Introduction: Navigating the Global Market for custom leather die cutter

In the competitive landscape of leather goods manufacturing, sourcing the right custom leather die cutter is crucial for businesses aiming to enhance their production efficiency and product quality. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, you face the challenge of identifying reliable suppliers who can meet your specific design and production needs while adhering to budget constraints. This guide serves as a comprehensive resource, addressing critical aspects such as types of die cutters, their applications, the supplier vetting process, and cost considerations.

Understanding the nuances of custom leather die cutters can empower you to make informed purchasing decisions that align with your operational goals. Whether you are looking to create intricate designs for high-end leather products or streamline the production of standard cuts, our guide will equip you with the insights needed to navigate the complexities of the global market. We will delve into the essential features to look for in a supplier, such as quality assurance, turnaround times, and post-purchase support, ensuring that you can confidently partner with manufacturers who understand the demands of your industry.

By leveraging the knowledge and strategies presented in this guide, you can optimize your sourcing process, minimize risks, and ultimately drive profitability in your leather production endeavors.

Table Of Contents

- Top 5 Custom Leather Die Cutter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather die cutter

- Understanding custom leather die cutter Types and Variations

- Key Industrial Applications of custom leather die cutter

- 3 Common User Pain Points for ‘custom leather die cutter’ & Their Solutions

- Strategic Material Selection Guide for custom leather die cutter

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather die cutter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather die cutter’

- Comprehensive Cost and Pricing Analysis for custom leather die cutter Sourcing

- Alternatives Analysis: Comparing custom leather die cutter With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather die cutter

- Navigating Market Dynamics and Sourcing Trends in the custom leather die cutter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather die cutter

- Strategic Sourcing Conclusion and Outlook for custom leather die cutter

- Important Disclaimer & Terms of Use

Understanding custom leather die cutter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Rule Dies | Made from hardened steel; precise cutting; customizable shapes | Leather goods manufacturing; crafts | Pros: High durability; precise cuts. Cons: Higher initial cost. |

| Acrylic Mounted Dies | Easy alignment; suitable for various materials; customizable | High-volume production; prototyping | Pros: Reduces material waste; versatile. Cons: Limited to specific thicknesses. |

| Clicker Press Dies | Designed for manual or hydraulic presses; robust design | Large-scale leather cutting operations | Pros: Efficient for mass production; consistent results. Cons: Requires compatible machinery. |

| Ejection Dies | Incorporates rubber for easy part removal; customizable | High-speed production environments | Pros: Reduces handling time; improves efficiency. Cons: May have higher costs due to added features. |

| Custom Engraved Dies | Offers engraving options for branding; tailored designs | Promotional items; custom leather goods | Pros: Enhances brand visibility; unique designs. Cons: Longer lead times for custom designs. |

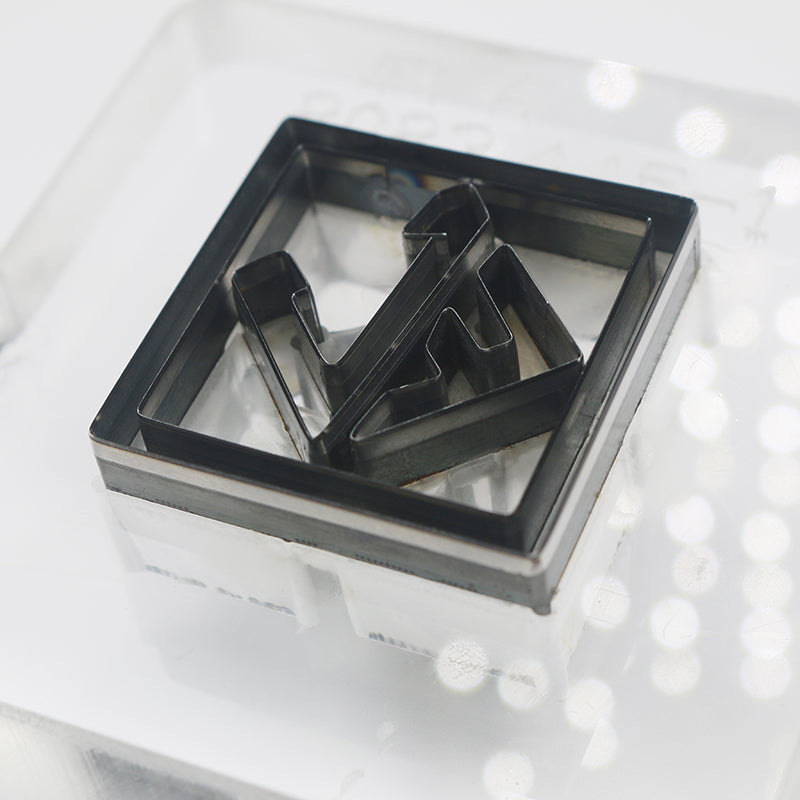

What are Steel Rule Dies and Their Applications?

Steel rule dies are crafted from hardened steel, making them ideal for high-precision cutting across various materials, particularly leather. They are customizable to accommodate different shapes and sizes, allowing businesses to create specific designs according to their needs. These dies are commonly used in the leather goods manufacturing sector and crafts, providing durability and consistent results. B2B buyers should consider the initial investment, as these dies can be more expensive, but the long-term performance often justifies the cost.

Why Choose Acrylic Mounted Dies?

Acrylic mounted dies are distinguished by their ease of material alignment, which significantly reduces waste during production. These dies can cut through leather, paper, and other materials, making them versatile for various applications, including high-volume production and prototyping. For B2B buyers, the benefits include quick setup times and the ability to work with different materials. However, it’s essential to note that these dies may be limited by the thickness of materials they can cut effectively.

How Do Clicker Press Dies Enhance Production?

Clicker press dies are specifically designed for use with manual or hydraulic presses, making them suitable for large-scale leather cutting operations. Their robust construction ensures they can handle repetitive cutting tasks with ease, which is crucial for businesses aiming to maintain efficiency in production. While they offer consistent results, buyers must ensure they have compatible machinery, as this could limit their use in smaller operations or those without the required equipment.

What Are Ejection Dies and Their Benefits?

Ejection dies feature integrated rubber components that facilitate the easy removal of cut parts, streamlining the production process. They are particularly beneficial in high-speed manufacturing environments where efficiency is paramount. The primary advantage for B2B buyers is the reduction in handling time, which can lead to increased output. However, the inclusion of ejection features may raise the overall cost of the dies, making it essential for buyers to evaluate their production needs against the investment.

