Introduction: Navigating the Global Market for custom made leather garments

In an increasingly competitive marketplace, sourcing custom made leather garments presents unique challenges for international B2B buyers. Whether you represent a fashion house in Europe, a retail outlet in South America, or an artisanal workshop in Africa, understanding the intricacies of this niche market is crucial. This guide serves as a comprehensive resource, covering various types of custom leather products, their applications across diverse industries, and effective strategies for vetting suppliers. By delving into key considerations such as material quality, craftsmanship, and cost implications, you will be equipped to make informed purchasing decisions that align with your business objectives.

Navigating the global market for custom made leather garments requires awareness of regional preferences and sourcing dynamics. Buyers from the Middle East may prioritize luxury and durability, while those in Germany might seek sustainable production methods. This guide not only highlights the importance of aligning your sourcing strategies with local market trends but also emphasizes best practices in supplier negotiations and quality assurance.

By leveraging the insights provided, you can confidently approach your procurement processes, ensuring that the custom leather garments you source not only meet your specifications but also resonate with your target audience. Empower your business with the knowledge needed to thrive in the global leather market, transforming challenges into opportunities for growth and innovation.

Table Of Contents

- Top 8 Custom Made Leather Garments Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom made leather garments

- Understanding custom made leather garments Types and Variations

- Key Industrial Applications of custom made leather garments

- 3 Common User Pain Points for ‘custom made leather garments’ & Their Solutions

- Strategic Material Selection Guide for custom made leather garments

- In-depth Look: Manufacturing Processes and Quality Assurance for custom made leather garments

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom made leather garments’

- Comprehensive Cost and Pricing Analysis for custom made leather garments Sourcing

- Alternatives Analysis: Comparing custom made leather garments With Other Solutions

- Essential Technical Properties and Trade Terminology for custom made leather garments

- Navigating Market Dynamics and Sourcing Trends in the custom made leather garments Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom made leather garments

- Strategic Sourcing Conclusion and Outlook for custom made leather garments

- Important Disclaimer & Terms of Use

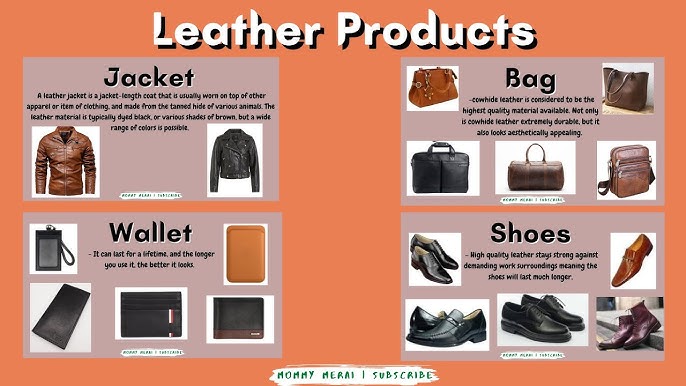

Understanding custom made leather garments Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Leather Jackets | Tailored fit, various styles (biker, bomber, blazer) | Fashion retailers, promotional apparel | Pros: Unique branding opportunities; Cons: Higher cost per unit. |

| Bespoke Leather Coats | Made-to-measure, luxurious materials (e.g., horsehide) | High-end fashion boutiques, luxury markets | Pros: Premium quality; Cons: Longer lead times. |

| Custom Leather Bags | Functional designs, branding options, various sizes | Corporate gifts, promotional items | Pros: Versatile use; Cons: May require minimum order quantities. |

| Specialty Leather Apparel | Unique styles (medieval, cosplay, superhero) | Themed events, film production, cosplay markets | Pros: Niche market appeal; Cons: Limited audience. |

| Custom Leather Accessories | Personalized items (wallets, belts, pouches) | Fashion accessory shops, promotional giveaways | Pros: High demand for personalization; Cons: Smaller margins. |

What Are the Characteristics of Custom Leather Jackets for B2B Buyers?

Custom leather jackets are characterized by their tailored fit and versatility in style, ranging from biker and bomber jackets to blazers. They are often made from high-quality leathers such as lambskin or cowhide, allowing for a range of finishes and colors. For B2B buyers, these jackets serve as excellent promotional apparel, offering unique branding opportunities through embroidery or logos. However, the cost per unit can be higher than mass-produced options, making it essential for buyers to consider their budget and marketing strategy.

How Do Bespoke Leather Coats Stand Out in the Market?

Bespoke leather coats are made-to-measure garments that emphasize luxurious materials, often sourced from high-end tanneries. These coats are typically tailored to the individual specifications of the buyer, ensuring a perfect fit and exclusive design. They are predominantly used in high-end fashion boutiques and luxury markets, appealing to clientele who prioritize quality and exclusivity. B2B buyers should be prepared for longer lead times due to the bespoke nature of these garments, but the resulting product can significantly enhance their brand’s prestige.

What Makes Custom Leather Bags a Practical Choice for Businesses?

Custom leather bags offer a combination of functionality and branding potential, making them highly sought after in various B2B applications. They can be tailored in terms of size, design, and branding options, making them suitable for corporate gifts or promotional items. The versatility of leather bags allows them to appeal to a wide audience, though buyers should be aware of potential minimum order quantities that could affect inventory management. The investment in custom bags can yield high returns if positioned correctly within the market.

Why Are Specialty Leather Apparel Options Important for Niche Markets?

