Introduction: Navigating the Global Market for polyurethane leather fabric

In the ever-evolving landscape of global textiles, sourcing high-quality polyurethane leather fabric presents a unique challenge for international B2B buyers. As businesses seek durable, versatile, and cost-effective materials for various applications—from automotive upholstery to commercial furniture—understanding the nuances of PU leather becomes paramount. This guide aims to illuminate the complexities of the polyurethane leather market, equipping buyers with essential insights into types, applications, supplier vetting processes, and cost considerations.

By delving into the multifaceted world of polyurethane leather fabric, this comprehensive resource empowers businesses, particularly those operating in Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—to make informed purchasing decisions. The guide not only outlines the advantages of PU leather over traditional materials, such as its affordability and ease of maintenance, but also addresses potential drawbacks, ensuring a balanced perspective for discerning buyers.

With a focus on actionable insights and strategic sourcing techniques, this guide is designed to facilitate smarter procurement practices. Whether you’re looking to enhance your product offerings or streamline supply chain operations, understanding the attributes and market dynamics of polyurethane leather fabric will enable you to navigate the complexities of this vibrant sector with confidence.

Table Of Contents

- Top 6 Polyurethane Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for polyurethane leather fabric

- Understanding polyurethane leather fabric Types and Variations

- Key Industrial Applications of polyurethane leather fabric

- 3 Common User Pain Points for ‘polyurethane leather fabric’ & Their Solutions

- Strategic Material Selection Guide for polyurethane leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane leather fabric’

- Comprehensive Cost and Pricing Analysis for polyurethane leather fabric Sourcing

- Alternatives Analysis: Comparing polyurethane leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for polyurethane leather fabric

- Navigating Market Dynamics and Sourcing Trends in the polyurethane leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane leather fabric

- Strategic Sourcing Conclusion and Outlook for polyurethane leather fabric

- Important Disclaimer & Terms of Use

Understanding polyurethane leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PU Leather | Soft, flexible, and closely resembles genuine leather | Furniture upholstery, automotive interiors, fashion accessories | Pros: Cost-effective, easy to clean; Cons: Less durable over time compared to genuine leather. |

| Bicast Leather | Genuine leather base with a polyurethane coating | High-end furniture, luxury automotive interiors | Pros: Combines genuine leather feel with affordability; Cons: May not be fully vegan; susceptible to wear. |

| Vegan Leather | 100% synthetic, made from thermoplastic polymers | Eco-friendly fashion, upholstery for vegan-conscious brands | Pros: Animal-friendly, diverse styles; Cons: Can look synthetic, less breathable. |

| Split Leather | Made from leftover leather scraps, coated with PU | Budget-friendly furniture, commercial applications | Pros: Utilizes waste materials, affordable; Cons: Durability concerns, may lack premium feel. |

| Corrected Grain Leather | Coated with PU for a uniform appearance | Upholstery in commercial settings, automotive applications | Pros: Consistent look, affordable; Cons: Lacks the natural texture of genuine leather. |

What are the Characteristics of PU Leather?

PU leather, or polyurethane leather, is a widely used synthetic alternative to genuine leather. Its soft, flexible nature makes it ideal for various applications, particularly in furniture upholstery and automotive interiors. B2B buyers should consider its cost-effectiveness and ease of maintenance, as PU leather is resistant to stains and water, making it a practical choice for high-traffic areas. However, it may not offer the same durability as genuine leather over the long term, which could impact its lifecycle in demanding environments.

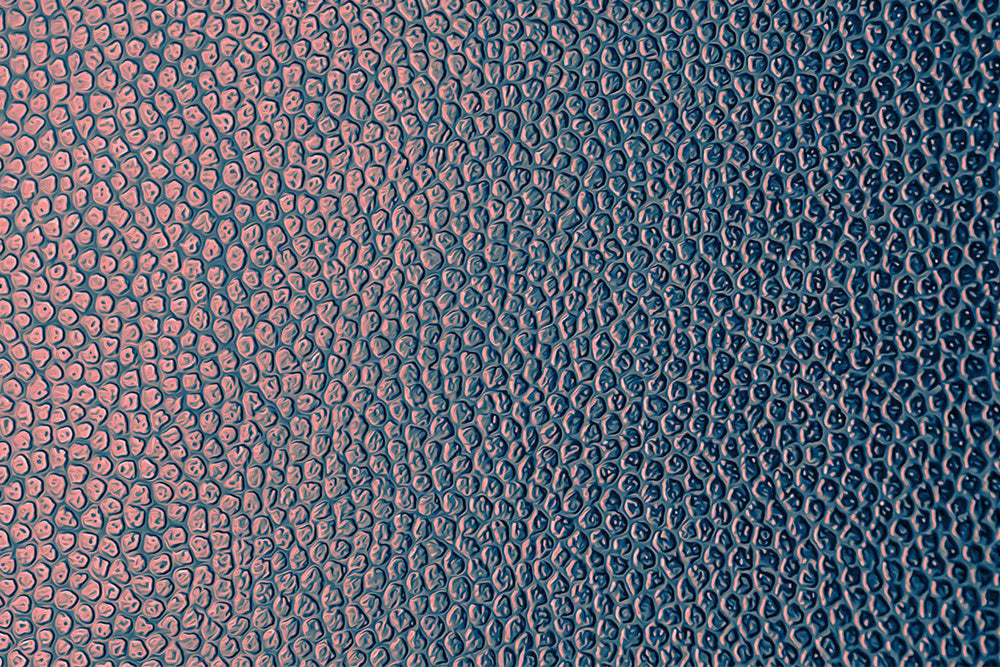

Illustrative image related to polyurethane leather fabric

How Does Bicast Leather Differ from Other Variants?