How Can Custom Engraved Dies Add Value?

Custom engraved dies allow businesses to incorporate branding elements into their products, enhancing visibility and uniqueness. These dies can be tailored to specific designs, making them ideal for promotional items and bespoke leather goods. However, B2B buyers should be aware that the lead times for custom designs may be longer, which can affect production schedules. Investing in engraved dies can provide a competitive edge, but careful planning is necessary to align with business timelines.

Key Industrial Applications of custom leather die cutter

| Industry/Sector | Specific Application of custom leather die cutter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Cutting intricate leather patterns for garments | Enhances design precision, reduces material waste | Need for high-quality, durable dies; quick turnaround time |

| Automotive | Creating custom leather interiors and upholstery | Customization options increase market appeal | Compatibility with various leather types; bulk order capabilities |

| Footwear | Producing unique shoe components and designs | Enables differentiation in a competitive market | Requirement for precision and repeatability; quick prototyping |

| Accessories & Handbags | Crafting bespoke leather goods like bags and wallets | Increases product personalization and customer satisfaction | Strong support for design adjustments; reliable customer service |

| Home Decor & Furnishings | Cutting leather for furniture and home accessories | Adds luxury and uniqueness to home products | Consideration of material thickness; ability to handle large designs |

How Is Custom Leather Die Cutting Used in the Fashion & Apparel Industry?

In the fashion and apparel sector, custom leather die cutters are essential for producing intricate patterns that form the basis of high-quality garments. These tools allow designers to create unique shapes and styles, ensuring that every piece is both aesthetically pleasing and functional. By utilizing precise cutting methods, businesses can minimize material waste, ultimately enhancing profitability. International buyers, particularly those in Europe and South America, should prioritize sourcing dies that offer quick turnaround times and high durability to keep up with fast-paced fashion trends.

What Role Does Custom Leather Die Cutting Play in the Automotive Sector?

The automotive industry leverages custom leather die cutters to fabricate bespoke interiors and upholstery for vehicles. This application allows manufacturers to offer tailored options that cater to consumer preferences, significantly boosting their competitive edge. Precision is crucial in this sector, as any discrepancies can lead to costly reworks. Buyers from regions like the Middle East and Africa should consider sourcing dies that can work with various leather types and that provide bulk order capabilities to meet production demands.

Why Is Custom Leather Die Cutting Important for Footwear Manufacturers?

Footwear manufacturers utilize custom leather die cutters to produce unique shoe components, such as insoles and decorative elements. This capability not only fosters creativity in design but also allows for differentiation in a crowded marketplace. The precision and repeatability of die cutting ensure that each component meets quality standards, reducing the risk of defects. Buyers should look for suppliers that offer quick prototyping services and can accommodate intricate designs, especially in regions like Brazil, where fashion innovation is rapidly evolving.

How Does Custom Leather Die Cutting Enhance Accessories & Handbag Production?

In the accessories and handbag sector, custom leather die cutters are used to create bespoke leather goods, enabling businesses to offer personalized products that resonate with consumers. This customization fosters customer loyalty and satisfaction, as clients can obtain items that reflect their individual styles. Buyers should seek suppliers with strong support for design adjustments and reliable customer service to facilitate smooth order processes, particularly important for international transactions.

In What Ways Is Custom Leather Die Cutting Utilized in Home Decor & Furnishings?

Custom leather die cutting is increasingly popular in the home decor and furnishings industry, where it is used to create unique leather pieces for furniture and accessories. This application adds a touch of luxury and individuality to home products, appealing to discerning customers. Buyers should consider the thickness of materials that can be accommodated by the die cutters and the ability to handle large designs, ensuring that their sourcing aligns with their product offerings.

