Introduction: Navigating the Global Market for how to make a leather knife sheath

In the competitive landscape of the leather goods market, sourcing high-quality leather knife sheaths can present a formidable challenge for international B2B buyers. Whether you are a retailer in Europe, a craftsman in South America, or a distributor in Africa or the Middle East, understanding the nuances of crafting a durable and aesthetically pleasing leather knife sheath is essential. This comprehensive guide addresses various aspects of the leather knife sheath-making process, including types of leather, applications for different market segments, supplier vetting strategies, and cost considerations.

By delving into the intricacies of leather sheath production, this guide empowers B2B buyers to make informed purchasing decisions that align with their business needs. We will explore the diverse materials available, the best practices for sourcing leather, and insights into effective production techniques that ensure quality and longevity. Additionally, the guide will highlight key considerations for ensuring compliance with local regulations and market preferences, particularly relevant for buyers in regions like Saudi Arabia and Nigeria.

Equip yourself with the knowledge to navigate the global market for leather knife sheaths effectively. With the right information, you can enhance your product offerings, meet customer demands, and ultimately drive profitability in your business.

Table Of Contents

- A Look at How To Make A Leather Knife Sheath Manufacturers & Suppliers

- Introduction: Navigating the Global Market for how to make a leather knife sheath

- Understanding how to make a leather knife sheath Types and Variations

- Key Industrial Applications of how to make a leather knife sheath

- 3 Common User Pain Points for ‘how to make a leather knife sheath’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather knife sheath

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather knife sheath

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather knife sheath’

- Comprehensive Cost and Pricing Analysis for how to make a leather knife sheath Sourcing

- Alternatives Analysis: Comparing how to make a leather knife sheath With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather knife sheath

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather knife sheath Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather knife sheath

- Strategic Sourcing Conclusion and Outlook for how to make a leather knife sheath

- Important Disclaimer & Terms of Use

Understanding how to make a leather knife sheath Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Sheath | Simple design, often hand-stitched, single layer | Custom knife manufacturers | Pros: Classic appeal, craftsmanship. Cons: Time-consuming to produce. |

| Folded Sheath | Constructed from a single piece of leather, folded to create pockets | Outdoor gear retailers | Pros: Efficient use of material. Cons: Limited design variations. |

| Pouch Sheath | Encloses the knife entirely, often with a snap or buckle | Tactical gear suppliers | Pros: Enhanced protection for the blade. Cons: Bulkier design. |

| Multi-Layer Sheath | Composed of multiple leather layers for durability | High-end knife artisans | Pros: Superior strength and longevity. Cons: Higher production costs. |

| Decorative Sheath | Incorporates intricate designs or tooling | Artisan markets, gift shops | Pros: Unique aesthetic appeal. Cons: May prioritize style over function. |

What are the Characteristics and Suitability of a Traditional Leather Knife Sheath?

The traditional leather knife sheath is characterized by its simple design, typically hand-stitched and made from a single layer of leather. This type is often favored by custom knife manufacturers looking to provide a classic, artisanal product. B2B buyers should consider the craftsmanship involved, as these sheaths often embody quality and durability. However, the time-intensive production process may lead to higher costs, making it essential for buyers to weigh the value of craftsmanship against budget constraints.

How Does a Folded Leather Knife Sheath Enhance Efficiency?

The folded sheath is crafted from a single piece of leather, folded over to create pockets for the knife. This design is particularly appealing to outdoor gear retailers who prioritize efficiency in material use. The folded construction minimizes waste, which can be a compelling selling point for environmentally conscious buyers. However, the design offers limited variations, which may not satisfy all consumer preferences. B2B buyers should assess market demand for unique designs versus the benefits of streamlined production.

What Advantages Does a Pouch Leather Knife Sheath Offer?

Pouch sheaths enclose the knife completely, often secured with a snap or buckle. This design is popular among tactical gear suppliers due to its enhanced protection for the blade during transport. The pouch sheath is ideal for buyers looking for functional, rugged solutions that cater to outdoor enthusiasts and professionals. However, its bulkier design may be a downside for those seeking lightweight options. Buyers should evaluate their target market’s needs for protection versus portability.

Illustrative image related to how to make a leather knife sheath

Why Choose a Multi-Layer Leather Knife Sheath for Durability?

Multi-layer sheaths are composed of several layers of leather, providing increased durability and longevity. These sheaths are often favored by high-end knife artisans who want to create premium products. B2B buyers interested in luxury markets will find that the multi-layer design justifies a higher price point due to its strength and aesthetic quality. However, the increased production costs should be factored into pricing strategies to ensure profitability without alienating potential customers.

How Can Decorative Leather Knife Sheaths Appeal to Niche Markets?

Decorative leather sheaths feature intricate designs or tooling, making them attractive for artisan markets and gift shops. Their unique aesthetic appeal can set them apart in a crowded marketplace, catering to consumers looking for personalized or artisanal gifts. However, these sheaths may prioritize style over function, potentially limiting their appeal to practical users. B2B buyers should consider the balance between artistic value and usability when sourcing decorative sheaths, ensuring they align with customer expectations.

