Introduction: Navigating the Global Market for leather jacket custom embroidery

In an increasingly competitive landscape, sourcing high-quality leather jacket custom embroidery solutions presents a unique challenge for B2B buyers across the globe. Whether you are looking to enhance your brand identity, provide bespoke gifts, or offer personalized fashion items, understanding the intricacies of this specialized market is essential. This guide aims to equip international buyers, particularly those from Africa, South America, the Middle East, and Europe—such as Nigeria and Brazil—with actionable insights into the diverse types of custom embroidery available, their applications, and the critical factors for vetting suppliers.

Navigating the complexities of leather jacket custom embroidery involves considering various elements, including design options, material quality, and pricing structures. Buyers will benefit from an in-depth exploration of the latest trends, technology in embroidery techniques, and how to effectively communicate their vision to suppliers. By understanding these nuances, you will be empowered to make informed purchasing decisions that align with your business objectives and customer expectations.

Moreover, this guide will delve into cost considerations, helping you establish budget parameters while maximizing the value of your investment. With a focus on ethical sourcing and manufacturing practices, you can ensure that your custom leather jackets not only meet aesthetic standards but also resonate with the values of your target market. Get ready to elevate your product offerings and create memorable customer experiences through the art of custom leather jacket embroidery.

Table Of Contents

- Top 4 Leather Jacket Custom Embroidery Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather jacket custom embroidery

- Understanding leather jacket custom embroidery Types and Variations

- Key Industrial Applications of leather jacket custom embroidery

- 3 Common User Pain Points for ‘leather jacket custom embroidery’ & Their Solutions

- Strategic Material Selection Guide for leather jacket custom embroidery

- In-depth Look: Manufacturing Processes and Quality Assurance for leather jacket custom embroidery

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather jacket custom embroidery’

- Comprehensive Cost and Pricing Analysis for leather jacket custom embroidery Sourcing

- Alternatives Analysis: Comparing leather jacket custom embroidery With Other Solutions

- Essential Technical Properties and Trade Terminology for leather jacket custom embroidery

- Navigating Market Dynamics and Sourcing Trends in the leather jacket custom embroidery Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather jacket custom embroidery

- Strategic Sourcing Conclusion and Outlook for leather jacket custom embroidery

- Important Disclaimer & Terms of Use

Understanding leather jacket custom embroidery Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Logo Embroidery | Custom logos stitched onto jackets, often in branded colors | Corporate uniforms, promotional items | Pros: Enhances brand visibility; Cons: Limited to logo designs only. |

| Monogramming | Personalized initials or names elegantly embroidered | Gifts, luxury fashion lines | Pros: Unique personalization; Cons: May increase production time. |

| Graphic Embroidery | Detailed images or designs, often in multi-color threads | Fashion, art collaborations | Pros: High visual impact; Cons: Complexity can increase costs. |

| Thematic Embroidery | Designs that reflect specific themes (e.g., events, culture) | Event merchandise, cultural apparel | Pros: Strong emotional connection; Cons: Requires careful design planning. |

| Custom Patches | Removable embroidered patches for versatility | Custom collections, promotional events | Pros: Easy to change or update; Cons: May require additional attachment methods. |

What Are the Key Characteristics of Logo Embroidery on Leather Jackets?

Logo embroidery is a popular choice among B2B buyers seeking to enhance brand identity. This type involves stitching a company logo onto leather jackets, usually in designated colors that align with corporate branding. It is widely used in corporate uniforms and promotional items, making it an effective marketing tool. Buyers should consider the visibility and placement of the logo, as well as the durability of the embroidery, which can withstand wear and tear.

How Does Monogramming Enhance Personalization in Leather Jackets?

Monogramming adds a touch of personalization by allowing buyers to have initials or names embroidered onto the jacket. This is particularly appealing for luxury fashion lines and gift items. Monogrammed jackets can create a sense of exclusivity and personal connection, making them ideal for high-end markets. However, buyers should be aware that monogramming may extend production times and add to costs, so planning is essential.

What Advantages Do Graphic Embroidery Designs Offer for B2B Buyers?

Graphic embroidery allows for intricate designs and images to be stitched onto leather jackets, making it a favored choice in the fashion industry and for artistic collaborations. This type of custom embroidery can produce striking visual effects that capture attention. However, the complexity of the designs can lead to higher production costs and longer lead times, requiring buyers to balance aesthetics with budget considerations.

Illustrative image related to leather jacket custom embroidery

In What Contexts Is Thematic Embroidery Most Effective?

Thematic embroidery involves designs that reflect specific themes, such as cultural motifs or event-related imagery. This type is particularly useful for creating merchandise tied to specific events or cultural celebrations. Buyers should consider the emotional resonance of the designs, as they can foster strong connections with customers. However, careful planning is necessary to ensure that the themes align with target audience preferences.

How Do Custom Patches Provide Versatility in Embroidered Leather Jackets?

Custom patches are another popular option, offering removable embroidered designs that can be easily attached or detached from jackets. This flexibility allows brands to create limited edition collections or promotional items that can be updated frequently. While custom patches offer ease of change, buyers should consider the methods for attachment, as they may require additional materials or processes to ensure durability.

