Introduction: Navigating the Global Market for fabric upholstery car

In the fast-evolving automotive industry, sourcing high-quality fabric upholstery for cars presents a significant challenge for international B2B buyers. As businesses strive to enhance vehicle interiors while balancing comfort and durability, understanding the nuances of fabric upholstery becomes crucial. This guide delves into the diverse landscape of automotive fabrics, exploring various types, applications, and critical factors such as supplier vetting and cost analysis.

With a focus on the unique needs of buyers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Saudi Arabia and Vietnam—this comprehensive resource equips decision-makers with the knowledge required to make informed purchasing choices. By examining trends in materials ranging from luxurious velvets to durable synthetics, and highlighting important considerations such as flame retardancy and abrasion resistance, this guide aims to streamline the procurement process for fabric upholstery.

Furthermore, it offers actionable insights to navigate the complexities of the global market, enabling businesses to select upholstery solutions that not only enhance aesthetics but also ensure longevity and performance. As the demand for tailored automotive interiors continues to rise, leveraging this guide will empower B2B buyers to confidently address their upholstery needs, ultimately driving customer satisfaction and business success.

Table Of Contents

- Top 8 Fabric Upholstery Car Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric upholstery car

- Understanding fabric upholstery car Types and Variations

- Key Industrial Applications of fabric upholstery car

- 3 Common User Pain Points for ‘fabric upholstery car’ & Their Solutions

- Strategic Material Selection Guide for fabric upholstery car

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric upholstery car

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric upholstery car’

- Comprehensive Cost and Pricing Analysis for fabric upholstery car Sourcing

- Alternatives Analysis: Comparing fabric upholstery car With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric upholstery car

- Navigating Market Dynamics and Sourcing Trends in the fabric upholstery car Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric upholstery car

- Strategic Sourcing Conclusion and Outlook for fabric upholstery car

- Important Disclaimer & Terms of Use

Understanding fabric upholstery car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Velvet Upholstery | Soft texture, luxurious appearance, and high durability | Luxury vehicles, custom interiors | Pros: Elegant look, comfortable feel. Cons: Can be expensive, requires regular maintenance. |

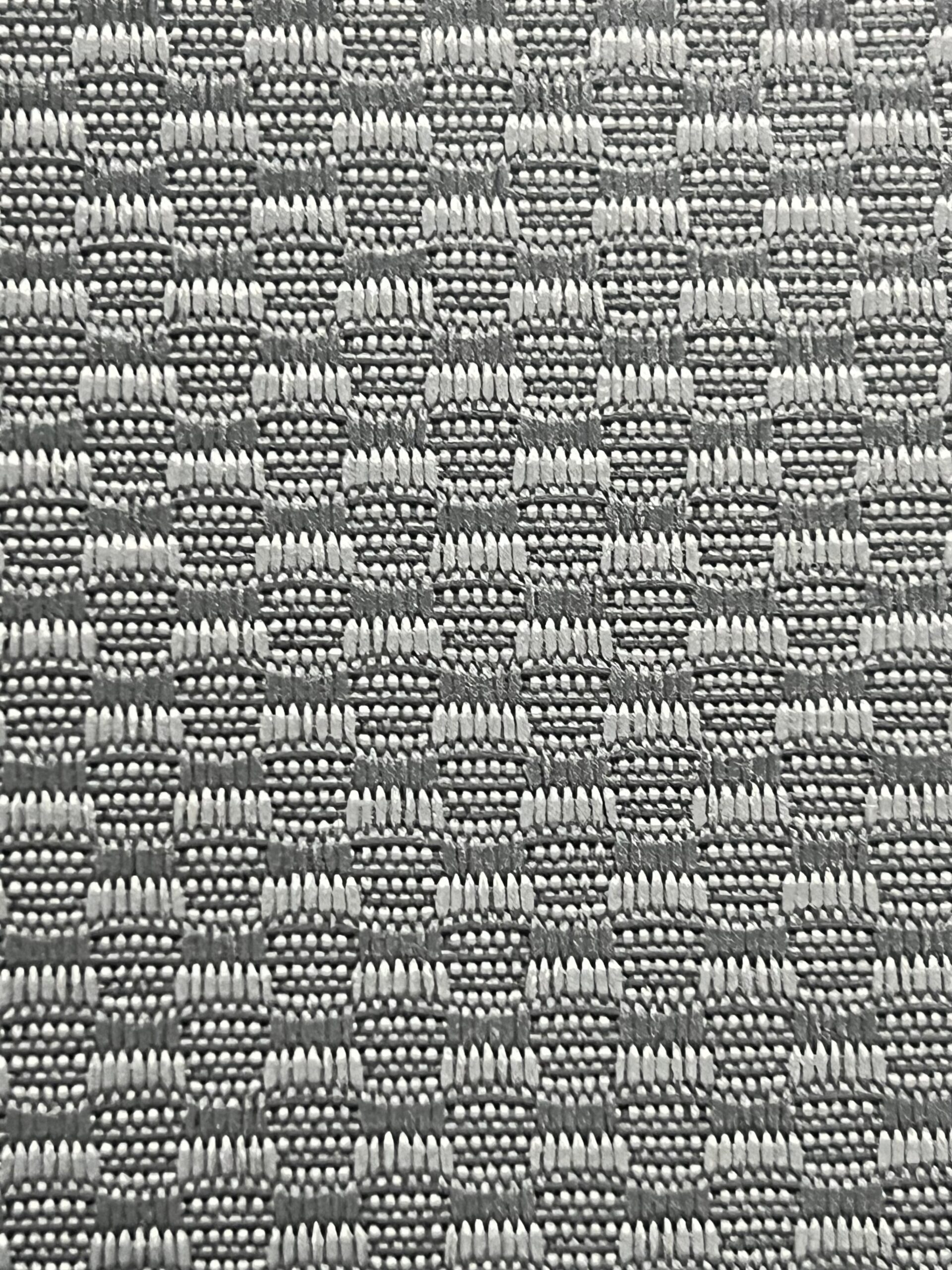

| Tweed Upholstery | Textured surface, excellent abrasion resistance | Trucks, RVs, and off-road vehicles | Pros: Durable, resistant to wear. Cons: May not be as soft as other options, limited color choices. |

| Microfiber Upholstery | Soft, plush feel with stain resistance | Family vehicles, everyday cars | Pros: Affordable, easy to clean. Cons: Can wear out faster than leather, less luxurious feel. |

| Polyester Upholstery | Versatile, available in various colors and patterns | Mass-market vehicles, fleet cars | Pros: Cost-effective, good durability. Cons: Less breathable, may fade over time. |

| Vinyl Upholstery | Budget-friendly, easy to maintain, water-resistant | Commercial vehicles, taxis | Pros: Affordable, easy to clean. Cons: Less comfortable in extreme temperatures, less durable than fabric. |

What Are the Key Characteristics of Velvet Upholstery?