Key Industrial Applications of how to make a leather knife sheath

| Industry/Sector | Specific Application of how to make a leather knife sheath | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Culinary Arts | Custom sheaths for chef knives and culinary tools | Enhances brand image through bespoke craftsmanship | Quality of leather, customization options, local artisans |

| Outdoor Equipment | Sheaths for hunting and camping knives | Increases product durability and user satisfaction | Weather resistance, thickness of leather, style options |

| Artisan Crafts | Handmade leather sheaths for display and sale | Unique selling proposition in artisanal markets | Sourcing sustainable materials, design flexibility |

| Safety Equipment | Protective sheaths for utility knives in industrial settings | Reduces workplace injuries and tool damage | Compliance with safety standards, durability requirements |

| Fashion Accessories | Fashion-forward knife sheaths as part of leather goods collections | Expands product lines and attracts fashion-conscious buyers | Trend alignment, leather quality, production scalability |

How is ‘how to make a leather knife sheath’ utilized in the Culinary Arts?

In the culinary arts sector, custom leather sheaths are often crafted for high-end chef knives and culinary tools. These sheaths not only serve a protective function but also enhance the brand image of culinary professionals and businesses by showcasing bespoke craftsmanship. Buyers in this sector typically require high-quality leather that can withstand regular use and maintain its aesthetic appeal over time. Sourcing considerations include finding reliable suppliers who can provide durable materials that can be customized to fit various knife shapes and sizes.

What role do leather knife sheaths play in Outdoor Equipment?

For businesses in the outdoor equipment industry, leather knife sheaths are essential for hunting and camping knives. These sheaths enhance the durability of the knives, providing protection from the elements and ensuring that users can safely transport their tools. International buyers, particularly in regions with diverse outdoor activities like Africa and South America, seek sheaths that are weather-resistant and made from thick leather to withstand rugged use. Sourcing must focus on the leather’s quality and the sheath’s design to ensure it meets the practical needs of outdoor enthusiasts.

Illustrative image related to how to make a leather knife sheath

How do Artisan Crafts benefit from making leather knife sheaths?

Artisan crafts benefit significantly from handmade leather knife sheaths, which can be sold as unique items in local markets or online platforms. These sheaths provide a unique selling proposition, allowing artisans to differentiate their products in a competitive marketplace. Buyers in this sector often look for sustainable materials and the ability to customize designs. Therefore, sourcing considerations should prioritize local suppliers who can provide high-quality leather and support artisanal craftsmanship.

Why are protective leather knife sheaths important in Safety Equipment?

In industrial settings, protective sheaths for utility knives are crucial for reducing workplace injuries and preventing tool damage. These sheaths ensure that knives are stored safely when not in use, thereby minimizing the risk of accidents. For international buyers, especially in regions with stringent safety regulations, sourcing must focus on compliance with safety standards, the durability of materials, and the effectiveness of the sheath design. This focus not only enhances workplace safety but also contributes to overall operational efficiency.

How can Fashion Accessories leverage leather knife sheaths?

In the fashion accessories sector, leather knife sheaths can be integrated into stylish leather goods collections. These sheaths serve as both functional items and fashion statements, appealing to consumers who appreciate unique designs. Buyers in this industry are particularly interested in sourcing high-quality leather that aligns with current fashion trends and offers customization options. Businesses must consider scalability in production to meet varying demand levels while maintaining quality and design integrity.

3 Common User Pain Points for ‘how to make a leather knife sheath’ & Their Solutions

Scenario 1: Sourcing Quality Leather Materials for Knife Sheaths

The Problem: B2B buyers often struggle to find high-quality leather suitable for knife sheaths that meets their specifications. In regions like Africa and South America, access to reliable suppliers can be limited, leading to inconsistent quality and higher costs. This inconsistency can impact product durability and customer satisfaction, as inferior leather can lead to sheaths that crack, fray, or fail to protect the blade adequately.

The Solution: Establish partnerships with reputable leather suppliers who specialize in high-grade materials. Buyers should conduct thorough research, utilizing online platforms and trade shows to identify suppliers with a track record of quality. When sourcing, focus on leather types like vegetable-tanned or full-grain leather, as these offer durability and longevity. Additionally, consider bulk purchasing options to negotiate better pricing and ensure a consistent supply chain. Engaging local artisans who understand the regional leather quality can also provide access to unique and high-quality materials while supporting local economies.

Illustrative image related to how to make a leather knife sheath

Scenario 2: Mastering the Leather Sheath Design Process

The Problem: Many B2B buyers lack the expertise in leatherworking techniques necessary to create effective knife sheath designs. This gap can lead to poorly fitting sheaths that do not adequately secure the knife, resulting in safety issues and decreased product reliability. Additionally, buyers may find the design process overwhelming, especially if they are new to leather crafting or do not have a clear vision of what they want.

The Solution: Invest in comprehensive training programs or workshops that focus on leatherworking skills specific to sheath design. These can be organized in collaboration with experienced leather craftsmen or through online platforms that offer step-by-step tutorials. Creating detailed templates using software can help streamline the design process, allowing buyers to visualize their designs before cutting leather. Furthermore, utilizing prototyping techniques with less expensive materials before finalizing the design can prevent costly mistakes and refine the design process for better outcomes.

Scenario 3: Ensuring Seam Durability and Aesthetic Appeal

The Problem: A common issue faced by B2B buyers is ensuring that the seams of leather knife sheaths are both durable and visually appealing. Poor seam quality can lead to functional failures, such as the sheath coming apart over time. Additionally, aesthetic appeal is crucial in a competitive market, where buyers are looking for products that not only perform well but also look professional and attractive.

Illustrative image related to how to make a leather knife sheath

The Solution: To address seam durability, buyers should utilize high-quality threads designed for leatherwork, such as nylon or polyester, which offer excellent tensile strength. Employing techniques like saddle stitching, which uses two needles to create a stronger seam, can also enhance durability. For aesthetic appeal, consider incorporating decorative stitching patterns or edge treatments that complement the overall design of the sheath. Finally, investing in proper tools, such as a sewing machine specifically designed for leather or hand tools that facilitate clean and consistent stitching, will ensure a professional finish.