Specialty leather apparel, including medieval, cosplay, and superhero garments, caters to niche markets that are often underserved. These unique styles attract specific audiences, such as those involved in themed events or film production. For B2B buyers, this presents an opportunity to tap into a passionate consumer base willing to invest in high-quality, unique apparel. However, the limited audience may result in slower sales, so careful market research and targeted marketing strategies are crucial for success.

How Can Custom Leather Accessories Enhance Product Offerings?

Custom leather accessories, such as wallets, belts, and pouches, are increasingly popular due to their personalization options. These items can serve as fashion statements or practical gifts, appealing to a broad range of consumers. For B2B buyers, the demand for personalized accessories provides an opportunity to differentiate their product offerings. However, it’s essential to consider the smaller margins associated with these items and the potential need for higher minimum order quantities to ensure profitability.

Key Industrial Applications of custom made leather garments

| Industry/Sector | Specific Application of custom made leather garments | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom leather jackets and coats | Enhances brand identity through unique designs and quality | Sourcing high-quality leather, skilled craftsmanship, and customization options |

| Automotive | Leather interiors and custom upholstery | Increases vehicle luxury appeal and resale value | Durability, color matching, and compliance with automotive standards |

| Entertainment & Events | Costumes for film, theater, and cosplay | Creates authentic, high-quality costumes that attract attention | Specific design requirements, material durability, and production timelines |

| Military & Tactical | Custom tactical gear and uniforms | Provides durability and functionality for extreme conditions | Compliance with military specifications, material strength, and design adaptability |

| Equestrian | Custom riding apparel and accessories | Enhances performance and comfort for riders | Material breathability, fit customization, and safety features |

How Are Custom Made Leather Garments Used in the Fashion & Apparel Industry?

In the fashion and apparel sector, custom made leather garments, such as jackets and coats, are pivotal for brands aiming to establish a unique identity. These garments allow businesses to cater to niche markets with specific style preferences, enhancing brand loyalty. Buyers in this sector must consider the quality of leather, the craftsmanship involved, and the ability to customize designs to meet their clientele’s demands. Customization not only appeals to consumers but also sets brands apart in a competitive market.

What Role Do Custom Leather Garments Play in the Automotive Industry?

In the automotive industry, custom leather garments are primarily used for vehicle interiors and upholstery. High-quality leather seats and trims significantly elevate the luxury appeal of vehicles, contributing to higher resale values. B2B buyers in this sector should prioritize sourcing durable leather that meets automotive standards for wear and tear, as well as color matching to ensure a cohesive design. Additionally, partnerships with skilled upholsterers can ensure that the craftsmanship meets the aesthetic and functional requirements of the automotive market.

How Are Custom Leather Garments Utilized in Entertainment & Events?

Custom leather garments are essential in the entertainment and events industry, particularly for creating costumes in film, theater, and cosplay. These garments are designed to provide authenticity and visual impact, often becoming iconic representations of characters. Buyers in this sector should focus on specific design requirements, material durability, and production timelines to meet performance needs during events. Collaborating with experienced costume designers can ensure that the final products not only look great but also withstand the rigors of performances.

What Are the Applications of Custom Leather Garments in Military & Tactical Sectors?

In the military and tactical sectors, custom leather garments are utilized for tactical gear and uniforms that require high durability and functionality. These garments must withstand extreme conditions while providing comfort and mobility. B2B buyers must ensure compliance with military specifications regarding material strength and design adaptability. Sourcing partners should be able to provide robust materials that can be tailored for specific missions, enhancing operational effectiveness.

How Do Custom Leather Garments Benefit the Equestrian Industry?

In the equestrian industry, custom leather garments such as riding apparel and accessories enhance both performance and comfort for riders. Tailored riding jackets, boots, and gloves can significantly improve a rider’s experience and effectiveness. Buyers should consider the breathability of materials, fit customization, and safety features when sourcing these products. Collaborating with manufacturers who specialize in equestrian gear ensures that the garments meet both aesthetic and functional needs of riders, fostering a loyal customer base.

3 Common User Pain Points for ‘custom made leather garments’ & Their Solutions

Scenario 1: Quality Assurance for Custom Leather Garments

The Problem: B2B buyers often face the daunting challenge of ensuring the quality of custom-made leather garments. The risks are high, especially when sourcing from international suppliers in diverse regions like Africa or South America. Variability in leather quality, craftsmanship, and adherence to specifications can lead to significant financial losses and reputational damage if the products do not meet expectations. Buyers may receive subpar materials or poorly constructed garments, which can result in returns, lost sales, and dissatisfied customers.

The Solution: To mitigate these risks, it is essential for buyers to implement a rigorous quality assurance process. Start by establishing clear specifications for the garments, including type of leather, stitching techniques, and finishing details. Engage with reputable suppliers who have a proven track record and ask for samples before placing larger orders. Conduct factory visits or utilize third-party inspection services to evaluate the production process. Additionally, consider building long-term relationships with suppliers, as this fosters better communication and accountability. Implementing a comprehensive quality control checklist can also help in identifying potential issues before the garments reach the market.

Scenario 2: Navigating Cultural Differences in Design Preferences

The Problem: Another common pain point for B2B buyers in the custom leather garment industry is navigating cultural differences in design preferences. Buyers from different regions may have unique tastes and expectations regarding style, color, and functionality. Misunderstandings can lead to mismatched products that do not resonate with the target market, resulting in poor sales performance and wasted inventory.

