Introduction: Navigating the Global Market for louis vuitton leather fabric

In today’s competitive landscape, sourcing authentic Louis Vuitton leather fabric can be a daunting challenge for international B2B buyers. With the luxury fabric market becoming increasingly saturated, discerning high-quality materials that maintain brand integrity while meeting cost constraints is crucial. This guide serves as a comprehensive resource for businesses across Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—seeking to navigate the complexities of sourcing Louis Vuitton leather fabric.

Within this guide, we delve into the diverse types of Louis Vuitton leather fabrics available, their various applications in fashion, upholstery, and crafting, and essential considerations for supplier vetting. Additionally, we provide insights into pricing structures and cost-effectiveness, ensuring that buyers can make informed purchasing decisions that align with their business objectives.

By equipping B2B buyers with actionable insights and expert advice, this guide empowers them to confidently select the right materials that not only enhance their product offerings but also resonate with their target markets. Whether you are a small designer or a large-scale manufacturer, understanding the nuances of sourcing Louis Vuitton leather fabric will position your business for success in the global marketplace.

Table Of Contents

- Top 5 Louis Vuitton Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for louis vuitton leather fabric

- Understanding louis vuitton leather fabric Types and Variations

- Key Industrial Applications of louis vuitton leather fabric

- 3 Common User Pain Points for ‘louis vuitton leather fabric’ & Their Solutions

- Strategic Material Selection Guide for louis vuitton leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for louis vuitton leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘louis vuitton leather fabric’

- Comprehensive Cost and Pricing Analysis for louis vuitton leather fabric Sourcing

- Alternatives Analysis: Comparing louis vuitton leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for louis vuitton leather fabric

- Navigating Market Dynamics and Sourcing Trends in the louis vuitton leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of louis vuitton leather fabric

- Strategic Sourcing Conclusion and Outlook for louis vuitton leather fabric

- Important Disclaimer & Terms of Use

Understanding louis vuitton leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Empreinte Leather | Textured finish, embossed pattern | Luxury handbags, high-end accessories | Pros: Distinctive look, durability. Cons: Higher cost, specific care requirements. |

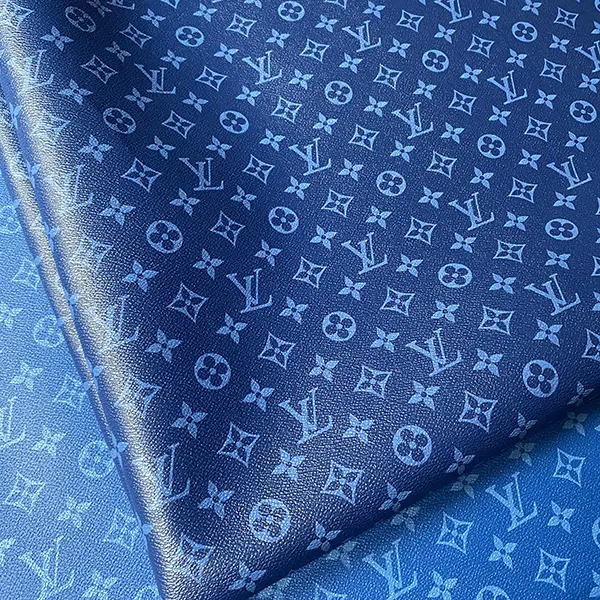

| Monogram Canvas | Iconic LV print, coated for water resistance | Fashion items, luggage, small leather goods | Pros: Brand recognition, versatile. Cons: Limited to specific styles. |

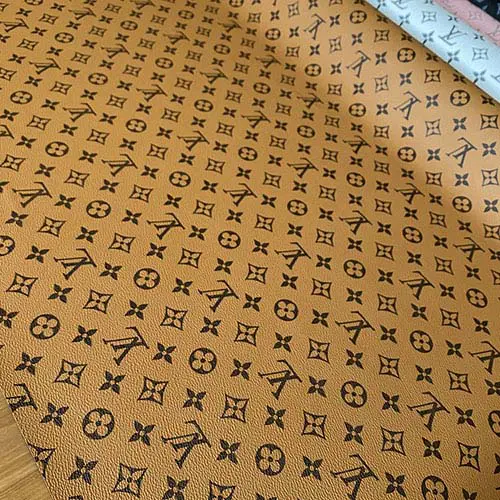

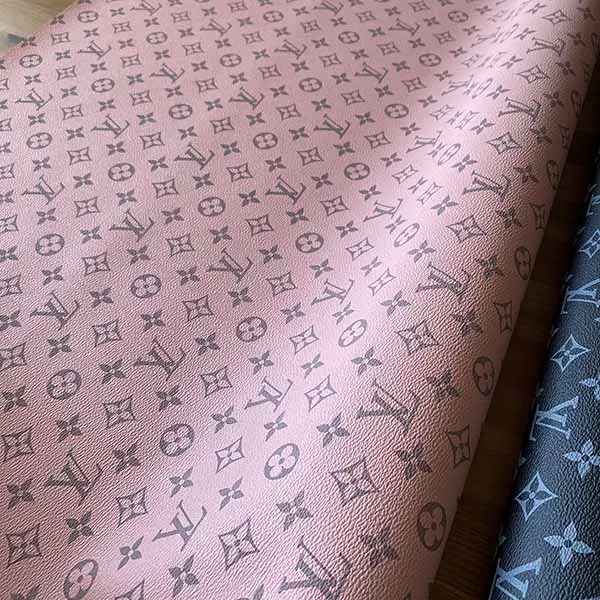

| Vinyl Fabric | Synthetic, available in various colors and patterns | Crafting, upholstery, fashion accessories | Pros: Cost-effective, easy to clean. Cons: Less luxurious feel compared to leather. |

| Denim-Look Leather | Denim pattern, soft texture | Casual bags, youth-oriented accessories | Pros: Trendy appeal, comfortable. Cons: May not suit formal applications. |

