Introduction: Navigating the Global Market for nuback leather

In the competitive landscape of international trade, sourcing high-quality nubuck leather presents both opportunities and challenges for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, including countries like Germany and Vietnam. Nubuck leather, known for its luxurious, velvety texture and aesthetic appeal, has gained popularity across various sectors, from fashion to upholstery. However, understanding the nuances of this material—including its sourcing, applications, and maintenance—is crucial for making informed purchasing decisions.

This comprehensive guide delves into the intricacies of nubuck leather, providing valuable insights into its types, applications, and supplier vetting processes. We will explore key factors influencing cost and quality, helping you to identify reliable suppliers who meet your specific needs. Additionally, we will address best practices for maintaining nubuck leather products, ensuring longevity and satisfaction for your end-users.

By equipping international B2B buyers with the knowledge needed to navigate the global market for nubuck leather, this guide empowers you to make strategic decisions that align with your business goals. Whether you are looking to enhance your product line or ensure your supply chain is robust and reliable, our insights will facilitate a deeper understanding of this luxurious material, ultimately leading to successful procurement outcomes.

Table Of Contents

- Top 4 Nuback Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for nuback leather

- Understanding nuback leather Types and Variations

- Key Industrial Applications of nuback leather

- 3 Common User Pain Points for ‘nuback leather’ & Their Solutions

- Strategic Material Selection Guide for nuback leather

- In-depth Look: Manufacturing Processes and Quality Assurance for nuback leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘nuback leather’

- Comprehensive Cost and Pricing Analysis for nuback leather Sourcing

- Alternatives Analysis: Comparing nuback leather With Other Solutions

- Essential Technical Properties and Trade Terminology for nuback leather

- Navigating Market Dynamics and Sourcing Trends in the nuback leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of nuback leather

- Strategic Sourcing Conclusion and Outlook for nuback leather

- Important Disclaimer & Terms of Use

Understanding nuback leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Nubuck | Soft, velvety texture; prone to staining | Footwear, luxury handbags | Pros: Luxurious feel, aesthetic appeal. Cons: Requires regular maintenance, less durable. |

| Waterproof Nubuck | Treated for water resistance; stain-resistant | Outdoor apparel, high-end footwear | Pros: Durable, easy to clean. Cons: Higher cost, may sacrifice some softness. |

| Italian Nubuck | Premium quality with a refined finish; often dyed | Luxury fashion items, upholstery | Pros: Elegant appearance, superior craftsmanship. Cons: Expensive, limited availability. |

| Suede-like Nubuck | Mimics suede texture; often softer and more plush | Fashion accessories, casual footwear | Pros: Soft feel, appealing look. Cons: Less durable than standard nubuck, more maintenance required. |

| Heavy-duty Nubuck | Thicker, more robust; designed for heavy wear | Work boots, industrial applications | Pros: Increased durability, suitable for rugged use. Cons: Stiffer texture, less luxurious feel. |

