Introduction: Navigating the Global Market for custom leather engraving

In today’s competitive landscape, sourcing high-quality custom leather engraving services presents a unique challenge for international B2B buyers. Whether you’re in Brazil, Nigeria, or any other part of the globe, the need for personalized leather products that resonate with your brand’s identity is paramount. This guide aims to streamline your journey in navigating the global market for custom leather engraving, providing essential insights into various types of leather, engraving techniques, and applications.

Understanding the nuances of different leather types—from full-grain to faux leather—will enable you to make informed decisions that align with your business needs. Furthermore, we will delve into the intricacies of supplier vetting, ensuring that you can identify reputable partners who meet your quality standards and logistical requirements. Cost considerations are also addressed, offering a comprehensive overview of pricing structures to aid in budget planning.

By equipping you with this crucial knowledge, this guide empowers B2B buyers across Africa, South America, the Middle East, and Europe to make strategic purchasing decisions. The world of custom leather engraving is rich with opportunities, and being well-informed will not only enhance your product offerings but also strengthen your brand’s market presence. Let’s embark on this journey together, unlocking the potential of custom leather engraving for your business.

Table Of Contents

- Top 6 Custom Leather Engraving Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather engraving

- Understanding custom leather engraving Types and Variations

- Key Industrial Applications of custom leather engraving

- 3 Common User Pain Points for ‘custom leather engraving’ & Their Solutions

- Strategic Material Selection Guide for custom leather engraving

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather engraving

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather engraving’

- Comprehensive Cost and Pricing Analysis for custom leather engraving Sourcing

- Alternatives Analysis: Comparing custom leather engraving With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather engraving

- Navigating Market Dynamics and Sourcing Trends in the custom leather engraving Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather engraving

- Strategic Sourcing Conclusion and Outlook for custom leather engraving

- Important Disclaimer & Terms of Use

Understanding custom leather engraving Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Laser Engraving | High precision, permanent marks with varied depth and contrast | Fashion accessories, promotional items | Pros: High customization; Cons: Initial setup cost can be high. |

| Debossing | Creates an impression by pressing into leather | High-end leather goods, luxury branding | Pros: Elegant finish; Cons: Less visible than engraving. |

| Foil Stamping | Uses heat and pressure to apply metallic foil | Gifts, awards, and special editions | Pros: Eye-catching and unique; Cons: Limited to specific designs. |

| Hand Engraving | Manual technique using tools to carve designs | Artisan products, bespoke items | Pros: Unique craftsmanship; Cons: Time-consuming and higher labor costs. |

| Digital Printing | Utilizes inkjet technology for full-color designs | Promotional products, bulk orders | Pros: Cost-effective for large runs; Cons: Less durable than engraving. |

What Are the Characteristics and B2B Considerations for Laser Engraving?

Laser engraving is a modern technique that offers high precision and the ability to create intricate designs on leather. This method utilizes a laser beam to permanently mark the leather, resulting in a clean and professional look. It is particularly suitable for businesses looking to produce promotional items, fashion accessories, or personalized gifts at scale. B2B buyers should consider the initial investment in laser equipment and the learning curve associated with operating the machinery. However, the potential for high customization and quick turnaround times can make this a worthwhile investment.

How Does Debossing Differ from Other Techniques?

Debossing involves pressing a design into the leather, creating a subtle impression that adds texture and sophistication. This technique is commonly used in high-end leather goods and for branding luxury products. The key consideration for B2B buyers is the level of visibility; while debossed designs can be elegant, they may not stand out as much as engraved designs. Buyers should also evaluate the durability of the impression, as it can wear over time if not properly treated.

What Are the Benefits of Foil Stamping for B2B Buyers?

Foil stamping employs heat and pressure to apply metallic foil to leather, resulting in a shiny, eye-catching finish. This technique is ideal for creating unique gifts, awards, and special edition products. B2B buyers benefit from the distinctive look that foil stamping provides, which can elevate a brand’s image. However, the limitation to specific designs and the higher cost compared to standard engraving may require careful planning and budgeting.

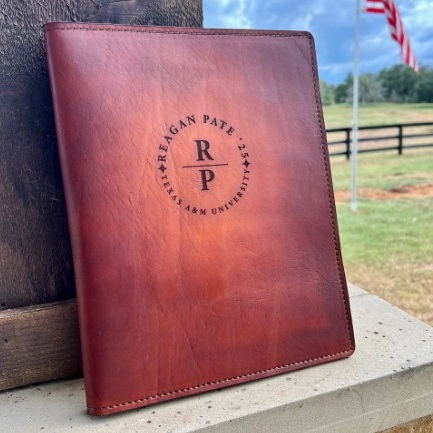

Illustrative image related to custom leather engraving

Why Choose Hand Engraving for Artisan Products?

Hand engraving is a traditional method that involves manually carving designs into leather, offering a unique and artisanal touch. This technique is favored for bespoke items and artisan products where craftsmanship is paramount. B2B buyers should consider the time and labor costs associated with hand engraving, as it is generally more expensive and slower than automated methods. However, the uniqueness and personal touch can justify the higher price point for luxury brands.

How Can Digital Printing Enhance Promotional Product Offerings?

Digital printing utilizes inkjet technology to apply full-color designs directly onto leather, making it an excellent option for businesses looking to create vibrant promotional products. This method is particularly advantageous for bulk orders, as it is cost-effective and allows for quick production times. However, buyers should be aware that digital prints may not be as durable as engraved designs and may require special care to maintain their appearance over time.

Key Industrial Applications of custom leather engraving

| Industry/Sector | Specific Application of custom leather engraving | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Personalized handbags and wallets | Enhances brand value and customer loyalty through customization | Ensure compatibility with various leather types and finishes. |

| Corporate Gifts | Engraved leather portfolios and notebooks | Creates a lasting impression and strengthens client relationships | Look for suppliers with experience in corporate branding. |

| Promotional Products | Customized keychains and coasters | Increases brand visibility and engagement | Consider minimum order quantities and shipping options. |

| Automotive | Engraved leather seat covers and accessories | Adds luxury appeal and personalization to vehicles | Verify material durability and resistance to wear and tear. |

| Home Decor | Customized leather wall art and furniture accents | Differentiates products in a competitive market | Assess design capabilities and production timelines. |

How is custom leather engraving used in the fashion and accessories industry?

