Introduction: Navigating the Global Market for leather boot companies

In today’s competitive landscape, sourcing high-quality leather boots can be a daunting task for international B2B buyers, particularly those in emerging markets like Nigeria, Brazil, and the Middle East. The challenge lies not just in finding suppliers who offer durability and style, but also in ensuring that these products align with local market demands and consumer preferences. This comprehensive guide addresses these complexities by providing insights into various types of leather boots, their applications across different industries, and effective supplier vetting techniques.

Throughout this guide, B2B buyers will explore essential aspects such as the cost dynamics of leather boots, the importance of ethical sourcing, and the latest trends in design and functionality. We delve into the intricacies of navigating international trade regulations and highlight successful case studies of companies that have effectively established themselves in the global market.

By empowering buyers with the knowledge needed to make informed purchasing decisions, this guide aims to streamline the procurement process and enhance the overall buying experience. Whether you’re a retailer looking to expand your product line or a distributor seeking reliable suppliers, this resource will serve as your roadmap to navigating the global leather boot market with confidence.

Table Of Contents

- Top 7 Leather Boot Companies Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather boot companies

- Understanding leather boot companies Types and Variations

- Key Industrial Applications of leather boot companies

- 3 Common User Pain Points for ‘leather boot companies’ & Their Solutions

- Strategic Material Selection Guide for leather boot companies

- In-depth Look: Manufacturing Processes and Quality Assurance for leather boot companies

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather boot companies’

- Comprehensive Cost and Pricing Analysis for leather boot companies Sourcing

- Alternatives Analysis: Comparing leather boot companies With Other Solutions

- Essential Technical Properties and Trade Terminology for leather boot companies

- Navigating Market Dynamics and Sourcing Trends in the leather boot companies Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather boot companies

- Strategic Sourcing Conclusion and Outlook for leather boot companies

- Important Disclaimer & Terms of Use

Understanding leather boot companies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heritage Boot Makers | Focus on traditional craftsmanship and high-quality materials | Retail, luxury brands, specialty stores | Pros: Timeless style, durable; Cons: Higher price point, longer lead times. |

| Work and Safety Boots | Engineered for durability, safety features like steel toes | Construction, industrial sectors, outdoor work | Pros: Enhanced protection, comfort; Cons: Can be bulky, limited style options. |

| Fashion Boots | Trend-focused, diverse designs and colors | Retail, e-commerce platforms | Pros: High demand, varied styles; Cons: May sacrifice durability for style. |

| Western and Cowboy Boots | Distinctive styles, often handcrafted with exotic leathers | Western wear retailers, niche markets | Pros: Unique appeal, strong brand loyalty; Cons: Seasonal demand fluctuations. |

| Eco-Friendly Brands | Use of sustainable materials and ethical manufacturing | Green retailers, conscious consumer markets | Pros: Growing market appeal, ethical branding; Cons: Potentially higher costs, limited availability. |

What Are the Key Characteristics of Heritage Boot Makers?

Heritage boot makers prioritize traditional craftsmanship, often using time-honored techniques and high-quality materials. These boots are typically designed for longevity and classic appeal, making them suitable for luxury retail and specialty stores. B2B buyers should consider the investment in quality and brand reputation, as these boots often carry a higher price point but offer durability and timeless style that can attract discerning customers.

How Do Work and Safety Boots Differ from Other Types?

Work and safety boots are engineered for durability and protection, featuring safety elements like steel toes and slip-resistant soles. They are primarily used in industries such as construction and manufacturing, where employee safety is paramount. B2B buyers should evaluate the specific safety standards required in their industry when purchasing, as these boots provide essential protection but may be bulkier and less stylish than other options.

Illustrative image related to leather boot companies

What Makes Fashion Boots a Popular Choice for Retail?

Fashion boots are characterized by their trend-focused designs, vibrant colors, and diverse styles. They cater to the retail market and e-commerce platforms where consumer preferences shift rapidly. B2B buyers should be aware of the fast-paced nature of fashion trends, as these boots can drive sales but may sacrifice durability for aesthetic appeal. Understanding seasonal trends is crucial for maximizing inventory turnover.

Why Are Western and Cowboy Boots Unique in the Market?

Western and cowboy boots boast distinctive styles, often handcrafted from exotic leathers, making them appealing to niche markets and western wear retailers. These boots have a strong cultural significance and brand loyalty among consumers. B2B buyers should consider the seasonal demand and cultural relevance of these products, as they can be highly sought after during specific times of the year, impacting inventory planning.

What Are the Benefits of Partnering with Eco-Friendly Brands?

Eco-friendly boot brands focus on sustainable materials and ethical manufacturing practices, appealing to a growing segment of environmentally conscious consumers. These brands are increasingly relevant in green retail markets. B2B buyers should assess the potential for higher costs against the benefits of ethical branding and market differentiation. While these products may have limited availability, they offer a unique selling proposition that can attract a loyal customer base.

Key Industrial Applications of leather boot companies

| Industry/Sector | Specific Application of Leather Boot Companies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Durable work boots for farming and ranching | Enhanced protection and comfort for long hours outdoors | Quality materials, slip resistance, and waterproofing |

| Construction | Safety boots for construction sites | Compliance with safety regulations and worker protection | Steel-toe options, slip resistance, and durability |

| Hospitality | Stylish leather boots for staff uniforms | Improved brand image and employee comfort | Customization options, style variety, and comfort |

| Mining | Heavy-duty boots for underground work | Safety and durability in hazardous conditions | Electrical hazard protection and reinforced materials |

| Retail | Fashionable leather boots for retail display | Attract customers with quality and style | Trend alignment, seasonal styles, and competitive pricing |

How Are Leather Boots Utilized in Agriculture?