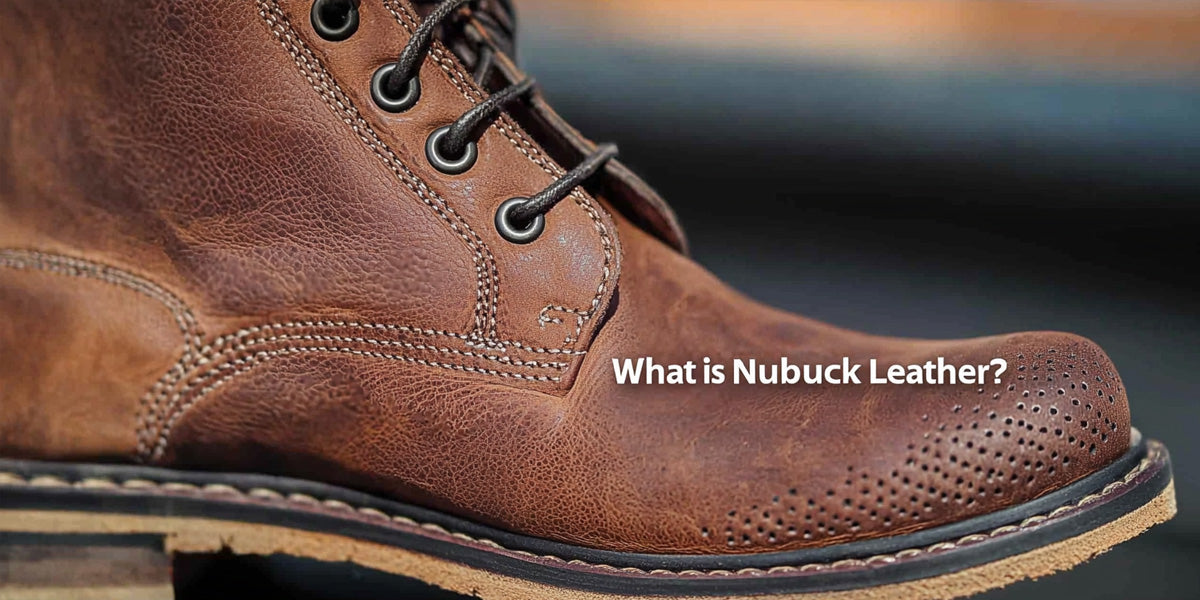

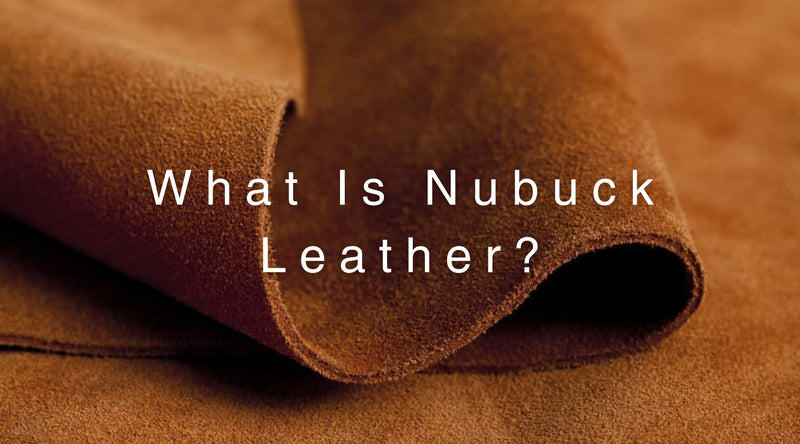

What Are the Characteristics of Standard Nubuck Leather?

Standard nubuck leather is renowned for its soft, velvety texture achieved through the sanding of the outer layer of the hide. This type of nubuck is widely used in the production of footwear and luxury handbags, appealing to consumers who prioritize aesthetics and comfort. However, its susceptibility to staining necessitates regular care and cleaning, making it a consideration for buyers who must balance luxury with maintenance efforts.

How Does Waterproof Nubuck Differ from Traditional Variants?

Waterproof nubuck is treated to resist moisture, making it an excellent choice for outdoor apparel and high-end footwear. This variation retains the softness of standard nubuck while offering enhanced durability and ease of cleaning. Buyers should consider the higher cost associated with waterproof nubuck, as well as the potential trade-off in softness compared to untreated variants, which may influence their purchasing decisions.

Why Is Italian Nubuck Considered a Premium Option?

Italian nubuck stands out due to its premium quality, refined finish, and often vibrant dyeing options. It is primarily used in luxury fashion items and high-end upholstery, appealing to discerning buyers who seek elegance and superior craftsmanship. However, its higher price point and limited availability can be significant factors for B2B buyers, particularly those in competitive markets where cost is a critical consideration.

What Are the Benefits of Suede-like Nubuck?

Suede-like nubuck mimics the plush texture of suede but retains some of the durability associated with nubuck. It is often employed in fashion accessories and casual footwear, appealing to buyers looking for a soft feel combined with stylish aesthetics. While this type offers an attractive appearance, it also poses challenges in terms of durability and maintenance, which buyers must weigh against their specific product applications.

How Does Heavy-duty Nubuck Serve Industrial Needs?

Heavy-duty nubuck is engineered for robustness, making it suitable for work boots and industrial applications. This thicker variant provides increased durability, ideal for environments where wear and tear are prevalent. However, buyers should note that while heavy-duty nubuck offers strength, it may compromise the luxurious feel found in softer nubuck types, influencing decisions based on target market preferences and application requirements.

Illustrative image related to nuback leather

Key Industrial Applications of nuback leather

| Industry/Sector | Specific Application of nuback leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-end footwear and accessories | Provides a luxurious feel and aesthetic appeal | Ensure consistent quality and availability of waterproof options. |

| Automotive | Interior upholstery for luxury vehicles | Enhances comfort and elegance in vehicle interiors | Consider durability and ease of maintenance, especially in varying climates. |

| Furniture and Upholstery | Premium sofas and chairs | Offers a sophisticated look while being durable | Verify the stain resistance and color retention for long-lasting appeal. |

| Sports and Outdoor Gear | Performance footwear and apparel | Combines style with functionality for outdoor use | Look for options that balance weight, durability, and water resistance. |

| Home Decor | Decorative items and wall coverings | Adds texture and warmth to interior spaces | Focus on sourcing from reputable suppliers for consistent quality and design. |

How is Nubuck Leather Used in Fashion and Apparel?

Nubuck leather is a favored choice in the fashion industry, particularly for high-end footwear and accessories. Its soft, velvety texture elevates the aesthetic of luxury products, appealing to discerning consumers. For B2B buyers, sourcing nubuck requires attention to quality assurance, especially regarding waterproof and stain-resistant options. Ensuring consistent supply and quality is crucial, especially when catering to international markets in Africa, South America, and Europe, where climate and consumer preferences can vary.

What Role Does Nubuck Leather Play in Automotive Interiors?

In the automotive sector, nubuck leather is commonly used for luxury vehicle interiors. Its plush feel enhances passenger comfort and adds a touch of elegance to car designs. For businesses in this industry, it is essential to consider the leather’s durability against wear and tear, particularly in regions with diverse weather conditions. Buyers should seek suppliers who offer high-quality nubuck that meets industry standards for performance and maintenance, ensuring a long-lasting investment.

How is Nubuck Leather Beneficial in Furniture and Upholstery?

Nubuck leather is increasingly popular in the furniture industry, particularly for premium sofas and chairs. Its durability combined with a sophisticated appearance makes it ideal for high-end residential and commercial spaces. B2B buyers should prioritize sourcing options that offer stain resistance and color retention, as these qualities enhance the longevity and appeal of the furniture. Understanding the specific needs of the target market, such as style preferences in different regions, can guide effective purchasing decisions.

Why is Nubuck Leather Ideal for Sports and Outdoor Gear?

In the sports and outdoor gear sector, nubuck leather is utilized for performance footwear and apparel, marrying style with functionality. Its softness and flexibility provide comfort during physical activities, while its aesthetic appeal attracts consumers looking for fashionable options. For international buyers, it is vital to consider sourcing nubuck that balances lightweight characteristics with durability and water resistance, catering to a global audience that values both performance and style in outdoor environments.

