Introduction: Navigating the Global Market for custom leather biker jackets

The global market for custom leather biker jackets presents a unique challenge for B2B buyers seeking quality, style, and functionality. As international demand grows, particularly from regions like Africa, South America, the Middle East, and Europe, buyers often grapple with the complexities of sourcing the right products. This guide aims to demystify the process of procuring custom leather biker jackets, offering a comprehensive overview of types, applications, and supplier vetting strategies.

From understanding the various styles and materials available to evaluating the cost implications and quality assurance processes, this resource equips buyers with the essential knowledge needed to make informed purchasing decisions. We delve into the intricacies of customization options, ensuring that your selections not only meet the functional needs of your clients but also resonate with their personal styles and preferences.

Additionally, this guide addresses the logistical considerations of sourcing from international suppliers, including shipping, tariffs, and compliance with local regulations. By empowering B2B buyers with actionable insights and best practices, we aim to streamline the procurement process, helping you confidently navigate the vibrant landscape of custom leather biker jackets. Whether you are looking to enhance your product offerings or satisfy a growing customer base, this guide serves as your trusted companion in the global marketplace.

Table Of Contents

- Top 5 Custom Leather Biker Jackets Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather biker jackets

- Understanding custom leather biker jackets Types and Variations

- Key Industrial Applications of custom leather biker jackets

- 3 Common User Pain Points for ‘custom leather biker jackets’ & Their Solutions

- Strategic Material Selection Guide for custom leather biker jackets

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather biker jackets

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather biker jackets’

- Comprehensive Cost and Pricing Analysis for custom leather biker jackets Sourcing

- Alternatives Analysis: Comparing custom leather biker jackets With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather biker jackets

- Navigating Market Dynamics and Sourcing Trends in the custom leather biker jackets Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather biker jackets

- Strategic Sourcing Conclusion and Outlook for custom leather biker jackets

- Important Disclaimer & Terms of Use

Understanding custom leather biker jackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Biker Jacket | Typically features a front zipper, snap-down collar, and side pockets. Often made from thick cowhide leather. | Motorcycle clubs, general retail, and promotional events. | Pros: Timeless style; durable material. Cons: Limited customization options. |

| Race-Inspired Jacket | Aerodynamic design, often includes padding and armor for protection. Made for high-speed riding. | Racing teams, high-performance motorcycle shops. | Pros: Enhanced safety; performance-oriented. Cons: May be too specialized for casual riders. |

| Customizable Street Jacket | Offers various customization options like colors, liners, and fit adjustments. | Fashion retailers, bespoke leather shops. | Pros: Unique branding opportunity; tailored fit. Cons: Longer production time; potential higher costs. |

| Vintage Style Jacket | Distressed leather look, often with retro design elements like patches and embroidery. | Vintage clothing retailers, niche markets. | Pros: Appeals to retro enthusiasts; unique aesthetic. Cons: May lack modern protective features. |

| Women’s Biker Jacket | Designed specifically for women, featuring tailored fits and styles. Often includes additional details like embellishments. | Women’s fashion retailers, motorcycle gear shops. | Pros: Tailored for comfort; diverse styles. Cons: Market may be smaller; varying demand. |

What Are the Characteristics of Classic Biker Jackets?

Classic biker jackets are characterized by their robust construction and timeless design. Typically made from thick cowhide leather, they feature a front zipper, snap-down collar, and side pockets, making them both functional and stylish. B2B buyers should consider their appeal in motorcycle clubs and general retail environments, as they resonate well with consumers seeking durability and a classic aesthetic. However, customization options may be limited, which can be a drawback for brands looking to differentiate their offerings.

How Do Race-Inspired Jackets Enhance Rider Safety?

Race-inspired jackets are designed with performance in mind, featuring an aerodynamic shape and built-in padding or armor for added protection during high-speed rides. These jackets cater primarily to racing teams and high-performance motorcycle shops. Buyers in these sectors should note the importance of safety features, as they are critical for competitive riding. While these jackets provide enhanced safety, they may not appeal to casual riders due to their specialized nature and higher price points.

Why Choose Customizable Street Jackets for Fashion Retail?

Customizable street jackets stand out for their flexibility in design, allowing buyers to choose colors, liners, and fit adjustments. This adaptability makes them ideal for fashion retailers and bespoke leather shops that want to offer unique products. B2B buyers should consider the potential for branding and customer loyalty through personalized options. However, the production time can be longer, and costs may be higher than ready-made alternatives, which could impact inventory management.

What Makes Vintage Style Jackets Popular Among Niche Markets?

Vintage style jackets are crafted to evoke a sense of nostalgia with their distressed leather and retro design elements, such as patches and embroidery. They appeal to vintage clothing retailers and niche markets, particularly among consumers who appreciate unique aesthetics. B2B buyers should evaluate the potential for this style to attract retro enthusiasts. However, these jackets may lack modern protective features, which could limit their appeal to safety-conscious riders.

How Do Women’s Biker Jackets Cater to a Growing Market?

Women’s biker jackets are specifically tailored to fit female bodies, often incorporating additional details like embellishments for added style. They are popular among women’s fashion retailers and motorcycle gear shops. B2B buyers should recognize the growing demand for women’s motorcycle apparel, as it reflects a broader trend toward inclusivity in the riding community. However, the market for women’s gear may be smaller, so understanding regional demand and preferences is crucial for successful inventory planning.