Key Industrial Applications of leather jacket custom embroidery

| Industry/Sector | Specific Application of leather jacket custom embroidery | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom branding for fashion lines | Enhances brand identity and customer loyalty | Quality of embroidery, lead times, and customization options |

| Motorcycle & Automotive | Club and event jackets for motorcycle enthusiasts | Fosters community and brand allegiance | Durability of materials, design consultation, and sizing |

| Corporate & Promotional Gifts | Employee jackets with logos and messaging | Boosts brand visibility and team unity | Minimum order quantities, customization options, and pricing |

| Sports Teams | Team jackets featuring logos and player names | Strengthens team spirit and fan engagement | Design flexibility, quality control, and turnaround times |

| Military & Security Services | Customized jackets for uniformed personnel | Enhances professionalism and unit cohesion | Compliance with regulations, durability, and customization |

How is leather jacket custom embroidery utilized in the fashion and apparel industry?

In the fashion sector, custom embroidery on leather jackets serves as a powerful branding tool. Designers can incorporate logos, graphics, and personalized messages to create unique pieces that stand out in a competitive market. This helps in building brand identity and fosters customer loyalty, especially important for B2B buyers looking to differentiate their offerings. For international buyers, sourcing high-quality materials and skilled artisans is crucial to ensure the desired aesthetic and durability.

What role does leather jacket custom embroidery play in motorcycle and automotive sectors?

In the motorcycle and automotive industries, custom embroidered jackets are popular among clubs and event organizers. These jackets often feature club logos or event-specific designs, creating a sense of community and loyalty among members. For B2B buyers in these sectors, considerations include the durability of the embroidery and leather, as well as the ability to accommodate various sizes and styles. Ensuring quality control during production is vital to maintain brand standards.

How can corporate and promotional gifts leverage leather jacket custom embroidery?

Corporate entities utilize custom embroidered leather jackets as promotional gifts for employees or clients. These jackets, adorned with company logos and messages, enhance brand visibility while promoting a sense of unity among staff. B2B buyers should focus on minimum order quantities and the range of customization options available to suit their branding needs. Additionally, establishing clear communication regarding design specifications is essential for achieving the desired outcome.

In what ways do sports teams benefit from custom leather jacket embroidery?

Sports teams often use custom embroidered leather jackets to display team logos and player names, which strengthens team spirit and engages fans. These jackets can be sold as merchandise, providing an additional revenue stream for teams. B2B buyers in this sector must consider the flexibility of design options and the quality of materials to ensure that the final product reflects the team’s brand effectively. Timely production and delivery are also critical to align with event schedules.

How does leather jacket custom embroidery support military and security services?

Custom embroidered jackets are commonly used in military and security services to promote professionalism and unit cohesion. These jackets often feature insignias and rank identifiers, enhancing the identity of personnel. For B2B buyers in this field, compliance with specific regulations and standards is paramount, along with the need for durable materials that can withstand rigorous conditions. Customization options should also allow for various ranks and roles to be clearly represented.

Illustrative image related to leather jacket custom embroidery

3 Common User Pain Points for ‘leather jacket custom embroidery’ & Their Solutions

Scenario 1: Navigating Quality Control in Custom Embroidery Projects

The Problem: A common challenge faced by B2B buyers in the leather jacket custom embroidery sector is ensuring that the final product meets their quality expectations. This is particularly significant when dealing with multiple suppliers or manufacturers across different regions, such as Africa or South America, where standards may vary. Buyers often worry about discrepancies in thread quality, embroidery precision, and overall craftsmanship, leading to potential rejections from end customers or damage to their brand reputation.

The Solution: To mitigate quality control issues, B2B buyers should establish a clear and detailed specification document for their custom embroidery projects. This document should outline the exact requirements for thread types, color matching, embroidery techniques, and placement on the jacket. Additionally, incorporating a sample approval process can be highly beneficial. Before proceeding with large orders, request a prototype or sample jacket that showcases the embroidery. This allows for adjustments before mass production. Regular communication with the manufacturer, coupled with on-site quality checks or third-party inspections, can further ensure that the final products align with the expected standards, minimizing the risk of costly errors.

Scenario 2: Overcoming Sizing and Fit Challenges for Custom Leather Jackets

The Problem: Sizing discrepancies can significantly impact the satisfaction of B2B clients purchasing custom leather jackets. Buyers often encounter issues where the jackets do not fit the intended audience—this is particularly problematic when catering to diverse markets with varying body types, such as those in Europe or the Middle East. Miscalculations in size can lead to increased returns, customer dissatisfaction, and ultimately loss of business.

The Solution: Implement a comprehensive measurement guide that clients can follow to provide accurate sizing information. This guide should include detailed instructions on how to measure different parts of the body, ensuring that buyers can gather the correct data without confusion. Additionally, consider leveraging virtual fitting technologies that allow clients to input their measurements online, providing an accurate fit recommendation. It can also be beneficial to offer a tailored fit service where your team assists clients in taking measurements via video call. By prioritizing accurate sizing and offering clear communication, buyers can significantly reduce the risk of fit-related issues, resulting in higher customer satisfaction and retention.

Scenario 3: Managing Lead Times and Delivery Expectations

The Problem: B2B buyers often struggle with long lead times associated with custom leather jacket embroidery, which can lead to missed deadlines and dissatisfied clients. Factors such as the complexity of designs, availability of materials, and logistical issues can contribute to extended production times, especially when dealing with international shipping to regions like Africa or South America.