In the agriculture sector, leather boot companies provide durable work boots designed to withstand the rigors of farming and ranching. These boots are essential for protecting workers’ feet from sharp objects, mud, and water, ensuring comfort during long hours spent outdoors. For international buyers from regions like Nigeria or Brazil, sourcing boots that offer slip resistance and waterproofing is crucial, as these features enhance safety and longevity in challenging terrains.

Illustrative image related to leather boot companies

What Role Do Leather Boots Play in Construction?

Leather boots are vital in the construction industry, where safety is paramount. Companies offer specialized safety boots equipped with steel-toe protection to guard against heavy objects and slips on uneven surfaces. For B2B buyers in the Middle East and Europe, ensuring compliance with local safety regulations is essential. Factors such as slip resistance and overall durability are key considerations when sourcing these boots, as they directly impact worker safety and productivity on construction sites.

How Are Leather Boots Used in Hospitality?

In the hospitality industry, leather boot companies provide stylish yet comfortable footwear for staff uniforms. High-quality leather boots enhance the professional appearance of employees while ensuring comfort during long shifts. International buyers should consider customization options to align with their brand image and the latest fashion trends. Comfort and style are critical as they impact employee satisfaction and customer perceptions, making it vital to source boots that meet these needs.

What Are the Applications of Leather Boots in Mining?

Mining operations require heavy-duty leather boots designed to withstand harsh underground conditions. These boots often include features such as electrical hazard protection and reinforced materials to ensure the safety of workers. B2B buyers in mining should prioritize sourcing boots that meet stringent safety standards while also providing comfort for long hours of wear. The ability to withstand extreme conditions is a top requirement, making quality assurance a critical factor in sourcing decisions.

How Can Retailers Benefit from Leather Boots?

Retailers can leverage leather boots to enhance their product offerings and attract customers. Fashionable and high-quality leather boots create a compelling retail display, encouraging purchases through their aesthetic appeal. For international buyers, aligning with seasonal trends and providing a variety of styles can significantly influence consumer interest. Competitive pricing and quality assurance are essential when sourcing these products, as they can impact sales and brand reputation in a crowded market.

Illustrative image related to leather boot companies

3 Common User Pain Points for ‘leather boot companies’ & Their Solutions

Scenario 1: Sourcing Quality Leather Boots for Diverse Markets

The Problem: B2B buyers often struggle with sourcing high-quality leather boots that meet the varied demands of their customer base across different regions. Factors such as climate, cultural preferences, and usage scenarios (e.g., work, fashion, or outdoor activities) can complicate the selection process. Buyers may face issues with inconsistent quality, leading to customer dissatisfaction and returns. Furthermore, the challenge of finding reliable suppliers who can provide documentation for ethical sourcing and environmental compliance adds another layer of complexity.

The Solution: To overcome these challenges, buyers should establish robust criteria for evaluating potential suppliers. Start by conducting a comprehensive market analysis to identify specific needs based on regional preferences. Prioritize suppliers known for their commitment to quality and ethical sourcing practices. Engaging in direct communication with manufacturers can also clarify quality standards, production methods, and material sourcing. Consider leveraging trade shows and industry expos to build relationships with reputable manufacturers and gain firsthand insights into product offerings. Lastly, implementing a sample order process can help assess quality and fit before committing to larger orders.

Scenario 2: Ensuring Size and Fit Consistency Across Orders

The Problem: In the leather boot industry, size and fit consistency can be a significant pain point for B2B buyers. Variability in sizing can lead to high return rates, negatively impacting profitability and customer satisfaction. Different brands may have different sizing standards, making it difficult for buyers to create a cohesive inventory that meets customer expectations. This issue is particularly pronounced in markets where customers have specific fit preferences, such as wider or narrower options.

The Solution: To mitigate sizing issues, buyers should adopt a multi-faceted approach. First, create a standardized sizing chart that aligns with the most common brands in your inventory. This allows for easier comparisons and helps customers make informed purchasing decisions. Next, establish a partnership with manufacturers that offer comprehensive fitting guides, including details on variations in toe shapes, heel heights, and construction methods. When possible, request pre-production samples to evaluate the fit and comfort before placing bulk orders. Additionally, consider implementing a customer feedback loop to continuously gather data on fit preferences, which can guide future purchasing decisions.

Scenario 3: Managing Inventory and Seasonal Demand Fluctuations

The Problem: B2B buyers in the leather boot market often face challenges related to inventory management, particularly in relation to seasonal demand fluctuations. For example, demand for insulated boots may surge during winter months, while summer may see an uptick in demand for lighter styles. Without effective inventory management, buyers risk overstocking or understocking, leading to lost sales opportunities and increased holding costs.

The Solution: To effectively manage inventory, B2B buyers should implement a data-driven inventory management system that tracks sales trends and forecasts demand based on historical data. Utilizing software that analyzes past sales performance can help predict seasonal trends and adjust orders accordingly. Additionally, establishing a flexible ordering system with suppliers can allow for quicker turnaround times on reorders, minimizing the risk of stockouts. Collaborating with suppliers on promotional strategies can also help align inventory levels with anticipated demand. By integrating these practices, buyers can maintain a balanced inventory that meets customer needs while optimizing operational costs.