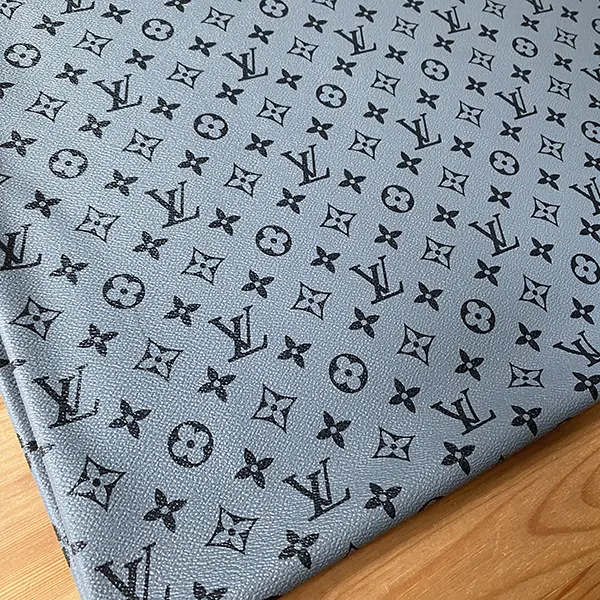

| Embossed Leather | Raised designs, available in multiple colors | Luxury goods, fashion apparel | Pros: Unique designs, high durability. Cons: Can be more expensive than flat leather. |

What Are the Key Characteristics of Empreinte Leather?

Empreinte leather is characterized by its unique embossed patterns that provide both texture and visual appeal. This type of leather is often used in luxury handbags and high-end accessories, making it a sought-after material for brands looking to convey exclusivity. When considering a purchase, B2B buyers should evaluate the leather’s durability and care instructions, as maintaining its quality is essential for long-term use. Its distinctive look can enhance product offerings, but the higher price point may require justification in luxury markets.

Illustrative image related to louis vuitton leather fabric

How Does Monogram Canvas Stand Out in the Market?

Monogram canvas is instantly recognizable due to its iconic LV print and is coated for water resistance, making it a practical choice for various applications. This fabric is primarily used in fashion items, luggage, and small leather goods, appealing to brands that want to leverage the strong brand identity associated with Louis Vuitton. B2B buyers should consider the versatility of this material, as it allows for a wide range of product designs. However, the limited styles may restrict creativity for some brands.

What Advantages Does Vinyl Fabric Offer for B2B Applications?

Vinyl fabric is a synthetic material known for its affordability and ease of maintenance, making it an attractive option for crafting, upholstery, and fashion accessories. Available in various colors and patterns, it allows for creativity without the hefty price tag associated with genuine leather. Buyers should consider the trade-off between cost-effectiveness and the luxury feel, as vinyl may not convey the same level of prestige. Its practicality makes it a popular choice for businesses targeting budget-conscious consumers.

Why Is Denim-Look Leather Gaining Popularity?

Denim-look leather features a soft texture and a trendy denim pattern, appealing particularly to younger demographics. This material is suitable for casual bags and youth-oriented accessories, aligning well with current fashion trends. B2B buyers should assess the target market’s preferences, as this type of leather may not fit formal applications. Its trendy appeal can help brands attract a niche audience, but careful consideration is needed to ensure it aligns with overall product strategy.

What Makes Embossed Leather a Unique Choice?

Embossed leather features raised designs and comes in various colors, making it a unique option for luxury goods and fashion apparel. This type of leather is valued for its durability and distinctive aesthetics, allowing brands to offer products that stand out in a crowded marketplace. B2B buyers should weigh the benefits of unique designs against the potential for higher costs. While embossed leather can elevate a product line, it requires a commitment to quality that may not suit all budgetary constraints.

Illustrative image related to louis vuitton leather fabric

Key Industrial Applications of louis vuitton leather fabric

| Industry/Sector | Specific Application of louis vuitton leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-end handbags and accessories | Enhances brand prestige and offers unique design options | Verify authenticity, consider local regulations on imports |

| Automotive | Interior upholstery for luxury vehicles | Elevates customer experience and retains vehicle value | Assess durability, color options, and custom patterns |

| Furniture and Home Décor | Upholstery for luxury furniture | Provides a premium look and feel, attracting affluent customers | Look for fire-retardant options and maintenance guidelines |

| Crafting and DIY Projects | Custom crafting for fashion items and decor | Allows for personalization and creativity in product offerings | Ensure availability of various patterns and textures |

| Hospitality and Events | Custom decor for luxury venues and events | Creates a memorable and upscale atmosphere for guests | Consider bulk purchasing options and lead times for delivery |

How is louis vuitton leather fabric used in the fashion and apparel industry?

In the fashion and apparel sector, louis vuitton leather fabric is predominantly utilized in the creation of high-end handbags and accessories. This luxurious material not only enhances the aesthetic appeal of products but also elevates brand prestige. For B2B buyers, particularly those from Africa and South America, ensuring the authenticity of the fabric is crucial, as counterfeit products can tarnish brand reputation. Additionally, understanding local import regulations will help streamline sourcing processes.

What role does louis vuitton leather fabric play in the automotive industry?

In the automotive sector, louis vuitton leather fabric is used for premium interior upholstery in luxury vehicles. This application significantly enhances the customer experience by providing a sophisticated and comfortable environment. For international buyers, particularly from Europe and the Middle East, it’s essential to evaluate the durability of the fabric, as well as the availability of various color options and custom patterns to meet specific design needs.