Illustrative image related to leather jacket custom embroidery

The Solution: To effectively manage lead times, buyers should engage in proactive project planning. This involves setting realistic timelines based on the complexity of the embroidery work and potential sourcing delays. Communicate these timelines clearly to clients to set expectations from the outset. It can also be advantageous to build relationships with multiple suppliers to ensure flexibility in sourcing materials. Additionally, consider implementing a project management tool that allows for real-time tracking of production stages and shipping status. This transparency can help in managing client expectations and enable buyers to inform customers promptly about any changes or delays, fostering trust and reliability in the business relationship.

Strategic Material Selection Guide for leather jacket custom embroidery

When selecting materials for leather jacket custom embroidery, it’s essential for international B2B buyers to understand the unique properties, advantages, and limitations of various options. This knowledge can significantly influence the quality, durability, and appeal of the final product. Below, we analyze four common materials used in leather jacket custom embroidery, focusing on their key properties and considerations for buyers from diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Full Grain Leather in Custom Embroidery?

Full grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain and imperfections, which adds character and uniqueness to each jacket.

- Key Properties: Full grain leather is highly durable, resistant to wear and tear, and develops a beautiful patina over time. It provides excellent temperature regulation, making it suitable for various climates.

- Pros & Cons: While it offers superior durability and aesthetic appeal, full grain leather can be expensive and may require more complex manufacturing processes. It is also heavier than other leather types, which may affect comfort.

- Impact on Application: Full grain leather is compatible with high-quality embroidery threads, allowing for intricate designs that stand out. However, its thickness may limit the types of embroidery techniques that can be employed.

- Considerations for International Buyers: Buyers should ensure compliance with local leather sourcing regulations and standards, such as the EU’s REACH regulation. In regions like Africa and South America, where leather quality may vary, sourcing from reputable tanneries is crucial.

How Does Suede Compare for Custom Embroidery Applications?

Suede, made from the underside of the hide, offers a soft texture and a unique aesthetic.

- Key Properties: Suede is less durable than full grain leather but provides excellent breathability and comfort. It is also lighter, making it suitable for warmer climates.

- Pros & Cons: The softness of suede enhances comfort and allows for detailed embroidery. However, it is more susceptible to staining and damage from moisture, requiring careful maintenance.

- Impact on Application: Suede works well with embroidery, but its texture may absorb some thread colors, affecting the vibrancy of designs. This can be a consideration for brands aiming for bold visual statements.

- Considerations for International Buyers: Buyers should be aware of the specific care requirements for suede, especially in humid environments. Compliance with local textile regulations is also essential, particularly in European markets.

What Role Does Synthetic Leather Play in Custom Embroidery?

Synthetic leather, or faux leather, is an alternative to traditional leather made from plastic materials.

- Key Properties: Synthetic leather is generally water-resistant and easy to clean, making it suitable for various applications. It can mimic the appearance of real leather while being lighter and more flexible.

- Pros & Cons: The primary advantage is cost-effectiveness, making it accessible for budget-conscious buyers. However, it may not offer the same durability or aesthetic appeal as genuine leather, and its environmental impact can be a concern.

- Impact on Application: Synthetic leather is compatible with a wide range of embroidery techniques. However, the longevity of the embroidery may be compromised compared to natural leather.

- Considerations for International Buyers: Buyers should check for compliance with environmental regulations, especially in Europe, where sustainability is increasingly prioritized. Understanding local market preferences for synthetic versus natural materials is also crucial.

How Does Nappa Leather Enhance Custom Embroidery Designs?

Nappa leather is known for its softness and smooth finish, making it a popular choice for high-end jackets.

- Key Properties: Nappa leather is highly supple and offers excellent comfort. It is also more resistant to cracking than other leather types, maintaining its appearance over time.

- Pros & Cons: Its luxurious feel and appearance make it ideal for premium products. However, it can be more expensive and may require careful handling to avoid scratches and scuffs.

- Impact on Application: Nappa leather allows for intricate embroidery, as its smooth surface provides a perfect backdrop for detailed designs. However, its softness may limit the types of structural elements that can be integrated into the jacket.

- Considerations for International Buyers: Buyers should consider the sourcing of Nappa leather, ensuring it meets ethical standards. Additionally, understanding local consumer preferences for luxury materials can guide purchasing decisions.

| Material | Typical Use Case for leather jacket custom embroidery | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | High-end jackets requiring durability and character | Superior durability and patina | Expensive and complex to manufacture | High |

| Suede | Casual jackets for comfort and style | Soft texture and breathability | Less durable and moisture-sensitive | Medium |

| Synthetic Leather | Budget-friendly options for mass production | Cost-effective and easy to clean | Lower durability and environmental concerns | Low |

| Nappa Leather | Luxury jackets needing a smooth finish | Luxurious feel and appearance | Higher cost and vulnerability to scratches | High |

This strategic material selection guide provides essential insights for B2B buyers in diverse markets, enabling informed decisions that align with their brand values and customer expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for leather jacket custom embroidery

What Are the Main Stages in the Manufacturing Process of Custom Leather Jacket Embroidery?