Bicast leather is unique as it combines genuine leather with a polyurethane coating, providing a luxurious feel at a lower price point. This type is often used in high-end furniture and luxury automotive interiors. B2B buyers should note that while it retains some characteristics of real leather, it may not be entirely vegan, as it utilizes genuine leather scraps. The appeal lies in its aesthetic quality, but businesses should be aware of potential durability issues, especially in high-use settings.

What Makes Vegan Leather an Attractive Option for Businesses?

Vegan leather is composed entirely of synthetic materials, making it an appealing choice for brands focused on sustainability and animal welfare. It is widely used in eco-friendly fashion and upholstery for businesses that cater to vegan consumers. While it offers a variety of styles and colors, B2B buyers should consider that some options may appear synthetic and lack breathability. Despite these drawbacks, the growing demand for sustainable products makes vegan leather a viable option for forward-thinking companies.

Why Choose Split Leather for Budget-Conscious Projects?

Split leather is created from leftover pieces of genuine leather, coated with polyurethane to enhance its durability and appearance. This cost-effective option is often used in budget-friendly furniture and commercial applications. B2B buyers should weigh the affordability against potential durability concerns, as split leather may not offer the same premium feel or longevity as higher-end alternatives. Nonetheless, it provides a practical solution for projects requiring a leather-like aesthetic without the associated costs.

What are the Benefits of Corrected Grain Leather?

Corrected grain leather features a uniform surface due to a polyurethane coating, making it an excellent choice for commercial upholstery and automotive applications. This type of leather offers a consistent appearance and is typically more affordable than full-grain leather. For B2B buyers, the main considerations include its aesthetic appeal and cost-effectiveness. However, it may lack the natural texture and character found in genuine leather, which could be a deciding factor for brands emphasizing authenticity in their products.

Key Industrial Applications of polyurethane leather fabric

| Industry/Sector | Specific Application of polyurethane leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for residential and commercial furniture | Cost-effective, durable, and easy-to-clean alternative to genuine leather | Ensure compliance with local safety standards and regulations |

| Automotive | Interior seating and trim materials for vehicles | Lightweight, water-resistant, and customizable for design needs | Seek suppliers with experience in automotive-grade materials |

| Marine | Upholstery for boat seats and cushions | Resistant to moisture and UV light, enhancing longevity in harsh environments | Verify resistance to saltwater and mold for marine applications |

| Fashion | Production of bags, shoes, and apparel | Eco-friendly, versatile, and available in diverse styles and colors | Look for sustainable sourcing practices and certifications |

| Healthcare | Upholstery for medical furniture and equipment | Easy to clean, antimicrobial properties, and durability for high-use environments | Ensure compliance with health and safety regulations |

How is Polyurethane Leather Fabric Used in Furniture Manufacturing?

In the furniture manufacturing sector, polyurethane leather fabric is extensively used for upholstery in both residential and commercial settings. This material offers a cost-effective alternative to genuine leather while providing similar aesthetic appeal and durability. It solves the problem of high maintenance associated with real leather, as PU leather is easy to clean and resistant to stains. For international buyers, especially in Africa and South America, sourcing PU leather requires careful consideration of local regulations regarding fire safety and environmental impact, ensuring compliance with relevant standards.

What Role Does Polyurethane Leather Play in the Automotive Industry?

In the automotive industry, polyurethane leather fabric is utilized for interior seating and trim materials, providing a lightweight option that does not compromise on style or comfort. Its water-resistant properties make it ideal for use in various climates, particularly in regions prone to humidity, such as parts of the Middle East. Buyers should focus on finding suppliers with experience in automotive-grade materials, ensuring that the PU leather meets specific durability and safety requirements mandated by the automotive sector.

How is Polyurethane Leather Fabric Beneficial in Marine Applications?

Polyurethane leather is an excellent choice for marine upholstery, specifically for boat seats and cushions. Its resistance to moisture and UV light significantly enhances the longevity of marine furnishings, making it a practical option for boat manufacturers. Additionally, it addresses concerns related to mold and mildew, which are common in marine environments. Buyers in Europe and Africa should prioritize suppliers who can provide materials that meet rigorous marine standards, ensuring safety and durability in their products.

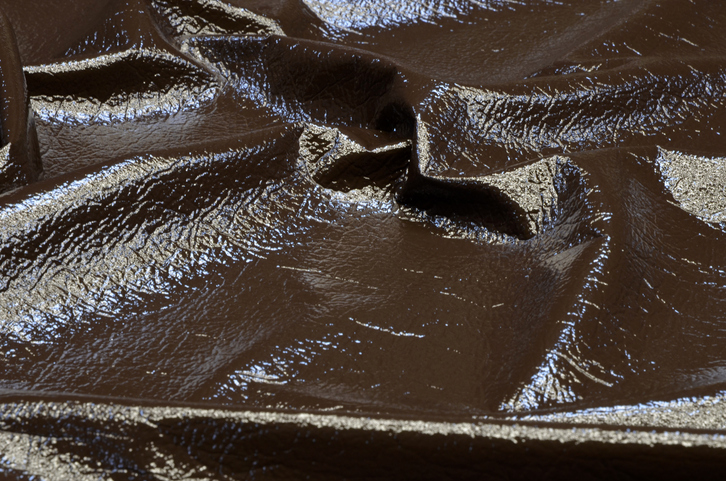

Illustrative image related to polyurethane leather fabric

Why Choose Polyurethane Leather for Fashion Products?

In the fashion industry, polyurethane leather fabric is favored for producing bags, shoes, and apparel due to its eco-friendly nature and versatility. This material can be manufactured in a variety of colors and styles, allowing designers to create unique products that appeal to a broad audience. For international buyers, especially in markets like Europe, it is crucial to seek suppliers who adhere to sustainable sourcing practices and have certifications that guarantee the ethical production of PU leather.