Strategic Material Selection Guide for leather boot companies

What Are the Key Materials Used in Leather Boot Manufacturing?

When selecting materials for leather boots, companies must consider various factors that affect performance, durability, and cost. Here, we analyze four common materials used in leather boot production: full-grain leather, suede, rubber, and synthetic materials. Each material has unique properties, advantages, and limitations that can influence the final product’s suitability for different markets.

How Does Full-Grain Leather Perform in Leather Boot Production?

Full-grain leather is renowned for its durability and natural aesthetic. It retains the original texture and grain of the hide, making it resistant to wear and tear. This material typically performs well in extreme temperatures and offers excellent breathability, which is crucial for comfort in various climates. However, full-grain leather is one of the more expensive options and requires careful maintenance to prevent damage from water or stains.

Illustrative image related to leather boot companies

From a B2B perspective, international buyers should be aware of the varying quality standards for leather across regions. Compliance with standards such as ASTM or DIN can impact sourcing decisions. In markets like Nigeria and Brazil, where humidity can be high, the moisture resistance of full-grain leather becomes a significant consideration.

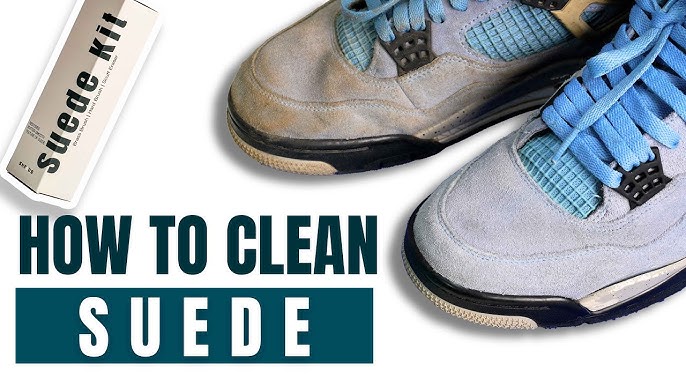

What Advantages Does Suede Offer for Leather Boots?

Suede, made from the underside of animal hides, is softer and more flexible than full-grain leather. It provides a unique texture and aesthetic appeal, making it popular for fashion-oriented boots. Suede is generally lighter and more comfortable for casual wear, but it is less durable and more susceptible to staining and water damage.

For B2B buyers in the Middle East and Europe, understanding the local climate is essential when considering suede. In dry regions, suede can be a viable option, but in areas with high moisture levels, its limitations may deter buyers. Additionally, compliance with environmental regulations regarding animal sourcing is critical in many European markets.

How Does Rubber Contribute to Boot Performance?

Rubber is often used for soles due to its excellent slip resistance and durability. It can withstand various environmental conditions, making it suitable for work and outdoor boots. Rubber soles provide good insulation and shock absorption, enhancing comfort for wearers who spend long hours on their feet.

However, rubber can be heavier than other materials, which may affect the overall weight of the boot. For international buyers, understanding the manufacturing complexities associated with rubber, such as sourcing and production capabilities, is vital. Compliance with safety standards for footwear in different regions, such as ASTM for North America, is also a key consideration.

Illustrative image related to leather boot companies

What Role Do Synthetic Materials Play in Modern Boot Design?

Synthetic materials, including nylon and polyester, are increasingly popular due to their lightweight properties and resistance to water and stains. These materials are often used in combination with leather to enhance breathability and comfort. Synthetic options can be more cost-effective than natural materials, making them attractive for budget-conscious consumers.

However, synthetic materials may lack the durability and aesthetic appeal of leather, which can affect their marketability in regions like Europe, where craftsmanship and quality are highly valued. Buyers from Africa and South America should consider the environmental impact of synthetic materials, as well as local regulations regarding their use.

Summary Table of Material Selection for Leather Boot Companies

| Material | Typical Use Case for leather boot companies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end fashion and durable work boots | Exceptional durability and breathability | High cost and maintenance required | High |

| Suede | Casual and fashion-oriented boots | Soft texture and comfort | Less durable and water-sensitive | Medium |

| Rubber | Work and outdoor boots | Slip resistance and shock absorption | Heavier than other materials | Medium |

| Synthetic | Budget-friendly and lightweight boots | Cost-effective and water-resistant | Less durable and less aesthetic appeal | Low |

By understanding the properties and implications of each material, B2B buyers can make informed decisions that align with their market needs and compliance requirements. Selecting the right materials is crucial for ensuring product performance, customer satisfaction, and long-term brand reputation.

In-depth Look: Manufacturing Processes and Quality Assurance for leather boot companies

What Are the Key Stages in the Manufacturing Process of Leather Boots?

The manufacturing process of leather boots involves several critical stages, each contributing to the final product’s quality and durability. Understanding these stages can help B2B buyers assess potential suppliers and ensure they are sourcing from reputable manufacturers.

Material Preparation: How Is Leather Processed for Boot Making?

The first stage is material preparation, which includes sourcing high-quality leather and other materials such as rubber, synthetic materials, and linings. Leather is often sourced from tanneries that adhere to international standards, ensuring it meets quality and sustainability benchmarks.

The leather is treated and dyed to achieve the desired look and feel. This stage may involve vegetable tanning or chrome tanning, with the former being favored for its eco-friendliness. Buyers should inquire about the tanning process, as it impacts the leather’s durability and environmental footprint.