The Solution: To overcome this challenge, buyers should invest time in understanding the cultural nuances of their target market. This can be achieved through market research, surveys, and focus groups to gather insights on local preferences. Collaborating with local designers or consultants can also provide invaluable guidance on style trends and consumer expectations. When working with manufacturers, ensure that they are aware of these cultural considerations and can adapt their designs accordingly. Offering customization options can also cater to diverse preferences and help create products that appeal to a broader audience.

Scenario 3: Managing Lead Times and Supply Chain Delays

The Problem: Timeliness is critical in the fashion industry, and B2B buyers of custom leather garments often struggle with managing lead times and supply chain delays. Factors such as shipping logistics, production capacity, and material availability can result in extended wait times, jeopardizing launch dates and seasonal collections. This can lead to lost sales opportunities and strained relationships with retail partners.

The Solution: To effectively manage lead times, buyers should establish clear timelines with their suppliers and build a buffer into their production schedules. Communication is key; maintain regular contact with suppliers to stay informed about any potential delays. Utilizing technology, such as supply chain management software, can help streamline operations and provide visibility into the production process. Additionally, consider diversifying your supplier base to reduce dependency on a single source, which can help mitigate the impact of unexpected delays. Implementing a just-in-time inventory approach may also enhance responsiveness to market demands while minimizing excess stock.

Strategic Material Selection Guide for custom made leather garments

When selecting materials for custom-made leather garments, understanding the properties, advantages, and limitations of various leather types is crucial for B2B buyers. This guide analyzes four common leather materials: cowhide, lambskin, goatskin, and suede, providing insights tailored for international buyers from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Cowhide Leather for Custom Garments?

Cowhide leather is one of the most durable and widely used materials in the leather garment industry. It offers excellent abrasion resistance and is suitable for high-stress applications, such as jackets and protective gear. Cowhide can withstand a range of temperatures and pressures, making it versatile for various climates.

Pros: Cowhide is known for its durability, making it ideal for products requiring long-lasting wear. It is also relatively cost-effective compared to other leathers, which can be beneficial for bulk orders.

Cons: The thickness of cowhide can limit its flexibility, which may not be suitable for all garment styles. Additionally, it can be heavier than other leathers, impacting comfort.

Impact on Application: Cowhide is compatible with various dyeing and finishing processes, allowing for a wide range of aesthetic options. However, it may not be suitable for applications requiring extreme softness or lightweight characteristics.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers should also consider local preferences for leather thickness and finish, which can vary significantly across regions.

How Does Lambskin Leather Compare for Custom Garments?

Lambskin leather is renowned for its softness and luxurious feel, making it a popular choice for high-end fashion garments. It has a lower temperature and pressure tolerance compared to cowhide but excels in comfort and style.

Pros: The primary advantage of lambskin is its supple texture, which provides a comfortable fit and a premium appearance. It is also lighter, making it suitable for tailored garments.

Cons: Lambskin is less durable than cowhide, which may limit its use in rugged applications. It is also more expensive, which could be a consideration for budget-conscious buyers.

Impact on Application: Lambskin is ideal for fashion-forward designs but may not perform well in environments requiring heavy-duty protection. Its compatibility with various finishes allows for creative design options.

Considerations for International Buyers: Buyers should be aware of the higher price point and ensure that the end product aligns with market expectations for luxury goods.

What are the Unique Benefits of Goatskin Leather for Custom Garments?

Goatskin leather is gaining popularity due to its unique combination of durability and softness. It offers good resistance to wear and tear while maintaining a lightweight feel, making it suitable for various garment types.

Pros: Goatskin is known for its flexibility and ability to conform to the body, providing a comfortable fit. It is also resistant to moisture, which can be advantageous in humid climates.

Cons: While goatskin is durable, it may not have the same level of abrasion resistance as cowhide. Additionally, it can be more expensive than cowhide, affecting overall production costs.

Impact on Application: Goatskin is suitable for both fashion and functional garments, providing versatility in design. Its moisture resistance makes it a good choice for outdoor apparel.

Considerations for International Buyers: Compliance with local leather quality standards is crucial. Additionally, understanding regional preferences for leather types can enhance market acceptance.

How Does Suede Leather Fit into the Custom Garment Market?

Suede leather, derived from the underside of animal hides, is known for its soft texture and unique appearance. It is often used in fashion garments, accessories, and footwear.

Pros: Suede offers a distinctive look and feel, which can elevate the aesthetic appeal of garments. It is also lightweight and comfortable to wear.

Cons: Suede is less durable than other leather types and can be more challenging to clean and maintain. It is also sensitive to water, which may limit its use in certain applications.

Impact on Application: Suede is ideal for fashion garments but may not be suitable for heavy-duty use. Its unique texture can enhance the visual appeal of custom designs.

Considerations for International Buyers: Buyers should consider the care instructions and maintenance requirements for suede, as well as its market demand in specific regions.

Summary of Material Properties for Custom Leather Garments

| Material | Typical Use Case for custom made leather garments | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide | Jackets, protective gear | Highly durable | Less flexible, heavier | Medium |

| Lambskin | High-end fashion garments | Soft and luxurious | Less durable, more expensive | High |

| Goatskin | Versatile garments, outdoor apparel | Flexible and moisture-resistant | Lower abrasion resistance | Medium-High |

| Suede | Fashion garments, accessories | Unique texture | Sensitive to water, less durable | Medium |

This guide provides essential insights into material selection for custom-made leather garments, helping B2B buyers make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom made leather garments

What Are the Key Stages in the Manufacturing Process of Custom Made Leather Garments?