Velvet upholstery is known for its plush texture and luxurious appearance, making it a favored choice in high-end vehicles and custom interiors. Its durability is a significant advantage, as it can withstand frequent use without showing wear. For B2B buyers, considering velvet means evaluating its cost versus the luxury appeal it provides. Regular maintenance is essential to keep it looking its best, which may influence long-term cost-effectiveness.

Why Choose Tweed Upholstery for Heavy-Duty Applications?

Tweed upholstery features a textured surface that offers exceptional abrasion resistance, making it ideal for trucks, RVs, and off-road vehicles. This material is particularly suitable for environments where durability is paramount, such as in vehicles subjected to heavy use. B2B buyers should weigh the long-term durability against the potential for limited color and design options, ensuring that the aesthetic meets their brand or customer needs.

How Does Microfiber Upholstery Compare in Terms of Comfort and Maintenance?

Microfiber upholstery provides a soft, plush feel while offering stain resistance, making it an attractive option for family vehicles and everyday cars. Its affordability and ease of cleaning are significant benefits for B2B buyers looking for practical solutions. However, it may not provide the same level of luxury as leather or velvet, and its durability can be a concern, particularly in high-traffic areas.

What Makes Polyester Upholstery a Versatile Choice?

Polyester upholstery is highly versatile, available in various colors and patterns, and is commonly used in mass-market and fleet vehicles. Its cost-effectiveness and decent durability make it appealing for budget-conscious buyers. However, B2B purchasers should consider its breathability and potential for fading over time, which may affect the vehicle’s long-term appearance and comfort.

Why Is Vinyl Upholstery Popular in Commercial Vehicles?

Vinyl upholstery stands out for its affordability, ease of maintenance, and water-resistant properties, making it a popular choice for commercial vehicles and taxis. While it offers a practical solution for high-traffic environments, buyers must consider its comfort level, especially in extreme temperatures. The trade-off between cost and comfort can be crucial for B2B buyers aiming for a balance between budget constraints and customer satisfaction.

Key Industrial Applications of fabric upholstery car

| Industry/Sector | Specific Application of fabric upholstery car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Upholstery for passenger vehicles | Enhances comfort and aesthetic appeal, attracting buyers | Durability, flame retardancy, and compliance with safety standards |

| Transportation Services | Upholstery for commercial vehicles (buses, trucks) | Provides durability and ease of maintenance for high-use environments | Stain resistance, ease of cleaning, and comfort for long journeys |

| Hospitality | Upholstery for rental and fleet vehicles | Creates a welcoming atmosphere, enhancing customer experience | Customization options and durability to withstand frequent use |

| Recreational Vehicles | Upholstery for RVs and campers | Combines comfort with style, appealing to leisure travelers | Weather resistance, durability, and aesthetic variety |

| Marine Industry | Upholstery for boats and yachts | Offers luxurious, weather-resistant interiors for high-end markets | UV stability, water resistance, and easy maintenance |

How is Fabric Upholstery Used in Automotive Manufacturing?

In the automotive manufacturing sector, fabric upholstery plays a crucial role in enhancing both comfort and aesthetics within passenger vehicles. The right fabric can significantly affect consumer perception and purchasing decisions. Manufacturers often seek materials that not only provide a luxurious feel but also meet rigorous safety and durability standards, such as flame retardancy and abrasion resistance. For international buyers, particularly in regions like Europe and the Middle East, understanding local regulations and preferences for sustainable materials is essential for successful sourcing.

Illustrative image related to fabric upholstery car

What are the Benefits of Fabric Upholstery in Transportation Services?

For transportation services, including buses and trucks, fabric upholstery is vital for creating a comfortable and durable seating environment. Given the high frequency of use, upholstery must withstand wear and tear while remaining easy to clean. Buyers in this sector prioritize materials that offer stain resistance and long-lasting durability, ensuring minimal downtime for maintenance. International buyers must also consider the climate variations in their regions, which can influence the choice of fabric, such as UV-resistant materials in sunny areas like South America.

How Does Fabric Upholstery Enhance Hospitality Vehicles?

In the hospitality industry, fabric upholstery is used in rental and fleet vehicles to create a welcoming atmosphere for guests. The right upholstery can enhance the overall customer experience, making it a critical factor for businesses aiming to stand out in a competitive market. Sourcing considerations include customization options to reflect the brand’s identity and durability to handle frequent usage. Buyers from diverse regions, such as Africa and Europe, should focus on fabrics that can endure varying climate conditions while still providing comfort.

What Role Does Fabric Upholstery Play in Recreational Vehicles?

For recreational vehicles (RVs) and campers, fabric upholstery combines style with comfort, appealing to leisure travelers. The right fabric not only enhances the visual appeal of the vehicle but also provides a cozy environment for long journeys. Buyers in this sector often look for weather-resistant materials that can withstand outdoor conditions while maintaining aesthetic variety. International buyers should consider local preferences for colors and patterns that resonate with their target markets.

Why is Fabric Upholstery Important in the Marine Industry?

In the marine industry, fabric upholstery is essential for boats and yachts, offering both luxury and functionality. High-quality upholstery materials must be weather-resistant and easy to maintain, ensuring they can withstand the harsh marine environment. Buyers in this sector prioritize UV stability to prevent fading and deterioration. For international buyers, understanding the specific requirements of different marine applications is crucial, as regulations and consumer expectations can vary significantly across regions.