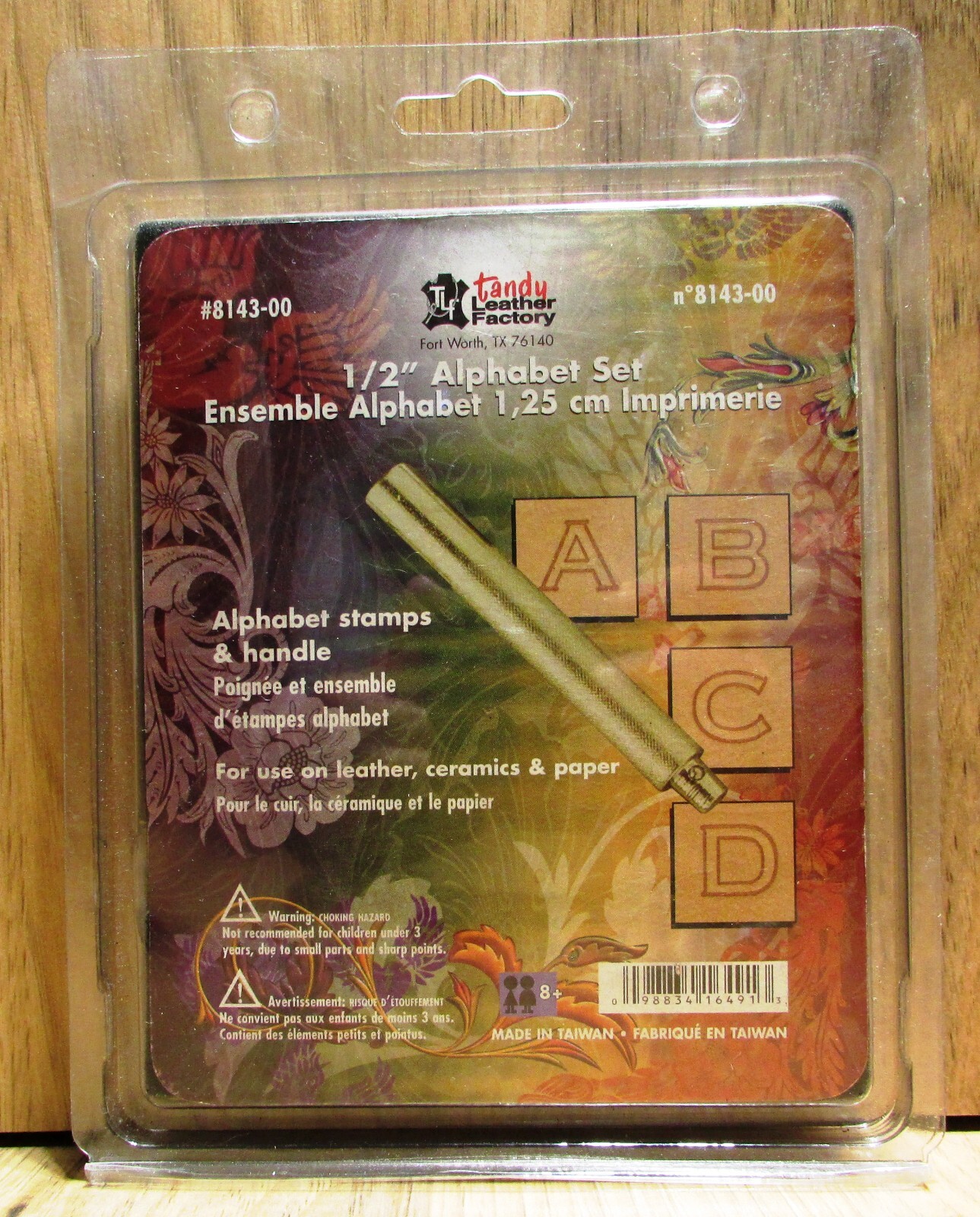

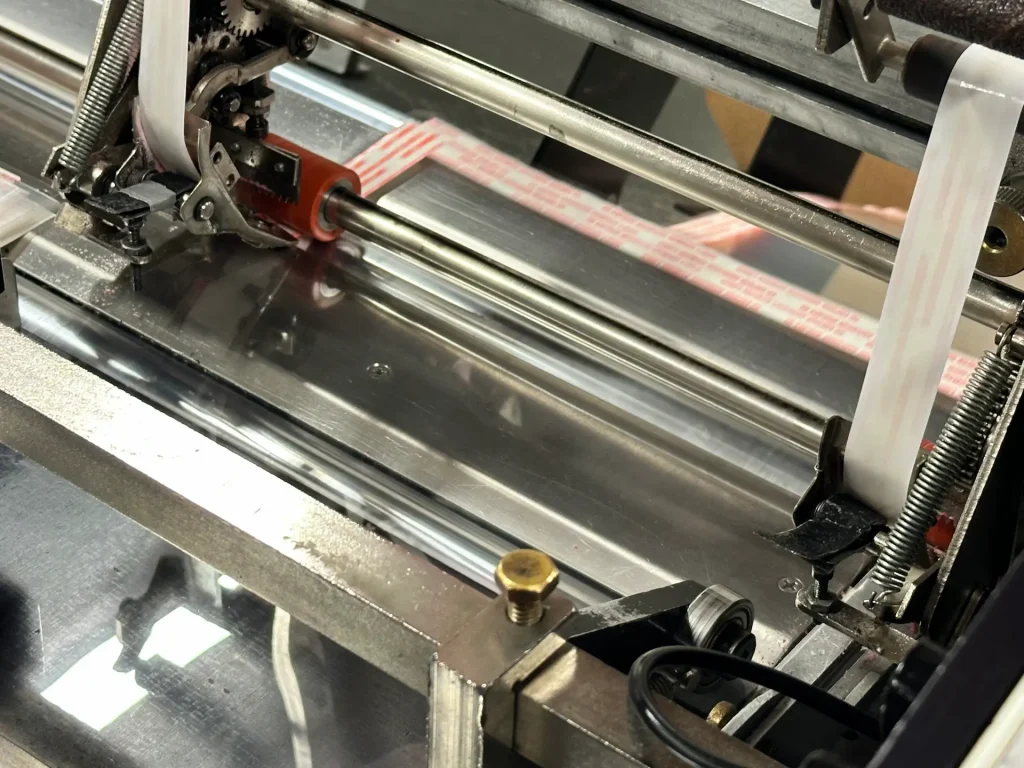

Illustrative image related to custom leather die cutter

3 Common User Pain Points for ‘custom leather die cutter’ & Their Solutions

Scenario 1: Inconsistent Quality in Die Production

The Problem: B2B buyers often face challenges with inconsistent quality in custom leather die cutters. This inconsistency can lead to defects in production, resulting in wasted materials and increased costs. Buyers may find that the dies do not perform as expected, leading to variations in the final product’s quality. This is particularly problematic for businesses that rely on high precision for leather goods, as any misalignment can result in significant financial losses and damage to brand reputation.

The Solution: To mitigate these quality issues, it is essential to partner with a reputable supplier known for their stringent quality control processes. Buyers should ensure that the supplier uses advanced technologies, such as CAD software, for die design and precision manufacturing. When sourcing dies, request samples to assess their quality before committing to larger orders. Establish clear communication with the supplier regarding specifications, tolerances, and expected outcomes. Additionally, buyers should take advantage of post-purchase support services, such as resharpening and maintenance, to extend the lifespan and performance of their dies.

Scenario 2: Long Lead Times Affecting Production Schedules

The Problem: International B2B buyers often experience long lead times when ordering custom leather die cutters, which can disrupt production schedules. This issue is particularly acute for businesses that operate on tight timelines and need to deliver products to customers promptly. Delays can stem from multiple factors, including complex design requirements, shipping logistics, and inadequate supplier communication.

The Solution: To avoid long lead times, buyers should work with suppliers that offer expedited services and transparent timelines. When placing an order, provide comprehensive design files and specifications to minimize the back-and-forth communication that can cause delays. Opt for suppliers that have robust logistics networks, especially those familiar with international shipping regulations. Establishing a relationship with a supplier who can offer quick turnaround times can significantly enhance production efficiency. Additionally, consider keeping a small inventory of standard dies that can be used for common designs, allowing for quicker production runs without the need for custom orders.

Illustrative image related to custom leather die cutter

Scenario 3: Difficulty in Sourcing Custom Designs

The Problem: B2B buyers often struggle to find suppliers willing to create highly customized die cutters that meet specific design requirements. Many suppliers have minimum order quantities or may not accommodate small-scale orders, which can hinder businesses that are experimenting with new products or designs. This limitation can stifle creativity and innovation, as buyers may be forced to compromise on their design vision.

