Communication Channels

Effective communication with your supplier is crucial throughout the process. Ensure they are responsive and open to discussions regarding your project.

– Preferred Communication Methods: Determine if they prefer email, phone calls, or online meetings for updates and discussions.

– Language Proficiency: Ensure that language barriers will not hinder your ability to convey technical specifications or resolve issues.

By following this checklist, international B2B buyers can streamline the process of sourcing custom leather stamp logos, ensuring they select a supplier that aligns with their quality standards and operational needs.

Illustrative image related to custom leather stamp logo

Comprehensive Cost and Pricing Analysis for custom leather stamp logo Sourcing

Understanding the cost structure and pricing dynamics for sourcing custom leather stamp logos is crucial for international B2B buyers. This comprehensive analysis breaks down the cost components, examines price influencers, and offers valuable buyer tips tailored for markets across Africa, South America, the Middle East, and Europe.

What are the Key Cost Components in Custom Leather Stamp Logo Production?

When sourcing custom leather stamps, buyers should consider several cost components:

-

Materials: The choice of material significantly impacts costs. Brass is commonly used due to its durability and resistance to rust, while aluminum offers a lower price point. The thickness and complexity of the design also influence material costs.

-

Labor: Skilled labor is required to create high-precision stamps. The labor cost can vary based on the complexity of the design and the expertise of the engravers.

-

Manufacturing Overhead: This includes costs related to equipment maintenance, factory utilities, and administrative expenses. Established suppliers may have optimized processes that reduce these overheads.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. This involves the creation of molds or dies that may require significant upfront investment but can lead to cost savings over larger production runs.

-

Quality Control (QC): Ensuring that the stamps meet quality standards is crucial. QC processes can add to the overall cost, but they help mitigate risks associated with defective products.

-

Logistics: Shipping costs vary significantly based on distance, volume, and chosen shipping methods. International buyers should consider customs duties and import taxes that may apply.

-

Margin: Suppliers add a profit margin to cover their costs and ensure business sustainability. This margin can vary based on the supplier’s market position and the perceived value of their products.

How Do Price Influencers Affect Custom Leather Stamp Costs?

Several factors influence the pricing of custom leather stamps:

-

Volume/MOQ: Bulk orders typically result in lower per-unit costs. Suppliers often have minimum order quantities (MOQs), and negotiating these can lead to significant savings.

-

Specifications/Customization: Highly customized designs may incur additional costs. Buyers should clarify their requirements to receive accurate quotes.

-

Materials and Quality Certifications: Stamps made from higher-quality materials or those that meet specific certifications will generally have higher prices. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: The reputation and location of the supplier can affect pricing. Suppliers with established credibility may charge premium prices, while newer entrants may offer competitive rates.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is essential, as they define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs. This knowledge can help buyers avoid unexpected costs.

What Negotiation Strategies Can International Buyers Use to Ensure Cost-Efficiency?

-

Research and Benchmarking: Conduct thorough market research to understand standard pricing and quality benchmarks. This information can empower buyers during negotiations.

-

Leverage Volume Discounts: If planning to place large orders, negotiate for bulk pricing or discounts based on future orders.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs associated with maintenance, durability, and potential replacement.

-

Flexible Payment Terms: Discuss payment options that could ease cash flow, such as staggered payments based on delivery milestones.

-

Local Partnerships: For buyers in Africa, South America, and the Middle East, forming local partnerships can reduce shipping costs and provide insights into local market dynamics.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices for custom leather stamps range from $68 to over $200, it is vital for international buyers to understand that these are subject to fluctuations based on the discussed factors. Engaging in open communication with suppliers and being clear about requirements can lead to better pricing and quality outcomes. Buyers are encouraged to request multiple quotes and consider not just the price, but the overall value provided by the supplier.

Alternatives Analysis: Comparing custom leather stamp logo With Other Solutions

Exploring Alternatives to Custom Leather Stamp Logos

In the realm of leather branding and personalization, the custom leather stamp logo is a popular choice for businesses looking to leave a lasting impression on their products. However, several alternative solutions exist that can achieve similar branding goals. This analysis will compare the custom leather stamp logo with two viable alternatives: heat branding and laser engraving. Each method offers unique benefits and drawbacks, catering to different business needs.