Illustrative image related to fabric upholstery car

3 Common User Pain Points for ‘fabric upholstery car’ & Their Solutions

Scenario 1: Durability Concerns in High-Usage Environments

The Problem: B2B buyers in sectors like transportation, logistics, or ride-sharing face significant challenges with fabric upholstery durability. Frequent use can lead to rapid wear and tear, resulting in unsightly stains, fraying, or fading, which can affect the overall customer experience. In markets with high traffic, such as those in the Middle East or South America, where heat and humidity are prevalent, the longevity of upholstery materials becomes even more critical. Buyers may struggle to find fabrics that withstand daily usage while maintaining an attractive appearance.

The Solution: To combat durability issues, B2B buyers should prioritize sourcing fabrics with high abrasion resistance ratings, such as those exceeding 50,000 double rubs (DR) on the Martindale scale. Fabrics like synthetic blends or specially treated polyester offer enhanced durability and are resistant to fading and stains. When specifying materials, look for options labeled with flame retardancy certifications, such as MVSS302 or California T.B. 117, ensuring compliance with safety regulations. Additionally, implementing a regular maintenance schedule that includes professional cleaning can significantly extend the life of upholstery, keeping vehicles looking their best. Partnering with suppliers who offer warranty programs on their products can also provide an added layer of assurance against premature wear.

Scenario 2: Difficulty in Color and Design Customization

The Problem: B2B buyers often encounter challenges when trying to customize the color and design of fabric upholstery for vehicles. This is particularly true for businesses aiming to reflect brand identity through their vehicle interiors. In regions like Africa and Europe, where cultural aesthetics can significantly vary, finding the right fabric that meets specific design requirements while still being functional can be a daunting task. Buyers may find limited selections that do not align with their branding or client preferences, leading to a compromise on style.

The Solution: To overcome customization hurdles, B2B buyers should collaborate with manufacturers that offer a wide range of upholstery options, including various colors, textures, and patterns. Engaging with suppliers who provide by-the-yard fabric purchasing can allow businesses to test different designs without committing to large quantities upfront. It’s also beneficial to explore digital tools or fabric swatches that enable visualization of how different materials will look in a vehicle setting. For unique branding needs, consider working with suppliers who can facilitate custom dyeing or printing services, allowing buyers to create bespoke upholstery solutions that resonate with their brand image.

Scenario 3: Maintenance and Cleaning Challenges

The Problem: Maintaining the cleanliness and appearance of fabric upholstery can be particularly challenging for B2B buyers in industries like car rentals or fleet management. In environments where vehicles are frequently used by different drivers or passengers, spills, stains, and general dirt accumulation can quickly degrade the upholstery’s appearance, leading to customer dissatisfaction. Buyers may struggle with choosing fabrics that are both easy to clean and aesthetically pleasing, often resulting in higher maintenance costs and the need for frequent replacements.

The Solution: To address maintenance issues effectively, B2B buyers should opt for fabrics that are inherently stain-resistant or treated with protective coatings. Materials like microfiber or specially engineered polyester can offer ease of cleaning while maintaining a stylish look. When sourcing upholstery, inquire about the fabric’s care instructions and consider those that allow for quick spot cleaning or machine washing. Additionally, implementing a preventive maintenance program that includes regular inspections and cleaning can mitigate long-term wear and preserve the upholstery’s condition. Offering training to staff on proper cleaning techniques can also enhance the longevity of the materials, ensuring a consistently high-quality experience for users.

Strategic Material Selection Guide for fabric upholstery car

When selecting materials for fabric upholstery in cars, it’s crucial for B2B buyers to consider various factors that influence performance, durability, and overall suitability. Below is an analysis of four common materials used in automotive upholstery, focusing on their properties, advantages, disadvantages, and specific considerations for international markets.

What Are the Key Properties of Polyester in Automotive Upholstery?

Polyester is a synthetic fabric known for its versatility and durability. It typically exhibits high abrasion resistance, making it suitable for high-traffic areas such as car seats. Polyester upholstery can withstand temperatures ranging from -40°C to 120°C, ensuring stability in diverse climates. Additionally, it is resistant to shrinking and stretching, which helps maintain the integrity of the upholstery over time.

Pros and Cons of Polyester Upholstery

The primary advantage of polyester is its affordability and ease of maintenance. It is available in various colors and patterns, allowing for customization. However, it may not provide the same luxurious feel as leather or high-end fabrics, which could be a drawback for premium vehicle markets.

Impact on Application

Polyester upholstery is compatible with most automotive interior designs and can be treated for stain resistance. However, it may not perform as well in extreme heat, potentially leading to fading or discoloration.

Considerations for International Buyers

Buyers from regions like Africa and the Middle East should ensure that the polyester used meets local standards for UV resistance and flame retardancy, such as ASTM or DIN regulations.

How Does Vinyl Compare as a Cost-Effective Upholstery Material?

Vinyl is a popular choice for automotive upholstery due to its durability and low cost. It is moisture-resistant and easy to clean, making it ideal for families and commercial vehicles. Vinyl upholstery can withstand temperatures between -20°C and 60°C, although it may become sticky in extreme heat.

Illustrative image related to fabric upholstery car

Pros and Cons of Vinyl Upholstery

Vinyl’s main advantage is its affordability and ease of maintenance. It mimics the look of leather while being significantly cheaper. However, it lacks breathability, which can lead to discomfort in hot climates.

Impact on Application

Vinyl is suitable for a variety of automotive applications, particularly in vehicles that require frequent cleaning, such as taxis or delivery vans. However, it may not be suitable for luxury vehicles where a premium feel is essential.

Considerations for International Buyers

B2B buyers in regions like South America should be aware of local preferences for materials that can withstand humidity and heat, ensuring that the vinyl selected meets relevant standards for durability.

What Are the Benefits and Limitations of Leather Upholstery?