The manufacturing process for custom leather jackets, particularly when integrating embroidery, consists of several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential for ensuring that the final product meets both aesthetic and functional requirements.

Material Preparation

This initial stage involves sourcing high-quality leather, which is often selected based on specific characteristics such as grain, thickness, and color. Suppliers may use full-grain leather, which is the highest quality available, ensuring durability and a premium look. Additionally, the preparation of materials includes choosing the appropriate threads and fabrics for embroidery, which can range from cotton to polyester, depending on the desired finish and durability.

Forming

During the forming stage, patterns are cut from the prepared leather according to the specified measurements. Advanced technologies such as CAD (Computer-Aided Design) are often utilized to create precise patterns that minimize waste and ensure uniformity. This stage may also involve the application of any pre-embroidery treatments to the leather, such as softening or conditioning, to facilitate better embroidery results.

Assembly

Once the leather pieces are cut, they are assembled. This may involve stitching components together using high-quality threads to ensure durability. Custom embroidery is typically applied at this stage, allowing for the integration of logos, designs, or other embellishments. Techniques such as direct embroidery or appliqué may be employed, depending on the design complexity and customer preferences.

Finishing

The final stage involves adding finishing touches, which may include additional treatments for water resistance, color setting, and quality checks. This stage also encompasses the attachment of hardware, such as zippers and buttons, which can serve both functional and decorative purposes. The finishing process is crucial, as it enhances the overall quality and appearance of the jacket.

How Is Quality Control Implemented in Custom Leather Jacket Manufacturing?

Quality control (QC) is paramount in the leather jacket manufacturing process, ensuring that products meet international standards and customer expectations. Key international standards include ISO 9001, which focuses on quality management systems, and specific industry standards like CE marking for safety.

QC Checkpoints

The QC process typically includes several checkpoints:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival. For leather, this includes checking for defects such as discoloration, grain inconsistencies, and thickness variations.

– In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to ensure that processes are being followed correctly. This can involve monitoring stitching quality, alignment, and the accuracy of embroidery placements.

– Final Quality Control (FQC): After the jackets are completed, a comprehensive inspection is conducted to verify that all specifications have been met. This includes assessing the overall appearance, functionality of zippers, and ensuring that the embroidery is flawless.

Illustrative image related to leather jacket custom embroidery

What Testing Methods Are Commonly Used in Quality Assurance for Leather Jackets?

Several testing methods are employed to ensure that custom leather jackets meet quality and durability standards. These tests can include:

- Physical Testing: Evaluating the strength and durability of the leather through tensile strength tests and abrasion resistance tests.

- Colorfastness Testing: Ensuring that colors do not bleed or fade over time, particularly important for embroidered elements.

- Water Resistance Testing: Assessing how well the leather and any coatings repel water, a critical factor for consumer satisfaction.

- Dimensional Stability Testing: Checking that the jacket maintains its shape and size after washing or exposure to environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers looking to verify supplier quality control processes have several avenues to explore:

- Supplier Audits: Conducting on-site audits allows buyers to observe manufacturing processes and quality control practices firsthand. This can include reviewing documentation and witnessing inspections in real-time.

- Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC practices, including any certifications they hold and results from recent inspections.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These services often provide detailed reports that outline findings and recommendations.

What Are the Nuances of QC and Certification for International B2B Buyers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is critical. Buyers should consider:

- Regional Standards: Different regions may have varying standards for leather quality and manufacturing practices. Familiarizing oneself with local regulations can prevent compliance issues.

- Certification Validity: Ensure that any certifications claimed by suppliers are valid and current. This may involve checking with certifying bodies to confirm authenticity.

- Cultural Considerations: Different markets may have specific preferences or standards regarding leather quality and manufacturing ethics. Understanding these cultural nuances can help in selecting the right supplier.

Conclusion: The Importance of Rigorous Manufacturing and QC Processes

In the competitive landscape of custom leather jacket embroidery, rigorous manufacturing processes and quality assurance are essential. By understanding the stages of production, implementing effective QC checkpoints, and verifying supplier capabilities, B2B buyers can secure high-quality products that meet their specifications and enhance their brand offerings. This thorough approach not only mitigates risks but also builds strong supplier relationships, ensuring long-term success in the global marketplace.

Illustrative image related to leather jacket custom embroidery

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather jacket custom embroidery’

To successfully procure leather jackets with custom embroidery, a structured approach is essential. This checklist will guide B2B buyers through each critical step, ensuring that the final product meets quality standards and aligns with brand expectations.

Step 1: Define Your Design Requirements

Before engaging with suppliers, clarify your design needs. This includes the type of leather, embroidery design, colors, and any specific features such as zippers or pockets. Having a detailed design brief will help suppliers understand your vision and provide accurate quotes.

- Considerations:

- What style of leather jacket do you want (biker, bomber, etc.)?

- Are there specific logos or text you need embroidered? Ensure you have high-resolution files ready for the supplier.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers specializing in custom leather jackets. Look for companies with a proven track record and positive reviews.

- Action Items:

- Visit supplier websites and check for customer testimonials.

- Search for case studies that demonstrate their capability in handling similar projects.