How is louis vuitton leather fabric applied in furniture and home décor?

Louis vuitton leather fabric finds its place in the furniture and home décor industry, where it is used for upholstery on luxury furniture items. This application not only adds a premium look and feel but also attracts affluent customers looking for unique home furnishings. Buyers should look for fire-retardant options and maintenance guidelines to ensure longevity and safety in their products, especially in regions with stringent safety regulations.

Illustrative image related to louis vuitton leather fabric

In what ways can crafting and DIY projects benefit from louis vuitton leather fabric?

Crafting and DIY projects leverage louis vuitton leather fabric for creating custom fashion items and decorative pieces. This fabric allows artisans and designers to personalize their creations, adding a unique touch that can set their offerings apart in a competitive market. Buyers should ensure a diverse availability of patterns and textures to cater to various project requirements, particularly for those targeting niche markets in Africa and South America.

How can the hospitality and events sector utilize louis vuitton leather fabric?

In the hospitality and events industry, louis vuitton leather fabric is used to create custom decor for luxury venues and events. This application helps in crafting a memorable and upscale atmosphere that enhances guest experiences. B2B buyers should consider bulk purchasing options and lead times for delivery, as timely availability of materials is critical for event planning and execution.

3 Common User Pain Points for ‘louis vuitton leather fabric’ & Their Solutions

Scenario 1: Sourcing Authentic Louis Vuitton Leather Fabric

The Problem: B2B buyers often struggle with sourcing authentic Louis Vuitton leather fabric due to the prevalence of counterfeit products in the market. This challenge is especially pronounced for businesses in regions like Africa and South America, where quality assurance can be difficult. Buyers may find themselves receiving inferior materials that do not meet their specifications, leading to financial losses and reputational damage. This issue is exacerbated by the lack of clear guidelines on identifying genuine materials.

The Solution: To ensure the authenticity of Louis Vuitton leather fabric, buyers should establish relationships with reputable suppliers who specialize in luxury materials. Conduct thorough due diligence by researching suppliers’ backgrounds, customer reviews, and certifications that verify their authenticity. Additionally, request samples before committing to larger orders. When evaluating a sample, look for specific characteristics such as texture, weight, and the distinct Louis Vuitton branding. This proactive approach not only safeguards your investment but also builds trust with your clientele by ensuring that the products you offer are genuine.

Scenario 2: Managing Inventory and Demand Fluctuations

The Problem: A common challenge for B2B buyers of Louis Vuitton leather fabric is managing inventory levels in response to fluctuating demand. For instance, a sudden increase in orders for luxury handbags or upholstery can lead to stock shortages, while overestimating demand can result in excess inventory that ties up capital. This balancing act can be particularly challenging for businesses operating in diverse markets with varying consumer preferences.

Illustrative image related to louis vuitton leather fabric

The Solution: Implementing a robust inventory management system can significantly enhance the ability to predict and respond to demand fluctuations. Utilize data analytics to track sales trends, seasonal demands, and market changes. Establish a minimum order quantity (MOQ) with suppliers to ensure that you can quickly replenish stock without overcommitting financially. Additionally, consider using a just-in-time (JIT) inventory approach, which allows you to order materials based on current demand rather than holding large quantities. Collaborating with suppliers who offer flexible ordering options can further streamline this process, enabling you to adapt quickly to market changes.

Scenario 3: Ensuring Fabric Quality for Specific Applications

The Problem: Buyers often face difficulties in ensuring that the Louis Vuitton leather fabric they purchase meets the specific quality standards required for their intended applications, such as fashion, upholstery, or crafting. Each application may require different attributes, such as durability, flexibility, or resistance to wear and tear. Without proper guidance, businesses may end up with materials that are unsuitable, leading to product failures and customer dissatisfaction.

The Solution: To mitigate this risk, buyers should develop a clear understanding of their application requirements before sourcing materials. Create a detailed specification document that outlines the necessary attributes, such as weight, thickness, finish, and colorfastness. Communicate these requirements clearly to suppliers and seek their expertise in recommending the most suitable fabric variants. Additionally, consider partnering with a textile engineer or consultant who can help assess fabric samples and ensure they align with your quality standards. By taking these steps, businesses can enhance product quality and customer satisfaction while minimizing the risk of returns or complaints.

Illustrative image related to louis vuitton leather fabric

Strategic Material Selection Guide for louis vuitton leather fabric

What Are the Key Materials Used in Louis Vuitton Leather Fabric?

When selecting Louis Vuitton leather fabric, international B2B buyers must consider various materials, each with distinct properties and applications. Below is an analysis of four common materials used in this premium fabric, focusing on their performance, advantages, disadvantages, and specific considerations for buyers from diverse regions.

1. Vinyl Leather

Key Properties:

Vinyl leather is known for its durability and resistance to moisture and stains. It typically performs well under moderate pressure and is easy to clean, making it suitable for various applications, including bags and upholstery.

Pros & Cons:

The primary advantage of vinyl leather is its cost-effectiveness compared to genuine leather. It is also lightweight and resistant to fading. However, it may not offer the same level of breathability or luxury feel as natural leather, which can limit its appeal for high-end products.

Impact on Application:

Vinyl leather is compatible with a wide range of crafting media, including adhesives and paints, making it versatile for custom designs. However, it may not be suitable for applications requiring high-temperature resistance.

Illustrative image related to louis vuitton leather fabric

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding synthetic materials, particularly in regions like Europe, where environmental standards are stringent. Understanding ASTM and DIN standards can aid in assessing product quality.

2. Genuine Leather

Key Properties:

Genuine leather boasts high tensile strength and excellent durability, making it suitable for luxury goods. It can withstand varying temperatures and has a natural moisture-wicking ability.

