Introduction: Navigating the Global Market for custom leather cutting dies

In the ever-evolving landscape of leather production, sourcing high-quality custom leather cutting dies presents a significant challenge for businesses aiming to streamline their operations while maintaining craftsmanship. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe (including Saudi Arabia and Brazil) navigate this market, understanding the nuances of custom leather cutting dies becomes crucial. This comprehensive guide delves into various types of cutting dies, their applications in mass production and bespoke crafting, and the critical factors to consider when vetting suppliers.

By addressing essential topics such as die materials, precision requirements, and cost considerations, this guide empowers buyers to make informed purchasing decisions. You will learn how to evaluate suppliers based on their manufacturing processes, customer service, and delivery capabilities, ensuring that your investment aligns with your production needs. Furthermore, we explore the advantages of using clicker presses and the impact of technology on die-making, providing insights that can enhance efficiency and quality in your leather projects.

Whether you are a small artisan or a large-scale manufacturer, this guide equips you with the knowledge necessary to navigate the global market for custom leather cutting dies confidently. By leveraging this information, you can optimize your sourcing strategies, reduce waste, and ultimately elevate the quality of your leather products.

Table Of Contents

- Top 5 Custom Leather Cutting Dies Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather cutting dies

- Understanding custom leather cutting dies Types and Variations

- Key Industrial Applications of custom leather cutting dies

- 3 Common User Pain Points for ‘custom leather cutting dies’ & Their Solutions

- Strategic Material Selection Guide for custom leather cutting dies

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather cutting dies

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather cutting dies’

- Comprehensive Cost and Pricing Analysis for custom leather cutting dies Sourcing

- Alternatives Analysis: Comparing custom leather cutting dies With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather cutting dies

- Navigating Market Dynamics and Sourcing Trends in the custom leather cutting dies Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather cutting dies

- Strategic Sourcing Conclusion and Outlook for custom leather cutting dies

- Important Disclaimer & Terms of Use

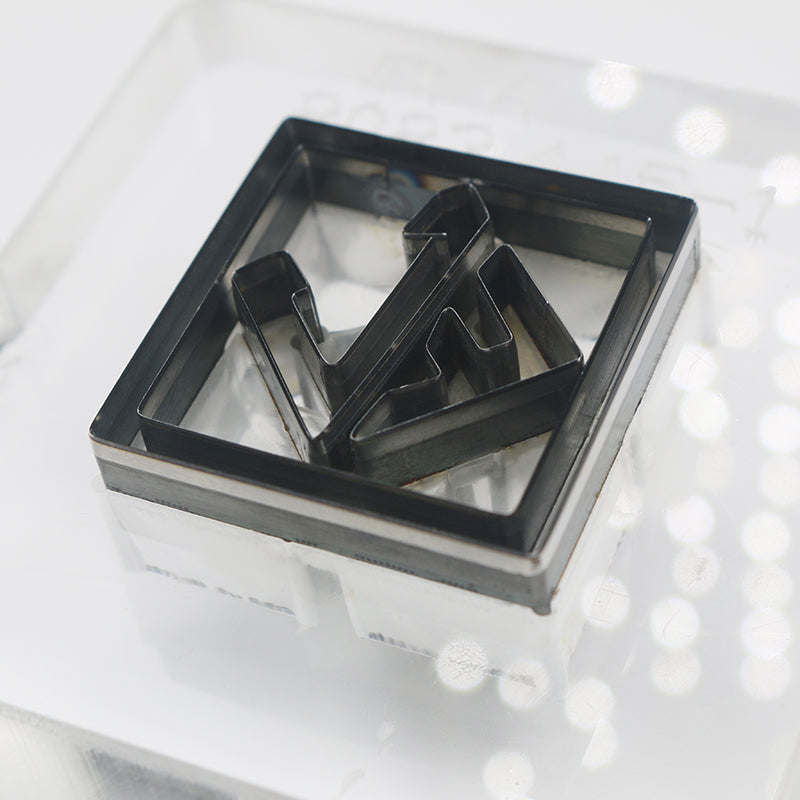

Understanding custom leather cutting dies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Rule Dies | Durable steel construction, high precision cutting | Mass production of leather goods | Pros: Long-lasting, precise cuts. Cons: Higher initial cost. |

| Polycarbonate Dies | Lightweight, impact-resistant material | Small to medium batch production | Pros: Cost-effective, versatile. Cons: Less durable than steel. |

| Acrylic Mount Dies | Easy material alignment, customizable thickness | Prototyping and custom designs | Pros: Reduces waste, quick turnaround. Cons: Limited cutting depth. |

| Clicker Dies | Designed for use with clicker presses, available in various shapes | High-volume leather production | Pros: Increases efficiency, consistent results. Cons: Requires investment in machinery. |

| Custom Dies | Tailored to specific designs and dimensions | Unique product offerings, bespoke items | Pros: Perfect fit for unique projects. Cons: Longer lead times. |

What Are Steel Rule Dies and Why Are They Popular Among B2B Buyers?

Steel rule dies are a favored choice for businesses engaged in mass production of leather goods. Characterized by their robust steel construction, these dies provide high-precision cutting for a variety of materials, including leather and paper. B2B buyers often appreciate their longevity and ability to produce consistent results over time. However, the initial investment is higher than other types, making it essential for buyers to consider their production volume to justify the cost.

How Do Polycarbonate Dies Offer Versatility for Small-Batch Production?

Polycarbonate dies are lightweight and impact-resistant, making them ideal for small to medium batch production. They are a cost-effective solution for businesses looking to cut leather without the higher expenses associated with steel dies. Their versatility allows for a wide range of designs, but they may not hold up as well under heavy use compared to steel options. Buyers should assess their project needs and expected production volume when choosing polycarbonate dies.

Why Choose Acrylic Mount Dies for Prototyping and Custom Designs?

Acrylic mount dies are distinguished by their easy alignment features, which help reduce material waste during the cutting process. This type of die is particularly advantageous for businesses focusing on prototyping or custom designs, as they can be tailored to specific project requirements. While acrylic mounts offer quick turnaround times, they have limitations in cutting depth, making them less suitable for thicker materials. Buyers should weigh the benefits of speed and customization against the potential limitations in material thickness.

What Advantages Do Clicker Dies Provide for High-Volume Leather Production?

Clicker dies are specifically designed for use with clicker presses, facilitating high-volume production of leather items. They come in various shapes and sizes, allowing businesses to scale their operations efficiently. The main advantages include improved cutting speed and uniformity, which are crucial for maintaining quality in large runs. However, the requirement for specialized machinery represents a significant investment that buyers must consider in relation to their production goals.

How Can Custom Dies Meet Unique Business Needs?

Custom dies are crafted to meet specific design and dimensional requirements, making them invaluable for companies that offer bespoke leather products. These dies ensure a perfect fit for unique designs, enhancing the overall quality of the final product. While they provide significant advantages in terms of customization, the trade-off often includes longer lead times and potentially higher costs. Businesses should evaluate their need for uniqueness against the time and financial implications of custom die production.