The manufacturing of custom made leather garments involves several critical stages that ensure high-quality outputs. Each stage requires skilled craftsmanship and attention to detail, particularly when catering to international B2B buyers.

Material Preparation: How Is Leather Selected and Treated?

The first step in the manufacturing process is the selection of leather. Suppliers typically source leather from reputable tanneries, ensuring that it meets specific quality standards. Common types of leather include cowhide, sheepskin, goatskin, and more exotic varieties like buffalo-hide. The selection is based on the desired durability, texture, and finish.

Once selected, leather undergoes various treatments to enhance its properties. This includes tanning, which preserves the leather and makes it more pliable. Buyers should inquire about the tanning processes used, as these can vary significantly and affect the final product’s quality.

Forming: What Techniques Are Used to Shape Leather?

After preparation, the leather is cut into patterns that correspond to the design specifications of the garment. This process often uses advanced cutting techniques, such as laser cutting or die-cutting, to ensure precision. The accuracy in this stage is paramount; any deviation can lead to issues in the final fit and appearance of the garment.

In some cases, leather is subjected to molding techniques, especially for structured garments. Techniques like heat molding can give leather unique shapes that enhance the garment’s aesthetic appeal. B2B buyers should look for manufacturers who utilize modern equipment and skilled artisans to ensure consistency and quality.

Assembly: How Are Garments Constructed?

The assembly phase involves stitching the leather pieces together. High-quality stitching is vital for durability and aesthetic appeal. Manufacturers typically use specialized sewing machines designed for leather, ensuring that stitches are tight and even.

This stage may also involve adding components such as zippers, buttons, and embellishments. The choice of hardware can significantly impact the final product’s quality and should align with the buyer’s specifications. Customization options in this phase are often a selling point for B2B buyers looking to differentiate their offerings.

Finishing: What Steps Ensure a Polished Final Product?

Finishing involves several processes that enhance the garment’s look and feel. This may include edge finishing, dyeing, and applying protective coatings. Each of these steps is crucial in determining the garment’s final appearance and durability.

Finishing techniques can vary widely, and B2B buyers should ask about the specific methods used. For instance, the application of water-resistant coatings can be a valuable feature for certain markets, particularly in regions with adverse weather conditions.

What International Quality Standards and Industry-Specific Certifications Should Buyers Know?

Quality assurance is integral to the production of custom leather garments. Understanding international standards and certifications can help B2B buyers make informed decisions when selecting suppliers.

Which International Standards Are Relevant for Leather Garment Manufacturing?

ISO 9001 is one of the most recognized quality management standards globally. It focuses on ensuring consistent quality in products and services. Manufacturers that adhere to this standard demonstrate a commitment to quality, which is essential for B2B buyers.

Additionally, specific industry certifications like CE (Conformité Européenne) ensure that products meet EU safety and health standards. For leather garments, compliance with these standards can enhance marketability in regions that prioritize consumer safety.

What Are the Key Quality Control Checkpoints in Leather Garment Production?

Quality control (QC) checkpoints are critical throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): Regular checks during the manufacturing process help identify any defects early on, allowing for corrections before the final assembly.

- Final Quality Control (FQC): This final inspection assesses the finished product against quality standards before shipping.

Buyers should inquire about the frequency and methods of these checks, as they are indicators of a manufacturer’s commitment to quality.

What Common Testing Methods Are Used to Verify Leather Quality?

Testing methods for leather quality can include:

- Physical Tests: Assessing tensile strength, tear resistance, and abrasion resistance.

- Chemical Tests: Evaluating the leather’s resistance to water, oils, and other substances.

- Visual Inspections: Checking for color consistency, texture, and any visible defects.

B2B buyers should ensure that suppliers conduct these tests and maintain documentation that can be provided upon request.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s quality control processes is crucial for B2B buyers, especially when dealing with international manufacturers.

What Steps Should Buyers Take to Audit Supplier QC?

Buyers should consider conducting audits of potential suppliers. This can involve on-site visits to assess their facilities, equipment, and quality control measures. During these audits, it’s important to ask about their quality assurance processes and any certifications they hold.

How Can Buyers Request Reports and Third-Party Inspections?

Buyers can request detailed quality control reports from suppliers. These reports should outline the QC processes, testing methods, and results. Additionally, third-party inspections can provide an unbiased assessment of the manufacturer’s quality standards. Engaging a third-party service can help verify that the supplier meets the required quality benchmarks.

What Are the QC Nuances for International Buyers from Different Regions?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, understanding regional compliance and consumer preferences is essential.

How Do Regional Standards Affect Quality Assurance?

Different regions may have specific regulations regarding leather products, including environmental standards and consumer safety. For example, the European Union has strict regulations on the use of chemicals in leather production. Buyers should ensure that their suppliers comply with these regulations to avoid potential legal issues.

What Should Buyers Consider Regarding Cultural Preferences?

Cultural preferences can influence design choices and quality expectations. Buyers from Europe may prioritize high craftsmanship and environmentally friendly practices, while those from Africa or South America may focus on durability and functionality. Understanding these nuances can guide buyers in selecting manufacturers who align with their market needs.

In conclusion, the manufacturing processes and quality assurance for custom made leather garments are intricate and vital for ensuring high-quality products. B2B buyers must take a proactive approach in understanding these processes, verifying supplier capabilities, and ensuring compliance with international standards to secure successful partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom made leather garments’

To ensure a successful procurement process for custom-made leather garments, it’s vital to follow a structured approach. This checklist outlines key steps to guide international B2B buyers in sourcing high-quality leather products tailored to their specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for aligning your expectations with the supplier’s capabilities. This includes details about leather types, garment styles, sizes, and any custom features you require. Providing comprehensive specifications helps suppliers understand your vision and minimizes the risk of miscommunication.