Strategic Material Selection Guide for how to make a leather knife sheath

What Are the Key Properties of Leather for Knife Sheath Production?

Leather is the most traditional and widely used material for crafting knife sheaths. Its natural properties provide excellent durability and flexibility, making it suitable for various applications. Key properties include high tensile strength, resistance to wear, and the ability to withstand varying temperatures. Leather can also be treated to enhance its water resistance, which is crucial for outdoor use.

Pros & Cons:

The advantages of leather include its aesthetic appeal, durability, and ability to conform to the shape of the knife, providing a snug fit. However, it can be more expensive than synthetic alternatives and may require more complex manufacturing processes, such as tanning and finishing. Additionally, leather may not perform well in extreme wet conditions unless treated properly.

Impact on Application:

Leather sheaths are compatible with a range of knives and are particularly favored in artisanal and high-end markets. However, buyers must consider the environmental impact of leather sourcing and processing, which can vary significantly across regions.

How Do Synthetic Materials Compare for Knife Sheath Applications?

Synthetic materials, such as nylon or polyester, are increasingly popular for knife sheath production. These materials are lightweight, resistant to moisture, and often more affordable than leather. Key properties include high tensile strength, UV resistance, and easy maintenance.

Pros & Cons:

The main advantages of synthetic materials are their cost-effectiveness and resistance to environmental factors. They can also be produced in various colors and patterns, appealing to a broader market. However, they may lack the aesthetic appeal and tactile qualities of leather. Additionally, synthetic materials can degrade over time with exposure to UV light and extreme temperatures, which may limit their lifespan.

Impact on Application:

Synthetic sheaths are compatible with a range of outdoor and tactical knives, making them suitable for military and adventure markets. International buyers should be aware of the differences in manufacturing standards, as some synthetic materials may not meet local compliance requirements.

What Are the Benefits of Using Canvas for Knife Sheaths?

Canvas, a durable woven fabric, is another option for knife sheath production. It offers excellent durability and can be treated to be water-resistant. Key properties include high abrasion resistance and breathability, making it suitable for various environments.

Illustrative image related to how to make a leather knife sheath

Pros & Cons:

Canvas is often less expensive than leather and can be produced in various colors and patterns. It is also relatively easy to sew and manipulate, which simplifies the manufacturing process. However, canvas may not provide the same level of protection against moisture and may wear out faster than leather or synthetic options.

Impact on Application:

Canvas sheaths are ideal for casual and outdoor knives, appealing to budget-conscious consumers. Buyers in regions with high humidity or moisture should consider the need for additional waterproofing treatments.

How Do Rubber and Neoprene Materials Function in Knife Sheath Manufacturing?

Rubber and neoprene are less common but viable options for knife sheaths, particularly for specialized applications. These materials offer excellent water resistance and shock absorption. Key properties include flexibility and resistance to extreme temperatures.

Pros & Cons:

The primary advantage of rubber and neoprene is their waterproof nature, making them ideal for marine or wet environments. However, they can be bulkier than leather or synthetic options and may not provide the same level of aesthetic appeal. Additionally, they can be more expensive due to their specialized manufacturing processes.

Illustrative image related to how to make a leather knife sheath

Impact on Application:

These materials are suitable for tactical and survival knives, especially in regions with harsh weather conditions. International buyers should ensure compliance with local regulations regarding the use of synthetic materials.

Summary Table of Material Selection for Knife Sheath Production

| Material | Typical Use Case for how to make a leather knife sheath | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | High-end, artisanal knife sheaths | Durable and aesthetically pleasing | Higher cost and complex manufacturing | High |

| Synthetic | Tactical and outdoor knife sheaths | Cost-effective and moisture-resistant | Lacks aesthetic appeal and can degrade over time | Medium |

| Canvas | Budget-friendly knife sheaths | Affordable and easy to sew | Less moisture protection and durability | Low |

| Rubber/Neoprene | Specialized tactical and marine knife sheaths | Excellent waterproofing | Bulkier and less visually appealing | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials for knife sheath production, facilitating informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather knife sheath

What Are the Key Stages in the Manufacturing Process of a Leather Knife Sheath?

The manufacturing process of a leather knife sheath involves several critical stages: material preparation, forming, assembly, and finishing. Each stage requires specific techniques to ensure quality and functionality, which are paramount for B2B buyers looking for durable and reliable products.

How Is Material Prepared for Leather Knife Sheath Production?

Material preparation begins with sourcing high-quality leather, which can vary in thickness, grain, and finish. For optimal results, manufacturers typically utilize vegetable-tanned or chrome-tanned leather, as these types offer durability and ease of handling.

Illustrative image related to how to make a leather knife sheath

The leather is often cut into manageable pieces using precise cutting tools, such as utility knives or die-cutting machines, to ensure consistent dimensions. It’s also advisable to incorporate a paper template during this stage to minimize waste and enhance accuracy. Additionally, checking for defects in the leather is crucial to avoid compromising the final product’s quality.