Forming: What Techniques Shape the Leather into Boots?

In the forming stage, leather is cut and shaped into boot components. This process often employs advanced cutting technology, such as laser cutting or die cutting, to ensure precision. Handcrafting techniques may also be used, especially in premium lines, to maintain a traditional aesthetic and high-quality finish.

The components include the upper, lining, and sole. Each piece must be cut with accuracy to minimize waste and ensure a proper fit. Buyers should look for manufacturers that optimize material use while maintaining high-quality standards.

Assembly: How Are the Components Joined Together?

Assembly is where the boot begins to take shape. This stage typically involves stitching the upper to the lining and attaching the sole. Manufacturers may use various methods, including Goodyear welting or Blake stitching, which enhance the boot’s durability and comfort.

Quality control is essential during assembly. Workers often perform checks to ensure that stitching is even and that the components fit correctly. B2B buyers should ask suppliers about their assembly methods and the expertise of their workforce to gauge the quality of the final product.

Illustrative image related to leather boot companies

Finishing: What Processes Enhance the Boot’s Appearance and Performance?

The finishing stage includes polishing, conditioning, and applying protective coatings to enhance the boot’s appearance and longevity. This may also involve additional processes such as waterproofing or adding specialized finishes for specific market needs.

Buyers should be aware of the finishing techniques used, as they can significantly impact the boot’s performance in various environments, especially in markets with unique climatic conditions.

What Quality Assurance Standards Should B2B Buyers Expect?

Quality assurance in leather boot manufacturing is critical for ensuring the longevity and performance of the product. B2B buyers should familiarize themselves with both international and industry-specific standards that govern manufacturing practices.

Illustrative image related to leather boot companies

Which International Standards Are Relevant for Leather Boot Manufacturing?

One of the primary international standards relevant to leather boot manufacturing is ISO 9001, which outlines requirements for a quality management system. Compliance with this standard indicates that a manufacturer has established a systematic approach to managing quality and continual improvement.

Additionally, CE marking may be required for products sold within the European Union, ensuring that they meet safety, health, and environmental protection standards. Understanding these standards can help buyers assess the credibility of potential suppliers.

What Are the Industry-Specific Quality Control Protocols?

Beyond international standards, there are industry-specific protocols that may be applicable, such as ASTM (American Society for Testing and Materials) and API (American Petroleum Institute) standards for specialized boots. These guidelines help ensure that boots designed for specific applications, like work or hunting, meet safety and performance criteria.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process to ensure that each stage meets specified standards.

What Are the Key QC Checkpoints in Boot Manufacturing?

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Suppliers should provide documentation proving that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections ensure that processes adhere to quality standards. This includes checks on stitching, alignment, and assembly.

-

Final Quality Control (FQC): Once boots are completed, a thorough inspection is conducted to check for defects in stitching, finishing, and overall appearance. This is the last line of defense before products are shipped to buyers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is crucial for B2B buyers looking to establish long-term relationships with reliable manufacturers.

Illustrative image related to leather boot companies

What Methods Can Buyers Use to Assess Supplier Quality?

-

Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should consider both announced and unannounced audits for a comprehensive view.

-

Reports: Requesting detailed quality control reports can help buyers understand how a manufacturer measures and maintains quality. This documentation should include statistics on defect rates and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality standards. These services can conduct inspections at various stages of production to ensure compliance with agreed-upon specifications.

What Are the Specific QC and Certification Nuances for International Buyers?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is vital.

How Do Regional Differences Impact Quality Assurance?

Different regions may have varying regulatory requirements and standards. For instance, buyers from Europe may have stricter environmental regulations compared to those in South America. It’s essential to understand these differences when sourcing products.

Additionally, cultural expectations regarding quality and craftsmanship can vary significantly between regions. Buyers should engage with suppliers who understand these expectations and can deliver products that meet local demands.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance in Leather Boots

For B2B buyers, understanding the intricacies of manufacturing processes and quality assurance in leather boots is essential for making informed purchasing decisions. By focusing on these aspects, buyers can ensure they are sourcing high-quality products that meet both their standards and the expectations of their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather boot companies’

This guide aims to assist B2B buyers in effectively sourcing leather boot companies. By following these actionable steps, you can ensure that you partner with reliable suppliers who meet your business needs and quality standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify your specific requirements for leather boots. Consider factors such as material quality, design styles, sizes, and intended use (e.g., casual, work, or fashion). This step is crucial as it sets the foundation for your sourcing strategy and helps suppliers understand your needs clearly.

Illustrative image related to leather boot companies

Step 2: Conduct Market Research

Thoroughly research the leather boot market to identify potential suppliers and understand current trends. Look for companies with a strong presence in your target regions, such as Africa, South America, the Middle East, and Europe. Pay attention to customer reviews and industry ratings, which can provide insight into the reputation and reliability of potential partners.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities, quality control processes, and adherence to international standards. A supplier’s history and experience in the leather industry can significantly influence the quality and reliability of your orders.

Step 4: Verify Supplier Certifications

Confirm that your chosen suppliers hold relevant certifications that demonstrate their commitment to quality and sustainability. Look for certifications such as ISO 9001 for quality management and any eco-friendly certifications if sustainability is a priority for your business. These certifications not only affirm the supplier’s credibility but also ensure compliance with international labor and environmental standards.