Key Industrial Applications of custom leather cutting dies

| Industry/Sector | Specific Application of Custom Leather Cutting Dies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Cutting intricate patterns for clothing and accessories | Enhances design precision and reduces production time | Need for customization, material compatibility, and delivery timelines |

| Automotive | Manufacturing leather interiors and upholstery | Improves quality and consistency of finished products | Durability of dies, ability to handle thick materials, and precision |

| Footwear | Creating unique shoe components | Increases production efficiency and design versatility | Sourcing for specific shapes, sizes, and compatibility with machinery |

| Leather Goods & Crafts | Producing custom bags, wallets, and crafts | Allows for mass production while maintaining craftsmanship | Custom design capabilities, material types, and fast turnaround times |

| Furniture | Upholstering leather furniture | Enhances aesthetic appeal and durability of furniture | Sourcing for large-scale projects, material specifications, and lead times |

How Are Custom Leather Cutting Dies Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, custom leather cutting dies are essential for creating intricate patterns used in clothing and accessories. These dies enable designers to produce consistent shapes quickly, which is vital for maintaining the quality and appeal of fashion items. Buyers in this industry should consider sourcing dies that allow for high customization, as unique designs are critical. Additionally, compatibility with various leather types and a reliable delivery schedule are crucial for keeping up with fast-paced fashion cycles, especially for international buyers from regions like Europe and South America.

Illustrative image related to custom leather cutting dies

What Role Do Custom Leather Cutting Dies Play in the Automotive Sector?

The automotive industry utilizes custom leather cutting dies for manufacturing high-quality leather interiors and upholstery. These dies ensure precision in cutting, which is vital for fitting components seamlessly within vehicles. A key consideration for buyers in this sector is the durability of the dies, particularly when cutting thick materials. Furthermore, suppliers must guarantee timely delivery to align with automotive production schedules, which can be demanding, especially in regions like the Middle East, where luxury vehicles are in high demand.

How Are Custom Leather Cutting Dies Beneficial for Footwear Production?

In footwear manufacturing, custom leather cutting dies are used to create unique components such as insoles, uppers, and decorative elements. The ability to produce complex shapes efficiently helps brands differentiate their products in a competitive market. Buyers should focus on sourcing dies that offer flexibility in design and can accommodate various leather thicknesses. The speed of production and accuracy in cutting are also critical factors, particularly for businesses in regions like Brazil, where footwear trends can change rapidly.

In What Ways Do Custom Leather Cutting Dies Enhance Leather Goods and Crafts?

For businesses involved in leather goods and crafts, custom leather cutting dies facilitate the mass production of items like bags and wallets without sacrificing quality. These dies help artisans replicate intricate designs consistently, which is essential for building a brand identity. Buyers should prioritize suppliers that offer quick turnaround times and the ability to work with various materials. Additionally, sourcing dies that can handle detailed engravings or unique shapes will further enhance product offerings, appealing to international markets across Africa and Europe.

Why Are Custom Leather Cutting Dies Important for Furniture Upholstery?

In the furniture industry, custom leather cutting dies are critical for upholstering leather furniture, ensuring that each piece fits perfectly and looks aesthetically pleasing. The precision provided by these dies leads to higher quality and more durable furniture products, which can command premium prices. Buyers should consider sourcing dies that can accommodate large-scale projects and provide the necessary specifications for different leather types. Timely delivery and the ability to handle bulk orders are also essential for maintaining production efficiency, particularly in regions experiencing rapid growth in furniture demand.

3 Common User Pain Points for ‘custom leather cutting dies’ & Their Solutions

Scenario 1: Inconsistent Cutting Quality Compromises Production Efficiency

The Problem:

B2B buyers in the leather manufacturing sector often face the issue of inconsistent cutting quality when using standard dies. This inconsistency can lead to wasted materials, increased labor costs, and ultimately, delays in production schedules. When dies do not perform accurately, it can result in poorly cut pieces that require reworking, which not only hampers productivity but also affects the quality of the final product.

The Solution:

To mitigate this issue, it is crucial to invest in custom leather cutting dies that are manufactured to precise specifications. Buyers should engage with reputable suppliers who utilize advanced CAD technology to ensure that the dies are symmetrical and accurately represent the desired design. When placing an order, providing detailed design files (such as .ai or .pdf formats) will help manufacturers create dies that meet exact tolerances. Additionally, opting for pre-sharpened steel clicker dies can enhance cutting precision and durability, ensuring that the dies maintain their effectiveness over time. Establishing a strong line of communication with the supplier can also facilitate adjustments based on ongoing production needs, allowing for continuous improvements in cutting quality.

Scenario 2: Long Lead Times Affecting Market Responsiveness

The Problem:

In a fast-paced market, long lead times for custom dies can hinder a company’s ability to respond swiftly to changing customer demands. B2B buyers may find themselves waiting weeks for new dies to arrive, which can stall production and ultimately lead to missed opportunities and lost sales. This challenge is particularly pronounced in regions with limited access to reliable manufacturing facilities or those that face logistical delays.

Illustrative image related to custom leather cutting dies

The Solution:

To address this concern, buyers should prioritize suppliers that offer expedited manufacturing and shipping options. When negotiating with potential vendors, inquire about their capabilities for rapid prototyping and express production services. Some companies can produce dies within a few days for an additional fee, which can be a worthwhile investment for urgent projects. Additionally, establishing long-term relationships with suppliers can lead to improved response times as they become more familiar with your needs and can prioritize your orders. Keeping a stock of frequently used dies can also buffer against lead time issues, enabling quicker turnaround for popular designs.

Scenario 3: Uncertainty in Design Specifications Leads to Increased Costs

The Problem:

B2B buyers often encounter challenges related to unclear or incomplete design specifications when ordering custom leather cutting dies. This uncertainty can lead to back-and-forth communications with suppliers, resulting in additional costs and delays. If a design needs to be adjusted after the initial quote, it may incur extra fees or require a new order altogether, which can disrupt project timelines and inflate budgets.

The Solution:

To minimize the risk of miscommunication and ensure that custom dies meet the exact requirements, buyers should invest time in preparing comprehensive design briefs. This includes detailed sketches, measurements, and material specifications. Engaging with suppliers that offer design consultations can also be beneficial; they can provide expert insights and help refine designs before production begins. Furthermore, requesting samples or prototypes before finalizing large orders can ensure that the die meets your expectations without incurring high costs from changes later in the process. Building a collaborative relationship with the supplier can foster a clearer understanding of your needs, ultimately leading to more accurate and cost-effective solutions.

Strategic Material Selection Guide for custom leather cutting dies

What Are the Key Materials Used for Custom Leather Cutting Dies?

When selecting materials for custom leather cutting dies, it’s essential to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and cost-effectiveness of the dies, especially for international B2B buyers. Below are analyses of four common materials used in the manufacturing of these dies.