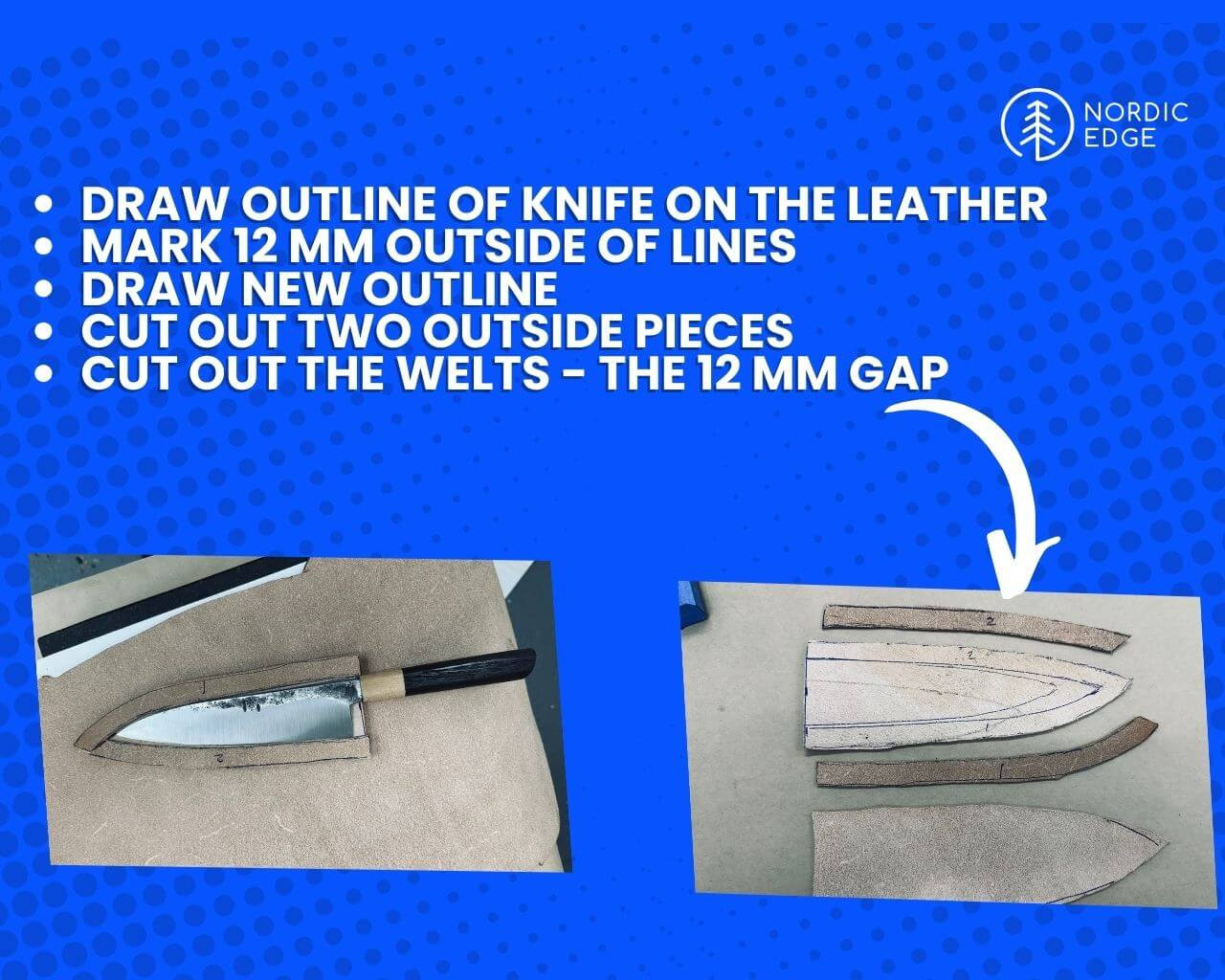

What Techniques Are Used for Forming Leather Knife Sheaths?

The forming stage involves shaping the leather into the desired sheath design. This is often done through techniques such as molding or folding, where the leather is dampened to facilitate bending. Manufacturers may use molds to achieve specific shapes that provide a snug fit for the knife.

Burnishing the edges is another essential technique during this phase. This process smooths out rough edges and prevents fraying, enhancing the sheath’s aesthetic appeal and longevity. Using specialized burnishing tools or even improvising with household items can expedite this process and yield high-quality results.

How Is the Assembly of Leather Knife Sheaths Conducted?

Assembly involves several steps, including gluing, stitching, and fastening components. Manufacturers typically apply contact cement to bond different layers of leather. This ensures a strong adhesive bond that can withstand daily use.

Sewing techniques are critical at this stage, with options ranging from hand-stitching to machine sewing. Hand-stitching provides a bespoke finish, while machine sewing can enhance production speed. Fasteners, such as snap buttons, are also integrated during assembly, requiring precision to ensure they function correctly.

Illustrative image related to how to make a leather knife sheath

What Finishing Touches Are Applied to Leather Knife Sheaths?

The finishing stage includes dyeing, polishing, and adding protective coatings to enhance the sheath’s appearance and durability. Manufacturers may use natural dyes or synthetic options, depending on the desired color and finish. Burnishing is also repeated to ensure all edges are smooth and visually appealing.

A final quality check is performed to ensure the sheath meets all design specifications and functional requirements. This may include checking for uniformity in color, texture, and overall craftsmanship.

What Quality Assurance Measures Are Essential for Leather Knife Sheaths?

Quality assurance (QA) is critical in maintaining product integrity and meeting international standards. For B2B buyers, understanding these QA measures is essential for ensuring that suppliers deliver high-quality products.

Illustrative image related to how to make a leather knife sheath

Which International Standards Should Buyers Be Aware Of?

Adhering to international standards such as ISO 9001 is crucial for manufacturers. This standard focuses on quality management systems and ensures that processes consistently meet customer and regulatory requirements. Additionally, industry-specific standards such as CE marking and API specifications can apply, depending on the intended market and use of the leather knife sheath.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. The following are critical QC checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for defects and ensuring they meet specified quality standards before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators conduct regular inspections to identify any deviations from quality standards. This includes monitoring stitching accuracy, adhesive application, and edge finishing.

