Introduction: Navigating the Global Market for patent leather fabric

In the dynamic landscape of global trade, sourcing high-quality patent leather fabric presents a unique challenge for international B2B buyers. The glossy finish and versatile applications of patent leather make it a sought-after material in various industries, from fashion and accessories to upholstery and automotive sectors. However, navigating the complexities of sourcing this specialized fabric—such as understanding material types, assessing supplier capabilities, and managing costs—can be daunting.

This comprehensive guide aims to equip B2B buyers from Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Vietnam, with the essential knowledge needed to make informed purchasing decisions. We will explore the different types of patent leather, including the classic smooth variant and the textured Naplak leather, along with their respective applications in diverse products. Additionally, we will provide insights into effective supplier vetting practices, enabling buyers to identify reliable sources of quality materials.

By addressing key considerations such as pricing, production techniques, and environmental impacts, this guide empowers international buyers to streamline their procurement processes. With the right information at your fingertips, you can confidently navigate the global market for patent leather fabric, ensuring that your sourcing strategy aligns with your business needs and quality expectations.

Table Of Contents

- Top 8 Patent Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for patent leather fabric

- Understanding patent leather fabric Types and Variations

- Key Industrial Applications of patent leather fabric

- 3 Common User Pain Points for ‘patent leather fabric’ & Their Solutions

- Strategic Material Selection Guide for patent leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for patent leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘patent leather fabric’

- Comprehensive Cost and Pricing Analysis for patent leather fabric Sourcing

- Alternatives Analysis: Comparing patent leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for patent leather fabric

- Navigating Market Dynamics and Sourcing Trends in the patent leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of patent leather fabric

- Strategic Sourcing Conclusion and Outlook for patent leather fabric

- Important Disclaimer & Terms of Use

Understanding patent leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Patent Leather | Smooth, shiny, mirror-like finish; uniform color application | Fashion accessories, footwear, upholstery | Pros: Luxurious appearance, easy to clean. Cons: Can be prone to scratches. |

| Naplak Leather | Wrinkled texture; less shiny and more vintage appearance | Handbags, fashion items, decorative uses | Pros: Unique aesthetic, hides imperfections. Cons: Less glossy finish may appeal to fewer markets. |

| Embossed Patent Leather | Textured patterns (e.g., crocodile, alligator) on glossy finish | Luxury goods, high-end fashion, interiors | Pros: Adds depth and character, differentiates products. Cons: May require higher production costs. |

| Metallic Patent Leather | Reflective, metallic finish; vibrant colors | Evening wear, special occasion items | Pros: Eye-catching, trendy. Cons: Limited versatility in everyday applications. |

| Eco-Friendly Patent Leather | Made from sustainable materials; similar glossy finish | Eco-conscious brands, sustainable fashion | Pros: Appeals to eco-friendly markets. Cons: May have a higher price point due to materials. |

What are the Characteristics of Classic Patent Leather?

Classic patent leather is known for its high-gloss finish that resembles a mirror, achieved through multiple layers of lacquer or paint. This type of leather is often used in fashion accessories, footwear, and upholstery due to its luxurious appearance and ease of cleaning. When considering a purchase, B2B buyers should evaluate the durability of the finish, as scratches can detract from its overall look. Classic patent leather is ideal for brands aiming for a sophisticated image.

How Does Naplak Leather Differ from Classic Patent Leather?

Naplak leather features a unique wrinkled texture, providing a vintage aesthetic that is less shiny than traditional patent leather. It is commonly used in handbags and fashion items where a more casual, artistic look is desired. Buyers should consider the target market’s preferences, as the less polished appearance may not appeal to all consumers. Additionally, Naplak leather can effectively disguise imperfections, making it a practical choice for manufacturers focused on cost-effectiveness.

What are the Benefits of Embossed Patent Leather?

Embossed patent leather is characterized by its textured patterns, such as crocodile or alligator prints, combined with a glossy finish. This type is often utilized in luxury goods and high-end fashion, providing a distinctive look that can help brands stand out. When purchasing, businesses should assess the cost implications of embossing, as it may increase production expenses. However, the unique designs can justify the investment by enhancing product desirability.

When Should You Use Metallic Patent Leather?

Metallic patent leather offers a striking reflective finish and is available in various vibrant colors. It is primarily used for evening wear and special occasion items, catering to consumers looking for standout fashion pieces. B2B buyers should consider the seasonal trends and market demand for metallic items, as they may not be suitable for everyday applications. While this type can create a bold statement, it may limit its use to specific product lines.

What Makes Eco-Friendly Patent Leather a Smart Choice?

Eco-friendly patent leather is produced from sustainable materials while maintaining a glossy finish similar to traditional patent leather. It appeals to eco-conscious brands and consumers increasingly prioritizing sustainability. Buyers should weigh the potential for higher costs against the growing market demand for environmentally responsible products. Investing in eco-friendly options can enhance brand reputation and attract a loyal customer base committed to sustainable practices.