How Does Nubuck Leather Enhance Home Decor?

Nubuck leather finds applications in home decor, particularly in decorative items and wall coverings. Its unique texture and warmth can transform interior spaces, adding a layer of sophistication to design aesthetics. When sourcing nubuck for home decor, businesses should focus on collaborating with reputable suppliers to ensure consistent quality and innovative design options. Understanding regional design trends and preferences can further enhance the effectiveness of sourcing strategies, appealing to diverse customer bases across international markets.

3 Common User Pain Points for ‘nuback leather’ & Their Solutions

Scenario 1: The Challenge of Staining and Maintenance

The Problem: B2B buyers, particularly those in the fashion and upholstery industries, often face the significant challenge of nubuck leather’s susceptibility to staining. This can be a major concern for companies producing high-end products, as any stain can compromise the luxurious appearance that nubuck is known for. Buyers need to ensure that the nubuck leather they source maintains its aesthetic appeal over time, especially in environments where the leather is exposed to spills or dirt.

The Solution: To mitigate the risk of staining, buyers should prioritize sourcing waterproof and stain-resistant nubuck options, such as the Italia Nubuck Collection. When specifying nubuck for production, it is crucial to communicate the need for protective treatments to suppliers, ensuring that the leather has undergone processes that enhance its resistance to stains. Additionally, educating end-users on proper care techniques—such as using specialized nubuck erasers and brushes—can prolong the life and appearance of the leather. Providing care instructions with the final product can significantly enhance customer satisfaction and reduce returns due to appearance-related issues.

Scenario 2: Misunderstanding Nubuck vs. Full-Grain Leather

The Problem: Many B2B buyers are often confused about the differences between nubuck leather and full-grain leather, which can lead to misinformed purchasing decisions. This misunderstanding can result in selecting a leather type that does not meet the desired durability and aesthetic requirements for their products, particularly in sectors like footwear or luxury goods. Such errors can lead to increased costs and customer dissatisfaction if products fail to perform as expected.

The Solution: To overcome this challenge, B2B buyers should invest time in education about the characteristics of nubuck versus full-grain leather. Creating detailed comparison charts and guides that outline the pros and cons of each leather type can serve as valuable resources during the sourcing process. Additionally, establishing strong communication with suppliers to clarify the intended use of the leather can ensure that the right type is selected for the specific application. Engaging in product samples and testing can also help buyers evaluate the leather’s performance and suitability before making bulk purchases.

Scenario 3: Sourcing Quality Nubuck Leather

The Problem: Sourcing high-quality nubuck leather can be particularly challenging for B2B buyers who prioritize both aesthetics and durability. With varying grades of nubuck available in the market, it can be difficult to ensure that the leather meets the necessary quality standards, particularly for luxury brands that demand excellence. Inconsistent quality can lead to production delays and increased costs due to returns or complaints.

The Solution: To address this issue, buyers should develop a robust supplier vetting process that includes assessing the quality of the leather being offered. This can involve visiting suppliers’ facilities to inspect the leather firsthand and requesting certifications or guarantees about the materials used. Establishing long-term relationships with reputable suppliers who have a proven track record in the industry can also ensure consistent quality. Additionally, buyers should consider utilizing third-party testing services to validate the quality of nubuck leather prior to production. Investing in quality assurance not only enhances the end product but also builds trust with consumers who value premium materials.

Strategic Material Selection Guide for nuback leather

What Are the Key Materials Used in Nubuck Leather Production?

Nubuck leather is derived from the top grain of the hide, typically from cow or calf, and is known for its soft, velvety texture. Various treatments and finishes are applied to enhance its properties, making it suitable for a range of applications. Below are some common materials and treatments associated with nubuck leather, along with their respective properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Nubuck Leather?

1. Top Grain Cowhide

Key Properties: Top grain cowhide is the primary material used for nubuck leather. It offers a robust structure, which is more durable than suede. The hide undergoes sanding to create a soft surface, while maintaining its strength.

Pros & Cons:

– Pros: High durability, luxurious feel, and versatility in applications such as footwear, upholstery, and fashion accessories.

– Cons: More expensive than lower-grade leathers and requires specialized care to maintain its appearance.

Illustrative image related to nuback leather

Impact on Application: Top grain cowhide is suitable for high-end products where aesthetics and comfort are paramount. However, it is essential to consider its susceptibility to stains, which may affect its use in environments prone to spills.

Considerations for International Buyers: Buyers should ensure compliance with international leather standards, such as ASTM or DIN, particularly in markets like Germany and Europe, where quality assurance is critical.

2. Nubuck Finishing Agents

Key Properties: Various finishing agents are used to enhance the water and stain resistance of nubuck leather. These agents can include silicone-based sprays or waxes that provide a protective layer.

Illustrative image related to nuback leather

Pros & Cons:

– Pros: Improved resistance to water and stains, prolonging the life of the leather and maintaining its aesthetic appeal.

– Cons: Some treatments can alter the leather’s texture or color, requiring careful selection based on the intended application.

Impact on Application: The use of finishing agents can significantly extend the usability of nubuck leather in outdoor or high-traffic environments, making it suitable for products like jackets and shoes.

Considerations for International Buyers: Buyers should verify that finishing agents comply with local regulations regarding chemical use, especially in regions with strict environmental laws, such as the European Union.

3. Synthetic Nubuck Alternatives

Key Properties: Synthetic nubuck is made from polyester or polyurethane materials designed to mimic the look and feel of genuine nubuck leather.