Pros & Cons:

While genuine leather offers a premium feel and aesthetic, it comes at a higher cost. Its production can be complex, requiring specific tanning processes that may not be available in all regions.

Impact on Application:

Genuine leather is ideal for high-end products such as handbags and accessories, where quality and aesthetics are paramount. However, it may require special care to maintain its appearance over time.

Illustrative image related to louis vuitton leather fabric

Considerations for International Buyers:

Buyers must be aware of the sourcing and ethical considerations surrounding genuine leather. Compliance with international standards, such as JIS and ISO, is essential to ensure product integrity and marketability.

3. Embossed Leather

Key Properties:

Embossed leather features a textured surface created through heat and pressure, enhancing its aesthetic appeal while maintaining the properties of genuine leather.

Pros & Cons:

The key advantage of embossed leather is its unique design possibilities, allowing for customization that can attract a specific market segment. However, the embossing process can add to manufacturing complexity and cost.

Impact on Application:

This material is particularly suitable for products that benefit from a distinctive look, such as fashion accessories. However, embossed patterns may require careful handling to prevent wear.

Illustrative image related to louis vuitton leather fabric

Considerations for International Buyers:

Buyers should consider the cultural significance of patterns and designs in their target markets, particularly in regions like Africa and South America, where traditional motifs may resonate more with consumers.

4. Faux Leather

Key Properties:

Faux leather is made from synthetic materials that mimic the look and feel of genuine leather. It is generally lightweight and resistant to water and stains.

Pros & Cons:

The main advantage of faux leather is its affordability and ethical appeal, as it does not involve animal products. However, it may lack the durability and premium feel of genuine leather, which could affect its acceptance in luxury markets.

Impact on Application:

Faux leather is suitable for a wide range of applications, including fashion and upholstery. However, it may not perform well under extreme conditions, limiting its use in high-stress applications.

Considerations for International Buyers:

Understanding local market preferences for sustainable and ethical products is crucial, especially in regions like Europe, where consumers increasingly demand eco-friendly options.

Illustrative image related to louis vuitton leather fabric

Summary Table of Material Selection

| Material | Typical Use Case for louis vuitton leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vinyl Leather | Bags, upholstery, crafting | Cost-effective and durable | Less breathable than genuine leather | Medium |

| Genuine Leather | Luxury handbags, accessories | Premium feel and durability | Higher cost and complex manufacturing | High |

| Embossed Leather | Fashion accessories, custom products | Unique design possibilities | Increased manufacturing complexity | High |

| Faux Leather | Fashion items, upholstery | Ethical and affordable | Lacks durability compared to genuine leather | Low |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding Louis Vuitton leather fabric, ensuring they choose the right materials for their specific needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for louis vuitton leather fabric

What Are the Key Stages in the Manufacturing Process of Louis Vuitton Leather Fabric?

The manufacturing of Louis Vuitton leather fabric involves several meticulous stages that ensure both quality and aesthetic appeal. These stages can be broadly categorized into material preparation, forming, assembly, and finishing. Each stage is crucial in creating the high-end products that the brand is known for.

Material Preparation: How Are Raw Materials Selected and Treated?

The journey begins with the selection of high-quality raw materials. Louis Vuitton sources premium leather from reputable tanneries, ensuring that only the finest hides are used. The selection process includes rigorous assessments of the leather’s texture, durability, and color consistency. Once selected, the leather undergoes a treatment process that may include tanning, dyeing, and conditioning. This not only enhances the leather’s appearance but also prepares it for further processing, ensuring longevity and resilience.

Forming: What Techniques Are Used to Shape the Fabric?

Once the leather is prepared, it enters the forming stage. This phase typically involves cutting the leather into specific patterns and shapes according to design specifications. Advanced cutting techniques, such as die-cutting and laser cutting, are employed to achieve precise dimensions. Additionally, Louis Vuitton often utilizes embossing techniques to imprint their iconic patterns and logos onto the leather, adding a distinctive touch that enhances brand recognition.

Assembly: How Are Different Components Joined Together?

The assembly stage is where craftsmanship shines. Skilled artisans meticulously assemble the cut pieces using specialized sewing techniques. This may include hand-stitching for certain high-end products, ensuring durability and attention to detail. The assembly process is not only about joining materials; it also involves integrating hardware components like zippers and clasps, which are often sourced from trusted suppliers to maintain quality standards.

Illustrative image related to louis vuitton leather fabric

Finishing: What Final Touches Are Applied to Ensure Quality?

The finishing stage is where the leather fabric is polished to perfection. This includes applying protective coatings to enhance water resistance and durability, as well as final inspections for any defects. The finishing process may also involve additional treatments, such as aging or patina application, to give the leather a unique character that appeals to luxury consumers.

What Quality Assurance Measures Are Implemented for Louis Vuitton Leather Fabric?

Quality assurance is an integral part of the manufacturing process for Louis Vuitton leather fabric. The brand adheres to international standards such as ISO 9001, which ensures a consistent quality management system across all manufacturing processes.

How Are International Standards Integrated into the Quality Control Process?

ISO 9001 outlines the criteria for an effective quality management system, focusing on meeting customer expectations and regulatory requirements. Louis Vuitton integrates these standards into their manufacturing processes, ensuring that every batch of leather fabric meets high-quality benchmarks. Additionally, industry-specific standards like CE marking may apply, particularly when the fabric is used in products intended for markets in Europe.

Illustrative image related to louis vuitton leather fabric

What Are the Key Quality Control Checkpoints During Production?

To maintain quality throughout the manufacturing process, several quality control checkpoints are established. These typically include:

- Incoming Quality Control (IQC): Before production begins, raw materials undergo rigorous inspections to verify their quality and compliance with specifications.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to ensure that processes are followed correctly, and any deviations are addressed immediately.