Illustrative image related to custom leather cutting dies

How Do Steel Cutting Dies Perform in Leather Applications?

Key Properties: Steel cutting dies are known for their exceptional durability and strength. They can withstand high temperatures and pressures, making them suitable for various leather thicknesses. Steel also has good corrosion resistance, especially when treated.

Pros & Cons: The primary advantage of steel is its longevity; it can handle extensive use without significant wear. However, the manufacturing process can be complex and costly, particularly for custom shapes. Steel dies are ideal for high-volume production but may require a higher initial investment.

Impact on Application: Steel cutting dies are compatible with a wide range of leather types, from soft to rigid, allowing for versatile applications. They are particularly effective for intricate designs that require precision.

Considerations for International Buyers: Buyers should ensure that the steel used meets international standards such as ASTM or DIN for quality assurance. Additionally, shipping steel dies can be costly due to weight, so understanding local tariffs and import regulations is crucial.

What Advantages Do Polycarbonate Cutting Dies Offer?

Key Properties: Polycarbonate cutting dies are lightweight and have excellent impact resistance. They can handle moderate temperatures and pressures, making them suitable for various cutting applications.

Pros & Cons: The main advantage of polycarbonate is its lower cost compared to steel, making it a more accessible option for smaller businesses or those just starting. However, polycarbonate dies may not last as long as steel, especially under heavy use.

Impact on Application: These dies are particularly effective for less dense materials and simpler designs. They are often used in crafts and smaller-scale production runs, where cost-effectiveness is more critical than longevity.

Considerations for International Buyers: Polycarbonate materials should comply with safety and environmental standards, particularly in regions with strict regulations. Buyers should check for certifications that ensure the material’s quality and safety.

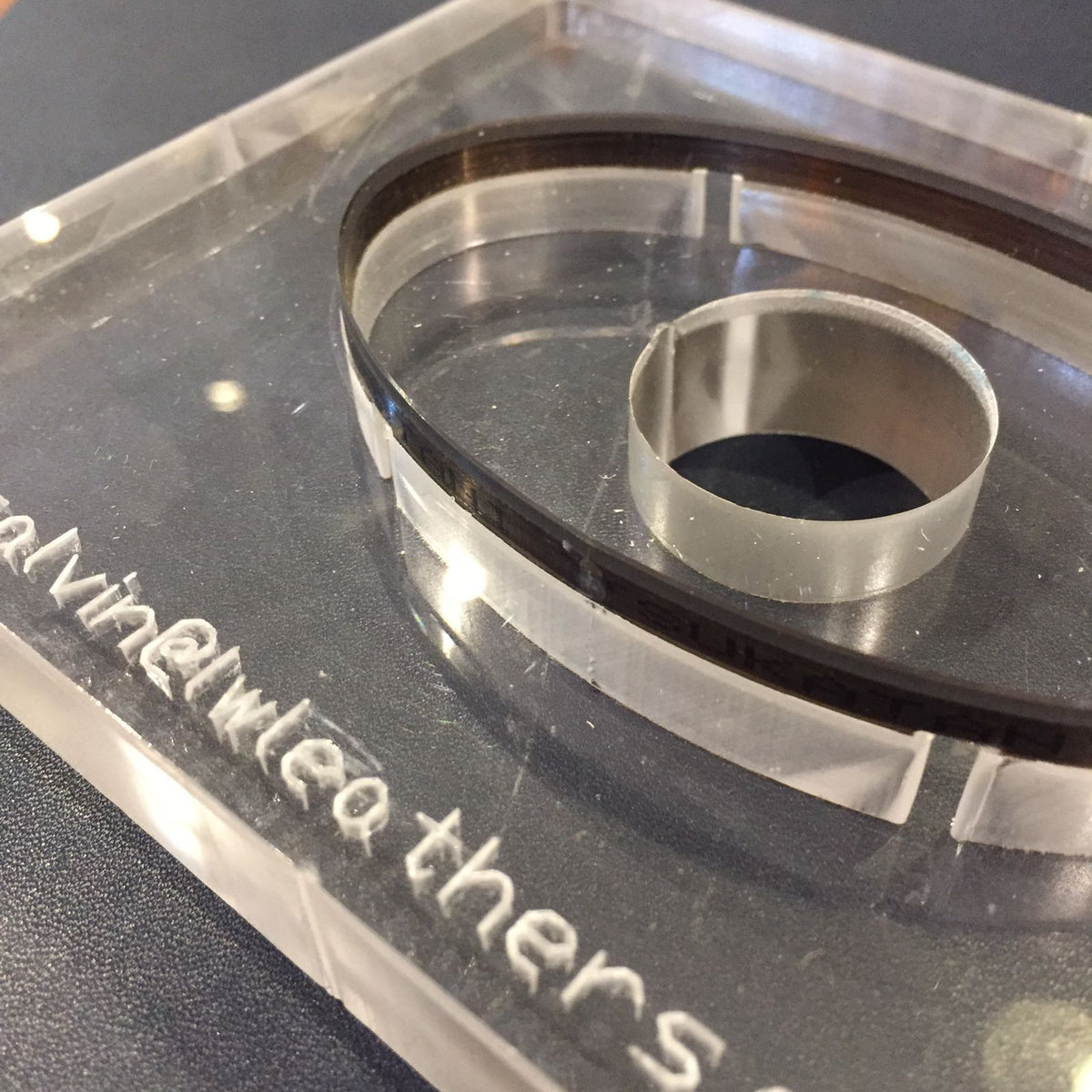

How Do Acrylic-Mounted Steel Rule Dies Enhance Precision?

Key Properties: Acrylic-mounted steel rule dies combine the durability of steel with the ease of alignment provided by acrylic. This dual-material approach allows for precise cutting with minimal waste.

Illustrative image related to custom leather cutting dies

Pros & Cons: The primary advantage is the ease of use; the acrylic mount helps align materials accurately, reducing errors. However, these dies can be more expensive due to the additional materials and manufacturing processes involved.

Impact on Application: These dies are suitable for various materials, including leather, paper, and thin plastics, making them versatile for different industries. They are particularly beneficial for businesses that require high precision in their cutting processes.

Considerations for International Buyers: Buyers should ensure compliance with relevant international standards for both steel and acrylic materials. Understanding local market preferences for material types can also influence purchasing decisions.

What Benefits Do Custom Laser-Engraved Dies Provide?

Key Properties: Custom laser-engraved dies offer high precision and can be made from various materials, including steel and acrylic. They provide detailed designs with minimal tolerance errors.

Pros & Cons: The main advantage is the customization aspect, allowing businesses to create unique designs tailored to their needs. However, the cost can be higher due to the complexity of the engraving process.

Impact on Application: These dies are particularly useful for intricate designs and branding applications, such as logos on leather goods. They are ideal for businesses looking to differentiate their products in competitive markets.