In the fashion and accessories sector, custom leather engraving is employed to create personalized handbags and wallets that resonate with consumers looking for unique products. This personalization enhances brand value by allowing businesses to offer distinctive items that foster customer loyalty. International buyers should focus on suppliers that can handle various leather types and finishes to meet diverse market demands.

What role does custom leather engraving play in corporate gifting?

Corporate gifts, such as engraved leather portfolios and notebooks, leverage custom leather engraving to create a lasting impression on clients and partners. This personal touch not only enhances the perceived value of the gifts but also strengthens business relationships. For B2B buyers in regions like Africa and Europe, sourcing from suppliers experienced in corporate branding can ensure high-quality products that align with their branding strategies.

How can promotional products benefit from custom leather engraving?

Promotional products, including customized keychains and coasters, utilize custom leather engraving to boost brand visibility and engagement. By offering engraved items as giveaways, businesses can effectively promote their brand while providing practical products to customers. Buyers should consider suppliers that offer flexible minimum order quantities and reliable shipping options to facilitate smooth procurement processes.

What advantages does custom leather engraving bring to the automotive industry?

In the automotive sector, custom leather engraving is used for creating personalized seat covers and accessories, adding a touch of luxury and personalization to vehicles. This application not only enhances the vehicle’s appeal but also caters to consumers seeking unique modifications. Buyers should verify the durability and wear resistance of the materials used, ensuring they withstand automotive environments.

How does custom leather engraving enhance home decor products?

Custom leather engraving in home decor allows businesses to create unique leather wall art and furniture accents that stand out in a competitive market. This differentiation can attract discerning customers looking for exclusive home items. For B2B buyers, assessing a supplier’s design capabilities and production timelines is crucial to ensure timely delivery and alignment with market trends.

3 Common User Pain Points for ‘custom leather engraving’ & Their Solutions

Scenario 1: Quality Consistency in Custom Leather Engraving

The Problem: B2B buyers often face challenges with quality consistency in custom leather engraving, particularly when sourcing from multiple suppliers. Differences in leather types, engraving techniques, and machine capabilities can lead to variations in the final product. This inconsistency can affect branding, customer satisfaction, and ultimately, business reputation. For instance, a company ordering engraved leather promotional items may receive products where the engraving is too shallow, poorly aligned, or lacks the desired contrast, resulting in a subpar customer experience.

The Solution: To mitigate quality inconsistencies, B2B buyers should prioritize establishing clear specifications and standards before placing orders. This includes defining the type of leather, the engraving depth, and the preferred contrast levels. Engaging suppliers in detailed discussions about their processes and capabilities can also help align expectations. Additionally, conducting a sample run before committing to larger orders allows businesses to evaluate quality firsthand. Buyers should request samples from multiple suppliers to compare engraving results, ensuring that they select a partner capable of delivering consistent quality that meets their branding needs.

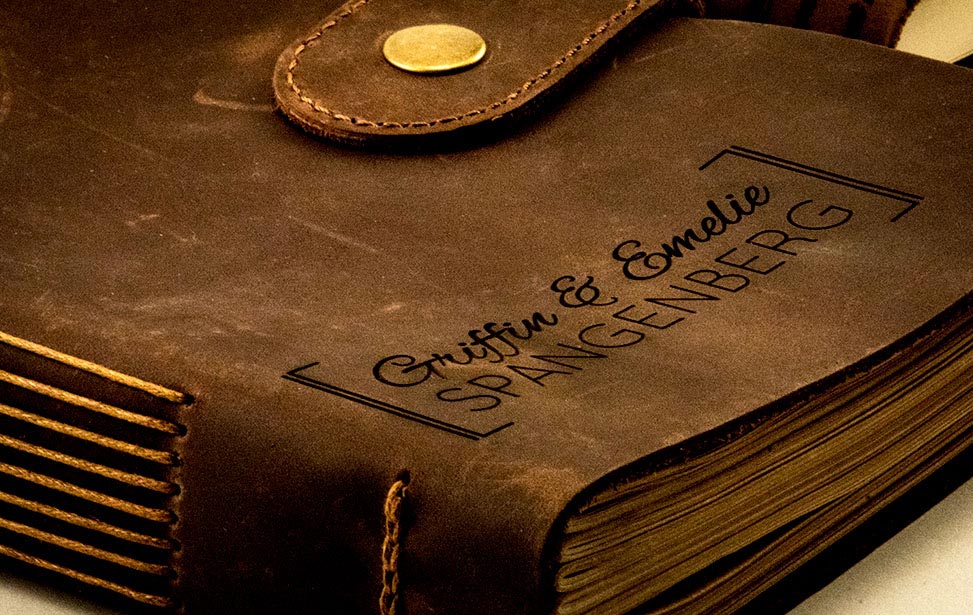

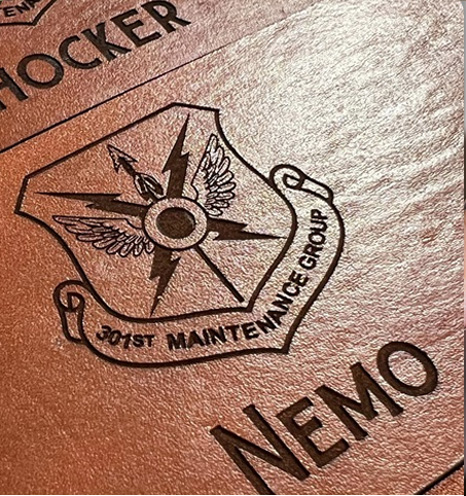

Illustrative image related to custom leather engraving

Scenario 2: Navigating Lead Times and Delivery Challenges

The Problem: Lead times and shipping delays can pose significant issues for B2B buyers when ordering custom leather engraved products. Businesses often operate on tight schedules, and delays in receiving engraved items can disrupt marketing campaigns or product launches. For instance, a company preparing for an upcoming trade show may find itself without the necessary branded leather goods due to unexpected shipping issues, leading to missed opportunities and potential revenue loss.