Key Industrial Applications of patent leather fabric

| Industry/Sector | Specific Application of patent leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Footwear manufacturing | Enhances aesthetic appeal and durability | Look for suppliers with a variety of colors and textures; ensure compliance with fashion trends. |

| Automotive | Interior upholstery | Provides a luxurious finish while being easy to clean | Prioritize suppliers who can provide large quantities and custom finishes; consider durability under various conditions. |

| Furniture and Home Décor | Upholstery for high-end furniture | Offers a chic, modern look and easy maintenance | Assess the environmental impact of sourcing; inquire about fire resistance and durability. |

| Accessories | Handbags and wallets | Elevates product appeal and brand perception | Ensure the supplier can provide consistent quality; check for colorfastness and scratch resistance. |

| Sporting Goods | Equipment and apparel | Combines style with functionality | Source from manufacturers who specialize in performance materials; consider weather resistance and ease of cleaning. |

How is Patent Leather Fabric Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, patent leather is predominantly utilized in footwear manufacturing. Its glossy finish not only enhances the aesthetic appeal of shoes but also contributes to their durability. For international buyers, especially from regions like Africa and South America, sourcing patent leather that aligns with local fashion trends is crucial. Buyers should prioritize suppliers that offer a diverse palette of colors and textures, ensuring the material meets both style and quality requirements.

What Role Does Patent Leather Play in Automotive Upholstery?

In the automotive industry, patent leather is favored for interior upholstery, providing a luxurious finish that is also easy to maintain. Its glossy surface helps in creating an upscale ambiance within vehicles, appealing to consumers in markets like the Middle East and Europe. Buyers should focus on suppliers capable of delivering large volumes and custom finishes, while also considering the material’s durability under varying climatic conditions to ensure long-term performance.

How is Patent Leather Fabric Applied in Furniture and Home Décor?

Patent leather is increasingly used in high-end furniture upholstery, offering a modern and chic aesthetic that is both visually appealing and easy to clean. For B2B buyers in Europe and the Middle East, assessing the environmental impact of sourcing is essential. It’s advisable to inquire about fire resistance and the durability of the material to ensure it meets safety standards while enhancing the overall design of furniture pieces.

What Are the Benefits of Using Patent Leather in Accessories?

In the accessories market, patent leather is commonly used for handbags and wallets, significantly elevating the product’s appeal and brand perception. Buyers should ensure their suppliers can consistently deliver high-quality materials, focusing on attributes like colorfastness and scratch resistance to maintain the product’s luxurious appearance. For international buyers, especially from regions with diverse fashion markets, aligning product offerings with local consumer preferences is key.

Illustrative image related to patent leather fabric

How Does Patent Leather Enhance Sporting Goods?

In the sporting goods industry, patent leather is utilized in both equipment and apparel, combining style with functionality. Its sleek appearance can attract consumers looking for fashionable yet practical items. Buyers should seek manufacturers specializing in performance materials that can withstand various weather conditions, ensuring that the patent leather used is not only visually appealing but also durable and easy to maintain.

3 Common User Pain Points for ‘patent leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality Patent Leather Without Compromising on Standards

The Problem: B2B buyers often struggle to find reliable suppliers who can provide high-quality patent leather that meets specific industry standards. The glossy finish and durability of patent leather are crucial for applications in fashion, upholstery, and accessories, but many suppliers may offer inferior products that do not withstand wear and tear. This can lead to a loss of customer trust and increased returns, negatively impacting the bottom line.

The Solution: To overcome this challenge, buyers should conduct thorough research to identify reputable suppliers that specialize in patent leather. Look for tanneries with certifications that demonstrate adherence to quality standards, such as ISO 9001 or environmental compliance certifications. Request samples to assess the leather’s quality, including its thickness, finish, and flexibility. Building a relationship with a supplier who understands your specific needs can also lead to better customization options and bulk pricing, ensuring that you receive consistent quality that aligns with your brand’s reputation.

Scenario 2: Managing Environmental Concerns in Patent Leather Production

The Problem: Environmental sustainability is becoming increasingly important for consumers and businesses alike. B2B buyers often face the dilemma of sourcing patent leather while ensuring that the production processes do not harm the environment. This concern is particularly significant in regions like Europe and South America, where regulations around sustainable practices are stringent. Buyers may find it challenging to balance quality with eco-friendliness, risking potential backlash from environmentally conscious clients.

The Solution: To address this pain point, buyers should prioritize suppliers who employ eco-friendly tanning methods and use sustainable raw materials. Look for patent leather made with water-based finishes and low-impact dyes, as these options minimize environmental damage. Additionally, inquire about the supplier’s waste management practices and their commitment to reducing carbon footprints. By partnering with environmentally responsible suppliers, buyers can confidently market their products as sustainable, appealing to a growing demographic of eco-conscious consumers.

Scenario 3: Preventing Damage During Storage and Transportation

The Problem: Patent leather is prone to damage if not stored and transported correctly. B2B buyers often encounter issues such as sticking, scratching, or scuffing, which can occur during shipping or when the material is stored improperly. Such damage not only affects the aesthetic appeal of the leather but can also lead to costly returns and dissatisfied customers.

The Solution: To mitigate these risks, buyers must establish proper handling and storage protocols for patent leather. Ensure that leather hides are stored in a climate-controlled environment to prevent humidity and temperature fluctuations that can cause deterioration. During transportation, use protective coverings that prevent contact between hides, such as placing them grain side to grain side. Additionally, educate your logistics team on the sensitivity of patent leather to ensure they handle it with care throughout the supply chain. Implementing these best practices will help maintain the integrity of the leather, ultimately preserving its quality for end-use.

