Introduction: Navigating the Global Market for washing chamois cloth

In the rapidly evolving global market, sourcing high-quality washing chamois cloth presents a significant challenge for international B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe. With a diverse range of products available—from genuine leather to synthetic alternatives—selecting the right chamois cloth requires careful consideration of factors like absorbency, durability, and maintenance. This guide offers a comprehensive overview of the various types of chamois cloth, their applications across different industries, and essential tips for vetting suppliers and managing costs effectively.

By delving into the specifics of washing chamois cloth, this resource aims to empower B2B buyers with the knowledge necessary to make informed purchasing decisions. We will explore the benefits of using chamois cloth in automotive care, household cleaning, and other specialized applications, highlighting the importance of proper care and maintenance to extend product life. Additionally, this guide addresses key considerations for international procurement, such as compliance with regional standards and best practices for shipping and logistics.

Whether you are looking to enhance your product offerings or ensure the best quality for your clients, understanding the nuances of washing chamois cloth will enable you to navigate the complexities of the market with confidence and efficiency.

Table Of Contents

- Top 7 Washing Chamois Cloth Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for washing chamois cloth

- Understanding washing chamois cloth Types and Variations

- Key Industrial Applications of washing chamois cloth

- 3 Common User Pain Points for ‘washing chamois cloth’ & Their Solutions

- Strategic Material Selection Guide for washing chamois cloth

- In-depth Look: Manufacturing Processes and Quality Assurance for washing chamois cloth

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘washing chamois cloth’

- Comprehensive Cost and Pricing Analysis for washing chamois cloth Sourcing

- Alternatives Analysis: Comparing washing chamois cloth With Other Solutions

- Essential Technical Properties and Trade Terminology for washing chamois cloth

- Navigating Market Dynamics and Sourcing Trends in the washing chamois cloth Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of washing chamois cloth

- Strategic Sourcing Conclusion and Outlook for washing chamois cloth

- Important Disclaimer & Terms of Use

Understanding washing chamois cloth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Leather Chamois | Made from natural animal hide, highly absorbent and durable | Automotive detailing, luxury car care | Pros: Long lifespan, excellent absorbency; Cons: Higher cost, requires careful maintenance. |

| Synthetic Chamois | Made from artificial materials, typically less expensive | General car cleaning, household use | Pros: Cost-effective, easy to maintain; Cons: Less absorbent, shorter lifespan compared to leather. |

| Microfiber Chamois | Hybrid materials that combine microfiber and chamois traits | Versatile cleaning, automotive and home | Pros: Highly versatile, effective for various surfaces; Cons: May not achieve the same streak-free finish as leather. |

| Heavy-Duty Chamois | Thicker, designed for industrial use and heavy cleaning | Commercial vehicle fleets, industrial settings | Pros: Durable, designed for tough jobs; Cons: Bulkier, may be overkill for standard applications. |

| Eco-Friendly Chamois | Made from recycled materials, biodegradable options available | Sustainable businesses, eco-conscious consumers | Pros: Environmentally friendly, promotes sustainability; Cons: May have varying performance based on material quality. |

What are the characteristics of Genuine Leather Chamois and their suitability for B2B buyers?

Genuine leather chamois is crafted from natural animal hides, renowned for its exceptional absorbency and durability. This type is ideal for high-end automotive detailing, where a streak-free finish is paramount. B2B buyers should consider the initial investment against the long-term value, as proper care can extend the lifespan significantly. Businesses in luxury car care or detailing services will find that genuine leather chamois enhances the quality of their service, justifying the higher cost.

How does Synthetic Chamois compare in terms of cost and maintenance?

Synthetic chamois offers a more budget-friendly alternative to genuine leather, made from artificial materials that mimic absorbency. This type is commonly used for general car cleaning and household applications, making it suitable for businesses that require a cost-effective solution without sacrificing too much on performance. While synthetic chamois is easier to maintain and can be washed in machines, buyers should be aware that it typically has a shorter lifespan and may not provide the same level of absorbency or finish quality as leather options.

What advantages do Microfiber Chamois provide for diverse cleaning tasks?

Microfiber chamois combines the absorbency of traditional chamois with the versatility of microfiber materials. This type is particularly popular in various cleaning applications, from automotive to household use. B2B buyers appreciate the multifunctionality of microfiber chamois, as they can be employed for washing, drying, and polishing surfaces. However, while they are effective, they may not achieve the same streak-free results as leather chamois, making it essential for buyers to assess their specific cleaning needs when selecting this option.

Illustrative image related to washing chamois cloth

When should Heavy-Duty Chamois be considered for industrial applications?

Heavy-duty chamois is designed for rigorous use, making it suitable for industrial environments and commercial vehicle fleets. Its thicker construction allows it to withstand demanding cleaning tasks without degradation. B2B buyers in sectors such as transportation and logistics will find this option beneficial for maintaining large vehicles and equipment. However, the bulkiness of heavy-duty chamois may not be necessary for standard cleaning applications, so businesses should evaluate their specific requirements before purchasing.

What are the benefits of Eco-Friendly Chamois for sustainable businesses?

Eco-friendly chamois is crafted from recycled or biodegradable materials, appealing to businesses focused on sustainability. This type supports environmentally conscious practices while still providing effective cleaning capabilities. B2B buyers in sectors that prioritize eco-friendliness can leverage eco-friendly chamois to enhance their brand image and meet consumer demand for sustainable products. However, performance can vary based on material quality, so it is crucial for buyers to assess the effectiveness of these options before integrating them into their cleaning protocols.