- Final Quality Control (FQC): After assembly, final inspections are conducted to assess the product’s overall quality, ensuring that it meets both aesthetic and functional criteria.

What Testing Methods Are Commonly Used to Ensure Fabric Quality?

Various testing methods are employed to assess the quality of Louis Vuitton leather fabric. These may include:

- Physical tests: Evaluating the fabric’s tensile strength, tear resistance, and abrasion resistance.

- Chemical tests: Assessing colorfastness and the presence of harmful substances.

- Visual inspections: Detecting any aesthetic flaws or inconsistencies in patterns.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure consistent product quality.

Illustrative image related to louis vuitton leather fabric

What Steps Should Buyers Take to Conduct Supplier Audits?

Conducting audits is a proactive approach to ensure that suppliers adhere to quality standards. Buyers should:

- Request audit reports: Suppliers should provide documentation of internal audits and quality control assessments.

- Schedule on-site visits: Direct inspections of the manufacturing facilities allow buyers to observe processes and standards firsthand.

- Engage third-party inspectors: Utilizing independent inspectors can provide an unbiased assessment of the supplier’s quality control measures.

What Are the Nuances of Quality Control and Certification for Different Regions?

Different regions may have varying expectations regarding quality control and certification. For instance, European buyers may prioritize compliance with CE marking, while those in Africa and South America may focus on adherence to local regulations and standards. Understanding these nuances is vital for B2B buyers to ensure that the products they source meet regional requirements.

Conclusion

In summary, the manufacturing processes and quality assurance measures for Louis Vuitton leather fabric are designed to uphold the brand’s reputation for excellence. By understanding these processes, B2B buyers can make informed decisions when sourcing high-quality leather fabrics. Engaging with suppliers who adhere to stringent quality control measures, and conducting thorough audits can significantly enhance the reliability of their procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘louis vuitton leather fabric’

This guide is designed to assist B2B buyers in navigating the procurement process for Louis Vuitton leather fabric, ensuring that all necessary steps are taken to secure high-quality materials that meet specific business needs. By following this checklist, buyers can streamline their sourcing efforts and establish reliable supplier relationships.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the first critical step in sourcing Louis Vuitton leather fabric. Consider the intended use of the fabric—whether for high-end fashion, upholstery, or accessories. Key specifications to define include texture, color, durability, and compliance with industry standards. This clarity will help you communicate effectively with suppliers and ensure you receive the right products.

Illustrative image related to louis vuitton leather fabric

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of Louis Vuitton leather fabric. Look for suppliers with a strong track record in the industry, especially those that cater to your geographical region. Utilize online directories, trade shows, and industry publications to compile a list of potential suppliers. Pay attention to customer reviews and testimonials to gauge their reliability.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify that potential suppliers hold the necessary certifications. This includes quality assurance certifications, environmental compliance, and ethical sourcing certifications. These credentials not only reflect the supplier’s commitment to quality but also ensure that your procurement aligns with sustainable and ethical business practices.

Step 4: Request Samples

Always request samples of the leather fabric before placing a bulk order. This allows you to assess the quality, texture, and appearance firsthand. When evaluating samples, consider how they align with your defined specifications and whether they meet your quality standards. This step minimizes the risk of receiving subpar materials that may not fulfill your project needs.

Step 5: Compare Pricing and Terms

Once you have shortlisted suppliers, compare pricing and terms of service. Request detailed quotes that include costs per yard, shipping fees, and any applicable taxes. Be aware of the payment terms, return policies, and lead times for delivery. A comprehensive understanding of these factors will enable you to make an informed decision based on your budget and timeline.

Illustrative image related to louis vuitton leather fabric

Step 6: Establish Clear Communication Channels

Effective communication is essential throughout the sourcing process. Clearly outline your expectations and maintain open lines of communication with suppliers. This includes discussing project timelines, order quantities, and any changes to specifications. Establishing a good rapport can facilitate smoother transactions and help address any issues that may arise promptly.

Step 7: Finalize the Agreement and Place Your Order

After evaluating all aspects, finalize your agreement with the chosen supplier. Ensure that all terms are documented in a formal contract, including delivery timelines and payment schedules. Once everything is in place, place your order confidently, knowing that you’ve conducted thorough due diligence throughout the sourcing process.

By following this checklist, B2B buyers can enhance their sourcing strategy for Louis Vuitton leather fabric, ensuring quality and reliability in their procurement efforts.

Illustrative image related to louis vuitton leather fabric

Comprehensive Cost and Pricing Analysis for louis vuitton leather fabric Sourcing

What Are the Key Cost Components in Sourcing Louis Vuitton Leather Fabric?

When sourcing Louis Vuitton leather fabric, understanding the cost structure is critical for effective budgeting and financial planning. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The raw materials used in producing Louis Vuitton leather fabrics—such as high-quality vinyl and leather—are often sourced from premium suppliers. This can lead to higher upfront costs compared to standard fabrics. Prices range from $25 to $59 per yard, depending on the specific type of leather or vinyl and its unique features.

-

Labor: Skilled labor is essential for the manufacturing of luxury fabrics. The complexity of the patterns and the finishing processes require a workforce trained in high-precision techniques. Labor costs can vary significantly by region, with labor-intensive production often occurring in countries with established textile industries.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Depending on the location of the manufacturing facility, these costs can fluctuate, impacting the overall price of the fabric.

-

Tooling: Initial tooling costs for specialized machinery or molds needed to produce unique patterns can be substantial. These costs are typically amortized over the production run, influencing the per-yard price of the fabric.