Strategic Material Selection Guide for patent leather fabric

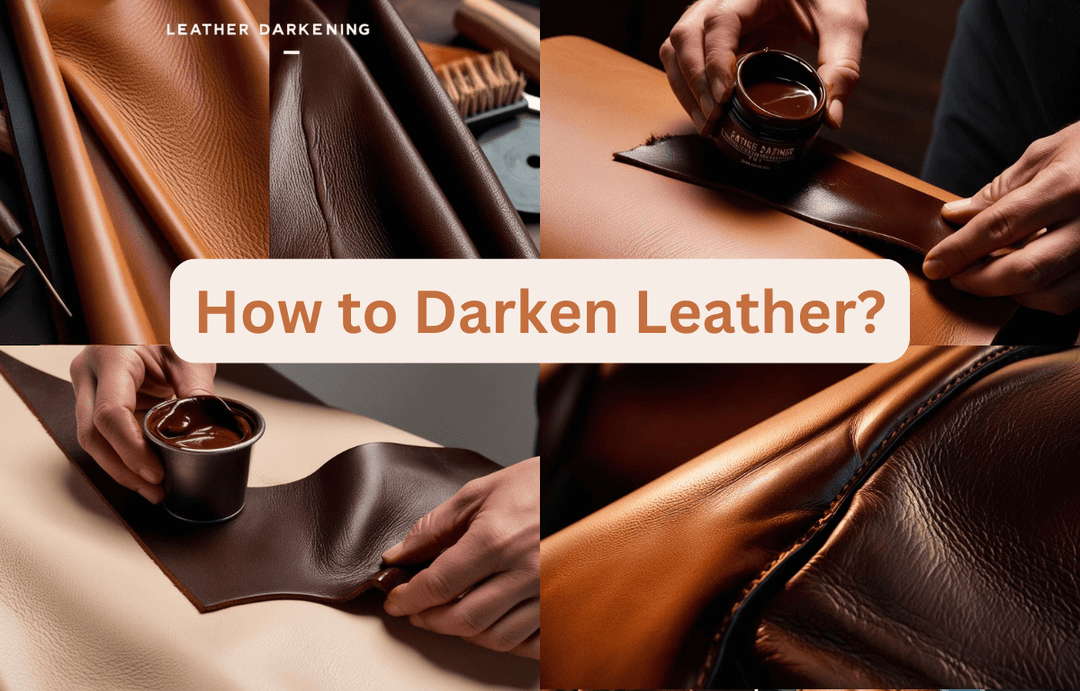

What Are the Key Materials Used in Patent Leather Fabric?

Patent leather is a unique material known for its glossy finish and durability, making it a popular choice in various industries, including fashion, automotive, and furniture. The selection of the right base material significantly influences the performance and characteristics of the final product. Below are analyses of four common materials used in the production of patent leather fabric, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to patent leather fabric

1. Bovine Leather

Key Properties: Bovine leather is robust, with a thickness typically ranging from 0.8 to 1.6 mm, making it suitable for various applications. It offers excellent tensile strength and durability.

Pros & Cons: The primary advantage of bovine leather is its durability and resistance to wear and tear. However, it can be more expensive than other options, and the manufacturing process is complex due to the need for specialized tanning and finishing to achieve the glossy effect.

Impact on Application: Bovine leather is highly compatible with high-pressure applications, such as automotive interiors. Its robust nature allows it to withstand significant wear, making it ideal for products requiring longevity.

Considerations for International Buyers: Buyers from regions like the Middle East and Europe should ensure compliance with local standards such as ASTM and DIN, particularly concerning environmental regulations in leather processing.

2. Goat Leather

Key Properties: Goat leather is lighter and softer than bovine leather, typically available in similar thickness ranges. It has a natural grain that can enhance the aesthetic appeal of patent leather.

Pros & Cons: The softness of goat leather provides excellent comfort and flexibility, making it suitable for fashion items. However, it may not be as durable as bovine leather and is more susceptible to scratches and damage.

Impact on Application: Goat leather is often used in fashion accessories and garments where a combination of style and comfort is essential. Its lighter weight makes it an attractive option for products requiring flexibility.

Illustrative image related to patent leather fabric

Considerations for International Buyers: Buyers should consider the sourcing and treatment processes, as goat leather may be subject to different regulations in various countries. Ensuring compliance with local standards is crucial.

3. Sheep Leather

Key Properties: Sheep leather is known for its softness and is often used in high-end fashion items. It typically has a thickness of 0.6 to 1.2 mm, making it lightweight and easy to work with.

Pros & Cons: The main advantage of sheep leather is its luxurious feel and aesthetic appeal. However, it is less durable than both bovine and goat leather, making it less suitable for heavy-duty applications.

Impact on Application: Sheep leather is ideal for luxury goods, such as handbags and shoes, where appearance and comfort are prioritized over durability.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for sheep leather across regions. Compliance with international quality standards is essential for maintaining product integrity.

4. Synthetic Leather (PU or PVC)

Key Properties: Synthetic leather, made from materials like polyurethane (PU) or polyvinyl chloride (PVC), offers a consistent finish and is often designed to mimic the look and feel of real leather.

Pros & Cons: The primary advantage of synthetic leather is its cost-effectiveness and ease of maintenance. However, it may lack the durability and breathability of natural leathers, and its environmental impact can be a concern.

Impact on Application: Synthetic leather is commonly used in budget-friendly fashion items, upholstery, and automotive interiors. Its versatility makes it suitable for a range of applications.

Considerations for International Buyers: Buyers should consider the environmental regulations associated with synthetic materials in their regions. Compliance with standards like REACH in Europe is crucial for market acceptance.