Pros & Cons:

– Pros: Generally more affordable, easier to clean, and often more resistant to stains and water than natural nubuck.

– Cons: Lacks the breathability and luxurious feel of real leather, which may affect customer perception in high-end markets.

Illustrative image related to nuback leather

Impact on Application: Synthetic alternatives are increasingly popular for mass-market products, particularly in regions where cost is a significant factor. However, they may not appeal to luxury buyers seeking authentic materials.

Considerations for International Buyers: Buyers should assess the market demand for synthetic versus genuine leather in their region, as preferences can vary widely between markets in Africa, South America, and Europe.

4. Nubuck Leather Treatments

Key Properties: Treatments such as dyeing and conditioning enhance the color and feel of nubuck leather. These processes can also improve durability and resistance to wear.

Pros & Cons:

– Pros: Enhanced aesthetic appeal and longevity of the leather, making it suitable for a variety of upscale applications.

– Cons: Treatment processes can increase production costs and may require more time, affecting lead times for buyers.

Impact on Application: Properly treated nubuck leather can be used in a wide range of products, from luxury handbags to high-end furniture, where appearance is critical.

Considerations for International Buyers: Buyers should consider the lead times and costs associated with various treatments and ensure that they meet local market demands for quality and aesthetics.

Summary Table of Materials for Nubuck Leather

| Material | Typical Use Case for nubuck leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Top Grain Cowhide | Footwear, upholstery, fashion items | High durability and luxurious feel | Requires specialized care | High |

| Nubuck Finishing Agents | Outdoor apparel, footwear | Improved water and stain resistance | May alter texture or color | Medium |

| Synthetic Nubuck Alternatives | Mass-market footwear, accessories | Affordable and easy to clean | Lacks breathability and luxury feel | Low |

| Nubuck Leather Treatments | Luxury handbags, furniture | Enhanced aesthetics and longevity | Increases production costs and lead times | Medium |

This guide provides B2B buyers with essential insights into the materials used in nubuck leather production, helping them make informed decisions based on their specific market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for nuback leather

What Are the Key Manufacturing Processes for Nubuck Leather?

The production of nubuck leather involves several intricate stages that are crucial for achieving its distinctive texture and durability. Understanding these processes can help B2B buyers make informed decisions when sourcing nubuck leather products.

Illustrative image related to nuback leather

How Is Material Prepared for Nubuck Leather?

The first stage in the manufacturing of nubuck leather is material preparation. High-quality hides, typically from cows or calves, are selected based on their thickness and grain quality. The top-grain layer is preferred as it offers the strength and durability that nubuck is known for.

Once selected, the hides undergo a process known as tanning, which preserves the leather and makes it suitable for further processing. Various tanning methods can be employed, including chrome tanning and vegetable tanning, each imparting unique characteristics to the leather. Chrome tanning is more common for nubuck due to its efficiency and ability to produce softer leather.

What Techniques Are Used in Forming Nubuck Leather?

After tanning, the hides are subjected to sanding and buffing to create the characteristic velvety texture of nubuck. This process involves removing the outermost layer of the hide, exposing the soft fibers beneath. It’s essential to control the sanding process carefully to avoid damaging the hide or removing too much material, which can compromise the leather’s integrity.

Once the desired texture is achieved, the hides are dyed using high-quality pigments that enhance their aesthetic appeal while ensuring color fastness. The dyeing process can vary, with some manufacturers opting for aniline dyes that preserve the natural characteristics of the leather, while others may use pigment dyes for a more uniform appearance.

What Finishing Processes Are Essential for Nubuck Leather?

The finishing stage is critical in determining the performance characteristics of nubuck leather. This process often includes applying protective coatings to enhance water resistance and stain repellency. Innovations in this area, such as the Italia Nubuck Collection, have introduced waterproof and stain-resistant options that are particularly appealing to buyers looking for durable yet luxurious materials.

Finishing techniques may also involve buffing to achieve a uniform sheen and applying conditioning agents to maintain suppleness. Quality assurance checks are typically integrated at this stage to ensure that the finished product meets specified standards.

How Is Quality Assurance Implemented in Nubuck Leather Production?

Quality assurance is a crucial aspect of nubuck leather manufacturing, ensuring that the final product meets both regulatory and customer standards. This involves several checkpoints throughout the production process.

What International Standards Are Relevant for Nubuck Leather?

For B2B buyers, understanding the relevant international standards is essential for ensuring product quality. ISO 9001 is a widely recognized standard for quality management systems, applicable across various industries, including leather production. Compliance with this standard indicates that the manufacturer has a systematic approach to managing quality, which can provide peace of mind for buyers.

Additionally, industry-specific certifications such as CE marking and API (American Petroleum Institute) standards may be relevant, depending on the intended use of the nubuck leather products. For example, CE marking is often necessary for products sold in the European market, ensuring they meet safety and health requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) in nubuck leather manufacturing typically includes several key checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw hides upon receipt to ensure they meet quality specifications, such as thickness, grain quality, and absence of defects.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor the quality of the leather at various stages, including tanning, sanding, and dyeing. This helps catch any issues early in the production cycle.

-

Final Quality Control (FQC): Once the nubuck leather is finished, a comprehensive final inspection is performed. This includes checking the texture, color consistency, and the effectiveness of any protective coatings applied.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of nubuck leather suppliers is essential. Here are several approaches:

-

Supplier Audits: Conducting audits of potential suppliers can provide direct insight into their manufacturing processes and quality control measures. Look for suppliers who are willing to provide access to their facilities and documentation.