-

Final Quality Control (FQC): Upon completion of the sheath, a comprehensive inspection is performed to ensure that the final product meets all design specifications and quality standards. This may involve functional testing, such as verifying the fit of the knife and the integrity of fasteners.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. This can include:

-

Conducting Audits: Regular audits of manufacturing facilities can provide insights into the QC practices and overall operational standards of suppliers. Buyers may consider third-party auditing services to ensure impartiality.

-

Requesting Quality Reports: Suppliers should be willing to provide detailed quality reports that outline their QC processes, inspection results, and any corrective actions taken.

-

Utilizing Third-Party Inspection Services: Engaging third-party inspection services can offer an additional layer of assurance, as these organizations can conduct independent evaluations of product quality prior to shipment.

What Are the Unique QC Considerations for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are specific QC nuances to consider.

-

Cultural and Regulatory Differences: Understanding the cultural and regulatory landscape in the supplier’s country can impact quality expectations. Buyers should familiarize themselves with local standards and practices to ensure compatibility.

-

Logistics and Shipping Challenges: International shipping can introduce risks that may affect product quality, such as exposure to moisture or temperature fluctuations. Buyers should discuss packaging and shipping methods with suppliers to mitigate these risks.

-

Communication Barriers: Language differences can lead to misunderstandings regarding quality specifications. Establishing clear communication channels and documentation can help prevent such issues.

In conclusion, understanding the manufacturing processes and quality assurance measures for leather knife sheaths is vital for B2B buyers. By focusing on these aspects, buyers can ensure they partner with reliable suppliers who deliver high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather knife sheath’

Introduction

This guide serves as a practical checklist for B2B buyers interested in procuring the materials and tools necessary for creating a leather knife sheath. Whether you are a manufacturer, artisan, or retailer, understanding the sourcing process is crucial for producing high-quality leather goods that meet your market’s demands.

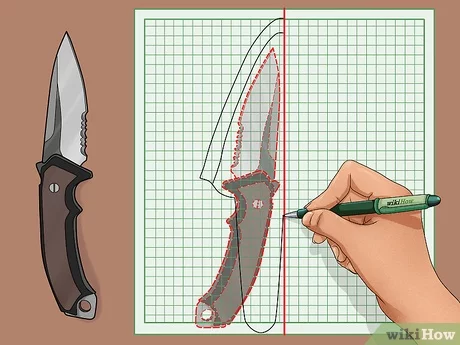

Step 1: Identify Your Design Requirements

Before sourcing materials, clearly define the design specifications for your leather knife sheath. Consider factors such as the knife type, sheath style, and any additional features like fasteners or belt loops.

– Action Items:

– Create sketches or templates to visualize your design.

– Determine the thickness and type of leather required based on durability and aesthetic preferences.

Step 2: Source Quality Leather

Leather quality is paramount for durability and appearance. Look for suppliers who provide high-grade leather suitable for knife sheaths, such as vegetable-tanned or chrome-tanned leather.

– Action Items:

– Request samples to evaluate texture, flexibility, and color.

– Inquire about the sourcing practices of the leather to ensure sustainability and ethical considerations.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Action Items:

– Check for certifications, such as ISO or environmental standards, to ensure compliance.

– Investigate the supplier’s reputation through online reviews and industry forums.

Step 4: Assess Tooling and Equipment Needs

Determine the tools required for your sheath-making process, such as leather punches, needles, and adhesive. Sourcing high-quality tools can enhance your production efficiency and product quality.

– Action Items:

– Compile a list of necessary tools and compare prices from different suppliers.

– Consider investing in specialized tools, like burnishing machines or sewing machines, to improve craftsmanship.

Step 5: Review Cost and Pricing Structures

Understanding the cost implications of your materials and tools is essential for budget management. Analyze pricing structures from multiple suppliers to ensure competitive rates without compromising quality.

– Action Items:

– Request detailed quotes, including shipping and handling fees.

– Look for bulk purchase discounts or loyalty programs that may provide cost savings.

Step 6: Finalize Your Supply Chain Logistics

Establishing a reliable logistics plan is vital for timely delivery and inventory management. Coordinate with suppliers regarding lead times and shipping options.

– Action Items:

– Discuss minimum order quantities and delivery schedules to align with production timelines.

– Consider local suppliers for shorter lead times and reduced shipping costs, particularly important for international operations.

Step 7: Monitor and Evaluate Supplier Performance

Once you begin sourcing, continuously monitor supplier performance to ensure they meet your quality and delivery expectations. Regular evaluations can help maintain strong supplier relationships and improve your sourcing strategy.

– Action Items:

– Set criteria for performance reviews, such as quality consistency and delivery punctuality.

– Maintain open communication with suppliers to address any issues promptly and collaboratively.

By following these steps, B2B buyers can successfully navigate the sourcing process for creating leather knife sheaths, ensuring high-quality products that meet market expectations.

Comprehensive Cost and Pricing Analysis for how to make a leather knife sheath Sourcing

When evaluating the costs associated with producing a leather knife sheath, it’s essential to break down the various components that contribute to the total cost structure. Understanding these elements can significantly impact pricing strategies and profitability for businesses in the leather goods sector.

Illustrative image related to how to make a leather knife sheath

What Are the Key Cost Components in Leather Knife Sheath Production?