Leather is often associated with luxury and high-end vehicles. It provides a sophisticated aesthetic and is known for its durability and comfort. Leather can withstand a wide temperature range, typically from -30°C to 80°C, making it suitable for various climates.

Pros and Cons of Leather Upholstery

The key advantage of leather is its luxurious feel and long lifespan. It is easy to clean and maintain if properly cared for. However, it is often the most expensive option and requires regular conditioning to prevent cracking.

Impact on Application

Leather upholstery is ideal for premium vehicles and can enhance resale value. However, it may not be suitable for all markets due to its higher cost.

Considerations for International Buyers

Buyers from Europe and the Middle East should consider compliance with local regulations regarding animal welfare and sustainability when sourcing leather upholstery.

How Do Synthetic Fabrics Like Microfiber Enhance Comfort and Durability?

Microfiber is a synthetic fabric that offers a soft, luxurious feel while being highly durable. It is resistant to stains and fading, making it an excellent choice for automotive upholstery. Microfiber can withstand temperatures from -20°C to 70°C, providing versatility across different climates.

Illustrative image related to fabric upholstery car

Pros and Cons of Microfiber Upholstery

The main advantage of microfiber is its comfort and ease of maintenance. It offers a plush feel similar to fabric while providing durability comparable to synthetic options. However, it may not be as resistant to heavy wear as leather or vinyl.

Impact on Application

Microfiber is suitable for both standard and luxury vehicles, offering a balance of comfort and durability. It is particularly beneficial in family vehicles where comfort is a priority.

Considerations for International Buyers

B2B buyers should ensure that microfiber upholstery meets local standards for flame resistance and durability, particularly in regions with extreme weather conditions.

Illustrative image related to fabric upholstery car

Summary Table of Upholstery Materials

| Material | Typical Use Case for fabric upholstery car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General automotive upholstery | Affordable and customizable | Less luxurious feel | Low |

| Vinyl | Family and commercial vehicles | Easy to clean and maintain | Lacks breathability | Low |

| Leather | Premium and luxury vehicles | Luxurious feel and durability | Expensive and requires maintenance | High |

| Microfiber | Standard and family vehicles | Soft and comfortable | May not withstand heavy wear | Medium |

This analysis provides a comprehensive overview of the key materials used in automotive upholstery, offering valuable insights for B2B buyers looking to make informed decisions tailored to their specific markets and requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fabric upholstery car

What Are the Key Stages in the Manufacturing Process of Fabric Upholstery for Cars?

The manufacturing process of fabric upholstery for cars is a multifaceted operation that involves several critical stages. Understanding these stages is essential for B2B buyers looking to ensure high-quality products from their suppliers.

Material Preparation: How Are Fabrics Selected and Processed?

The first stage of manufacturing begins with material preparation, where the selection of fabrics is vital. Manufacturers typically choose from a variety of materials, including polyester, nylon, and blends that offer durability and aesthetic appeal. Each fabric undergoes pre-treatment processes such as dyeing, finishing, and testing for qualities like flame retardancy and abrasion resistance, which are crucial for automotive applications.

Once the materials are selected, they are cut into specific shapes and sizes according to the design specifications of the vehicle. This process may involve automated cutting machines or manual labor, depending on the complexity and scale of production. The goal is to minimize waste while ensuring that the fabric maintains its integrity throughout the manufacturing process.

How Is Fabric Upholstery Formed and Assembled?

After material preparation, the next phase is forming, where the fabric is shaped into its final structure. This includes sewing the fabric pieces together to create upholstery components such as seat covers, door panels, and headliners. Advanced sewing techniques, including double stitching and reinforced seams, are often employed to enhance durability.

Following the sewing process, assembly takes place. This involves attaching the upholstery components to the car’s interior framework. Careful attention is paid to alignment and fit, ensuring that each piece complements the overall design of the vehicle. Some manufacturers use adhesives or mechanical fasteners to secure the upholstery, depending on the specific application and requirements.

What Finishing Techniques Are Used to Enhance Fabric Upholstery Quality?

The finishing stage is crucial for enhancing the appearance and functionality of automotive upholstery. This may involve several processes, including:

- Surface Treatments: Coatings may be applied to improve stain resistance and durability.

- Quality Inspection: Each piece undergoes visual and tactile inspection to ensure it meets the desired aesthetic and functional standards.

- Packaging: Once approved, upholstery components are packaged carefully to prevent damage during transport.

Employing advanced technologies, such as laser cutting and automated sewing, can also streamline the finishing process while ensuring consistent quality across batches.

What Are the Key Quality Control Measures in Fabric Upholstery Manufacturing?

Quality control (QC) is an essential component of the manufacturing process, particularly in the automotive industry, where safety and durability are paramount. Manufacturers typically adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system.

What Are the Major Quality Control Checkpoints?

Quality control in fabric upholstery manufacturing involves several key checkpoints:

- Incoming Quality Control (IQC): This initial inspection focuses on raw materials, ensuring they meet specifications before production begins.

- In-Process Quality Control (IPQC): Conducted during various stages of production, IPQC checks for conformity to design and quality standards.

- Final Quality Control (FQC): This final inspection assesses the finished products to ensure they meet all specifications and quality requirements before they are shipped.

Which International Standards and Testing Methods Are Relevant?

B2B buyers should be aware of the relevant international standards and testing methods that apply to automotive upholstery. Common standards include:

- Flame Retardancy Standards: Such as FMVSS 302 and California T.B. 117, which ensure that materials meet fire safety requirements.

- Durability Testing: Abrasion resistance tests (e.g., Martindale or Wyzenbeek) gauge how well fabrics withstand wear and tear.

- Lightfastness Testing: Tests that measure how well fabrics resist fading when exposed to UV light.

Understanding these standards helps buyers assess the quality and safety of upholstery materials.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is crucial. Here are actionable steps:

- Conduct Audits: Regular audits of potential suppliers can reveal their adherence to quality standards and manufacturing processes.

- Request Quality Reports: Suppliers should provide documentation detailing their quality control processes, including results from recent inspections and tests.

- Engage Third-Party Inspectors: Hiring independent inspectors can provide an unbiased assessment of a supplier’s quality control measures.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate additional complexities in quality control.