The Solution: To tackle this sourcing challenge, buyers should seek suppliers that specialize in custom die production and are open to smaller orders. Suppliers that encourage collaboration can provide valuable insights and suggestions during the design process. When approaching a supplier, be clear about your needs and consider offering to share future order volumes if the initial order is successful. Additionally, leverage technology by providing digital design files in formats like AI or PDF, which can facilitate easier modifications and faster production. Engaging in discussions about your long-term needs can also help suppliers accommodate your specific requirements while fostering a collaborative relationship that benefits both parties.

Strategic Material Selection Guide for custom leather die cutter

What Are the Key Materials for Custom Leather Die Cutters?

When selecting materials for custom leather die cutters, it’s essential to consider not only the properties of the materials but also how they align with the specific needs of your business. Here, we analyze four common materials used in the production of die cutters: steel, wood, acrylic, and rubber. Each material has unique characteristics that can significantly impact performance, durability, and cost-effectiveness.

How Does Steel Perform in Custom Leather Die Cutters?

Steel is the most widely used material for custom leather die cutters, particularly hardened steel. Its key properties include high tensile strength, excellent durability, and resistance to deformation under pressure. Steel dies can withstand significant wear and tear, making them suitable for high-volume production environments.

Illustrative image related to custom leather die cutter

Pros: Steel offers exceptional longevity and precision, which is critical for maintaining consistent cut quality over time. It is also relatively easy to sharpen and maintain, ensuring that dies can be reused effectively.

Cons: The initial cost of steel dies can be high, especially for intricate designs. Additionally, they require careful handling to prevent rust and corrosion, which can be an issue in humid environments.

Impact on Application: Steel is compatible with various leather thicknesses and types, allowing for versatility in product design. However, buyers must consider local environmental conditions that may affect the longevity of steel dies.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is crucial. Buyers in regions like Africa and South America should ensure that suppliers can meet these standards, especially in markets where quality assurance is paramount.

What Role Does Wood Play in Die Cutter Manufacturing?

Wood is often used as a base material for die cutters, especially in conjunction with steel cutting blades. Its primary properties include lightweight nature and ease of machining, which allows for quick adjustments and customizations.

Illustrative image related to custom leather die cutter

Pros: Wood bases are generally less expensive than steel and can be produced quickly. They also provide a stable platform for the cutting blade, enhancing the accuracy of cuts.

Cons: Wood is less durable than steel and can degrade over time, especially when exposed to moisture. This can lead to warping, which negatively impacts cutting precision.

Impact on Application: Wooden bases are suitable for lighter applications and can be used effectively for crafting and small-scale production runs. However, they may not hold up well in high-volume settings.

Considerations for International Buyers: Buyers should be aware of the sourcing of wood materials, as regulations regarding sustainable forestry practices can vary significantly between regions. Compliance with local environmental regulations is essential.

Illustrative image related to custom leather die cutter

How Does Acrylic Enhance Custom Die Cutters?

Acrylic is increasingly being used in the manufacturing of die cutters due to its lightweight and transparent properties. It allows for easy alignment of materials, reducing waste during the cutting process.

Pros: Acrylic is easy to manufacture and can be produced in various thicknesses. Its transparency aids in precise alignment, which is particularly beneficial for intricate designs.

Cons: Acrylic is less durable than steel and can be prone to scratching and cracking under pressure. It may not be suitable for heavy-duty applications.

Impact on Application: Acrylic is ideal for applications requiring precision and clarity, such as intricate leather designs. However, it may not withstand the same levels of pressure as steel dies.

Considerations for International Buyers: Buyers should verify that acrylic materials comply with safety and quality standards in their respective markets, particularly in Europe, where regulations can be strict.

What Advantages Does Rubber Bring to Die Cutting?

Rubber is often used as a cushioning material in die cutters, providing a layer that helps in the ejection of cut parts and reducing wear on the cutting edge.

Pros: Rubber enhances the longevity of the cutting die by absorbing impact and reducing the risk of damage. It also allows for smoother ejection of cut pieces, improving overall efficiency.

Cons: The effectiveness of rubber can diminish over time, especially in high-temperature environments. It may also add to the overall cost of the die cutter.

Illustrative image related to custom leather die cutter

Impact on Application: Rubber is particularly beneficial for applications involving multiple layers of material, as it aids in maintaining the integrity of cuts.

Considerations for International Buyers: Buyers should ensure that rubber materials meet local compliance standards and are sourced from reputable suppliers to avoid quality issues.

Summary Table of Material Selection for Custom Leather Die Cutters

| Material | Typical Use Case for custom leather die cutter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-volume production runs | Exceptional durability and precision | Higher initial cost; requires maintenance | High |

| Wood | Crafting and small-scale production | Lightweight and easy to customize | Less durable; prone to moisture damage | Low |

| Acrylic | Precision cutting for intricate designs | Easy alignment; lightweight | Less durable; prone to scratches | Medium |

| Rubber | Cushioning and ejection assistance | Enhances longevity of cutting edge | Can degrade in high temperatures | Medium |

By understanding the properties, advantages, and limitations of these materials, B2B buyers can make informed decisions that align with their production needs and market demands.

Illustrative image related to custom leather die cutter

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather die cutter

What Are the Key Stages in the Manufacturing Process of Custom Leather Die Cutters?

The manufacturing process for custom leather die cutters involves several critical stages, each designed to ensure that the final product meets the precise specifications required by B2B buyers.

Material Preparation: Selecting the Right Components

The first stage in manufacturing custom leather die cutters is material preparation. Steel is the most commonly used material due to its durability and ability to retain sharpness. Manufacturers typically source high-quality, hardened steel, which ensures longevity and performance. In addition to steel, other materials such as wood may be used for the die’s base or handle, depending on the design requirements.

Before any cutting begins, manufacturers will assess the material’s quality through visual inspections and measurements, ensuring that the steel meets the necessary thickness and hardness specifications. This step is crucial as the quality of the raw materials directly impacts the die’s performance.

Forming: Creating the Die Shapes

Once the materials are prepared, the next step is forming. This process generally involves precision techniques such as CNC (Computer Numerical Control) machining, which allows for high accuracy in shaping the dies. Using CAD (Computer-Aided Design) software, manufacturers can create detailed designs that are then translated into physical forms.

Laser engraving is often employed to create intricate patterns and ensure symmetry in the dies. This technology minimizes human error and guarantees that the dies are made to exact specifications. For complex designs, manufacturers may utilize 3D modeling to visualize the final product before actual production.