Key Industrial Applications of custom leather biker jackets

| Industry/Sector | Specific Application of custom leather biker jackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Retail | Custom jackets for motorcycle enthusiasts and clubs | Enhances brand loyalty and customer satisfaction | Quality of leather, customization options, delivery timelines |

| Motorsports | Team jackets for racing teams and sponsors | Promotes brand visibility and team identity | Durability, comfort, and protective features |

| Fashion & Lifestyle | High-end fashion lines incorporating biker aesthetics | Appeals to niche markets and boosts sales | Style, material options, and craftsmanship |

| Tourism & Travel | Biker tours offering branded jackets to participants | Provides additional revenue stream and enhances customer experience | Sizing accuracy, customization, and shipping logistics |

| Corporate Gifting | Custom biker jackets as corporate gifts for clients and partners | Strengthens business relationships and brand recognition | Design flexibility, branding options, and bulk order discounts |

How Are Custom Leather Biker Jackets Used in the Motorcycle Retail Sector?

In the motorcycle retail sector, custom leather biker jackets are tailored for enthusiasts and motorcycle clubs, allowing for personalization that reflects individual style and club identity. Retailers can leverage these jackets to foster brand loyalty, as customers often seek unique, high-quality gear that represents their passion for riding. B2B buyers must consider leather quality, customization options, and delivery timelines to ensure that they meet their customers’ demands effectively.

What Role Do Custom Leather Biker Jackets Play in Motorsports?

In motorsports, custom leather biker jackets serve as team uniforms that enhance brand visibility and team identity. These jackets are often adorned with sponsor logos and team colors, making them essential for promotional activities during races. Buyers in this sector should prioritize durability and comfort, as these jackets must withstand high speeds and diverse weather conditions while ensuring that team members look cohesive and professional.

How Are Custom Leather Biker Jackets Integrated into Fashion & Lifestyle Brands?

Fashion and lifestyle brands increasingly incorporate custom leather biker jackets into their collections to attract niche markets that appreciate the rugged aesthetic. These jackets can be designed with unique embellishments and materials, appealing to customers who value both style and function. B2B buyers in this sector should focus on style, material options, and craftsmanship to create jackets that resonate with fashion-conscious consumers.

In What Ways Do Custom Leather Biker Jackets Enhance Tourism & Travel Experiences?

For tourism and travel companies, offering branded custom leather biker jackets to participants in biker tours can significantly enhance the customer experience. These jackets not only provide a sense of belonging but also serve as memorable souvenirs. Buyers should ensure sizing accuracy, customization options, and efficient shipping logistics to meet the demands of diverse international clientele, particularly in regions like Africa and South America where biking culture is growing.

How Can Custom Leather Biker Jackets Be Used for Corporate Gifting?

Custom leather biker jackets can be an excellent choice for corporate gifting, allowing businesses to strengthen relationships with clients and partners. These jackets can be personalized with company logos, making them a stylish and practical gift that promotes brand recognition. When sourcing for this application, businesses should consider design flexibility, branding options, and potential bulk order discounts to maximize value and impact.

3 Common User Pain Points for ‘custom leather biker jackets’ & Their Solutions

Scenario 1: Navigating Sizing Challenges for Custom Leather Biker Jackets

The Problem:

B2B buyers often face significant challenges when it comes to sizing custom leather biker jackets. Given that these jackets are typically tailored to individual specifications, buyers can struggle with inaccurate measurements that lead to poor fit. This issue is exacerbated when dealing with international shipments, where returns and exchanges can be costly and time-consuming. In some cases, suppliers may not provide comprehensive measurement guides, leaving buyers unsure about how to accurately size their orders. This can lead to frustration and financial loss if products need to be reordered or altered.

Illustrative image related to custom leather biker jackets

The Solution:

To mitigate sizing issues, B2B buyers should prioritize suppliers who offer detailed measurement guidelines and support. When sourcing custom leather biker jackets, look for manufacturers that provide a comprehensive size chart along with instructions on how to take accurate measurements. Additionally, consider partnering with suppliers that offer virtual fitting consultations or personalized assistance in measuring. This proactive approach ensures that the jackets fit as intended and minimizes the risk of returns. Implementing a fit guarantee policy can also enhance buyer confidence, allowing for alterations or remakes until the desired fit is achieved. By focusing on accurate sizing from the outset, buyers can streamline their procurement process and reduce costs associated with returns.

Scenario 2: Ensuring Quality and Durability in Custom Leather Biker Jackets

The Problem:

Quality assurance is a major concern for B2B buyers in the custom leather biker jacket market. With varying standards among manufacturers, buyers may encounter products that do not meet their expectations in terms of material durability and craftsmanship. Poor-quality jackets can lead to increased returns and dissatisfaction among end customers, damaging the buyer’s reputation and bottom line. In regions with harsh climates, the need for durable leather that can withstand wear and tear becomes even more critical.

The Solution:

To ensure quality and durability, buyers should conduct thorough research on potential suppliers before making a purchase. Look for manufacturers that provide transparency regarding their materials, such as the type of leather used and the stitching techniques employed. Request samples to evaluate the quality firsthand and ask for references from other B2B clients who have successfully sourced from them. Additionally, consider suppliers that offer warranties or guarantees on their products, as this demonstrates confidence in their craftsmanship. Establishing long-term relationships with reputable manufacturers can also ensure consistent quality and reliability in future orders.