Key Industrial Applications of washing chamois cloth

| Industry/Sector | Specific Application of washing chamois cloth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Detailing | Drying and polishing vehicles | Ensures a streak-free finish, enhancing customer satisfaction | Quality of chamois (genuine leather vs. synthetic), absorption capacity, and durability |

| Hospitality and Cleaning | Maintenance of high-end fixtures and surfaces | Provides a spotless clean, essential for guest experience | Availability in bulk, ease of cleaning, and long-lasting performance |

| Industrial Manufacturing | Cleaning machinery and equipment | Prevents corrosion and maintains operational efficiency | Compatibility with various surfaces, resistance to harsh chemicals, and ease of maintenance |

| Marine and Boating | Drying and maintaining boats and equipment | Protects surfaces from water spots and corrosion | Resistance to saltwater, UV protection, and durability in harsh environments |

| Home Appliances | Cleaning glass and stainless steel surfaces | Achieves a high-shine finish without streaks | Versatility for different materials, ease of cleaning, and size options for various tasks |

How is washing chamois cloth used in automotive detailing?

In the automotive detailing industry, washing chamois cloth is essential for drying and polishing vehicles after washing. Its high absorbency allows for quick moisture removal, ensuring that surfaces are left streak-free and ready for waxing or polishing. This not only enhances the aesthetic appeal of the vehicle but also helps prevent water spots that can damage paintwork. B2B buyers in this sector should prioritize the quality of the chamois, considering genuine leather for durability and effectiveness, especially in regions like Europe where high-quality vehicle care is paramount.

What role does washing chamois cloth play in hospitality and cleaning?

In the hospitality sector, washing chamois cloth is utilized for maintaining high-end fixtures, glass surfaces, and stainless steel appliances. The cloth’s ability to provide a streak-free finish is crucial in creating a clean and polished environment that enhances the guest experience. For international buyers, especially in regions such as Africa and South America, sourcing chamois cloth in bulk can lead to cost efficiencies. Buyers should also consider the ease of cleaning and the longevity of the cloth to ensure it meets the demands of daily use in a busy hospitality setting.

How is washing chamois cloth beneficial in industrial manufacturing?

In industrial manufacturing, washing chamois cloth is employed to clean machinery and equipment, preventing the buildup of moisture that can lead to corrosion and operational inefficiencies. Its absorbent nature allows for effective drying, which is critical in maintaining equipment performance. Buyers in this sector should look for chamois that are resistant to harsh chemicals, ensuring they can be used safely across various manufacturing environments. The durability of the cloth is also a key consideration, particularly for businesses looking to minimize replacement costs.

Why is washing chamois cloth important for marine and boating applications?

For the marine and boating industry, washing chamois cloth is used to dry boats and maintain equipment, protecting surfaces from water spots and corrosion caused by saltwater exposure. The cloth’s effectiveness in achieving a high-shine finish is vital for both aesthetic and protective purposes. Buyers in this sector should seek chamois that offer UV protection and durability in harsh marine environments. Sourcing options should include suppliers that understand the specific needs of marine applications, ensuring that the cloth can withstand the rigors of boating life.

How does washing chamois cloth enhance cleaning of home appliances?

In home appliance maintenance, washing chamois cloth is ideal for cleaning glass surfaces and stainless steel, delivering a streak-free shine that enhances the appearance of kitchen and bathroom fixtures. Its versatility allows it to be used effectively on various surfaces, making it a valuable tool for both residential and commercial cleaning operations. International buyers should focus on the cloth’s ease of cleaning and size options, ensuring they can meet diverse cleaning needs efficiently. The longevity of the cloth also contributes to its cost-effectiveness in high-use environments.

3 Common User Pain Points for ‘washing chamois cloth’ & Their Solutions

Scenario 1: Difficulty in Properly Cleaning Chamois Cloths

The Problem: B2B buyers often face challenges when it comes to maintaining the integrity of their chamois cloths. Improper cleaning methods can lead to a decline in performance, resulting in streaks or damage to surfaces during use. For businesses reliant on high-quality finishes, such as automotive detailing services, the consequences of using a poorly maintained chamois can be detrimental to customer satisfaction and the company’s reputation.

The Solution: To address this issue, it is crucial to establish a standardized cleaning protocol for chamois cloths. Buyers should source high-quality, car wash-specific soaps that gently cleanse without stripping essential oils from the cloth. After each use, chamois cloths should be thoroughly rinsed in lukewarm water to remove dirt and debris, followed by a gentle wash with the chosen soap. It’s essential to avoid harsh chemicals, including bleach and ammonia, which can compromise the cloth’s integrity. Additionally, after cleaning, wring out the cloth completely and allow it to dry away from direct sunlight. Implementing these steps can significantly extend the lifespan of chamois cloths, ensuring they continue to deliver optimal performance.

Illustrative image related to washing chamois cloth

Scenario 2: Streaks and Lint Left Behind After Use

The Problem: Many B2B buyers report that their chamois cloths leave streaks or lint on surfaces after drying. This issue can be particularly problematic in sectors like automotive detailing or high-end home cleaning services where the appearance of the finished product is paramount. Streaks can indicate poor cleaning, leading to dissatisfaction from clients and potential loss of business.

The Solution: To prevent streaks and lint, it is advisable to invest in genuine leather chamois cloths over synthetic alternatives, which may not perform as well. Before initial use, buyers should wash the new chamois in lukewarm water with mild soap to remove any residual tanning oils that can lead to streaking. Each time before use, the chamois should be dampened and wrung out to enhance its absorbency. When drying surfaces, it is beneficial to use a technique that involves pulling the cloth across the surface in a consistent, straight motion to maximize contact and absorption. Regularly washing and maintaining the chamois will ensure its fibers remain intact and effective for streak-free finishes.

Scenario 3: Limited Knowledge on Chamois Cloth Usage

The Problem: B2B buyers often lack comprehensive knowledge about the optimal uses of chamois cloths, leading to underutilization or misuse. This can result in inefficiencies and poor results in various applications, from automotive detailing to cleaning high-gloss surfaces in commercial settings. Without proper guidance, businesses may fail to leverage the full potential of these versatile tools.