Comparison Table

| Comparison Aspect | Custom Leather Stamp Logo | Heat Branding | Laser Engraving |

|---|---|---|---|

| Performance | High durability; excellent for embossed designs | Effective for deep branding; consistent results | Precise detail; can handle intricate designs |

| Cost | Moderate (approximately $68-$89) | Varies (initial investment can be high) | Higher cost per unit, particularly for setup |

| Ease of Implementation | Simple; requires minimal training | Requires training and practice for consistent quality | Requires specialized equipment and training |

| Maintenance | Low maintenance; durable materials | Low maintenance; equipment can wear over time | Moderate; equipment needs calibration and maintenance |

| Best Use Case | Ideal for small to medium batches and artisanal products | Best for high-volume production with consistent results | Suitable for detailed designs and high customization |

Detailed Breakdown of Alternatives

Heat Branding

Heat branding involves using a heated metal stamp to create a mark on leather. This method is particularly effective for deep branding, ensuring a durable and long-lasting impression. The initial investment for heat branding equipment can be high, especially for businesses looking to produce large volumes, but it offers consistent results once the process is mastered. One downside is that it requires training to achieve the desired quality consistently. Additionally, while maintenance is low, the equipment can wear over time, necessitating periodic replacements.

Laser Engraving

Laser engraving uses a high-powered laser to etch designs onto leather, providing precise detail and the ability to handle intricate designs. This method is particularly effective for businesses that require a high level of customization, as it can replicate complex logos and patterns with ease. However, the cost per unit can be higher due to the need for specialized equipment and setup. Furthermore, while laser engraving offers exceptional detail, it may not be suitable for all types of leather, particularly thicker varieties. Maintenance of the laser equipment is also necessary to ensure optimal performance.

Conclusion: How to Choose the Right Solution for Your Branding Needs

When selecting the right branding method for your leather products, consider factors such as budget, desired design complexity, and production volume. Custom leather stamp logos are an excellent choice for businesses seeking a reliable and cost-effective solution for small to medium batches. Heat branding suits high-volume production environments, while laser engraving caters to those needing intricate designs. Understanding these alternatives will help B2B buyers make informed decisions that align with their specific branding goals and operational capabilities.

Essential Technical Properties and Trade Terminology for custom leather stamp logo

What Are the Key Technical Properties of Custom Leather Stamp Logos?

When considering a custom leather stamp logo, understanding the technical properties is crucial for ensuring product quality and suitability for specific applications. Here are some essential specifications:

-

Material Grade: The most common materials for custom leather stamps are brass, steel, and aluminum. Brass is favored for its durability and resistance to rust, making it ideal for wet stamping applications. Steel provides strength and longevity, while aluminum is cost-effective for less demanding tasks. Selecting the appropriate material affects the stamp’s performance and longevity, which is vital for B2B buyers looking for reliable solutions.

-

Stamp Thickness: The thickness of the stamp typically ranges from 8mm to 1 inch. A thicker stamp can provide more durability and withstand repeated use, which is particularly important for businesses that require consistent branding across large volumes. Understanding the thickness helps buyers assess the longevity and robustness of the stamp in their production processes.

-

Engraving Depth: This specification usually varies around 3mm for most stamps. Deeper engravings can produce more defined impressions, which is crucial for intricate designs. For businesses, this means that the quality of their branding will be reflected in the clarity of the stamp, affecting customer perceptions of their products.

-

Design Size: Custom stamps can accommodate a variety of design sizes, often limited to a maximum area (e.g., 10 cm²). Understanding the size limitations helps buyers plan their designs accordingly, ensuring that their logos or marks fit within the specified dimensions without compromising detail.

-

Tolerance Levels: Tolerance refers to the acceptable range of deviation from a specified dimension. In the context of custom stamps, tight tolerances ensure that the stamp produces consistent impressions, which is essential for maintaining brand integrity across different products. Buyers should inquire about tolerance levels to ensure that they meet their quality standards.

What Are Common Trade Terms Related to Custom Leather Stamps?

Familiarity with industry terminology is essential for effective communication and negotiation. Here are some common terms used in the custom leather stamp market:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that can be marketed under another company’s brand. For B2B buyers, working with OEMs can lead to customized solutions that align with their branding needs while leveraging the expertise of established manufacturers.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for businesses to manage inventory effectively and to negotiate better terms with suppliers, particularly when trying to minimize costs or test new products.

-

RFQ (Request for Quotation): An RFQ is a document that a buyer sends to suppliers to request pricing information for specific products or services. It is a vital step in the procurement process, enabling buyers to compare costs and make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers engaged in international transactions, as it clarifies who bears the risk and cost at various stages of shipping.