-

Quality Control: Ensuring that the fabric meets the high standards associated with the Louis Vuitton brand necessitates rigorous quality control measures, which can add to the overall cost. This may include multiple inspections and testing for durability and finish.

-

Logistics: Shipping costs are a significant factor, especially for international transactions. The choice of shipping methods and Incoterms can impact delivery times and costs, which should be factored into the total price.

-

Margin: Suppliers will add a margin to cover their costs and ensure profitability. This margin can vary widely based on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Affect the Cost of Louis Vuitton Leather Fabric?

Several factors can influence the price of Louis Vuitton leather fabric, particularly for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating MOQs can be beneficial, particularly for businesses looking to maintain inventory without incurring excessive costs.

-

Specifications and Customization: Custom orders or unique specifications may incur additional charges. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Fabrics with specific certifications (e.g., eco-friendly or hypoallergenic) may command higher prices. Buyers should weigh the importance of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may offer higher prices due to their brand value, while newer entrants might be more competitive.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is vital, as they determine the responsibilities for shipping, insurance, and tariffs. Buyers should choose terms that minimize their risk and overall costs.

What Are Essential Tips for Negotiating Prices on Louis Vuitton Leather Fabric?

-

Be Informed: Research market prices and trends in the leather fabric industry to negotiate effectively. Understanding the typical cost range can empower buyers during discussions.

-

Focus on Total Cost of Ownership: Consider not only the purchase price but also shipping, handling, and potential waste during production. This holistic view can lead to more cost-effective decisions.

-

Flexible Payment Terms: Negotiate payment terms that ease cash flow, such as staggered payments based on delivery milestones, which can be particularly beneficial for international transactions.

-

Long-term Relationships: Establishing a good rapport with suppliers can yield better pricing and terms over time. Consider long-term contracts to lock in favorable rates.

-

Stay Agile: Be prepared to pivot based on market conditions. If prices rise due to supply chain disruptions, consider alternative suppliers or materials to mitigate costs.

Disclaimer

The prices mentioned for Louis Vuitton leather fabrics are indicative and may vary based on market conditions, supplier negotiations, and specific order requirements. Always confirm current pricing directly with suppliers.

Alternatives Analysis: Comparing louis vuitton leather fabric With Other Solutions

Understanding Alternatives to Louis Vuitton Leather Fabric

When evaluating materials for high-end products such as bags, upholstery, or fashion accessories, it is crucial to consider alternatives to Louis Vuitton leather fabric. This analysis will help B2B buyers identify the best fit for their specific needs by comparing Louis Vuitton leather fabric with other viable solutions available in the market. The alternatives examined here are synthetic leather and genuine cowhide leather, both of which offer unique attributes that may align better with certain business objectives.

| Comparison Aspect | Louis Vuitton Leather Fabric | Synthetic Leather | Genuine Cowhide Leather |

|---|---|---|---|

| Performance | High durability and aesthetic appeal | Good durability; varies by quality | Excellent durability and natural feel |

| Cost | $35 – $59 per yard | $10 – $30 per yard | $50 – $150 per square foot |

| Ease of Implementation | Requires specialized skills for crafting | Easy to work with and manipulate | Requires skilled labor for processing |

| Maintenance | Low maintenance; resistant to stains | Low maintenance; easy to clean | Moderate maintenance; may require conditioning |

| Best Use Case | Luxury fashion items and accessories | Casual wear, bags, and upholstery | High-end products requiring a premium feel |

Exploring Synthetic Leather as an Alternative

Synthetic leather, often referred to as faux leather, offers a cost-effective solution for businesses seeking a versatile material. Its price range, typically between $10 and $30 per yard, makes it accessible for bulk purchasing. Additionally, synthetic leather is easy to manipulate, making it suitable for various applications, from casual wear to upholstery. However, while it can mimic the appearance of genuine leather, it may lack the premium feel and durability associated with luxury materials like Louis Vuitton leather. For businesses targeting budget-conscious consumers or those focused on sustainability, synthetic leather could be a practical choice.

Evaluating Genuine Cowhide Leather as an Alternative

Genuine cowhide leather is a traditional alternative that provides unmatched durability and a luxurious feel. Priced between $50 and $150 per square foot, it tends to be more expensive than both Louis Vuitton leather fabric and synthetic options. Its natural texture and aging properties can enhance the aesthetic appeal of products, making it a preferred choice for high-end brands. However, working with genuine cowhide requires skilled craftsmanship and a more complex maintenance routine to preserve its quality over time. This makes it ideal for businesses focusing on high-quality, artisanal products but may not be the best fit for mass production.

How Should B2B Buyers Choose the Right Material?

When selecting a material, B2B buyers should consider various factors, including target market, budget constraints, and product application. If luxury branding and high aesthetic value are priorities, Louis Vuitton leather fabric stands out as a premier choice. Conversely, businesses focused on affordability and versatility may find synthetic leather more appealing. For those aiming for a premium, authentic feel, genuine cowhide leather can enhance the overall quality of their offerings. Ultimately, the right choice will depend on aligning material attributes with business objectives and consumer expectations.

Essential Technical Properties and Trade Terminology for louis vuitton leather fabric

What Are the Key Technical Properties of Louis Vuitton Leather Fabric?