The Solution: To address lead time concerns, B2B buyers should communicate their timelines clearly to potential suppliers during the sourcing process. It’s essential to inquire about production and shipping times upfront, particularly if custom designs or bulk orders are involved. Establishing a buffer period in the project timeline can also account for unforeseen delays. Furthermore, partnering with suppliers who offer express shipping options or local production can help alleviate delivery issues. Buyers should also consider building a relationship with a reliable supplier who understands their business needs, as this can lead to prioritized service and faster turnaround times.

Scenario 3: Understanding Material Compatibility for Engraving

The Problem: B2B buyers may struggle with understanding which types of leather and finishes are best suited for engraving, leading to poor results. For example, using the wrong type of leather—such as bonded leather instead of full-grain—can result in inadequate engraving quality or durability. This lack of knowledge can result in wasted materials and financial losses if the products need to be redone or replaced.

The Solution: To ensure material compatibility, B2B buyers should educate themselves on the different types of leather and their properties. Engaging suppliers who can provide detailed insights into the engraving process for various leather types is crucial. Buyers should ask for guidance on selecting the best materials for their intended use, including any specific finishes that may affect the engraving quality. Additionally, conducting small test engravings on different leather types can provide valuable insights into the results before committing to larger orders. This hands-on approach not only minimizes risks but also enhances the overall quality of the final products.

Strategic Material Selection Guide for custom leather engraving

What Are the Key Properties of Different Leather Materials for Custom Engraving?

When selecting materials for custom leather engraving, understanding the properties of various leather types is crucial for B2B buyers. The choice of leather can significantly influence the end product’s quality, durability, and suitability for specific applications. Here, we analyze four common leather materials: full-grain leather, top-grain leather, corrected grain leather, and synthetic leather.

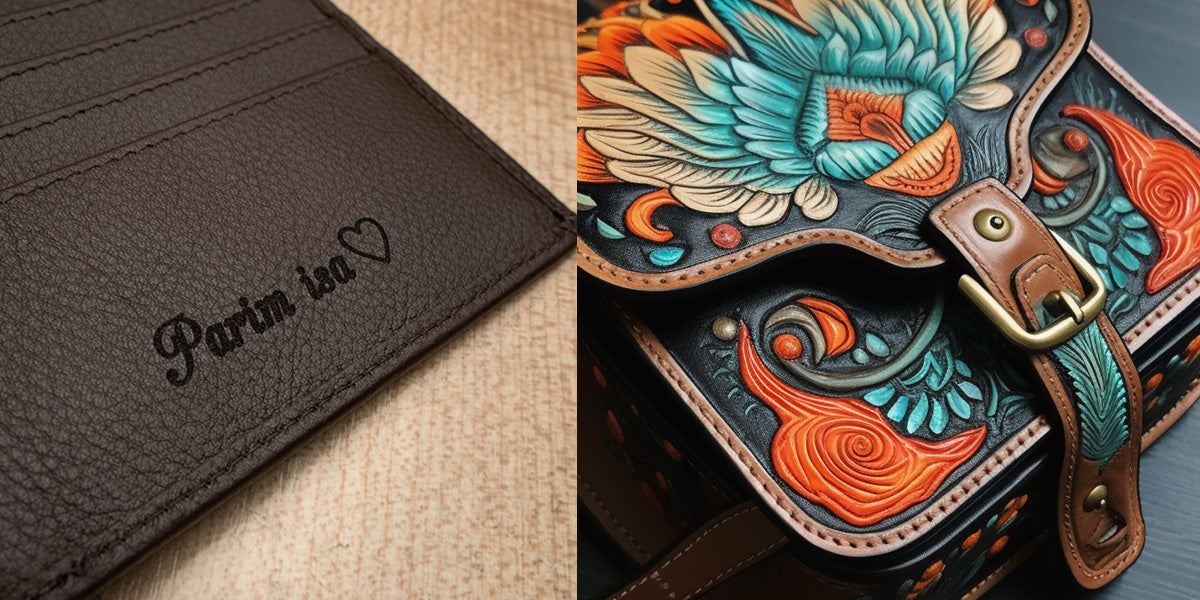

Illustrative image related to custom leather engraving

How Does Full-Grain Leather Perform in Custom Engraving?

Full-grain leather is the highest quality leather available, retaining the natural grain and imperfections of the hide. This material is highly durable and develops a rich patina over time, making it ideal for high-end products such as wallets, belts, and bags.

Pros: Full-grain leather offers excellent durability and longevity, making it suitable for products that require a premium feel. Its natural surface allows for deep and detailed engraving, enhancing the aesthetic appeal.

Cons: The higher cost of full-grain leather can be a barrier for some businesses. Additionally, it may require more careful handling during the engraving process to avoid damage.

Impact on Application: Full-grain leather is compatible with various engraving techniques and produces high-contrast results, especially with lighter shades.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local leather sourcing regulations and standards, as well as consider the environmental impact of sourcing full-grain leather.

What Advantages Does Top-Grain Leather Offer for Engraving?

Top-grain leather is the second-highest quality and is sanded and refinished to remove imperfections. This makes it slightly less durable than full-grain leather but still a popular choice for custom engraving.

Pros: Top-grain leather is more affordable than full-grain while still providing a luxurious appearance. It is also easier to work with during the engraving process due to its uniform surface.

Cons: While durable, top-grain leather may not develop the same rich patina as full-grain leather over time, which could affect its perceived value.

Impact on Application: This type of leather allows for clear and detailed engravings, making it suitable for a variety of products, including fashion accessories and corporate gifts.

Illustrative image related to custom leather engraving

Considerations for International Buyers: Buyers should verify the source of top-grain leather to ensure it meets international quality standards, such as ASTM or DIN, particularly in Europe and the Middle East.

How Does Corrected Grain Leather Compare for Custom Engraving?

Corrected grain leather, often referred to as “genuine leather,” is made from lower-quality hides that have been treated to mask imperfections.

Pros: This material is generally more affordable and widely available, making it a cost-effective option for businesses looking to produce large quantities of engraved products.

Cons: Corrected grain leather is less durable than full or top-grain leather and may not hold up as well over time. The engraving results may also be less striking due to the treated surface.