-

Materials: The primary costs stem from the leather itself, which can vary widely based on quality, type (e.g., cowhide, pigskin), and sourcing. Additional materials such as leather punches, needles, snap fasteners, and adhesives also contribute to the overall material cost. For instance, high-quality leather sourced from reputable suppliers may range from $5 to $20 per square foot, while scrap leather can reduce costs significantly.

-

Labor: Labor costs encompass the wages of skilled artisans who cut, sew, and finish the sheaths. Depending on the region, labor rates can vary; for instance, skilled labor in Europe may cost more compared to South America or Africa. A typical hourly wage for leather artisans can range from $15 to $35, depending on expertise and local economic conditions.

-

Manufacturing Overhead: This includes utilities, rent for workspace, and equipment maintenance. Overhead can be estimated at 10-20% of total production costs, depending on the efficiency of the operation and location.

-

Tooling Costs: Initial investments in tools, such as cutting dies and sewing machines, can be significant but are usually amortized over time. Tooling costs for a small-scale operation might be around $1,000 to $5,000, depending on the complexity of the designs.

-

Quality Control (QC): Ensuring that each sheath meets quality standards is critical, especially for B2B transactions where reputation is paramount. QC processes might add an additional 5-10% to production costs, involving inspections and testing to ensure durability and craftsmanship.

-

Logistics: Transportation costs for raw materials and finished products can vary widely based on distance and shipping methods. For international buyers, understanding Incoterms (International Commercial Terms) is crucial, as they dictate who bears responsibility for shipping costs, insurance, and tariffs.

-

Margin: Finally, businesses must consider their desired profit margin. Typical margins in the leather goods industry range from 20% to 50%, depending on the brand positioning and market competition.

How Do Price Influencers Affect B2B Leather Knife Sheath Sourcing?

-

Volume/MOQ: Bulk orders can significantly reduce per-unit costs. Suppliers often offer discounts for larger minimum order quantities (MOQs), making it beneficial for buyers to negotiate favorable terms.

-

Specifications and Customization: Custom designs or specifications can lead to higher costs due to additional labor and material requirements. Buyers should weigh the benefits of customization against the potential price increase.

-

Material Quality and Certifications: The choice of materials not only affects durability but also price. High-quality, certified leathers (e.g., vegetable-tanned) may come at a premium but can enhance the product’s marketability.

-

Supplier Factors: Supplier reputation, reliability, and location can influence pricing. Engaging with suppliers who have established quality standards and good practices may incur higher costs but often results in better product quality.

What Are Some Buyer Tips for Cost-Efficiency in Leather Knife Sheath Sourcing?

-

Negotiate Wisely: Building strong relationships with suppliers can lead to better pricing and terms. Understanding the supplier’s cost structure can provide leverage in negotiations.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the long-term costs associated with quality, durability, and potential returns. Investing in higher-quality materials may result in lower replacement costs over time.

-

Understand Pricing Nuances for International Markets: B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and regional market trends that can affect pricing.

-

Request Samples: Before committing to large orders, requesting samples can help assess quality and craftsmanship, ensuring that the final product meets expectations.

Disclaimer for Indicative Prices

It is important to note that the prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and regional economic factors. Always conduct thorough market research and supplier evaluations to obtain accurate pricing tailored to your specific needs.

Alternatives Analysis: Comparing how to make a leather knife sheath With Other Solutions

Introduction to Alternatives for Making a Leather Knife Sheath

When it comes to crafting a leather knife sheath, various methods and materials can be considered. While traditional leather crafting offers a time-honored approach, alternative solutions have emerged that may better suit the needs of different businesses. This section evaluates how to make a leather knife sheath against other viable alternatives, helping B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | How To Make A Leather Knife Sheath | Kydex Sheath Production | Fabric Sheath Creation |

|---|---|---|---|

| Performance | Durable and aesthetically pleasing | Highly durable, waterproof | Less durable, lightweight |

| Cost | Moderate, depending on leather quality | Moderate to high due to equipment | Low, inexpensive materials |

| Ease of Implementation | Requires skills and tools | Requires specialized equipment and training | Simple, can be done with basic sewing skills |

| Maintenance | Requires occasional conditioning | Low maintenance, wipe clean | May require washing and care |

| Best Use Case | Custom, high-quality, aesthetic sheaths | Tactical, outdoor use, water-resistant | Casual, light use, budget-friendly |

Detailed Breakdown of Alternatives

Kydex Sheath Production

Kydex is a thermoplastic material known for its durability and water resistance. It is often used in tactical environments where a sturdy sheath is essential. The production process typically involves heating Kydex sheets and molding them around the knife. While Kydex sheaths are highly functional, the initial setup can be costly, requiring specialized equipment. Additionally, this method may not appeal to buyers looking for a classic or aesthetic appeal. However, for businesses focused on durability and performance in harsh conditions, Kydex is an excellent choice.

Illustrative image related to how to make a leather knife sheath

Fabric Sheath Creation

Fabric sheaths offer a lightweight and cost-effective alternative to leather. They can be easily sewn using basic materials, making them accessible for small-scale operations or startups. While fabric sheaths are not as durable as leather or Kydex, they can be designed in various styles and colors, appealing to a broad market. However, they may require more frequent maintenance and are less suitable for heavy-duty applications. This option is best for businesses targeting casual users or those needing budget-friendly solutions.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the best method for creating a knife sheath, B2B buyers should consider their target market, budget, and desired performance attributes. Leather sheaths offer a blend of aesthetics and durability, making them ideal for high-end markets. In contrast, Kydex provides superior protection and functionality for tactical applications, while fabric sheaths cater to budget-conscious consumers. By assessing these factors, businesses can make a strategic choice that aligns with their goals and customer expectations.