Step 3: Evaluate Supplier Capabilities

Once you have a list of potential suppliers, assess their production capabilities. Ensure they can handle your specific requirements, including the quality of leather and the complexity of the embroidery.

Illustrative image related to leather jacket custom embroidery

- Key Aspects to Review:

- Do they use high-quality materials?

- What is their production capacity? Can they meet your deadlines?

Step 4: Request Samples

Before placing a bulk order, request samples of both the leather and embroidery. This will allow you to evaluate the craftsmanship and ensure it meets your expectations.

- Important Notes:

- Check the quality of stitching and the vibrancy of the embroidery.

- Ensure the leather feels right and matches your brand’s standards.

Step 5: Discuss Pricing and Terms

Negotiate pricing and payment terms with your chosen supplier. Ensure that you understand the full cost, including shipping and any potential customs duties for international orders.

- Questions to Ask:

- Are there bulk order discounts available?

- What are the payment terms, and do they offer flexible options?

Step 6: Review Production Timeline

Confirm the timeline for production and delivery. Clear communication regarding deadlines is essential to ensure that your jackets arrive when needed.

- Considerations:

- What is the estimated turnaround time for production?

- Are there any potential delays you should be aware of?

Step 7: Establish Quality Control Measures

Implement quality control checks throughout the production process. This may involve regular updates from the supplier and possibly visiting the manufacturing site if feasible.

Illustrative image related to leather jacket custom embroidery

- Quality Assurance Steps:

- Request progress photos of the jackets during production.

- Set up a final inspection process before shipment to catch any issues.

By following this checklist, B2B buyers can navigate the complexities of sourcing custom leather jackets with embroidery, ensuring high-quality products that resonate with their brand identity.

Comprehensive Cost and Pricing Analysis for leather jacket custom embroidery Sourcing

What Are the Key Cost Components in Leather Jacket Custom Embroidery?

When sourcing leather jackets with custom embroidery, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of leather (e.g., full-grain, top-grain, or suede) significantly affects the overall price. Premium materials often command higher prices but offer better durability and aesthetic appeal. Additionally, the costs of embroidery threads and backing materials should be considered.

-

Labor: Skilled craftsmanship is crucial for producing high-quality leather jackets. Labor costs vary based on the region and the expertise of the workers. Custom embroidery also requires specialized skills, which can add to labor costs.

-

Manufacturing Overhead: This includes rent, utilities, and maintenance of production facilities. Overhead can vary widely depending on the location of the manufacturer, impacting the final price.

-

Tooling: Custom embroidery may require specific tools or machinery, which can contribute to initial setup costs. These costs are typically amortized over the production run.

-

Quality Control (QC): Ensuring that each jacket meets quality standards incurs costs associated with inspections and testing. This is particularly important for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping costs can vary based on distance and the Incoterms agreed upon. For international shipments, customs duties and taxes may also apply.

-

Margin: Suppliers typically apply a markup to cover their costs and ensure profitability. Understanding the supplier’s pricing strategy can aid in negotiations.

How Do Price Influencers Affect Leather Jacket Custom Embroidery Costs?

Several factors influence the pricing of custom leather jackets, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often benefit from economies of scale, reducing the per-unit cost. Discussing flexible MOQs with suppliers can lead to better pricing structures.

-

Specifications and Customization: Highly customized designs, including intricate embroidery, may incur additional costs. Clear communication of design specifications can help avoid misunderstandings and unexpected charges.

-

Material Quality and Certifications: Premium materials and certifications (e.g., ethical sourcing, eco-friendliness) can increase costs but may also appeal to end consumers, enhancing brand value.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers may charge more due to their experience and quality assurance.

-

Incoterms: Understanding the agreed-upon Incoterms (e.g., FOB, CIF) is crucial, as they determine who is responsible for shipping costs and risks, affecting the total cost.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing?

B2B buyers should consider the following strategies to enhance cost-efficiency in sourcing custom leather jackets:

Illustrative image related to leather jacket custom embroidery

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Establishing a long-term relationship may also lead to better pricing and terms.

-

Total Cost of Ownership: Evaluate the total cost of ownership, which includes not only the purchase price but also shipping, duties, and potential alteration costs. This comprehensive view aids in making informed purchasing decisions.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and local market conditions. These factors can impact pricing and payment terms.

-

Local Regulations and Duties: Researching import duties and taxes in your country can prevent unexpected costs. Countries with trade agreements may offer reduced duties, further optimizing expenses.

Conclusion

Understanding the comprehensive cost structure and price influencers in sourcing leather jacket custom embroidery is vital for B2B buyers. By focusing on key cost components, leveraging negotiation strategies, and considering the total cost of ownership, businesses can make informed decisions that enhance their sourcing effectiveness. Note that prices can vary widely based on customization, material quality, and supplier factors, so it’s prudent to obtain multiple quotes and conduct thorough market research before finalizing orders.