- Regulatory Differences: Different regions may have varying regulations regarding material safety and environmental impact. Buyers should familiarize themselves with these requirements to ensure compliance.

- Supply Chain Transparency: Engaging suppliers with transparent supply chains can help buyers understand the quality control measures in place and the origin of materials.

- Cultural Considerations: Understanding cultural differences in manufacturing practices can facilitate better communication and expectation management between buyers and suppliers.

By employing these strategies, B2B buyers can better navigate the complexities of sourcing high-quality fabric upholstery for vehicles, ensuring their investments yield durable and appealing products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric upholstery car’

To ensure a successful procurement process for fabric upholstery for cars, this guide provides a systematic approach for B2B buyers. By following this step-by-step checklist, you will be equipped to make informed decisions that align with your business needs and regional requirements.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical specifications required for the upholstery fabric. Consider factors such as durability, flame retardancy, and resistance to wear and tear. This step is crucial as it sets the foundation for evaluating potential materials and ensures that the selected fabric meets industry standards and regulatory requirements.

Illustrative image related to fabric upholstery car

- Durability: Identify the expected usage intensity. For example, fabrics for commercial vehicles may require higher abrasion resistance.

- Safety Standards: Check compliance with local regulations regarding flame retardancy and toxicity.

Step 2: Assess Material Types and Their Applications

Understanding the various fabric types available for automotive upholstery is essential. Different materials serve different purposes, from aesthetics to durability.

- Natural vs. Synthetic: Evaluate options like leather, vinyl, and various synthetic fabrics. Each has unique benefits and trade-offs regarding comfort, maintenance, and cost.

- Customization Options: Determine if you need customizable colors or patterns to align with branding or customer preferences.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conducting thorough due diligence is vital. This helps ensure reliability and quality.

- Supplier Profiles: Request company profiles that include their history, industry experience, and client testimonials.

- Certifications: Verify that suppliers hold relevant certifications for the fabrics they offer, ensuring compliance with international standards.

Step 4: Request Samples

Always request samples of the fabric before making a bulk order. This allows you to assess the texture, durability, and overall quality firsthand.

- Testing: Evaluate how the fabric feels and looks in real-world conditions. Check for colorfastness, stain resistance, and ease of cleaning.

- Comparison: Use samples to compare different suppliers and materials side by side, facilitating better decision-making.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers and reviewed samples, it’s time to negotiate terms. A solid negotiation can lead to better pricing and favorable contract terms.

- Volume Discounts: Discuss bulk order pricing to maximize savings, especially if planning for large-scale projects.

- Payment Terms: Clarify payment terms, delivery schedules, and return policies to avoid future misunderstandings.

Step 6: Establish Quality Control Measures

Implement quality control measures to ensure the fabric delivered meets your expectations. This is crucial for maintaining product integrity and customer satisfaction.

- Inspection Protocols: Create protocols for inspecting the fabric upon delivery, focusing on defects, color consistency, and adherence to specifications.

- Feedback Loop: Establish a communication channel with suppliers to address any quality issues promptly.

Step 7: Plan for Long-term Partnerships

Consider building long-term relationships with suppliers who consistently meet your standards. This can lead to better collaboration and more favorable terms in future transactions.

- Performance Reviews: Regularly assess supplier performance based on quality, reliability, and service.

- Partnership Opportunities: Explore opportunities for joint ventures or co-development of new products that could benefit both parties.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing fabric upholstery for vehicles, ensuring they make informed decisions that align with their business needs and market demands.

Comprehensive Cost and Pricing Analysis for fabric upholstery car Sourcing

What Are the Key Cost Components in Fabric Upholstery for Cars?

When analyzing the cost structure for fabric upholstery in automotive applications, several key components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the profit margin.

-

Materials: The choice of fabric significantly influences costs. High-performance materials, such as polyester or microfiber, may cost more upfront but offer durability and resistance to wear and tear, which can be more cost-effective in the long run. Fabrics with certifications for flame retardancy or eco-friendliness may also command higher prices.

-

Labor: Labor costs vary based on the complexity of the upholstery design and the skills required. Skilled labor for intricate designs or customizations can increase overall costs.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with production. Efficient production processes can minimize these overhead costs.

-

Tooling: Initial tooling for custom designs can add to the upfront cost. However, once established, these costs can be amortized over larger production runs, making it essential to consider volume when sourcing upholstery.

-

Quality Control (QC): Ensuring that the fabric meets specific industry standards may involve additional QC processes, which can incur extra costs. This is particularly relevant for buyers looking for high-quality or certified materials.

-

Logistics: Shipping and handling costs can vary significantly based on the supplier’s location and the destination. International shipping may involve tariffs and customs duties, which should be factored into the total cost.

-

Margin: Suppliers will also include a profit margin, which can vary widely based on market conditions and competitive pricing.

How Do Price Influencers Impact Fabric Upholstery Sourcing?

Several factors influence the pricing of automotive upholstery fabrics, particularly for international buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Bulk orders typically reduce per-unit costs, making it essential for buyers to negotiate favorable terms based on their projected needs.

-

Specifications and Customization: Custom designs or specific fabric requirements can increase costs. Buyers should clearly outline their needs to avoid unexpected charges.

-

Materials: The choice between synthetic and natural fibers impacts pricing. High-quality materials may cost more but offer better durability and aesthetic appeal, which can lead to higher resale values.

-

Quality and Certifications: Fabrics with certifications for safety, sustainability, or durability often come at a premium. Buyers should weigh the benefits of these certifications against their costs.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more due to their quality assurance processes and consistency.

-

Incoterms: Understanding Incoterms is essential for international buyers to clarify responsibilities for shipping, insurance, and tariffs, which can affect overall costs.

What Are Effective Buyer Tips for Cost-Efficiency in Upholstery Sourcing?

-

Negotiate Terms: Leverage your purchasing power by negotiating better terms with suppliers, particularly for larger orders. Don’t hesitate to ask for discounts based on volume.