-

Heat Embossing vs. Wet Stamping: These are two common methods of applying custom designs to leather. Heat embossing uses heat and pressure to create a design, while wet stamping involves moistening the leather before stamping. Understanding these methods allows buyers to select the best technique for their specific leather type and desired outcome.

Incorporating this knowledge into the decision-making process enhances the ability of B2B buyers to choose the right custom leather stamp logo for their needs, ensuring both quality and brand integrity in their products.

Illustrative image related to custom leather stamp logo

Navigating Market Dynamics and Sourcing Trends in the custom leather stamp logo Sector

What Are the Key Market Dynamics and Trends in the Custom Leather Stamp Logo Sector?

The custom leather stamp logo sector is witnessing significant growth driven by various global factors. A surge in artisanal leather goods and personalization trends is propelling demand, particularly among small to medium enterprises (SMEs) and startups. International buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly looking for unique branding solutions that reflect their cultural identities and values. This has fostered a shift toward custom, high-quality leather stamps that can be tailored to specific designs and applications.

Emerging technologies, such as CNC milling and laser engraving, are revolutionizing production methods, allowing for precision and speed in creating custom stamps. These technologies facilitate rapid prototyping, enabling businesses to test designs before committing to larger orders. Furthermore, the rise of e-commerce platforms has made it easier for international buyers to source custom leather stamps, reducing lead times and increasing accessibility to suppliers across the globe.

As sustainability becomes a critical consideration, buyers are increasingly seeking suppliers who prioritize eco-friendly practices. This trend is especially pronounced in Europe, where stringent regulations on materials and processes are influencing sourcing decisions. B2B buyers are now more inclined to partner with manufacturers who can demonstrate a commitment to sustainable practices, including the use of vegetable-tanned leather and responsible sourcing of raw materials.

How Is Sustainability and Ethical Sourcing Impacting the Custom Leather Stamp Logo Market?

In today’s market, sustainability and ethical sourcing are not merely buzzwords; they are essential components of the B2B landscape for custom leather stamp logos. Environmental concerns surrounding the leather industry, such as water usage, chemical pollution, and animal welfare, have prompted buyers to prioritize suppliers that adhere to ethical practices. This trend is particularly relevant for international buyers who wish to enhance their brand reputation through responsible sourcing.

Illustrative image related to custom leather stamp logo

Buyers are increasingly interested in materials that are certified as environmentally friendly, such as vegetable-tanned leather, which avoids harmful chemicals typically used in conventional tanning processes. Certifications like the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming benchmarks for buyers to assess the sustainability of their suppliers.

Moreover, the demand for transparency in supply chains is growing. B2B buyers are looking for manufacturers who can provide documentation and proof of sustainable practices, ensuring that their products align with their own corporate social responsibility (CSR) goals. By prioritizing sustainability, businesses can not only reduce their ecological footprint but also appeal to a consumer base that increasingly values ethical practices.

What Is the Historical Context of Custom Leather Stamps for B2B Buyers?

The custom leather stamp industry has evolved significantly over the years, transitioning from traditional hand-carving techniques to modern manufacturing processes. Historically, leather stamping was a labor-intensive craft, primarily utilized by artisans and small leather goods makers. With the advent of technology in the 20th century, methods such as CNC machining and laser engraving began to emerge, allowing for higher precision and efficiency.

Illustrative image related to custom leather stamp logo

This evolution has democratized access to high-quality custom leather stamps, enabling businesses of all sizes to brand their products effectively. Today, the market is characterized by a blend of artisanal craftsmanship and technological innovation, catering to a diverse range of applications from fashion to functional leather goods. As the sector continues to grow, understanding its historical context can help B2B buyers appreciate the quality and craftsmanship that goes into creating custom leather stamps, ultimately guiding their sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamp logo