Alternatives Analysis: Comparing leather jacket custom embroidery With Other Solutions

Introduction: Exploring Alternatives to Leather Jacket Custom Embroidery

In the world of custom apparel, particularly leather jackets, buyers often seek unique personalization options. Leather jacket custom embroidery stands out as a popular choice, allowing businesses to showcase their brand identity or individual style through intricate designs. However, there are alternative solutions that can achieve similar customization goals, each with distinct advantages and limitations. Understanding these alternatives is crucial for B2B buyers looking to make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Leather Jacket Custom Embroidery | Direct-to-Garment Printing (DTG) | Heat Transfer Vinyl (HTV) |

|---|---|---|---|

| Performance | High-quality, durable designs | Good quality, less durable | Good quality, highly durable |

| Cost | Moderate to high | Moderate | Low to moderate |

| Ease of Implementation | Requires skilled labor | Simple, requires specialized printer | Easy, requires basic tools |

| Maintenance | Low, can last many years | Moderate, may fade over time | Low, resistant to wear |

| Best Use Case | High-end, bespoke designs | Short runs, intricate designs | Bulk orders, bold designs |

Detailed Breakdown of Alternatives

1. Direct-to-Garment Printing (DTG)

Direct-to-garment printing is a technology that allows for high-quality images to be printed directly onto fabric. This method excels in producing detailed and colorful designs, making it ideal for intricate graphics or photographic images. However, while DTG offers good quality, it may not be as durable as custom embroidery, especially after multiple washes. Moreover, the initial investment in a DTG printer can be significant, and the process may require skilled operators to achieve optimal results. This option is best suited for short runs or one-off designs where vibrant visuals are paramount.

2. Heat Transfer Vinyl (HTV)

Heat transfer vinyl is a versatile and cost-effective alternative to custom embroidery. It involves cutting out designs from vinyl sheets and applying them to fabric using heat. This method is straightforward, making it accessible for businesses without extensive production capabilities. HTV is particularly suitable for bulk orders, as it allows for quick application and uniformity across items. However, while HTV can produce bold and striking designs, it may not offer the same level of detail or longevity as embroidery, potentially leading to fading or peeling over time. This method is best for promotional items or fashion lines focused on high-volume production.

Conclusion: Choosing the Right Customization Solution

When selecting the right customization solution for leather jackets, B2B buyers must consider various factors, including performance, cost, ease of implementation, and maintenance. Leather jacket custom embroidery provides a luxurious and durable option for high-end, bespoke designs. In contrast, direct-to-garment printing offers vibrant visuals for detailed designs, while heat transfer vinyl presents a more economical choice for bulk production. Ultimately, the decision should align with the buyer’s branding objectives, production capabilities, and budget constraints, ensuring that the chosen method effectively communicates their unique identity in the marketplace.

Essential Technical Properties and Trade Terminology for leather jacket custom embroidery

What Are the Key Technical Properties Relevant to Leather Jacket Custom Embroidery?

Understanding the technical properties of leather jacket custom embroidery is crucial for B2B buyers seeking to make informed purchasing decisions. Here are some essential specifications to consider:

1. Material Grade

The grade of leather significantly impacts the quality and durability of the jacket. Full-grain leather, for example, is the highest quality and retains the natural texture and imperfections, making it more robust and long-lasting. For B2B buyers, selecting high-grade materials ensures that the end product meets customer expectations and withstands wear and tear.

2. Stitch Count

The stitch count refers to the number of stitches per inch in the embroidery design. A higher stitch count typically results in more detailed and durable embroidery, enhancing the overall aesthetic of the leather jacket. For businesses, this translates to higher customer satisfaction and potential for repeat orders, making it a critical factor to specify when discussing custom embroidery projects.

3. Tolerance Levels

Tolerance levels define the acceptable variation in size and design during the manufacturing process. In custom embroidery, maintaining tight tolerances ensures that the embroidery aligns perfectly with the jacket’s design and fits the specified dimensions. For B2B transactions, knowing the tolerance levels helps mitigate risks related to fit and design discrepancies, ensuring a smoother production process.

Illustrative image related to leather jacket custom embroidery

4. Thread Type and Quality

The type of thread used in embroidery can affect both the appearance and durability of the design. Polyester threads are commonly used for their strength and resistance to fading, while cotton threads offer a softer finish. B2B buyers should prioritize thread quality to ensure that the embroidered designs remain vibrant and intact over time, particularly in markets where clothing durability is a key selling point.

5. Backing Material

Backing material is essential for stabilizing the fabric during the embroidery process. Different types of backing, such as tear-away or cut-away, affect the final look and feel of the embroidered design. Understanding these options allows buyers to make informed decisions based on the intended use of the jacket, ensuring that the final product meets specific functional and aesthetic requirements.

What Are Common Trade Terms in Leather Jacket Custom Embroidery?

Familiarity with industry jargon is vital for effective communication and negotiation. Here are several common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. For leather jackets, this could mean sourcing embroidered patches or other components from specialized manufacturers. B2B buyers should seek OEMs that align with their quality standards and production capabilities.

Illustrative image related to leather jacket custom embroidery

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for budget planning and inventory management. Buyers should negotiate MOQs that suit their operational needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a standard business process in which a buyer requests pricing information from suppliers for specific products or services. For custom leather jackets, submitting an RFQ can help buyers compare costs and understand the offerings of various suppliers, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers know their obligations regarding shipping, insurance, and delivery, minimizing potential disputes and ensuring smooth logistics.