Considerations for International Buyers: Buyers should verify that the engraving process meets local regulations regarding product labeling and branding. Additionally, understanding the lead times for custom orders is critical for planning production schedules.

Summary Table of Material Selection for Custom Leather Cutting Dies

| Material | Typical Use Case for custom leather cutting dies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-volume production of intricate designs | Exceptional durability and precision | Higher initial cost and complexity | High |

| Polycarbonate | Crafts and smaller-scale production runs | Cost-effective and lightweight | Shorter lifespan under heavy use | Medium |

| Acrylic-Mounted Steel Rule | Precise cutting for various materials | Easy alignment reduces waste | Higher cost due to dual materials | High |

| Custom Laser-Engraved | Unique branding and intricate designs | High customization and precision | Higher cost and longer lead times | High |

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather cutting dies

What Are the Key Stages in the Manufacturing Process of Custom Leather Cutting Dies?

The manufacturing process for custom leather cutting dies is intricate and requires precision at every stage. This ensures that the final product meets the exact specifications of the buyer while maintaining high-quality standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Custom Leather Cutting Dies?

The first step in the manufacturing process involves selecting the appropriate materials, primarily steel or polycarbonate, known for their durability and cutting efficiency. For steel dies, high-carbon steel is commonly used due to its hardness and ability to retain sharp edges. Polycarbonate materials are often chosen for their lighter weight and corrosion resistance.

Once the material is selected, it undergoes surface treatment to remove any impurities and enhance bonding during the forming process. This treatment may include cleaning, sanding, or applying protective coatings. Accurate measurements are then taken, as precision is crucial for the die’s effectiveness. CAD (Computer-Aided Design) software is frequently utilized to create detailed designs, ensuring that the dimensions and specifications are met before moving on to the forming stage.

Illustrative image related to custom leather cutting dies

What Techniques Are Used in Forming Custom Leather Cutting Dies?

Forming is a critical stage where the prepared materials are shaped into the die. This typically involves laser cutting or die stamping, techniques that ensure high precision. Laser cutting is favored for its ability to create intricate designs without compromising the material’s integrity. In contrast, die stamping applies pressure to shape the material, making it suitable for larger, simpler designs.

After forming, the dies are subjected to a heat treatment process, which enhances their hardness and longevity. This is essential for ensuring that the dies maintain their cutting ability over time, especially when used in high-volume production settings.

How Are Custom Leather Cutting Dies Assembled?

Once the individual components are formed, assembly takes place. This involves fitting together various parts, such as the die body and cutting edges, and securing them with screws or welding. Attention to detail is crucial during this phase to ensure that all components align perfectly, as any misalignment can lead to inaccuracies in cutting.

Quality assurance begins in this phase, where initial checks are performed to confirm that the assembly adheres to the specified design. This might involve visual inspections and basic functional tests to ensure the die operates as intended.

What Finishing Techniques Enhance the Quality of Custom Leather Cutting Dies?

The finishing stage focuses on refining the surface of the die and ensuring it is free from defects. This may involve polishing the edges to ensure clean cuts and applying protective coatings to prevent rust and other forms of corrosion. Additionally, engraving can be done to add branding or specific markings that may be required by the buyer.

Illustrative image related to custom leather cutting dies

Final inspections are conducted to ensure that the dies meet all quality standards before they are packaged for shipping. This step is crucial for maintaining consistency and reliability in the product.

How Is Quality Assurance Implemented in the Manufacturing of Custom Leather Cutting Dies?

Quality assurance (QA) is an essential component of the manufacturing process for custom leather cutting dies. It ensures that products meet both international and industry-specific standards, providing buyers with confidence in their purchases.

What International Standards Should B2B Buyers Be Aware Of?

Many manufacturers adhere to international quality management standards such as ISO 9001, which focuses on process efficiency and customer satisfaction. Compliance with ISO standards signifies that a manufacturer has established a robust QA system, which is crucial for B2B buyers looking for reliability.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) standards for certain industrial applications may also apply. These certifications indicate that the dies meet specific regulatory requirements, further assuring buyers of their quality.

Illustrative image related to custom leather cutting dies

What Are the Key Checkpoints in the Quality Control Process?

Quality control (QC) checkpoints are established throughout the manufacturing process, typically categorized into three main stages:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon arrival. Buyers should look for suppliers that conduct thorough inspections to ensure only high-quality materials are used.

-

In-Process Quality Control (IPQC): During manufacturing, random sampling and checks are performed to monitor the production process. This includes verifying dimensions and testing functionality at various stages to catch any defects early.

-

Final Quality Control (FQC): Before packaging, a comprehensive inspection is conducted to ensure that the finished product meets all specifications. This may include functional testing and dimensional checks to confirm accuracy.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers should take proactive steps to verify a supplier’s quality control measures. This includes:

-

Conducting Audits: Requesting on-site audits can provide insight into a manufacturer’s processes and adherence to quality standards. This allows buyers to assess the supplier’s commitment to quality firsthand.

-

Reviewing Quality Reports: Suppliers should provide documentation of their quality control processes, including testing results and compliance certifications. Reviewing these reports can help buyers understand the supplier’s reliability.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process. This is particularly important for international buyers who may not have the ability to conduct onsite evaluations.

What Are the Unique Quality Control Considerations for International Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Factors such as local regulations, import/export standards, and cultural differences in business practices can affect the purchasing process.

Buyers should ensure that their suppliers are well-versed in the regulatory requirements of their specific markets. This might involve additional certifications or compliance documentation, which can be a determining factor in selecting a supplier.

Moreover, establishing clear communication channels is essential. Language barriers and time zone differences can complicate discussions about quality expectations and product specifications. Utilizing clear, written agreements can help mitigate misunderstandings and set clear quality expectations from the outset.

Illustrative image related to custom leather cutting dies

In summary, the manufacturing processes and quality assurance measures for custom leather cutting dies are multifaceted and require a deep understanding of both technical and regulatory factors. By focusing on these elements, B2B buyers can make informed decisions that align with their quality requirements and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather cutting dies’

Introduction

Navigating the procurement of custom leather cutting dies requires a systematic approach to ensure quality, efficiency, and cost-effectiveness. This checklist serves as a practical guide for B2B buyers looking to source these essential tools, helping you make informed decisions that align with your specific production needs.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for your custom leather cutting dies, including dimensions, shape complexity, and material type. This step is crucial as it directly impacts the die’s performance and suitability for your production processes. Be specific about tolerances and cutting depth to avoid issues later in production.

- Material Considerations: Decide whether you need steel, polycarbonate, or acrylic mounts based on the material you will be cutting.

- Complexity: Consider the intricacies of your design; more complex shapes may require specialized manufacturing techniques.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify suppliers that specialize in custom leather cutting dies. Look for manufacturers with a proven track record in quality and customer service. This step is essential to ensure that you partner with suppliers who can meet your specific needs.

Illustrative image related to custom leather cutting dies

- Check Reviews and Testimonials: Seek feedback from other B2B buyers to gauge reliability and product quality.