- Leather Type: Specify whether you need lambskin, cowhide, or other materials.

- Garment Style: Detail the design (e.g., jackets, coats) and any unique elements (e.g., embroidery, logos).

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in custom leather garments. Look for manufacturers with a solid reputation and experience in the industry. Utilize trade directories, industry forums, and referrals from other businesses to compile a list of candidates.

- Online Reviews: Check for customer feedback and testimonials.

- Industry Certifications: Verify if the suppliers hold relevant certifications that ensure quality standards.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This evaluation should focus not only on their product quality but also on their reliability and customer service.

- Past Projects: Ask for examples of similar custom orders they have fulfilled.

- Response Time: Assess how quickly and effectively they respond to inquiries.

Step 4: Request Samples

Always request samples before placing a bulk order. Samples provide an opportunity to evaluate the quality of materials and craftsmanship firsthand. This step is crucial for ensuring that the supplier meets your standards and that the final product will align with your expectations.

- Material Quality: Inspect the leather for texture, durability, and finish.

- Craftsmanship: Look for stitching quality and attention to detail.

Step 5: Discuss Pricing and Payment Terms

Engage in discussions about pricing and payment terms early in the process. Understand the pricing structure, including any additional costs for customizations or bulk orders. Clear payment terms, including deposits and payment schedules, can help prevent misunderstandings later on.

- Negotiation: Don’t hesitate to negotiate prices based on order volume.

- Payment Methods: Ensure that the payment methods are secure and suitable for international transactions.

Step 6: Review Production Timeline

Establish a clear timeline for production and delivery. Understanding the lead times helps you plan your inventory and ensures that the garments arrive when needed. Discuss potential delays and how they will be managed to avoid disruptions in your supply chain.

- Milestones: Set clear milestones for production phases.

- Contingency Plans: Ask about their policy for handling unexpected delays.

Step 7: Finalize Quality Control Procedures

Before production begins, finalize the quality control procedures to ensure that the garments meet your standards. This may include inspections at various stages of production and a final quality check before shipment. Establishing these procedures can significantly reduce the risk of receiving unsatisfactory products.

- Inspection Protocols: Determine who will conduct inspections and when.

- Acceptance Criteria: Clearly define what constitutes an acceptable product.

By following these steps, international B2B buyers can navigate the complexities of sourcing custom-made leather garments effectively, ensuring they receive high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for custom made leather garments Sourcing

What Are the Key Cost Components in Custom Made Leather Garments?

When sourcing custom made leather garments, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type and quality of leather significantly affect costs. High-quality leathers such as lambskin or buffalo hide command higher prices, while lower-tier options like goatskin may be more affordable. Buyers should also consider additional materials for linings, zippers, and other components.

-

Labor: Skilled craftsmanship is essential in leather garment production. Labor costs can vary based on the complexity of the design and the skill level required. For instance, bespoke items that require intricate stitching or detailed customization will entail higher labor costs.

-

Manufacturing Overhead: This includes expenses related to the factory’s operation, such as utilities, rent, and administrative costs. These overheads can vary widely depending on the location of the manufacturing facility.

-

Tooling: Custom tooling or molds needed for specific designs can incur additional costs. This is particularly relevant for unique shapes or features that require specialized equipment.

-

Quality Control (QC): Ensuring that each garment meets quality standards necessitates a dedicated QC process. This can increase costs, especially if rigorous testing and inspection protocols are implemented.

-

Logistics: Shipping and handling costs should not be overlooked. These can vary based on the destination, shipping method, and whether the goods are shipped via air or sea.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and to ensure profitability. This margin can vary based on market conditions and competition.

How Do Price Influencers Affect Custom Leather Garment Costs?

Several factors influence the final pricing of custom leather garments:

-

Volume/MOQ: Buying in larger quantities often leads to reduced per-unit costs. Suppliers may offer better pricing for bulk orders, making it essential for buyers to assess their needs.

-

Specifications/Customization: The more detailed and customized the specifications, the higher the price. Unique designs, specific color choices, and custom branding can all drive up costs.

-

Materials and Quality Certifications: The choice of materials impacts both cost and quality. Certifications that guarantee the leather’s origin and sustainability can also add to the price.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge a premium.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect shipping costs and responsibilities. Understanding these terms is vital for managing total costs effectively.

What Tips Can Help Buyers Optimize Their Sourcing of Custom Leather Garments?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Effectively: Always negotiate pricing with suppliers. Leverage bulk orders or long-term partnerships to secure better rates.

-

Focus on Cost Efficiency: Analyze the Total Cost of Ownership (TCO), which includes not only the purchase price but also shipping, duties, and potential costs of returns or defects. This holistic view can lead to more informed purchasing decisions.

-

Understand Pricing Nuances: Be aware that pricing can fluctuate based on market demand, currency exchange rates, and geopolitical factors. Staying informed about these trends can help in timing purchases effectively.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, priority service, and insights into upcoming trends or changes in pricing structures.

Disclaimer on Pricing

Prices for custom made leather garments can vary widely based on the factors discussed above. The figures presented in various sources are indicative and should be verified with suppliers for accuracy. Always request detailed quotes to ensure clarity and alignment with your sourcing objectives.