Summary Table

| Material | Typical Use Case for patent leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Bovine Leather | Automotive interiors, high-wear products | High durability and tensile strength | Higher cost and complex manufacturing | High |

| Goat Leather | Fashion accessories and garments | Softness and flexibility | Less durable, more prone to damage | Medium |

| Sheep Leather | Luxury handbags and shoes | Luxurious feel and aesthetic appeal | Less durable than other leathers | Medium |

| Synthetic Leather (PU/PVC) | Budget-friendly fashion items, upholstery | Cost-effective and easy to maintain | Lacks durability and environmental concerns | Low |

This comprehensive analysis provides B2B buyers with essential insights into the strategic selection of materials for patent leather fabric, enabling informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for patent leather fabric

What Are the Key Stages in the Manufacturing Process of Patent Leather Fabric?

The manufacturing process of patent leather fabric is intricate and requires precision at every stage to ensure a high-quality end product. Below are the main stages involved:

Material Preparation: How Are Hides Selected and Treated?

The journey of patent leather begins with the selection of hides, typically from bovine, sheep, or goatskin. Quality control starts at this stage, as hides must be free from macroscopic defects such as marks, holes, or deep wounds. Once selected, the hides undergo a rigorous tanning process designed to create a firm texture that prevents issues like grain loss and wrinkles. This is achieved through the use of specific recipes involving synthetic resins, which enhance the rigidity of the leather.

Illustrative image related to patent leather fabric

After tanning, the hides are sanded on the grain side to create a uniform substrate, which is essential for the subsequent impregnation phase. This phase involves saturating the leather with pigments to ensure an even color and surface quality.

Forming: What Techniques Are Used to Create the Glossy Finish?

Once the hides are prepared, the next step is the application of the varnish or lacquer that gives patent leather its characteristic glossy finish. This is typically done through a multi-layering technique where several coatings of varnish are applied. The choice of varnish, which may be based on nitrocellulose, polyurethane, or linseed oil, significantly impacts the final appearance and durability of the leather.

The application process must be conducted in a controlled environment to prevent dust and other contaminants from ruining the finish. This requires specialized machinery and a cleanroom-like atmosphere to ensure a flawless surface.

Finishing: How Is Quality Enhanced Before Packaging?

After the final coat of varnish is applied, the leather undergoes a drying and curing process. This step is crucial, as it allows the layers to bond effectively, contributing to the leather’s durability and gloss. Once dried, the leather is inspected for any surface imperfections, and corrections are made as necessary. This may involve additional sanding or polishing to achieve the desired level of shine.

The finishing stage also includes the application of protective treatments to enhance water and stain resistance, further solidifying the leather’s appeal for various applications, including fashion, upholstery, and accessories.

Illustrative image related to patent leather fabric

What Quality Assurance Measures Are Essential for Patent Leather Fabric?

Quality assurance (QA) is paramount in the patent leather manufacturing process, ensuring that the final product meets international standards and client expectations.

Which International Standards Apply to Patent Leather Production?

For B2B buyers, understanding the relevant international standards is critical. Compliance with ISO 9001 is often seen as a benchmark for quality management systems. This standard focuses on meeting customer and regulatory requirements while enhancing customer satisfaction through effective system implementation.

In addition to ISO standards, buyers should be aware of industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe, which ensures safety and environmental protection, and API (American Petroleum Institute) standards for materials used in specific applications.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control is divided into several checkpoints throughout the manufacturing process, including:

Illustrative image related to patent leather fabric

-

Incoming Quality Control (IQC): This step involves inspecting the raw hides for defects before they enter production. Ensuring high-quality raw materials is crucial for producing premium patent leather.

-

In-Process Quality Control (IPQC): During the production stages, ongoing inspections are performed to monitor the application of coatings and adherence to processing protocols. This helps identify issues early in the production cycle.

-

Final Quality Control (FQC): After the finishing stage, a thorough inspection of the finished product is conducted. This includes checking for surface imperfections, color consistency, and overall aesthetic appeal.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure that they receive products that meet their standards. Here are several methods to achieve this:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing process, equipment, and overall working conditions. This firsthand observation can provide insights into the supplier’s commitment to quality.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand their QC processes, including the frequency and results of inspections at various stages.

-

Third-Party Inspections: Engaging independent third-party inspection services can add an extra layer of assurance. These organizations can perform unbiased evaluations of the products before they are shipped.

What QC Considerations Should International Buyers Keep in Mind?

When dealing with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, several nuances should be taken into account:

-

Cultural Differences: Understanding the business culture of the supplier’s country can enhance communication and negotiation. What is considered standard practice in one region may be perceived differently in another.

-

Regulatory Compliance: Each region may have different regulations regarding leather production, including environmental standards and labor laws. Buyers must ensure that their suppliers comply with these regulations to avoid legal issues.

-

Sustainability Practices: Increasingly, buyers are looking for suppliers who prioritize sustainability in their manufacturing processes. This includes responsible sourcing of hides and eco-friendly production methods.

By understanding the complexities of patent leather manufacturing and quality assurance, B2B buyers can make informed decisions that align with their quality standards and business objectives.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘patent leather fabric’

This guide serves as a comprehensive checklist for B2B buyers looking to source patent leather fabric. It outlines the key steps to ensure you procure high-quality materials that meet your business needs and standards.