Illustrative image related to leather boot companies

Step 5: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the leather boots you intend to procure. Assess the samples for material quality, craftsmanship, and overall design. This step is vital for ensuring that the products meet your specifications and that the supplier’s quality aligns with your brand’s standards.

Step 6: Negotiate Terms and Conditions

Once you have selected a potential supplier, enter negotiations to establish favorable terms and conditions. Discuss pricing, minimum order quantities, lead times, and payment terms. Clear communication during this phase can help prevent misunderstandings and ensure that both parties are aligned on expectations.

Step 7: Establish a Strong Communication Channel

Effective communication is key to a successful partnership with your supplier. Set up regular check-ins and establish clear channels for feedback and updates. This ongoing dialogue will help address any issues promptly and foster a collaborative relationship, which can lead to better service and product quality over time.

Illustrative image related to leather boot companies

By following this structured approach, you can confidently navigate the sourcing process for leather boots, ensuring that you select the best suppliers to meet your business objectives.

Comprehensive Cost and Pricing Analysis for leather boot companies Sourcing

What Are the Key Cost Components in Leather Boot Manufacturing?

Understanding the cost structure of leather boot companies is essential for B2B buyers looking to source competitively priced products. The primary components of manufacturing costs include:

-

Materials: Leather quality significantly impacts pricing. Full-grain leather, for instance, offers durability and aesthetics but comes at a higher cost than split or corrected grain leather. Additionally, sourcing materials locally can affect prices due to varying import duties and taxes.

-

Labor: Skilled labor is crucial in leather boot production, particularly for handcrafted or bespoke styles. Labor costs can vary widely based on geographic location, with countries like Italy and the USA often commanding higher wages compared to regions in Africa or South America.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which is beneficial for maintaining competitive pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs or unique patterns. These costs should be factored into the total pricing, particularly for lower volume orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures product quality, which can prevent costly returns and enhance customer satisfaction. The investment in QC can vary depending on the complexity of the product and desired quality standards.

-

Logistics: Transportation and warehousing costs play a vital role in the overall cost structure. For international buyers, understanding shipping routes and associated costs (including customs) is critical.

-

Margin: Finally, manufacturers typically add a margin to cover profit. This margin can vary based on brand positioning, market demand, and competition.

How Do Price Influencers Affect Leather Boot Sourcing Decisions?

Several factors influence the pricing of leather boots that B2B buyers should consider:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect unit pricing. Larger orders often qualify for discounts, making it essential for buyers to evaluate their purchasing capacity against supplier requirements.

-

Specifications and Customization: Custom designs or specific materials can increase costs. Buyers should balance the need for customization with budget constraints.

-

Materials and Quality Certifications: Boots made from premium materials or those with certifications (like ISO or environmental standards) may be priced higher. Buyers should assess the long-term value of quality over initial costs.

-

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers may charge a premium due to their proven track record, while emerging brands may offer lower prices to gain market share.

-

Incoterms: Understanding international shipping terms is crucial. Incoterms define the responsibilities of buyers and sellers regarding shipping costs and risks, which can influence overall pricing.

What Negotiation and Cost-Efficiency Strategies Should B2B Buyers Use?

To optimize sourcing costs, B2B buyers can adopt several strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, MOQs, and payment terms. Building a good relationship can lead to better deals.

-

Evaluate Total Cost of Ownership (TCO): Consider all associated costs, including shipping, customs duties, and potential returns, rather than just the purchase price. This holistic view helps in selecting suppliers that offer true value.

-

Understand Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing variations. Currency fluctuations, local demand, and shipping logistics can all affect final costs.

-

Leverage Bulk Buying: If feasible, consider pooling orders with other buyers to meet MOQs and secure lower prices.

Conclusion: Why Is It Important to Analyze Pricing and Cost Structures?

In the competitive landscape of leather boot sourcing, understanding cost components, pricing influencers, and effective negotiation strategies is vital for B2B buyers. By taking a strategic approach to sourcing, businesses can not only reduce costs but also enhance the quality and reliability of their supply chains. As prices can vary greatly, it’s essential to engage in thorough market research and supplier assessment to ensure the best outcomes.

Alternatives Analysis: Comparing leather boot companies With Other Solutions

Understanding Alternatives in Leather Boot Procurement

When considering leather boots for commercial or industrial use, B2B buyers often explore various options beyond traditional leather boot companies. Alternatives may include synthetic boot solutions, custom boot manufacturing, or even footwear rental services. Each of these alternatives offers unique advantages and potential drawbacks, making it essential for international buyers to analyze them based on critical aspects such as performance, cost, and maintenance.

Comparison Table

| Comparison Aspect | Leather Boot Companies | Synthetic Boot Solutions | Custom Boot Manufacturing |

|---|---|---|---|

| Performance | High durability, comfort, and style | Good for specific environments, but may lack longevity | Tailored fit and high performance |

| Cost | Higher upfront investment | Generally lower cost | Can be expensive, depending on materials and design |

| Ease of Implementation | Readily available in various styles | Widely available, easy to source | Longer lead time for production |

| Maintenance | Requires regular care; recraftable | Low maintenance; easy to clean | Maintenance depends on materials used |

| Best Use Case | Fashion, long-term wear, rugged use | Industrial applications, short-term use | Specialized needs, unique designs |

Pros and Cons of Alternative Solutions

Synthetic Boot Solutions

Synthetic boots are made from various artificial materials designed to withstand harsh conditions. They often come at a lower price point, making them attractive for bulk purchasing. Their lightweight design and low maintenance requirements are significant advantages, especially in industries where employees may require frequent replacements. However, synthetic options may lack the durability and comfort of high-quality leather, making them less suitable for long-term wear or high-end fashion applications.