When sourcing Louis Vuitton leather fabric, understanding its technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade

Material grade refers to the quality classification of the leather used in manufacturing. High-grade materials typically exhibit superior durability, aesthetic appeal, and performance. For B2B buyers, selecting a high-grade material ensures that the final products meet consumer expectations, enhancing brand reputation and customer satisfaction. -

Thickness

The thickness of leather fabric can significantly impact its application. Thicker leather provides durability, making it ideal for items like bags and upholstery, while thinner options may be better suited for clothing. Understanding the thickness helps buyers choose the right fabric for their specific needs, ensuring optimal functionality and comfort. -

Finish Type

The finish type defines the surface treatment applied to the leather, which affects its texture, sheen, and overall appearance. Common finishes include matte, glossy, and embossed. Knowing the finish type is essential for buyers who want to achieve a specific aesthetic in their products while also considering factors like maintenance and wear. -

Colorfastness

Colorfastness measures the resistance of the fabric’s color to fading or running when exposed to light, washing, or friction. This property is vital for ensuring that the products maintain their visual appeal over time, especially for high-end goods where appearance is paramount. Buyers should prioritize fabrics with high colorfastness ratings to ensure longevity. -

Weight

The weight of leather fabric is typically measured in grams per square meter (GSM) and influences the fabric’s drape and durability. Lighter materials may be preferred for fashion items, while heavier materials are suitable for more robust applications. Understanding weight helps in making appropriate selections based on the intended use of the fabric.

What Common Trade Terms Should B2B Buyers Understand?

Familiarizing yourself with industry jargon can streamline the purchasing process and facilitate better negotiations. Here are some common terms related to sourcing Louis Vuitton leather fabric:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are then sold under another company’s brand name. For buyers, working with an OEM can provide access to high-quality materials and exclusive designs, often leading to enhanced product offerings. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for buyers to understand, as it affects inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases effectively and avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes for specific quantities of materials. B2B buyers often use RFQs to compare pricing and terms from multiple suppliers, ensuring they secure the best deal while maintaining quality. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers to clarify shipping responsibilities, risks, and costs, facilitating smoother transactions across borders. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For buyers, understanding lead times is crucial for inventory planning and ensuring timely product launches. Long lead times may necessitate earlier ordering to meet market demands.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing Louis Vuitton leather fabric, ensuring they make strategic decisions that align with their business goals.

Navigating Market Dynamics and Sourcing Trends in the louis vuitton leather fabric Sector

What are the Current Market Dynamics and Key Trends in the Louis Vuitton Leather Fabric Sector?

The global luxury market continues to witness robust growth, with Louis Vuitton leather fabric emerging as a significant player in this segment. Key drivers include rising disposable incomes, increasing urbanization, and a growing demand for high-quality, fashionable materials among consumers and businesses alike. In regions like Africa, South America, the Middle East, and Europe, particularly in countries such as Germany and Nigeria, the appetite for luxury goods is expanding rapidly. This shift presents substantial opportunities for B2B buyers looking to source Louis Vuitton leather fabrics for fashion, upholstery, and accessory production.

Current B2B tech trends are reshaping sourcing strategies. Digital platforms are facilitating direct connections between manufacturers and buyers, allowing for more streamlined procurement processes. Technologies like blockchain are also enhancing supply chain transparency, ensuring authenticity—a critical factor for luxury brands. As the market evolves, the demand for unique patterns and colors in leather fabric is rising. Buyers are increasingly seeking customizable options, which can cater to niche markets, thus driving innovation within the sector.

How is Sustainability and Ethical Sourcing Impacting the Louis Vuitton Leather Fabric Industry?

In today’s market, sustainability is not just a trend; it is a necessity. The environmental impact of leather production has led to increased scrutiny from consumers and regulators alike. B2B buyers must prioritize ethical sourcing practices when procuring Louis Vuitton leather fabrics. This includes understanding the sourcing of raw materials, such as leather and vinyl, and ensuring compliance with environmental regulations.

Buyers should also consider the importance of certifications that indicate sustainable practices, such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification. These certifications not only mitigate environmental impact but also enhance brand reputation and consumer trust. By aligning sourcing strategies with sustainability goals, businesses can differentiate themselves in a competitive market while meeting the growing demand for ethically produced materials.

What is the Brief Evolution and History of Louis Vuitton Leather Fabric?

Louis Vuitton, founded in 1854, has a rich history rooted in craftsmanship and luxury. Initially recognized for its durable trunks and travel bags, the brand diversified into leather goods, including innovative fabric designs. Over the years, Louis Vuitton has become synonymous with quality and exclusivity, setting benchmarks in the fashion and luxury sectors. The introduction of distinctive patterns and high-quality leather has made Louis Vuitton leather fabric a sought-after material worldwide. Understanding this evolution helps B2B buyers appreciate the brand’s legacy and the value it brings to their sourcing decisions.

Illustrative image related to louis vuitton leather fabric

In conclusion, navigating the complexities of the Louis Vuitton leather fabric market requires a strategic approach that encompasses market dynamics, sustainability, and an appreciation of the brand’s historical significance. By leveraging these insights, B2B buyers can make informed decisions that align with their business objectives and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of louis vuitton leather fabric

-

How do I ensure the quality of Louis Vuitton leather fabric before purchase?

To ensure the quality of Louis Vuitton leather fabric, request samples from potential suppliers. Inspect the samples for texture, durability, and color accuracy. Additionally, verify the supplier’s reputation through reviews and testimonials. Certifications related to quality standards can also provide assurance. Establishing a clear communication channel with the supplier will help clarify any questions regarding material specifications and quality control processes. -

What are the typical minimum order quantities (MOQs) for Louis Vuitton leather fabric?

MOQs for Louis Vuitton leather fabric can vary significantly by supplier and specific fabric type. Generally, MOQs can range from 5 to 20 yards or more. It’s crucial to discuss these terms upfront during negotiations to avoid surprises later. Some suppliers may offer flexibility on MOQs for first-time buyers or bulk orders, so consider leveraging your purchasing power to negotiate favorable terms. -

What payment terms should I expect when sourcing Louis Vuitton leather fabric internationally?