-

Quality Control Reports: Request detailed quality control reports that outline the results of IQC, IPQC, and FQC inspections. This documentation can provide assurance that the supplier adheres to rigorous quality standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These services can conduct inspections at various stages of production and offer a comprehensive report.

What Nuances Should International Buyers Consider?

International buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of certain nuances when sourcing nubuck leather. Different regions may have varying standards and preferences for quality, durability, and aesthetic characteristics.

For instance, European buyers may prioritize compliance with CE marking and environmental standards, while buyers from other regions might focus more on the product’s functionality and price. Additionally, understanding cultural preferences and market trends can significantly influence purchasing decisions.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance mechanisms for nubuck leather can empower B2B buyers to make informed sourcing decisions, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nuback leather’

In this practical sourcing guide, B2B buyers will find a step-by-step checklist designed to facilitate the procurement of nubuck leather. Nubuck leather is known for its luxurious feel and aesthetic appeal, making it a popular choice for high-end products. However, sourcing this specific type of leather requires careful consideration to ensure quality and suitability for your needs.

Illustrative image related to nuback leather

Step 1: Define Your Technical Specifications

Before initiating your search for nubuck leather, it’s essential to outline your specific requirements. Consider factors such as the thickness, finish, color, and intended application (e.g., footwear, upholstery, or fashion accessories). Clearly defined specifications will help you communicate effectively with suppliers and ensure you receive materials that meet your expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in nubuck leather. Look for manufacturers with a solid reputation and experience in producing high-quality leather. Utilize industry directories, trade shows, and online platforms to compile a list of potential vendors.

- Tip: Focus on suppliers that are known for ethical sourcing and sustainable practices, as these factors are increasingly important in global markets.

Step 3: Evaluate Supplier Credentials

Before making any commitments, it’s crucial to verify the credentials of potential suppliers. Request documentation such as certifications (e.g., ISO, Leather Working Group), quality assurance processes, and compliance with international standards. This step ensures that you’re partnering with a reputable supplier who adheres to industry regulations.

- Tip: Seek references or case studies from previous clients in your industry to assess the supplier’s reliability and quality of service.

Step 4: Request Samples for Assessment

Once you have narrowed down your list of suppliers, request samples of their nubuck leather. Evaluating physical samples allows you to assess the texture, color, and overall quality firsthand. This is a critical step to ensure that the leather meets your aesthetic and functional requirements.

- Tip: Consider testing the samples for durability, stain resistance, and maintenance requirements to gauge their suitability for your intended use.

Step 5: Understand Pricing and Payment Terms

Engage in discussions with suppliers regarding pricing structures and payment terms. Ensure you understand the cost breakdown, including any additional fees for custom orders or shipping. Transparent pricing will help you budget effectively and avoid unexpected expenses.

Illustrative image related to nuback leather

- Tip: Compare quotes from multiple suppliers to ensure you are receiving a competitive price, but remember that the cheapest option may not always be the best in terms of quality.

Step 6: Review Delivery and Lead Times

Establish clear expectations regarding delivery timelines and lead times for production. Reliable suppliers will provide realistic estimates based on their production capabilities and current workload. Understanding these timelines is crucial for planning your inventory and production schedules.

- Tip: Discuss contingency plans for delays to ensure that your supply chain remains uninterrupted.

Step 7: Formalize Your Agreement

Once you have selected a supplier, formalize your agreement with a detailed contract. This should include specifications, pricing, delivery schedules, and any warranties or guarantees. A well-drafted contract protects both parties and ensures accountability throughout the procurement process.

Following this checklist will help you navigate the complexities of sourcing nubuck leather effectively, ensuring that you secure high-quality materials that meet your business needs.

Comprehensive Cost and Pricing Analysis for nuback leather Sourcing

What Are the Key Cost Components in Nubuck Leather Sourcing?

Understanding the cost structure for nubuck leather is crucial for international B2B buyers. The primary cost components include:

Illustrative image related to nuback leather

-

Materials: Nubuck leather is derived from high-quality top-grain hides, typically from cattle. The price of raw hides can fluctuate based on market demand, quality, and sourcing location. Premium materials, such as Italian nubuck, may command higher prices due to their enhanced properties, such as waterproofing and stain resistance.

-

Labor: Labor costs vary significantly by region. In countries with higher wage standards, such as Germany or parts of Europe, labor costs are generally higher compared to regions in Africa or South America. Skilled artisans are often required for the sanding and finishing processes, which can add to labor costs.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and maintenance. Overhead can be higher in developed regions where operational standards and regulations are stringent.

-

Tooling: Specialized equipment is often needed to process nubuck leather, including machines for sanding and finishing. The initial investment in tooling can be substantial, but it is amortized over production runs.

-

Quality Control (QC): Ensuring that nubuck leather meets quality standards is vital, particularly for high-end products. QC processes can add to costs but are necessary for maintaining product integrity and customer satisfaction.

-

Logistics: Shipping and handling costs must be factored in, especially for international transactions. Incoterms like CIF (Cost, Insurance, and Freight) or FOB (Free on Board) can influence total costs, depending on the agreement between buyers and suppliers.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on market positioning, competition, and perceived value of the product.

What Influences the Pricing of Nubuck Leather?

Several factors influence the pricing of nubuck leather that international buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to bulk pricing, which can significantly lower the per-unit cost. Buyers should negotiate MOQs that align with their inventory needs.

-

Specifications and Customization: Custom requests, such as specific colors or finishes, can increase costs. Buyers should weigh the benefits of customization against the additional expense.