The Solution: To overcome this knowledge gap, companies should provide detailed training and resources on the various applications of chamois cloths. Highlighting the cloth’s strengths, such as its super absorbency and ability to achieve a streak-free finish, can encourage proper usage. For instance, during training sessions, demonstrate how to effectively use chamois cloths for drying vehicles, cleaning windows, and polishing chrome surfaces. Additionally, creating a user manual that outlines best practices and maintenance tips can serve as a valuable resource for employees. By fostering a better understanding of chamois cloth applications, businesses can enhance their operational efficiency and improve overall service quality.

Illustrative image related to washing chamois cloth

Strategic Material Selection Guide for washing chamois cloth

What Materials Are Commonly Used for Washing Chamois Cloth?

When selecting materials for washing chamois cloth, it is essential to consider various factors that impact performance, durability, and cost. Here, we analyze four common materials used in the production of chamois cloth, providing insights specifically for international B2B buyers.

How Does Genuine Leather Perform in Chamois Cloth Applications?

Genuine leather, traditionally sourced from sheep or goat skin, is renowned for its superior absorbency and durability. This material can withstand high temperatures and pressures, making it suitable for rigorous cleaning applications. However, it requires careful maintenance to prevent deterioration from harsh chemicals or improper drying methods.

Pros: Genuine leather chamois cloths offer excellent absorbency, resulting in a streak-free finish. They have a long lifespan when properly cared for, making them a cost-effective investment over time.

Cons: The high cost of genuine leather can be a barrier for some buyers. Additionally, the manufacturing process is complex, requiring skilled labor and adherence to strict quality standards.

Impact on Application: Genuine leather chamois is ideal for automotive and high-end cleaning applications where performance is critical. However, buyers must ensure compliance with environmental regulations regarding leather sourcing.

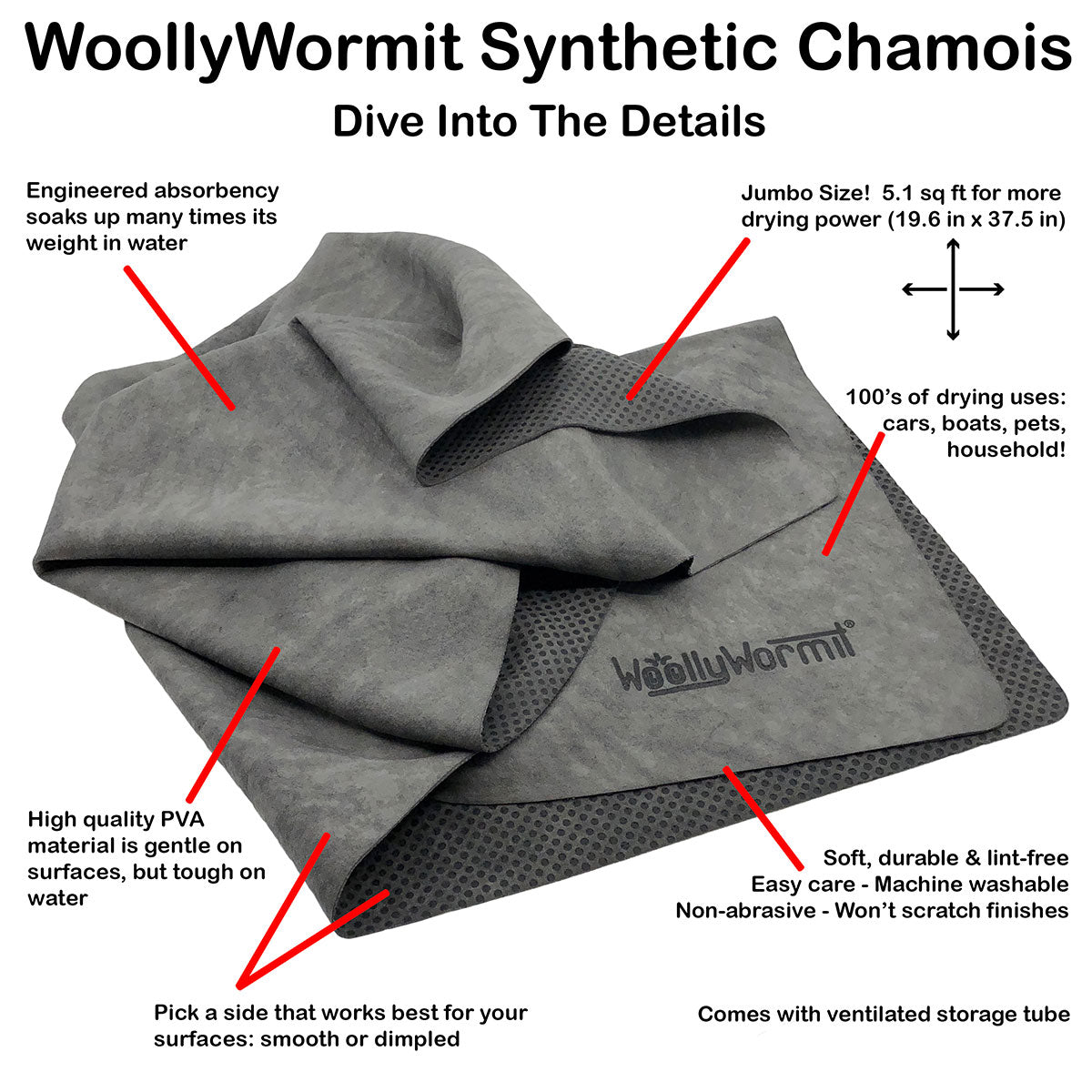

What Are the Benefits of Synthetic Chamois Cloths?

Synthetic chamois cloths, often made from materials like polyurethane or PVC, have gained popularity due to their affordability and ease of use. These materials are engineered to mimic the absorbency of genuine leather while being more resistant to chemicals and easier to clean.