-

Focus on Total Cost of Ownership (TCO): Assess the long-term costs associated with the upholstery fabric, including maintenance, durability, and replacement needs. Sometimes a higher upfront cost can lead to savings over time.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions and currency fluctuations that may affect pricing.

-

Consider Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead times. Additionally, local suppliers may offer more flexibility in customization.

-

Request Samples: Before making a large commitment, request samples to evaluate the material quality and ensure it meets your specifications. This can prevent costly mistakes later on.

Disclaimer on Indicative Prices

Pricing for automotive upholstery fabrics can vary widely based on the factors discussed above. The prices referenced are indicative and should be verified with suppliers for accuracy based on current market conditions and specific requirements.

Alternatives Analysis: Comparing fabric upholstery car With Other Solutions

Exploring Alternatives to Fabric Upholstery for Automotive Applications

When considering upholstery options for vehicles, fabric upholstery remains a popular choice among B2B buyers due to its comfort, versatility, and aesthetic appeal. However, there are several alternative solutions available that may better suit specific needs or preferences. This section provides a comparative analysis of fabric upholstery against two viable alternatives: leather upholstery and vinyl upholstery.

Illustrative image related to fabric upholstery car

| Comparison Aspect | Fabric Upholstery Car | Leather Upholstery | Vinyl Upholstery |

|---|---|---|---|

| Performance | Soft, breathable, and customizable; moderate durability | High durability; luxurious feel; less breathable | Durable and easy to clean; good resistance to stains |

| Cost | Generally affordable; varies with quality | Higher upfront cost; long-term investment | Budget-friendly; lower than leather but higher than basic fabric |

| Ease of Implementation | Requires skilled labor for installation | Requires specialized skills for quality installation | Easier to install; can be DIY-friendly |

| Maintenance | Needs regular cleaning; prone to stains | Requires conditioning and care; easy to clean | Minimal maintenance; wipe-clean surfaces |

| Best Use Case | Family vehicles, personal cars, customization options | Luxury vehicles, high-end applications | Commercial vehicles, family cars, budget-conscious users |

What are the Pros and Cons of Leather Upholstery?

Leather upholstery is renowned for its luxurious appearance and durability. It offers a premium feel that appeals to buyers looking for sophistication in their automotive interiors. Leather is also easy to clean, making it a practical choice for those who prioritize hygiene and maintenance. However, the cons include a significantly higher upfront cost compared to fabric, as well as the need for regular conditioning to prevent cracking and fading. Additionally, leather can be uncomfortable in extreme temperatures, making it less ideal for certain climates.

How Does Vinyl Upholstery Compare to Fabric Upholstery?

Vinyl upholstery serves as a cost-effective alternative that mimics the appearance of leather. It is particularly valued for its durability and ease of maintenance, making it an excellent choice for vehicles that experience heavy use, such as commercial fleets or family cars. Vinyl can withstand spills and is less susceptible to staining compared to fabric. On the downside, it lacks breathability and may feel sticky or uncomfortable in hot weather, which can detract from the overall driving experience. Despite its advantages, vinyl may not offer the same level of comfort and aesthetic appeal as fabric or leather.

Conclusion: Which Upholstery Solution is Right for Your Needs?

When selecting the right upholstery solution for automotive applications, B2B buyers should consider their specific requirements, including budget, usage patterns, and aesthetic preferences. Fabric upholstery is ideal for those seeking comfort and customization at an affordable price, while leather upholstery caters to luxury and durability seekers willing to invest more upfront. Vinyl upholstery stands out as a practical choice for budget-conscious buyers looking for ease of maintenance and durability. Ultimately, understanding the strengths and weaknesses of each option will empower buyers to make informed decisions that align with their operational needs and customer expectations.

Essential Technical Properties and Trade Terminology for fabric upholstery car

What Are the Key Technical Properties of Fabric Upholstery for Cars?

When sourcing fabric upholstery for automotive applications, understanding the key technical properties is crucial for making informed purchasing decisions. Here are several critical specifications that B2B buyers should consider:

1. Material Composition

The type of material used in upholstery significantly affects its durability, appearance, and maintenance. Common materials include polyester, nylon, and blends. For instance, 100% polyester fabrics are known for their resistance to wear and fading, while blended fabrics can offer enhanced comfort and cost-effectiveness. Understanding material composition is essential for aligning product quality with customer expectations.

2. Abrasion Resistance

Measured in double rubs (DR), abrasion resistance indicates how well a fabric can withstand friction and wear over time. For automotive applications, fabrics with abrasion resistance ratings of 30,000 DR or higher are typically recommended for durability. This property is particularly important for vehicles that experience heavy use, as higher ratings can translate into longer-lasting upholstery and reduced replacement costs.

3. Flame Retardancy

Compliance with flame retardancy standards (e.g., MVSS 302, California T.B. 117) is vital for automotive upholstery due to safety regulations. Fabrics that pass these standards help mitigate fire hazards, ensuring passenger safety. Buyers should prioritize upholstery that meets or exceeds these requirements, as it can also influence insurance premiums and customer trust.

4. Lightfastness

Lightfastness measures a fabric’s resistance to fading when exposed to sunlight. This is particularly critical for cars, especially in regions with high UV exposure. Fabrics rated for 200 hours of lightfastness or more are ideal for maintaining aesthetic appeal over time. B2B buyers should consider this property to ensure that the upholstery retains its color and quality, thereby enhancing customer satisfaction.

Illustrative image related to fabric upholstery car

5. Water and Stain Resistance

Given the diverse environments in which vehicles operate, water and stain resistance are key properties to look for. Fabrics treated with specialized coatings can repel moisture and stains, making them easier to clean and maintain. This is particularly beneficial for families or commercial vehicles that endure heavy use, as it reduces maintenance costs and extends the life of the upholstery.

What Are Common Trade Terms in the Fabric Upholstery Industry?