Alternatives Analysis: Comparing custom made leather garments With Other Solutions

Exploring Alternatives to Custom Made Leather Garments

In the realm of apparel, particularly in industries that require durable and stylish options, custom made leather garments stand out for their unique blend of quality, aesthetics, and functionality. However, businesses often face the challenge of choosing between various solutions that meet similar needs. This analysis delves into custom made leather garments and compares them with other viable alternatives, enabling B2B buyers to make informed decisions based on their specific requirements.

| Comparison Aspect | Custom Made Leather Garments | Alternative 1 Name: Synthetic Leather | Alternative 2 Name: Ready-to-Wear Leather Garments |

|---|---|---|---|

| Performance | High durability and longevity; tailored fit enhances comfort and style. | Moderate durability; less breathable but can mimic leather appearance. | Varies by brand; may lack personalization but offers standard quality. |

| Cost | Higher initial investment due to customization and quality materials. | Generally lower cost, making it accessible for bulk purchases. | Mid-range pricing; cost-effective for businesses needing quick solutions. |

| Ease of Implementation | Requires time for design and production; longer lead times. | Quick to manufacture; can be sourced from multiple suppliers easily. | Readily available in stores or online, enabling immediate acquisition. |

| Maintenance | Requires specific care to maintain quality; can last decades with proper maintenance. | Low maintenance; easy to clean but may not last as long as leather. | Standard care; longevity depends on material quality and usage. |

| Best Use Case | Ideal for bespoke needs, branding, or high-end fashion markets. | Suitable for budget-conscious projects or fashion lines with a focus on trends. | Best for companies needing quick inventory turnover and cost-effective options. |

What are the Pros and Cons of Synthetic Leather as an Alternative?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), serves as a popular alternative to traditional leather. One of its primary advantages is cost-effectiveness, making it an attractive option for brands focused on affordability. Additionally, synthetic leather is often easier to clean and maintain than genuine leather. However, it typically lacks the durability and breathability of real leather, which can affect comfort and longevity. For businesses targeting a budget-conscious market or looking for trendy seasonal items, synthetic leather can be a viable solution.

How Do Ready-to-Wear Leather Garments Compare?

Ready-to-wear leather garments offer immediate availability, which is a significant advantage for businesses needing quick stock replenishment. These garments come in a variety of styles and sizes, catering to a broad audience. However, the lack of customization limits their appeal for brands aiming to establish a unique identity or cater to specific clientele. Moreover, the quality can vary significantly between manufacturers, leading to potential inconsistencies. This option is best suited for businesses that prioritize speed and affordability over personalization.

Making the Right Choice for Your Business Needs

When choosing between custom made leather garments and alternative solutions, B2B buyers should assess their specific needs, including budget constraints, time requirements, and market positioning. Custom made leather garments excel in quality and personalization, making them ideal for high-end markets or bespoke projects. In contrast, synthetic leather and ready-to-wear options provide cost-effective and immediate solutions for businesses with different objectives. By carefully considering these factors, buyers can select the option that aligns best with their strategic goals and customer expectations.

Essential Technical Properties and Trade Terminology for custom made leather garments

What Are the Key Technical Properties of Custom Made Leather Garments?

When sourcing custom-made leather garments, understanding the critical technical properties is essential for ensuring product quality and meeting buyer specifications. Here are some key properties to consider:

1. Material Grade

Material grade refers to the quality classification of leather based on its origin, treatment, and finish. Common grades include full-grain, top-grain, genuine leather, and bonded leather. Full-grain leather, for example, is the highest quality, retaining the natural grain and durability, making it ideal for high-end garments. For B2B buyers, selecting the right material grade is crucial for aligning product offerings with market expectations and customer preferences.

2. Leather Thickness

Leather thickness is measured in ounces or millimeters and significantly impacts the garment’s feel, durability, and intended use. Thicker leather is typically more durable and suited for outerwear, while thinner leather offers a softer touch, ideal for fitted garments. Understanding the thickness needed for specific applications helps buyers ensure the final product meets functional and aesthetic requirements.

3. Tolerance

Tolerance refers to the acceptable limits of variation in the dimensions and characteristics of the leather during production. For example, a tolerance of ±1mm on garment dimensions ensures consistency and fit. In B2B transactions, maintaining strict tolerances is vital for minimizing returns and ensuring customer satisfaction, as well as maintaining brand reputation.

4. Finish Type

The finish type of leather affects its appearance and performance. Common finishes include aniline, semi-aniline, and pigmented finishes. Aniline leather is dyed without a protective topcoat, showcasing the natural beauty of the hide, while pigmented leather has a protective layer that enhances durability. Buyers should specify finish types that align with their brand identity and customer expectations.

5. Breathability

Breathability indicates how well the leather allows air and moisture to pass through. This property is particularly important for garments meant for active wear or warmer climates. Breathable leather enhances comfort and wearability, making it a critical factor for buyers targeting specific market segments.

What Are Common Trade Terms in the Custom Leather Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms used in the custom leather garment trade:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce goods that are marketed under another company’s brand. In the leather industry, an OEM might manufacture custom leather garments for a retailer. Understanding OEM relationships is crucial for buyers looking to leverage established brands while ensuring quality control.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For custom leather garments, MOQs can vary widely based on material and complexity. Buyers need to be aware of MOQs to manage inventory costs and negotiate effectively with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. In the leather garment industry, an RFQ typically includes details about materials, designs, and quantities. Understanding how to craft an RFQ can lead to better pricing and terms, ultimately benefiting the buyer’s bottom line.

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms widely used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to navigate international shipping logistics effectively.