Pros: Synthetic chamois cloths are lightweight, cost-effective, and can be produced in bulk with less complexity than leather. They also dry quickly and are resistant to mold and mildew.

Cons: While synthetic options are durable, they may not achieve the same level of absorbency or streak-free finish as genuine leather. Additionally, their lifespan may be shorter, leading to more frequent replacements.

Impact on Application: Synthetic chamois is suitable for general cleaning tasks and can be a good option for businesses looking to minimize costs. However, buyers should be aware of the potential environmental impact of synthetic materials.

Illustrative image related to washing chamois cloth

How Do Microfiber Cloths Compare for Washing Chamois Applications?

Microfiber cloths are made from a blend of polyester and polyamide, known for their exceptional cleaning capabilities. They are highly effective at trapping dirt and dust, making them a popular choice for both automotive and household applications.

Pros: Microfiber cloths are versatile and can be used for various cleaning tasks beyond drying, such as polishing and applying wax. They are also machine washable, which simplifies maintenance.

Cons: Microfiber is less absorbent than chamois cloths, requiring more effort to dry surfaces effectively. They can also become waterlogged quickly, reducing their efficiency during use.

Impact on Application: Microfiber cloths are suitable for businesses that require a multi-functional cleaning solution. However, they may not meet the specific needs of buyers looking for optimal drying performance.

What Role Does Cotton Play in Chamois Cloth Production?

Cotton chamois cloths, often blended with other materials, offer a softer touch and are commonly used in household cleaning. They are less absorbent than leather or synthetic options but provide a gentle cleaning surface.

Illustrative image related to washing chamois cloth

Pros: Cotton is a natural material that is biodegradable and environmentally friendly. It is generally less expensive than leather and synthetic options, making it accessible for various buyers.

Cons: Cotton chamois cloths may not perform as well in high-absorbency applications and can wear out more quickly than other materials. They also require careful washing to maintain their integrity.

Impact on Application: Cotton chamois is suitable for light-duty cleaning tasks, particularly in households. However, buyers should consider the limitations in absorbency and durability for more demanding applications.

Summary Table of Material Selection for Washing Chamois Cloth

| Material | Typical Use Case for washing chamois cloth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end automotive cleaning | Superior absorbency and durability | High cost and complex manufacturing | High |

| Synthetic | General cleaning tasks | Cost-effective and easy to clean | Less absorbent than genuine leather | Medium |

| Microfiber | Versatile cleaning applications | Multi-functional and machine washable | Less absorbent, can become waterlogged | Medium |

| Cotton | Household cleaning | Biodegradable and affordable | Limited absorbency and durability | Low |

This strategic material selection guide offers a comprehensive overview for B2B buyers, enabling informed decisions tailored to their specific cleaning needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for washing chamois cloth

What Are the Main Stages of Manufacturing Washing Chamois Cloth?

The manufacturing process of washing chamois cloth is a meticulous journey that ensures the final product meets high-quality standards and customer expectations. This process can be broken down into several key stages: material preparation, forming, assembly, and finishing.

Illustrative image related to washing chamois cloth

How Is Material Prepared for Chamois Cloth Production?

The first stage involves sourcing and preparing the raw materials. Traditionally, chamois cloth is made from the skins of goats or sheep. However, synthetic alternatives are increasingly popular due to their affordability and versatility. The material preparation phase includes:

-

Sourcing: High-quality leather or synthetic materials are sourced from reputable suppliers who adhere to ethical practices. This is crucial for ensuring the integrity of the end product.

-

Tanning: For genuine leather, the tanning process is vital. It involves treating the raw skins with tannins to preserve them and enhance their durability. Vegetable tanning is preferred for its eco-friendliness, while chrome tanning is quicker but may involve more chemicals.

-

Cleaning and Conditioning: The leather is thoroughly cleaned to remove any residual oils or impurities that could affect its performance. Conditioning agents are then applied to maintain suppleness.

What Techniques Are Used in Forming and Assembly?

The next phase, forming, involves cutting the prepared materials into the desired shapes and sizes. This is often done using precision cutting tools to ensure uniformity. Key techniques include:

-

Cutting: The leather or synthetic material is cut into sheets based on specifications. This can be automated for efficiency and consistency.

-

Sewing or Bonding: For products that require edges to be finished or additional layers to be bonded, sewing or adhesive bonding techniques are employed. This ensures that the chamois cloth maintains its structure during use.

-

Quality Checks During Assembly: Throughout the assembly process, quality control checkpoints are established to catch any defects early. This includes visual inspections and testing for flexibility and absorbency.

How Is the Finishing Process Conducted?

Finishing is the final stage of production and is crucial for enhancing the aesthetic and functional properties of the chamois cloth. This stage includes:

Illustrative image related to washing chamois cloth

-

Surface Treatment: Depending on the intended use, additional treatments such as waterproofing or anti-bacterial coatings may be applied. This is particularly relevant for chamois used in automotive applications.

-

Final Inspection: Each batch of chamois cloth undergoes a thorough inspection to ensure it meets the required standards for quality, performance, and appearance.

-

Packaging: The finished products are packaged in a way that protects them during shipping while also providing information on care and maintenance to end-users.

What Quality Assurance Standards Are Relevant for Chamois Cloth?

Quality assurance is critical in the manufacturing of washing chamois cloth, ensuring that the products meet international standards and customer expectations. Several standards and practices guide this process.

Which International Standards Should Buyers Look For?

-

ISO 9001: This is the most recognized quality management standard globally. It ensures that manufacturers have consistent processes in place to enhance customer satisfaction.

-

CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: Although primarily used in the oil and gas industry, certain API standards can apply to the chemical treatments used in the manufacturing process.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining product quality throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards before processing.

-

In-Process Quality Control (IPQC): During production, regular checks are performed to monitor adherence to production specifications. This includes assessing the cutting precision and assembly integrity.