Impact on Application: While suitable for promotional items and lower-end products, the quality of the engraving may not meet the expectations of high-end customers.

Considerations for International Buyers: Buyers in emerging markets should be cautious about the quality of corrected grain leather and ensure it complies with local regulations regarding leather products.

What Are the Benefits and Limitations of Synthetic Leather for Engraving?

Synthetic leather, or faux leather, is made from various materials, including polyurethane (PU) and polyvinyl chloride (PVC).

Pros: Synthetic leather is often more affordable and easier to maintain than natural leather. It can also be produced in various colors and textures, allowing for creative designs.

Illustrative image related to custom leather engraving

Cons: The durability of synthetic leather can vary significantly, and some types may not be suitable for engraving due to the presence of harmful chemicals like PVC.

Impact on Application: While synthetic leather can be used for a wide range of products, its engraving quality may not match that of natural leather, particularly in terms of depth and contrast.

Considerations for International Buyers: Buyers should confirm that the synthetic leather is laser-safe and does not contain harmful materials, especially when sourcing from manufacturers in regions with less stringent regulations.

Summary Table of Material Selection for Custom Leather Engraving

| Material | Typical Use Case for custom leather engraving | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end wallets, belts, bags | Exceptional durability and aesthetics | Higher cost, careful handling required | High |

| Top-Grain Leather | Fashion accessories, corporate gifts | Luxurious appearance at a lower cost | Less durable than full-grain | Medium |

| Corrected Grain Leather | Promotional items, budget-friendly products | Cost-effective for bulk production | Less durable, lower engraving quality | Low |

| Synthetic Leather | Fashion items, upholstery | Affordable and versatile | Variable durability, potential harmful materials | Low to Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions when sourcing materials for custom leather engraving.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather engraving

What Are the Key Stages in the Manufacturing Process for Custom Leather Engraving?

The manufacturing process for custom leather engraving consists of several critical stages that ensure both the quality and the precision of the final product. Each stage is vital to achieving a high-quality engraved item that meets the specific needs of B2B buyers.

1. Material Preparation: Selecting the Right Leather

The first step involves selecting the appropriate type of leather for engraving. Buyers should consider various types, including full-grain, top-grain, corrected grain, and bonded leather, each offering different qualities and price points. The choice of leather affects the engraving outcome, as lighter colors provide better contrast than darker shades. Once selected, the leather must be prepped by cutting it to the desired dimensions and treating it, if necessary, to ensure it is suitable for engraving.

2. Engraving Techniques: Laser vs. Traditional Methods

Engraving can be accomplished through various techniques, with laser engraving being the most prevalent in modern manufacturing. Laser engraving allows for precise, intricate designs without the risk of damaging the leather. The process involves using a high-powered laser to etch designs onto the leather surface, producing a clean debossed effect. Traditional methods such as hand carving are less common in a B2B context due to their time-consuming nature and higher labor costs.

3. Finishing Touches: Quality and Aesthetic Enhancements

Once the engraving is complete, the leather item undergoes finishing processes. This may include edge sealing, dyeing, or applying protective coatings to enhance durability and appearance. These finishing touches are crucial, as they not only improve the aesthetic value of the product but also prolong its lifespan, which is an essential consideration for B2B buyers looking for high-quality items.

4. Assembly: Ensuring Structural Integrity

In cases where the leather item is part of a more complex product (like bags or wallets), assembly is the next step. This stage involves stitching or otherwise securing multiple leather pieces together. Quality stitching is vital, as it affects both the durability and the overall look of the finished product. B2B buyers should inquire about the stitching techniques used, as these can vary significantly in quality.

How is Quality Assurance Maintained Throughout the Manufacturing Process?

Quality assurance is critical in the custom leather engraving process, ensuring that products meet international standards and buyer specifications. Adhering to established quality standards is particularly important for international B2B transactions.

1. Understanding International Standards: ISO and Industry-Specific Regulations

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards demonstrates a commitment to quality and consistency. Additionally, specific industries may have additional certifications, such as CE marking for products sold in Europe or API standards for certain applications. B2B buyers should verify that their suppliers comply with relevant standards to ensure product quality.

2. Implementing Quality Control Checkpoints: IQC, IPQC, FQC

Quality control checkpoints are integral to the manufacturing process. These typically include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Monitoring the engraving process to catch any deviations in real-time. This may involve checking laser settings, material quality, and engraving depth.

- Final Quality Control (FQC): Conducting a thorough inspection of the finished product before it is shipped to the buyer. This includes checking for defects, ensuring the engraving matches the specifications, and verifying the overall quality of the assembly.

3. Common Testing Methods: Ensuring Durability and Aesthetic Quality

Various testing methods are employed to ensure the quality of engraved leather products. These may include:

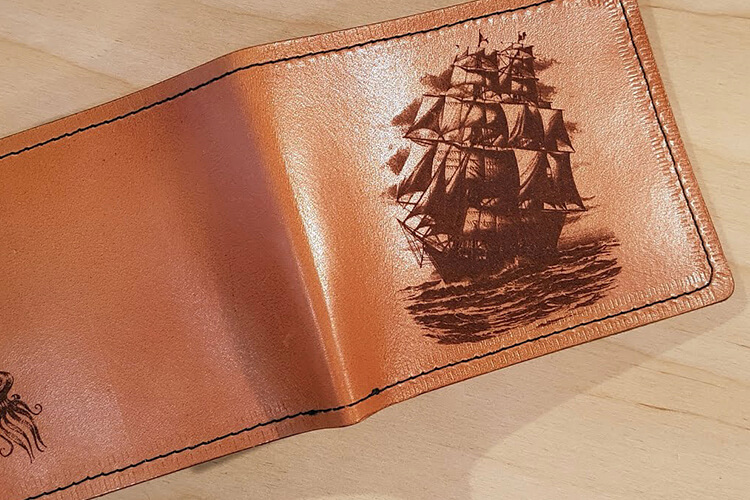

Illustrative image related to custom leather engraving

- Adhesion Tests: To ensure that any coatings or finishes applied to the leather are durable and will not peel or wear off.

- Color Fastness Tests: Evaluating how well the leather retains its color when exposed to various conditions, such as light or moisture.