Scenario 3: Managing Customization Options for Diverse Market Needs

The Problem:

B2B buyers catering to diverse customer bases often find it challenging to manage the wide array of customization options available for leather biker jackets. Clients may have specific requests regarding colors, styles, and features, making it difficult for buyers to fulfill orders that meet all specifications. This complexity can lead to confusion during the ordering process, increased lead times, and potential customer dissatisfaction if expectations are not met.

The Solution:

To effectively manage customization requests, buyers should implement a streamlined process for collecting and confirming client specifications. Utilize digital tools or platforms that allow clients to visualize their customizations, such as color swatches and style templates. This can minimize misunderstandings and ensure that clients have a clear understanding of what to expect. Establish a feedback loop with suppliers to clarify any ambiguous requests and confirm details before production begins. Additionally, consider offering a limited range of popular customization options to simplify the ordering process while still catering to diverse tastes. This strategic approach can enhance efficiency and improve customer satisfaction, leading to repeat business and positive referrals.

Strategic Material Selection Guide for custom leather biker jackets

When selecting materials for custom leather biker jackets, it is essential to consider not only the performance characteristics of the materials but also the specific needs and preferences of international buyers. This guide analyzes four common materials used in the production of custom leather biker jackets, focusing on their properties, advantages, disadvantages, and relevant considerations for B2B buyers from diverse regions.

What are the Key Properties of Cowhide Leather for Custom Biker Jackets?

Cowhide leather is one of the most popular materials for biker jackets due to its durability and resistance to wear and tear. With a thickness typically ranging from 1.2 to 1.4 mm, cowhide offers excellent abrasion resistance, making it suitable for high-speed riding conditions. It also provides good insulation against cold weather, ensuring comfort during rides in various climates.

Pros: Cowhide is known for its strength and longevity, making it a cost-effective choice over time. It can withstand significant pressure and is relatively easy to maintain.

Cons: On the downside, cowhide can be heavier than other leather types, which may affect comfort for some riders. Additionally, it can be more expensive than synthetic alternatives.

Impact on Application: Cowhide leather is compatible with various protective features, such as armor and padding, enhancing safety for riders.

Considerations for International Buyers: Buyers should ensure that the cowhide used complies with international standards such as ASTM for leather quality. Additionally, preferences for texture and finish may vary by region, so understanding local market trends is crucial.

How Does Goat Leather Compare as a Material for Biker Jackets?

Goat leather is another viable option for custom biker jackets, known for its lightweight and supple characteristics. It typically has a thickness of around 1.0 to 1.2 mm, providing a balance between flexibility and protection.

Pros: The lightweight nature of goat leather allows for greater comfort and ease of movement, making it ideal for long rides. It also has a natural sheen that many consumers find appealing.

Cons: Goat leather may not be as durable as cowhide, especially in extreme conditions. It can also be more susceptible to scratches and abrasions.

Impact on Application: Goat leather is suitable for jackets designed for urban riding, where style and comfort are prioritized over extreme protective features.

Considerations for International Buyers: Buyers from regions with humid climates, such as parts of South America, may prefer goat leather due to its breathability. However, they should also consider the need for additional protective features to compensate for its lower durability.

What are the Benefits of Using Synthetic Leather in Custom Biker Jackets?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is becoming increasingly popular in the biker jacket market. It offers a range of benefits that appeal to environmentally conscious consumers.

Illustrative image related to custom leather biker jackets

Pros: Synthetic leather is generally more affordable than genuine leather and is available in a variety of colors and finishes. It is also easier to clean and maintain.

Cons: However, synthetic leather may not provide the same level of durability or protection as natural leathers. It can also be less breathable, which may lead to discomfort in warmer climates.

Impact on Application: Synthetic leather is suitable for fashion-forward designs and can be easily integrated with various styling elements, making it popular among younger riders.

Considerations for International Buyers: Buyers should be aware of the environmental regulations regarding synthetic materials in their regions. Compliance with standards such as REACH in Europe may be necessary.

How Does Sheepskin Leather Perform in Custom Biker Jackets?

Sheepskin leather is known for its softness and comfort, making it an attractive option for custom biker jackets. Typically, sheepskin is thinner than cowhide, ranging from 0.8 to 1.0 mm in thickness.

Pros: The primary advantage of sheepskin is its lightweight and soft texture, which provides excellent comfort for everyday wear. It is also relatively warm, making it suitable for cooler climates.

Cons: However, sheepskin is less durable than cowhide and may not withstand harsh riding conditions as effectively. It is also more prone to wear and tear.

Impact on Application: Sheepskin is often used in jackets designed for casual riding or urban use, where style and comfort are prioritized over extreme protection.

Considerations for International Buyers: Buyers should consider the climate of their region when selecting sheepskin. In hotter climates, the breathability of sheepskin may be a plus, but its lack of durability could be a concern for long-distance riders.

Summary Table of Material Selection for Custom Leather Biker Jackets

| Material | Typical Use Case for custom leather biker jackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide Leather | Long-distance riding and rugged use | Excellent durability and abrasion resistance | Heavier and more expensive | High |

| Goat Leather | Urban riding and casual wear | Lightweight and comfortable | Less durable than cowhide | Medium |

| Synthetic Leather | Fashion-forward designs and affordable options | Cost-effective and easy to maintain | Less durable and breathable | Low |

| Sheepskin Leather | Casual riding and everyday wear | Soft and comfortable | Lower durability and wear resistance | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to source custom leather biker jackets. Understanding the properties, advantages, and limitations of each material will enable buyers to make informed decisions that align with their market demands and customer preferences.