5. Lead Time

Lead time refers to the amount of time from placing an order to receiving the finished product. For custom leather garments, lead times can vary based on complexity and material availability. Understanding lead times helps buyers plan inventory and align with market demand.

In conclusion, grasping these technical properties and trade terms is vital for B2B buyers in the custom leather garment industry. This knowledge not only aids in effective sourcing and negotiation but also enhances the overall quality and customer satisfaction of the products offered.

Navigating Market Dynamics and Sourcing Trends in the custom made leather garments Sector

What Are the Key Market Dynamics and Trends Shaping the Custom Made Leather Garments Sector?

The custom made leather garments market is experiencing a notable shift, driven by several global factors. Increasing consumer demand for personalized products, coupled with rising disposable incomes, particularly in emerging markets such as Africa and South America, is propelling growth in this sector. B2B buyers are now prioritizing customization options that cater to unique preferences, which has led to an uptick in the availability of tailored solutions from manufacturers. Additionally, advancements in technology, such as 3D modeling and digital prototyping, are enhancing the design and production process, allowing for quicker turnaround times and more intricate designs.

International B2B buyers, especially from regions like Europe and the Middle East, are also keenly aware of the competitive landscape. The rise of online platforms has facilitated access to a broader range of suppliers, enabling buyers to compare quality, pricing, and service levels more efficiently. Moreover, trends such as the integration of artificial intelligence in supply chain management are enabling companies to optimize inventory levels and reduce lead times. This dynamic environment necessitates that buyers stay informed about emerging trends and technologies to leverage potential opportunities effectively.

How Is Sustainability Reshaping Sourcing Practices in the Custom Made Leather Garments Market?

Sustainability has become a central theme in the sourcing of custom made leather garments. The environmental impact of traditional leather production, which often involves harmful chemicals and significant water usage, has prompted both consumers and businesses to seek more sustainable practices. Ethical sourcing is now a priority for many B2B buyers, who are increasingly demanding transparency in their supply chains. This shift is not just about compliance; it’s also about brand reputation and consumer loyalty.

Buyers are encouraged to look for suppliers that offer ‘green’ certifications or use eco-friendly materials. Certifications such as the Global Organic Textile Standard (GOTS) or Leather Working Group (LWG) can serve as indicators of a supplier’s commitment to sustainable practices. Furthermore, many manufacturers are now exploring alternative materials, such as vegetable-tanned leather or recycled leather, that reduce environmental impact while maintaining the high quality expected in custom garments. Engaging with suppliers who prioritize sustainability can enhance a buyer’s market position and align their products with evolving consumer expectations.

What Historical Context Is Important for B2B Buyers in the Custom Made Leather Garments Sector?

The custom made leather garments sector has evolved significantly over the years. Initially, leather was primarily used for functional purposes, but over time, it has transitioned into a fashion statement and a symbol of quality. The rise of bespoke tailoring in the early 20th century set the stage for the current market, where personalized leather garments are highly sought after. This evolution reflects broader changes in consumer preferences, from mass-produced items to unique, high-quality products that cater to individual tastes.

In recent decades, the globalization of trade has further diversified the market, allowing buyers from different regions to access a variety of styles and craftsmanship. This historical backdrop is essential for B2B buyers as it highlights the importance of understanding regional trends, cultural influences, and consumer behaviors that can impact sourcing decisions in the custom made leather garments sector. Recognizing these elements can provide buyers with a competitive edge in an increasingly complex market.

Frequently Asked Questions (FAQs) for B2B Buyers of custom made leather garments

-

How do I ensure the quality of custom-made leather garments?

To ensure quality, start by vetting suppliers thoroughly. Request samples of their leather and finished products to assess craftsmanship. Look for certifications or industry standards that the supplier adheres to, such as ISO or other quality management systems. Engage with previous clients or read testimonials to gauge reliability. Establish clear quality assurance protocols in your contract, including inspection points during production. -

What is the best way to customize leather garments for my brand?

The best way to customize leather garments is to collaborate closely with your supplier during the design phase. Specify your requirements regarding style, color, leather type, and any branding elements like logos or embroidery. Utilize CAD (Computer-Aided Design) tools to visualize your design before production begins. Ensure that your supplier has the capacity for your desired level of customization and can meet your timeline. -

What are the minimum order quantities (MOQs) for custom leather garments?

Minimum order quantities can vary significantly between suppliers, often depending on the complexity of the garment and the type of leather used. Many manufacturers may set MOQs ranging from 10 to 50 pieces per style. It’s advisable to discuss your requirements upfront to find a supplier willing to accommodate your needs or negotiate MOQs based on your budget and product line. -

How do I choose the right supplier for custom leather garments?

Choosing the right supplier involves assessing their experience, production capabilities, and reliability. Look for suppliers with a proven track record in the leather industry and positive customer feedback. Request references and evaluate their communication responsiveness. Additionally, consider visiting their facility if possible, or use virtual tours, to better understand their operations and quality control processes. -

What payment terms should I expect when ordering custom leather garments?

Payment terms can vary, but common practices include a deposit upfront (typically 30-50%) with the balance due upon completion or delivery. Some suppliers may offer payment plans or financing options for larger orders. Always clarify payment terms before finalizing your contract and ensure they are documented to avoid misunderstandings. -

How can I manage logistics for international shipments of leather garments?