How Does Polyurethane Leather Enhance Healthcare Furniture?

In healthcare settings, polyurethane leather fabric is increasingly used for upholstery on medical furniture and equipment. Its easy-to-clean surface and antimicrobial properties are essential for maintaining hygiene in high-use environments. This application addresses the challenge of sanitation in healthcare facilities, which is especially critical in regions like Africa and South America where healthcare standards are evolving. Buyers should ensure that the PU leather complies with health and safety regulations, facilitating a safer environment for patients and staff alike.

3 Common User Pain Points for ‘polyurethane leather fabric’ & Their Solutions

Scenario 1: Difficulty in Distinguishing Quality PU Leather

The Problem:

For B2B buyers, especially those in furniture manufacturing or automotive upholstery, sourcing high-quality polyurethane leather can be challenging. With numerous suppliers using different terminologies and variations, distinguishing between low-grade and premium PU leather becomes a daunting task. This uncertainty can lead to purchasing materials that don’t meet durability standards or fail to provide the desired aesthetic, resulting in increased costs due to replacements or customer dissatisfaction.

The Solution:

To effectively source quality PU leather, buyers should establish clear criteria for what constitutes “premium” PU leather in their specific applications. This includes understanding the difference between 100% PU leather and options that may incorporate other materials, such as bicast leather. Buyers should request detailed specifications from suppliers, including information on the thickness, backing material, and chemical treatments used. Additionally, visiting suppliers’ showrooms or requesting samples can provide valuable insights into the texture, appearance, and quality of the PU leather. By educating themselves on these factors, buyers can make informed decisions and ensure that their purchases align with their product quality standards.

Scenario 2: Managing Environmental Concerns with PU Leather

The Problem:

As sustainability becomes a crucial focus in global markets, B2B buyers face pressure to choose materials that align with eco-friendly practices. Although PU leather is often marketed as a vegan alternative to genuine leather, many buyers are unaware of the environmental impact of its production and disposal. This can lead to reputational risks for businesses that do not adequately address these concerns, especially in regions where consumers prioritize sustainability.

The Solution:

To mitigate environmental concerns, B2B buyers should seek suppliers that provide comprehensive information on the sustainability practices involved in their PU leather production. This includes looking for certifications or eco-labels that indicate adherence to sustainable manufacturing processes. Buyers can also explore options for recycled PU leather, which utilizes post-consumer waste in its production. Engaging in discussions with suppliers about their waste management practices and end-of-life solutions for PU leather products can further enhance a company’s sustainability profile. By prioritizing eco-friendly sourcing, businesses can better align with consumer expectations and reduce their environmental footprint.

Scenario 3: Challenges with Maintenance and Durability of PU Leather

The Problem:

B2B buyers often encounter issues related to the long-term maintenance and durability of polyurethane leather, especially in high-use environments like commercial furniture or automotive interiors. While PU leather is marketed as easy to clean and maintain, the reality can differ, with some products cracking or fading over time, leading to costly repairs and replacements. This inconsistency can create frustration for businesses that rely on the material for their products.

The Solution:

To ensure the durability and maintainability of PU leather, buyers should prioritize sourcing products specifically designed for high-traffic applications. This includes selecting PU leather that has been treated for enhanced abrasion resistance and UV protection. Buyers can also implement a regular maintenance schedule that includes using appropriate cleaning agents and methods to prolong the life of the material. Training staff on proper care techniques can further enhance the longevity of PU leather products. Additionally, establishing a relationship with suppliers who offer warranties or guarantees can provide an added layer of security against premature wear and tear. By taking these proactive measures, businesses can effectively manage the challenges associated with PU leather maintenance and durability.

Strategic Material Selection Guide for polyurethane leather fabric

What Are the Key Materials Used in Polyurethane Leather Fabric?

When considering polyurethane leather fabric for various applications, it’s essential to evaluate the materials used in its production. Here, we analyze four common materials, focusing on their properties, advantages and disadvantages, and implications for international B2B buyers.

1. Polyurethane (PU) Coating

Key Properties:

Polyurethane coatings are thermoplastic polymers that provide a soft, flexible surface. They are resistant to water, stains, and mildew, making them suitable for various environments. PU coatings can also withstand moderate temperatures and pressures, which is crucial for applications in automotive and furniture upholstery.

Pros & Cons:

The primary advantage of PU coatings is their affordability compared to genuine leather, often costing up to 75% less. They are easy to clean and maintain, contributing to their popularity. However, PU can be less durable than real leather, as it may crack or wear over time, especially in high-traffic areas.

Impact on Application:

PU coatings are ideal for applications requiring a leather-like appearance without the associated costs. They are compatible with various media, including upholstery and automotive interiors, but may not perform well in extreme conditions.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding material safety and environmental standards. For example, European buyers might refer to DIN standards, while those in the Middle East and Africa should consider local certifications.

Illustrative image related to polyurethane leather fabric

2. Polyester Backing

Key Properties:

Polyester is often used as a backing material for PU leather, providing structural integrity. It exhibits good tensile strength and is resistant to stretching and shrinking. Polyester can also withstand a range of temperatures, making it versatile for different applications.

Pros & Cons:

Polyester backing enhances the durability of PU leather, making it suitable for heavy-use environments. However, it can be less breathable than natural fibers, which may lead to discomfort in warmer climates. Additionally, while polyester is generally cost-effective, high-quality variants can be more expensive.

Impact on Application:

The combination of PU coating and polyester backing is particularly effective for furniture and automotive upholstery, where durability and aesthetics are paramount. However, buyers should be cautious about moisture retention, which could affect longevity.

Illustrative image related to polyurethane leather fabric

Considerations for International Buyers:

Buyers from regions with high humidity, such as parts of Africa and South America, should ensure that the polyester backing is treated for moisture resistance to prevent mold and mildew.