Step 1: Define Your Technical Specifications

Clearly outline the specifications you require for patent leather. This includes the type of leather (e.g., calfskin, goatskin), thickness (typically between 0.8mm and 1.6mm), and desired finish (glossy, wrinkled, or embossed). Defining these parameters upfront will help you communicate effectively with suppliers and ensure you receive materials that meet your quality standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of patent leather. Look for reputable tanneries that specialize in this type of leather, as it requires specific machinery and processes. Utilize platforms like trade shows, online directories, and industry associations to gather a list of candidates.

Illustrative image related to patent leather fabric

- Tip: Focus on suppliers with a strong online presence and positive reviews from other B2B buyers.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers have the necessary certifications to ensure compliance with industry standards. Certifications such as ISO 9001 for quality management or environmental certifications can indicate a supplier’s commitment to maintaining high production standards and sustainability practices.

- Key Focus: Ask suppliers for documentation that proves their adherence to these standards.

Step 4: Request Samples for Quality Assessment

Before making a bulk order, request samples of the patent leather you intend to purchase. This allows you to assess the texture, finish, and overall quality of the leather. Ensure that the samples reflect the specifications you defined in Step 1.

- Important: Check for any defects, consistency in color, and the durability of the finish during your evaluation.

Step 5: Inquire About Production Capacity and Lead Times

Discuss the supplier’s production capacity to ensure they can meet your order volume and deadlines. Understand their lead times, as delays can impact your supply chain and project timelines.

- Action Item: Ask for a production schedule and any potential factors that could affect delivery.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, negotiate the terms of your contract. This includes pricing, payment terms, minimum order quantities, and return policies. A clear agreement helps prevent misunderstandings and ensures both parties are aligned.

- Best Practice: Be transparent about your budget and seek flexibility in payment options to strengthen the partnership.

Step 7: Establish a Quality Control Process

Implement a quality control process for receiving your patent leather orders. This may involve inspecting the leather upon delivery for defects and ensuring it meets your initial specifications.

- Recommendation: Consider setting up a third-party inspection service if your orders are large or if you are working with a new supplier.

By following these steps, B2B buyers can effectively source high-quality patent leather fabric that meets their specific needs, ensuring a smooth procurement process and a reliable supply chain.

Comprehensive Cost and Pricing Analysis for patent leather fabric Sourcing

What Are the Key Cost Components for Sourcing Patent Leather Fabric?

When sourcing patent leather fabric, understanding the cost structure is essential for B2B buyers. The main cost components include:

-

Materials: The quality of raw hides significantly influences the cost. Patent leather is typically made from bovine, sheep, or goat hides, which can vary in price based on grade and availability. Higher-quality hides result in better finishes but at a higher price point.

-

Labor: Skilled labor is required for the tanning and finishing processes, which involve multiple steps to achieve the glossy finish characteristic of patent leather. Labor costs can differ based on the location of the manufacturing facility and the expertise of the workforce.

-

Manufacturing Overhead: This includes costs related to maintaining the production facility, utilities, and equipment depreciation. Specialized machinery for finishing patent leather contributes to higher overhead costs.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. Buyers should consider whether the tooling costs are amortized over large production runs to lower per-unit costs.

-

Quality Control (QC): Rigorous QC processes are essential to ensure that the final product meets the required standards. This may involve additional labor and material costs, especially if defects are detected.

-

Logistics: Shipping costs can be substantial, particularly for international orders. Factors such as distance, shipping method, and packaging all contribute to logistics costs.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary widely based on the supplier’s positioning in the market and the level of service they provide.

How Do Price Influencers Affect the Cost of Patent Leather?

Several factors influence the pricing of patent leather, which can impact total costs for buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders can often secure lower per-unit prices. Suppliers may impose MOQs, so understanding these requirements is crucial for budgeting.

-

Specifications and Customization: Custom colors, finishes, and patterns can increase costs. Buyers should clearly define specifications upfront to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., eco-friendly processes) can lead to higher prices. Buyers should assess the value of these certifications against their needs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers may offer competitive pricing to attract clients.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect total landed costs. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to avoid unexpected expenses.

What Are Effective Buyer Tips for Negotiating Patent Leather Prices?

Navigating the complexities of patent leather sourcing requires strategic negotiation and cost management:

-

Negotiate Effectively: Engage suppliers in discussions about pricing structures. Understanding their cost components can provide leverage in negotiations.

-

Focus on Cost-Efficiency: Assess not just the price per unit but also the Total Cost of Ownership (TCO). This includes considering durability, maintenance, and potential waste during production.

-

Consider Pricing Nuances for International Sourcing: Buyers from regions like Africa, South America, the Middle East, and Europe should account for currency fluctuations, import tariffs, and varying shipping costs, which can significantly impact overall expenses.

-

Build Relationships with Suppliers: Establishing long-term partnerships can lead to better pricing and terms. Suppliers may offer discounts for repeat business or loyalty.

-

Request Samples: Before finalizing orders, request samples to evaluate quality. This can prevent costly mistakes related to unsatisfactory materials or finishes.