- Durability Tests: Assessing how well the leather withstands wear and tear, which is crucial for items like bags and wallets.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to ensure that their suppliers maintain rigorous quality control practices. Here are several actionable strategies:

1. Conducting Audits: Assessing Supplier Facilities

One of the most effective ways to verify quality control is through supplier audits. Buyers can visit the manufacturing facility to observe processes, review quality control measures, and assess compliance with international standards. This hands-on approach provides valuable insights into the supplier’s commitment to quality.

2. Requesting Quality Assurance Reports: Documenting Compliance

Buyers should request quality assurance reports from their suppliers. These documents should detail the quality control processes, testing methods, and results from recent inspections. Suppliers should be transparent about their practices and willing to share relevant data.

Illustrative image related to custom leather engraving

3. Engaging Third-Party Inspections: Ensuring Objectivity

For added assurance, B2B buyers can engage third-party inspection services. These independent entities evaluate the manufacturing process and the final products to ensure compliance with specified standards. This can be particularly beneficial for international transactions, where buyers may not have direct access to supplier facilities.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several nuances when dealing with quality control in custom leather engraving:

- Cultural Differences: Understanding cultural attitudes towards quality and craftsmanship can influence supplier relationships. Buyers should communicate their quality expectations clearly and be open to discussions about local practices.

- Logistical Challenges: Shipping leather products internationally can introduce additional risks. Buyers should ensure that suppliers have robust packaging and handling procedures to minimize damage during transit.

- Regulatory Compliance: Different regions may have varying regulations regarding leather products. Buyers must ensure that their suppliers comply with all relevant local and international regulations to avoid legal issues and ensure product acceptance in their markets.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing custom leather engraving services, ensuring they receive high-quality products that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather engraving’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring custom leather engraving services. The engraving of leather products offers a unique opportunity for personalization and branding, making it an attractive option for various industries. By following this checklist, buyers can ensure they make informed decisions that align with their business needs and quality standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications for your engraving project. This includes the type of leather (e.g., full-grain, top-grain, or synthetic), dimensions of the items to be engraved, and the desired complexity of the designs. Providing these details upfront helps suppliers understand your requirements and offer accurate quotes.

- Material Considerations: Different leather types yield varying engraving results; ensure you specify which type you will be using.

- Design Complexity: Consider whether your design will require intricate details or larger, simpler engravings.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in custom leather engraving. Look for companies with established reputations and expertise in the industry.

- Online Reviews and Testimonials: Check platforms like Trustpilot or Google Reviews to gauge customer satisfaction.

- Portfolio of Work: Request samples or a portfolio to assess the quality of their previous projects.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers possess the necessary certifications and adhere to quality standards relevant to leather engraving. Certifications can indicate a supplier’s commitment to quality and sustainability practices.

- ISO Certifications: Look for ISO 9001 for quality management systems.

- Sustainability Standards: If important to your brand, check for eco-friendly practices and certifications.

Step 4: Request Samples

Before finalizing a supplier, request samples of their engraving work on similar leather products. This is crucial to ensuring that their engraving quality meets your expectations.

- Quality Assessment: Evaluate the clarity, detail, and finish of the samples.

- Material Compatibility: Ensure that the engraving technique used is compatible with the type of leather you intend to use.

Step 5: Discuss Pricing and Minimum Order Quantities

Engage in discussions regarding pricing structures and any minimum order quantities (MOQs) that may apply. Understanding these aspects upfront can help you budget accordingly and avoid unexpected costs.

Illustrative image related to custom leather engraving

- Bulk Discounts: Inquire about pricing tiers based on order volume.

- Additional Costs: Ask about potential extra charges for custom designs or expedited shipping.

Step 6: Clarify Lead Times and Shipping Options

Confirm the expected lead times for your orders and the shipping methods available. Timeliness is critical in B2B operations, especially when aligning with product launch schedules or marketing campaigns.

- Production Time: Understand how long it takes to complete your order after approval.

- Shipping Solutions: Discuss international shipping options and associated costs to ensure timely delivery.

Step 7: Establish Clear Communication Channels

Set up effective communication channels with your chosen supplier to facilitate smooth collaboration throughout the project. Regular updates and feedback loops can help address any issues promptly.

- Contact Methods: Confirm preferred contact methods (email, phone, messaging apps).

- Regular Check-Ins: Schedule regular updates to discuss progress and any adjustments needed.

By following this checklist, B2B buyers can streamline the sourcing process for custom leather engraving, ensuring they select the right suppliers and achieve high-quality results that enhance their product offerings.

Illustrative image related to custom leather engraving

Comprehensive Cost and Pricing Analysis for custom leather engraving Sourcing

What Are the Key Cost Components in Custom Leather Engraving?

Understanding the cost structure of custom leather engraving is crucial for B2B buyers looking to make informed sourcing decisions. The primary cost components include:

-

Materials: The type and quality of leather significantly influence pricing. Full-grain leather commands higher prices due to its durability and aesthetic appeal, while bonded leather is more affordable but offers less quality. Additionally, any special finishes or treatments can add to material costs.

-

Labor: Skilled labor is essential for precision engraving. The complexity of the design and the expertise of the engraver can vary labor costs. More intricate designs typically require more time and a higher skill level, leading to increased labor costs.

-

Manufacturing Overhead: This encompasses the costs of equipment, utilities, and facilities necessary for production. Laser engraving machines, for instance, represent a significant investment, impacting overall pricing. Maintenance and operational costs of these machines should also be factored in.

-

Tooling: Custom tooling for specific engraving designs can lead to additional costs. If a unique design requires special engraving tools, these will need to be factored into the overall price.

-

Quality Control (QC): Ensuring that each engraved item meets quality standards is vital. QC processes add to labor and operational costs but are necessary to maintain product quality, especially for B2B transactions where consistency is paramount.

-

Logistics: Shipping and handling costs can vary significantly based on the destination. International buyers should account for customs duties and tariffs when sourcing from overseas suppliers.

-

Margin: Suppliers will typically add a profit margin to their costs. Understanding the industry standard margins can help buyers gauge whether they are receiving fair pricing.

What Factors Influence Pricing for Custom Leather Engraving?