Essential Technical Properties and Trade Terminology for how to make a leather knife sheath

What Are the Key Technical Properties for Making a Leather Knife Sheath?

When it comes to producing a high-quality leather knife sheath, understanding the essential technical properties is crucial for manufacturers and suppliers. Here are some critical specifications to consider:

1. Material Grade

The grade of leather used significantly impacts the durability and aesthetics of the sheath. Common grades include full-grain, top-grain, and genuine leather. Full-grain leather is the most durable and retains the natural grain, making it ideal for high-end products. Understanding material grades helps B2B buyers select the appropriate quality for their target market, influencing both pricing and customer satisfaction.

2. Thickness

Leather thickness, typically measured in ounces or millimeters, is another vital property. A sheath should generally be between 3-5 mm thick to ensure it can withstand wear and tear while providing adequate protection for the knife. This specification is essential for manufacturers, as it influences both the product’s strength and its ability to hold its shape.

Illustrative image related to how to make a leather knife sheath

3. Tolerances

Tolerance levels refer to the acceptable variations in the dimensions and weight of the leather sheath. For instance, a tolerance of ±0.5 mm may be required for the sheath’s length and width to ensure a snug fit for the knife. Understanding tolerances is essential for maintaining quality control during production, ultimately minimizing returns and enhancing customer satisfaction.

4. Finish Type

The finish applied to the leather affects its appearance and resistance to water and stains. Common finishes include aniline, semi-aniline, and pigmented. Selecting the right finish is crucial for B2B buyers, as it not only influences the aesthetic appeal but also impacts the product’s longevity and care requirements.

5. Weight

The weight of the leather sheath should be balanced to ensure portability without compromising on protection. Typically, a lightweight sheath enhances usability, especially for outdoor or tactical knives. Buyers must consider weight specifications to align with consumer preferences and product usage scenarios.

Illustrative image related to how to make a leather knife sheath

What Common Trade Terms Should B2B Buyers Understand When Sourcing Leather Knife Sheaths?

Familiarizing oneself with industry jargon is key for effective communication in B2B transactions. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or products that are used in another company’s end product. For leather knife sheaths, understanding the OEM relationship helps buyers identify the source of their products and ensure quality control throughout the supply chain.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of product a supplier is willing to sell. It is crucial for B2B buyers to understand MOQs to manage inventory effectively and negotiate costs. This term helps in planning budget allocations and production timelines.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. Understanding how to formulate an effective RFQ can facilitate better negotiation and sourcing processes, ensuring competitive pricing for leather sheaths.

Illustrative image related to how to make a leather knife sheath

4. Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risk management, and delivery responsibilities, ensuring smoother cross-border transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Knowing the lead times for leather knife sheath production is critical for inventory management and meeting customer demands. It helps businesses plan their operations and avoid stockouts.

By understanding these essential properties and terms, B2B buyers can make informed decisions, streamline their procurement processes, and enhance their product offerings in the competitive leather goods market.

Navigating Market Dynamics and Sourcing Trends in the how to make a leather knife sheath Sector

What Are the Key Market Trends Affecting the Leather Knife Sheath Sector?

The leather knife sheath market is experiencing significant transformation driven by global demand for artisanal craftsmanship and outdoor recreational activities. Increasing consumer interest in handmade products, particularly in regions like Africa, South America, the Middle East, and Europe, is propelling the growth of this sector. The rise of e-commerce platforms has enabled small manufacturers and artisans to reach international B2B buyers, expanding market access. Additionally, advancements in digital manufacturing technologies, such as laser cutting and 3D modeling, are streamlining the production process, allowing for greater customization and efficiency in making leather knife sheaths.

Illustrative image related to how to make a leather knife sheath

Emerging trends indicate a shift toward multifunctional designs that cater to diverse user needs, particularly among outdoor enthusiasts and chefs. Buyers are increasingly looking for sheaths that not only protect knives but also offer added features such as integrated storage for tools or accessories. The demand for innovative designs that incorporate sustainable materials is also on the rise, reflecting a broader trend toward eco-conscious consumerism.

As B2B buyers navigate this dynamic market, understanding regional preferences becomes crucial. For instance, buyers in Saudi Arabia may prioritize durability and style, while those in Nigeria might focus on affordability and accessibility. Recognizing these nuances can help manufacturers tailor their offerings to meet specific market demands effectively.

How Is Sustainability Impacting the Leather Knife Sheath Supply Chain?

Sustainability is becoming a critical consideration in the leather knife sheath sector, with increasing pressure on manufacturers to adopt ethical sourcing practices. The environmental impact of traditional leather production processes, which often involve harmful chemicals, is prompting a shift toward more sustainable alternatives. B2B buyers are increasingly favoring suppliers who utilize vegetable-tanned leather and eco-friendly dyes, which minimize ecological footprints.

Moreover, the importance of ethical supply chains cannot be overstated. International buyers are now more vigilant about ensuring that their suppliers adhere to fair labor practices and provide transparency throughout their operations. Certifications such as the Leather Working Group (LWG) certification are gaining prominence, as they offer assurance regarding the sustainability and ethical standards of leather products.

Incorporating sustainable practices not only benefits the environment but also enhances brand reputation. B2B buyers are more likely to engage with suppliers who demonstrate a commitment to sustainability, which can lead to increased loyalty and long-term partnerships. As such, manufacturers in the leather knife sheath sector should prioritize sustainable sourcing and production methods to stay competitive in the evolving marketplace.