- Industry Experience: Prefer suppliers with experience in your region, as they may better understand local material availability and compliance requirements.

Step 3: Evaluate Supplier Capabilities

Once you have shortlisted suppliers, assess their manufacturing capabilities and technologies. Understanding their production processes will help you determine if they can deliver the quality and precision required for your projects.

- Technology Used: Inquire about the machinery and techniques they use, such as CAD for design accuracy.

- Production Lead Times: Understand their timelines for custom orders to align with your project deadlines.

Step 4: Request Samples and Prototypes

Before making a bulk order, request samples or prototypes of the dies to evaluate their performance. This step is critical to ensure that the dies meet your specifications and function correctly in your production setup.

- Test Cuts: Use the samples to perform test cuts on your materials to assess precision and quality.

- Adjustments: Provide feedback on any necessary adjustments to the supplier before finalizing your order.

Step 5: Verify Certifications and Compliance

Ensure that the supplier adheres to industry standards and certifications relevant to your region. Compliance with safety and quality standards is vital for maintaining the integrity of your products and avoiding potential legal issues.

- ISO Certification: Check if the supplier holds ISO certifications, indicating adherence to international quality standards.

- Environmental Compliance: Inquire about their practices regarding sustainability and waste management.

Step 6: Negotiate Terms and Pricing

Engage in discussions regarding pricing, payment terms, and delivery schedules. This step is crucial to secure the best possible deal while ensuring that both parties are clear on expectations.

- Bulk Discounts: Inquire about pricing structures for larger orders to maximize cost efficiency.

- Payment Flexibility: Discuss payment methods that suit your financial processes, including any necessary deposits or credit terms.

Step 7: Establish a Clear Communication Plan

Finally, set up a communication plan with your supplier to facilitate ongoing discussions throughout the production process. Clear communication helps in addressing any potential issues quickly and ensures that your needs are consistently met.

Illustrative image related to custom leather cutting dies

- Regular Updates: Schedule regular check-ins to monitor progress and address any concerns.

- Point of Contact: Designate a primary contact person on both sides to streamline communication.

By following this checklist, B2B buyers can effectively navigate the sourcing process for custom leather cutting dies, ensuring that they make informed and strategic procurement decisions.

Comprehensive Cost and Pricing Analysis for custom leather cutting dies Sourcing

What Are the Key Cost Components in Sourcing Custom Leather Cutting Dies?

When sourcing custom leather cutting dies, understanding the cost structure is crucial for effective budgeting and supplier negotiations. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Steel, polycarbonate, and acrylic are common materials for dies. Steel tends to be more expensive due to its durability and precision, while polycarbonate offers a cost-effective alternative for less demanding applications.

-

Labor: Skilled labor is essential in the manufacturing of cutting dies. The complexity of the design and the intricacy of the die will dictate labor costs. Custom designs often require more time and expertise, leading to higher labor expenses.

-

Manufacturing Overhead: This includes utilities, maintenance, and facility costs associated with production. Overhead can vary widely depending on the location of the manufacturing facility and its operational efficiency.

-

Tooling: Tooling costs encompass the creation of molds and dies required for production. This can be a significant upfront investment, especially for custom designs that require specialized tooling.

-

Quality Control (QC): Ensuring that each die meets precise specifications requires a robust QC process. This adds to the cost but is necessary to avoid defects that could disrupt production.

-

Logistics: Shipping and handling can vary based on the supplier’s location and the delivery method. International shipping, customs duties, and insurance can all influence final costs.

-

Margin: Suppliers will typically add a profit margin to their costs, which can vary based on market demand, competition, and the supplier’s brand positioning.

How Do Price Influencers Affect the Cost of Custom Leather Cutting Dies?

Several factors can influence the pricing of custom leather cutting dies:

-

Volume/MOQ: Suppliers often have a minimum order quantity (MOQ). Larger orders can lead to discounts due to economies of scale, making it beneficial for buyers to consolidate orders whenever possible.

-

Specifications and Customization: The more complex the die, the higher the cost. Customization options such as engraving or unique shapes will add to the price. Clear communication of specifications can help avoid unnecessary costs.

-

Materials and Quality Certifications: Higher-quality materials and certifications can increase costs but may lead to better performance and longevity of the dies. Buyers should assess their needs against these costs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding the terms of delivery is crucial. Incoterms dictate who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost.

What Buyer Tips Can Enhance Cost-Efficiency in Custom Leather Cutting Die Procurement?

To navigate the complexities of sourcing custom leather cutting dies, consider the following tips:

-

Negotiate: Always negotiate pricing and terms with suppliers. Many suppliers may have room for flexibility, especially for larger orders or repeat business.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the dies, including maintenance, potential rework, and the impact of die performance on production efficiency. This can provide a clearer picture than just initial purchase price.

-

Understand Pricing Nuances for International Purchases: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of additional costs associated with international transactions, such as tariffs, taxes, and currency fluctuations. Engaging with suppliers who understand these dynamics can lead to better pricing strategies.

-

Request Samples: Before committing to a large order, request samples to assess quality and suitability. This can prevent costly mistakes and ensure the die meets your specifications.

-

Consider Local Suppliers: Depending on your location, sourcing from local suppliers may reduce shipping costs and lead times, enhancing overall efficiency.

Disclaimer on Pricing

Prices for custom leather cutting dies can vary widely based on the factors mentioned above. The figures provided in various sources are indicative and may not reflect current market conditions. Always request updated quotes from suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing custom leather cutting dies With Other Solutions

In the realm of leather crafting, efficiency and precision are paramount. While custom leather cutting dies are a popular choice for many manufacturers, several alternative solutions can also achieve similar outcomes. This section explores these alternatives, providing B2B buyers with a comprehensive overview to make informed decisions.

| Comparison Aspect | Custom Leather Cutting Dies | Laser Cutting Technology | Manual Cutting Tools |

|---|---|---|---|

| Performance | High accuracy for complex shapes; consistent results across batches | Exceptional precision; capable of intricate designs | Variable accuracy; depends on the skill of the operator |

| Cost | Moderate initial investment; cost-effective for high volume | High upfront costs; lower operational costs for large runs | Low initial investment; labor-intensive, can lead to higher long-term costs |

| Ease of Implementation | Requires a clicker press; straightforward once set up | Requires skilled operators and software for design | Simple to use; no machinery needed, but labor-intensive |

| Maintenance | Low maintenance; durable steel or polycarbonate materials | Moderate; requires regular calibration and maintenance of machines | Low; minimal maintenance required for tools |

| Best Use Case | Ideal for mass production of consistent shapes | Best for intricate designs and small to medium runs | Suitable for prototyping and small-scale production |

How Does Laser Cutting Technology Compare to Custom Leather Cutting Dies?