-

Material Quality and Certifications: Higher-quality materials or certifications (e.g., environmentally sustainable tanning processes) can lead to increased costs. Buyers should assess the importance of these certifications for their market.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer lower prices to gain market share.

What Are the Best Negotiation Strategies for B2B Buyers?

For international B2B buyers, effective negotiation is essential for cost-efficiency:

-

Conduct Market Research: Understanding market rates for nubuck leather can provide leverage during negotiations. Buyers should gather data on various suppliers to compare pricing and offerings.

-

Emphasize Long-Term Relationships: Building a long-term relationship with suppliers can lead to better pricing and terms. Suppliers are often more willing to negotiate when they see potential for repeat business.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as maintenance, durability, and logistics in the TCO analysis. A higher upfront cost may be justified by lower long-term maintenance needs.

-

Understand Pricing Nuances for International Transactions: Different regions may have varied expectations regarding payment terms, lead times, and quality standards. Familiarize yourself with local practices to facilitate smoother negotiations.

Disclaimer on Pricing Variability

Prices for nubuck leather can vary widely based on numerous factors, including market conditions, supplier pricing strategies, and material quality. The information provided here is indicative and should be used as a guideline rather than a definitive price list. B2B buyers are encouraged to conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing nuback leather With Other Solutions

Exploring Alternatives to Nubuck Leather for B2B Buyers

As B2B buyers consider nubuck leather for their product lines, it’s crucial to evaluate alternative materials that can meet similar needs. Understanding the strengths and weaknesses of various options allows businesses to make informed decisions based on performance, cost, maintenance, and specific use cases. Below, we explore two viable alternatives: full-grain leather and synthetic leather.

| Comparison Aspect | Nubuck Leather | Full-Grain Leather | Synthetic Leather |

|---|---|---|---|

| Performance | Soft, luxurious feel; moderate durability | Extremely durable; develops patina | Good durability; varies by quality |

| Cost | Moderate to high | Typically higher due to quality | Generally lower; budget-friendly |

| Ease of Implementation | Requires careful sourcing and treatment | Easy to source; standard processes | Widely available; easy to manufacture |

| Maintenance | High; needs regular care and protective treatments | Moderate; develops character with use | Low; easy to clean and maintain |

| Best Use Case | Fashion items, luxury upholstery | High-end products, footwear | Budget-friendly goods, casual wear |

What Are the Advantages and Disadvantages of Full-Grain Leather?

Full-grain leather is known for its unparalleled durability and ability to develop a rich patina over time. It retains the hide’s natural grain, making each piece unique. While it generally comes at a higher price point than nubuck leather, its longevity and robustness make it an excellent investment for products that require durability, such as footwear and bags. However, it may not offer the same level of softness or luxurious feel that nubuck provides, and it can be less uniform in texture, which might not appeal to all consumers.

Illustrative image related to nuback leather

How Does Synthetic Leather Compare to Nubuck Leather?

Synthetic leather, often made from polyurethane or PVC, is an increasingly popular alternative to natural leathers like nubuck. It is typically more budget-friendly, making it an attractive option for businesses looking to reduce costs. Synthetic materials are also easier to clean and maintain, as they are less prone to staining and wear. However, synthetic leather may lack the luxurious feel and aesthetic appeal of nubuck and can vary significantly in quality. Lower-quality synthetic options may not provide the same durability as nubuck, especially in high-use applications.

How Should B2B Buyers Choose the Right Leather Solution?

In choosing the right leather solution, B2B buyers should consider the specific needs of their target market and product applications. If the goal is to create high-end, luxury items where aesthetics and tactile quality are paramount, nubuck leather may be the best choice despite its maintenance requirements. Conversely, for products that demand durability and ease of care, full-grain leather or synthetic options may be more suitable. Ultimately, understanding the trade-offs between luxury, durability, and cost will empower buyers to make choices that align with their brand values and customer expectations.

Essential Technical Properties and Trade Terminology for nuback leather

What Are the Key Technical Properties of Nubuck Leather?

1. Material Grade

Nubuck leather is classified as a top-grain leather, which is the outer layer of the hide. This grade is critical as it indicates the quality and durability of the leather. High-grade nubuck is more resilient and less likely to suffer from wear and tear, making it suitable for high-end applications such as luxury footwear and upholstery. Buyers should prioritize material grade to ensure they are investing in products that will withstand daily use.

2. Tolerance Levels

Tolerance refers to the allowable variation in the thickness and finish of the leather. For nubuck, a typical thickness ranges from 1.0 mm to 1.4 mm. Tighter tolerances ensure a more uniform appearance and enhance the leather’s durability. In a B2B context, understanding these tolerances helps buyers specify their requirements accurately and avoid subpar products that could lead to increased costs and customer dissatisfaction.

3. Stain Resistance

Traditionally, nubuck is known for its susceptibility to stains due to its soft, velvety texture. However, modern treatments can enhance its stain resistance, making it more suitable for various applications. Buyers should assess the level of stain resistance offered, especially for products intended for environments where spills and stains are likely, such as in hospitality or family-oriented markets.

Illustrative image related to nuback leather

4. Breathability

One of the lesser-known properties of nubuck is its breathability. The sanding process leaves small pores in the leather, allowing air circulation. This is particularly important in footwear and apparel, where moisture management is essential for comfort. Understanding breathability can help buyers make informed decisions about the performance characteristics of nubuck products, especially in climates with high humidity.