Custom Boot Manufacturing

Custom boot manufacturing allows businesses to create footwear tailored to their specific needs, including fit, style, and functionality. This option is ideal for organizations with unique requirements, such as specialized safety features or specific branding. While the performance of custom boots can be excellent, the costs associated with bespoke solutions can be substantial, and the lead times may be longer than other alternatives. Custom boots also require careful maintenance, particularly if they are made from premium materials.

Conclusion: How to Choose the Right Footwear Solution

Selecting the right footwear solution involves assessing your specific needs, budget, and the environment in which the boots will be used. For organizations that prioritize longevity and style, investing in leather boot companies may be the best choice. In contrast, businesses seeking a cost-effective solution for temporary use might find synthetic boots more advantageous. Custom manufacturing is ideal for those with specialized requirements but requires a more significant investment in both time and money. By weighing these factors, B2B buyers can make informed decisions that align with their operational goals and workforce needs.

Essential Technical Properties and Trade Terminology for leather boot companies

What Are the Key Technical Properties for Leather Boot Companies?

When engaging in the leather boot industry, understanding critical technical properties is vital for ensuring product quality and meeting market demands. Here are some essential specifications that B2B buyers should consider:

1. Material Grade

Material grade refers to the quality of leather used in boot production. Common grades include full-grain, top-grain, and genuine leather. Full-grain leather, made from the top layer of the hide, is the most durable and develops a rich patina over time. This quality is crucial for brands that market longevity and craftsmanship. Choosing the right grade can significantly impact customer satisfaction and brand reputation.

2. Tolerance Levels

Tolerance levels indicate the acceptable variances in dimensions during production. For leather boots, tolerances can affect fit, comfort, and overall aesthetics. Accurate tolerances ensure that products meet specified standards, reducing returns and enhancing customer trust. This is particularly important for companies that cater to specific markets or demographics with unique sizing needs.

3. Waterproofing and Breathability

These properties determine how well a boot can withstand water while allowing moisture to escape. Technologies such as Gore-Tex or proprietary waterproof membranes enhance performance, making boots suitable for various climates and activities. For international buyers, offering products with these features can expand market reach, especially in regions with diverse weather conditions.

4. Soling Materials

The choice of sole material—whether rubber, leather, or synthetic—affects durability, traction, and comfort. Rubber soles provide excellent grip and are ideal for outdoor and work boots, while leather soles offer a classic look for dress boots. Understanding the end-use of the boots can guide buyers in selecting the right soling material to meet customer expectations.

Illustrative image related to leather boot companies

5. Weight and Flexibility

The weight of a boot can influence its comfort and usability, particularly for long-wear situations. Lighter materials may enhance flexibility, making them ideal for casual or fashion-forward markets. Buyers should evaluate their target demographic’s needs, balancing durability with comfort.

What Are Common Trade Terms in the Leather Boot Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the leather boot sector. Here are key terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or products that are used in another company’s end product. For leather boot companies, this often means sourcing from manufacturers who create components like soles or leather uppers. Understanding OEM relationships can help buyers streamline their supply chain and ensure product quality.

Illustrative image related to leather boot companies

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and cash flow. Knowing MOQs can help companies plan their purchases and optimize their inventory levels to avoid excess stock or shortages.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific quantities of goods or services. For leather boot companies, issuing an RFQ can help in comparing prices and terms from different manufacturers, leading to more informed purchasing decisions.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers mitigate risks and clarify shipping responsibilities, impacting overall costs and delivery times.

5. SKU (Stock Keeping Unit)

An SKU is a unique identifier for each distinct product and service that can be purchased. In the leather boot industry, SKUs help track inventory levels and sales performance. Familiarity with SKU management can aid buyers in optimizing their product offerings and inventory systems.

Illustrative image related to leather boot companies

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they procure high-quality leather boots that meet market demands while optimizing their supply chain processes.

Navigating Market Dynamics and Sourcing Trends in the leather boot companies Sector

What Are the Current Market Dynamics and Key Trends Influencing Leather Boot Companies?

The global leather boot market is experiencing significant transformation driven by evolving consumer preferences, technological advancements, and sustainability concerns. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek high-quality products, companies are increasingly focusing on craftsmanship, durability, and style. Notably, brands that emphasize traditional manufacturing techniques while integrating modern designs are gaining traction.

Emerging technologies, such as 3D printing and digital customization, are revolutionizing production processes, enabling brands to offer personalized products at scale. Moreover, the rise of e-commerce platforms is reshaping how buyers engage with suppliers, allowing for a more streamlined purchasing experience. Buyers are encouraged to explore partnerships with companies that utilize advanced data analytics for better inventory management and forecasting, ensuring they meet market demands efficiently.

In addition, the growing trend of direct-to-consumer (DTC) models is reshaping supply chains, allowing brands to interact more closely with their customers. This shift provides valuable insights into consumer behavior, enabling companies to adapt swiftly to market changes. For B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with current market demands.

How Is Sustainability and Ethical Sourcing Reshaping the Leather Boot Industry?