Laser cutting technology offers a high level of precision and is capable of handling complex designs that may be challenging for traditional cutting dies. This method uses focused laser beams to cut through materials, providing clean edges and intricate detailing. However, the initial investment in laser cutting machines can be substantial, making it less viable for smaller operations. Moreover, the need for skilled operators and software adds complexity to the implementation process. While operational costs can be lower for large runs, the setup and training costs can be a barrier for some businesses.

Illustrative image related to custom leather cutting dies

What About Manual Cutting Tools as an Alternative to Custom Leather Cutting Dies?

Manual cutting tools, such as knives and rotary cutters, are perhaps the simplest option for leather cutting. They require no machinery and can be easily used by anyone, making them a good choice for small-scale operations or prototyping. However, the performance heavily relies on the skill of the operator, leading to inconsistent results, especially in larger batches. While the initial investment is low, the labor costs can add up, making this method less efficient for mass production.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When considering the right cutting solution, B2B buyers should assess their specific production needs, budget, and the complexity of designs they intend to create. Custom leather cutting dies are an excellent choice for those looking to achieve consistent results in mass production, while laser cutting technology is ideal for businesses that prioritize intricate designs and have the budget for advanced machinery. Manual cutting tools can be beneficial for smaller projects or prototyping but may not be suitable for high-volume production. Ultimately, understanding the unique advantages and limitations of each option will guide businesses in selecting the most effective solution for their leather crafting needs.

Essential Technical Properties and Trade Terminology for custom leather cutting dies

What Are the Key Technical Properties of Custom Leather Cutting Dies?

When sourcing custom leather cutting dies, several critical specifications should be evaluated to ensure optimal performance and suitability for your projects. Here are some essential properties to consider:

1. Material Grade

The material from which the cutting die is made significantly impacts its durability and performance. Common materials include high-grade steel and polycarbonate. Steel dies are preferred for their longevity and ability to cut through thicker materials, while polycarbonate dies offer a lightweight alternative for intricate designs. Selecting the appropriate material is crucial for achieving consistent results in mass production.

Illustrative image related to custom leather cutting dies

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions, typically measured in millimeters. A tolerance of ±0.2mm is common in high-quality dies. This precision is vital for ensuring that the cuts are accurate, which in turn affects the fit and finish of the final leather products. In a B2B context, maintaining strict tolerances minimizes waste and enhances production efficiency.

3. Cutting Depth

Cutting depth indicates how thick a material the die can effectively cut. Standard cutting depths range from 8mm to 10mm for most leather applications. Understanding the maximum cutting depth is essential for buyers who work with various leather thicknesses, as it ensures the die will meet their production requirements without compromising quality.

4. Die Height

The height of the cutting die, often including both the blade and the mount, affects the ease of use and compatibility with different cutting presses. A typical height might be around 24mm, but this can vary based on the design. Buyers should consider the press they will use to ensure compatibility and efficiency in their cutting process.

5. Customization Options

Customization is a significant advantage in the B2B market. Options like text engraving or adding specific features (e.g., round hole punches) can tailor the die to meet unique project requirements. This flexibility enables businesses to create distinctive products that stand out in a competitive market.

What Are Common Trade Terms Used in Custom Leather Cutting Dies?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some common terms related to custom leather cutting dies:

Illustrative image related to custom leather cutting dies

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of custom leather cutting dies, an OEM may create dies that are branded and sold by another company. This term is important for buyers looking for specific branding opportunities or partnerships.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. For custom dies, this could vary significantly based on the supplier and the complexity of the die design. Understanding MOQ helps buyers plan their budgets and production schedules effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. In the custom leather cutting die sector, submitting an RFQ allows buyers to compare prices and specifications from multiple suppliers, ensuring they secure the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the shipping process. Familiarity with Incoterms helps businesses understand shipping costs, risk transfer, and delivery responsibilities, which are crucial for smooth international transactions.

5. CAD (Computer-Aided Design)

CAD refers to software used for creating precise drawings and technical illustrations. In the context of custom cutting dies, CAD ensures that the designs are accurate and can be easily converted into die patterns. This technology is essential for maintaining quality and consistency in production.

By familiarizing yourself with these technical properties and trade terms, you can make informed purchasing decisions that enhance your leather product offerings and streamline your production processes.

Navigating Market Dynamics and Sourcing Trends in the custom leather cutting dies Sector

What Are the Key Market Dynamics and Trends Affecting Custom Leather Cutting Dies?

The custom leather cutting dies market is experiencing significant growth driven by several global factors. Increasing demand for bespoke leather products, particularly in fashion and automotive industries, is propelling the need for precision cutting solutions. International buyers, especially from Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality, customizable cutting dies to enhance their production efficiency. Technological advancements in die manufacturing, such as the use of CAD software for precision design and automated production techniques, are enabling suppliers to deliver more intricate and tailored solutions.

Emerging trends also indicate a rising preference for polycarbonate and steel dies, which offer durability and longevity, essential for high-volume production. Additionally, the integration of digital technologies in the sourcing process is transforming how B2B buyers interact with suppliers. Online platforms now facilitate easier access to a variety of cutting die options, enabling buyers to compare products and prices effectively. The shift towards sustainable and ethical sourcing is also becoming a key consideration for international buyers, as they look for suppliers who can demonstrate responsible practices in their manufacturing processes.

How Is Sustainability Influencing the Sourcing of Custom Leather Cutting Dies?

Sustainability has become a pivotal factor in the sourcing of custom leather cutting dies, reflecting a broader industry trend towards environmental responsibility. The leather industry, traditionally viewed as resource-intensive, is undergoing a transformation as buyers demand greener alternatives. This includes sourcing dies made from eco-friendly materials, such as recycled steel or sustainably produced polycarbonate, which minimize environmental impact.

Moreover, ethical supply chains are gaining importance, with B2B buyers increasingly scrutinizing their suppliers’ practices to ensure compliance with labor and environmental standards. Certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification can provide assurance of responsible sourcing practices. Buyers are encouraged to engage with suppliers who prioritize sustainability, not only to meet regulatory requirements but also to enhance their brand reputation and appeal to environmentally conscious consumers.

What Has Been the Evolution of Custom Leather Cutting Dies?

The evolution of custom leather cutting dies has been marked by significant technological advancements and shifts in market demands. Historically, leather cutting was a manual process, reliant on hand tools and basic dies, which limited precision and scalability. As the demand for customized leather goods increased, manufacturers began adopting more sophisticated techniques, including the introduction of steel rule dies and clicker presses, which allowed for greater accuracy and consistency in production.

In recent years, the incorporation of CAD technology has revolutionized the design and manufacturing of cutting dies. This innovation allows for rapid prototyping and customization, catering to the diverse needs of international B2B buyers. Furthermore, the rise of e-commerce platforms has simplified the sourcing process, enabling buyers to access a global marketplace for custom leather cutting dies, thus fostering competition and driving innovation within the sector. Today, the market is characterized by a blend of traditional craftsmanship and modern technology, ensuring that buyers can achieve both quality and efficiency in their leather production endeavors.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather cutting dies

-

How do I select the right supplier for custom leather cutting dies?