Disclaimer

The prices mentioned in this analysis are indicative and subject to fluctuations based on market conditions, supplier pricing strategies, and other economic factors. Always confirm current prices with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing patent leather fabric With Other Solutions

Exploring Alternatives to Patent Leather Fabric for B2B Buyers

In the realm of leather and synthetic materials, patent leather fabric stands out due to its glossy, high-shine finish. However, various alternatives offer distinct benefits that might better suit specific applications and market needs. This analysis compares patent leather fabric with two prominent alternatives: synthetic leather and traditional leather. Understanding these options can help B2B buyers make informed decisions based on performance, cost, and application.

| Comparison Aspect | Patent Leather Fabric | Synthetic Leather | Traditional Leather |

|---|---|---|---|

| Performance | Highly durable, water-resistant, and easy to clean. | Good durability and water resistance; however, quality varies widely. | Excellent durability and breathability; requires more care. |

| Cost | Generally higher due to the manufacturing process. | Typically lower cost, especially for lower-quality options. | Can be expensive depending on the type and tanning process. |

| Ease of Implementation | Requires specialized handling and storage. | Easy to cut and sew; compatible with most manufacturing processes. | Requires skilled labor for cutting and sewing; potential for longer lead times. |

| Maintenance | Low maintenance; easy to wipe clean. | Varies by quality; some may not withstand heavy use. | Requires regular conditioning and care to maintain appearance. |

| Best Use Case | Fashion items, accessories, and high-end products. | Budget-friendly fashion items, upholstery, and bags. | Luxury goods, traditional footwear, and durable outdoor gear. |

Detailed Breakdown of Alternatives

Synthetic Leather

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to patent leather. Its affordability makes it appealing for mass production, particularly in fashion items and upholstery. While it can mimic the appearance of leather, quality can vary significantly, with some synthetic leathers not holding up under rigorous use. Additionally, it is generally easier to work with during manufacturing, as it can be cut and sewn without the need for specialized tools. However, synthetic leather may lack the breathability and luxurious feel of genuine leather, which could deter some consumers.

Traditional Leather

Traditional leather, derived from animal hides, is renowned for its durability, breathability, and aesthetic appeal. It can offer a premium feel that synthetic alternatives cannot replicate. Traditional leather products, however, require more maintenance to keep them looking their best and can be more expensive, especially if sourced from high-quality tanneries. The lead time for production may also be longer due to the extensive tanning process involved. This alternative is ideal for luxury goods, footwear, and items requiring longevity and a classic appearance. However, the ethical considerations of sourcing animal hides may present challenges in certain markets.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between patent leather fabric and its alternatives, B2B buyers should consider their specific application, budget constraints, and the desired aesthetic of their products. Patent leather excels in high-end fashion and accessories due to its distinctive shine and ease of maintenance. In contrast, synthetic leather offers an economical solution for larger production runs, while traditional leather remains the choice for premium products requiring a classic touch. Evaluating these factors against market demand and production capabilities will guide buyers to the most suitable material for their business needs.

Illustrative image related to patent leather fabric

Essential Technical Properties and Trade Terminology for patent leather fabric

What are the Key Technical Properties of Patent Leather Fabric?

When sourcing patent leather fabric for commercial purposes, understanding its technical properties is essential. Here are some critical specifications to consider:

-

Material Composition

Patent leather is typically made from various hides, including bovine, sheep, or goat. The outer layer is treated with paints or lacquers, often containing linseed oil, nitrocellulose, or synthetic resins. The material composition affects the leather’s durability, glossiness, and overall quality, making it crucial for buyers to specify the type of hide and finishing they require. -

Thickness

The ideal thickness for patent leather usually ranges between 0.8 mm to 1.6 mm. This specification is vital as it influences the leather’s rigidity and suitability for various applications, from fashion accessories to upholstery. A thickness outside this range may lead to quality issues, such as wrinkling or loss of gloss. -

Finish Quality

The finish quality of patent leather is characterized by its high gloss and smooth surface. A high-quality finish indicates that the leather has undergone rigorous processing to achieve a uniform appearance, free from defects. This is particularly important for luxury products where aesthetic appeal is paramount. -

Environmental Resistance

Patent leather is generally resistant to water and stains, making it suitable for products that may face exposure to moisture or dirt. However, buyers should ensure that the specific treatment used in the finishing process meets their requirements for environmental resistance, especially in varying climates. -

Grain Texture

The grain texture can vary significantly between different types of patent leather, such as smooth patent and Naplak leather, which has a wrinkled appearance. Understanding the grain texture helps buyers select the right type of leather for their specific design needs, whether for fashion or functional purposes.

What are Common Trade Terms in the Patent Leather Industry?

Familiarity with industry-specific terminology is essential for effective communication and negotiation. Here are some common trade terms associated with patent leather:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products based on specifications provided by another company. In the patent leather industry, OEMs can produce custom leather goods tailored to the buyer’s design and quality requirements. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. This term is crucial for B2B buyers, as it affects inventory management and pricing. Understanding the MOQ helps businesses plan their purchasing strategies and budget accordingly. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. When dealing with patent leather, buyers should provide detailed specifications to ensure accurate quotes, including material types, thicknesses, and finishes. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping and freight. Understanding Incoterms is vital for B2B buyers engaging in international trade, as they clarify who bears the costs and risks during transportation. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. This term is critical for businesses that rely on timely deliveries for production schedules. Buyers should inquire about lead times when negotiating contracts to ensure they meet their operational timelines. -

Bespoke

In the context of patent leather, bespoke refers to custom-made products tailored to specific client requirements. This term emphasizes the uniqueness and exclusivity of the leather goods, appealing to high-end markets looking for personalized solutions.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing patent leather fabric, ensuring they meet their production needs while navigating the complexities of global trade.