Several factors can influence the pricing of custom leather engraving, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to lower per-unit costs. Suppliers may offer significant discounts for larger orders, so negotiating MOQ can yield cost savings.

-

Specifications and Customization: Highly customized orders usually incur higher costs due to the additional labor and time required. Buyers should clearly define their specifications to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials with certifications (e.g., eco-friendly, ethically sourced) may come at a premium. Buyers should consider the long-term value of investing in quality materials versus lower-cost alternatives.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can all impact pricing. Established suppliers with a track record of quality may charge more but can offer reliability.

-

Incoterms: Understanding Incoterms is essential for international transactions. They dictate who is responsible for shipping costs, insurance, and risks during transit, which can significantly affect total costs.

What Tips Can Help B2B Buyers Optimize Their Sourcing for Custom Leather Engraving?

To achieve cost-efficiency and optimize sourcing strategies, buyers should consider the following tips:

-

Negotiation: Always negotiate pricing, especially for larger orders. Suppliers often have flexibility in their pricing models, particularly for bulk purchases.

-

Total Cost of Ownership (TCO): Evaluate the TCO instead of just the upfront cost. This includes assessing the durability of the product, potential maintenance costs, and any long-term value it may provide.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and local market conditions that can impact overall pricing.

-

Request Samples: Before committing to large orders, requesting samples can help assess quality and suitability, allowing buyers to make informed decisions without incurring significant costs upfront.

-

Consider Local Suppliers: If feasible, sourcing from local suppliers can reduce shipping costs and lead times, enhancing the overall supply chain efficiency.

Disclaimer

The prices and insights provided in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and obtain quotes tailored to your specific needs.

Alternatives Analysis: Comparing custom leather engraving With Other Solutions

Understanding Alternative Solutions to Custom Leather Engraving

In the realm of personalized leather products, custom leather engraving stands out as a popular choice for businesses seeking to create unique items. However, buyers should be aware of alternative methods that can also achieve similar results. This comparison will explore custom leather engraving against two viable alternatives: embossing and digital printing on leather. By understanding the strengths and weaknesses of each method, businesses can make informed decisions that align with their branding and operational needs.

Illustrative image related to custom leather engraving

Comparison Table

| Comparison Aspect | Custom Leather Engraving | Embossing | Digital Printing on Leather |

|---|---|---|---|

| Performance | High durability and contrast; precise designs | Creates a tactile effect; limited color options | Vibrant colors and intricate designs possible |

| Cost | Moderate; varies by complexity and volume | Generally lower than engraving; setup costs can add up | Higher initial costs for equipment; cost-effective for large runs |

| Ease of Implementation | Requires specialized equipment and expertise | Simpler setup; less training needed | Requires digital design expertise and printing technology |

| Maintenance | Low; occasional equipment upkeep needed | Low; simple machinery maintenance | Moderate; regular maintenance of printing equipment |

| Best Use Case | High-end personalized gifts, branding | Simple logos or patterns on products | Complex designs, large orders, promotional items |

Pros and Cons of Each Alternative

What Are the Advantages and Disadvantages of Embossing?

Embossing is a method that creates a raised design on leather, offering a tactile quality that can enhance the perceived value of products. One of the primary advantages of embossing is its cost-effectiveness, especially for simpler designs. It’s also relatively easy to implement, requiring less specialized equipment than laser engraving. However, embossing is limited in terms of color and detail; complex designs may not translate well, making it less suitable for high-end personalized items.

How Does Digital Printing on Leather Compare?

Digital printing on leather allows for vibrant, full-color images and intricate designs, making it an attractive option for businesses looking to create eye-catching products. This method can be particularly advantageous for promotional items or bulk orders where complex graphics are desired. However, the initial investment in high-quality printing equipment can be significant, and maintaining the machinery requires regular upkeep. Additionally, while digital prints can be durable, they may not offer the same level of longevity as engraved designs, particularly in high-wear applications.

Making the Right Choice for Your Business

When considering which solution is best for your business, it’s essential to evaluate your specific needs. Custom leather engraving excels in durability and precision, making it ideal for high-end products that require a personal touch. Embossing is suitable for simpler applications where cost and ease of implementation are priorities, while digital printing is best for vibrant, complex designs in larger quantities. By assessing your target market, budget, and desired product features, you can choose the method that aligns best with your business goals and enhances your product offerings.

Essential Technical Properties and Trade Terminology for custom leather engraving

What Are the Key Technical Properties of Custom Leather Engraving?

When engaging in custom leather engraving, understanding the technical specifications is critical for ensuring product quality and meeting client expectations. Here are the essential properties that should be considered:

1. Material Grade

Material grade refers to the quality of leather used for engraving. The four primary grades are full-grain, top-grain, corrected grain, and bonded leather. Full-grain leather is the highest quality, retaining the natural grain and durability, making it ideal for high-end products. Understanding material grade is crucial for B2B buyers as it directly impacts the engraving quality, product longevity, and overall customer satisfaction.

2. Thickness Tolerance

Thickness tolerance indicates the acceptable variation in the leather’s thickness, which can significantly affect the engraving process. Common thickness ranges for engraving are between 1/16” and 1/4”. Buyers must consider this specification to ensure compatibility with their engraving equipment and to achieve desired engraving results. Inconsistent thickness can lead to uneven engraving and affect product aesthetics.

Illustrative image related to custom leather engraving

3. Surface Finish

The surface finish of the leather can influence how well it accepts engraving. Leather types can vary from smooth to textured finishes, with each providing different contrast levels when engraved. For example, smooth finishes tend to exhibit clearer contrasts, while textured surfaces may yield more subtle effects. Selecting the right surface finish is vital for achieving the desired visual impact and enhancing the product’s appeal to end-users.

4. Laser Settings

Different leather types require specific laser settings, including speed, power, and frequency. These settings influence the depth and clarity of the engraving. For instance, higher power settings may be needed for denser leather types, while faster speeds can be used for thinner materials. Understanding how to adjust these settings is essential for producing high-quality engravings that meet client specifications.

5. Color Contrast

The color contrast between the engraved design and the leather itself is an important aesthetic factor. Light-colored leathers typically provide greater contrast, making engravings stand out more prominently. Conversely, darker leathers may offer a more subtle appearance. Buyers should be aware of how color contrast can affect product perception and branding efforts.