Choosing the right supplier involves assessing their experience, production capabilities, and customer service. Look for manufacturers with a proven track record in leather cutting dies, as well as positive reviews from previous clients. Request samples or case studies to evaluate the quality of their dies. Additionally, ensure they can accommodate your specific requirements, such as custom designs and materials. It’s also beneficial to communicate directly with their team to gauge their responsiveness and willingness to collaborate. -

What factors should I consider when requesting a custom leather cutting die?

When requesting a custom die, consider the complexity of your design, the type of leather you will be using, and the die’s intended purpose. Provide clear specifications, including dimensions, materials, and any special features like engravings or multiple cutting depths. Discuss lead times and production capabilities with the supplier to ensure they can meet your deadlines. Additionally, inquire about any minimum order quantities (MOQs) and pricing structures to better understand your budget. -

What are the typical lead times for custom leather cutting dies?

Lead times for custom leather cutting dies can vary based on complexity and supplier workload. Generally, expect a timeframe of 2 to 4 weeks for standard orders, but it can be longer for intricate designs or larger quantities. For urgent needs, many suppliers offer rush services for an additional fee, reducing the lead time to as little as 2 to 3 business days. Always confirm lead times upfront and factor in shipping times for international orders. -

What payment terms are common in international B2B transactions for cutting dies?

Payment terms can vary significantly based on the supplier and your relationship with them. Common options include upfront payment, 50% deposit with the balance upon delivery, or net terms (e.g., net 30 or net 60 days). It’s crucial to discuss these terms early in negotiations and ensure they align with your cash flow needs. Always verify the supplier’s payment security measures, especially for international transactions, to minimize risk. -

How can I ensure quality assurance for my custom leather cutting dies?

To ensure quality, request detailed specifications and prototypes before full production. Many suppliers offer samples of the die to confirm accuracy in cutting and design. Establish clear communication regarding your quality expectations, including tolerances and finish. Additionally, consider suppliers that provide warranties or guarantees on their products, which can offer peace of mind regarding performance and durability. -

What are the logistics considerations for importing custom leather cutting dies?

When importing dies, consider shipping methods, customs regulations, and potential tariffs. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure the supplier provides accurate shipping documentation to facilitate customs clearance. Familiarize yourself with local import regulations in your country to avoid delays and additional fees. It may also be wise to partner with a freight forwarder for smoother logistics management. -

What customization options are typically available for leather cutting dies?

Most suppliers offer a range of customization options, including size adjustments, shape alterations, and material choices (steel, polycarbonate, etc.). You can also request features like engravings, multiple cutting depths, or specific tolerances. Discuss your design requirements in detail with the supplier to explore all available options. Some suppliers may also provide design services if you have only a sketch or concept, which can streamline the process. -

What are the advantages of using custom leather cutting dies over manual cutting?

Custom leather cutting dies significantly enhance efficiency and precision compared to manual cutting methods. They allow for consistent cuts, reducing material waste and ensuring uniformity across large production runs. This saves time and labor costs, enabling your team to focus on other aspects of craftsmanship. Furthermore, custom dies can handle complex shapes that may be difficult or time-consuming to achieve manually, enhancing your design capabilities.

Top 5 Custom Leather Cutting Dies Manufacturers & Suppliers List

1. Weaver Leather Supply – Clicker Dies & Sets

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Clicker Dies & Sets – Weaver Leather Supply offers a variety of steel and polycarbonate leather cutting dies designed for efficiency in leather crafting. Key features include:

– High impact polycarbonate construction for durability and precision.

– Custom Polycarb Leather Cutting Dies available upon request.

– Ideal for mass production, saving time and ensuring consistency in cutting complex sh…

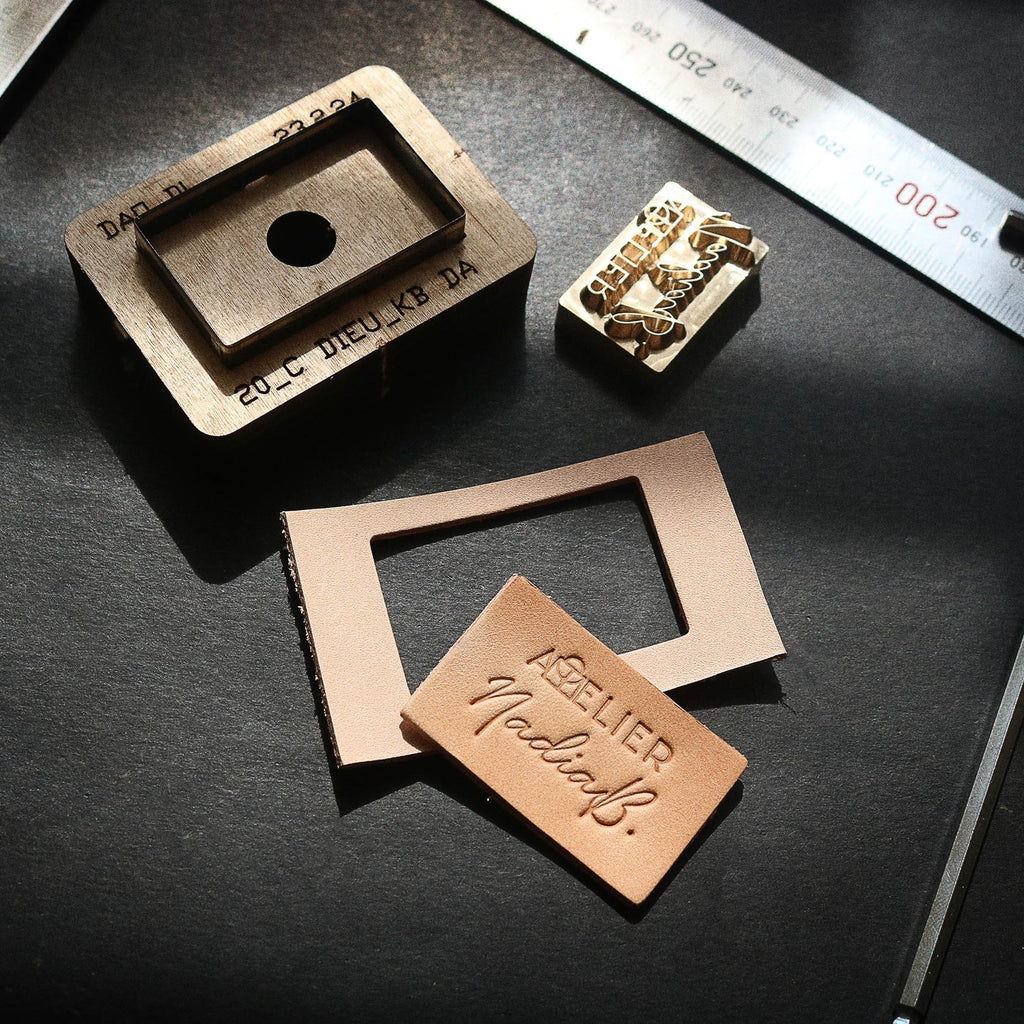

2. LW Leathers – Leather Die Cut with Acrylic Mount

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Leather Die Cut with Acrylic Mount”, “category”: “Leather Cutting and Paper Cutting”, “regular_price”: “US$138.00”, “sizes_available”: [“Up to 3×3 inch”, “Up to 4×4 inch”, “Up to 5×5 inch”, “Up to 6×6 inch”], “description”: “Custom made laser engraved leather die cut / steel rule die cut for cutting leather, paper, card stock, silicone, thin magnet, etc. Acrylic mount steel rule …