Sustainability has become a paramount concern in the leather boot industry, influencing sourcing strategies and consumer choices alike. The environmental impact of leather production, including deforestation and water usage, is prompting companies to adopt more sustainable practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable materials.

The importance of ethical supply chains cannot be overstated. Buyers are looking for brands that source leather from certified tanneries that adhere to environmental and labor standards. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential for companies aiming to build trust and credibility in the market.

Furthermore, the adoption of alternative materials, such as plant-based leathers and recycled synthetics, is gaining popularity as brands strive to reduce their ecological footprint. B2B buyers should seek partnerships with companies that not only prioritize sustainability but also transparently communicate their sourcing practices and certifications. This approach not only aligns with consumer values but also helps mitigate risks associated with supply chain disruptions.

What Is the Historical Context of Leather Boot Companies in the B2B Market?

The leather boot industry has a rich history that underscores its evolution into a global marketplace. Originating from traditional shoemaking practices, the industry has evolved significantly since the 19th century. Early leather boots were handcrafted with an emphasis on durability and functionality, often tailored to meet the needs of specific professions, such as farming and military service.

As industrialization took hold, mass production techniques emerged, allowing for greater accessibility and variety in leather boots. This transition laid the foundation for contemporary brands that combine traditional craftsmanship with modern design sensibilities. The resurgence of interest in artisanal, handcrafted products in recent years reflects a desire for authenticity and quality, further influencing B2B sourcing strategies.

Illustrative image related to leather boot companies

Today, international buyers are not only seeking high-quality leather boots but also a connection to the heritage and craftsmanship behind them. Understanding this historical context can enhance B2B relationships, as buyers recognize the value of partnering with brands that honor their legacy while innovating for the future.

Frequently Asked Questions (FAQs) for B2B Buyers of leather boot companies

-

How do I choose a reliable leather boot supplier?

When selecting a leather boot supplier, prioritize companies with a proven track record of quality and reliability. Look for manufacturers that provide clear information about their sourcing practices, production processes, and materials used. Verify their certifications and industry standards compliance. Request samples to assess the quality firsthand. Additionally, seek reviews or testimonials from other B2B buyers to gauge their experiences. Establishing clear communication about expectations and timelines is also critical to ensure a successful partnership. -

What customization options are typically available for leather boots?

Many leather boot companies offer a range of customization options, including materials, colors, sizes, and styles. You can often choose specific leathers (e.g., full-grain, suede), add personalized branding, or select unique design features such as stitching patterns or sole types. Discuss these options with potential suppliers early in the negotiation process to understand their capabilities and limitations. Ensure that the customization aligns with your target market’s preferences to enhance product appeal. -

What are the minimum order quantities (MOQs) for leather boots?

MOQs for leather boots can vary significantly between manufacturers, typically ranging from 50 to 500 pairs. Smaller companies may have lower MOQs, while larger brands might require higher quantities to justify production costs. When negotiating with suppliers, inquire about their flexibility on MOQs, especially if you are testing a new market or product line. This can help you manage inventory risks while still meeting customer demand. -

What payment terms should I expect when sourcing leather boots internationally?

Payment terms can vary widely, but common practices include upfront payments, deposits, or payment upon delivery. Many suppliers may request a 30% deposit before production and the remaining balance upon shipment. Be sure to clarify these terms in your contract to avoid misunderstandings. Consider using secure payment methods such as letters of credit or escrow services to protect your investment, especially in international transactions. -

How can I ensure quality assurance (QA) for my leather boot orders?

To maintain high-quality standards, establish a comprehensive QA process that includes pre-production samples, in-line inspections, and final audits before shipment. Specify your quality criteria in the contract, including material specifications, craftsmanship standards, and acceptable defect rates. Consider hiring third-party inspection services to verify compliance with your requirements. Regular communication with the supplier throughout the production process can also help address any issues promptly. -

What logistics considerations should I keep in mind when importing leather boots?

When importing leather boots, consider factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder experienced in handling footwear to streamline the logistics process. Factor in lead times for production and shipping to ensure timely delivery. Understanding the import duties and taxes applicable in your country is crucial for cost management. Additionally, ensure that all necessary documentation is prepared to facilitate smooth customs clearance. -

What are the key trends in the leather boot market that I should be aware of?

Current trends in the leather boot market include a growing demand for sustainable and ethically sourced materials, increased interest in customization, and the popularity of multifunctional designs that cater to both casual and formal settings. Additionally, the rise of e-commerce has shifted consumer behavior towards online shopping, making it essential for B2B buyers to consider digital presence and marketing strategies. Staying informed about these trends can help you align your offerings with market demands. -

How can I effectively market leather boots in diverse international markets?

To successfully market leather boots across different regions, conduct thorough market research to understand local preferences, cultural influences, and purchasing behaviors. Tailor your marketing strategies to resonate with specific demographics, utilizing local languages and cultural references. Leverage social media, influencer partnerships, and targeted online advertising to reach your audience effectively. Additionally, consider participating in international trade shows and events to showcase your products and connect with potential buyers.