Navigating the fabric upholstery industry requires familiarity with specific trade terminology. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of automotive upholstery, OEM fabrics are those supplied by the original manufacturer, ensuring quality and compatibility with specific vehicle models.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory levels effectively and minimize excess stock. It also helps in negotiating better pricing terms, especially for larger orders.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers for specific products. This process allows businesses to compare costs, negotiate terms, and ensure they are getting the best value for their upholstery materials.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms is crucial for international transactions, as they clarify shipping costs, risk management, and delivery obligations, thus helping avoid misunderstandings.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. In the upholstery industry, lead times can vary based on material availability and production schedules. Buyers should consider lead time when planning inventory and production schedules to ensure timely delivery of their automotive projects.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions that align with their specific needs and market demands. This knowledge not only enhances procurement strategies but also fosters stronger supplier relationships, leading to successful business outcomes.

Navigating Market Dynamics and Sourcing Trends in the fabric upholstery car Sector

What Are the Current Market Dynamics and Key Trends in the Fabric Upholstery Car Sector?

The fabric upholstery car sector is experiencing significant growth driven by a combination of consumer preferences, technological advancements, and regional market dynamics. With an increasing focus on comfort and aesthetics in vehicle interiors, buyers are gravitating towards materials that not only enhance the visual appeal but also offer durability and ease of maintenance. Key trends include the rise of synthetic fabrics, such as microfiber and polyester, which provide a balance of luxury and practicality. In regions like Africa and South America, where economic growth is spurring automotive sales, there is a heightened demand for cost-effective yet stylish upholstery options. Meanwhile, in Europe and the Middle East, consumers are leaning towards high-end fabrics that offer both sustainability and luxury.

Emerging B2B technologies are reshaping sourcing practices, with digital platforms facilitating direct connections between manufacturers and buyers. This shift allows for greater transparency in the supply chain and improved access to a wider variety of materials. For international buyers, understanding local regulations and market preferences is crucial, especially in diverse regions like Saudi Arabia and Vietnam, where cultural aesthetics significantly influence upholstery choices. As manufacturers adapt to these dynamics, they are increasingly offering custom solutions that cater to local tastes while maintaining global quality standards.

How Is Sustainability and Ethical Sourcing Shaping the Fabric Upholstery Car Sector?

Sustainability has become a pivotal concern in the fabric upholstery car sector, influencing sourcing strategies and consumer choices alike. The environmental impact of textile production, particularly in terms of water usage and chemical waste, has prompted a shift towards more eco-friendly materials and practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through the use of recycled materials, low-impact dyes, and certified manufacturing processes.

Illustrative image related to fabric upholstery car

Ethical sourcing is also gaining traction, with buyers seeking transparency in their supply chains to ensure fair labor practices. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® provide assurance that materials meet stringent environmental and social criteria. Incorporating these certified materials not only enhances the brand image but also appeals to a growing segment of eco-conscious consumers. For international buyers, aligning sourcing practices with sustainability goals not only mitigates environmental risks but also positions their businesses favorably in an increasingly competitive market.

How Has the Fabric Upholstery Car Sector Evolved Over Time?

The evolution of the fabric upholstery car sector reflects broader trends in consumer behavior and technological advancements. Initially dominated by leather and basic fabrics, the industry has expanded to embrace a diverse range of materials, driven by innovations in synthetic fibers and manufacturing techniques. As automotive design began prioritizing user experience, the demand for comfortable, durable, and aesthetically pleasing upholstery surged.

In recent decades, the introduction of advanced textiles has transformed the market, leading to the development of performance fabrics that resist stains, fading, and wear. This evolution has been complemented by a growing awareness of environmental and ethical considerations, prompting both manufacturers and consumers to seek materials that align with sustainable practices. As the sector continues to adapt to changing preferences, the focus on quality, sustainability, and technological integration will remain key drivers of its future growth.

Frequently Asked Questions (FAQs) for B2B Buyers of fabric upholstery car

-

How do I choose the right fabric for automotive upholstery?

Selecting the right fabric for automotive upholstery involves evaluating several factors. Start by considering durability—look for materials that resist wear and tear, especially if the vehicle will see heavy use. Aesthetics are also crucial; choose colors and patterns that align with your brand or customer preferences. Additionally, assess the functionality, such as moisture resistance and ease of cleaning. Finally, consider your budget against the longevity of the material to ensure a good return on investment. -

What is the best fabric for car upholstery that balances durability and comfort?

For a balance of durability and comfort, synthetic fabrics like microfiber or high-quality polyester are excellent choices. These materials offer a soft feel while being resistant to stains and fading. Additionally, they are often more affordable than leather, making them suitable for both luxury and budget-conscious projects. Fabrics like these can withstand the rigors of daily use and are easy to maintain, making them ideal for various automotive applications. -

What are the key considerations when vetting suppliers for automotive upholstery fabric?

When vetting suppliers, assess their reputation by checking reviews and ratings from previous customers. Ensure they have experience in the automotive sector, as this knowledge can be critical for meeting industry standards. Request samples to evaluate fabric quality and durability. Additionally, inquire about their production capacity to meet your order volumes and timelines. Lastly, confirm their compliance with international regulations regarding flame retardancy and environmental standards. -

What is the typical minimum order quantity (MOQ) for automotive upholstery fabrics?

Minimum order quantities can vary widely among suppliers, typically ranging from 50 to 500 yards, depending on the fabric type and supplier policies. For custom or specialty fabrics, MOQs may be higher. It’s essential to discuss your specific needs with potential suppliers to determine their MOQs and negotiate if necessary, especially if you are considering a long-term partnership. -

What payment terms should I expect when sourcing automotive upholstery fabric internationally?

Payment terms can vary significantly based on the supplier and the country of origin. Common practices include a deposit (usually 30-50%) upfront, with the balance due upon shipment or delivery. Some suppliers may offer letters of credit for larger orders, providing security for both parties. Always clarify the payment terms before finalizing any contracts to avoid misunderstandings and ensure smooth transactions. -

How can I ensure quality assurance in my fabric upholstery orders?

Implementing a quality assurance (QA) process is crucial when sourcing fabric upholstery. Request detailed specifications and certifications from suppliers, including flame retardancy and durability tests. Conduct pre-shipment inspections to verify that the fabrics meet your standards. Establish clear communication channels for addressing any quality issues promptly. Additionally, consider building a long-term relationship with suppliers who consistently deliver high-quality products. -

What logistics considerations should I keep in mind for international fabric orders?