Assembly: Bringing the Components Together

After forming, the next stage is assembly. Depending on the design, this may involve attaching the cutting edges to the die’s body and ensuring that all components fit together seamlessly. Quality assurance during assembly is vital; manufacturers will check for alignment and stability, as any misalignment can lead to inaccurate cuts and wasted materials.

In some cases, manufacturers may add features such as ejection rubber, which aids in the removal of cut pieces from the die. This not only improves efficiency but also enhances the overall user experience for businesses relying on these tools for production.

Finishing: Ensuring Quality and Readiness for Use

The finishing stage is where the die undergoes final touches, such as sharpening the edges and applying protective coatings to prevent rust and wear. This step often includes a thorough cleaning process and packaging, ensuring that the die is ready for shipment. Manufacturers may also conduct a final inspection to verify that the product meets all specifications and quality standards.

How Do Quality Assurance Processes Ensure the Reliability of Custom Leather Die Cutters?

Quality assurance (QA) is a critical component of the manufacturing process for custom leather die cutters. Implementing a robust QA framework helps ensure that products meet international standards and buyer expectations.

Illustrative image related to custom leather die cutter

What International Standards Should B2B Buyers Consider?

B2B buyers should look for manufacturers that comply with recognized international standards such as ISO 9001, which focuses on quality management systems. Compliance with such standards ensures that manufacturers maintain consistent quality and continuously improve their processes.

In addition to ISO certifications, specific industry standards such as CE marking may be relevant, particularly for buyers in Europe. This certification indicates that the product meets EU safety, health, and environmental protection requirements.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are essential throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During manufacturing, random samples are taken to verify that the production process adheres to quality standards. This helps catch any defects early in the process.

- Final Quality Control (FQC): After assembly and finishing, a final inspection ensures that the product is free from defects and meets the required specifications before shipping.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers, especially from regions like Africa, South America, and the Middle East, can take several steps to verify supplier quality assurance:

Illustrative image related to custom leather die cutter

-

Requesting Certifications and Compliance Documents: Buyers should ask for copies of ISO certifications and any other relevant quality assurance documents.

-

Conducting Audits: Periodic audits can provide insights into a manufacturer’s quality processes. Buyers may choose to conduct these audits themselves or hire third-party inspection services.

-

Reviewing Quality Control Reports: Suppliers should provide detailed QC reports, showcasing their testing methods and results. This transparency can help build trust.

-

Utilizing Third-Party Inspection Services: Engaging independent inspection firms can offer an unbiased evaluation of product quality before shipment.

What Testing Methods Are Commonly Used for Custom Leather Die Cutters?

Testing methods for custom leather die cutters are vital for ensuring performance and durability. Common methods include:

- Dimensional Inspection: Verifying that the die dimensions match specifications using calipers and gauges.

- Cutting Performance Tests: Assessing how well the die cuts through various materials, including leather, paper, and synthetic materials.

- Durability Testing: Subjecting the dies to stress tests to evaluate their longevity and performance under regular use conditions.

What Are the Specific Quality Assurance Challenges for International Buyers?

International buyers may face unique challenges regarding quality assurance:

-

Cultural Differences in Quality Expectations: Different regions may have varying standards for quality, which can lead to misunderstandings. Clear communication of expectations is crucial.

-

Logistical Challenges: Shipping times and customs regulations can impact the timely delivery of high-quality products. Buyers should factor in these elements when negotiating terms.

-

Supplier Reliability: Not all manufacturers maintain the same level of quality assurance. Researching suppliers and relying on established manufacturers can mitigate risks.

In conclusion, understanding the manufacturing processes and quality assurance practices for custom leather die cutters is essential for B2B buyers. By focusing on material selection, precision forming, thorough assembly, and rigorous quality control, buyers can ensure they source reliable and effective tools for their production needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather die cutter’

To assist international B2B buyers in the procurement of custom leather die cutters, this guide offers a structured checklist. By following these steps, businesses can ensure they select the right supplier and product that meets their specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes dimensions, shape complexity, and material types. Precise specifications help in obtaining accurate quotes and reduce the likelihood of errors in the final product.

- Considerations: Include details such as the thickness of leather you plan to cut and any unique features you need, such as ejection rubber or specific engravings.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in custom leather die cutters. Look for companies with a strong reputation in the industry and positive customer reviews.

- Evaluation Criteria: Focus on their experience, product range, and the technology they use for die manufacturing, such as CAD programs for accuracy.

Step 3: Request Samples and Prototypes

Before making a bulk order, request samples or prototypes of the dies you are considering. This allows you to evaluate the quality, durability, and precision of the cuts.

- Quality Check: Inspect the samples for any inconsistencies or defects. Ensure that the dies perform well with the leather types you intend to use.

Step 4: Verify Supplier Certifications and Quality Assurance Processes

Ensure that your chosen supplier adheres to international quality standards and has the necessary certifications. This is particularly important when sourcing from regions with varying manufacturing practices.

- Key Certifications: Look for ISO certifications or similar quality assurance credentials that demonstrate the supplier’s commitment to quality.

Step 5: Understand Pricing Structures and Payment Terms

Discuss pricing in detail, including the costs associated with the design, production, and any additional services such as delivery and installation. Understanding the total cost upfront helps prevent unexpected expenses.

- Negotiation Tips: Inquire about bulk order discounts or payment plans that could ease financial burdens, especially for larger projects.

Step 6: Evaluate Customer Support and After-Sales Service

Assess the level of customer support provided by the supplier. A responsive and knowledgeable support team can be invaluable, especially when issues arise post-purchase.

- Support Options: Check if the supplier offers after-sales services such as die resharpening or repair, which can extend the life of your investment.

Step 7: Confirm Shipping and Delivery Terms

Finally, clarify shipping options and delivery timelines to ensure that your dies arrive when needed. Understanding the logistics involved is crucial, particularly for international transactions.

- Shipping Considerations: Ask about the shipping methods used, estimated delivery times, and whether tracking is available for peace of mind.

By adhering to this checklist, B2B buyers can streamline their procurement process for custom leather die cutters, ensuring they select a supplier that meets their specific needs while minimizing risks.

Comprehensive Cost and Pricing Analysis for custom leather die cutter Sourcing

What Are the Key Cost Components for Custom Leather Die Cutters?