Managing logistics involves working closely with your supplier to establish clear shipping terms, such as Incoterms (e.g., FOB, CIF). Choose a reliable freight forwarder with experience in handling leather products to ensure compliance with import regulations in your country. Track shipments regularly and communicate with your supplier about any potential delays or issues that arise during transit. -

What quality assurance processes should I implement when sourcing custom leather garments?

Implementing quality assurance processes involves defining specific quality criteria in your supplier agreement. Schedule regular quality checks throughout the production cycle, including pre-production samples and in-line inspections. Utilize third-party quality control services if needed, and establish a clear return policy for defective items to protect your investment and maintain customer satisfaction. -

How do I handle returns or defects in custom leather garments?

Handling returns or defects requires a clear policy outlined in your contract with the supplier. Ensure that the policy includes conditions for returns, timelines, and responsibilities for shipping costs. Document any defects with photographs and detailed descriptions to facilitate discussions with your supplier. Maintaining open communication is essential for resolving issues amicably and ensuring future orders meet your standards.

Top 8 Custom Made Leather Garments Manufacturers & Suppliers List

1. Magnoli Clothiers – Custom Leather Jackets

Domain: magnoliclothiers.com

Registered: 2006 (19 years)

Introduction: Custom made leather jackets by Magnoli Clothiers, offering a range of styles and options for personalization.

2. The Jacket Maker – Custom Leather Jackets

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Custom Leather Jackets & Coats available for design with options for embroidery, logo, and color customization. Categories include Custom Leather Jackets, Custom Bomber Jackets, Custom Varsity Jackets, Custom Embroidered Jackets, Custom Denim Jackets, Custom Windbreaker Jackets, Custom Trench Coats, Custom Motorcycle Jackets, Custom Parka Jackets, and Custom Leather Vests. The service also include…

3. Himel Bros – $55 Delivery

Domain: himelbros.com

Registered: 2010 (15 years)

Introduction: This company, Himel Bros – $55 Delivery, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. LeatherCult – Premium Leather Apparel and Accessories

Domain: leathercult.com

Registered: 2010 (15 years)

Introduction: LeatherCult offers a wide range of leather products for men, women, and boys, including leather jackets, blazers, long coats, vests, suits, pants, shorts, and chaps. Accessories include leather pocket squares, wristbands, hoods, belts, caps, bows, and ties. The products are handmade from premium leather, ensuring high quality and a perfect fit tailored to individual measurements. They provide cust…

5. Vanson Leathers – Handcrafted Motorcycle Jackets

Domain: vansonleathers.com

Registered: 1997 (28 years)

Introduction: Vanson Leathers offers high-quality handcrafted American leather motorcycle jackets, including custom men’s and women’s leather jackets, off-the-rack leather motorcycle jackets and suits, custom racing suits, Cafe Racer Jackets, and Concealed Carry Jackets. Their product line includes Adventure Touring, Traditional, SportRider, Casual and Street, Military and Police, and various accessories. Vanso…

6. Aero Leather Clothing – Custom Vintage Leather Jackets

Domain: aeroleatherclothing.com

Registered: 1997 (28 years)

Introduction: Custom leather jackets made to order, expertly hand-crafted since 1981. Extensive range of vintage designs from the 1920s to 1960s, including utility jackets and motorcycle recreations. Over 100 classic coats available, customizable with various leather and lining options, including stitch color. Unique, high-quality craftsmanship synonymous with the Aero brand.

7. The Cast – Custom Leather Jackets & Vests

Domain: thecast.com

Registered: 1999 (26 years)

Introduction: CUSTOM LEATHER JACKETS & VESTS – MADE IN NYC – The Cast offers premium Custom Leather Jackets and Vests with superior quality & craftsmanship made locally in New York City. Clients can choose from various styles, leathers, linings, and hardware, with made-to-measure specifications available. Custom orders have a lifetime guarantee for stitching, construction, and hide quality, except in cases of c…

8. Clament Custom Leather – Custom Leather Jackets

Domain: clamentcustomleather.com

Registered: 2009 (16 years)

Introduction: Custom Made Leather Clothing for Men and Women, Free shipping, Customer Support: +1-830-266-7450, Categories include: Jackets & Coats, Blazer & Vest, Pants & Shorts, Dress & Skirt, Kids, Custom Leather Jackets, Embroidered Leather Jackets. Products on sale include: Suede Leather Flippy Mini Skirt, Brown Suede Leather Maxi Skirt, High Fashion Black Leather Jacket, Luxurious Red Leather Jacket, Burg…

Strategic Sourcing Conclusion and Outlook for custom made leather garments

In the evolving landscape of custom-made leather garments, strategic sourcing emerges as a pivotal element for B2B buyers seeking high-quality products. The insights gained from leading manufacturers highlight the importance of selecting suppliers who prioritize craftsmanship, sustainability, and adaptability to market trends. Buyers should consider not only the aesthetic appeal and functionality of leather garments but also the sourcing practices that ensure ethical production and material integrity.

Establishing strong partnerships with suppliers from diverse regions, including Africa, South America, the Middle East, and Europe, enables businesses to leverage unique materials and skilled craftsmanship. This global approach not only enhances product offerings but also aligns with consumer demands for authenticity and sustainability.

Looking ahead, the custom leather garment market presents significant opportunities for innovation and differentiation. B2B buyers are encouraged to explore collaborative design processes, embrace technological advancements in production, and remain responsive to changing consumer preferences. By strategically sourcing from reliable partners, businesses can position themselves for success in an increasingly competitive marketplace. Engage with suppliers today to craft bespoke leather solutions that resonate with your customers and elevate your brand.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.