5. Customization Options

Customization options encompass the various ways a product can be tailored to meet specific buyer requirements, such as fabric choice, embroidery design, and fit adjustments. For B2B buyers, a clear understanding of available customization options allows for better alignment with market trends and consumer preferences.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of leather jacket custom embroidery more effectively, ensuring successful partnerships and high-quality products.

Navigating Market Dynamics and Sourcing Trends in the leather jacket custom embroidery Sector

What Are the Current Market Dynamics Influencing the Leather Jacket Custom Embroidery Sector?

The leather jacket custom embroidery sector is experiencing significant growth driven by several global trends. The rise of e-commerce and digital platforms has made it easier for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, to access high-quality custom products. The demand for personalized and unique fashion items is increasing, as consumers seek to express individuality through custom designs. Emerging technologies, such as 3D modeling and virtual fitting solutions, are enhancing the customization experience, allowing buyers to visualize their designs before purchase. This tech-savvy approach is particularly appealing to younger demographics, creating an opportunity for businesses to target niche markets.

Additionally, sustainability is becoming a cornerstone of market dynamics. As consumers grow more environmentally conscious, B2B buyers are increasingly prioritizing suppliers who implement ethical sourcing and production practices. This shift is evident in the demand for high-quality, durable materials that minimize waste and promote longevity, thereby reducing the need for frequent replacements. International trade dynamics are also crucial, with favorable trade agreements and reduced tariffs benefiting buyers from specific regions, making high-quality custom leather more accessible and affordable.

Illustrative image related to leather jacket custom embroidery

How Is Sustainability Shaping the Leather Jacket Custom Embroidery Industry?

Sustainability and ethical sourcing are no longer optional considerations in the leather jacket custom embroidery sector; they are essential for business success. The environmental impact of leather production is significant, prompting companies to adopt more sustainable practices. This includes sourcing leather as a byproduct of the meat industry, thus minimizing waste. Many B2B buyers are now seeking suppliers who offer eco-friendly materials, such as vegetable-tanned leather, which eliminates harmful chemicals from the tanning process.

Furthermore, the importance of ethical supply chains is becoming increasingly recognized among consumers and businesses alike. Buyers are more likely to partner with brands that demonstrate transparency in their sourcing and production processes. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) serve as benchmarks for sustainable practices, making it easier for buyers to identify reputable suppliers. Brands that prioritize ethical production not only contribute to environmental conservation but also enhance their marketability by aligning with the values of socially conscious consumers.

What Is the Historical Context of the Leather Jacket Custom Embroidery Sector?

The evolution of leather jackets dates back to the early 20th century, when they were primarily associated with aviators and military personnel. Over the decades, these jackets transitioned into fashion statements, becoming symbols of rebellion and individuality, especially in youth culture. The introduction of custom embroidery into this sector allowed for further personalization, enabling wearers to showcase their unique styles and affiliations.

Illustrative image related to leather jacket custom embroidery

As the demand for tailored and bespoke products grew, the leather jacket custom embroidery market expanded significantly. Today, technological advancements and changing consumer preferences have revolutionized the way leather jackets are designed and produced, offering B2B buyers a wealth of opportunities to cater to diverse markets. Understanding this historical context can help businesses appreciate the roots of current trends and the ongoing shift towards customization in the fashion industry.

Frequently Asked Questions (FAQs) for B2B Buyers of leather jacket custom embroidery

-

How do I choose the right supplier for custom leather jacket embroidery?

Choosing the right supplier involves assessing their reputation, quality of materials, and manufacturing capabilities. Start by reviewing their portfolio and customer testimonials to understand their craftsmanship. Look for suppliers who specialize in leather jackets and offer customization options like embroidery, as this indicates expertise. Verify their production capacity to ensure they can meet your order volume and timelines. Lastly, consider their communication style and responsiveness, as a reliable supplier should facilitate clear and prompt interactions throughout the ordering process. -

What factors should I consider when setting minimum order quantities (MOQ) for custom leather jackets?

When setting MOQs, consider your target market, production costs, and inventory management. A lower MOQ may be beneficial for testing new designs or entering new markets, allowing you to gauge demand without significant financial risk. Conversely, higher MOQs can lead to cost savings per unit, making it economical if you have established demand. Additionally, factor in lead times and supplier capabilities; ensure they can meet your requirements while maintaining quality. Ultimately, align your MOQ with your business goals and market strategies. -

What payment terms are common in B2B transactions for custom leather jackets?

Common payment terms in B2B transactions include upfront deposits, partial payments during production, and final payments upon delivery. Many suppliers require a deposit (typically 30-50%) to initiate production, securing the order and covering initial costs. It’s advisable to negotiate terms that suit your cash flow while ensuring the supplier’s security. Additionally, consider using secure payment methods, such as letters of credit or escrow services, to protect both parties in international transactions, especially when dealing with new suppliers. -

How can I ensure the quality of custom leather jackets before finalizing my order?

To ensure quality, request samples before placing a bulk order. This allows you to evaluate the leather quality, craftsmanship, and embroidery details firsthand. Additionally, establish clear quality standards and specifications in your contract, including material grades, stitching methods, and finish. Regular communication during the production process, including progress updates and quality checks, can help identify issues early. Finally, consider third-party quality assurance services to inspect products before shipment, especially for large international orders. -

What are the logistics considerations for importing custom leather jackets?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable shipping partner familiar with international trade to handle customs clearance efficiently. Understand the import duties and taxes applicable to your country and factor these costs into your budget. Additionally, coordinate with your supplier to ensure proper documentation, such as invoices and certificates of origin, to avoid delays. Planning for contingencies, such as potential shipping delays or customs inspections, is also crucial for a smooth import process. -

How can I customize the design of my leather jackets effectively?