Top 7 Leather Boot Companies Manufacturers & Suppliers List

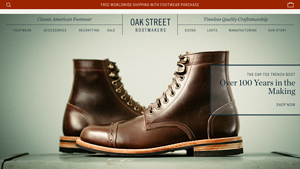

1. Oak Street Bootmakers – Classic American Footwear

Domain: oakstreetbootmakers.com

Registered: 2010 (15 years)

Introduction: Boots & Shoes Made in USA, Free Worldwide Shipping with Footwear Purchase, Classic American Footwear, Limited Editions, Everyday Boots, Chukkas, Bluchers & Oxfords, Loafers, Moccasins, Accessories, Footwear Care, Belts, Caps, Scarves, & Socks, Wallets & Key Fobs, Bags & Totes, Recrafting Services, Factory Guarantee, 100% Recraftable, Made in USA with domestic & international materials, Oak Street …

2. Boot Brands – Quality Alternatives

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Quality boot brands mentioned include Solovair, Jack Erwin, and Red Wing. Solovair is noted as a better alternative to Doc Martens due to a decline in Doc Martens’ quality. Bruno Marc is suggested as a budget-friendly option that still offers decent durability.

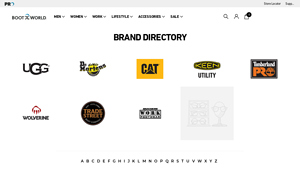

3. Timberland PRO – Safety Toe Work Boots

Domain: bootworld.com

Registered: 1996 (29 years)

Introduction: Brands: Timberland PRO, Wolverine, UGG, Dr. Martens, Keen UTILITY, Reebok Work; Footwear Types: Safety Toe Work, Soft Toe Work, Slip Resistant Work, Sheepskin Footwear, Slippers; Activities: Work, Casual, Sport, Dress, Hiking; Safety Features: Safety Toe, Slip Resistant, Metatarsal Guard, EH Rated, Waterproof; Accessories: Insoles, Socks, Care Products, Clothing, Headgear, Bags & Wallets.

4. White’s Boots – Key Products

Domain: whitesboots.com

Registered: 1997 (28 years)

Introduction: Key product details include: 55 Arch-Ease™ Last C350 Cruiser ($640.00), 55 Arch-Ease™ Last C350 Cutter ($640.00), 55 Arch-Ease™ Last C350-CS ($650.00), 1972 Arch-Ease™ Last Perry 6″ Select ($400.00), 55 Arch-Ease™ Last The Original 350 Cruiser ($750.00), 55 Arch-Ease™ Last The Original 350 Cutter ($750.00), 690 Arch-Ease™ Last The Original Packer ($725.00). White’s Boots are hand-sewn stitchdown b…

5. Irish Setter – Marshall Men’s Waterproof Safety Toe Boot

Domain: irishsetterboots.com

Registered: 1997 (28 years)

Introduction: {“products”:[{“name”:”Marshall Men’s 11-inch Waterproof Leather Safety Toe Pull-On Boot”,”price”:”$249.99″,”features”:[“Non-Metallic Toe”,”Waterproof”,”Slip Resistant”,”Electrical Hazard”]},{“name”:”Nisswa Women’s Safety Toe Hiking Boot”,”price”:”$169.99″,”features”:[“Non-Metallic Toe”,”Slip Resistant”,”Electrical Hazard”]},{“name”:”VaprTrek™ Men’s 8-inch Waterproof Leather Camo Boot”,”price”:”$21…

6. Blundstone – Key Products

Domain: blundstone.com

Registered: 1999 (26 years)

Introduction: {“products”:[{“name”:”Women’s Classics #585″,”price”:”$209.95″},{“name”:”Men’s Classics #558″,”price”:”$209.95″},{“name”:”Women’s Originals #1351″,”price”:”$209.95″},{“name”:”Men’s Originals #500″,”price”:”$199.95″},{“name”:”Women’s Classics #587″,”price”:”$209.95″},{“name”:”Men’s Classics #585″,”price”:”$209.95″},{“name”:”Women’s Originals #510″,”price”:”$199.95″},{“name”:”Men’s Classics #1609″,”…

7. Lucchese Bootmaker – Cowboy Boots

Domain: lucchese.com

Registered: 1997 (28 years)

Introduction: Lucchese Bootmaker offers a variety of cowboy boots and western wear for men and women. Key product categories include:

– Cowboy Boots: Best sellers include styles like the Priscilla ($1,095), Luke ($895), and Charles ($895). New arrivals include the Straight Shooter ($995) and Sweetheart ($995).

– Apparel: Includes denim, sport coats, tees, tops, bottoms, and outerwear. Notable items include th…

Strategic Sourcing Conclusion and Outlook for leather boot companies

In conclusion, strategic sourcing is vital for leather boot companies looking to enhance their market presence and operational efficiency. By establishing reliable partnerships with trusted suppliers, businesses can ensure the consistent quality and craftsmanship that consumers expect. As highlighted, the emphasis on durable, high-quality materials and innovative designs is essential for meeting the diverse preferences of international markets, particularly in regions like Africa, South America, the Middle East, and Europe.

International B2B buyers should prioritize sourcing from manufacturers who offer not only premium products but also comprehensive support services, such as recrafting and warranty guarantees. This not only extends the lifecycle of the products but also fosters customer loyalty.

Looking ahead, the leather boot industry is poised for growth as global consumers increasingly value sustainability and craftsmanship. Buyers are encouraged to explore emerging brands that align with these values, ensuring they stay ahead of trends and customer demands. Engaging with suppliers who prioritize ethical practices will not only enhance brand reputation but also contribute to a more sustainable future in the leather footwear market. Embrace the opportunities that strategic sourcing presents to elevate your business and meet the evolving needs of your customers.

Illustrative image related to leather boot companies

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.