Illustrative image related to custom leather biker jackets

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather biker jackets

What Are the Key Stages in the Manufacturing Process of Custom Leather Biker Jackets?

The manufacturing process for custom leather biker jackets typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring that the final product meets the desired specifications for quality, durability, and aesthetics.

Material Preparation: How Is Leather Selected and Processed?

The first step in the manufacturing process is selecting the right type of leather. High-quality full-grain leather is often preferred due to its durability and ability to age beautifully. Suppliers typically source leather from reputable tanneries that adhere to environmental and ethical standards. Once the leather is selected, it undergoes a series of treatments to enhance its properties, such as water resistance and color fastness.

During this stage, manufacturers also prepare additional materials that may be needed, such as linings, zippers, and protective armor. This preparation includes cutting materials into specific patterns and sizes, ensuring that they align with the design specifications provided by the client.

Forming: What Techniques Are Used to Shape the Jacket?

Forming involves the shaping of the leather into the desired jacket design. This stage often employs techniques such as cutting, stitching, and molding. Advanced cutting methods, such as die-cutting, ensure precision and reduce material waste.

Illustrative image related to custom leather biker jackets

Stitching is a critical technique that not only contributes to the aesthetic appeal of the jacket but also affects its durability. Double or triple stitching is commonly employed in high-stress areas to prevent seams from splitting. For custom designs, manufacturers may use specialized stitching techniques to create unique patterns or features.

Assembly: How Are Components Put Together?

During the assembly stage, all components of the jacket are brought together. This includes attaching sleeves, collars, and any additional features such as pockets or armor. Quality assurance checkpoints are integrated throughout this process. For instance, inline inspections may be conducted to verify that components are assembled correctly and meet the design specifications.

Manufacturers may use automated machinery for specific tasks, such as applying zippers or installing armor, but skilled artisans often handle more intricate details to ensure a high level of craftsmanship.

Finishing: What Processes Enhance the Final Product?

Finishing is the final stage in the manufacturing process, where the jacket undergoes several treatments to enhance its appearance and performance. This may include dyeing, polishing, and applying protective coatings.

Illustrative image related to custom leather biker jackets

At this stage, quality control inspectors examine the jackets for any defects, ensuring that they meet both aesthetic and functional standards. Common finishing techniques include edge finishing and adding embellishments such as patches or logos.

How Is Quality Assurance Implemented in Custom Leather Jacket Manufacturing?

Quality assurance (QA) is a critical component in the manufacturing of custom leather biker jackets. It ensures that the products meet international standards and industry-specific requirements, which is particularly important for B2B buyers.

What International Standards Should B2B Buyers Be Aware Of?

Manufacturers often adhere to international quality management standards, such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that the manufacturer has effective processes in place to ensure product quality.

Additionally, industry-specific certifications may apply, such as CE marking for products sold within the European Economic Area, which ensures compliance with safety standards. For protective gear, certifications from organizations such as the American National Standards Institute (ANSI) or the European Committee for Standardization (CEN) may also be relevant.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This occurs when raw materials, such as leather and zippers, are received. Inspectors verify that materials meet quality standards before production begins.

-

In-Process Quality Control (IPQC): Throughout the assembly process, inspectors perform inline checks to ensure that the manufacturing processes are being followed correctly. This may involve measuring dimensions and inspecting stitching quality.

-

Final Quality Control (FQC): Once the jackets are completed, a final inspection is conducted. This includes checking for defects in craftsmanship, fit, and functionality.

What Common Testing Methods Are Used to Ensure Quality?

Manufacturers utilize various testing methods to ensure the quality and durability of their products. Common tests include:

-

Tensile Strength Testing: Measures the leather’s resistance to tearing and stretching.

-

Water Resistance Testing: Assesses the material’s ability to repel water, which is crucial for biker jackets.

-

Color Fastness Testing: Evaluates how well the color holds up against washing and exposure to light.

These tests help manufacturers identify potential issues before products reach the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of potential suppliers.

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality assurance reports and certifications from suppliers. These documents should outline the supplier’s adherence to international standards and any relevant industry-specific certifications.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a manufacturer’s quality control processes. These inspections can occur at various stages of production and provide buyers with confidence that the products meet their specifications.

Illustrative image related to custom leather biker jackets

What Are the Specific Quality Control Nuances for International B2B Buyers?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, it’s essential to consider regional standards and regulations that may affect product compliance. Understanding these nuances can help buyers avoid costly delays or rejections at customs.

How Can Buyers Navigate Customs Regulations?

Buyers should familiarize themselves with the customs regulations specific to their country, including any applicable duties and taxes for imported goods. Collaborating with experienced import/export professionals can streamline the process and ensure compliance with local laws.

By understanding the manufacturing processes and quality assurance measures in place for custom leather biker jackets, B2B buyers can make informed decisions when selecting suppliers, ultimately ensuring that they receive high-quality, durable products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather biker jackets’

This guide serves as a practical checklist for B2B buyers looking to procure custom leather biker jackets. It provides a systematic approach to ensure that you find the right supplier and product that meets your specific needs while maintaining high quality and compliance with industry standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in the sourcing process. This includes the type of leather, thickness, and any specific features you want, such as armor protection or custom sizing. By having a precise list of requirements, you can communicate effectively with potential suppliers and ensure they understand your needs.