3. PVC (Polyvinyl Chloride)

Key Properties:

PVC is a synthetic plastic polymer known for its robustness and chemical resistance. It can be formulated to be flexible or rigid, depending on the application. PVC is also water-resistant and can withstand various environmental conditions.

Pros & Cons:

PVC is often less expensive than PU, making it a cost-effective alternative. However, it is less environmentally friendly and can emit harmful chemicals during production. Additionally, PVC lacks the softness and flexibility of PU leather, which may limit its use in high-end applications.

Impact on Application:

PVC is commonly used in applications requiring high durability, such as marine upholstery and outdoor furniture. Its chemical resistance makes it suitable for environments where exposure to harsh substances is likely.

Considerations for International Buyers:

International buyers should be aware of the environmental regulations surrounding PVC use, particularly in Europe, where stricter guidelines may apply. Compliance with ASTM and JIS standards is also vital for ensuring product quality.

4. Recycled Materials

Key Properties:

Recycled materials, including recycled polyurethane and polyester, are increasingly used in the production of faux leather. These materials offer a sustainable alternative, reducing waste and resource consumption.

Pros & Cons:

The key advantage of using recycled materials is their lower environmental impact, appealing to eco-conscious consumers. However, the quality can vary significantly based on the source of the recycled materials, potentially affecting durability and performance.

Impact on Application:

Recycled PU leather can be used in various applications, from fashion to furniture. Its sustainability credentials can enhance brand image, particularly in markets prioritizing eco-friendliness.

Considerations for International Buyers:

Buyers should verify the source and quality of recycled materials, ensuring compliance with local sustainability standards. This is particularly important in European markets, where consumers are increasingly demanding transparency in sourcing.

Summary Table

| Material | Typical Use Case for polyurethane leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Coating | Automotive upholstery, furniture | Affordable and easy to clean | Less durable than genuine leather | Low |

| Polyester Backing | Furniture, automotive interiors | Enhances durability | Less breathable than natural fibers | Med |

| PVC | Marine upholstery, outdoor furniture | Cost-effective | Less environmentally friendly | Low |

| Recycled Materials | Fashion, eco-friendly furniture | Lower environmental impact | Variable quality | Med |

This strategic material selection guide provides B2B buyers with valuable insights into the materials used in polyurethane leather fabric, enabling informed purchasing decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane leather fabric

What Are the Main Stages of Manufacturing Polyurethane Leather Fabric?

The manufacturing process for polyurethane (PU) leather fabric involves several critical stages that ensure the final product meets quality and performance standards. Understanding these stages is essential for B2B buyers looking for reliable suppliers.

Material Preparation: What Raw Materials Are Used?

The first step in the production of PU leather involves sourcing and preparing raw materials. The primary component is the polyurethane polymer, which is combined with a fabric backing, typically made from polyester or cotton. This backing provides the necessary support and durability for the final product. During this stage, suppliers must ensure that the raw materials are of high quality and free from defects. This includes verifying the chemical composition of the polyurethane and the integrity of the fabric backing.

How is PU Leather Formed?

Once the raw materials are prepared, the next stage is forming. This involves applying the polyurethane coating to the fabric backing through various techniques, including:

- Casting: The polyurethane is poured onto the backing material and allowed to cure, creating a uniform layer.

- Coating: This technique involves spreading the polyurethane over the fabric surface, often using rollers or spray systems for an even application.

- Hot Pressing: In some cases, heat and pressure are applied to bond the polyurethane to the backing, enhancing adhesion and durability.

These methods can affect the texture, appearance, and overall quality of the PU leather, making it essential for manufacturers to choose the appropriate technique based on the desired product specifications.

What Happens During the Assembly Stage?

The assembly stage involves cutting the formed PU leather into specific shapes and sizes required for various applications, such as upholstery or fashion items. This may also include adding any additional components, such as zippers or fasteners, if the PU leather is being used for bags or garments. Quality control during this stage is crucial to ensure that the dimensions and finishes meet the specifications provided by B2B clients.

How is Finishing Applied to Enhance Quality?

The finishing process is vital for enhancing the aesthetic and functional properties of PU leather. This may include:

- Embossing: Creating textures that mimic the look of genuine leather.

- Coating: Applying protective topcoats to enhance durability, stain resistance, and ease of cleaning.

- Coloring: Using dyes and pigments to achieve the desired color palette.

Each of these finishing techniques adds value to the product, making it more appealing to end consumers and increasing its marketability.

What Quality Assurance Measures Should B2B Buyers Expect?

Quality assurance (QA) is a critical aspect of the manufacturing process for PU leather. B2B buyers should look for suppliers that adhere to international quality standards to ensure product reliability and safety.

Which International Standards Should Be Considered?

Suppliers should be compliant with relevant international standards, such as:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

B2B buyers should inquire about the supplier’s certifications and quality management practices to ensure compliance.

Illustrative image related to polyurethane leather fabric

What Are the QC Checkpoints in the Manufacturing Process?

Quality control checkpoints should be integrated at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to verify their quality and compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to ensure adherence to quality standards and to identify any defects early.

- Final Quality Control (FQC): A thorough inspection of the finished product to ensure it meets the agreed specifications before shipping.

Implementing these checkpoints helps in minimizing defects and ensuring the delivery of high-quality products to buyers.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is crucial for B2B buyers to mitigate risks associated with product quality. Here are some ways to effectively assess supplier QC:

Illustrative image related to polyurethane leather fabric

What Audits and Reports Should Be Requested?

Buyers should request detailed quality audits and reports from potential suppliers. These documents should outline the supplier’s quality control procedures, inspection results, and any corrective actions taken to address issues. Regular audits can also help in understanding the supplier’s commitment to maintaining quality standards.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspections can verify compliance with international standards and offer insights into the supplier’s manufacturing capabilities. Buyers should consider incorporating third-party inspections into their procurement processes, especially for high-value or critical projects.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in verifying quality control. Factors such as varying regulatory standards, cultural differences in manufacturing practices, and logistical challenges can complicate the procurement process.