Illustrative image related to custom leather engraving

What Common Trade Terminology Should B2B Buyers Know in Custom Leather Engraving?

Familiarity with trade terminology can enhance communication and streamline transactions in the custom leather engraving industry. Here are several key terms to understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on the specifications provided by another company, often for branding purposes. In the leather engraving industry, buyers may work with OEMs to create customized leather goods that align with their brand identity.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to produce or sell. Understanding MOQ is essential for B2B buyers to manage inventory costs and ensure sufficient production runs. Negotiating favorable MOQs can also help businesses scale their engraving operations effectively.

Illustrative image related to custom leather engraving

3. RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers for specific products or services. Providing detailed specifications in an RFQ can help suppliers offer accurate pricing and terms, facilitating better decision-making for buyers.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international transactions to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers engaged in cross-border transactions to avoid misunderstandings and ensure compliance with international trade regulations.

5. Customization Options

This term refers to the various ways products can be tailored to meet specific client needs, including design, material, and size adjustments. Understanding customization options is vital for B2B buyers looking to differentiate their products in competitive markets.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, enhance product quality, and improve their competitive edge in the custom leather engraving industry.

Navigating Market Dynamics and Sourcing Trends in the custom leather engraving Sector

What Are the Key Trends Driving the Custom Leather Engraving Market?

The custom leather engraving sector is experiencing significant growth driven by various global factors. The rise of personalization in consumer goods is a primary catalyst, as businesses seek to differentiate their offerings in competitive markets. This trend is particularly pronounced in regions such as Africa and South America, where cultural significance is placed on customized products. Additionally, the increasing adoption of advanced engraving technologies, such as laser engraving, enhances efficiency and precision, making it easier for suppliers to meet diverse customer demands.

Illustrative image related to custom leather engraving

Emerging B2B tech trends also play a crucial role. The integration of e-commerce platforms allows international buyers to source custom leather products seamlessly from manufacturers across the globe. In regions like the Middle East and Europe, where luxury and personalization are highly valued, B2B buyers are increasingly turning to online platforms for bulk orders, creating a more streamlined supply chain. Moreover, advancements in digital design tools enable businesses to create intricate patterns and designs, further enhancing the appeal of custom leather items.

Market dynamics are shifting towards flexibility in order quantities, with suppliers offering no minimum order requirements. This is particularly beneficial for small and medium-sized enterprises (SMEs) looking to enter the market without significant upfront investment. As a result, international B2B buyers can capitalize on these trends by sourcing high-quality, customized leather products that cater to their specific needs, ensuring a competitive edge in their respective markets.

How Is Sustainability Influencing Sourcing in the Custom Leather Engraving Sector?

Sustainability and ethical sourcing are increasingly pivotal in the custom leather engraving sector, reflecting a growing awareness of environmental impacts among consumers and businesses alike. The leather industry has historically faced scrutiny over its environmental footprint, including water usage, chemical treatments, and waste management. Consequently, B2B buyers are prioritizing suppliers who adopt sustainable practices, such as using vegetable-tanned leather or sourcing hides from ethical farms that adhere to animal welfare standards.

Illustrative image related to custom leather engraving

The importance of ethical supply chains cannot be overstated. International buyers, particularly from regions like Europe, are demanding greater transparency in sourcing practices. This shift is pushing manufacturers to obtain certifications that demonstrate their commitment to sustainability, such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification. These certifications not only enhance the credibility of suppliers but also appeal to environmentally conscious consumers, ultimately driving sales.

In addition, the trend towards using eco-friendly materials is becoming more prevalent. Faux leather and other sustainable alternatives are gaining traction, providing buyers with options that minimize environmental impact without compromising on quality. By aligning their sourcing strategies with sustainability goals, B2B buyers can enhance their brand reputation, cater to a growing market segment, and contribute to a more responsible leather industry.

How Has the Custom Leather Engraving Sector Evolved Over Time?

The evolution of the custom leather engraving sector has been marked by significant technological advancements and shifting consumer preferences. Traditionally, leather engraving relied on manual techniques that were labor-intensive and limited in design complexity. However, the introduction of laser engraving technology revolutionized the industry, allowing for precise, intricate designs that can be replicated consistently across multiple items. This technological leap has enabled businesses to cater to a broader range of customer needs, from personalized gifts to corporate branding.

Moreover, the increasing demand for customized products has driven the growth of the sector. As consumers seek unique items that reflect their individuality, B2B buyers have recognized the potential of custom leather products in various applications, from fashion accessories to promotional items. This shift in consumer behavior has encouraged manufacturers to innovate continually, ensuring that the custom leather engraving sector remains dynamic and responsive to market trends.

Illustrative image related to custom leather engraving

In summary, the custom leather engraving market is positioned for continued growth, driven by personalization trends, technological advancements, and a strong focus on sustainability. By understanding these dynamics, international B2B buyers can make informed sourcing decisions that align with their business goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather engraving

-

How do I select the right type of leather for engraving?

Choosing the appropriate leather type is crucial for achieving the desired engraving results. Full-grain leather offers the highest quality and durability, making it ideal for premium products. Top-grain leather is also a strong choice but may have slight imperfections. Corrected grain (genuine leather) is budget-friendly and suitable for various applications, while bonded leather is less durable and should be used cautiously. Always consider the end-use of the product and desired aesthetic; testing samples can help ensure you achieve the best results. -

What are the typical minimum order quantities (MOQ) for custom leather engraving?

MOQs can vary significantly based on the supplier and the complexity of the engraving project. Many suppliers offer flexibility, allowing orders as small as one item for custom engraving. However, for wholesale pricing or bulk orders, a minimum order of 50-100 units is common. It’s essential to clarify MOQ details with your supplier during the initial discussions to ensure it aligns with your business needs. -

What customization options are available for leather engraving?

Customization options for leather engraving are extensive and can include logos, text, and intricate designs. Most suppliers allow clients to submit their artwork for approval before production begins. It’s advisable to provide high-resolution files in formats like .eps or .ai for the best results. Additionally, inquire about color options and potential additional features like embossing or debossing to enhance the final product. -

What payment terms should I expect when sourcing custom leather engraving?