5. Color Fastness

Color fastness refers to the leather’s ability to retain its color over time, especially when exposed to light and moisture. Nubuck can be dyed in various colors, but the quality of the dye and the finishing process significantly impact color fastness. Buyers should inquire about the color fastness ratings of nubuck products to ensure they meet the aesthetic and durability standards required for their specific applications.

What Are Common Trade Terminology and Jargon in the Nubuck Leather Industry?

1. OEM (Original Equipment Manufacturer)

In the context of nubuck leather, OEM refers to companies that produce leather goods for other brands under their specifications. This term is crucial for B2B buyers looking to partner with manufacturers who can deliver customized products that meet their branding requirements.

Illustrative image related to nuback leather

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers, as it impacts inventory management and cash flow. For nubuck leather, manufacturers may set MOQs based on the costs associated with processing specific hides.

3. RFQ (Request for Quotation)

An RFQ is a document sent by potential buyers to suppliers requesting pricing and terms for specific products. When dealing with nubuck leather, an RFQ can help clarify pricing, delivery timelines, and customization options, ensuring that buyers receive comprehensive information to make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping and delivery. For nubuck leather transactions, understanding Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital for managing logistics and costs effectively in international trade.

5. Tannage

Tannage refers to the process of treating animal hides to produce leather. Nubuck leather undergoes specific tanning processes that enhance its softness and durability. Buyers should be aware of the tanning methods used, as they can impact the leather’s characteristics, including environmental sustainability and chemical safety.

In summary, understanding the technical properties and trade terminology related to nubuck leather is essential for making informed purchasing decisions. Buyers should prioritize material grade, tolerance levels, and specialized features such as stain resistance and breathability while also familiarizing themselves with key industry terms to facilitate effective communication with suppliers.

Illustrative image related to nuback leather

Navigating Market Dynamics and Sourcing Trends in the nuback leather Sector

What Are the Current Market Dynamics and Key Trends in Nubuck Leather?

The global nubuck leather market is driven by a combination of increasing consumer demand for luxury products and advancements in production technology. Nubuck, known for its soft texture and aesthetic appeal, is increasingly favored in high-end fashion, upholstery, and accessories. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to differentiate their product offerings, the demand for premium nubuck leather is rising. Notably, the integration of technology in sourcing, such as digital platforms for procurement and blockchain for supply chain transparency, is reshaping the way buyers engage with suppliers.

Emerging trends include a growing preference for innovative products, such as waterproof and stain-resistant nubuck options, which address traditional vulnerabilities associated with nubuck leather. Additionally, the rise of e-commerce has made it easier for buyers to explore a broader range of suppliers and materials, allowing for more competitive pricing and unique sourcing opportunities. This trend is particularly pronounced in markets like Germany and Vietnam, where consumer expectations for quality and style are high.

How Is Sustainability and Ethical Sourcing Influencing Nubuck Leather Procurement?

Sustainability is increasingly becoming a focal point in the nubuck leather sector, driven by consumer awareness and regulatory pressures. The environmental impact of leather production, including water usage, chemical treatments, and waste generation, necessitates a shift towards ethical sourcing practices. B2B buyers must prioritize suppliers who adhere to sustainable practices, such as using eco-friendly tanning methods and sourcing hides from certified farms that maintain animal welfare standards.

The importance of ‘green’ certifications, such as the Leather Working Group (LWG) certification, cannot be overstated. These certifications not only assure buyers of a supplier’s commitment to sustainable practices but also enhance the marketability of the final products. Buyers should actively seek partnerships with suppliers who demonstrate transparency in their sourcing processes and invest in environmentally friendly technologies. By aligning with ethical suppliers, businesses can improve their brand image and appeal to a growing segment of environmentally conscious consumers.

Illustrative image related to nuback leather

What Is the Evolution and History of Nubuck Leather in the B2B Market?

Nubuck leather has its origins in traditional leatherworking techniques, evolving significantly over the past century. Initially, it was primarily used for high-quality footwear and garments, valued for its soft texture and luxurious appearance. The production process, which involves sanding the grain side of top-grain leather, was refined over time, leading to greater consistency and quality in the final product.

As global trade expanded, nubuck leather found its way into diverse markets, adapting to the varied tastes and preferences of consumers worldwide. Today, it is a staple in both fashion and functional products, combining elegance with durability. The continuous innovation in treatment processes, such as the development of waterproof nubuck, reflects the industry’s response to changing market demands and consumer expectations. This evolution positions nubuck leather as a versatile option for international B2B buyers seeking to enhance their product offerings with high-quality materials.

Frequently Asked Questions (FAQs) for B2B Buyers of nuback leather

-

How do I choose the right nubuck leather supplier for my business needs?

When selecting a nubuck leather supplier, consider their experience in the industry, product quality, and range of offerings. Request samples to evaluate the texture and durability of their nubuck leather. Additionally, check for certifications that ensure compliance with international quality standards. It’s also beneficial to review customer testimonials and case studies. Finally, engage in discussions about their supply chain capabilities to ensure timely delivery and consistent product availability. -

What is the best way to ensure the quality of nubuck leather products?

To ensure quality, establish clear specifications for the nubuck leather you require, including grain type, thickness, and finish. Implement a quality assurance process that includes inspections at different stages of production. Collaborate closely with your supplier and consider third-party inspections to validate the quality before shipment. Additionally, inquire about their sourcing practices to ensure they use high-grade hides and adhere to ethical standards. -

What customization options are available for nubuck leather?