When sourcing custom leather die cutters, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials directly affects the price. Steel is a common choice for durability, with costs varying based on thickness and treatment (e.g., pre-sharpened vs. standard). Additional materials like acrylic for mounts can also influence costs.

-

Labor: Skilled labor is required for the design and manufacturing processes. This encompasses the expertise of craftsmen who create the dies, as well as the labor involved in quality assurance and any post-manufacturing modifications.

-

Manufacturing Overhead: Overhead costs include utilities, equipment maintenance, and facilities management. These are typically proportionally distributed across all products and can vary based on the manufacturer’s operational efficiency.

-

Tooling: This involves the cost of the tools and machines used to create the dies. Investments in advanced technology, such as CAD software for design accuracy, can enhance precision but also increase initial costs.

-

Quality Control (QC): Ensuring that each die meets specified tolerances involves rigorous QC processes. This adds to labor and overhead costs but is crucial for maintaining product quality and reliability.

-

Logistics: Shipping and handling costs can be significant, especially for international orders. Factors such as shipping method, distance, and the chosen Incoterms (e.g., FOB, CIF) play a crucial role in determining logistics expenses.

-

Margin: Manufacturers will include a profit margin in their pricing, which can vary widely depending on the supplier’s business model and market positioning.

What Influences the Pricing of Custom Leather Die Cutters?

Several factors can influence the pricing of custom leather die cutters:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often come with discounts. Negotiating for a lower price per unit is more feasible when ordering larger quantities.

-

Specifications and Customization: The complexity of the die design affects pricing. Intricate designs with multiple functionalities will generally cost more due to the additional labor and tooling required.

-

Material Quality and Certifications: Higher-quality materials and certifications (such as ISO standards) can increase costs but may also offer better durability and performance, impacting the Total Cost of Ownership (TCO).

-

Supplier Factors: The reputation, location, and reliability of the supplier can influence pricing. Established suppliers with a history of quality may charge more but offer better service and support.

-

Incoterms: Understanding the chosen Incoterms is vital. They dictate who is responsible for shipping costs, insurance, and risks associated with transportation, which can significantly impact the total cost.

What Are the Best Tips for B2B Buyers When Sourcing Custom Leather Die Cutters?

-

Negotiate Smartly: Leverage your purchasing power. Don’t hesitate to negotiate prices, especially if you are ordering in bulk. Discuss potential discounts based on volume or long-term partnerships.

-

Focus on Cost-Efficiency: Consider not just the purchase price but the TCO, which includes maintenance, re-sharpening, and potential downtimes. Investing in higher-quality dies may save costs in the long run.

-

Be Aware of Pricing Nuances: For international buyers, factors such as import duties, taxes, and currency fluctuations can affect the final cost. Ensure to account for these variables when evaluating quotes.

-

Request Detailed Quotes: Ensure that all aspects of pricing are transparent. A detailed quote should break down costs into materials, labor, tooling, and logistics to help you understand where your money is going.

-

Quality Over Cost: While it may be tempting to choose the lowest-priced option, prioritize quality. A more expensive, high-quality die may yield better performance and longevity, leading to reduced costs over time.

By understanding these cost components and pricing influencers, B2B buyers can make informed decisions when sourcing custom leather die cutters, ensuring they achieve the best value for their investments.

Alternatives Analysis: Comparing custom leather die cutter With Other Solutions

Understanding Alternatives to Custom Leather Die Cutters

In the competitive landscape of leather crafting, businesses often seek efficient and cost-effective solutions for cutting leather. While custom leather die cutters offer precision and reliability, exploring alternative methods can provide valuable insights into achieving similar results. This section compares custom leather die cutters with other viable options, helping B2B buyers make informed decisions based on their unique operational needs.

| Comparison Aspect | Custom Leather Die Cutter | Manual Cutting Tools | Laser Cutting Machines |

|---|---|---|---|

| Performance | High precision; ideal for intricate designs. | Moderate precision; dependent on user skill. | Very high precision; can handle complex shapes effortlessly. |

| Cost | $100-$500+ for dies; additional costs for services. | Low initial investment, but labor costs can add up. | High initial cost for machinery, but low per-unit cost over time. |

| Ease of Implementation | Requires specialized knowledge for die creation and usage. | Simple to use but labor-intensive; requires skilled labor. | Requires training but offers automation for large runs. |

| Maintenance | Regular maintenance needed for die integrity. | Minimal; tools can be easily replaced. | High maintenance for machinery; requires technical expertise. |

| Best Use Case | Best for high-volume production of consistent shapes. | Ideal for small batches and prototyping. | Best for mass production and intricate designs. |

Detailed Breakdown of Alternatives

Manual Cutting Tools

Manual cutting tools, such as knives and rotary cutters, offer a straightforward approach to leather crafting. These tools are affordable and widely accessible, making them an attractive option for small businesses or artisans. However, the effectiveness of manual cutting largely depends on the skill and experience of the user. While they can produce satisfactory results for simple designs, achieving the same level of precision as a custom die cutter is challenging. Manual methods are best suited for small batches or unique, one-off pieces, where the cost of dies is prohibitive.

Laser Cutting Machines

Laser cutting technology represents a significant advancement in the leather cutting process. These machines utilize high-powered lasers to achieve extremely precise cuts, making them ideal for complex designs and detailed patterns. While the initial investment in laser cutting equipment can be substantial, the long-term savings in labor and material waste can offset these costs, particularly for high-volume production runs. Additionally, laser cutting can handle a variety of materials beyond leather, offering versatility for businesses that may expand into other markets. However, the need for technical expertise and regular maintenance can be a drawback for smaller operations.

Conclusion: Making the Right Choice for Your Business

When considering the best cutting solution for leather products, B2B buyers should evaluate their specific production needs, budget constraints, and long-term goals. Custom leather die cutters are ideal for high-volume, precision-required applications, while manual cutting tools may serve small-scale operations effectively. Laser cutting machines, though costly, provide unmatched precision and efficiency for businesses prepared to invest in advanced technology. Ultimately, the choice will depend on balancing cost, performance, and the desired quality of the final product, ensuring alignment with the company’s operational strategy and market demands.

Essential Technical Properties and Trade Terminology for custom leather die cutter

What Are the Essential Technical Properties of a Custom Leather Die Cutter?