How Can Buyers Navigate Regulatory Differences?

Buyers should familiarize themselves with the regulatory requirements in their respective regions and ensure that their suppliers are compliant with both local and international standards. This may involve additional documentation, certifications, and quality checks tailored to specific markets.

Illustrative image related to polyurethane leather fabric

What Cultural Factors Should Be Considered?

Understanding cultural differences in business practices can enhance communication and negotiation with suppliers. Buyers should be aware of varying expectations regarding quality assurance, timelines, and product specifications. Building strong relationships with suppliers based on trust and transparency can lead to more successful long-term partnerships.

Conclusion

The manufacturing processes and quality assurance measures for polyurethane leather fabric are vital considerations for B2B buyers. By understanding the stages of production, recognizing the importance of quality control, and navigating international regulations, buyers can make informed decisions that ensure they receive high-quality PU leather products. Investing time in assessing suppliers and their practices can lead to successful procurement outcomes and long-lasting business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane leather fabric’

Introduction

Sourcing polyurethane leather fabric, often referred to as PU leather, requires a structured approach to ensure that buyers make informed decisions. This guide serves as a practical checklist for B2B buyers to effectively navigate the procurement process, focusing on quality, supplier reliability, and product specifications.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to clearly outline your technical requirements for PU leather. This includes factors such as thickness, texture, color, and intended application (e.g., upholstery, automotive, or marine use). Having defined specifications will help streamline communication with suppliers and ensure that the products meet your business needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in PU leather. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers. Pay attention to their market reputation and customer reviews, as these will provide insight into their reliability and product quality.

Illustrative image related to polyurethane leather fabric

Step 3: Evaluate Supplier Certifications

Once you have shortlisted potential suppliers, it’s critical to verify their certifications. Look for certifications that demonstrate compliance with international standards, such as ISO 9001 for quality management systems or OEKO-TEX for eco-friendly production. These certifications not only validate the supplier’s credibility but also ensure the safety and sustainability of the materials you are sourcing.

Step 4: Request Samples

Before making a bulk order, request samples of the PU leather fabric from your shortlisted suppliers. This allows you to evaluate the material’s quality, texture, and durability firsthand. Assess the samples against your defined specifications and consider factors such as color fastness, flexibility, and ease of cleaning.

Step 5: Negotiate Pricing and Terms

Engage in negotiations regarding pricing, payment terms, and delivery schedules. Understanding the cost structure will help you gauge whether the pricing aligns with your budget while ensuring the supplier can meet your project timelines. Don’t hesitate to ask for discounts on bulk orders or long-term contracts.

Illustrative image related to polyurethane leather fabric

Step 6: Assess Shipping and Logistics

Evaluate the supplier’s shipping and logistics capabilities. Ensure they can provide reliable shipping options that meet your delivery requirements. Discuss shipping costs, lead times, and any potential import duties or tariffs that may apply, especially if you are sourcing from international suppliers.

Step 7: Establish a Quality Assurance Process

After selecting a supplier and placing an order, establish a quality assurance process to monitor the quality of the PU leather fabric upon delivery. This may include inspection for defects, compliance with your specifications, and testing for durability. Implementing a robust QA process will help mitigate risks and ensure that the fabric meets your business standards.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing polyurethane leather fabric efficiently and effectively, ensuring that they select the best materials for their needs.

Comprehensive Cost and Pricing Analysis for polyurethane leather fabric Sourcing

What Are the Key Cost Components in Sourcing Polyurethane Leather Fabric?

When sourcing polyurethane leather fabric, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials, primarily the thermoplastic polymer used in PU leather production, significantly influences pricing. The quality and type of backing fabric also affect costs. For example, higher-quality backing materials will increase the price but may offer better durability and aesthetics.

-

Labor: Labor costs encompass the wages of workers involved in the production process, including cutting, sewing, and finishing the fabric. In regions with higher labor costs, such as Europe, the overall price of PU leather may be elevated compared to countries with lower labor costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, thereby impacting the final price.

-

Tooling: Custom tooling for unique designs or specifications can add to initial costs. Buyers requiring specific textures or patterns should consider these costs when negotiating prices.

-

Quality Control: Implementing rigorous QC processes ensures that the finished products meet required standards. While this may increase manufacturing costs, it ultimately contributes to customer satisfaction and reduces returns.

-

Logistics: Transportation and shipping costs can vary significantly based on the distance between the supplier and the buyer. Incoterms chosen during the transaction will also influence logistics costs, with terms like FOB (Free on Board) or CIF (Cost Insurance and Freight) impacting the buyer’s total expenditure.

-

Margin: Suppliers will typically mark up prices to cover their costs and generate profit. Understanding the market pricing dynamics can help buyers assess if the margins are reasonable.

What Factors Influence the Pricing of Polyurethane Leather Fabric?

Several factors can influence the pricing of polyurethane leather fabric, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically qualify for bulk pricing, which can significantly reduce per-unit costs. Buyers should negotiate MOQs that align with their purchasing capacity and inventory needs.

-

Specifications and Customization: Customized fabrics with specific colors, textures, or patterns may incur additional costs. Buyers must weigh the benefits of customization against budget constraints.

-

Quality and Certifications: Fabrics that meet specific quality standards or certifications (e.g., ISO, REACH) may command higher prices. Buyers should consider the long-term benefits of investing in certified materials.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers may charge a premium due to their perceived quality and service reliability.

How Can B2B Buyers Optimize Their Sourcing Strategy for PU Leather?