Many suppliers offer customization options for nubuck leather, such as color, texture, and thickness. You can also request specific treatments, like waterproofing or stain resistance, to enhance durability. Discuss your design requirements with the supplier to explore possibilities for embossing, perforation, or other decorative finishes. It’s advisable to obtain samples of customized products to ensure they meet your expectations before placing larger orders. -

What are the minimum order quantities (MOQs) for nubuck leather?

Minimum order quantities for nubuck leather can vary significantly between suppliers. Generally, MOQs can range from 50 to 100 square meters, depending on the supplier’s production capabilities and the specific type of nubuck leather. When negotiating, consider discussing lower MOQs for initial orders or samples to test market demand. Always clarify the terms to avoid unexpected costs, especially when sourcing from international suppliers. -

What payment terms should I expect when sourcing nubuck leather internationally?

Payment terms for international orders of nubuck leather typically include options such as advance payment, letters of credit, or net payment terms (e.g., 30, 60, or 90 days). Discuss and negotiate these terms with your supplier upfront to avoid misunderstandings. Be mindful of currency fluctuations and transaction fees associated with international payments. Establishing a reliable payment method can help facilitate smoother transactions and build trust with your supplier. -

How do I handle logistics and shipping for nubuck leather orders?

When arranging logistics for nubuck leather, consider factors such as shipping method, customs regulations, and delivery timelines. Work closely with your supplier to understand their shipping capabilities and whether they provide door-to-door service. It’s wise to partner with a freight forwarder experienced in handling leather shipments to navigate customs and ensure compliance with import regulations. Additionally, factor in insurance for high-value shipments to protect against loss or damage. -

What are the common uses of nubuck leather in various industries?

Nubuck leather is widely used in fashion, upholstery, and luxury goods. In the footwear industry, it’s popular for high-end shoes due to its soft texture and aesthetic appeal. The automotive sector utilizes nubuck for seating and interior finishes, while furniture manufacturers often use it for stylish upholstery. Understanding the applications of nubuck leather can help you identify potential markets and tailor your offerings to meet specific industry needs. -

What care and maintenance practices should I recommend for nubuck leather products?

To maintain nubuck leather products, recommend regular brushing with a soft brush to remove dirt and restore the nap. For stains, advise using a specialized nubuck eraser or cleaner. It’s also essential to apply a protective spray designed for nubuck to enhance its resistance to water and stains. Educating your customers on proper care will extend the life of nubuck leather products and ensure they retain their luxurious appearance.

Top 4 Nuback Leather Manufacturers & Suppliers List

1. Leather Hide Store – Nubuck Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Nubuck is a top grain leather that has been lightly sanded and brushed to create a supple, velvety-like surface. The sanding process removes the top layer of the hide exposing a layer of tiny soft fibers or nap. Nubuck is compared to suede, but is a stronger upholstery grade leather. Traditional Nubuck is susceptible to staining, but the Italia Nubuck Collection offers an ultra-luxe Italian nubuck…

2. Carl Friedrik – Nubuck Leather Care

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: Nubuck leather is durable, made from the outer layer of animal hide, and has a velvety surface known as the ‘nap’. It is breathable but prone to oil and grease stains. Care involves using a nubuck brush to clean and re-fluff, applying waterproofing spray 2-3 times yearly, and conditioning with nubuck conditioner sprays. Cleaning requires a nubuck-specific brush, eraser, and cleaner for stains. The…

3. Olpr – Nubuck Leather

Domain: olpr.com

Registered: 2006 (19 years)

Introduction: Nubuck is a type of leather with a brushed and buffed surface, featuring a frosted, velvety texture. It is made from the top grain of hides, primarily from calves, goats, or deer. The manufacturing process involves sanding the hide to create a napped finish, resulting in a durable and soft material. Nubuck is often used in high-quality footwear, bags, coats, and furniture. It is more durable than …

4. Bedrock – Mountain Clog

Domain: bedrocksandals.com

Registered: 2011 (14 years)

Introduction: {‘name’: ‘Mountain Clog – Nubuck Leather’, ‘price’: ‘$175.00 USD’, ‘shipping’: ‘Free US Shipping’, ‘returns’: ‘Free US Returns / Exchanges’, ‘material’: ‘Oiled Nubuck Ecco® Leather’, ‘color’: ‘Light Brown’, ‘features’: [‘Water resistant’, ‘Single piece unlined leather upper’, ‘3-point adjustment strap system’, ‘Vibram® Megagrip outsole’, ‘Climbing rubber toe cap’, ‘Cushioned PU footbed’, ‘Anatomic…

Strategic Sourcing Conclusion and Outlook for nuback leather

In today’s competitive marketplace, strategic sourcing of nubuck leather presents a unique opportunity for international B2B buyers. Nubuck, with its luxurious feel and aesthetic appeal, is increasingly favored in high-end fashion, upholstery, and luxury goods. Its distinct qualities—sourced from the top grain of hides and treated for durability—make it a valuable material for businesses seeking to differentiate their offerings.

However, it is essential to recognize the importance of care and maintenance in maximizing the longevity and appearance of nubuck leather products. As buyers, understanding the nuances of nubuck versus other leather types, such as full-grain and suede, will empower you to make informed purchasing decisions that align with your brand’s quality standards.

Illustrative image related to nuback leather

Looking forward, the demand for innovative and premium materials like nubuck leather is expected to grow, especially in emerging markets across Africa, South America, and the Middle East. By establishing strong supplier relationships and leveraging strategic sourcing practices, you can secure high-quality nubuck leather that meets evolving consumer expectations. Embrace this opportunity to enhance your product offerings and stay ahead in the competitive leather goods market. Reach out today to explore partnerships that will elevate your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.