When sourcing custom leather die cutters, understanding the technical specifications is crucial for ensuring the final product meets your manufacturing needs. Here are some key properties to consider:

Illustrative image related to custom leather die cutter

1. Material Grade

The most common materials used for die cutters are hardened steel and wood. Steel dies provide durability and precision, making them ideal for high-volume cutting. Wood may be used for prototypes or simpler designs. Choosing the right material is vital; steel dies typically offer longer lifespans and better performance, particularly in rigorous industrial applications.

2. Tolerance

Tolerance refers to the allowable deviation from a specified measurement. In the context of die cutters, a tolerance of ±0.2mm is common and indicates how precise the cuts will be. High tolerance levels ensure that each cut piece aligns perfectly with design specifications, reducing waste and enhancing the quality of the final product. In B2B manufacturing, precise tolerances can significantly impact production efficiency and product consistency.

3. Thickness

Die thickness can vary, with common options being 3mm and 4mm. Thicker dies tend to be more robust and suitable for cutting through denser materials. When considering die thickness, it’s essential to factor in the type of leather being used and the complexity of the design. A thicker die might be necessary for intricate cuts or when working with tougher leather grades.

4. Cutting Depth

The effective cutting depth indicates how thick a material the die can cut through. Many dies can handle materials up to 8.8mm thick. Understanding the cutting depth is essential for ensuring that the die can accommodate the specific leather or other materials you plan to use, thereby preventing costly errors during production.

5. Ejection Mechanism

Some dies come equipped with ejection rubber, which aids in the removal of cut pieces from the die. This feature can significantly speed up production times and reduce the manual labor required to extract each piece, making it a valuable consideration for high-volume manufacturers.

What Common Trade Terms Should You Know in the Custom Leather Die Cutter Industry?

Familiarity with industry jargon can facilitate smoother transactions and better communication with suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of leather die cutters, an OEM might produce dies that are branded and sold by a different company. Understanding OEM relationships can help you identify quality sources for your production needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and planning your inventory. Some manufacturers may set high MOQs, which can be a barrier for smaller businesses or startups.

Illustrative image related to custom leather die cutter

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing information from suppliers. When sourcing custom leather die cutters, submitting an RFQ can help you compare costs and specifications from different manufacturers, ensuring you get the best deal.

4. Incoterms

Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers in international trade. They specify who pays for shipping, insurance, and tariffs, making them essential for understanding the total cost of acquiring custom leather die cutters from overseas suppliers.

5. CAD (Computer-Aided Design)

CAD refers to software used to create precise drawings and technical illustrations. In the die-cutting industry, CAD is often used to design die patterns, ensuring accuracy and consistency in production. Familiarity with CAD processes can help you communicate effectively with manufacturers about your design specifications.

Illustrative image related to custom leather die cutter

By understanding these technical properties and trade terms, you can make informed decisions when sourcing custom leather die cutters, ultimately enhancing your production efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the custom leather die cutter Sector

What Are the Key Market Dynamics and Trends in the Custom Leather Die Cutter Sector?

The custom leather die cutter sector is experiencing significant growth, driven by a surge in demand for personalized leather products across various industries, including fashion, automotive, and home décor. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers that can provide high-quality, custom solutions. The adoption of advanced technologies, such as CAD software and precision cutting machines, is enhancing the accuracy and efficiency of die production. This technological shift allows manufacturers to offer rapid prototyping and shorter lead times, making it easier for businesses to meet their customers’ evolving needs.

Emerging trends indicate a growing preference for sustainable materials and ethical manufacturing practices. Buyers are prioritizing suppliers who utilize eco-friendly leather alternatives and adhere to ethical sourcing standards. Additionally, the rise of e-commerce platforms is facilitating direct connections between manufacturers and international buyers, streamlining the procurement process. In the context of a global supply chain, understanding local market conditions and regulatory environments is crucial for successful sourcing strategies.

Illustrative image related to custom leather die cutter

How Are Sustainability and Ethical Sourcing Influencing the Custom Leather Die Cutter Market?

The importance of sustainability in the custom leather die cutter sector cannot be overstated. The environmental impact of traditional leather production methods has prompted many B2B buyers to seek out suppliers who prioritize eco-friendly practices. This includes the use of vegetable-tanned leather, which is less harmful to the environment compared to chrome-tanned options. Furthermore, suppliers are increasingly adopting ‘green’ certifications, such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certification, to demonstrate their commitment to sustainable practices.

Ethical sourcing is also becoming a critical factor in supplier selection. Buyers are demanding transparency in the supply chain to ensure that materials are sourced responsibly and that workers are treated fairly. This shift is driving manufacturers to establish robust ethical guidelines and certifications that assure buyers of their commitment to social responsibility. By aligning with suppliers that prioritize sustainability and ethical practices, businesses can not only enhance their brand image but also meet the growing consumer demand for responsible products.

How Has the Custom Leather Die Cutter Sector Evolved Over Time?

The evolution of the custom leather die cutter sector reflects broader technological advancements and changing consumer preferences. Initially, die cutting was a manual process, heavily reliant on craftsmanship and skilled labor. As the demand for precision and customization grew, manufacturers began adopting mechanical and later digital technologies, such as laser cutting and CNC machining. These innovations have allowed for greater precision, consistency, and efficiency in die production.

In recent years, the rise of e-commerce and globalization has transformed the sourcing landscape, enabling international buyers to access a wider range of suppliers and products. This evolution has been further accelerated by the increasing importance of sustainability and ethical sourcing, which now play a pivotal role in shaping buyer decisions. Today, B2B buyers are not only looking for quality and efficiency but also for suppliers who align with their values and contribute positively to the environment and society.

Illustrative image related to custom leather die cutter

By understanding these market dynamics, trends, and historical contexts, international B2B buyers can navigate the custom leather die cutter sector more effectively, making informed decisions that align with their business goals and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather die cutter

-

How do I solve challenges related to sourcing custom leather die cutters internationally?

When sourcing custom leather die cutters from international suppliers, it’s essential to conduct thorough research to identify reputable manufacturers. Start by checking online reviews, industry certifications, and their history of successful projects. Engage in direct communication to clarify your specific requirements and assess their responsiveness. Consider requesting samples or prototypes to evaluate quality before placing larger orders. Finally, ensure that the supplier has experience with international shipping and customs to avoid delays or complications during the import process. -

What is the best approach for evaluating suppliers of custom leather die cutters?