To ensure cost-efficiency and value in sourcing polyurethane leather fabric, buyers should consider the following tips:

-

Negotiate Effectively: Understanding market trends and competitor pricing can empower buyers during negotiations. Leveraging bulk orders or long-term contracts can lead to better pricing agreements.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors like durability, maintenance, and potential waste when evaluating costs. High-quality PU leather may have a higher upfront cost but lower long-term maintenance expenses.

-

Understand Pricing Nuances for International Sourcing: International buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of currency fluctuations, import duties, and local regulations that may affect pricing. Knowledge of Incoterms is essential to avoid unexpected costs.

-

Evaluate Multiple Suppliers: Conducting a comprehensive supplier analysis can reveal variations in pricing and quality. Request samples to assess the quality before finalizing orders.

Disclaimer for Indicative Prices

Prices for polyurethane leather fabric can vary widely based on the aforementioned factors. It is advisable for buyers to request quotes from multiple suppliers to obtain a clearer understanding of current market rates. Always consider the total cost of ownership when making procurement decisions.

Alternatives Analysis: Comparing polyurethane leather fabric With Other Solutions

Exploring Alternatives to Polyurethane Leather Fabric

In the ever-evolving landscape of upholstery materials, B2B buyers are increasingly seeking alternatives to polyurethane leather fabric. Understanding these alternatives is crucial for informed decision-making, especially when considering factors such as performance, cost, and sustainability. Below, we compare polyurethane leather fabric with two viable alternatives: genuine leather and PVC (Polyvinyl Chloride) leather.

Comparison Table

| Comparison Aspect | Polyurethane Leather Fabric | Genuine Leather | PVC Leather |

|---|---|---|---|

| Performance | Durable, water-resistant, and easy to clean. | Highly durable, develops a patina over time. | Moderate durability, less flexible than PU. |

| Cost | 75% less than genuine leather. | Premium pricing, often expensive. | Generally low-cost, cheaper than PU. |

| Ease of Implementation | Easy to source and cut; available in various colors. | Requires specialized crafting skills; sourcing can be challenging. | Readily available; easy to work with. |

| Maintenance | Minimal maintenance; easily cleaned with a damp cloth. | Requires regular conditioning and care. | Easy to clean but can fade over time. |

| Best Use Case | Ideal for commercial furniture and automotive upholstery. | Best for high-end furniture and luxury products. | Suitable for budget-friendly projects and temporary uses. |

Detailed Breakdown of Alternatives

Genuine Leather

Genuine leather is often seen as the gold standard in upholstery due to its luxurious feel and durability. It can withstand significant wear and tear, making it a preferred choice for high-end furniture and automotive applications. However, it comes at a premium price point, which may not be feasible for all businesses. Additionally, genuine leather requires regular maintenance, including conditioning to prevent cracking and drying. This ongoing care can add to the overall cost of ownership. While genuine leather develops a unique patina over time, it may not be the best choice for projects with tight budgets or those requiring a more sustainable solution.

PVC Leather

PVC leather, also known as vinyl, is an affordable alternative that is widely used in various industries. It is easy to clean and maintain, making it suitable for high-traffic areas. However, PVC leather lacks the durability and flexibility of polyurethane leather, and it may not perform as well under stress. While it is generally lower in cost, it can fade over time and may not provide the same aesthetic appeal as PU or genuine leather. PVC leather is best suited for temporary applications or projects where budget constraints are a primary concern.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right upholstery material for your business, it’s essential to consider your specific requirements and constraints. Polyurethane leather fabric offers a balanced combination of durability, cost-effectiveness, and ease of maintenance, making it ideal for a wide range of applications. Genuine leather, while luxurious and durable, may not align with budgetary or sustainability goals. On the other hand, PVC leather presents an economical option but may compromise on quality and longevity. By carefully evaluating these alternatives, B2B buyers can make informed decisions that meet their project needs and align with their business objectives.

Essential Technical Properties and Trade Terminology for polyurethane leather fabric

What Are the Key Technical Properties of Polyurethane Leather Fabric?

Understanding the technical properties of polyurethane leather fabric is crucial for B2B buyers to make informed purchasing decisions. Here are several critical specifications to consider:

1. Material Grade

Material grade refers to the quality of the polyurethane used in the fabric. Higher grades typically offer better durability, flexibility, and resistance to wear and tear. For B2B buyers, selecting the appropriate material grade ensures that the final product meets industry standards and customer expectations, especially in sectors like automotive and furniture manufacturing.

2. Thickness

The thickness of polyurethane leather is measured in millimeters (mm) and can significantly impact its application. Thicker materials are often more durable and suitable for high-traffic environments, whereas thinner materials may be more cost-effective for items like fashion accessories. Buyers should assess the intended use to determine the appropriate thickness for their projects.

3. Abrasion Resistance

Abrasion resistance is a measure of how well a material can withstand wear from friction. This property is vital for upholstery and automotive applications where durability is essential. A high abrasion resistance rating indicates that the fabric will last longer and maintain its appearance, reducing the frequency of replacement and repair costs.

4. Water Resistance

Polyurethane leather is inherently water-resistant, making it suitable for applications that may be exposed to moisture, such as outdoor furniture or marine upholstery. Understanding the level of water resistance can help buyers choose the right material for environments where spills and humidity are a concern.

Illustrative image related to polyurethane leather fabric

5. UV Resistance

UV resistance indicates how well the fabric can withstand exposure to sunlight without fading or degrading. This property is particularly important for outdoor applications. Buyers should consider UV resistance to ensure that the upholstery maintains its color and quality over time, thereby minimizing the need for replacement.

6. Flexibility and Softness

Flexibility and softness are crucial for applications where comfort and aesthetics are important, such as clothing and interior upholstery. A supple PU leather mimics the feel of genuine leather, appealing to consumers who prioritize touch and comfort. Buyers should assess these properties to ensure customer satisfaction in their end products.