Payment terms for international orders of Louis Vuitton leather fabric typically include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit upfront, often around 30%, with the balance due before shipment. Clarifying these terms in advance is essential to ensure transparency and avoid payment disputes later in the transaction process. -

How can I customize Louis Vuitton leather fabric for my business needs?

Customization options for Louis Vuitton leather fabric may include selecting specific colors, patterns, or textures. Contact suppliers directly to discuss your customization requirements. Some suppliers may have design capabilities to create bespoke fabrics based on your specifications. Be prepared to provide detailed descriptions or samples of what you envision, as this will facilitate better communication and a more accurate outcome. -

What logistics considerations should I keep in mind when importing Louis Vuitton leather fabric?

When importing Louis Vuitton leather fabric, consider factors such as shipping methods, customs regulations, and delivery timelines. Choose a reliable logistics partner experienced in handling textiles and ensure they are familiar with the import regulations specific to your country. Additionally, factor in potential delays due to customs processing, and prepare necessary documentation such as invoices and packing lists to streamline the process. -

How do I vet suppliers of Louis Vuitton leather fabric?

To vet suppliers, conduct thorough research to assess their credibility and reliability. Look for established companies with a proven track record in the industry. Request references and check for certifications relevant to textile production. Engaging in direct communication, asking for detailed product information, and reviewing their production capacity can also help ensure they meet your business standards and requirements. -

What are the best practices for negotiating contracts with suppliers of Louis Vuitton leather fabric?

Best practices for negotiating contracts include clearly defining the terms of sale, including price, delivery schedules, and payment terms. It’s also essential to include clauses related to quality assurance, returns, and dispute resolution. Be prepared to compromise, but don’t hesitate to stand firm on critical aspects that affect your business. Document all agreements in writing to prevent misunderstandings and ensure both parties are aligned. -

How can I manage quality assurance for imported Louis Vuitton leather fabric?

To manage quality assurance, establish a quality control process that includes inspecting the fabric upon arrival. Implement a checklist that covers aspects like color consistency, texture, and defect rates. Consider third-party inspection services to ensure compliance with your quality standards before shipment. Regular communication with your supplier regarding quality expectations can also help maintain standards and foster a long-term partnership.

Top 5 Louis Vuitton Leather Fabric Manufacturers & Suppliers List

1. Louis Vuitton – Leather Fabric Range

Domain: woucom

Introduction: Louis Vuitton Leather Fabric Range for sale by the yard in 2024. Multiple variants available for each product. Price range for most fabrics is $35 to $59. Key products include: LL01 White leather fabric, LL02 Orange Leather Fabric, LL03 Green Louis Vuitton Empreinte Leather Fabric, LL04 Ivory Leather Fabric, LL06 Green Fabric, LL07 Blue Fabric, LL08 Black fabric with gold pattern, LL09 Gray Leathe…

2. Louis Vuitton – Leather Sheets

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Louis Vuitton – Leather Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. LV Fashion – Fashion LV Vinyl Crafting Leather Fabric

Domain: jackfabricstore.com

Registered: 2024 (1 years)

Introduction: Collection: LV Fashion

Total Products: 424

In Stock: 423

Out of Stock: 7

Price Range: From $10.00 to $620.00

Key Products:

1. Fashion LV vinyl crafting leather fabric for handmade goods – Regular price: From $10.00 USD

2. Fashion Embossed LV Crafting Leather Fabric for Handmade Bags, Shoes, and DIY Handicrafts (Black) – Regular price: From $10.00 USD

3. Classic LV vinyl crafting leather fabric fo…

4. Louis Vuitton – Classic LV Designer Leather Sheet Fabric

Domain: wendycustom.com

Registered: 2022 (3 years)

Introduction: Collection: Louis Vuitton, Total Products: 411, In Stock: 409, Out of Stock: 2, Price Range: From $5.00 to $458.00, Key Products: Classic Louis Vuitton LV Designer Leather Sheet fabric for bag leather, sofa leather ($25.00), Black embossed LV craft Faux leather fabric by yard ($10.00), Classic black grey Louis Vuitton LV Designer Leather custom leather fabric for bag leather, sofa leather ($5.00),…

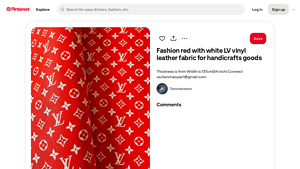

5. LV – Fashion Red and White Vinyl Leather Fabric

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: {“product_name”:”Fashion red and white LV vinyl leather fabric”,”usage”:”handicrafts”,”thickness”:”1mm”,”width”:”137cm (54 inch)”}

Strategic Sourcing Conclusion and Outlook for louis vuitton leather fabric

In the evolving landscape of luxury materials, Louis Vuitton leather fabric stands out as a premium choice for businesses aiming to meet high consumer expectations. The diverse range of offerings, from vibrant colors to textured patterns, provides numerous options for manufacturers in sectors such as fashion, automotive, and home décor. By strategically sourcing these materials, businesses can enhance their product lines, ensuring they align with current trends while maintaining a commitment to quality.

International buyers, particularly from Africa, South America, the Middle East, and Europe, are encouraged to explore the benefits of direct sourcing. Establishing strong supplier relationships can lead to favorable pricing, exclusive designs, and enhanced supply chain efficiencies. Furthermore, investing in Louis Vuitton leather fabric not only elevates brand prestige but also appeals to discerning customers seeking luxury and durability.

As we look to the future, the demand for high-quality materials will only increase. Businesses should act now to secure their supply chains and differentiate themselves in a competitive market. Engage with trusted suppliers today to access the finest Louis Vuitton leather fabrics and position your offerings for success in tomorrow’s marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to louis vuitton leather fabric

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.