-

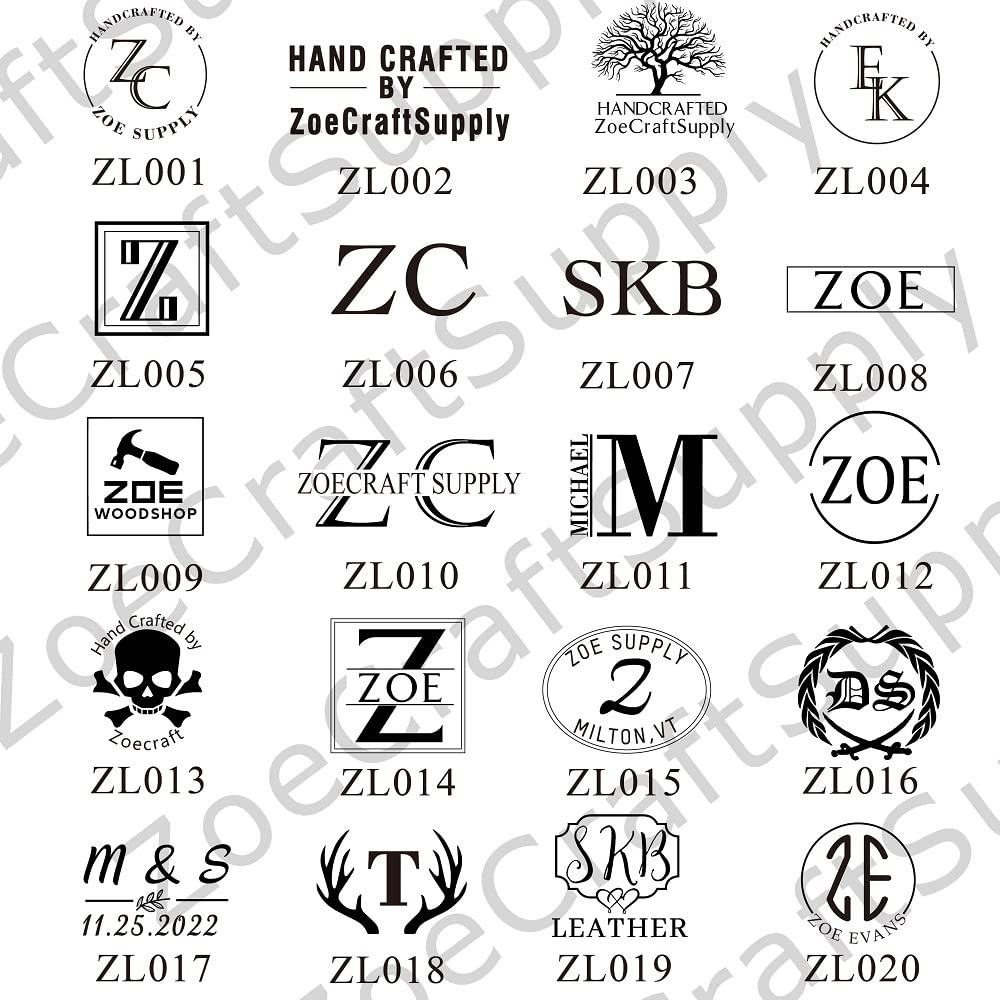

How do I choose the right custom leather stamp logo for my business?

Selecting the appropriate custom leather stamp logo requires understanding your branding needs and the types of leather you’ll be working with. Consider factors like the size of the stamp, the design intricacy, and the material of the stamp—brass is often preferred for its durability and resistance to rust. Collaborate with suppliers who can guide you in designing a logo that aligns with your brand identity and is suitable for your specific leather type, whether it’s vegetable-tanned or chrome-tanned leather. -

What is the typical turnaround time for custom leather stamps?

The production time for custom leather stamps varies by supplier, but many offer expedited services. Generally, you can expect a standard turnaround of 2-3 working days for production. If you require rush orders, some suppliers may provide next-day shipping for an additional fee. Always confirm the expected delivery times with the supplier before placing your order to ensure it aligns with your project deadlines. -

What are the minimum order quantities (MOQs) for custom leather stamps?

Minimum order quantities for custom leather stamps can vary significantly by supplier. Some may allow single-unit orders, while others may have MOQs of 5-10 units, particularly for custom designs. If you’re a small business or just starting, look for suppliers that offer flexible MOQ options. Always clarify this aspect during your initial communication to avoid unexpected costs. -

What payment terms should I expect when ordering custom leather stamps?

Payment terms for custom leather stamps typically include upfront payment, especially for first-time orders. Some suppliers may offer net terms (e.g., net 30) for repeat customers or larger orders. Be sure to discuss payment methods accepted, such as credit cards, bank transfers, or trade financing options, to find a solution that works for your business’s financial processes. -

How can I ensure the quality of my custom leather stamp?

To guarantee the quality of your custom leather stamp, work with reputable suppliers known for their craftsmanship. Request samples or previous work examples to assess their quality. Additionally, ask about their manufacturing processes and quality assurance measures. A supplier that offers a satisfaction guarantee or allows revisions before finalizing the design is also a good indicator of their commitment to quality. -

What factors should I consider when vetting suppliers for custom leather stamps?