Illustrative image related to custom leather biker jackets

Step 2: Conduct Market Research

Before reaching out to suppliers, it’s essential to conduct thorough market research. Investigate current trends in custom leather biker jackets, including popular styles, colors, and materials. Understanding the market landscape will help you identify potential suppliers who specialize in the styles and features you are interested in.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers to ensure they can meet your quality and delivery requirements. Request company profiles, product samples, and case studies of past projects. This step is crucial for assessing the supplier’s reliability and understanding their production capabilities.

- Look for certifications: Ensure that the supplier complies with industry standards, such as ISO certifications or environmental regulations.

- Check references: Ask for testimonials from other B2B clients, especially those in your region or industry.

Step 4: Assess Customization Options

Customization is a key selling point for leather biker jackets, so it’s vital to understand what options are available. Discuss the range of customization available, including color choices, style variations, and additional features such as lining materials or logos. This will help you gauge how well the supplier can meet your specific requirements.

Step 5: Review Pricing and Payment Terms

Pricing transparency is critical in B2B transactions. Request detailed pricing information that breaks down costs for materials, labor, and any additional fees for customization. Additionally, clarify payment terms and conditions to avoid any misunderstandings later on.

- Negotiate bulk pricing: If you’re ordering in large quantities, don’t hesitate to discuss discounts or payment plans that can benefit both parties.

Step 6: Understand Shipping and Delivery Times

Confirm shipping methods and estimated delivery times with your chosen supplier. This information is crucial for planning inventory and meeting customer demand. Ensure that the supplier can provide reliable shipping options and understand any potential customs duties that may apply, especially for international orders.

Step 7: Establish a Quality Assurance Process

Finally, set up a quality assurance process to ensure the delivered products meet your specifications. Discuss inspection methods and procedures with the supplier before production begins. A proactive approach to quality control will help prevent issues and ensure that the final products align with your expectations.

By following this checklist, B2B buyers can streamline their procurement process for custom leather biker jackets, ensuring they select the right suppliers and receive high-quality products tailored to their needs.

Comprehensive Cost and Pricing Analysis for custom leather biker jackets Sourcing

What Are the Key Cost Components for Custom Leather Biker Jackets?

When sourcing custom leather biker jackets, understanding the cost structure is crucial for effective budgeting and pricing strategy. The primary cost components include:

-

Materials: The choice of leather (e.g., full grain, top grain) significantly impacts costs. High-quality leather not only enhances durability but also raises the price. Additional materials such as zippers, linings, and armor can also add to the overall cost.

-

Labor: Skilled craftsmanship is essential in producing high-quality jackets. Labor costs vary depending on the region; for instance, labor in countries with a lower cost of living may yield savings, but quality should never be compromised.

-

Manufacturing Overhead: This includes factory utilities, equipment maintenance, and administrative costs. Efficient production processes can help minimize overhead, thereby reducing the final price.

-

Tooling: Initial setup costs for custom designs can be significant. Custom patterns and molds require investment, which is often amortized over larger production runs.

-

Quality Control (QC): Rigorous quality checks ensure that the finished products meet specified standards. This process is vital, particularly for international buyers who require compliance with specific regulations.

-

Logistics: Shipping costs vary widely based on destination, mode of transport, and Incoterms agreed upon. Efficient logistics can significantly affect the total cost.

-

Margin: Suppliers typically mark up costs to maintain profitability. Understanding the supplier’s margin can help in negotiations.

How Do Price Influencers Affect Custom Leather Biker Jacket Costs?

Several factors influence the pricing of custom leather biker jackets:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk discounts. Buyers should assess their needs to maximize cost efficiency.

-

Specifications and Customization: The degree of customization (e.g., bespoke designs, unique colors) can lead to increased costs. Clearly defining specifications can help avoid unexpected expenses.

-

Materials and Quality Certifications: Jackets that use premium materials or come with quality certifications (such as CE marking for safety) will typically command higher prices.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record and quality assurance processes.

-

Incoterms: The agreed terms of shipping (e.g., FOB, CIF) can impact logistics costs and risk allocation. Understanding these terms is essential for budgeting.

What Are Effective Buyer Tips for Negotiating Custom Leather Biker Jacket Prices?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

Illustrative image related to custom leather biker jackets

-

Negotiate Prices and Terms: Establishing a good relationship with suppliers can facilitate negotiations on pricing and payment terms. Don’t hesitate to ask for discounts or flexible terms, especially for larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with the product, including maintenance, shipping, and potential tariffs. This holistic view can reveal the best overall value.

-

Understand Pricing Nuances for International Transactions: Be aware of fluctuating exchange rates, import duties, and local regulations that may affect total costs. It’s advisable to engage with local experts or consultants to navigate these complexities.

-

Request Samples: Before placing a large order, request samples to assess quality. This can prevent costly mistakes and ensure the product meets your expectations.

-

Explore Multiple Suppliers: Don’t settle for the first supplier. Comparing multiple quotes can provide leverage in negotiations and may lead to better pricing.