Effective customization begins with a clear vision of your design goals. Collaborate with your supplier to discuss your ideas, including preferred colors, styles, and embroidery designs. Providing visual references, such as sketches or images, can help convey your requirements accurately. Utilize the supplier’s expertise in materials and techniques to enhance your design, ensuring it aligns with current trends and your brand identity. Regular feedback during the design process is vital to achieve the desired outcome, so maintain open communication with your supplier. -

What are the common challenges faced in international trade for custom leather jackets?

Challenges in international trade for custom leather jackets include fluctuating exchange rates, varying customs regulations, and potential language barriers. Understanding the local laws and trade agreements of both countries can help mitigate legal issues. Additionally, navigating cultural differences in business practices may pose challenges in communication and negotiation. It’s essential to establish clear contracts and terms to avoid misunderstandings. Engaging local experts or logistics partners can also help streamline the process and navigate these complexities effectively. -

How can I build a long-term relationship with my leather jacket supplier?

Building a long-term relationship with your supplier involves consistent communication, trust, and mutual benefit. Start by establishing clear expectations and maintaining open lines of communication throughout the production process. Provide constructive feedback and express appreciation for quality work to foster a collaborative environment. Consider negotiating favorable terms for future orders or providing insights into your market needs, which can help the supplier align their offerings with your business. Regularly reviewing performance and discussing growth opportunities can further solidify your partnership.

Top 4 Leather Jacket Custom Embroidery Manufacturers & Suppliers List

1. The Jacket Maker – Custom Embroidered Jackets

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Custom embroidered jackets including options for embroidered denim jackets, leather jackets, bomber jackets, and coats. Available for customization with logos and artworks. Quantity options range from 1 to 50+. Consultation to start the design process.

2. Lussol Leather – Custom Leather Jackets

Domain: lussoleather.com

Registered: 2016 (9 years)

Introduction: Product: Custom Leather Jackets

Price: Regular price $484.00, Sale price $367.00

Shipping: Free shipping on all jackets, shipped from Niagara Falls, New York

Return Policy: 30 days for returns/alterations, perfect fit guarantee for custom size orders

Sizes Available: XSmall, Small, Medium, Large, Xlarge, XXL, Custom Size, Custom Plus Size

Custom Size Pricing: Custom Size – $367.00, Custom Plus Siz…

3. Leather Skin Shop – Custom Leather Jackets

Domain: leatherskinshop.com

Registered: 2014 (11 years)

Introduction: Custom Leather Jackets – Design Your Own Leather Jacket – Leather Skin Shop. Available for Men and Women in various sizes. Men Sizes: XS (34), S (36), M (38), L (40), XL (42), 2XL (44), 3XL (46), 4XL (48). Women Sizes: XXS (30), XS (32), S (34), M (36), L (38), XL (40), 2XL (42), 3XL (44). To Fit Measurements for Men: Chest (34-50), Waist (30-46), Sleeves (25-27.5). To Fit Measurements for Women: …

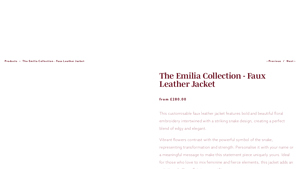

4. Beth Wilson – Emilia Collection Faux Leather Jacket

Domain: bethwilsonembroidery.com

Registered: 2019 (6 years)

Introduction: The Emilia Collection – Faux Leather Jacket from £280.00. Customisable faux leather jacket featuring bold floral embroidery and a snake design. Personalisation options include adding a name or meaningful message. Designed with a regular fit, boxy shape, off-centre zip, epaulettes, and poppered waistband. Over 217,300 stitches used in the design. Available in sizes 6 to 24 and colors including blac…

Strategic Sourcing Conclusion and Outlook for leather jacket custom embroidery

In the rapidly evolving landscape of leather jacket custom embroidery, strategic sourcing emerges as a pivotal factor for B2B buyers looking to enhance their product offerings. By leveraging high-quality materials and ethical manufacturing practices, businesses can not only meet consumer demand for unique and personalized products but also ensure sustainable growth. The ability to customize designs, from embroidery to fabric selection, empowers buyers to differentiate their brands in competitive markets across Africa, South America, the Middle East, and Europe.

As international buyers consider their sourcing strategies, the importance of partnering with reliable manufacturers cannot be overstated. Establishing strong relationships with suppliers who prioritize craftsmanship and customer satisfaction will yield long-term benefits. Additionally, the integration of advanced design technologies can streamline the customization process, allowing for quicker turnarounds and enhanced customer experiences.

Looking ahead, the potential for growth in the custom leather jacket market is vast. Now is the time for B2B buyers to embrace this trend, invest in quality sourcing, and tap into the creative possibilities of custom embroidery. By doing so, businesses can not only meet the demands of a discerning clientele but also position themselves as leaders in a niche market that celebrates individuality and craftsmanship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to leather jacket custom embroidery