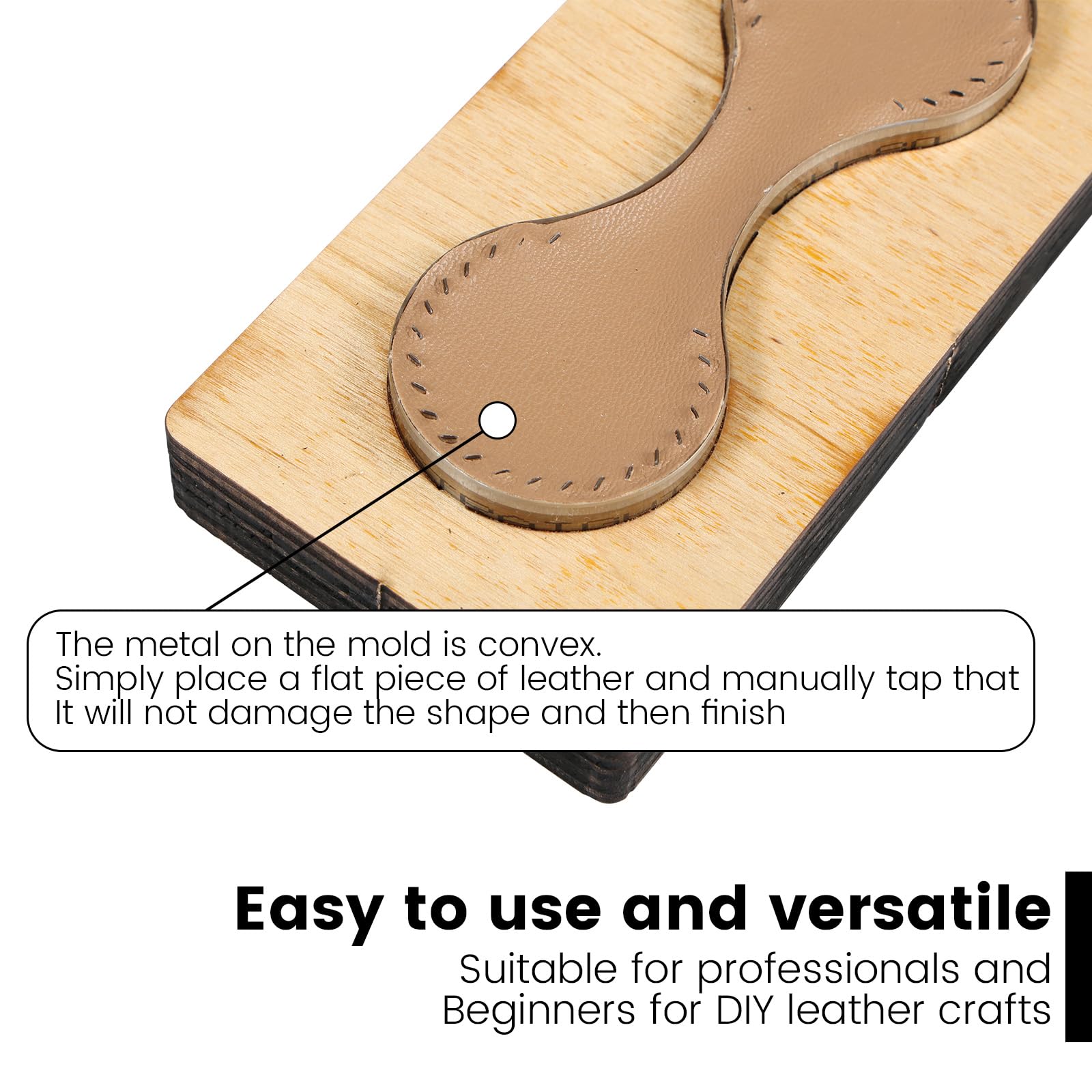

3. DM Leather Studio – Custom Leather Cutting Dies

Domain: dmleatherstudio.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Custom Leather Cutting Dies, Steel Die for Cutting Leather”, “product_code”: “X09-LCD”, “price”: “$2.00”, “availability”: “Many in stock”, “materials”: [“wood”, “steel”], “description”: “This die cut is for leather, paper, felt cloth projects etc. It can cut any shape perfectly, great for crafts!”, “customization_options”: [“Custom Made – A”, “Custom Made – B”, “Custom Made – C”,…

4. Leather Stamp Maker – Custom Steel Cutting Dies

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Steel Leather Cutting Dies by Leather Stamp Maker, made in the USA. Custom leather cutting dies available. Full Letter Sets include: trio of each letter A-Z, three copies of numbers 0-9, special characters (period, comma, at symbol, ampersand, hash, slash, dash, exclamation mark), four blank spacers, stamping handle, 4-inch holder, packaged in a box. Mini Font Sets include: full set of 26 uppercas…

5. USA Cutting Die – Custom Die Cutting Services

Domain: usacuttingdie.com

Registered: 2009 (16 years)

Introduction: Die cutting services for customers without a press, custom saddle dies, small key fobs, coaster dies.

Strategic Sourcing Conclusion and Outlook for custom leather cutting dies

In the dynamic landscape of custom leather cutting dies, strategic sourcing emerges as a crucial element for international B2B buyers seeking efficiency and quality. By investing in high-quality steel or polycarbonate dies, businesses can significantly enhance production speed and precision, reducing labor costs and minimizing material waste. Customization capabilities allow for tailored solutions that meet specific design requirements, fostering innovation in product offerings.

For companies across Africa, South America, the Middle East, and Europe, establishing partnerships with reliable suppliers can lead to sustained competitive advantages. Engaging with manufacturers that prioritize customer service and provide comprehensive support—such as rapid prototyping and precision accuracy—ensures a seamless procurement process.

Illustrative image related to custom leather cutting dies

Looking ahead, as the demand for bespoke leather products continues to rise, embracing advanced sourcing strategies will be paramount. By proactively exploring partnerships and leveraging technology in sourcing, businesses can position themselves for success in an increasingly global marketplace. Take the next step today: evaluate your sourcing strategies and consider how custom leather cutting dies can elevate your production capabilities and product quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to custom leather cutting dies

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.