Disclaimer on Indicative Prices

Pricing for custom leather biker jackets can vary widely based on the aforementioned factors and market conditions. It is advisable for buyers to obtain detailed quotes from multiple suppliers to ensure a comprehensive understanding of costs involved. This will facilitate informed decision-making and optimal sourcing strategies.

Alternatives Analysis: Comparing custom leather biker jackets With Other Solutions

Understanding Alternatives to Custom Leather Biker Jackets

When considering custom leather biker jackets, it’s essential to evaluate viable alternatives that can fulfill similar functions, whether in terms of style, protection, or comfort. Buyers must assess various options to make informed decisions that align with their specific needs, budget constraints, and market demands. The following analysis compares custom leather biker jackets with other potential solutions.

Comparison Table

| Comparison Aspect | Custom Leather Biker Jackets | Textile Motorcycle Jackets | Synthetic Leather Jackets |

|---|---|---|---|

| Performance | High durability and protection; personalized fit with armor options | Good breathability; often lighter weight | Moderate durability; less protective than leather |

| Cost | Typically higher due to customization (e.g., $400-$800) | Generally more affordable (e.g., $200-$400) | Competitive pricing (e.g., $150-$300) |

| Ease of Implementation | Requires specific measurements; longer production time (6-8 weeks) | Readily available in stores; quick purchase | Easy to find; often off-the-shelf |

| Maintenance | Requires specific care for leather; may need conditioning | Easy to clean; machine washable | Generally low maintenance; easy to wipe down |

| Best Use Case | Ideal for serious riders seeking style and protection | Suitable for casual riders and warmer climates | Good for budget-conscious buyers or casual use |

Detailed Breakdown of Alternatives

Textile Motorcycle Jackets

Textile jackets are crafted from various synthetic materials designed for breathability and comfort, especially in warmer climates. They often come with CE-approved armor for protection, making them a good choice for casual riders. However, while they offer a lighter weight and more options for color and style, they typically do not provide the same level of durability or weather resistance as leather. Consequently, they may not be suitable for long-distance riders or those who frequently encounter harsh weather conditions.

Synthetic Leather Jackets

Synthetic leather jackets present a cost-effective alternative for those who appreciate the aesthetics of leather but are budget-conscious. These jackets mimic the look and feel of genuine leather while being easier to maintain. However, they often lack the durability and protective qualities inherent in real leather, making them less ideal for serious motorcyclists. They may also not provide the same level of comfort over long rides, especially in varying weather conditions.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, the choice between custom leather biker jackets and their alternatives hinges on specific requirements such as budget, intended use, and desired performance. Custom leather jackets excel in durability and personalization, making them the preferred option for serious riders who prioritize protection and style. In contrast, textile and synthetic leather jackets offer affordability and convenience, appealing to casual riders or those in warmer climates. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to select the most appropriate solution for their clientele and market demands.

Essential Technical Properties and Trade Terminology for custom leather biker jackets

What Are the Key Technical Properties of Custom Leather Biker Jackets?

When sourcing custom leather biker jackets, understanding the technical specifications is crucial for ensuring product quality and meeting market demands. Here are several critical properties to consider:

-

Material Grade

The grade of leather used in biker jackets significantly affects durability, comfort, and appearance. Common grades include full-grain, top-grain, and corrected-grain leather. Full-grain leather, made from the top layer of the hide, offers the highest durability and breathability, making it ideal for high-performance jackets. B2B buyers should prioritize suppliers that provide clear details on material grading to ensure they meet their customers’ expectations. -

Thickness

The thickness of the leather, typically measured in millimeters, is a vital specification. A thickness of 1.2 to 1.4 mm is standard for motorcycle jackets, offering a balance between protection and flexibility. Thicker leather provides better abrasion resistance but can compromise comfort and mobility. Understanding the optimal thickness for specific market segments (e.g., touring vs. sport) helps buyers make informed purchasing decisions. -

Stitching and Seam Construction

The stitching technique and seam construction contribute significantly to the jacket’s durability. Double or triple stitching is recommended for high-stress areas, such as shoulders and cuffs, to prevent tearing. This is particularly important for jackets intended for high-performance use. B2B buyers should inquire about the stitching standards used by manufacturers to ensure quality assurance. -

Armor and Protective Features

Many custom leather biker jackets incorporate CE-approved armor for additional protection, particularly at the shoulders, elbows, and back. Buyers should evaluate the type and placement of armor, as well as options for upgrading to higher levels of protection (e.g., titanium armor). Providing detailed specifications on protective features can enhance the perceived value of the product in competitive markets. -

Lining and Comfort Features

The lining material (e.g., mesh, satin) impacts breathability and comfort. Features such as adjustable cuffs, stretch panels, and pre-curved sleeves enhance the fit and riding experience. Buyers should consider the intended use of the jackets when selecting lining materials and comfort features to cater to specific customer needs. -

Water Resistance and Care Instructions

Water resistance is an important property for motorcycle jackets, especially in regions with varying weather conditions. Buyers should ensure that the leather is treated to repel water and that care instructions are clear to end-users. This not only extends the product’s lifespan but also enhances customer satisfaction.

What Are Common Trade Terms in the Custom Leather Biker Jacket Industry?