When vetting suppliers, assess their experience, reputation, and customer reviews. Look for suppliers with a proven track record in producing custom leather stamps and those who can handle international shipping efficiently. Additionally, inquire about their production capabilities, lead times, and after-sales support. Establishing communication with potential suppliers can also provide insights into their responsiveness and customer service. -

Are there specific regulations for importing custom leather stamps into my country?

Import regulations for custom leather stamps can vary by country, so it’s essential to research the specific requirements for your region. In general, check for any customs duties, import taxes, and necessary documentation, such as invoices or certificates of origin. Engaging with a customs broker can streamline the process and ensure compliance with local regulations, helping to avoid delays in shipment. -

What customization options are available for leather stamps?

Customization options for leather stamps are extensive and can include size, shape, material, and design. Most suppliers can create stamps based on your specific artwork or logo, and they often accept various file formats, including vector files. Consider whether you want additional features, such as heat embossing capabilities or the inclusion of handles for ease of use. Discuss your specific needs with the supplier to tailor the stamp to your exact requirements.

Top 7 Custom Leather Stamp Logo Manufacturers & Suppliers List

1. LW Leathers – Custom Leather Stamp

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Custom Leather Stamp”, “regular_price”: “US$68.00”, “size_options”: [“Up to 1.25 x 1.25 inch / 3 x 3 cm”, “Up to 1.5 x 1.5 inch / 4 x 4 cm”, “Up to 2 x 2 inch / 5 x 5 cm”, “Up to 3 x 3 inch / 7.5 x 7.5 cm”, “Up to 4 x 4 inch / 10 x 10 cm”], “production_lead_time”: “2-5 working days”, “rush_order_option”: “Next working day (additional cost applies)”, “applications”: [“Leather embo…

2. Infinity Stamps – Custom Brass & Steel Stamps

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: This company, Infinity Stamps – Custom Brass & Steel Stamps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Custom Leather Stamps – Durable Branding Solutions

Domain: buckeyeengraving.com

Registered: 2015 (10 years)

Introduction: Custom leather stamps, dies, and brands for leather stamping and embossing needs. Made from aluminum, steel, or brass. Aluminum stamps are cost-effective; brass is popular for durability and rust resistance. Customization options available for artwork, logos, and designs. Heavy-duty removable steel handle for hand stamps; press stamps include only the engraved stamp face. Hand-made in the USA. Sui…

4. Leather Stamp Maker – Custom Brass Stamps

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Leather & Custom Brass Stamps by Leather Stamp Maker. All custom stamps ship next business day. Made in the USA. Custom brass stamps, cutting dies, lettersets, and more. Custom stamps are CNC milled from solid brass, available up to 1″ thickness and custom size. Compatible with branding irons and standard presses. Custom leather cutting dies made from solid steel, usable with mechanical, hydraulic…

5. Tandy Leather – Custom Logo Stamps

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Custom Logo Stamps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Steel Stamps Inc – Custom Leather Stamps

Domain: steelstampsinc.com

Registered: 2009 (16 years)

Introduction: Custom Leather Stamps are available from Steel Stamps Inc. The collection includes various types of custom stamps designed for leatherwork, including specialized designs such as Sheridan flowers/leaves, state stamps, and jewelry design stamps. The company also offers a range of other custom stamps for different applications, including steel stamps for knife makers, blacksmiths, farriers, and locks…

7. Leatherstampstools – Custom Leather Stamps

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom leather stamps, good price point, quality stamp, options from Leatherstampstools on Etsy, Springfield Leather, leatherstampmaker, and TyraCraftTools. Prices mentioned include $55 for a 2.5 cm x 5 cm stamp.

Strategic Sourcing Conclusion and Outlook for custom leather stamp logo

In the competitive landscape of custom leather stamp logos, strategic sourcing is paramount for B2B buyers seeking to enhance their branding efforts. High-quality, custom leather stamps not only ensure a lasting impression on products but also reflect the craftsmanship and authenticity of your brand. The ability to source stamps made from durable materials, such as solid brass or steel, allows for versatility across various leather types, whether for embossing or stamping.

Moreover, the swift turnaround times offered by manufacturers—often as quick as 2-3 business days—enable businesses to meet tight deadlines without compromising quality. Engaging with suppliers who understand your specific needs and can assist in design development adds significant value to your sourcing strategy.

As international markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for customized branding solutions will only increase. Now is the time to leverage these opportunities and establish strong partnerships with reliable manufacturers. Embrace the potential of custom leather stamps to elevate your brand presence and secure a competitive edge in your market. Start your sourcing journey today, and watch your brand leave a lasting mark.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather stamp logo