Illustrative image related to how to make a leather knife sheath

What Is the Historical Context of Leather Knife Sheath Crafting?

The art of crafting leather knife sheaths has a rich history that dates back centuries, with origins rooted in the necessity of protecting tools. Traditionally, artisans would use locally sourced materials and techniques passed down through generations, often reflecting the cultural heritage of their regions. As societies evolved, so did the craftsmanship, with advancements in leatherworking techniques leading to more intricate and durable designs.

In recent years, there has been a resurgence of interest in traditional crafting methods, driven by the contemporary movement toward artisanal and handmade products. This revival is particularly significant in markets such as Europe and South America, where consumers value the story behind each product. For B2B buyers, understanding this historical context can provide insights into the craftsmanship and authenticity of leather knife sheaths, enhancing their purchasing decisions and fostering deeper connections with suppliers.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather knife sheath

-

How do I choose the right leather for making a knife sheath?

Selecting the right leather is crucial for durability and aesthetics. Full-grain leather is often preferred due to its strength and natural finish, making it ideal for knife sheaths. When sourcing leather, consider local suppliers who can provide quality hides suited for your specific needs. For international buyers, ensure that the leather complies with local regulations regarding animal products. It’s also beneficial to request samples before committing to a larger order, allowing you to assess texture, thickness, and overall quality. -

What tools do I need to make a leather knife sheath?

To create a leather knife sheath, you will need essential tools such as leather punches, a sharp utility knife or scalpel, leather glue, and a needle set specifically for leatherwork. Additionally, investing in burnishing tools will help you finish the edges neatly. Depending on your production scale, consider sourcing tools from local artisans or suppliers who understand the specific demands of your market. Make sure to assess the quality of tools to ensure efficiency and precision in your crafting process. -

How can I ensure quality control when sourcing leather sheaths?

Implementing a robust quality assurance process is vital. Start by establishing clear specifications for the leather sheaths, including dimensions, materials, and finishing techniques. Request samples from potential suppliers to evaluate their craftsmanship. Additionally, consider conducting factory visits or audits to assess production practices. Engaging a third-party quality inspection service can also provide an objective assessment before shipment, ensuring that the products meet your standards and specifications. -

What are the common customization options for leather knife sheaths?

Customization options for leather knife sheaths include varying sizes, colors, and styles, such as sheaths with or without belts or additional pockets. You can also opt for embossed logos or personalized engravings to enhance brand visibility. Discussing customization capabilities with your supplier is essential to ensure they can meet your design requirements. Be sure to inquire about minimum order quantities (MOQs) for customized items, as these can vary significantly between manufacturers. -

What are the typical payment terms when sourcing leather products internationally?

Payment terms can vary widely depending on the supplier and your negotiating power. Common terms include a deposit upfront (often 30% to 50%) with the balance payable upon shipment or delivery. It’s advisable to use secure payment methods, such as letters of credit or escrow services, to mitigate risk. Always clarify terms in your contract, including timelines for payment and penalties for late payments, to ensure a smooth transaction process. -

How do I handle logistics and shipping when importing leather sheaths?

When importing leather sheaths, coordinate closely with your supplier to understand their shipping capabilities. Choose reliable logistics partners familiar with customs regulations in your country. Consider factors such as shipping costs, delivery times, and insurance coverage. Additionally, ensure that all necessary documentation, including invoices and certificates of origin, is in order to avoid delays at customs. Familiarize yourself with import duties and taxes applicable to leather products in your region. -

What should I look for in a supplier for leather knife sheaths?

When selecting a supplier, prioritize those with a proven track record in the leather goods industry. Evaluate their experience, production capacity, and quality certifications. Request references from other clients to gauge their reliability. Additionally, assess their communication skills and responsiveness, as these are critical for successful international transactions. A supplier who understands your market needs and can offer flexibility in production will be invaluable for long-term partnerships. -

How can I market my leather knife sheaths effectively?

To effectively market your leather knife sheaths, identify your target audience and tailor your messaging accordingly. Utilize social media platforms and online marketplaces to showcase product images and customer testimonials. Emphasize the craftsmanship, quality materials, and customization options available. Collaborating with influencers or bloggers in the outdoor or culinary space can also enhance visibility. Lastly, consider participating in trade shows to connect with potential buyers and showcase your products directly to the market.

A Look at How To Make A Leather Knife Sheath Manufacturers & Suppliers

Could not verify enough suppliers for how to make a leather knife sheath to create a list at this time.

Strategic Sourcing Conclusion and Outlook for how to make a leather knife sheath

In the competitive landscape of leather goods manufacturing, understanding the nuances of strategic sourcing is paramount for businesses aiming to create high-quality leather knife sheaths. Leveraging local resources, such as scrap leather from nearby artisans or manufacturers, not only reduces costs but also promotes sustainability—a key value proposition in today’s market. Collaborating with local suppliers can enhance supply chain resilience, ensuring timely access to materials while fostering community relationships.

As international buyers from regions like Africa, South America, the Middle East, and Europe explore opportunities in leather craftsmanship, it is crucial to prioritize quality and durability in sourcing decisions. The process outlined in this guide emphasizes the importance of skilled craftsmanship combined with strategic material selection, which can significantly impact product performance and customer satisfaction.

Looking ahead, businesses should consider embracing innovation in both design and production techniques. By investing in new technologies and sustainable practices, companies can differentiate themselves in a crowded marketplace. We encourage you to take actionable steps toward refining your sourcing strategies and enhancing your product offerings, thereby positioning your brand for success in the global leather market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to how to make a leather knife sheath

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.