What Are Common Trade Terms Related to Polyurethane Leather Fabric?

Navigating the world of polyurethane leather fabric involves understanding specific industry terminology. Here are some key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are then marketed by another company under its brand name. For buyers, understanding OEM relationships can be vital for sourcing high-quality PU leather products that meet specific standards and branding requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers manage inventory and production costs effectively. It’s crucial for planning purchases, especially when dealing with various suppliers across different regions.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for a specific quantity of goods or services. B2B buyers use RFQs to obtain competitive pricing and terms from multiple suppliers, allowing them to make informed procurement decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding these terms helps buyers manage logistics and shipping costs effectively, ensuring that the terms of delivery align with their business needs.

5. Lead Time

Lead time is the amount of time from placing an order to receiving the goods. This metric is crucial for planning production schedules and meeting customer deadlines. Buyers should consider lead times when selecting suppliers to ensure timely delivery of polyurethane leather products.

6. Compliance Standards

Compliance standards refer to the regulations that products must meet to be sold in specific markets. For PU leather, this could include environmental regulations and safety standards. Buyers should be aware of these standards to avoid legal issues and ensure that their products are market-ready.

By familiarizing themselves with these properties and terms, B2B buyers can make more informed decisions when sourcing polyurethane leather fabric for their projects, ultimately enhancing their product offerings and market competitiveness.

Illustrative image related to polyurethane leather fabric

Navigating Market Dynamics and Sourcing Trends in the polyurethane leather fabric Sector

What Are the Key Market Dynamics and Trends Affecting Polyurethane Leather Fabric?

The polyurethane leather fabric market is experiencing significant growth, driven by the increasing demand for cost-effective and versatile alternatives to genuine leather. Global trends indicate a rising preference for sustainable materials, particularly in regions like Europe, where consumers are increasingly conscious of environmental issues. The shift towards online sourcing platforms is also notable, allowing international buyers in Africa, South America, and the Middle East to access a wider range of PU leather products.

Technological advancements in manufacturing processes have improved the quality and durability of PU leather, making it harder to differentiate from real leather. Innovations such as eco-friendly coatings and enhanced production methods are emerging, catering to both aesthetic and functional needs of various industries, including automotive, furniture, and fashion. Furthermore, the growth of e-commerce is facilitating the entry of new players into the market, intensifying competition and providing buyers with more options. As a result, international B2B buyers should remain vigilant regarding supplier capabilities, product specifications, and market pricing strategies.

How Is Sustainability Influencing Sourcing Decisions for Polyurethane Leather Fabric?

Sustainability has become a central theme in sourcing decisions for polyurethane leather fabric. The environmental impact of traditional leather production, which often involves harmful chemicals and significant land use, is prompting buyers to seek alternatives that align with eco-friendly practices. PU leather, made from synthetic materials, presents a more sustainable option as it requires fewer resources and avoids the ethical concerns associated with animal hides.

Ethical sourcing is also gaining traction among international buyers, particularly in regions like Europe and North America, where regulations around sustainable practices are tightening. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 can provide assurance regarding the environmental credentials of PU leather products. As businesses increasingly prioritize ethical supply chains, the demand for PU leather that meets these standards is likely to grow, making it essential for B2B buyers to engage with suppliers who can demonstrate compliance with sustainability initiatives.

What Is the Historical Context of Polyurethane Leather Fabric in the B2B Sector?

The evolution of polyurethane leather fabric dates back to the early 20th century when synthetic alternatives to genuine leather began to emerge. Initially developed to provide a more affordable and versatile option for various applications, PU leather gained popularity due to its ease of maintenance and durability. Over the decades, advancements in manufacturing technology have led to improved texture and appearance, making PU leather an increasingly desirable choice in sectors like furniture, automotive, and fashion.

Today, PU leather stands as a significant player in the global textile market, appealing to both cost-conscious consumers and environmentally aware buyers. Its journey from a simple synthetic alternative to a sophisticated product that mimics the qualities of real leather reflects broader trends in consumer preferences towards sustainability and ethical sourcing. For international B2B buyers, understanding this historical context is crucial, as it provides insights into the product’s evolution and its growing relevance in modern markets.

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane leather fabric

-

1. How do I choose the right supplier for polyurethane leather fabric?

When selecting a supplier for polyurethane leather fabric, consider factors such as their industry reputation, product quality, and compliance with international standards. Look for suppliers who have experience in your specific market, particularly those familiar with regulations in Africa, South America, the Middle East, and Europe. Request samples to evaluate the fabric’s quality and durability. Additionally, assess their customer service and responsiveness, as a reliable partner will facilitate smoother communication and problem resolution. -

2. What is the best way to ensure product quality in polyurethane leather?

To ensure the quality of polyurethane leather, establish a comprehensive quality assurance (QA) process with your supplier. This may include requesting certifications for materials used, conducting factory audits, and implementing regular quality checks throughout the production process. Additionally, consider third-party testing for durability, stain resistance, and other performance metrics. Building a strong relationship with your supplier will also help you gain insights into their quality control practices. -

3. What customization options are available for polyurethane leather fabric?

Many suppliers offer customization options for polyurethane leather, including colors, textures, and finishes. You can also specify dimensions and patterns tailored to your project needs. Discuss your requirements early in the negotiation process to ensure the supplier can meet your specifications. Be aware that customization may affect minimum order quantities (MOQs) and lead times, so it’s essential to clarify these details upfront. -

4. What are typical payment terms for purchasing polyurethane leather fabric?

Payment terms for polyurethane leather fabric can vary by supplier and region. Common terms include a deposit (usually 30%) upon order confirmation, with the balance due before shipment. Some suppliers may offer credit terms for established businesses. Ensure you have a clear understanding of the payment schedule, methods accepted (such as bank transfer or letter of credit), and any potential penalties for late payments. Negotiating favorable terms can improve your cash flow management. -