-

Final Quality Control (FQC): After finishing, a final inspection is conducted to evaluate the overall quality of the chamois cloth, checking for defects, absorbency, and durability.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in international markets such as Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential. Here are some actionable strategies:

Illustrative image related to washing chamois cloth

-

Conduct Supplier Audits: Periodic audits can provide insight into the supplier’s manufacturing processes, quality control practices, and adherence to international standards.

-

Request Quality Control Reports: Suppliers should be able to provide documentation detailing their QC processes, inspection results, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s products before shipment. This is particularly useful in ensuring that the products meet the required specifications.

What Are the Nuances of QC and Certification for International Buyers?

B2B buyers must navigate various nuances related to quality control and certification when sourcing chamois cloth internationally:

-

Understanding Local Regulations: Different regions may have specific regulations regarding product safety and environmental impact. Familiarizing yourself with these regulations can help avoid compliance issues.

-

Cultural Considerations: Building strong relationships with suppliers can enhance trust and communication. Understanding cultural differences can also facilitate smoother negotiations and collaborations.

-

Language Barriers: Ensure that documentation and communication are clear. Using professional translation services can help mitigate misunderstandings related to quality specifications.

-

Sustainability Practices: Increasingly, buyers are looking for suppliers who demonstrate a commitment to sustainable practices. Inquire about the environmental impact of the manufacturing process and the sourcing of materials.

In summary, understanding the manufacturing processes and quality assurance measures for washing chamois cloth is essential for B2B buyers seeking reliable suppliers. By focusing on these areas, buyers can ensure they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘washing chamois cloth’

In the competitive landscape of chamois cloth procurement, ensuring quality and compliance is paramount for B2B buyers. This guide provides a structured checklist for sourcing and washing chamois cloth effectively, aimed at enhancing product longevity and performance.

Illustrative image related to washing chamois cloth

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the chamois cloth you intend to procure. Consider factors such as material type (natural vs. synthetic), size, absorbency, and intended use (automotive, household, etc.). These specifications will help you communicate your needs effectively to suppliers and ensure you receive products that meet your operational requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for companies with a proven track record in the chamois cloth market. Focus on their production capabilities, quality control processes, and compliance with international standards.

- Tip: Utilize platforms such as trade shows, industry directories, and business networks to gather insights and recommendations.

Step 3: Request Samples for Evaluation

Before finalizing any procurement, always request samples. Testing samples allows you to assess the quality, absorbency, and durability of the chamois cloth firsthand. This step is crucial to determine if the product meets your specifications and performance expectations.

Illustrative image related to washing chamois cloth

- Consider: Evaluate how the cloth performs under various conditions, such as drying a vehicle or cleaning surfaces.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications that validate their manufacturing processes. Look for certifications related to quality management (ISO 9001), environmental management (ISO 14001), and product safety standards. This verification helps mitigate risks associated with non-compliance and ensures product quality.

Step 5: Assess Production Capacity and Lead Times

Understanding the supplier’s production capacity and lead times is essential for planning your supply chain effectively. Inquire about their ability to meet your order volumes and delivery schedules. This is particularly important for businesses operating in regions with fluctuating demand.

- Important: Discuss contingency plans for delays to ensure your operations remain unaffected.

Step 6: Establish Clear Payment Terms and Conditions

Negotiate clear and mutually agreeable payment terms with your supplier. This includes discussing payment methods, invoicing procedures, and any potential discounts for bulk purchases. Transparent financial arrangements can prevent misunderstandings and foster a solid working relationship.

Step 7: Implement a Quality Control Process Post-Purchase

Once you’ve procured the chamois cloth, implement a quality control process to monitor its performance and condition. Regularly assess the cloth for signs of wear, staining, or degradation. This proactive approach ensures that you maintain high standards in your operations and can address any issues promptly.

By following these steps, B2B buyers can streamline their sourcing process for washing chamois cloth, ensuring they select high-quality products that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for washing chamois cloth Sourcing

What Are the Key Cost Components in Sourcing Washing Chamois Cloth?

When analyzing the cost structure of washing chamois cloth, several components contribute to the overall price.

-

Materials: The primary cost driver is the type of material used. Genuine leather chamois, made from goat or sheep skin, tends to be significantly more expensive than synthetic alternatives. The quality of the leather, including its tanning process, affects pricing. High-quality, well-tanned leather will incur higher costs but offers better durability and performance.

-

Labor: The labor cost varies based on the region and the complexity of the manufacturing process. Skilled labor is often required for leather processing and quality control, especially for genuine chamois. In regions where labor costs are lower, such as some parts of Africa and South America, manufacturers may offer more competitive pricing.

-

Manufacturing Overhead: Overhead costs include utilities, facility maintenance, and other operational expenses. Efficient manufacturing processes can help reduce these costs, impacting the final price.

-

Tooling: Investment in specialized machinery for cutting, shaping, and finishing chamois cloth can also add to costs. If a supplier uses advanced technology for production, this may reflect in higher prices but could also lead to better quality and consistency.

-

Quality Control (QC): Ensuring that each piece of chamois meets quality standards is crucial, especially for high-end markets. QC processes can add to the cost, but they are essential for maintaining brand reputation and customer satisfaction.

-

Logistics: Transportation and shipping costs can vary significantly based on the supplier’s location and the destination market. International shipping, tariffs, and customs fees must be factored into the total cost.

-

Margin: Suppliers will include a profit margin, which can vary based on market competition, brand strength, and perceived value.

What Influences Prices for Washing Chamois Cloth?

Several factors influence the pricing of washing chamois cloth:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQ), and larger orders can lead to better pricing due to economies of scale.

-

Specifications/Customization: Customization options, such as size, thickness, and branding, can affect the price. Tailoring products to specific customer needs may incur additional costs.