To effectively evaluate suppliers, develop a set of criteria that includes experience, quality of materials, customer service, and manufacturing capabilities. Request references from previous clients and assess their feedback on product quality and delivery timelines. Additionally, inquire about their production processes, including quality assurance measures and the technology used for die cutting. Visiting the manufacturing facility, if possible, can provide further insights into their operations. Lastly, compare quotes and ensure that pricing aligns with the quality and service offered. -

What are typical minimum order quantities (MOQs) for custom leather die cutters?

Minimum order quantities for custom leather die cutters can vary significantly among suppliers, often ranging from 10 to several hundred units. Factors influencing MOQs include the complexity of the die design, the materials used, and the supplier’s production capacity. When negotiating, consider discussing lower MOQs for initial orders or samples. This flexibility can help build a long-term relationship with the supplier, allowing for larger orders in the future as your needs grow. -

How can I customize my order for a leather die cutter to meet specific needs?

Customization options for leather die cutters typically include size adjustments, shape modifications, and material selection. Most suppliers allow you to submit your design files in various formats (e.g., CAD, PDF, JPEG) for precise production. Communicate your specifications clearly, including dimensions and any additional features like ejection rubber or engraving. Engaging with the supplier during the design phase can also help ensure that the final product meets your expectations and production requirements. -

What payment terms are commonly offered by suppliers of custom leather die cutters?

Payment terms can vary widely, but common practices include upfront payments, partial deposits, and net payment terms (e.g., net 30 or net 60). For international transactions, suppliers may prefer secure payment methods such as letters of credit or PayPal to mitigate risks. Clarify any additional costs associated with shipping or customs duties in the payment agreement. It’s advisable to establish clear terms upfront to avoid misunderstandings and ensure a smooth transaction process. -

What quality assurance processes should I expect from a supplier of custom leather die cutters?

Reputable suppliers should have robust quality assurance processes in place to ensure that the die cutters meet your specifications. This may include using CAD programs for precision design, conducting regular inspections during production, and providing certification of materials used. Ask about their return or replacement policies in case the delivered products do not meet agreed-upon standards. Engaging in a dialogue about their QA practices can provide confidence in their commitment to quality. -

How do logistics and shipping affect the procurement of custom leather die cutters?

Logistics play a crucial role in the procurement process for custom leather die cutters. Consider factors such as shipping methods, lead times, and customs clearance when planning your order. Suppliers may offer different shipping options, including express or standard delivery, affecting costs and timelines. Ensure that the supplier provides tracking information and support for any potential customs issues. Collaborating with logistics experts can help streamline the process and minimize delays upon arrival. -

What should I know about the durability and maintenance of custom leather die cutters?

The durability of custom leather die cutters largely depends on the materials used and the manufacturing process. High-quality steel dies are typically more durable and require less frequent maintenance. It’s important to follow the supplier’s guidelines for care, which may include cleaning and occasional sharpening. Additionally, inquire about any warranty or service options for repairs or replacements. Understanding these aspects can help maximize the lifespan of your die cutters and ensure consistent production quality.

Top 5 Custom Leather Die Cutter Manufacturers & Suppliers List

1. Weaver Leather Supply – Custom Cutting Dies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Custom Leather Clicker & Cutting Dies by Weaver Leather Supply are made from hardened, pre-sharpened steel for quality and dependability. They are available in 3 mm and 4 mm thicknesses with heights of 3/4″ or 1-1/4″. The dies are constructed for maximum strength and are guaranteed to meet specifications or your money back. The process includes CAD drawing for accuracy, and patterns can be submitt…

2. DM Leather Studio – Custom Leather Cutting Dies

Domain: dmleatherstudio.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Custom Leather Cutting Dies”, “product_type”: “Steel Die for Cutting Leather”, “product_code”: “X09-LCD”, “price”: “$2.00”, “availability”: “Many in stock”, “materials”: [“wood”, “steel”], “default_height”: “24mm (0.95in)”, “customization_options”: [“Custom Made – A”, “Custom Made – B”, “Custom Made – C”, “Custom Made – D”, “Custom Made – E”, “Custom Made – F”, “Custom Made – G”,…

3. Texas Custom Dies – Leather Cutting Press Dies

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Press dies for cutting patterns in leather are available from various companies, including Texas Custom Dies and Weaver. These dies can be handmade or machine-made, with some users noting that handmade dies may have imperfections. Companies like Bradshaw Steel Rule Dies in Canada are also mentioned for their quality products. Custom dies can be found on platforms like Etsy and AliExpress, although…

4. Texas Custom Dies – Custom Die Making Services

Domain: usacuttingdie.com

Registered: 2009 (16 years)

Introduction: Texas Custom Dies offers custom die making services including saddle dies, small key fobs, and coaster dies. They provide die cutting services for customers without a press. The company emphasizes honesty, quality, and value in their services.

5. Leather Stamp Maker – Custom Steel Leather Cutting Dies

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Steel Leather Cutting Dies by Leather Stamp Maker, Made in the USA. Custom Leather Cutting Dies available. Full Letter Sets include: trio of each letter A-Z, three copies of numbers 0-9, special characters (period, comma, at symbol, ampersand, hash, slash, dash, exclamation mark), four blank spacers, stamping handle, 4-inch holder, packaged in a box. Mini Font Sets include: full set of 26 uppercas…

Strategic Sourcing Conclusion and Outlook for custom leather die cutter

In today’s competitive market, the importance of strategic sourcing for custom leather die cutters cannot be overstated. By collaborating with reputable manufacturers who emphasize quality, accuracy, and customer support, businesses can significantly enhance their production efficiency. Key takeaways include the necessity of clear communication regarding design specifications, the value of choosing suppliers with a solid track record in die-making, and the benefits of leveraging advanced technologies like CAD for precision.

Moreover, international buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize suppliers that offer not only high-quality products but also comprehensive after-sales support. This ensures that any potential issues can be swiftly addressed, minimizing downtime and maintaining production flow.

As the demand for customized leather goods continues to rise, now is the opportune time for businesses to invest in reliable custom leather die cutters. By adopting a strategic approach to sourcing, companies can position themselves for success in an evolving marketplace. Reach out to potential suppliers today and take the first step towards enhancing your leather product offerings.

Illustrative image related to custom leather die cutter

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather die cutter