Navigating Market Dynamics and Sourcing Trends in the patent leather fabric Sector

What Are the Current Market Dynamics and Key Trends in the Patent Leather Fabric Sector?

The patent leather fabric market is experiencing significant growth, driven by rising demand in various sectors such as fashion, automotive, and upholstery. The glossy finish of patent leather offers aesthetic appeal and durability, making it a preferred choice for luxury products. Global economic recovery post-pandemic has led to increased consumer spending, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Countries like Saudi Arabia and Vietnam are seeing a surge in the demand for stylish and premium leather goods, bolstering the market for patent leather.

In terms of sourcing trends, technology is playing a vital role. Digital platforms are streamlining the procurement process, allowing B2B buyers to access a wider range of suppliers and materials with greater transparency. Innovations in manufacturing processes, such as the use of eco-friendly resins and efficient tanning methods, are also gaining traction. Buyers are increasingly looking for suppliers that can provide customized solutions, with a focus on quality and speed to market. Additionally, the rise of e-commerce in the leather industry is transforming how businesses interact and transact, making it essential for buyers to adapt to these changes.

How Is Sustainability and Ethical Sourcing Impacting the Patent Leather Fabric Industry?

Sustainability is becoming a cornerstone of the patent leather fabric sector. As environmental awareness grows, businesses are under pressure to adopt ethical sourcing practices and minimize their ecological footprint. The production of patent leather typically involves chemicals that can be harmful to the environment. However, advancements in sustainable practices are emerging, such as the use of vegetable-tanned leathers and water-based coatings that reduce toxicity.

B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability. Certifications like Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are becoming essential credentials that buyers look for when sourcing patent leather. These certifications ensure that the leather is produced in an environmentally friendly manner and that labor practices are ethical. By choosing suppliers with these certifications, businesses not only enhance their brand image but also contribute to a more sustainable leather industry.

What Is the Historical Context of Patent Leather Fabric in B2B Markets?

Patent leather has its roots in the 18th century, originally developed as a cost-effective alternative to traditional leather. The glossy finish was achieved through a process of layering varnishes and lacquers, which made the leather more appealing and durable. As fashion evolved, patent leather gained popularity in the 20th century, particularly in luxury footwear and accessories. Today, it remains a staple in high-end fashion and design, adapting to contemporary trends while maintaining its classic allure.

Illustrative image related to patent leather fabric

This historical evolution highlights the material’s versatility and enduring appeal, making it a valuable asset for B2B buyers seeking to offer stylish and durable products. Understanding this context can help businesses appreciate the craftsmanship behind patent leather and the importance of quality sourcing in maintaining its legacy.

Frequently Asked Questions (FAQs) for B2B Buyers of patent leather fabric

-

How do I choose the right supplier for patent leather fabric?

Choosing the right supplier for patent leather fabric involves several key factors. Start by researching suppliers with a proven track record in producing high-quality patent leather. Verify their certifications and compliance with international standards, especially regarding environmental and labor practices. Request samples to assess the quality and finish of the leather. Additionally, consider their production capacity to meet your order volume and their ability to provide customization options. Engaging in direct communication can also help gauge their responsiveness and reliability. -

What are the minimum order quantities (MOQ) for patent leather fabric?

Minimum order quantities for patent leather fabric can vary significantly among suppliers. Typically, MOQs can range from 50 to 200 square meters, depending on the supplier’s production capabilities and the type of leather requested. For customized colors or finishes, MOQs may be higher due to the extra resources required for production. It’s advisable to confirm the MOQ with your potential supplier before placing an order to ensure it aligns with your business needs and budget. -

What payment terms should I expect when sourcing patent leather fabric?

Payment terms for patent leather fabric can differ widely based on the supplier and the nature of the transaction. Common arrangements include a deposit of 30-50% upfront, with the balance due upon delivery or before shipment. Some suppliers may offer letters of credit or payment through escrow services to provide additional security. It’s crucial to negotiate terms that suit both parties, ensuring transparency and reducing the risk of disputes. -

How can I ensure the quality of patent leather fabric?

To ensure the quality of patent leather fabric, request detailed product specifications and samples from suppliers. Conduct a thorough inspection of the samples, focusing on factors like finish, color uniformity, and texture. You may also consider third-party quality assurance services to inspect bulk orders before shipment. Establishing clear quality standards in your purchase agreement can help safeguard against receiving subpar materials. -

What customization options are available for patent leather fabric?

Many suppliers offer customization options for patent leather fabric, including variations in color, texture, and finish. You can request specific patterns, embossing, or even custom thicknesses to meet your design requirements. When discussing customization, be clear about your needs and ask for samples of similar custom work previously done by the supplier to ensure they can meet your expectations. -

What logistics considerations should I be aware of when importing patent leather?

When importing patent leather, consider logistics factors such as shipping methods, lead times, and customs regulations in your country. It’s essential to work with freight forwarders experienced in handling leather products to navigate the complexities of international shipping. Additionally, check the import duties and taxes applicable to patent leather in your destination country to factor these costs into your budget. -

How can I verify the environmental practices of my patent leather supplier?

Verifying the environmental practices of a patent leather supplier involves requesting documentation related to their production processes and sustainability certifications. Look for certifications like ISO 14001, which indicates compliance with environmental management standards. Additionally, inquire about their waste management practices, use of eco-friendly materials, and adherence to regulations regarding chemical usage in leather production. -

What are common uses for patent leather fabric in B2B applications?