-

Materials and Quality/Certifications: Higher quality materials and certifications (e.g., eco-friendly or sustainable sourcing) will typically command higher prices. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly impact the total cost. Terms that place more responsibility on the buyer for logistics and insurance may lead to lower initial prices but higher overall costs.

What Tips Can Help Buyers in Negotiating Prices for Washing Chamois Cloth?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, the following tips can enhance negotiation outcomes:

-

Understand Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider long-term costs such as maintenance, durability, and replacement frequency. A higher upfront investment in quality chamois cloth may yield savings over time.

-

Leverage Volume Discounts: If feasible, consolidate orders to meet MOQ requirements and negotiate bulk pricing.

-

Research Market Prices: Familiarize yourself with average market prices for chamois cloth. This knowledge will empower you during negotiations and help identify fair pricing.

-

Consider Local Suppliers: Explore sourcing from local manufacturers to reduce shipping costs and lead times. Additionally, local suppliers may offer more favorable terms due to lower logistics expenses.

-

Negotiate Payment Terms: Flexible payment terms can ease cash flow concerns and should be a part of any negotiation strategy.

Conclusion

When sourcing washing chamois cloth, understanding the cost components and price influencers is crucial for making informed purchasing decisions. By employing strategic negotiation tactics, buyers can secure competitive pricing while ensuring they receive quality products that meet their needs. Always remember that prices can vary widely, and it’s essential to verify the credibility of suppliers and the quality of their offerings before finalizing any agreements.

Alternatives Analysis: Comparing washing chamois cloth With Other Solutions

When evaluating cleaning solutions, particularly for drying and detailing vehicles, it’s essential to consider various alternatives to washing chamois cloths. Each option has unique benefits and drawbacks that can influence decision-making for B2B buyers, especially in regions with diverse automotive care needs such as Africa, South America, the Middle East, and Europe.

| Comparison Aspect | Washing Chamois Cloth | Microfiber Towel | Cotton Towel |

|---|---|---|---|

| Performance | Highly absorbent, streak-free results | Versatile, good absorbency, but not as effective as chamois | Moderate absorbency, prone to linting |

| Cost | Higher initial investment for genuine leather | Affordable, widely available | Low cost, easily sourced |

| Ease of Implementation | Requires preparation and maintenance | Ready to use, minimal prep | Readily available, no special care needed |

| Maintenance | Requires careful washing and drying | Machine washable, durable | Machine washable, less durable |

| Best Use Case | Ideal for drying vehicles and achieving a high shine | Great for various cleaning tasks, including applying wax | Suitable for general cleaning, but may leave lint |

What Are the Pros and Cons of Microfiber Towels Compared to Chamois Cloths?

Microfiber towels are a popular alternative to washing chamois cloths due to their versatility. They are effective for various cleaning applications, including washing, drying, and applying wax or polish. Microfiber’s synthetic fibers can trap dirt and dust, making them excellent for cleaning surfaces without scratching. However, they are not as absorbent as chamois, meaning they may require more passes to dry a vehicle fully. Additionally, microfibers can become saturated quickly, diminishing their drying capabilities over time.

Illustrative image related to washing chamois cloth

How Do Cotton Towels Stack Up Against Chamois Cloths?

Cotton towels are another option but generally offer lower performance compared to chamois cloths. While they are affordable and easy to find, cotton towels often leave lint behind, which can mar the finish of a vehicle. Their absorbency is moderate, and they are not specifically designed for automotive detailing, making them less effective for achieving streak-free results. Cotton towels can be useful for general cleaning tasks but fall short when it comes to specialized drying applications.

Conclusion: Which Solution is Right for Your Needs?

Choosing the right cleaning solution depends on specific needs, budget, and the desired outcomes. For B2B buyers focused on high-quality automotive care, investing in genuine washing chamois cloths may be the best choice due to their superior absorbency and ability to deliver a streak-free finish. However, for more versatile applications and a lower cost, microfiber towels offer a practical alternative, while cotton towels can serve basic cleaning purposes. Understanding these alternatives allows buyers to make informed decisions that align with their operational requirements and customer expectations.

Essential Technical Properties and Trade Terminology for washing chamois cloth

What Are the Key Technical Properties of Chamois Cloth?

When considering chamois cloth for various applications, several technical properties are vital for B2B buyers. Understanding these specifications can significantly influence purchasing decisions and ensure the longevity and effectiveness of the product.

1. Material Grade

Chamois cloths can be made from genuine leather (sheep or goat skin) or synthetic materials. Genuine leather offers superior absorbency and durability, making it ideal for high-end applications such as automotive detailing. Synthetic alternatives are often more affordable but may lack the same performance qualities. Buyers should evaluate their needs and budget when selecting between these material grades.

2. Absorbency Rate

The absorbency rate indicates how much moisture the chamois can hold relative to its weight. High-quality chamois cloths can absorb several times their weight in water, making them excellent for drying surfaces without streaks. For B2B applications, especially in automotive and industrial cleaning, this property is crucial as it impacts efficiency and effectiveness.

Illustrative image related to washing chamois cloth

3. Durability and Lifespan

Durability is a critical property that reflects how well the chamois withstands repeated use and cleaning cycles. Genuine leather chamois, when properly maintained, can last for years, reducing replacement costs over time. Buyers should consider the expected lifespan in relation to their usage frequency to determine the overall value of the investment.

4. Tolerance to Chemicals

Chamois cloths are sensitive to harsh chemicals. The tolerance of the material to various cleaning agents is essential, especially for B2B applications involving automotive or industrial cleaning. Using the wrong type of soap or cleaner can degrade the chamois, leading to increased costs and reduced performance. Buyers should ensure that the chamois is compatible with their cleaning products.