When dealing with international fabric orders, consider shipping methods, customs regulations, and lead times. Choose reliable logistics partners with experience in handling textile shipments. Understand the import duties and taxes in your destination country to avoid unexpected costs. Additionally, plan for potential delays by placing orders well in advance and maintaining open communication with your supplier regarding shipment statuses. -

Are there eco-friendly options available for automotive upholstery fabrics?

Yes, many suppliers now offer eco-friendly upholstery fabrics made from sustainable materials such as organic cotton, recycled polyester, and other biodegradable options. These fabrics not only reduce environmental impact but can also appeal to a growing market of environmentally conscious consumers. When sourcing, inquire specifically about the sustainability practices of suppliers and the certifications of their eco-friendly products to ensure they align with your business values.

Top 8 Fabric Upholstery Car Manufacturers & Suppliers List

1. A·1 Foam & Fabrics – 555 Portfolio Tweed Collection

Domain: a1foamandfabrics.com

Registered: 2003 (22 years)

Introduction: Automotive Car Interior Fabrics available at A·1 Foam & Fabrics include various collections such as Velvets, Suedes, and Tweeds suitable for automotive, RV, and trucking applications. Key products include: 1. 555 Portfolio Tweed Collection – Abrasion resistance: 50,000+ DR #10 Cotton Duck, Flame Retardancy: California T.B. 117 Section E-Class 1 (Pass), NFPA 260-Class 1 (Pass), UFAC Class 1 (Pass),…

2. Midwest Fabrics – Automotive Upholstery Solutions

Domain: midwestfabrics.com

Registered: 1999 (26 years)

Introduction: Automotive Upholstery Fabric, Original OEM Detroit Number Fabrics, GM CLOSEOUT ORIGINAL FABRIC, FORD Closeout Original Fabric, Chrysler Original Closeout Fabric, Honda Fabric, Toyota Closeout Original Fabric, Mazda Nissan OEM Fabric, Quincy Heavy Duty Flock fabric, Culp Contract Classic, Culp Ribby Contract Fabric, Culp Ground Control Teflon AB Contract Classic Fabric, various Culp fabrics includi…

3. JJ Auto Fabrics – Automotive and Marine Vinyl Supplies

Domain: jjautofabrics.com

Registered: 2001 (24 years)

Introduction: Automotive-Marine Vinyl and Upholstery Supplies including: Classic Automotive Vinyl, Heavy Weight Vinyl, SoftSide/SoftTouch Automotive Vinyl, Corinthian, Longitude, Sierra, Monticello, Milled Pebble, Soho, Rawhide, Oxen, Heidi, Ex Madrid, G-Grain, Verona, Wallaby, Ezy Vinyls, Knit Back Automotive Vinyl, Enduratex/CGPC, Highland Perforated, Palma Plain, Rosette, Morbern, Volkswagen Woven, Futura Xt…

4. Original Auto Fabric – Vintage & New Upholstery Materials

Domain: oemautofabric.com

Registered: 2018 (7 years)

Introduction: Original Auto Fabric offers a wide selection of vintage and new auto upholstery materials, including specialty car cloths, marine and automotive vinyls, custom carpets, floor mats, and vinyl tops. They provide over 230 licensed logos for floor mats, molded carpet to OEM specifications, and are specialists in vinyl tops. Their product categories include soundproofing materials, auto cloths, leather…

5. Fabric Wholesale Direct – Automotive Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Automotive Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. SMS Auto Fabrics – Classic Auto Interiors

Domain: smsautofabrics.com

Registered: 2000 (25 years)

Introduction: SMS Auto Fabrics offers the largest selection of classic auto interiors, including cloth, vinyl, leather, door panels, headliners, vinyl tops, and carpets for American cars from the 1930s to the 1990s. Featured products include various plaid fabrics for Chevrolet models from 1972 and 1973, as well as door panels for models such as the 1968 Dodge Polara Convertible, 1970 Chevrolet Malibu Sport Coup…

7. Sailrite – Vinyl Automotive Upholstery Fabrics

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Our Favorite Vinyl Automotive Upholstery Fabrics – Sailrite offers durable, waterproof, and easy-to-clean vinyl upholstery fabrics ideal for reupholstering car seats. Vinyl fabrics resemble real leather in texture and style, making them a cost-effective alternative. Key benefits include: easy cleaning, high abrasion resistance, UV resistance, waterproof properties, economical pricing compared to l…

8. Kovi Fabrics – Automotive Upholstery

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Automotive Upholstery: Durable, Affordable Car Interior Fabric. High Performance Fabric that is waterproof, spill proof, stain proof, and weatherproof. Some fabrics have anti-microbial properties. Available in a variety of styles including prints, patterns, and solids. Vinyl options include matte, glossy, distressed, animal hide, and reptile replications. Premium selection of brand new top quality…

Strategic Sourcing Conclusion and Outlook for fabric upholstery car

In today’s competitive automotive market, strategic sourcing for fabric upholstery is essential for businesses aiming to enhance product quality while managing costs effectively. By understanding the nuances of various upholstery materials—ranging from luxurious leather to durable synthetic options—buyers can make informed decisions that align with their brand identity and customer expectations. Prioritizing attributes such as durability, aesthetics, functionality, and sustainability will not only optimize customer satisfaction but also ensure long-term value.

Illustrative image related to fabric upholstery car

International B2B buyers from regions like Africa, South America, the Middle East, and Europe must leverage partnerships with reliable suppliers who offer diverse and innovative fabric solutions. This approach can streamline procurement processes, reduce lead times, and foster collaboration for custom projects.

As the automotive industry evolves, the demand for unique and high-quality upholstery will continue to grow. Now is the time to invest in strategic sourcing practices that will position your business ahead of the curve. Embrace this opportunity to explore new materials and suppliers, ensuring your offerings remain competitive and appealing to a global market. Your next step in enhancing your automotive upholstery portfolio could be just a conversation away.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.