Patent leather fabric is widely used in various B2B applications, including fashion accessories, footwear, upholstery, and automotive interiors. Its glossy finish and durability make it a popular choice for high-end products, such as handbags and luxury shoes. Understanding the specific applications within your industry can help you make informed sourcing decisions and align your product offerings with market trends.

Top 8 Patent Leather Fabric Manufacturers & Suppliers List

1. Fashion Fabric LA – Patent Faux Leather Apparel

Domain: fashionfabricla.com

Registered: 2014 (11 years)

Introduction: Patent Faux Leather Apparel Costume Dance Vinyl Fabric – By The Yard

2. Buy Leather Online – Premium Leather Goods

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Introduction: {“price_range”:”$0.00 – $290.00″,”colors”:[{“name”:”White”,”count”:3},{“name”:”Ivory – Off-White”,”count”:5},{“name”:”Beige – Natural”,”count”:4},{“name”:”Sand Beige”,”count”:1},{“name”:”Pinky Beige – Powder”,”count”:4},{“name”:”Greenish Beige – Kaki”,”count”:2},{“name”:”Lime”,”count”:1},{“name”:”Fluo Yellow”,”count”:1},{“name”:”Mustard”,”count”:2},{“name”:”Light Orange – Salmon”,”count”:1},{“name…

3. RYC Fabrics – Patent Leather Vinyl

Domain: rycfabrics.com

Registered: 2010 (15 years)

Introduction: Patent leather vinyl is a high-gloss, durable material that is often used in fashion and upholstery. It is known for its shiny finish and is available in various colors and patterns. This material is easy to clean and maintain, making it a popular choice for items that require a stylish yet practical surface. It is suitable for applications such as handbags, shoes, and furniture.

4. Online Fabric Store – Vinyl and Leather Fabrics

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: Vinyl and leather fabrics available in various colors and patterns. Ideal for upholstery, crafts, and fashion projects. Durable and easy to clean. Suitable for indoor and outdoor use.

5. Import – Patent Leather Vinyl Yellow Fabric

Domain: fabricmill.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “Patent Leather Vinyl Yellow Fabric”, “SKU”: “434087”, “Manufacturer”: “Import”, “Price”: “$19.99”, “Description”: “This patent leather yellow vinyl is great for upholstery, table coverings, headboards, and cornices. Mesh backing for stability. Use your imagination, this unique fabric has fun possibilities!”, “Fiber Content”: “100% VINYL”, “Width”: “54”, “Type of Fabric”: “Vinyl”,…

6. Interior Decorating – Patent Leather Vinyl Upholstery Fabric

Domain: interiordecorating.com

Registered: 1998 (27 years)

Introduction: Patent Leather Vinyl upholstery fabric available online by the yard. Made of vinyl, featuring a shiny look in various colors for upholstery and home decor. Price per yard: Cheetah colors ($12.50), Wet Look colors ($14.50), Patent colors ($20.50), and specialty colors like Pax White ($62.16) and Sway White ($62.72). Samples available.

7. Fabricsight – Patent Faux Leather

Domain: fabricsight.com

Registered: 2019 (6 years)

Introduction: {“product_name”: “Patent Faux Leather”,”colors_available”: 11,”sku”: “MC_CHAROL_RED_4001″,”original_price”: “€10,45″,”current_price”: “€10,45″,”weight”: “150 g/m²”,”width”: “1.55 m”,”minimum_order_quantity”: “12 Meters”,”composition”: “85% Polyurethane, 15% Polyester”,”description”: “Shiny patent leather, perfect for outerwear garments. Design jackets, bottoms and accessories.”,”swatch_price”: “€1…

8. Lagarza – Reptile Embossed Leather Hides

Domain: lagarzarara.com

Registered: 2005 (20 years)

Introduction: [{‘name’: ‘Reptile Embossed Leather Hides’, ‘description’: ‘Greyish green CROCODILE leather hide, glossy printed PEARLIZED cowhide, soft embossed…’, ‘reference’: ‘B18051-ST’, ‘price’: ‘€39.00’, ‘availability’: ‘Last items in stock – Still available 1 piece’}, {‘name’: ‘Distressed and Vintage Leather’, ‘description’: ‘Green yellow glossy leather skin, WRINKLED soft glossy goatskin, SHADED hide fo…

Strategic Sourcing Conclusion and Outlook for patent leather fabric

As the demand for patent leather fabric continues to rise across various sectors—including fashion, automotive, and luxury goods—strategic sourcing becomes paramount for international buyers. Key takeaways emphasize the importance of partnering with reputable suppliers who understand the complexities of patent leather production. This material, known for its glossy finish and durability, requires specialized knowledge in sourcing, quality control, and sustainable practices to meet diverse market needs.

In regions like Africa, South America, the Middle East, and Europe, navigating the supply chain effectively can yield significant competitive advantages. Establishing long-term relationships with manufacturers not only ensures consistent quality but also fosters innovation in product offerings. Additionally, buyers should consider leveraging technology for streamlined procurement processes, enhancing transparency, and reducing lead times.

Looking ahead, the patent leather market is poised for growth as trends in sustainable fashion and customization gain momentum. International B2B buyers are encouraged to engage proactively with suppliers and explore innovative applications for patent leather in their product lines. By doing so, businesses can position themselves at the forefront of this dynamic market, driving profitability and customer satisfaction.

Illustrative image related to patent leather fabric

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.