Payment terms can vary by supplier and should be discussed upfront. Common practices include a deposit of 30-50% before production begins, with the balance due upon completion or before shipping. Some suppliers may offer net payment terms (e.g., net 30 days) for established clients. Always confirm the terms in writing to avoid misunderstandings and ensure a smooth transaction process. -

How can I ensure quality control for my custom leather engraving orders?

Implementing quality control measures is vital for maintaining product standards. Request samples of the engraving before placing a large order to assess the craftsmanship and materials used. Additionally, inquire about the supplier’s quality assurance processes, such as inspections during production and final checks before shipping. Establishing clear communication about your quality expectations will help align the supplier’s output with your standards. -

What shipping options are available for international orders of engraved leather products?

International shipping options typically include carriers like UPS, FedEx, and DHL. Most suppliers can provide express shipping for urgent orders, but this may incur higher costs. It’s important to clarify shipping times, costs, and tracking capabilities with your supplier. Additionally, understand any customs duties or import taxes that may apply in your country to avoid unexpected expenses. -

How do I vet suppliers for custom leather engraving?

Vetting suppliers is essential for ensuring reliability and quality. Start by reviewing their portfolio to assess the quality of their previous work. Look for client testimonials and ask for references to gauge their reputation. Additionally, check their certifications and compliance with international quality standards. Engaging in direct communication about your specific needs will help evaluate their responsiveness and willingness to collaborate. -

What are the advantages of using laser engraving for leather products?

Laser engraving offers numerous benefits for leather products, including precision, speed, and the ability to create intricate designs. The process results in a clean, debossed effect that enhances the product’s aesthetic appeal. Unlike traditional engraving methods, lasers can handle a variety of leather types without damaging the material. This technology also allows for consistent results across large orders, making it an excellent choice for businesses looking to personalize products efficiently.

Top 6 Custom Leather Engraving Manufacturers & Suppliers List

1. Custom Laser Design – Engraved Leather Products

Domain: customlaserdesign.com

Registered: 2006 (19 years)

Introduction: Custom laser-engraved leather products including:

– Family photos engraved on leather

– Rawhide leather photo engravings

– Name and musical notes on leather satchels

– Monogrammed leather briefcases

– Hand drawings on leather briefcases

– Logos laser engraved on various leather items (briefcases, satchels, guitar straps)

– Personalized leather journals and notebook holders

– Engraved text and imag…

2. Gravotech – LS100 & LS100EX Laser Engravers

Domain: gravotech.us

Registered: 2007 (18 years)

Introduction: Laser tables: LS100 – Small CO2 laser engraver, Marking area: 460 x 305 mm, Materials: Plastics, wood, glass, organic materials, painted surfaces, Applications: Personalization, creative, signage. LS100EX – Medium CO2 or Fiber laser engraver, Marking area: 610 x 305 mm, Materials: Plastics, wood, glass, organic materials, painted surfaces, metals, Applications: Personalization, signage, creative. …

3. Jubilee Trading Co – Custom Leather Engraving

Domain: jubileetradingco.com

Registered: 2019 (6 years)

Introduction: Custom Leather Engraving offers personalized engraving on leather items. Customers can provide names, initials, dates, or short messages for engraving. For logos or graphics, customers are instructed to type ‘Graphic’ and email the file. Products available include: Custom Juniper Valet Tray ($30), Custom Simple Juniper Valet Tray ($30), Custom Coaster Set of Four ($26), Custom Atlas Keychain Wrist…

4. Spinneybeck – Custom Laser Engraving

Domain: spinneybeck.com

Registered: 1996 (29 years)

Introduction: {‘name’: ‘Custom Laser Engraving’, ‘maximum_size’: ‘2’-3” x 4’-0” (61 x 121.9 cm)’, ‘edge_tolerance’: ‘Laser engrave to within 3 mm of edge of material’, ‘leather_types’: ‘AD, AL, AQ, AU, BL, CA, CO, CV, DE, DL, DT, ES, ET, FE, FT, HT, LU, PT, RA, RU, SA, SL, VO, VP, VZ’, ‘leather_colors’: ‘Refer to Color Book for available colors’, ’embellishment_option’: ‘Painted’, ‘primary_uses’: ‘Magnetic Back…

5. Yelp – Engraved Jewelry

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Engraved Jewelry, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Light Force – Custom Leather Bags

Domain: lightforcelaserengraving.com

Registered: 2022 (3 years)

Introduction: {“products”:[{“name”:”Custom Leather Crossbody Handbag with Personalized Engraving”,”price”:”$120.00 USD”},{“name”:”Custom Leather Toiletry Bag – Personalized Travel Gift for Men”,”price”:”$125.00 USD”},{“name”:”Hand-Crafted Rustic Satchel with Bronze Hardware (13\” W x 10.5\” H)”,”price”:”$175.00 USD”},{“name”:”Custom Leather Pint Glass Sleeve with Engraved Personalization”,”price”:”$42.00 USD”},…

Strategic Sourcing Conclusion and Outlook for custom leather engraving

In the rapidly evolving market for custom leather engraving, strategic sourcing emerges as a crucial factor for B2B buyers seeking to enhance their product offerings and competitive edge. By leveraging quality materials, such as full-grain and top-grain leather, businesses can deliver personalized products that resonate with customers, especially in regions like Africa, South America, the Middle East, and Europe. The choice of engraving technology, particularly laser engraving, allows for precision and consistency, enabling companies to produce a diverse range of high-value items—from fashion accessories to promotional products.

Furthermore, understanding the nuances of different leather types and their engraving characteristics can significantly impact product quality and customer satisfaction. As B2B buyers, it is essential to establish relationships with reliable suppliers who offer flexibility in order quantities and customization options, ensuring that your business can adapt to market demands swiftly.

Looking ahead, the potential for growth in the custom leather engraving sector is substantial. Companies that prioritize strategic sourcing and invest in innovative engraving technologies will not only meet evolving consumer preferences but will also position themselves as leaders in the market. Now is the time to explore partnerships that will elevate your product line and amplify your brand’s presence in this dynamic landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.