Understanding industry jargon can streamline communication and negotiations between buyers and suppliers. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of custom leather biker jackets, it indicates that a supplier can create jackets based on the buyer’s specifications or branding. This term is essential for buyers seeking exclusive designs or private labeling. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory levels and production costs effectively. Suppliers often set MOQs based on production efficiency, and negotiating this can impact overall pricing. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. This process is critical for determining pricing, lead times, and other terms of sale. Buyers should provide detailed specifications in their RFQ to receive accurate and competitive quotes. -

Incoterms

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping, insurance, and freight costs. Familiarity with Incoterms helps buyers mitigate risks related to logistics and customs. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. This is particularly important in the custom apparel industry, where design and production can vary significantly. Understanding lead times helps buyers plan their inventory and marketing strategies effectively. -

Customization Options

This term encompasses the various choices available to buyers when designing jackets, including color, size, material, and additional features. Clear communication about customization options allows buyers to tailor products to their target markets, enhancing customer satisfaction and brand loyalty.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing custom leather biker jackets, ensuring they meet market demands while maintaining high standards of quality and service.

Illustrative image related to custom leather biker jackets

Navigating Market Dynamics and Sourcing Trends in the custom leather biker jackets Sector

What Are the Key Market Trends Influencing Custom Leather Biker Jackets?

The global custom leather biker jackets market is witnessing a transformative phase driven by several key factors. Firstly, the rise in motorcycle culture and the increasing popularity of leisure biking, particularly in regions like Africa and South America, is expanding the customer base. In Europe and the Middle East, the trend leans towards high-performance and stylish protective gear, prompting manufacturers to innovate continuously. Moreover, the emergence of e-commerce platforms is reshaping how buyers source these products, allowing for a wider variety of customization options and enhanced customer engagement.

Emerging technologies such as 3D design tools are enabling manufacturers to offer personalized products at scale. This trend is particularly appealing to B2B buyers who seek to differentiate their offerings in competitive markets. Blockchain technology is also beginning to play a role in supply chain transparency, allowing buyers to verify the authenticity of materials used in their custom leather jackets. Such innovations are essential for businesses looking to align with modern consumer expectations for quality and transparency.

In addition, demographic shifts, especially among younger consumers who prioritize unique and individualized products, are influencing market dynamics. The increasing demand for custom leather biker jackets that resonate with personal identity and lifestyle is leading to a surge in bespoke services offered by manufacturers.

How Does Sustainability and Ethical Sourcing Impact the Custom Leather Biker Jackets Industry?

Sustainability is becoming a pivotal consideration in the sourcing of custom leather biker jackets. With growing awareness about the environmental impact of leather production, B2B buyers are increasingly looking for suppliers who prioritize ethical sourcing and sustainable practices. The leather industry is often scrutinized for its carbon footprint and resource-intensive processes, prompting manufacturers to adopt more eco-friendly practices.

Illustrative image related to custom leather biker jackets

Investing in sustainable materials, such as vegetable-tanned leather or leather sourced from certified tanneries, is gaining traction. B2B buyers are encouraged to seek suppliers who possess recognized certifications, such as the Leather Working Group (LWG) certification, which indicates adherence to environmental and social standards. This not only enhances the brand’s reputation but also aligns with the values of increasingly conscious consumers.

Furthermore, the demand for traceability in supply chains is leading manufacturers to implement more transparent practices. By ensuring that their leather is sourced from ethical suppliers, businesses can mitigate risks associated with labor practices and environmental degradation. As a result, B2B buyers can foster strong partnerships with suppliers committed to sustainability, ultimately enhancing their market positioning.

What Is the Historical Context of Custom Leather Biker Jackets in the B2B Market?

The custom leather biker jacket has a rich history that dates back to the early 20th century, evolving from functional wear for motorcyclists to a fashion statement. Initially designed for protection, these jackets became symbols of rebellion and freedom, largely influenced by motorcycle culture and popular media. Over the decades, the demand for customization grew, reflecting individual styles and preferences.

In recent years, this evolution has taken a more pronounced turn towards bespoke services, driven by technological advancements and changing consumer behaviors. The ability to customize jackets with unique designs, colors, and features has transformed the landscape of B2B sourcing in this sector. Buyers are now more inclined to seek manufacturers who can offer tailored solutions, blending functionality with personal expression. This historical context serves as a foundation for understanding the current dynamics and emerging trends within the custom leather biker jackets market.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather biker jackets

-

How do I ensure the quality of custom leather biker jackets from suppliers?

To ensure quality, start by vetting suppliers through reviews and testimonials from previous clients. Request samples of their leather and craftsmanship to assess quality firsthand. Establish clear quality assurance standards, including material specifications and finish, and consider including a third-party inspection service to verify compliance before shipment. Additionally, look for suppliers who offer guarantees or warranties on their products, as this reflects their confidence in the quality of their work. -

What are the typical lead times for custom leather biker jackets?

Lead times for custom leather biker jackets can vary significantly based on the supplier and the complexity of the order. Generally, expect production to take between 4 to 12 weeks, depending on customization levels and order volume. It’s advisable to discuss timelines upfront and factor in additional time for shipping, especially for international orders. For urgent needs, inquire if the supplier offers expedited options for an additional fee. -

What is the minimum order quantity (MOQ) for custom leather biker jackets?

MOQs for custom leather biker jackets typically range from 10 to 50 units, depending on the supplier’s policies and production capabilities. Lower MOQs may be available for certain designs or when using standard materials. Always confirm the MOQ with your supplier before placing an order, as it can affect pricing and production timelines. Negotiating terms may also be possible, especially for repeat orders or larger contracts. -

What customization options are available for leather biker jackets?