5. Weight and Thickness

The weight and thickness of chamois cloth can influence its performance. Heavier and thicker chamois are typically more absorbent and durable, but they may also be more cumbersome to handle. A balance between weight and usability should be considered, especially in environments where ease of use is paramount.

What Are Common Trade Terms Related to Chamois Cloth?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some key terms relevant to chamois cloth procurement:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of chamois cloth, it could relate to suppliers who provide chamois for automotive manufacturers or cleaning equipment brands. Knowing OEM partners can ensure buyers receive high-quality, compatible products.

2. MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and purchasing decisions. Understanding MOQ can help businesses negotiate better terms and manage stock levels effectively.

3. RFQ (Request for Quotation)

An RFQ is a document issued when an organization wants to receive pricing and other relevant information from suppliers. When sourcing chamois cloth, businesses should prepare an RFQ that outlines their specific requirements, including material, size, and quantity, to ensure they receive accurate and competitive offers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and ensure smooth cross-border transactions for chamois products.

5. Lead Time

Lead time refers to the time between placing an order and receiving the product. Understanding lead times is crucial for inventory planning and ensuring that businesses have adequate supplies of chamois cloth when needed. Buyers should discuss lead times with suppliers to align with their operational needs.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions, optimize their procurement processes, and ultimately enhance their operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the washing chamois cloth Sector

What Are the Key Market Trends Affecting the Washing Chamois Cloth Sector?

The washing chamois cloth market is witnessing dynamic shifts driven by several global factors. Increased consumer awareness of vehicle maintenance and care is propelling demand for high-quality chamois cloths, particularly in emerging markets across Africa, South America, and the Middle East. These regions are experiencing a surge in vehicle ownership, which creates a robust need for effective cleaning solutions. Moreover, the rise of e-commerce platforms is transforming traditional sourcing methods, allowing international B2B buyers to access a wider range of suppliers and products, often at competitive prices.

Technological advancements are also influencing the chamois cloth sector. Manufacturers are investing in innovative production techniques to improve the absorbency and durability of chamois materials, including the development of synthetic alternatives that mimic the qualities of traditional leather. This trend is particularly relevant for cost-conscious buyers who seek effective solutions without compromising quality. Additionally, there is a growing trend toward customization, where businesses can order chamois cloths tailored to specific needs, such as size, texture, and branding.

Furthermore, the ongoing shift towards sustainable practices is reshaping sourcing strategies. Buyers are increasingly prioritizing suppliers who adhere to environmentally responsible manufacturing processes, signaling a potential pivot towards greener alternatives in the chamois cloth market.

How Is Sustainability and Ethical Sourcing Impacting B2B Practices in the Washing Chamois Cloth Sector?

Sustainability has become a cornerstone of B2B sourcing practices in the washing chamois cloth sector. The environmental impact of traditional chamois production—especially those derived from animal hides—has prompted buyers to seek alternatives that minimize ecological footprints. The rise of synthetic chamois cloths, which can be produced with less environmental degradation, presents a viable solution for businesses looking to align with green initiatives.

Illustrative image related to washing chamois cloth

Ethical sourcing is increasingly prioritized among international buyers, particularly in markets like Africa and South America, where local communities are often affected by manufacturing practices. Buyers are urged to scrutinize their supply chains for transparency, ensuring that materials are sourced responsibly and that workers are treated fairly. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® can serve as benchmarks for evaluating the sustainability of chamois cloths.

Moreover, businesses that embrace ethical sourcing not only enhance their brand reputation but also appeal to a growing segment of environmentally conscious consumers. This shift in purchasing behavior underscores the importance of integrating sustainability into procurement strategies to remain competitive in today’s market.

What Is the Historical Context of the Washing Chamois Cloth Industry?

The history of chamois cloth dates back centuries, originally crafted from the skins of chamois goats, which were prized for their exceptional absorbency and softness. Over time, the production of chamois cloth evolved, with leather being replaced by synthetic alternatives in response to rising costs and ethical considerations regarding animal welfare.

The introduction of synthetic chamois cloths in the latter half of the 20th century marked a significant shift, allowing for greater affordability and accessibility. Today, the market includes a diverse range of products, from traditional leather to high-performance synthetic materials, catering to various applications beyond automotive care, such as household cleaning and industrial uses.

Illustrative image related to washing chamois cloth

As global demand continues to grow, the washing chamois cloth sector remains poised for innovation and sustainability, reflecting broader trends in consumer preferences and ethical responsibility.

Frequently Asked Questions (FAQs) for B2B Buyers of washing chamois cloth

-

How do I ensure the quality of washing chamois cloth before purchasing?

To ensure quality, request samples from potential suppliers to assess the texture, absorbency, and durability of the chamois cloth. Check for certifications that validate the material’s authenticity, especially for genuine leather options. Additionally, research customer reviews and testimonials about the supplier’s previous deliveries and product performance. Establish clear communication regarding your quality standards and ask for detailed product specifications to avoid any discrepancies. -

What factors should I consider when selecting a supplier for washing chamois cloth?

When selecting a supplier, consider their industry experience, product quality, and production capacity. Evaluate their compliance with international standards and certifications, such as ISO or ASTM. Investigate their ability to provide customization options, including size, thickness, and packaging. Assess their responsiveness and willingness to collaborate on logistics, as well as their payment terms and reliability in shipping timelines, particularly for international transactions. -

What is the best material for washing chamois cloth used in automotive care?

The best material for washing chamois cloth in automotive care is genuine leather, particularly from sheep or goat skin. These natural chamois are known for their superior absorbency and ability to provide a streak-free finish. However, high-quality synthetic chamois can also be effective and more cost-efficient for regular use. Always consider the intended application and the balance between performance and budget when making a decision. -

How can I customize washing chamois cloth for my brand?