5. What are the minimum order quantities (MOQs) for polyurethane leather fabric?

Minimum order quantities for polyurethane leather can differ significantly between suppliers and depend on factors such as the type of fabric and customization options. Standard MOQs may range from 50 to 500 yards or more. Always confirm the MOQ with the supplier before placing an order, as lower MOQs may be available for standard fabrics. Understanding these requirements will help you plan your inventory and budget effectively. -

6. How do I handle logistics and shipping for international orders of polyurethane leather?

When managing logistics for international orders of polyurethane leather, collaborate closely with your supplier to determine the best shipping method and route. Consider factors such as shipping costs, transit times, and customs regulations in your destination country. Utilize a reputable freight forwarder to navigate these complexities, and ensure all necessary documentation, such as bills of lading and customs declarations, is prepared. Planning for potential delays can also help mitigate risks associated with international shipping. -

7. What certifications should I look for in polyurethane leather fabric?

When sourcing polyurethane leather, seek suppliers that possess relevant certifications. Common certifications include ISO 9001 for quality management systems and OEKO-TEX for safety and environmental standards. Additionally, if sustainability is a priority, consider suppliers with certifications like GOTS (Global Organic Textile Standard) or bluesign® that indicate responsible manufacturing practices. These certifications can enhance your product’s marketability and ensure compliance with international regulations. -

8. How can I assess the environmental impact of polyurethane leather?

To evaluate the environmental impact of polyurethane leather, inquire about the manufacturing processes used by your supplier. Look for information regarding the sourcing of raw materials, energy consumption, and waste management practices. Additionally, consider the lifecycle of the product, including its recyclability and biodegradability. Engaging with suppliers who prioritize sustainable practices and materials can help you align with eco-conscious market trends and enhance your brand’s reputation.

Top 6 Polyurethane Leather Fabric Manufacturers & Suppliers List

1. Naugahyde – Faux Leather Upholstery

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: PU Leather & Faux Leather | Vinyl Upholstery Fabric

– Terms: Free Shipping Coupon Code: SHIPFREE for Most $199 Orders

– Product Types: Faux Leather, Vinyl Upholstery Fabric

– Characteristics: Durable, easy to clean, available in rich colors, lower cost than genuine leather

– Brands: Naugahyde, Omnova Boltaflex, Nassimi, Spradling

– Uses: Furniture, Automotive, Marine, Commercial projects

– Fabric …

2. Manuel Dreesmann – PU Leather Alternatives

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: PU leather is a synthetic material made from polyurethane, often used as a cheaper alternative to genuine leather. It is important to avoid PU leather due to its environmental impact and lower durability compared to real leather.

3. Mitchell Faux Leathers – Polyurethane Solutions

Domain: mitchellfauxleathers.com

Registered: 2011 (14 years)

Introduction: Polyurethane (PU) is a composite material made of polymer resins joined by urethane links and a textile backing (polyester, cotton, nylon, or ground leather). It is water resistant, lightweight, flexible, and provides a realistic imitation of leather. PU does not require plasticizers, preventing cracking or peeling, and remains soft and supple. It is considered greener than vinyl and costs less th…

4. Boulies – PU Leather

Domain: boulies.com

Registered: 2017 (8 years)

Introduction: PU leather (polyurethane leather) is a synthetic material that resembles real leather but is made without animal products. It consists of a fabric base, such as polyester or cotton, coated with a thin layer of polyurethane. Key features include a layered structure, eco-friendliness (70% less carbon emissions than real leather), and ethical appeal (cruelty-free). Advantages of PU leather include be…

5. HowStuffWorks – PU Leather Guide

Domain: home.howstuffworks.com

Registered: 1998 (27 years)

Introduction: PU (Polyurethane) leather is an artificial leather made from polyurethane, a type of plastic. It is 100% vegan and does not contain animal skin. There are two types of PU leather: full-synthetic (totally vegan) and semi-synthetic (contains a natural leather base). PU leather is water-resistant, easy to clean, and available in a wide variety of colors. However, it lacks the authentic appearance and…

6. Kovi Fabrics – Faux Leather Fabric

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Faux leather fabric is a synthetic alternative to genuine leather, made from polyester or other fabric bases coated for a leather-like texture. It is soft, easy to clean, and resistant to water and marks. The main types are PU leather, which is eco-friendly and breathable, and PVC leather, which is waterproof and stain-resistant but less sustainable. Faux leather is more ethical, practical, and of…

Strategic Sourcing Conclusion and Outlook for polyurethane leather fabric

In the dynamic landscape of polyurethane leather fabric, strategic sourcing emerges as a pivotal factor for international buyers. By leveraging the advantages of PU leather—such as its cost-effectiveness, durability, and versatility—businesses can enhance their product offerings while catering to diverse market needs. This synthetic material not only provides an appealing alternative to genuine leather but also aligns with sustainability goals by being animal-friendly and resource-efficient.

For B2B buyers in Africa, South America, the Middle East, and Europe, the ability to source PU leather strategically can lead to significant competitive advantages. Buyers are encouraged to explore a variety of suppliers, ensuring they select high-quality materials that meet their specific requirements in terms of application, design, and durability. Furthermore, as trends shift towards more sustainable practices, adopting PU leather can position companies favorably in the eyes of environmentally conscious consumers.

Looking ahead, the market for polyurethane leather fabric is set to expand, driven by innovations in manufacturing and rising demand across various sectors such as automotive, furniture, and fashion. Now is the opportune moment for international B2B buyers to capitalize on these trends and secure reliable partnerships, ensuring they remain at the forefront of this evolving market.

Illustrative image related to polyurethane leather fabric

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.