Customization options can include material type, color, lining, armor integration, and design features like zippers and pockets. Many suppliers allow clients to submit their designs or select from a catalog of styles. Ensure that you provide detailed specifications to avoid miscommunication. Some manufacturers also offer personalized branding options, such as adding logos or custom lettering, so be sure to discuss these possibilities during the design phase. -

How should I approach payment terms with international suppliers?

When dealing with international suppliers, it’s crucial to clarify payment terms upfront. Common practices include a deposit (typically 30-50%) at the time of order, with the balance due upon completion or before shipping. Consider using secure payment methods like letters of credit or escrow services to protect your investment. Additionally, be aware of currency exchange rates and potential transaction fees, which can impact overall costs. -

What logistics should I consider for shipping custom leather jackets internationally?

When shipping internationally, factor in customs duties, taxes, and shipping costs, which can vary by country. Discuss logistics options with your supplier, including preferred carriers and delivery timelines. It’s beneficial to work with a logistics partner familiar with international shipping regulations to ensure compliance and avoid delays. Tracking capabilities and insurance for high-value shipments are also recommended to mitigate risks during transit. -

How can I effectively communicate my design requirements to a supplier?

To communicate effectively, provide a detailed design brief that includes sketches, color swatches, and material preferences. Use clear language to describe the desired fit, style, and functionality. Consider setting up a video call to discuss specifics and answer any questions in real-time. Establishing a feedback loop during the design process will help ensure that the final product meets your expectations and reduces the risk of costly revisions. -

What quality assurance measures should I implement before accepting delivery?

Before accepting delivery, implement a quality assurance checklist that includes verifying the materials, craftsmanship, and overall finish of the jackets. Arrange for a pre-shipment inspection if possible, where a third-party service can assess the products against your specifications. Upon receipt, conduct an immediate inspection to check for defects or discrepancies. Establish a clear return or alteration policy with your supplier for any items that do not meet agreed-upon standards.

Top 5 Custom Leather Biker Jackets Manufacturers & Suppliers List

1. The Jacket Maker – Custom Motorcycle Jackets

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Custom Motorcycle Jackets, Vests & Moto | The Jacket Maker. Design custom leather jackets with your embroidery, logo & color. Quantity options available: 1, 2-5, 6-20, 21-50, 50+. Available for various countries.

2. Bison Track – Custom Leather Jackets

Domain: bisontrack.com

Registered: 2018 (7 years)

Introduction: Custom Leather Street Jackets from Bison Track. Options for custom built gear including jackets, gloves, suits, and more. Features include a fitment guarantee policy and various leather colors. Shop Pay available for payment options. Additional categories include accessories, hoodies, and t-shirts.

3. Vanson – Handcrafted Leather Motorcycle Jackets

Domain: vansonleathers.com

Registered: 1997 (28 years)

Introduction: This company, Vanson – Handcrafted Leather Motorcycle Jackets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

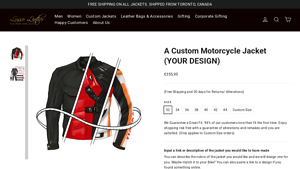

4. Lusso Leather – Custom Motorcycle Jacket

Domain: lussoleather.com

Registered: 2016 (9 years)

Introduction: A Custom Motorcycle Jacket (YOUR DESIGN) – Regular price $415.00. Free shipping and 30 days for returns/alterations. Available sizes: 32, 34, 36, 38, 40, 42, 44, and Custom Size. Made from heavy duty 1.2-1.3 mm thick cowhide leather, with triple-stitched panels for durability. Features CE approved removable armor padding on back, elbows, and shoulders. Customization options include logos and lette…

5. Langlitz Leathers – Custom Leather Goods

Domain: langlitz.com

Registered: 1996 (29 years)

Introduction: Langlitz Leathers offers high-quality, custom-built leather goods made in Portland, Oregon since 1947. Their products include leather jackets, vests, pants, and accessories, all hand-built to fit individual measurements. Customers can add custom features to their garments. The company emphasizes a personal connection with customers, treating them as part of the family. They guarantee a no-risk ord…

Strategic Sourcing Conclusion and Outlook for custom leather biker jackets

In the evolving market for custom leather biker jackets, strategic sourcing emerges as a pivotal factor for international B2B buyers. By prioritizing quality, craftsmanship, and customization options, businesses can differentiate themselves in a competitive landscape. Leveraging insights from leading manufacturers, such as Dainese and Bison Track, highlights the importance of tailoring products to meet diverse consumer preferences across regions, particularly in Africa, South America, the Middle East, and Europe.

Understanding local market demands and the significance of cultural aesthetics can drive successful partnerships with suppliers. Establishing strong relationships with manufacturers who offer customizable features, like fit guarantees and a variety of leather choices, not only enhances product offerings but also fosters brand loyalty among customers.

As we look to the future, the demand for bespoke leather apparel is set to rise, driven by a growing consumer emphasis on individuality and quality. Now is the time for international B2B buyers to engage with reputable suppliers and explore innovative sourcing strategies that cater to regional tastes and preferences. By doing so, they can position themselves effectively within this vibrant market and capitalize on emerging opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to custom leather biker jackets

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.