To customize washing chamois cloth for your brand, collaborate with your supplier to discuss your specific requirements, such as size, color, and branding options. Many suppliers offer embroidery or printed logos on the cloth, which can enhance brand visibility. Be clear about your minimum order quantities (MOQ) and any additional costs associated with customization. Ensure that the final product aligns with your brand identity and target market preferences. -

What are the typical payment terms for international purchases of washing chamois cloth?

Payment terms can vary widely based on the supplier and the specifics of your transaction. Common options include advance payment, letters of credit, or payment upon delivery. It’s crucial to negotiate terms that protect both parties, ensuring that you can verify product quality before full payment. Discuss potential escrow services for larger transactions to mitigate risks. Always confirm accepted payment methods, including wire transfers and credit cards, as part of your agreement. -

What logistics considerations should I keep in mind when importing washing chamois cloth?

When importing washing chamois cloth, consider shipping costs, delivery timelines, and customs regulations in your country. Collaborate with your supplier to determine the best shipping methods, whether by air or sea, based on your urgency and budget. Ensure that all necessary import documentation is prepared, including invoices, packing lists, and any required certifications. Familiarize yourself with any tariffs or duties that may apply to your shipment to avoid unexpected costs. -

How can I effectively communicate my requirements to a supplier for washing chamois cloth?

To effectively communicate your requirements, provide a detailed specification sheet that outlines the desired material, dimensions, absorbency levels, and any customization needs. Use clear language and include visual aids, such as photos or diagrams, to illustrate your expectations. Establish regular communication channels, whether through email or video calls, to discuss progress and address any concerns. Building a strong relationship with your supplier can facilitate better understanding and cooperation. -

What should I know about quality assurance for washing chamois cloth?

Quality assurance is crucial to ensure that the washing chamois cloth meets your standards. Implement a quality control process that includes inspecting samples before bulk orders and conducting random checks on received shipments. Request detailed reports from your supplier regarding their quality assurance practices, including testing for absorbency, durability, and the absence of harmful chemicals. Establish clear return and complaint policies to handle any issues with substandard products effectively.

Top 7 Washing Chamois Cloth Manufacturers & Suppliers List

1. Tanner’s Select – Chamois Care Guide

Domain: tannersselect.com

Registered: 2017 (8 years)

Introduction: Proper care and maintenance of a chamois significantly extends its life and performance. Instructions are provided on product packaging. To prepare a chamois for use, wash it in lukewarm water with mild car soap to remove residual tanning oils, avoiding degreasing soaps, harsh chemicals, or laundry detergents. After washing, rinse until the water is clear and hang to dry in the shade. A dry chamoi…

2. AutoGeek – Synthetic Chamois & Microfiber Waffle Weave Towel

Domain: autogeekonline.net

Registered: 2006 (19 years)

Introduction: 1. Synthetic Chamois: Mentioned as a type of chamois, specifically a ‘black magic chamois’ similar to the Absorber. 2. Microfiber Waffle Weave Drying Towel: Recommended as a safer alternative to chamois for drying cars. It is machine washable, does not trap debris, and can be washed with an anti-bacterial wash. 3. The Ultimate Guzzler Waffle Weave Microfiber Drying Towel: Described as pricey but w…

3. Carrand – 45076 Microfuse Towels

Domain: largeformatphotography.info

Introduction: Carrand 45076 Microfuse Towels – infused with microfiber, designed for lens cleaning, tough and non-tearing, can be stored in a zip-lok bag.

4. PeachParts – Leather Chamois Care

Domain: peachparts.com

Registered: 2009 (16 years)

Introduction: Leather chamois should be cleaned with mild soap or leather cleaner. For stubborn stains, use liquid dish soap directly on the chamois fibers. Rinse thoroughly after cleaning. It is recommended to wash the chamois in warm water and mild liquid dish soap for 3 to 4 minutes. The chamois should be used only after the car has been washed thoroughly to avoid scratching the paint. New leather chamois sh…

5. Meguiar’s – Natural Leather Chamois

Domain: meguiarsonline.com

Registered: 2003 (22 years)

Introduction: Natural leather chamois requires storage in airtight containers to prevent it from turning into a hard piece of cardboard and developing unpleasant odors. It should be rinsed after use and hung to dry completely, as storing it wet or damp can lead to rot and mildew. Synthetic chamois are easier to care for and can be hung to dry; they become stiff when dry but regain softness when wet. Some users …

6. Window Cleaner – Chamois Challenges

Domain: community.windowcleaner.com

Registered: 1998 (27 years)

Introduction: This company, Window Cleaner – Chamois Challenges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Swedespeed – Premium Car Care Towels

Domain: swedespeed.com

Registered: 1999 (26 years)

Introduction: $4 chenille cotton mit, $12 medium sized chamois, micro-fiber towels, synthetic chamois called the Absorber, big blue microfiber towel, natural sponge, sheepskin mit.

Strategic Sourcing Conclusion and Outlook for washing chamois cloth

In the competitive landscape of washing chamois cloth, strategic sourcing plays a pivotal role in ensuring quality, cost-effectiveness, and sustainability. By understanding the nuances of chamois care and maintenance, B2B buyers can enhance their product offerings while maximizing the longevity and performance of these essential tools. Proper sourcing of high-quality chamois, whether genuine leather or synthetic alternatives, will not only meet customer expectations but also reduce replacement costs over time.

Investing in education around the proper use and maintenance of chamois cloth is vital. This knowledge empowers buyers to position themselves as industry experts, fostering trust and loyalty among their clientele. Furthermore, as global markets evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, there is a growing demand for sustainable and efficient cleaning solutions.

As we look to the future, international B2B buyers are encouraged to explore partnerships that prioritize quality and sustainability in their sourcing strategies. By aligning with reliable manufacturers and suppliers, companies can not only improve their bottom line but also contribute to a more sustainable cleaning industry. Embrace the opportunity to elevate your product line and meet the rising expectations of environmentally-conscious consumers.

Illustrative image related to washing chamois cloth

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.